Features of air exchange

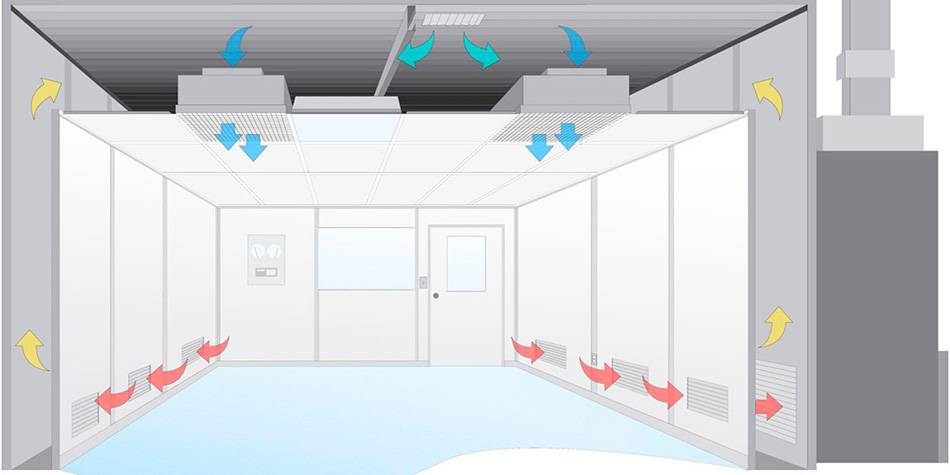

To maintain the purity of the air, in technologically clean rooms, ventilation with an excess volume of inflow should be used, compared with the exhaust in adjacent rooms.

- If the room is without windows, then the inflow should prevail over the exhaust by 20%.

- If the emergency room has windows that allow infiltration, then the air supply capacity should be 30% higher than the exhaust.

It is this air exchange system that prevents the penetration of contaminants and ensures the movement of air from a clean room to adjacent rooms.

Much attention of designers is paid to the methods of supplying the air mixture to such objects and depends on their purpose.

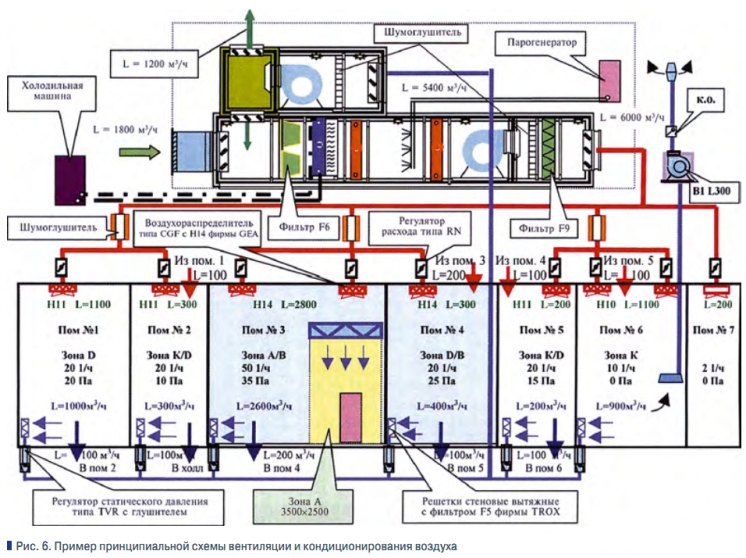

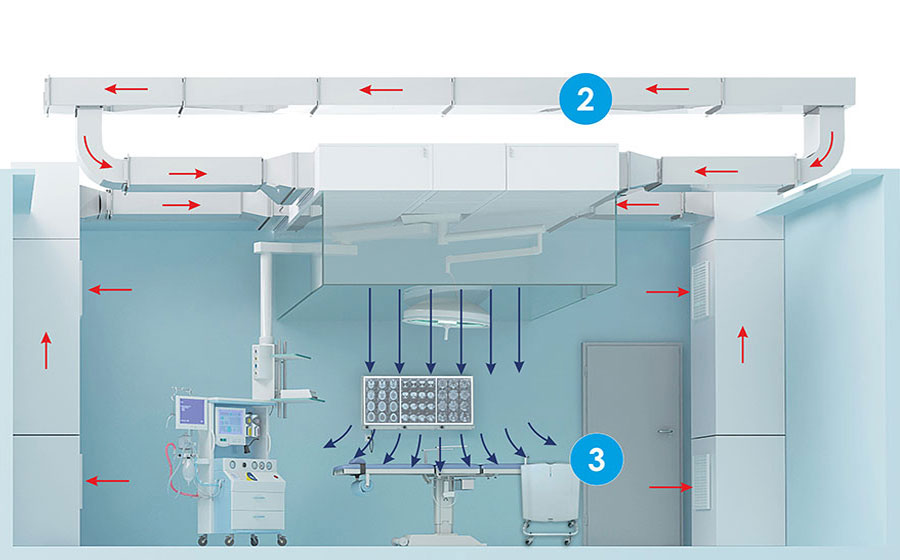

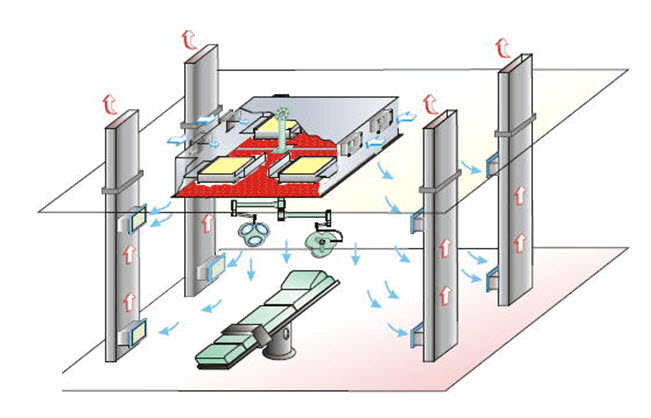

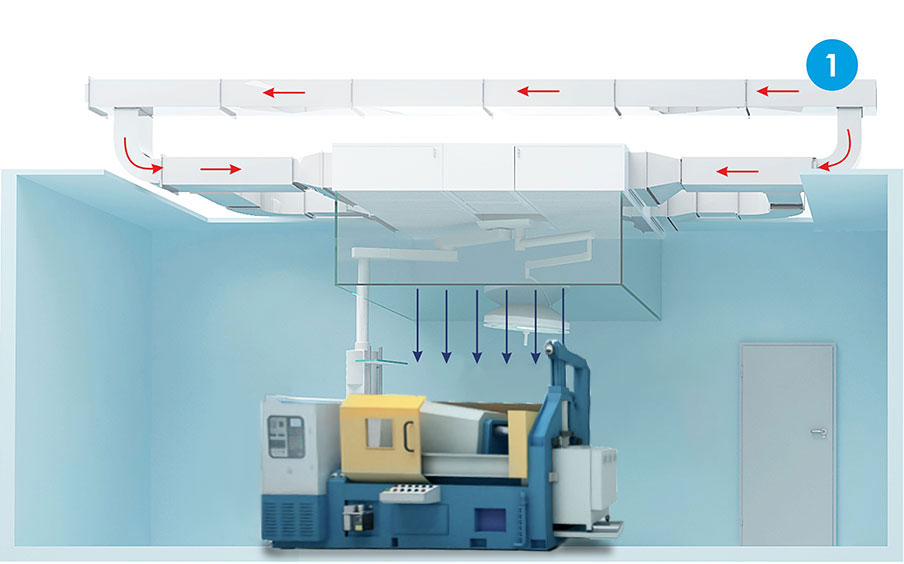

The inflow to the emergency room with a purity class from 1 to 6 must be supplied by an air distribution device from top to bottom, creating uniform unidirectional air flows of low speed, from 0.2 to 0.45 m/s. In rooms with a lower cleanliness class, it is allowed to create a non-unidirectional flow by means of several ceiling diffusers.The frequency of air exchange for PE is set depending on their purpose, from 25 to 60 times per hour.

Types of cleanrooms

There are 2 types of clean rooms. They differ in the way they purify the air. There are rooms with both turbulent ventilation and laminar flow (directed in one direction).

Read more: How to independently install a split system at home.

The latter makes it possible to maintain a higher level of cleanliness, because a unidirectional flow better displaces polluted air masses from the space in which it is operated.

When processing air in a turbulent way, the streams cleaned with the help of filters are supplied using ceiling distributors. Fresh air masses, upon entering the room, are combined with the air present, in which some degree of pollution is already present, and it is diluted. Then, through the air intake grilles, which are present at the bottom of the walls, some of the air is taken out. For a day, ventilation made according to this principle can remove the exhaust air mixture up to 20 times.

Read more: What to do if the ventilation in the apartment blows in the opposite direction.

When the need arises to improve the quality of air in a clean room, a unidirectional flow type is chosen. The essence of laminar ventilation is the installation of highly efficient filter elements to supply air masses.

A fresh stream, after it enters the room, moves along it in one direction (from top to bottom), while the particles of dust present are captured and removed through the genital openings. The process occurs at a speed of air masses up to 0.4 m/s.

The use of laminar flow contributes to the minimum spread of suspended particles due to the direction of the air.

Main design stages

There are no standard schemes for residential and amenity premises due to the architectural and functional diversity of buildings.

To make a decision on creating an optimal air exchange system, it is necessary to adhere to the general principles of organizing ventilation, observing the air balance, the rules for developing technical specifications and recommendations for its practical implementation (+)

Development of technical specifications

Drawing up a technical task is the first stage in the design of ventilation. Here it is necessary to prescribe the requirements for the volume and type of air exchange for all rooms of the house.

An example of a technical task (in terms of air exchange) for the development of a ventilation system for a house. You can create such a document yourself.

For each individual room, depending on its purpose, the parameters of air exchange are determined.

Yes, for apartments private houses use ventilation needed as follows:

- Living rooms, living rooms, gyms. Constant flow. The volume depends on the average daily number of people in the room. Requirements for the temperature and humidity of the incoming stream are possible.

- Bathroom, toilet, laundry. Permanent natural extraction. The operation of mechanical devices during the use of the premises.

- Kitchen. Permanent natural extraction. Activation of forced draft during intensive use of gas, or in the event of significant emissions of steam into the air during open cooking methods.

- Corridor and hallway.Free movement of air.

- Pantry. Natural exhaust ventilation.

- Boiler or furnace. When calculating the air balance, it is necessary to take into account the presence of exhaust ventilation due to the removal of combustion products through the chimney.

- Working premises (workshop, garage). Autonomous ventilation depending on the purpose of the rooms.

The terms of reference can be developed independently or by third-party specialists. In the latter case, when concluding a contract, designers will have to adhere to Russian regulatory documents regulating the air speed in the duct and the air exchange rate.

Choosing the best ventilation scheme

Based on the terms of reference create a diagram of the ventilation system. The plan for the location of its elements must be agreed before the interior decoration of the premises. Otherwise, in the case of installation after repair, there will be an additional task of fitting them into the interface of the house.

Air circulation in the house. A separate exhaust from the pool is necessary to reduce the amount of condensate in the heat exchanger. A separate cycle in the boiler room - fire safety requirements. Separate cycle in the garage - technical simplicity of the solution

As a rule, any ventilation plan can be implemented in several ways.

The best solution should fully meet the requirements of the technical specifications and take into account the following wishes:

- contain a minimum number of nodes and elements that are prone to breakage;

- regular maintenance should be simple and, if possible, carried out by residents;

- the use of ventilation in climate control should be understandable to people who do not have special knowledge about the technical nuances of the system;

- availability of backup solutions in case of failure of one of the nodes;

- the system should be inconspicuously integrated into the interior of the apartment or house.

In financial calculations, it is necessary to take into account both a one-time investment in the purchase of system elements and their installation, as well as regular costs for periodic maintenance and electricity spent on heating and humidifying the air.

Modern solutions for domestic ventilation systems contain a compact electronic control unitwith which you can easily adjust the microclimate of any room in the house

5.3 Ventilated ceilings

5.3.1 Ventilated ceiling

performs a role similar to local suction, occupying all or a significant

part of the ceiling surface of the hot shop.

As well as local sucks,

ventilated ceilings serve to contain and remove kitchen secretions. AT

ventilated ceilings can be placed devices for supplying air

air.

5.3.2 By design

ventilated ceilings are divided into two types: open and closed (Figure 3).

Figure 3 - Ventilated ceilings:

a) open

ventilated ceiling with removable filters;

b) open

ventilated ceiling with removable filters and condensate drains;

c) closed

ventilated ceiling with insulated supply and exhaust air ducts;

d) closed ventilated ceiling with exhaust ducts and open

supply air

in ventilated ceilings

closed type exhaust air ducts are connected directly to the airtight

metal exhaust duct with filters.

in ventilated ceilings

open type exhaust duct and ventilated ceiling are not connected

metal box. The walls and ceiling of the hot shop room form

closed volume above a ventilated ceiling. Exhaust duct connected

directly to this volume.

5.3.3 Ventilated ceilings

made of stainless steel or a combination of stainless steel and

aluminum with an oxide or enamel protective coating. directly above

gas kitchen equipment, it is allowed to install ventilated panels

ceilings made only of stainless steel.

5.3.4 Filters installed in

ventilated ceilings, should be easy to clean or be of a removable design for

subsequent cleaning.

5.3.5 Ventilated ceilings

closed type should be set in all cases where kitchen discharge

contain combustion products of solid fuel or vapors and fat particles. In all

in other cases, it is allowed to install ventilated ceilings as closed,

and open type.

6 Mechanical filters

6.1 Air vented by local

suction and ventilated ceilings, must be cleaned of fat particles to

entry into exhaust ducts.

6.2 Design of mechanical

filters must satisfy the conditions set out in 6.2.1 to 6.2.5.

6.2.1 Filters should be

installed at an angle to the horizon from 45° to 90°, so that the kitchen

the secretions accumulated in the filters flowed freely into the fat collection trough.

Note - In ventilated ceilings, installation is allowed

filters at an angle to the horizon of less than 45°, if the design of the filter provides

effective removal of fat in the collectors mounted under filters.

6.2.2 Fat construction

filter should prevent the spread of fire from kitchen equipment to

exhaust duct.

6.2.3. The filter must be

easily removable for periodic cleaning or replacement.

Note

— Non-removable filters may be used in ventilated ceilings if they are

the design provides a constant outflow of the collected fat and accumulated in

extraction filter do not change the air resistance of the filter by more than 20

Pa at the calculated air flow.

6.2.4 Dimensions of removable

filters should not exceed 500×500 mm so that they can be washed in

dishwashers.

6.2.5 Installation not allowed

homemade grease filters. Grease filter manufacturers must supply

filters with a passport containing:

- name and address

manufacturer;

- Permits received

documents (certificates) of supervisory authorities operating on the territory of the Russian Federation

Federations;

— overall dimensions and weight of the filter;

- the name of the material from which

filter is made

— air flow range

(minimum, maximum), m3/s;

— aerodynamic resistance of the filter at

minimum and maximum air flow, Pa;

is the filter efficiency

particle retention at minimum and maximum air flow.

Presented in the form of a graph or table - filter efficiency in

depending on the particle size at a given air flow and resistance

air;

- Grease filter efficiency

in the particle size range from 5 to 7 microns should be at least 40% at

calculated air flow.