- How to do it yourself

- Installation of the mounting frame - step by step instructions

- The device and parameters of a wooden bath

- How is this type of plumbing arranged?

- Wooden bath options

- Is it worth making a bath out of wood

- Pros and cons of the design solution

- Design requirements

- Recommended Settings

- Structure construction methods

- Wooden details for decorating the bathroom

- Tools for the job

- What wood is better

- The choice of material for the font

- Pros and cons of various building materials

- List of building materials

- List of tools

- Wall, floor and ceiling decoration

- What floor to make in the bathroom?

- Features of wall decoration

- The subtleties of the arrangement of the ceiling

- Oak barrel firing

- Do-it-yourself work

- Floor cabinets

- Shelves with mirrors

- Dressing tables

- Lockers and storage

- What wood is better

- Description of characteristics

- Advantages

- Flaws

- Description, functions and device of the hot tub

- In the interior

- Washbasins without bottom

- Sink in solid wood

- wooden bath

How to do it yourself

The advantages of making a font with your own hands are most correctly compared with the purchase of a finished product. Here are the most notable benefits of this solution:

- Lower cost, for the same money you can get a font of a much larger capacity;

- Any configuration and size, with self-production, it is always selected according to the size of the bath;

- The ability to use valuable wood species, safety-tested sealants and adhesives.

These advantages are quite weighty, so making a do-it-yourself wooden bath font with the right manufacture will be much better than taking a factory one. In order to meet this condition, it is necessary to ensure the same machining accuracy as in the factory. With the wide distribution of construction power tools of any complexity class, this is easy to do.

Important! Often, self-production is divided into two stages: ordering parts to a factory where there is powerful machine equipment, then self-assembly, fitting and gluing a set of parts.

Installation of the mounting frame - step by step instructions

For the bathroom, it is not customary to do wall insulation, soundproofing, and other types of finishing work. Because of this, the space between the lining and the wall is not filled with anything, which means that in order to save usable space, it is worth constructing a thin but strong frame.

List of required tools:

- Powerful drill (if possible with a drummer);

- A set of drills for working on stone;

- Screwdriver or nozzle "screwdriver" for a drill;

- A set of dowels + self-tapping screws;

- Water or laser level;

- Jigsaw or hacksaw for metal.

A good choice of material for the construction will be wide, but thin slats (1-2 cm thick). They are easy to install with dowels and screws. Mount the frame to the wall in a horizontal position, maintaining an angle relative to the water level, and not the floor level.Focusing "by eye", you can spoil a lot of material, because with an error of several degrees, the unevenness of the structure will be visually visible. For a room with a height of 2.5 meters, 5 rails along the length of the walls will be required (the distance between them is at least 0.5 meters).

After drilling the holes, it is necessary to hammer in the dowels (for greater strength, you can lubricate the dowel in glue or plaster solution). Holes in the slats should be made with a drill 1 size smaller - in order for the self-tapping screw to hold firmly in place.

A frame made of metal profiles can also be used for these works. It is often used to mount PVC sheets, as wooden ones can be too heavy. Metal profiles are also mounted to the wall using dowels, self-tapping screws, U-shaped fasteners. Such a frame is a little easier to align in one plane, its adjustment and wear resistance are higher than that of a tree. However, the price is much higher and a special tool is required to work with it (at least a hacksaw, ideally an angle grinder with a cutting wheel) and the ability to use this tool. Wood is better suited for beginners.

Finishing the bathroom clapboard can only be done after all the above stages of repair (including the ceiling and floor), preparatory work, etc. have been completed.

The device and parameters of a wooden bath

Having decided to create an original and colorful plumbing fixture made of wood, you will have to get acquainted with its structure and parameters in more detail. This is not an easy task - you just won’t see such a product on the market. They are proud of well-known companies that have been producing plumbing for decades.

How is this type of plumbing arranged?

A bathtub made of wood is a functional container designed for bathing, like its steel, acrylic, and cast-iron counterparts. Therefore, it has all the elements characteristic of this kind of product - a hole for draining, overflowing, legs.

Moreover, depending on the model, it can be equipped with additional devices - jets for hydroprocedures or air massage, lighting for chromotherapy, musical accompaniment, remote control and other features.

The bathtub model may include various installation options. Sometimes a pedestal or wooden legs is required. In the first case, there must be a large room where the bowl will occupy a central place. And in the second - you can get by with a more modest room.

Wooden bath options

A wooden bathing container can have different dimensions, weight, shape, wall thickness. Characteristics depend on the features of the model you like.

If this product is in the shape of a barrel, then here we are talking about the height of the sides and the diameter, which is affected by capacity - for one, two, four, six or more people.

Italian companies offering wooden models of sanitary ware focus on developments and a special technology that allows you to create a bowl whose wall thickness is on the verge - this is an exquisite thin-walled bathtub. A fundamentally different approach is taken by manufacturers who make emphatically rough designs that are in demand for creating interiors in country houses in the Rustic or Primitivism style.

A fundamentally different approach is taken by manufacturers who make emphatically rough designs that are in demand for creating interiors in country houses in the Rustic or Primitivism style.

The length of a bathtub made of such material can be 1.8-2 m or more, and the width is 70-76, 78, 90 and this is not the limit. The main feature is that most bowls are made to order. Therefore, in the manufacturing process, the wishes of a particular customer are taken into account.

The height of the bath rim is also taken into account, which is essentially the distance from the floor to the top edge. This parameter, as well as the overall dimensions of the bowl, actually repeat the standards of the usual types of plumbing.

As for the volume, dimensions also affect it - it can be either 280 or 500-700 liters, for example, if the container is intended for 3-4 people.

Is it worth making a bath out of wood

Expensive materials, handicraft, individual project - all this creates extremely high prices for the finished product. Depending on the type of wood, design, volume of the bowl, they range from 50 thousand rubles. up to $25-30 thousand

However, the tree today is experiencing a rebirth in the interior, the styles that are in the world trend (Scandinavian, rustic, eco-style, primitivism) are based on the use of this material. It is considered the most environmentally friendly and has healing properties. Products from cedar, larch, for example, have a beneficial effect on the human nervous system.

These shortcomings are eliminated by the use of special types of wood and professional processing (lacquering, impregnation). Proper care makes them comparable in terms of service life to bathtubs made of steel and cast iron.

Pros and cons of the design solution

When deciding to order a wooden bath, you need to weigh all the pros and cons of this step.

The advantages of the product include:

-

aesthetics (created in accordance with the artistic tastes of the owner and is a spectacular element of bathroom decor);

-

uniqueness (performed in a single copy);

-

status (indicates prosperity, high position of the owner of the house);

-

environmental friendliness;

-

durability;

-

health properties.

The cons are:

-

high price;

-

increased absorption of fats, dirt;

-

strict care requirements (thorough cleaning, no bathing of animals);

-

danger of drying out of structural elements;

-

the need to periodically update the protective layer;

-

weight, which averages 150-200 kg, cannot be less than 60 kg.

Design requirements

constructive product features are determined by the way they are manufacture:

-

Klepkoy. The container is assembled from boards, which are pulled together with metal strips.

-

Set. The elements are connected with dowels and waterproof deep fixation glue (polyvinyl acetate), epoxy resin.

-

Hollowing. The bowl is made from a single piece of wood, which ensures its strength and tightness. This method, close to wooden sculpture, allows you to give the product any arbitrary shape.

A flat bottom, special platforms in spacious rooms, as well as legs or lowered goats, combined with a large weight of the product, provide it with reliability and stability.

A large number of original design solutions are based on a combination of a wooden base with decorative elements made of glass and metal. This achieves a futuristic effect, an unusual visual interpretation.

Recommended Settings

When determining the size of the product, one should focus on the area of \u200b\u200bthe room, as well as on the wishes of the customer.

If this information is missing, the parameters are calculated as follows:

-

A person of average height should take a reclining position and measure the distance between the projections on the plane (floor, board, slab) of the toes and back. Add 10-12 cm to the result, which will be the length of the bottom.

-

The width is determined by measuring the hips with the addition of 5-7 cm on each side.

-

It is recommended to use the same height as for mass-produced products (60-70 cm).

The parameters of a round bath are determined based on the number of people that are planned to be placed in the bowl.

Structure construction methods

Bath frames are different:

- In the form of a support on legs from a metal profile. Rectangular pipes are used. The design consists of several elements that support the bowl. The set includes legs with which to adjust the height. Only the bottom of the bath is installed on the support.

- Flat frame with legs - this option is more complex and durable. The bottom rests on a support from the profile, the base corresponds to the bottom of the bowl. Stability is added by transverse ribs. The vertical elements support the sides. It is used for baths of complex shape and corner models.

- The one-piece welded frame is the strongest. This is a three-dimensional design that holds the bowl securely. It has several reference points, distributes the load from the bottom and sides of the product. The stiffening ribs are in places of the main load.

When choosing the type of support, consider:

- bath dimensions;

- configuration;

- wall thickness.

The thinner the structure, the stronger the support should be.

Wooden details for decorating the bathroom

Wooden baths are still exotic for our market, and such plumbing models are expensive. Such products are designed to create elite interiors, however, wood can also be used when doing budget repairs with your own hands. Consider which wood details are most often used in the bathroom:

The easiest option is a wooden grate installed on the bath. This grid is very handy. It can be placed across the bath on the sides, in this case, you get a convenient stand for the basin. The grate can be placed on the floor and used as a rug. Leaving the bath, it is much more pleasant to step with your bare foot on a smoothly planed wooden surface than on a cold floor. The lattice can be purchased in stores, and home craftsmen will make this functional element of the interior with their own hands.

The wooden screen installed under the bath looks very stylish. This element of the interior will harmoniously fit into the interior of ecological or ethnic style. A wooden screen can be purchased at the store, as a rule, there are models on sale that are designed to be installed under a 150 or 170 cm long bath. If a bathtub of a non-standard size or shape is installed in the room, you will have to make a screen to order or make it yourself.

- Wall and floor decoration with wood. When planning to recreate the atmosphere of a bath in the bathroom, you can finish the walls with wood paneling and make a wooden floor. Properly treated with antiseptics and moisture-repellent impregnations, wooden parts allow you to create reliable and beautiful surfaces.

- Furniture. Many manufacturers offer bathroom furniture made of wood.This is a stylish and practical solution for decorating a bathroom.

So, a wooden bathtub made of moisture-resistant wood is an elegant and practical element of an elite interior. Other details of the bathroom equipment are also made of wood. Some of them (for example, a grate on a bathtub or a screen) can be made by hand.

Tools for the job

Wooden bathtubs can be made in the shape of a barrel, they can look like a regular acrylic bathtub, and there are many other ways to make a bathtub original. You just have to show your imagination. And in order to make this possible, you will need the following tools:

- Moisture-resistant tree species that have already been previously cleaned of bark and all sorts of roughness and irregularities;

- A thin bar, which will be equal in length to the bath;

- Bars, which must be made of the same material as the bath itself;

- Nails;

- Varnish on wood;

— Sealant and silicone;

- Square;

- Adhesive for bathtub assembly.

What wood is better

When deciding how to make a font in the bath, you need to pay attention to the wood. Independent production of a font significantly expands the possibilities for choosing wood species

From the options for the initial price level, you can choose larch and red beech.

A rather unusual solution is aspen and linden. Of these, the font will be bright white. In order for it to be preserved, it is necessary to have a good protective coating, which largely levels the ecological qualities of wood.

Hardwoods such as oak and larch can be used uncoated. Chemical compounds are used only for gluing rivets. Compared to full coverage with multiple coats, they will have little effect.

Important! Regardless of the species, you need to purchase only well-dried wood of the first grade. For a font, this is especially important, since if it is made from damp wood, it will dry out and begin to leak.

The choice of material for the font

Thinking about what to build a font from, the choice is made in favor of metal, wood, plastic, concrete or composite material. Concrete is suitable only for the case when the container needs to be made deep. Plastic and composite structures are considered the most economical options. And wood is a traditional material for making a font, which has a beneficial effect on health, but needs careful care.

Pros and cons of various building materials

Font rarely used metal, since its only plus is the ability to maintain a low temperature of the poured water. The disadvantages of a metal construction for swimming include:

- difficulties in installation;

- unattractive design.

The design of the product rarely supports the main interior solution of the bath, which significantly worsens the appearance of the room.

A concrete bath has the following advantages:

- it is created in those forms and dimensions that the owner of the bath likes;

- maintains the desired water temperature for a long time;

- does not collapse and does not lose its appearance for a long time.

But, despite all the positive aspects, one should not forget about the lack of design - investing a lot of work in its construction.

A simple concrete structure is capable of maintaining the required water temperature for a long period of time.

Some refuse plastic due to the fact that this material quickly becomes hot.But, if you do not pay attention to this minus, then a plastic font can have many advantages:

- small financial costs;

- fast assembly of the finished product;

- strength and long service life.

Plastic fonts can have a variety of shapes and colors.

Composite material hot tubs deserve special attention because they have the following advantages:

- are sold assembled or disassembled;

- they are distinguished by excellent strength, incomparable with the quality of plastic or concrete;

- weigh little and at the same time do not raise doubts about reliability;

- easy to install.

The strength of a font made of composite material is several times higher than that of plastic or concrete

Containers made of wood are very popular due to such features as:

- environmental friendliness and reliability of the material;

- the benefits of exposure to natural wood on the human body.

True, it is somewhat difficult to build a font from wood, and also expensive. In addition, wood products must be looked after with special care.

Despite the fact that a wooden bath tub is a classic option, its cost significantly exceeds other options.

In the bath, it is best to put a container made of certain types of wood. For the manufacture of the font, it is recommended to take:

- larch, relaxing the muscles of the body;

- cedar, which improves the condition of the skin and has a beneficial effect on the nervous system;

- oak, which enhances immunity and eliminates insomnia;

- beech, cleansing blood vessels and calming the heart.

List of building materials

To make a traditional wooden font, you need to stock up on the following materials and fasteners:

- wooden slats 10 * 4 cm in size with a selection on the side terminals (9 pieces for the bottom and 15-16 pieces for the walls);

- supporting beams measuring 10 * 10 cm;

- metal hoops (2 pcs.);

- plastic drain;

- silicone;

- self-tapping screws;

- bolts and nuts (for fastening hoops).

For ease of assembly, the boards are equipped with grooves and ledges.

List of tools

When building a font, you will need certain tools:

- drill;

- clamp;

- hammer with rubber coating;

- electric jigsaw;

- screwdriver;

- sandpaper;

- moisture resistant glue for wood.

Wall, floor and ceiling decoration

After the reliable waterproofing is ready and completely dry, the turn of finishing works comes. When choosing materials, you should take into account the features of the room, which is located in a wooden house.

What floor to make in the bathroom?

The basis for finishing the floor will be a concrete screed, poured over the waterproofing layer. It should have a slight slope, thanks to which an emergency drain is equipped in the floor.

All materials purchased for finishing the bathroom must meet the main requirement for any finishing material for a wooden house - moisture resistance

This is the first thing you need to pay attention to when buying. For finishing the floor most often used:

For finishing the floor most often used:

- laminate;

- porcelain stoneware/ceramic tiles;

- linoleum;

- moisture resistant wood.

An elementary and far from the worst cladding option is ceramic tile. The wooden floor looks beautiful and organic in the bathroom. If you want to save money, you can get by with linoleum.

The laying of hard types of coatings on the floor in wooden houses is carried out according to a floating pattern. That is, they are not fixed rigidly to the base and between the walls of the building and the screed, together with the tiles laid on it, for example, leave a gap of 1.5 - 2 cm.

A “floating floor” is needed to compensate for the linear movements of timber structures. From above, the gap is closed with a plinth, which is fixed exclusively on the wall.

Features of wall decoration

When decorating walls, you need to take into account the characteristic features of natural wood. Under the influence of moisture and temperature fluctuations, it shrinks and cracks.

To avoid deformation, the surfaces are prepared for subsequent finishing by installing a crate and fixing a false wall on top. This design is erected from moisture-resistant drywall or a sliding frame made of a metal profile in compliance with the ventilation gap.

Such preparation will allow you to perform almost any type of finishing. But if it is planned to use wood for cladding, then there is no need to build false structures.

Bathroom tiles can be combined with wood or special paint to create beautiful combinations.

Now the following finishing materials for walls in the bathroom are in demand:

- Wooden lining. It is polished and additionally processed with paints and varnishes. It is better that it be made of moisture-resistant teak or larch;

- Tile. It is presented in a huge assortment: smooth and embossed, plain, with an ornament, large or mosaic. It is attached with waterproof glue, and the seams are treated with polyurethane elastic sealant;

- Wall panels. It can be plastic plates or aquapanels. Under them, a crate for a ventilation gap must be installed.

A variety of materials for finishing allows you to realize any design fantasy. You can combine several types of materials, create color compositions, play with textures.

Tiling is the perfect solution for bathrooms. It is durable, water resistant and easy to care for.

Those who want to tile walls made of logs or timber with ceramic tiles will have much more work to do. To do this, a frame is first built along the walls, allowing the decoration to move separately. A plasterboard base is arranged along the frame, tiles are laid on it.

The subtleties of the arrangement of the ceiling

The ceilings of bathrooms located in private wooden houses are usually finished with suspended or tension structures made of glossy PVC panels, moisture-resistant drywall.

Suspended ceilings are valued for numerous benefits. They are a powerful shield against moist air, under them it is easy to disguise elements of the electrical and ventilation systems.

If the choice fell on drywall, then the profile for it should be treated with zinc and coated with additional corrosion protection. In order for the plasterboard ceiling to retain its original attractiveness longer, it is pasted over with glass wallpaper.

Stretch, suspended and rack ceiling structures will allow you to realize any ideas for lighting

Oak barrel firing

The main purpose of firing the finished barrel is to eliminate the acquisition of wood flavors in stored products. For example, wine stored in such barrels does not give off sawdust, but rather acquires exquisite notes of taste.

The firing process looks like this:

- The barrel is laid on its side and shavings or sawdust of any fruit tree are placed in it.

- The sawdust is set on fire.

- After a slight burning is noted, the barrel is rolled from one side to the other, controlling the degree of burning.

- It is forbidden to blow a big fire inside the barrel, otherwise, instead of burning it, you will burn it.

- Means for quick ignition cannot be used either. Everything should be as environmentally friendly and natural as possible.

Another example of making a wooden barrel with your own hands:

As you can see, the manufacturing process is within the power of everyone. A do-it-yourself wooden barrel is not just an exciting process of creation, but also an opportunity to provide a family with an environmentally friendly container for storing various food or liquids.

Do-it-yourself work

When making your own, you need to follow the instructions. For each type of structures there are corresponding drawings.

Floor cabinets

If your apartment has a separate bathroom, then it is better to choose a console modification of floor cabinets and not try to fit it to the size of the sink. Constant contact with moisture may damage the headset.

But you can equip the sink with shelves for storing various small items or compact shelves. This is a convenient layout, since during hygiene procedures it will be possible to move the sliding table towards you. If you enjoy taking a bath, reading books, and watching your favorite TV shows, this is the best option for you.

If the bathroom is combined, then you can build a full-fledged floor cabinet. In this case, the problem of the negative impact of moisture on furniture will be less pronounced, so you can use laminated chipboard and MDF for assembly.

Modifications of curbstones like kitchen models look no less stylish. They can be adapted to the conditions of use, while maintaining the height.

Floor cabinet in the bathroom.

Inside the cabinets, you can install shelves and drawers, mesh storage systems and bottle holders. For storing large items, such as basins, buckets, laundry baskets, it is better to use more spacious designs.

Shelves with mirrors

If there is no problem of lack of space in the room, it is better to fix the shelves with mirrors away from the shower or bath. This will eliminate the problem of fogging glasses and allow you to comfortably carry out cosmetic procedures.

In addition, placing a mirror above the washbasin will help organize additional storage space for various small things. The shelves themselves can have any shape:

- Rectangular.

- Rounded, etc.

Rectangular shelf with mirror in the bathroom.

You can use either 1 design or several. The second option is preferable due to the presence of large reserves of usable space.

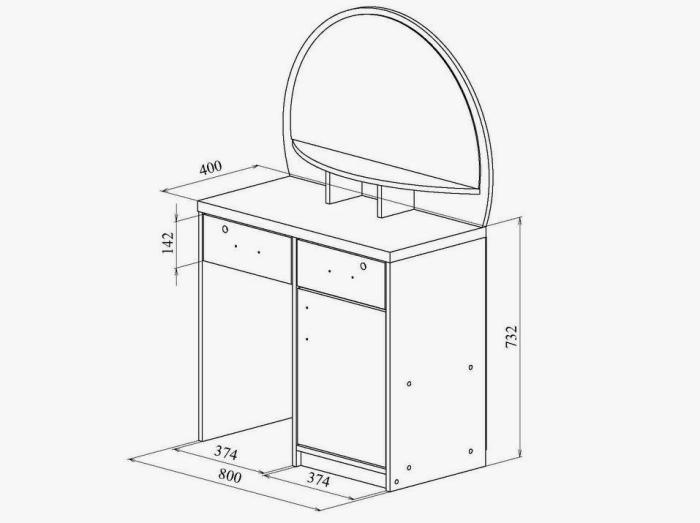

Dressing tables

To build a practical table in the bathroom, you need to prepare a competent project. For the upcoming assembly you will need:

- Materials (chipboard, plywood, MDF, wood).

- Elements of accessories.

- Attachments for connecting and processing parts.

- Finishing materials (paint, varnish, plastic panels, etc.).

- Related accessories.

Bathroom vanity drawing.

Bathroom vanity drawing.

Having completed the preparation of drawings and improvised means, you need to cut the material using a jigsaw. Next, you need to clean the samples with toilet paper and perform a 2-fold primer of the end parts with Moment glue. Then it is necessary to glue the end edge, and drill holes in the indicated attachment points.

The side elements are duplicated with a corner to increase the reliability and durability of the structure. Then the boxes are assembled.

The surface of the dressing table is both monophonic and multi-colored. It can be treated with stain, varnish or other paintwork materials. If an acrylic composition is used, the coating will receive a stylish wood structure.

Lockers and storage

Cabinets in the bathroom will be a good alternative or addition to the shelves. If there are no problems with lack of space, 2 designs can be used. Suspended modifications are more practical, because. mounted on the wall without taking up much space. They can be equipped with mirrored doors, forming 2 stylish interior elements.

There are ideas for organizing furniture for storing useful things under the bathroom. Folding and retractable designs are popular in Western countries, but they are rare in Russia. Such kits are suitable for country cottages without a pronounced problem of lack of space.

Hanging cabinets in the bathroom.

What wood is better

When deciding how to make a font in the bath, you need to pay attention to the wood. Independent production of a font significantly expands the possibilities for choosing wood species. From the options for the entry price level, you can choose larch and red beech

From the options for the initial price level, you can choose larch and red beech.

A rather unusual solution is aspen and linden. Of these, the font will be bright white. In order for it to be preserved, it is necessary to have a good protective coating, which largely levels the ecological qualities of wood.

Hardwoods such as oak and larch can be used uncoated. Chemical compounds are used only for gluing rivets.Compared to full coverage with multiple coats, they will have little effect.

Important! Regardless of the species, you need to purchase only well-dried wood of the first grade. For a font, this is especially important, since if it is made from damp wood, it will dry out and begin to leak.

Description of characteristics

So, what do we get by purchasing and installing a wooden bath?

Advantages

The highest level of environmental friendliness and the presence of a healing effect. Wood has a positive effect on human health, calming the nervous system and preventing many chronic diseases.

Wooden font has a positive effect on the human body

Natural beauty and uniqueness. The wood pattern never repeats, moreover, these bathtubs are made exclusively by hand, which guarantees originality. Warm colors are pleasing to the eye. This design will decorate not only the bathroom, but the whole house.

Beauty and originality are the main features of any wooden bath

- Pleasant tactile sensations. While taking water procedures, you are in contact with the surface of the bath with your whole body, and with warm soft wood this contact is much more pleasant than with cold and hard cast iron and acrylic.

- Wide range of shapes. The pliability of wood allows you to create the most bizarre designs from it.

The unusual shape of the container brings an additional effect of "Wow!"

Durability. With proper care, a wood structure will last you for decades.

Regular contact with the liquid, the wood will not dry out

It is noteworthy that if you can’t afford a full-fledged wooden font, then you can easily install a wooden screen under a cast-iron or acrylic bath. This will give an interesting visual effect.

A wood-effect bathtub adds cosiness to the room

Flaws

But there are also obvious disadvantages, some of which, however, can be successfully dealt with:

- High price. There is nothing you can do about it, because, firstly, expensive varieties of trees are used, and secondly, all wooden baths are made by hand, which is also not cheap.

- Complicated care instructions. We have already mentioned this above, so that the wood does not start to rot, it is impossible to allow damage to the protective coating during operation.

Description, functions and device of the hot tub

A font is a large container in the form of an oval or a circle. The depth of such a bath can be different, so it is often compared with a mini-pool. By the way, fantasy and modern materials allow you to make a font of a non-standard look. In addition to the usual round and oval bathing containers, there are corner, square and rectangular fonts.

Rectangular and square fonts save space in the room

The way the font is used is hinted at by its name. The product performs the same function as a bath, that is, it helps a person to keep the body clean. In addition to this task, the font has another one - wellness. Swimming in the mini-pool, sauna lovers harden. In addition, the font is most often made of wood, which has healing properties and “gifts” a person with them.

The device of a stationary font can be done in any bath, except for a room standing on a foundation of slabs.A font is a separate structure that does not in the least interfere with the use of a bathhouse and does not spoil its walls.

In the interior

So far, it is rare to find wooden sinks in interiors. It may seem that they are not compatible with plumbing at all, but this is not the case, for which there are enough examples.

When there was no faience and porcelain, almost everything was made of wood, not to mention fonts, barrels and troughs. Then it was possible to surprise guests with a bathroom made of cast iron, but not made of wood.

The material familiar to our great-great-grandfathers today is a curiosity for many. At the same time, lovers of natural and eco-friendly interiors believe that this is a mandatory attribute of a stylish and expensive room design.

Corner sink with wood cabinet

We have long been accustomed to fine wood furniture, floors, so if you want to really surprise your friends and amaze them to the core, make or buy a wooden sink.

| Beauty and form | The decoration of plumbing will be its luxurious and unique texture. Thanks to the skill, it can be turned into any form:

|

| Breed | It is advisable to use moisture-resistant and hard wood species for manufacturing. These include:

|

| Treatment |

|

Washbasins without bottom

Manufacturers often surprise us with their models, sometimes leading us into a stupor.For example, the company "Lago" offered a variant of a wooden sink, in which "there is no bottom." Of course, this is only an optical illusion and it is present, but you must admit that such an unconventional approach can lead both to delight and bewilderment.

Sink "without a bottom"

If you study the design and execution of the model, we can say that it will be possible to reproduce it with your own hands. To do this, you will need a worktop with a thickness of 80-90 mm, made from finger-jointed wooden beams. It will need to make a rectangular hole in it, which will serve as a sink.

For this design, keep the wood structure intact and coat the surface of the countertop with several coats of lacquer. Have you forgotten that the most interesting thing in this model is hidden at the bottom?

For it, prepare a transparent glass, placing under it, for example, 3D images. So you can get interesting visual effects.

If you do not use anything, then you get the illusion of the illusion of the absence of a bottom. Which will also be interesting.

General view of the sink in the interior

A specially designed water drainage allows you to get all of the above effects. It does not leave from below, as in ordinary shells, but passes through a slot located on the back wall of the bottom, and then enters the siphon along the chute.

This made it possible:

- make the bottom cover whole;

- surprise acquaintances and friends with the "lack of a bottom" at the sink, if you hide the siphon and use transparent glass.

Sink in solid wood

This option shows how to make a do-it-yourself wooden sink in an array of glued beams.

Below is the process instruction:

- It is necessary to glue the bars together. The thickness depends only on your wishes.

Wooden beams glued together

- Mark them up.

Approximately this markup

- Take a circular saw and cut it to the desired depth.

We cut through the circular

- Take a chisel and a hammer and remove the excess.

Remove excess with a hammer and chisel

- Sand the resulting container.

Take a drill with a grinding wheel and sand the bottom

- We make a hole for the drain.

Drill with a nozzle to make a drain hole

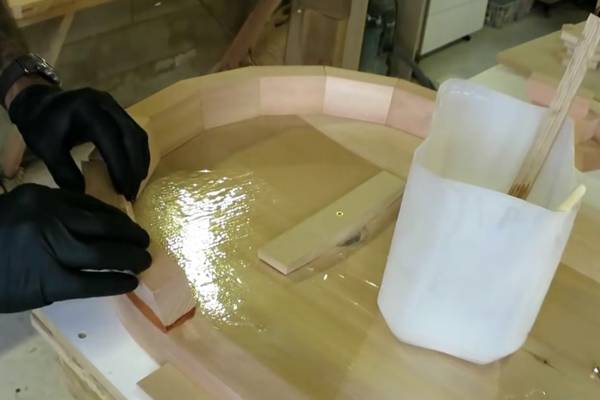

- Take epoxy glue and coat the resulting sink.

Brush the sink with epoxy

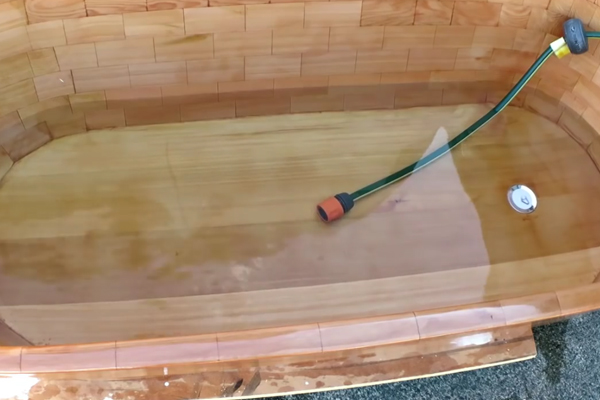

wooden bath

Now let's talk about a larger sink - a bathroom. Its price in retail chains goes off scale, so why not make it yourself if you have the time and desire?

The process cannot be called simple, but it can still be done.

- You also need to prepare special woodworking tools.

- The principle of operation is one thing - you need to make a sealed wooden box. What is the need for a high-quality fit of wooden structural elements to each other. Do not hope that the wood will swell from the water and close all the cracks.

- An important moment in the manufacture of a wooden bathtub is the polished surface at the end of the stripping stage. Otherwise, it will be unsafe to take water procedures in it.