- Ventilation in a boiler room with a gas boiler

- For solid fuel boiler

- Exhaust pipe made of stainless steel

- Air exchange requirements

- Is it necessary to ventilate a boiler room in a private house, and why?

- The main rules and requirements for ventilation of the boiler room in accordance with SNiP (+ video)

- Air exchange calculation with formula and example (+ video with more detailed explanations)

- Boiler project

- Types of chimneys

- Brick

- galvanized pipe

- coaxial chimney

- Ceramic

- Stainless steel

- Checking the operation of the ventilation system

- Criteria and standards

- Options for gas ducts for a country house

- Selection Guide

- Chimney of solid fuel boiler

- Types of systems

- Natural supply

- Forced

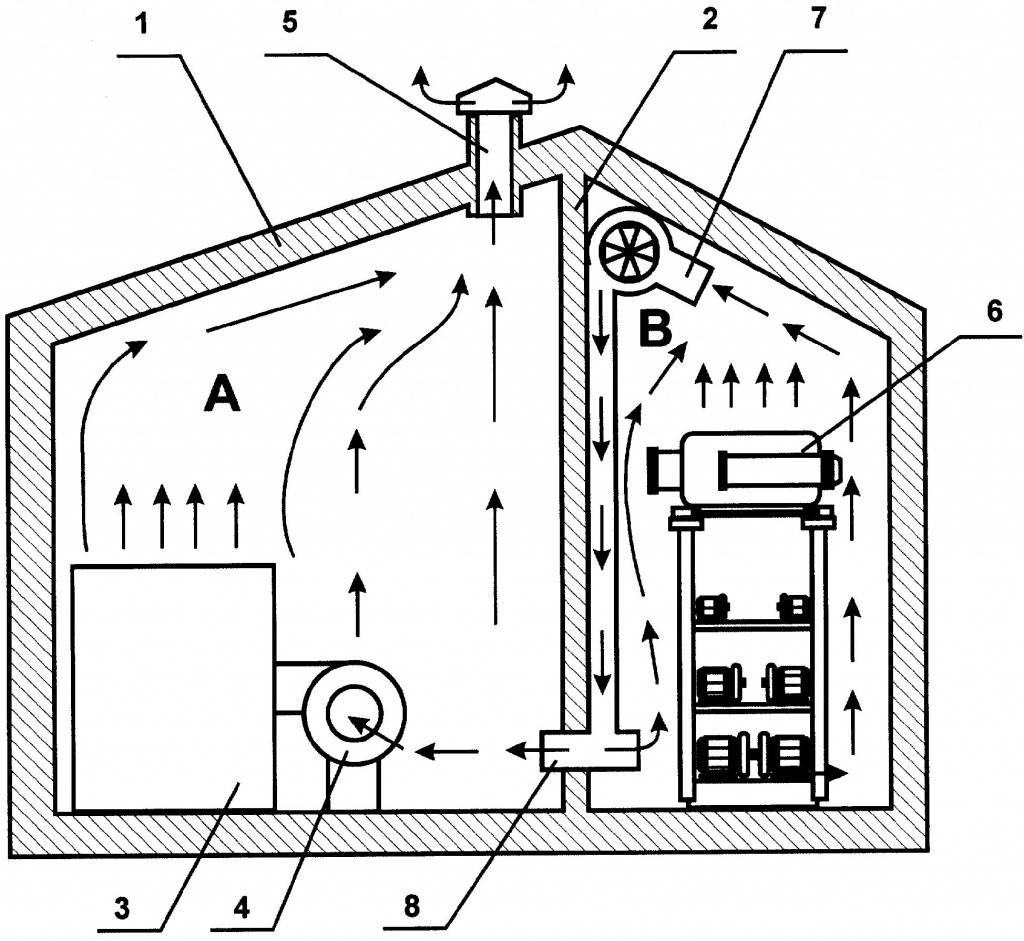

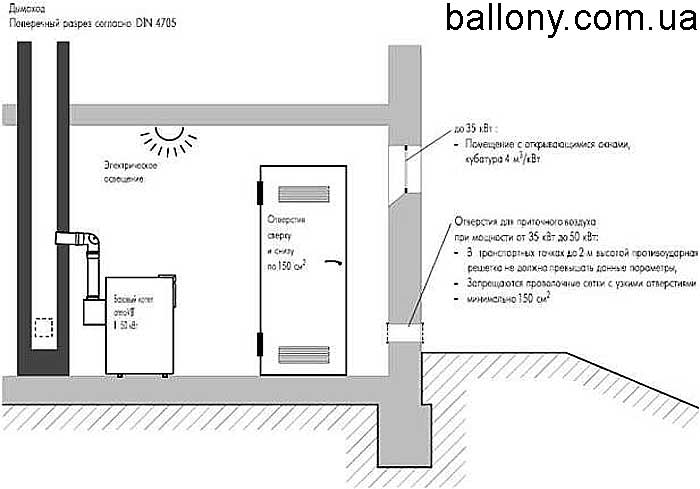

Ventilation in a boiler room with a gas boiler

For gas equipment, the regulatory documents indicate the minimum air exchange rate of 3 times per 1 hour. But in fact, they take into account the design, device and characteristics of the model. If the burner is open type, calculate the amount of oxygen consumed. To generate 1 kW of thermal energy, 0.12 m³ of gas is required. For equipment with a power of 24 kW, this figure will be 2.88 m³. The average oxygen consumption is 10 times greater, 28.8 m³ per hour.

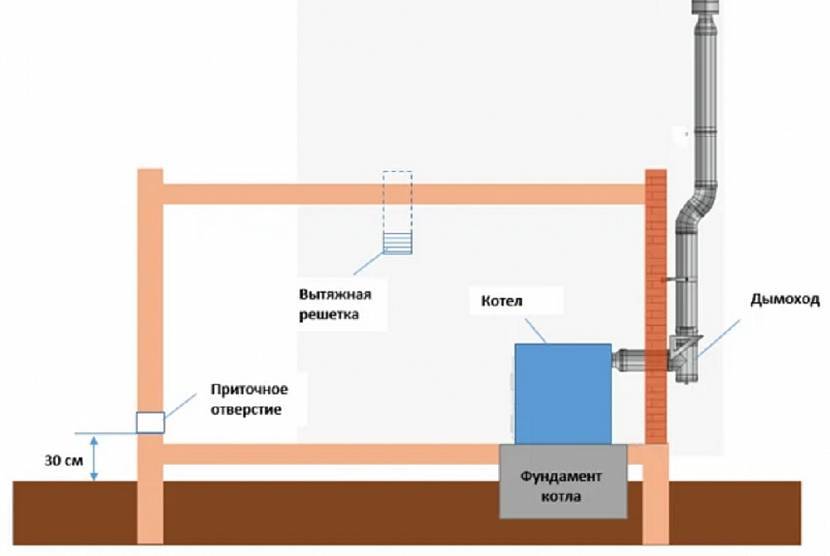

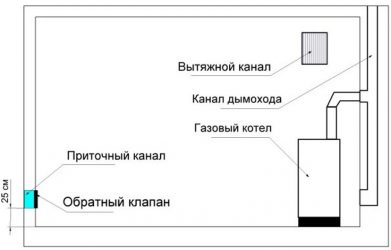

Effective ventilation of a gas boiler room is done according to the following rules:

- The supply pipe for supply is installed at the bottom of the wall opposite the heating device.

- The exhaust is mounted above the combustion chamber.

- A non-return valve is installed in the supply air to prevent a change in the direction of the air flow.

- The hood for a gas boiler in a private house is larger in diameter than the channels.

The latter is necessary to distribute the flow from the supply ventilation duct between the exhaust port and the chimney of the heating installation. Otherwise, less pressure will be created in the combustion chamber, which will lead to a decrease in power. Read all about smoke extraction systems here.

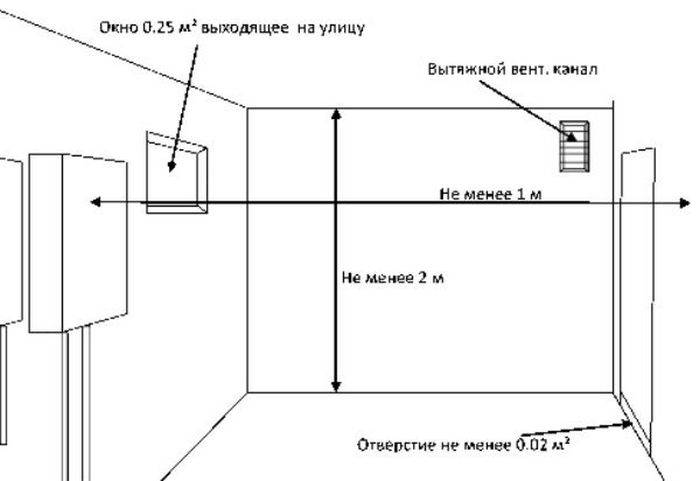

Layout of ventilation elements and windows in the boiler room

For solid fuel boiler

A feature of solid fuel heat supply is the periodic ingress of combustion products into the room. This happens during fuel loading, ash removal. Therefore, for heating with a solid fuel boiler, the air exchange rate is increased by 10-15% compared to a gas-fired one.

What to consider:

- The circulation channel outlet is installed vertically in the ceiling above the soot formation area.

- The minimum distance between it and the chimney is 0.5 m.

- Chimney draft protection. It is necessary to periodically clean it from soot, check the integrity.

For artificial convection of air, standard fans are installed. Their power provides an inflow equal to the sum of the flow rate of the exhaust duct and the chimney.

The length of the vertical element for the convection movement of air masses must be at least 3 meters. The inlet pipe is located above the firebox and ash pan.

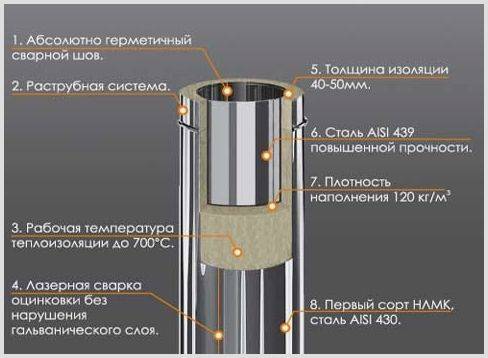

Exhaust pipe made of stainless steel

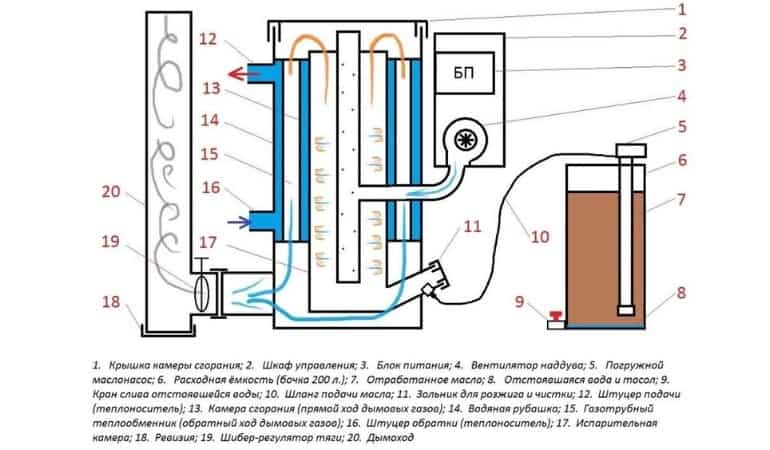

Steel chimneys are available in different versions.A single-wall pipe is placed in a brickwork. A similar scheme is also used for the restoration of a channel that worked with a solid fuel boiler. It is assembled from ready-made factory sections, any of them consists of an outer shell and an inner one. The space between them is filled with material for thermal insulation. Such structures are intended for installation in the house or from the outside. Specialized building channels are not needed.

To protect the structure from the destructive processes of acid, which appears from the sulfur contained in the exhaust gases, a special stainless metal is used. The cost of similar structures is higher than brick and ceramic, but they have significant good qualities. They are mounted from some modules, the walls are perfectly even and smooth, easy to clean, not prone to the accumulation of condensate. Light weight does not require a base device. To clean the channels that are inside, it is disassembled into component parts.

The material is not flammable, will withstand the temperature of the outgoing smoke. The factory equipment takes into account the expected purchase of tees, elbows, which makes it possible to create any configuration at the required angle. To make a chimney in an already built house does not require serious alterations, even if it is not expected by the project. Can be attached to the wall. The diameter of the inner channel is selected to match the size of the hole for the outlet of the gas boiler.

The external placement of a single-wall structure leads to a very high formation of condensate, which interferes with normal draft. To avoid bad consequences, it is placed in a brick channel or a sandwich model with thermal insulation is used.In order to reduce the cost of such products, along with stainless steel, zinc coated steel is used. The inner tube is 0.5–0.6 mm thick. Two-stage devices are more economical than other metal hoods due to good thermal insulation, they do not require the construction of an external brick channel.

The ventilation pole accumulates in this order:

- start from the lower segment, installing one pipe into another;

- suggest a large number of stealth hatches;

- holders for wall mounting are installed after 1.5 m;

- the length of horizontal sections cannot be more than 1 meter without mechanical ventilation.

When buying a double-circuit model, attention is paid to the material of the pipes. For the inside, only stainless steel is allowed, galvanized metal is not suitable. At a temperature of just over 400 °, it begins to oxidize, toxic fumes appear

High humidity exacerbates the situation. A similar design is very easy to make with your own hands. For insulation use basalt-based cotton wool, expanded clay sand, polyurethane

At a temperature of just over 400 °, it begins to oxidize, toxic fumes appear. High humidity exacerbates the situation. A similar design is very easy to make with your own hands. For insulation, basalt-based cotton wool, expanded clay sand, polyurethane are used.

Air exchange requirements

When designing ventilation in kitchens with gas stoves, it is necessary to comply with the requirements of both sanitary and fire safety standards (GOSTs, SNiPs, SanPiNs and SPs). Gas supply to apartments and cottages is an undoubted boon, as it can significantly reduce utility costs. But there are a number of points.

Both delivery options: main gas transported through pipes and LPG from a gas tank or cylinder are a source of danger. It is impossible to neglect the regulations and forget about the safety rules.

The design and installation of kitchens with gas stoves are regulated by several documents at once. Plus, there are all sorts of recommendations based on the given standards.

If the exhaust and air supply in a gasified kitchen room is not organized correctly, then the room can become a source of serious problems associated with open fire and a possible explosion of "blue fuel".

Gas stoves are allowed to be installed both in private houses and in apartment buildings. The height of the building can be no more than 10 floors. At the same time, the premises for them should have a window and be well lit by natural sunlight.

If the air exhaust in the kitchen with a gas stove is insufficient, then when the burner attenuates or the pipe breaks, the gas will accumulate in the room and sooner or later will explode

A kitchen for installing a gas stove must:

- be with ceilings from 2.2 m and above;

- have ventilation with natural air supply / removal;

- have a window that has an opening sash either at the top of a transom or a vent.

The cubic capacity of a room with a household stove on gas should be at a minimum (and preferably more):

- 8 m3 - with two burners;

- 12 m3 - with three burners;

- 15 m3 - with four burners.

In some cases, it is permissible to deviate slightly from these norms, but only if such deviations are agreed with the inspectors from the Ministry of Emergency Situations and other regulatory bodies.

In order to avoid problems with the stove, the air in the kitchen should be enough to burn the gas, and it should also be constantly replaced by a new street

When organizing air exchange in the kitchen, it is important to ensure that new air comes exclusively from the street. This will prevent air masses with excess odors and moisture, as well as low oxygen content from entering the kitchen room.

Only methane or propane-butane gas stoves are not enough to work.

The air exchange rate for a kitchen with a gas stove is 100 m3 / hour. At the same time, in most apartment buildings, ventilation ducts with a width of 130–150 mm of the general ventilation system are designed for a flow rate of up to 180 m3/hour.

It is only necessary to provide the required air flow from the outside. In a private house, everything depends on the project. Here it is necessary to look at a specific example, what the existing ventilation system is designed for.

Is it necessary to ventilate a boiler room in a private house, and why?

Yes, in the boiler rooms of private houses it is imperative to organize ventilation that meets the standards of SNiP.

In this room, the ventilation system will perform the following functions:

- Provide oxygen supply for normal combustion. If there is not enough oxygen, any fuel will not burn completely. As a result, less heat is released, more fuel is spent to maintain the desired temperature in residential premises, the wear of the boiler is accelerated, and ashes accumulate inside the chimney.

- Remove carbon monoxide. Not all combustion products can be removed through the chimney - in a small amount they can enter the room. If ventilation does not provide sufficient air exchange, the concentration of carbon monoxide can rise to critical levels and penetrate into other rooms.

- Remove gas if possible.Over time, the gas line to the boiler may lose its tightness, and gas may accumulate in the room. If this is not noticed, an explosion or poisoning is possible.

That is, properly equipped furnace ventilation gives the following effect:

- reduces the risk of fire or explosion;

- reduces the likelihood of natural or carbon monoxide poisoning;

- the boiler works with full efficiency, without exceeding loads (which means it can last longer without repair);

- the temperature in the house is maintained without excessive load on the boiler and without exceeding the fuel consumption.

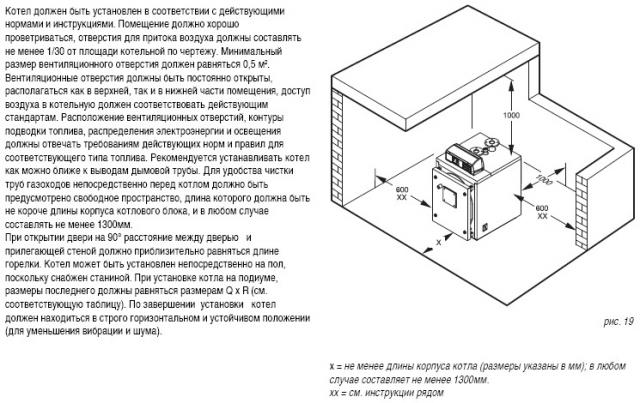

The main rules and requirements for ventilation of the boiler room in accordance with SNiP (+ video)

Do you need a ventilation system - found out. Now about the main rules and requirements for its arrangement.

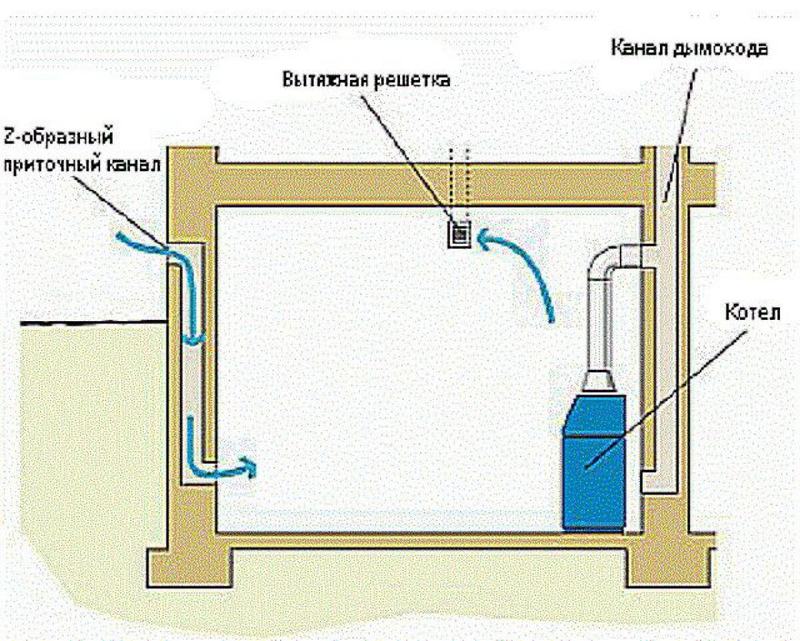

Simplified boiler room ventilation scheme

The boiler room can be equipped in such premises:

- Freestanding building or block module.

- Annex.

- Room inside the house.

- Kitchen (permissible if the boiler power does not exceed 30 kW).

- Attic.

During the construction of private houses, furnaces are usually equipped in a separate room on the ground floor, next to a garage or other room.

Requirements and standards for the arrangement of boiler rooms in private homes are regulated in SNiP 42-02-2002.

From the main requirements:

- Requirements for the room, if the boiler is placed in a separate room: volume - from 7.5 m³, area - from 6 m², ceiling height - from 2.5 m.

- Boilers with a capacity of 30+ kW - should be installed only in a separate room. Boilers with less power - can be placed in the kitchen.

- When installing the boiler in the kitchen, its area must be more than 15 m²

- The boiler room must have a separate door to the street.

- The cross-sectional area of the openings for inflow: from the street - from 8 cm² for every 1 kW of boiler power, from an adjacent room (for example - from the kitchen, through the wall) - from 30 cm² for every 1 kW of power.

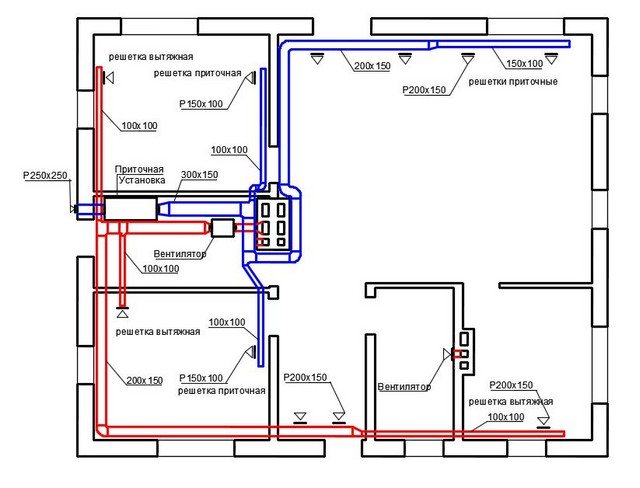

Air exchange calculation with formula and example (+ video with more detailed explanations)

It is necessary to choose the sections of the ventilation ducts and the power of the exhaust fan based on the desired air exchange.

To calculate the right amount of air, you need to know:

The rate of air exchange. According to SNiP - for boiler rooms it is 3 (that is, in 1 hour in the boiler room, the air must be completely updated 3 times).

The volume of the room. To measure, you need to multiply the height by the width and multiply by the length (all values \u200b\u200bare taken in meters).

How much air does the boiler need for combustion

For gas boilers (it doesn’t matter - with an open or closed combustion chamber) in private homes, high accuracy is not necessary, so you can take 10 “cubes” of air per 1 “cube” of gas for calculations. For diesel fuel - 12.

Let's give an example - let's calculate the ventilation system for a boiler room in a separate room attached to the house:

- We calculate the volume of the room. For example, let's take the dimensions 2.5 x 3.5 x 2.5 = 21.875 m³. For a more accurate calculation, you can subtract the volume (size) of the boiler itself from the “total” volume.

- We look in the characteristics of our boiler how much gas it can burn maximum in 1 hour. For example, we have a model Viessmann Vitodens 100 (35 kW), with a maximum consumption of 3.5 "cubes". This means that for normal combustion at maximum load, the boiler needs 3.5 x 10 = 35 m³ / h of air. This characteristic is not covered by the rule about three times, so we simply add it to the result.

Now we perform the calculation using all indicators:

21.875 x 3 (three air changes) + 35 = 100 m³/h

Just in case, you need to make a reserve - on average up to + 20-30% of the resulting value:

100 + 30% = 130 m³/h (rounded up) must be supplied and removed by the ventilation system in the boiler room at maximum load on the boiler. For example, we took the maximum margin (30%), in fact, you can limit yourself to 15-20%.

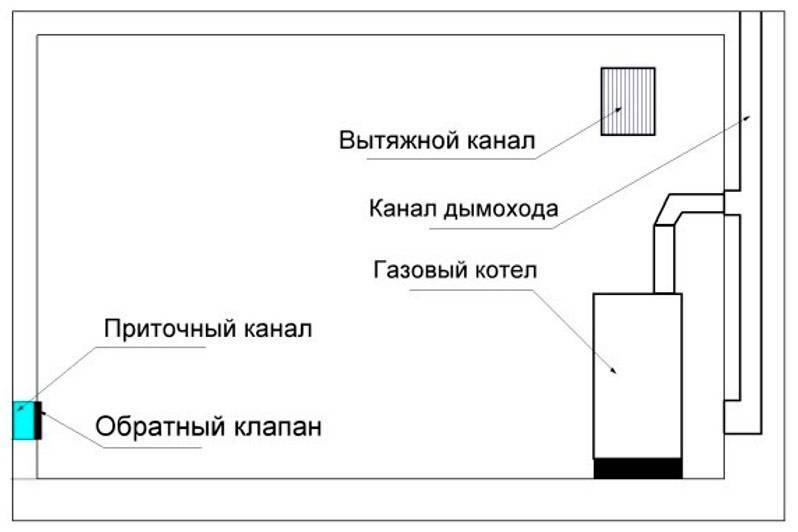

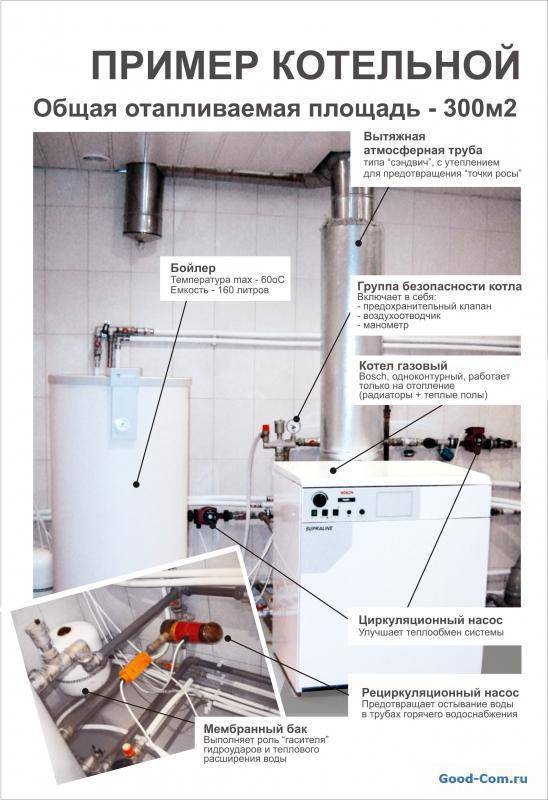

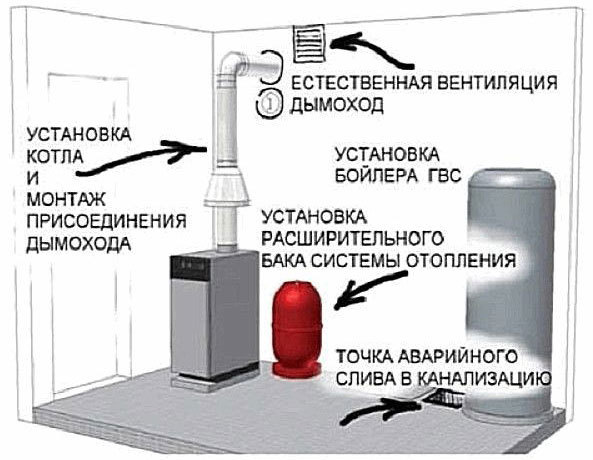

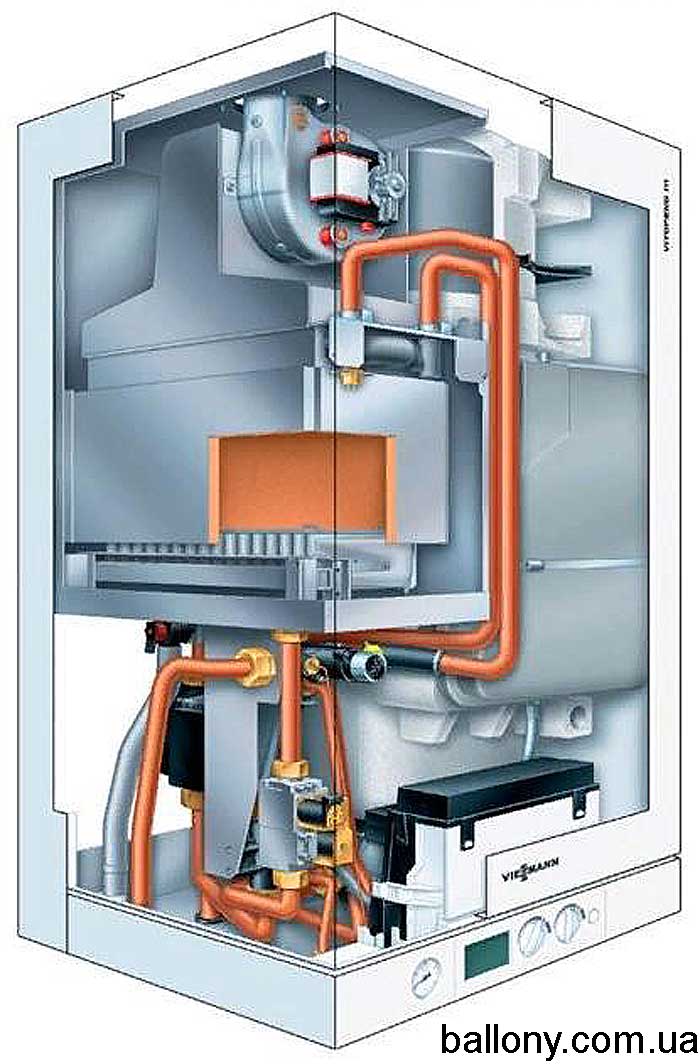

Boiler project

Designing a boiler room for a private house is the most important stage in its construction. It is impossible to carry it out on your own - experienced designers who have all the necessary permits for this type of activity must deal with the project.

During the design process, thermal engineering calculation of the building and selection of the necessary equipment, working drawings are being made. All technical solutions are described in the explanatory note. It is this set of documents that is subsequently submitted for approval to the relevant authorities.

Gas boiler in the basement

At the design stage, the type of boiler room is also selected. The main selection criteria are as follows:

- Type of energy carrier: selected according to the conditions of the construction site. Somewhere it is cheaper to use gas, but somewhere you have to be content with firewood.

- Heating mode: if, for example, the house is used for occasional living, designers can provide software control of the heating system. In this case, the temperature regime can be controlled at the discretion of the owner: in his absence, it will be enough to maintain a temperature of +10 degrees, and by his arrival the house will warm up to a comfortable +20 degrees.

- Location of the boiler room: in case of new construction, it is advisable to provide a separate furnace room in the project.In an already built house, it is not always possible to find a suitable place for installing boiler equipment, so you have to build an additional building or extension.

After a thorough study of the above issues, you can proceed to the design.

For heating a country house, there are various types of heating boilers. You just need to choose the type of fuel. In this regard, combined heating boilers are a win-win option. combining two types of fuel. Read about the features of the design and operation of such systems.

You will find a detailed example of calculating the power of a heating boiler here.

An ordinary heating stove, be it Swedish, Dutch or Russian, can only heat a small house. But what if there are many large rooms in the house? Furnace heating with water circuit will solve the problem of heating the home. Everything about the arrangement of this system is here.

Types of chimneys

Pipes are made from different materials, which we will consider in more detail.

Brick

Classic brick chimneys for a gas boiler are still in demand, regardless of their many disadvantages and poor thermal performance. At the same time, they comply with sanitary standards and rules, which state:

- The pipe is made of fireclay bricks.

- For the construction of walls, a solution of clay or special glue is used.

- To improve draft, the chimney rises above the level of the roof ridge.

Standards regulate the height of the pipe in relation to the roof ridge, depending on the distance between them

- The masonry provides tightness.

- At the inner hole, the deviation is no more than 3 mm per 1 m.

- To protect against precipitation, a deflector is installed on the head of the pipe.

And also the chimney can have a mono design, which, due to low thermal characteristics, is repaired every 5-7 years.

galvanized pipe

A sandwich device is today the most effective chimney design option. The undoubted advantage of these chimneys is their resistance to aggressive environments and various mechanical influences.

The product consists of two pipes of different sizes, with one inserted into the other. Basalt wool is usually used as a filler between them.

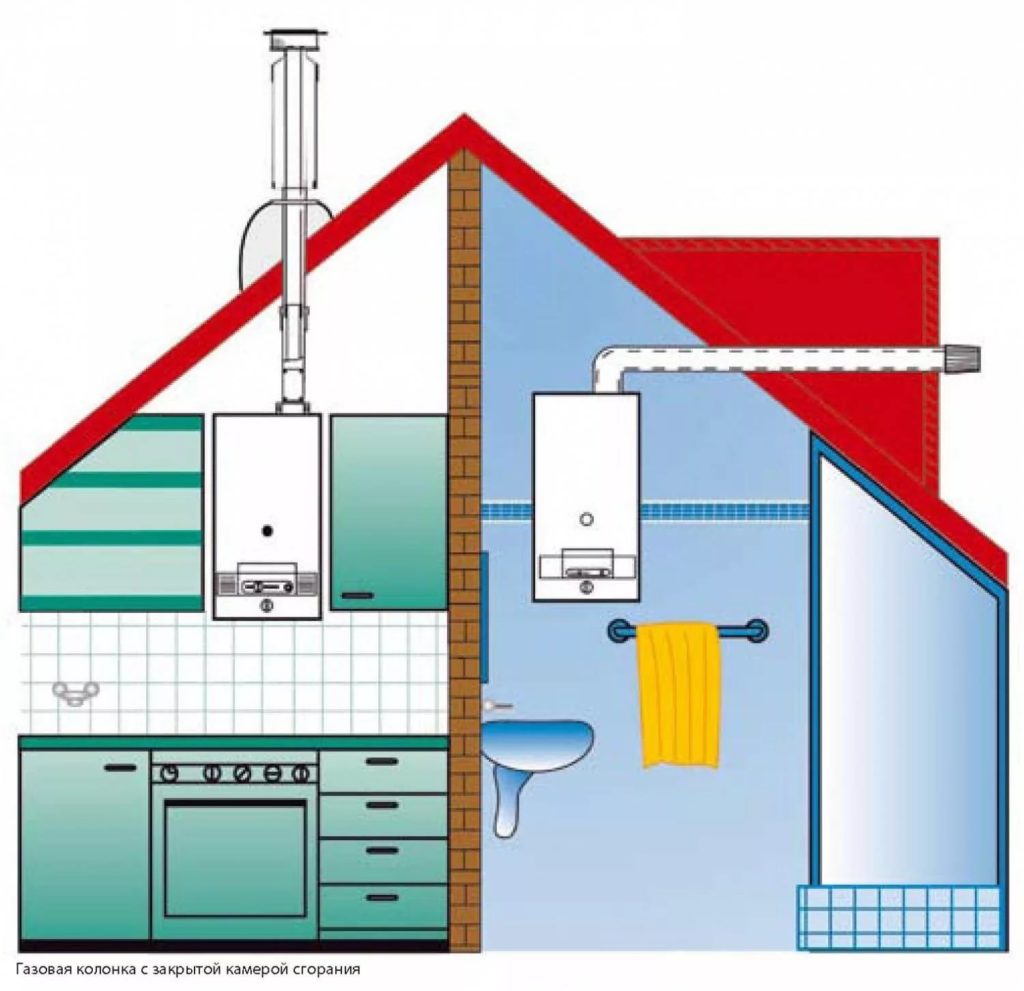

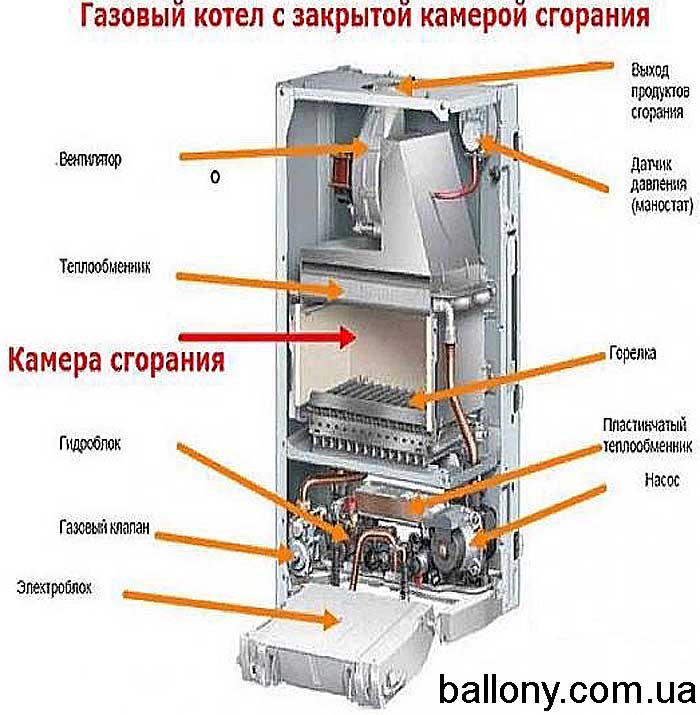

coaxial chimney

Currently, gas boilers use closed-type combustion chambers. Here, air intake and smoke removal are produced by a coaxial pipe. This is an original device, relatively recently introduced, but already very popular among users.

The non-standard solution lies in the intake of air through a pipe that removes combustion products. It turns out that one pipe performs two functions due to the design features.

A coaxial chimney is a pipe in a pipe

And its characteristic difference from ordinary pipes is as follows ... A smaller pipe (60-110mm) is located in a pipe of a larger diameter (100-160mm) in such a way that they do not touch each other.

At the same time, the structure is a single whole due to the jumpers along the entire length and is a rigid element. The inner pipe serves as a chimney, and the outer pipe serves as fresh air.

Air exchange at different temperatures creates traction and sets the air mass in a directed motion.The air in the room is not used during the operation of the boiler, thus maintaining the microclimate in the room.

Ceramic

Such a chimney is a composite structure, including:

- Smoke duct made of ceramic material.

- Insulation layer or air space.

- Claydite concrete outer surface.

This complex design is due to several reasons. First, the chimney pipe is too fragile to be left unprotected.

A ceramic pipe is always located inside a solid block.

Secondly, ceramics has a high thermal conductivity, and therefore it needs reliable insulation. The inner tube of a circular cross section has a smooth surface, while on the outer tube, roughnesses are allowed that do not affect the integrity of the product.

Typically, such chimneys are available in lengths from 0.35 to 1 m, depending on the manufacturer. The connection of the inner and outer pipes occurs by means of a lock, which is a thinning in external size from one end and an expansion of the inner pipe from the other side.

The expanded clay concrete outer surface is made of a square shape with a round hole inside. In addition, this product provides a place for a heater, which is held by metal jumpers. At the same time, they are fixed on the outer surface and make a reliable fastening for this pipe.

Stainless steel

A gas chimney made of steel seems to be more reliable than a brick one. They are resistant to corrosion, immune to temperature fluctuations, they are not affected by increased air humidity and aggressive environments.

Stainless steel chimney

In addition, such stainless steel pipes have a number of advantages:

- Long period of operation.

- Multifunctionality.

- Relatively low cost.

- Great strength.

- Probable realization of a product of any complexity.

For chimneys made of this material, an assembly of modules is characteristic, which allows the replacement of a damaged segment if necessary. The installation of chimneys is made with the help of special bends, which allow them to harmoniously fit into certain elements of the roof.

Checking the operation of the ventilation system

Boiler room ventilation in the wall

Boiler room ventilation in the wall

You can check the operation of ventilation yourself. To do this, just bring a piece of notebook paper or a napkin to the ventilation duct. If there is traction, then the sheet will be fixed at the grate. If this does not happen, then perhaps errors were made in the calculation or the requirements were not observed during the installation of air exchange systems. Although the cause may be clogging of the air ducts.

If the boiler is in the kitchen with an interior door without a special slot at the bottom, and the ventilation ducts for the inflow and outflow of air are installed in different rooms, then there will be no draft with the doors closed. To avoid stagnation of air in practice, plastic door ventilation grilles are used. They can be round or rectangular. Depending on the material, the purchase price may be different.

The safe operation of the heater depends on ventilation. Therefore, it is worth taking seriously the design and choice of the type of ventilation. Make the right calculations and installation. If knowledge and experience are not enough, then it is better to resort to the services of specialists

It is important that the area of \u200b\u200bthe room corresponds to the installed equipment.The floor in the boiler room must be made of non-combustible materials

It is best to use a cement screed.

Criteria and standards

There are ventilation standards for a gas boiler and a room with it. The type of combustion chamber of the apparatus matters - closed or open.

Boilers with a closed combustion chamber must be equipped with a coaxial duct. Two processes go synchronously along it: air from the street enters the burner, and the results of combustion are eliminated.

Ventilation in a room with a gas boiler is mounted taking into account the following criteria:

- The maximum number of units of gas equipment for connection to the chimney is 2. At the same time, their distance and position do not matter.

- Combustion products penetrate the chimneys at a distance of at least 50 cm to various levels. When supplying from only one level, a cut is placed in the chimney, having a height of 50 cm or more.

- Absolute tightness of the entire ventilation system. Even minimal leakage of fuel and soot must be excluded.

- The seams at the joints of the chimneys are covered with a heat-resistant sealant.

- All elements of the system are equipped with thermal insulation. This is a key fire prevention measure.

- Ventilation is equipped so that an outflow is formed in a three-fold air exchange, there is a supply with one outflow, and an air volume is added for combustion.

For devices with an open combustion chamber, the main criteria are reflected in SNiP 2.04. 05-91. If their power does not exceed 30 kW, they can be mounted in the kitchen, only there should be no stove there.

And models with a closed compartment in these rooms are allowed to be used.

If the power of the device is more than 30 kW, a separate extension is created for it - a boiler room.It has the following requirements:

The presence of two options for air exchange: forced and natural.

Area - at least 15 sq.m.

The smallest ceiling height is 2.4 m. According to the norms, this is an indicator of 6 m, but if it is less, a correction value of 0.25 is applied for each meter down.

For 1 cubic meter, windows in area reach 300 sq.cm.

The presence of a separate entrance. In the extension, you can arrange a door leading to the residential sector.

The equipment installation site is covered with non-combustible materials, such as metal or asbestos board sheets.

If equipment with an open burner is installed, the minimum length of the chimney is 4 m, the number of turns in the corners is no more than 3

This is an important condition for the formation of traction.

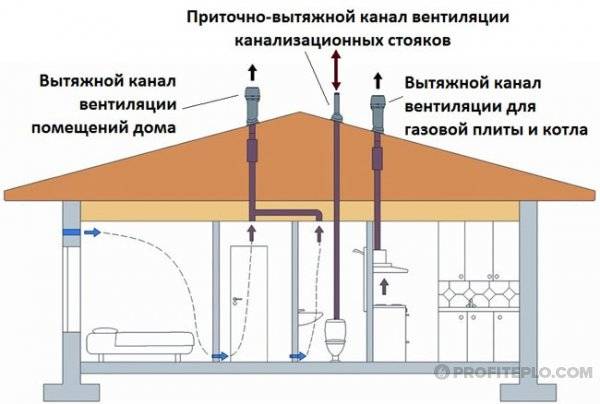

Schematically, the ventilation in the boiler room is displayed as follows:

Channels for air circulation must be created at the construction stage. Their minimum diameter is 20 cm. After the final calculations, fans and small grilles with adapter sleeves can be mounted.

Options for gas ducts for a country house

To discharge combustion products with a relatively low temperature (up to 120 ° C) emitted by gas boilers, the following types of chimneys are suitable:

- three-layer modular stainless steel sandwich with non-combustible insulation - basalt wool;

- a channel made of iron or asbestos-cement pipes, protected by thermal insulation;

- ceramic insulated systems such as Schiedel;

- brick block with a stainless steel pipe insert, covered from the outside with heat-insulating material;

- the same, with an internal polymer sleeve of the FuranFlex type.

Three-layer sandwich device for smoke removal

Let us explain why it is impossible to build a traditional brick chimney or put an ordinary steel pipe connected to a gas boiler. The exhaust gases contain water vapor, which is a product of the combustion of hydrocarbons. From contact with cold walls, moisture condenses out, then events develop as follows:

- Thanks to numerous pores, water penetrates into the building material. In metal chimneys, condensate flows down the walls.

- Since gas and other high-efficiency boilers (on diesel fuel and liquefied propane) operate periodically, frost has time to grab moisture, turning it into ice.

- Ice granules, increasing in size, peel the brick from the inside and out, gradually destroying the chimney.

- For the same reason, the walls of an uninsulated steel flue closer to the head are covered with ice. The passage diameter of the channel decreases.

Ordinary iron pipe insulated with non-combustible kaolin wool

Selection Guide

Since we initially undertook to install an inexpensive version of the chimney in a private house, suitable for do-it-yourself installation, we recommend using a stainless steel pipe sandwich. Installation of other types of pipes is associated with the following difficulties:

- Asbestos and thick-walled steel pipes are heavy, which complicates the work. In addition, the outer part will have to be sheathed with insulation and sheet metal. The cost and duration of construction will definitely exceed the assembly of a sandwich.

- Ceramic chimneys for gas boilers are the best choice if the developer has the means. Systems such as Schiedel UNI are reliable and durable, but too expensive and out of reach for the average homeowner.

- Stainless and polymer inserts are used for the reconstruction - lining of existing brick channels, previously built according to old projects. Specially fencing such a structure is unprofitable and pointless.

Flue variant with ceramic insert

A turbocharged gas boiler can also be connected to a conventional vertical chimney by organizing the supply of outside air through a separate pipe. The technical solution should be implemented when a gas duct has already been made in a private house, brought to the roof. In other cases, a coaxial pipe is mounted (shown in the photo) - this is the most economical and correct option.

Noteworthy is the last, cheapest way to build a chimney: make a sandwich for a gas boiler with your own hands. A stainless pipe is taken, wrapped in basalt wool of the required thickness and sheathed with galvanized roofing. The practical implementation of this solution is shown in the video:

Chimney of solid fuel boiler

The mode of operation of wood and coal heating units involves the release of hotter gases. The temperature of the combustion products reaches 200 ° C or more, the smoke channel warms up completely and the condensate practically does not freeze. But it is replaced by another hidden enemy - soot deposited on the inner walls. Periodically, it ignites, causing the pipe to heat up to 400-600 degrees.

Solid fuel boilers are suitable for the following types of chimneys:

- three-layer stainless steel (sandwich);

- single-wall pipe made of stainless or thick-walled (3 mm) black steel;

- ceramics.

Brick gas duct of rectangular section 270 x 140 mm is lined with an oval stainless pipe

It is contraindicated to put asbestos pipes on TT-boilers, stoves and fireplaces - they crack from high temperatures. A simple brick channel will work, but due to roughness it will become clogged with soot, so it is better to sleeve it with a stainless insert. Polymer sleeve FuranFlex will not work - the maximum operating temperature is only 250 ° C.

Types of systems

Natural supply

Such ventilation is used in small private houses equipped with low-power heating devices. Openings for the inflow of clean air from the outside are equipped at opposite ends of the boiler room. For example, if the boiler is installed opposite the door, then the exhaust opening is equipped above the gas device so that the air moves from below through the entire room and rises to the hood. The window can be on any wall.

If there is a window in the boiler room, it is necessary to regularly ventilate the room by opening the window. For a constant supply of fresh air from the outside, it is recommended to make a hole in the wall with a diameter of at least 150–200 mm. To drill a wall, you need a puncher or a drill with a crown nozzle (you can learn about the important features of installing ventilation in the wall with your own hands, as well as see the laying diagram here).

If there is a window in the boiler room, it is necessary to regularly ventilate the room by opening the window. For a constant supply of fresh air from the outside, it is recommended to make a hole in the wall with a diameter of at least 150–200 mm. To drill a wall, you need a puncher or a drill with a crown nozzle (you can learn about the important features of installing ventilation in the wall with your own hands, as well as see the laying diagram here).

If there is already a ventilation shaft in the wall, a grate is installed on that part of it that goes into the room, and on the other end (pipe brought to the roof) - a cap that protects the pipe from water and small debris getting into it (what are the features of installing ventilation outlets by hand?).

All openings, both inside and outside the room, must be equipped with gratings, since without a grating, garbage, water, and small rodents can enter the ventilation system.

Forced

Artificial ventilation is used when natural ventilation of the room is not enough. It will be necessary to install a duct fan or a combined system with several filters (to filter out small debris, dust), a water heating element (heater) and fans in the boiler room.

The system works like this: air enters the chamber, and combustion products are removed at the speed necessary for air exchange. Before buying a fan, you need to calculate its performance. According to the requirements of SNiP, in 1 hour the air in the boiler room must change at least 3 times. For example, if the volume of the boiler room is 10 m³, then 10 x 3 = 30 m³ / h is the minimum fan performance.

here