- When is the only solution to install a vacuum valve?

- Advantages and disadvantages of the sewer element

- How does a vacuum valve work and how is it arranged?

- Design, types and installation location

- In a private house

- In an apartment building

- Types of valves and principle of operation

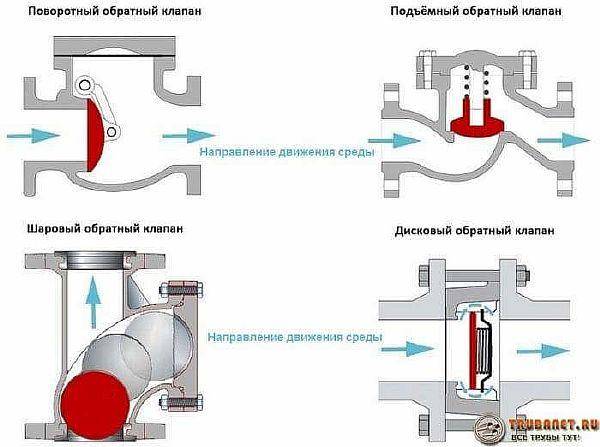

- Swivel

- Lift valve for sewerage

- ball valve

- Wafer type

- Connecting a return valve

- Installation of a sanitary accessory

- Types and sizes - 110, 50 mm, etc.

- Which valve to buy?

- Overview of manufacturers and prices

- The device and principle of operation of the fan valve

- Pros and cons of application

- About technical characteristics (diameter) and manufacturers

- Where is the fan aerator installed?

- Types of air valves and their sizes

- Ball check valve

- PVC check valve

- For pressure sewer

- Conclusion of a fan riser in a private house

When is the only solution to install a vacuum valve?

As a rule, pipes are used to connect the toilet to the central sewerage system, inside which gases are always present. In any case, a large amount of both cold and hot water is flushed into the sewer, while, according to the law of physics, hot steam rises.

To quickly solve such a problem, you need to immediately tighten the plug at the end of the riser. To eliminate unpleasant odors, you need to install special water seals. If there is no ventilation on the riser, then due to the powerful flow of water in the pipe, a vacuum is created when the toilet is drained. As a result of this phenomenon, the contents of the nearby water seal are taken. After some time, an unpleasant smell from the sewer may be felt in the room. To prevent such a nuisance, many experts recommend installing a vacuum valve at the highest point of the riser.

You can decide whether to install this element by paying attention to the following tips:

- Using a vacuum valve, you can effectively solve the problem of ventilation of the sewer riser in a low-rise building. If there is a simultaneous drain of several toilet bowls, then the device is unlikely to cope with its intended purpose;

- you cannot independently cut off the fan riser leading to the attic in a house with several floors in order to install a vacuum valve. In such situations, apartments located on the upper floors are unlikely to suffer from unpleasant odors, but on the lower floors there will be a clear sewer smell. One way or another, experts will identify the cause of the problem, which will have to be fixed at their own expense.

Advantages and disadvantages of the sewer element

The advantages of a vacuum valve include:

- no need to make a special hole in the roof to remove the riser pipe. The roofing remains intact, while the process of installing the sewerage system is greatly simplified;

- the sewer riser ends exactly inside the building, so the appearance of the house will not deteriorate due to the installation of numerous pipes to create ventilation, which are not cheap;

- there is no need to perform periodic maintenance and repair of the device.

The disadvantages include:

- danger of failure under heavy load on the sewer system;

- the vacuum valve is quite expensive, this is due to the fact that the device is made by hand.

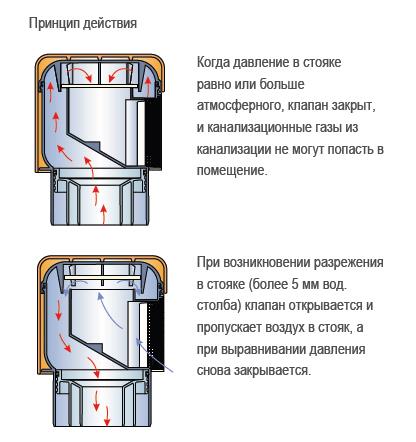

How does a vacuum valve work and how is it arranged?

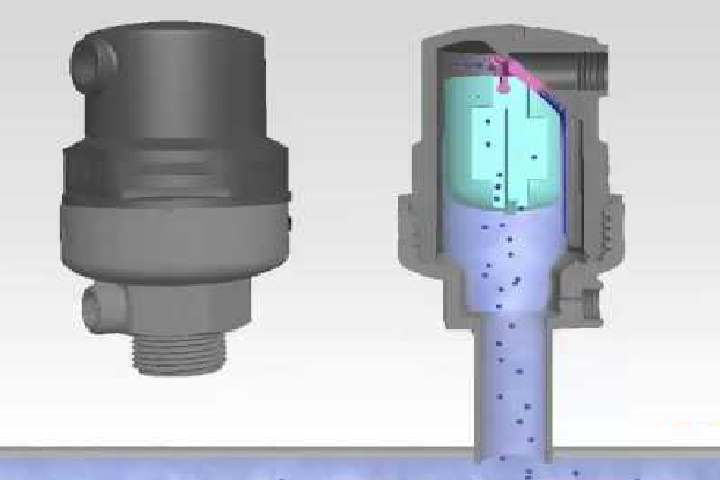

If normal pressure is observed in the sewer pipeline, then this device will be closed. As a result of this phenomenon, protection against the ingress of unpleasant odors and harmful fumes into the room is provided. When pressure is released, such as when flushing a toilet, the vacuum valve opens automatically, allowing air into the system. In the process, pressure equalization is performed.

Such an element for sewage can be used to create local aeration. To do this, the valve is installed on the pipes of plumbing devices, the use of which involves a large flow of water.

In order for such a solution to be as effective as possible, you must follow the installation rules:

- the valve must be installed on the sewer riser above the point of supply of the plumbing device;

- installation must be carried out in a room that is well ventilated, it can be an attic, a toilet or a bathroom. In addition, access to the device for periodic technical inspection should be provided;

- the vacuum valve should only be installed on the vertical area of the pipe.

This sewer device is a simple fitting, so you can attach it using a seal.

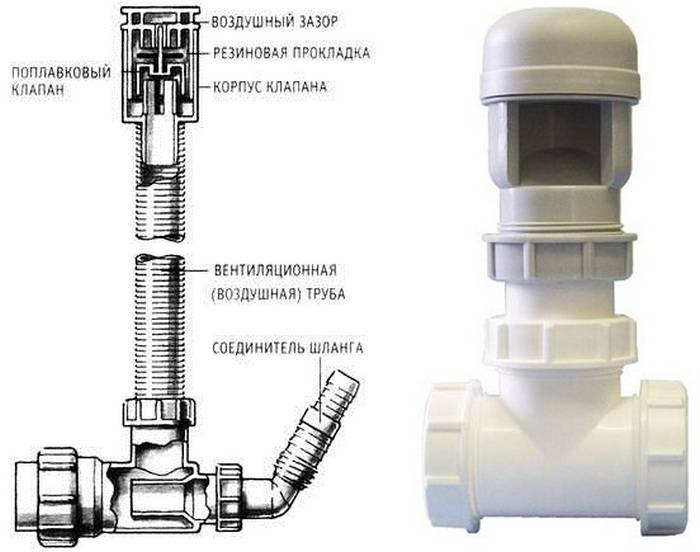

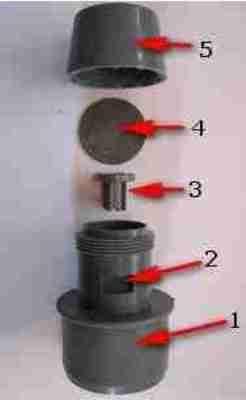

The item package includes the following parts:

- a plastic case with a side hole;

- a rod that, if necessary, is able to open a side hole;

- so that the stem does not move up, a special rubber gasket is installed;

- the rod assembly is securely closed with a protective cover connected to the body.

On sale there are vacuum valves having a diameter of 50 and 110 mm. The first option can be installed in homes equipped with no more than two plumbing fixtures or in cases where a small water flow is provided.

Design, types and installation location

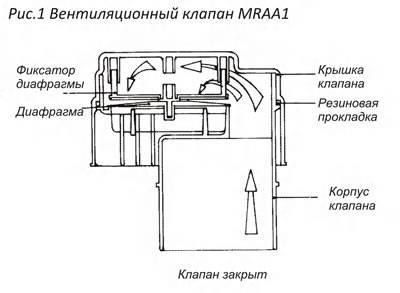

The design of the valve is simple and consists of the following elements:

- plastic case;

- a special hole for supplying air into the system when the mechanism is triggered;

- rod - the main working mechanism, which is activated when a pressure difference occurs;

- a rubber gasket is connected to the rod and is its limiter during movement;

- the cover closes special ventilation holes, preventing debris from entering the mechanism.

A membrane can be installed instead of the stem. The principle of operation remains unchanged. The disadvantage of the membrane is its rapid wear.

There are three types of air valves:

- The kinetic or anti-vacuum model operates at low pressure and has a large capacity.

- The automatic model has a low throughput. The aeration element helps to remove pressurized air from the system.

- The universal model is a combination of both valve types.

The difference between aerators is their size, which affects the throughput.

Local models are available with a diameter of 50 mm and they are designed for only one drain point. A 110 mm fan valve is installed on a common riser. The element provides ventilation for several branches of the sewer system.

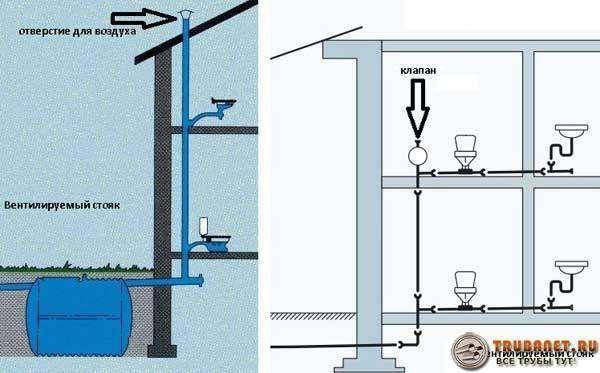

In a private house

For private houses, installing a valve is beneficial in terms of not having to destroy the roof in order to bring the riser to the street. However, it is necessary to take into account the type of sewer system.

For septic tanks, the use of aeration elements is unacceptable. If the pipe is brought only to the attic, and an aerator is installed on top, then such a system will be unventilated. Bacteria that digest sewage need access to oxygen. Only a ventilated system is capable of providing it, with a fan riser brought outside. The aerator is installed only as an auxiliary device if the hydraulic seal fails.

If the sewerage of a private house is connected to a centralized branch or simply goes into a cesspool, then an unventilated system will do.

The riser is taken out only to the attic and an aeration element is put on top. Unpleasant odors may develop during valve operation. The attic must be ventilated, spacious and unused. The riser is additionally insulated with any thermal insulation, but not a valve.

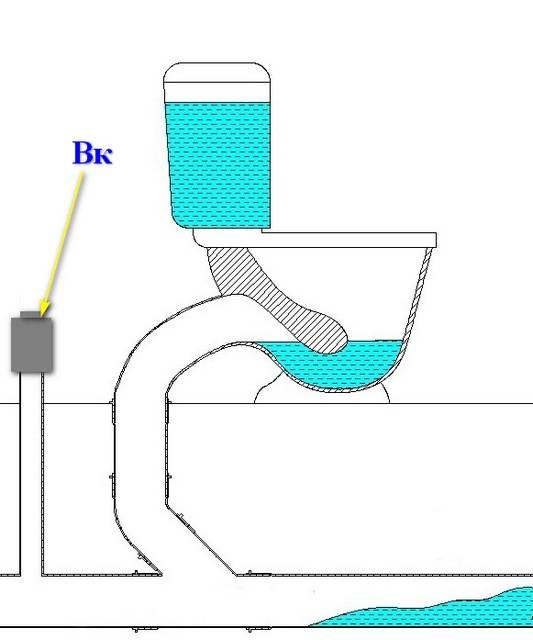

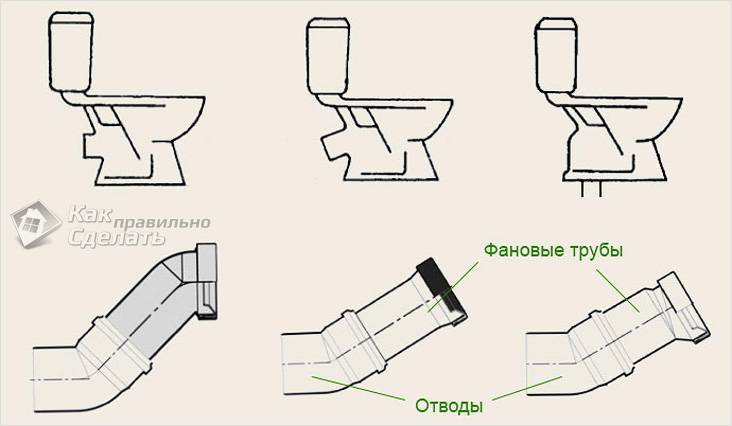

In an apartment building

In an apartment, like in any other room, an aerator is placed only on a vertical pipe. If a horizontal line passes, then a tee is cut.

The lateral exit of the shaped element forms a point for the vertical location of the fan element.

Types of valves and principle of operation

There are several varieties of sewer check valves for 110 and 50 millimeters, which differ in scope. Accordingly, all types of mechanisms have a different design and principle of operation of one element.

When waste liquids come up, the damper automatically rises, after which it returns to its original position again. It is according to the mechanism of operation of the damper that models of sewer check valves are classified.

Swivel

This type of sewer valves has a spring-loaded membrane (it is called a plate because of its round shape). In the case when the wastewater moves in the right direction, the plate turns and goes up without interfering with the movement of liquids.

However, with the opposite direction of the drains, the spring-loaded membrane is tightly pressed against the outer rim, as a result of which the working area of the pipeline is blocked.

Some models additionally have a built-in additional damper, which is controlled manually. A similar locking mechanism can be adjusted using a special button located on the device.

Thus, the pipeline has first an expanding and then a narrowing section, which is a possible place for the formation of a blockage in the sewer system. The solution to this problem is the placement of the cover mechanism at the top of the housing. Having removed it, it is possible to quickly and easily remove the blockage that has appeared.

Lift valve for sewerage

The name of this type of device is based on the mechanism of operation of the damper.When the wastewater moves in the right direction, the damper is at the top.

The name of this type of device is based on the mechanism of operation of the damper.When the wastewater moves in the right direction, the damper is at the top.

Principle of operation: the liquid exerts pressure on the membrane, which blocks the movement of drains, the internal spring is compressed, as a result of which the damper rises. If the sewage does not move, then the spring is in its normal state, and the path to the drains is blocked.

Due to the non-linear body shape, when the liquid moves in the opposite direction, the valve cannot be opened, which ensures complete safety against flooding.

This type of check valve for 110 or 50 mm sewerage is more reliable than a rotary (petal) model, but there is a drawback.

The peculiarities of the form are the reason for the need for regular cleaning of the system, because. it gets dirty from time to time. To perform this procedure, you will need to unscrew the bolts (4 pcs.), Then thoroughly clean or, if necessary, replace the working mechanism. If the owner has the opportunity to perform regular cleaning, then it is better to purchase just such a variant of the check valve.

ball valve

In this type of device, the locking element is a small ball. The upper part of the body is designed in such a way that during the flow of sewage, the ball enters a separate hole and allows the flow to move.

When there is no liquid, the working area of the pipe is blocked, as a result of which the flow is not able to pass in the wrong direction. However, such models have a drawback - in contrast to the rotary and lifting mechanism in this design, the valve-ball does not completely adjoin the rim of the device.

As a result of leakage, a small flow of sewage water may occur. Of course, the likelihood of serious flooding, as if the sewer check valve was completely absent, is minimal.

Wafer type

The main advantage of this type of locking mechanism is its small size, which makes installation possible even in the absence of free space behind plumbing fixtures. Externally, the device looks like a miniature cylinder with a special butterfly valve.

This element can consist of 2 components, which are fixed at the central rod, or in appearance resemble a small plate, which is fixed to the body using a spring mechanism.

It is advisable to install such an option only if other varieties cannot be installed. Even taking into account the small size, it is still desirable to give preference to other types of device. Wafer type reverse valve 50 mm for sewerage mounted quite rarely, because. belongs to the category of equipment for water supply. For sewer systems, its efficiency is quite low.

Another disadvantage of this design is the inability to quickly clean the device. Due to the nature of the shape, it will be necessary to completely disassemble the connection in order to clean the valve.

Connecting a return valve

Sometimes ventilation is equipped with a check valve. When installing it, you can not worry about the output of the pipe to the roof. The stand also performs a number of other functions. After installing the toilet, you can immediately connect the non-return valve. The number of valves is determined by the number of bathrooms.

The principle of operation of the structure is not complicated.When draining, the damper is raised and the waste flows through. If you do not use the toilet for a long time, then unpleasant odors will not appear in the house. The device will save the house from the unpleasant consequences of stagnation.

Check valve purpose:

- Eliminates problems associated with improper pipe slope;

- Protecting sewers from stagnant odors, rodents and beetles;

- An obstacle to the reverse movement of effluents.

You can install a check valve both outside and inside. Much depends on the type of element. The valve must face the movement of wastewater. The design details look like petals that are curved towards the toilet.

Internal installation assumes good cleaning of surfaces. You should also degrease the coating, but without the use of lubricants. All installation work is carried out on a dry surface.

Installation of a sanitary accessory

The work should be carried out in several stages.

The work should be carried out in several stages.

First of all, you need to decide on the place for mounting the device.

It is best to install the valve in the following places:

above the point of connection of plumbing fixtures to the sewer.

So the aerator will be able to most accurately and quickly perform the functions assigned to it;

in rooms with good ventilation.

If this is a private house, then the device must be installed in the attic (it must be well ventilated)

In apartments located in multi-storey buildings, the structure is mounted in a toilet or bathroom.

At the same time, do not forget to equip the room with an additional hood;

important condition!

In the room where the valve will be installed, the air temperature should not fall below 0 degrees Celsius.If this rule is ignored, the device will fail and its performance will be reduced to nothing;

do not forget that the device should only be placed in an upright position.

If there is no suitable section on the sewer pipe, then you need to embed an additional elbow, which will be an adapter;

in the toilet or bathroom there is a drain, here the valve must be mounted as high as possible.

In this case, a distance of at least 35 cm must be ensured from the floor to the fixture.

Remember to leave free access to the valve.

This is necessary for carrying out preventive work and forcing the mechanism to turn on.

Worth knowing!

The equipment needs periodic cleaning.

The next step.

It is necessary to check the product for tightness.

At home, this can be done in several ways:

- the unit must be filled with air and treated with soap.

If there is a small crack or chip on the body of the device, then air bubbles will appear in this place.

You can pump air into the mechanism using a bicycle pump;

- do not want to smear the valve with soap, it can be placed in water.

If it is not hermetic, then bubbles form on the surface of the liquid substance;

- valve can be filled with water.

If there are cracks on the body or the tightness of the joints is broken, the liquid will leak out.

Important information!

Important information!

As a rule, the product is checked for tightness at the factory, immediately after production.

The final stage of installation of the device.

After all the steps described above have been completed, installation work should begin.

Depending on the design features of the unit, installation can be carried out as follows:

- by means of a threaded connection.

On a pre-prepared section of a hollow object and on the valve, it is necessary to cut the thread and treat it with a special sealant.This must be done to avoid leakage of the docking points;

- into the socket

In this case, the use of a rubber cuff is provided, which will seal the joint and connect the device to the sewer pipe.

A simpler and more reliable installation is in the socket.

Types and sizes - 110, 50 mm, etc.

The aeration unit for sewerage differs in purpose, design, manufacturer and diameter.

The main types of devices:

- kinetic - designed to reduce the likelihood of accumulation of excess air in the sewer;

- automatic - necessary to remove air at high pressure;

- combined - have the functionality of kinetic and automatic varieties.

In most cases, for the effective functioning of the sewer system, a combined type of valve is used. The piping scheme is always layered and has both vertical and horizontal orientations. Depending on the angles of inclination, pipe diameter and other parameters, the most efficient devices are selected.

Types of sewer aerators by design:

- receiving - installed in front of the pumping pump in the horizontal parts of the sewer;

- ball - suitable for pipelines of small diameter and in most cases used for plumbing;

- non-return air valve - designed for septic tanks and pipes with a diameter of up to 40 cm;

- ball valve with gate spring;

- damper - mounted on long sections with an increased risk of water hammer;

- interflange - mounted on sections of the pipeline with a diameter of less than 20 cm, such devices are able to turn 90 degrees or pass the flow.

Each of these models can also differ in the type of mechanism. For example, wafer aerators are disc spring and bivalve. Valve fastening can be carried out by coupling method or by welding with fastening between flanges.

Size classification:

- 110 mm - means the diameter of the sewer system where the valve must be installed. There are 2 types of this aerator: external and internal. The outer one is installed on top of the pipe, and the inner one is inserted into it using a rubber cuff.

- 50 mm - used on local sewer branches. In most cases, it is mounted within a private house or apartment with a horizontal orientation of the pipeline.

A 110 mm sewer aeration unit is used when the ventilation pipe is led to the attic, and not to the roof (this prevents clogging and reduces the negative impact of low temperatures), as well as for auxiliary risers (thanks to the aerators installed on them, only the main riser can be brought to the roof ).

Advantages of this type of aerator:

- low cost;

- the footage of the pipeline is reduced, so it is saved;

- non-volatile, which allows the valve to automatically regulate pressure even in the absence of electricity.

The principle of operation of a 50 mm sewer aerator in most cases does not differ from 110 mm, but the scope of application differs.It is installed when several plumbing fixtures are simultaneously used in the room (for example, a toilet bowl, a bathtub and a sink); when there is an element in the pipeline where the diameter of the pipe changes dramatically; if, when installing the sewerage system, the slope is not done correctly.

The installation of large devices should be carried out by housing and communal services workers, and local 50 mm aerators must be installed independently. For the correct and durable operation of the aerator, it is recommended to follow certain rules during installation:

The installation of large devices should be carried out by housing and communal services workers, and local 50 mm aerators must be installed independently. For the correct and durable operation of the aerator, it is recommended to follow certain rules during installation:

- the fixture is mounted after the last plumbing element in the system and must be above the rest of the fixtures;

- it is necessary to connect the air valve to pipes of the smallest diameter;

- when using a drain, the device must be connected at least 35 cm above the floor. Otherwise, the risk of channel clogging and disruption of its performance increases.

Important to remember! A sewer aerator of any kind cannot be taken outside, its operation is possible only indoors or attic

Which valve to buy?

The question is not easy in the sense that there are no obvious “favorites” or “promoted” models. But at the same time - there is a very serious variation in prices. And plus everything - there are no clear selection criteria, except, perhaps, the diameter of the pipe on which the valve is mounted, dimensions, if the place for its installation is limited, and the most convenient way to connect to the pipe.

At one point, the drain pipes from the shower and washbasin converge. To protect this unit from the failure of the siphon, it was decided to install an aerator on a 50 mm pipe

In this case, of course, the dimensions of the device are important.

Of course, it should be assumed that the more well-known manufacturers of plumbing products and the valve will offer the most durable and reliable. But you can find a lot of examples when the most uncomplicated and inexpensive aerators of domestic production serve for decades and continue to serve.

Therefore - just a brief overview of the models offered for sale and their prices, but without any recommendations in favor of a particular product.

| "MkAlpine HC 50-50" - products of the company from the British Isles. Polypropylene. Model for pipe ø50 mm. Fits in a standard bell. Throughput - 3 l / s. | 850 rub. | |

| Model "MkAlpine" for pipe DN110 mm. Polypropylene. | 2500 rub | |

| "HL900NECO" Austrian company "HUTTERER & LECHNER GmbH". Available in three versions - for pipes DN50, DN70 and DN110 mm. Polypropylene. Mesh on the side of the case. The capacity of the DN110 valve is 37 l/s. Thermally insulated housing walls. | For model DN110 - 2800 rubles. | |

| Air valve "Wavin Optima Mini vent" of the famous Dutch company. Compact models for installation on sewer pipes with a diameter of 30, 40 and 50 mm. Polyvinyl chloride. Throughput - 7.5 l / s. Installation - in a standard socket. | 3600 rub. | |

| The product of the Finnish company UPONOR is the HTL vacuum valve. It is made for 110 mm, it is completed with adapters for 50 and 70 mm. Polypropylene. | 4700 rub. |

| Valve of the German brand "Ostendorf" of Russian production. Diameter - 110 mm. Polypropylene. | 1900 rub. |

| Vacuum valve manufactured in Russia by Rosturplast. Diameter - 110 mm. | 190 rub. |

| The valve of the Russian production of the Politron company. Polypropylene. Diameter - 110 mm. | 240 rub. |

Probably, this is already enough to understand how the prices for such products “dance”. Moreover, with approximately equal characteristics, material of manufacture, etc. So the author of this article in no way assumes the responsibility to recommend certain models - everything is too non-obvious.

True, they may ask a question - why do some DN110 aerators have one common head, and others have two small ones?

There is no particular secret here. It's just that the manufacturer produces models for both 50 mm and 110 mm pipes. And it is technologically easier for him to combine two smaller valve heads in one body to get an aerator for a larger diameter. And this does not affect the operation of the device itself. Unless you have to take care of two membranes. But if one fails, it will cost less to replace than one large one.

Overview of manufacturers and prices

Among

The most famous manufacturers of such devices can be identified as follows

companies:

- Hutterer

& Lechner, DN110. The average price is about 3000 rubles; - McAlpine.

The cost ranges from 400 to 1400 rubles, depending on the specific model.

The most famous models are MRAA1S-CLEAR, MRAA1N, etc.; - Ostendorf. polypropylene

device, the price of which will be 500 rubles.

There are also cheaper models of domestic production, the cost of which does not exceed 100-200 rubles. The choice is due to the need, the specifics of the system and the capabilities of the owner.

All useful information about sewerage

The device and principle of operation of the fan valve

Now let's look at how the air vent valve for sewage is arranged and how it works.

The fan valve has the following device:

-

A housing having a hole on the side (through which air enters).It is produced from a polymeric material (polypropylene or PVC).

-

Removable cover. Required to disassemble the aeration valve (for cleaning or repair).

-

Stem or membrane. Made from rubber.

-

Rubber seal. Limits the stroke of the rod, seals the structure.

The vacuum vent valve for the riser works as follows:

-

when the pressure inside the pipe is the same as atmospheric (or slightly exceeds it), the valve is closed;

-

when water (from the toilet, washing machine, faucet) enters the drain, a vacuum occurs inside the pipe, displaces the stem (membrane), and opens the valve;

-

the air entering through the valve equalizes the pressure, after which the stem (diaphragm) returns to the seat (the valve closes).

Pros and cons of application

Of the advantages of using a sewer aerator:

-

the ability to prevent the appearance of an unpleasant smell inside the room (in case the normal operation of the ventilation of the riser is disrupted);

-

the ability to do without laying a fan pipe (which means not making an extra hole in the roof).

It should be noted that it is possible to use the valve on a non-ventilated riser, but this will only be effective in low-rise buildings. For multi-storey buildings, ventilation valves are considered an additional component to the pipe leading to the roof.

In principle, they can also be used separately, but only as a last resort. And in this case, an accurate calculation of both the number of devices and their throughput will be required (which should be performed at the design stage of the building itself).

The device and principle of operation of the sewer air valve

Of the obvious disadvantages of the sewer aerator, one can note the possibility of its jamming. The movement of the stem (membrane) can deteriorate both from time (natural wear of parts) and from getting inside some kind of debris. The second option is unlikely, since foreign objects can only get inside when the lid is opened.

About technical characteristics (diameter) and manufacturers

The main technical characteristics of the sewer aerator are:

-

Diameter. According to this parameter, a model is selected for the diameter of the pipe.

-

Throughput (how much air will pass per unit of time).

The diameter of the product can be 50, 75 or 110 mm. Models with a diameter of 50 and 75 mm - suitable for installation for individual devices. Products with a diameter of 110 mm - are intended for installation on the riser itself.

Ventilation valve on the riser

The devices of some valves are designed in such a way that they are suitable for several diameters at once (they have a stepped nozzle). For example, the HL900N model can be used for pipes with a diameter of 50, 75 or 110 mm. Adapters can be used for mounting on pipes of other diameters (32, 40 mm).

With regard to throughput: it was already mentioned above that 25 l/s of air can be consumed per 1 l / s of water. Valve capacity - from 7-8 l / s (for HL903 and Minivent) and up to 32-37 l / s (for HL900N).

There are about a dozen manufacturers' products on the Russian market. Here are some specific brands:

- HL (Austrian company, its products are the most expensive).

- McAlpine (McAlpin, English company, mid-price segment).

- Wavin (Polish manufacturer, mid-price and expensive segment).

- Evroplast (Ukrainian brand, cheap segment).

Where is the fan aerator installed?

The ventilation valve can be installed in two ways (by location):

-

For a stand. In this case, it is located on its upper part, which can either be displayed in the attic, or located directly in the room (bathroom).

-

For a separate appliance (for example, for a washing machine).

Types of air valves and their sizes

- Simple air (kinetic). Works to release air from the system. Can be installed indoors.

- Auto. Removes air masses under very high pressure from the line.

- Combined. It can simultaneously supply and remove air masses to / from the line. Such aerators are not allowed to be mounted inside the house. Combined devices are installed only outside the building in a specially equipped unit.

Fan valves are produced in a standard section of 50 or 110 mm. The first are designed to be installed on a sink or shower. The second - for mounting on a pipe of a common riser. However, you can find aerators with a cross section of 75 or 100 mm.

According to the method of installing the air valve, external and internal are distinguished. The first is inserted into the socket and fixed with corrugated rubber. The second is simply put on the tee connector.

If the pipes in the house have a non-standard diameter, the air valve can be installed using adapters.

Ball check valve

The most common type of check valve is the ball valve. It prevents the flow of wastewater in the opposite direction. The device of such a valve is simple, it looks like this: the shutter device here is a metal ball, which is pressed by a spring when back pressure appears.

Where to install a ball valve depends on its design. For example, a sleeve check valve is standardly installed in a vertical pipeline, and a flanged check valve is installed in both a vertical and a horizontal sewer pipeline.

A sleeve valve is installed if a check valve is installed on small diameter pipes (up to 2.5 inches). With a pipe diameter of 40-600 mm, a flanged check valve is installed.

A ball valve with a moving ball closes the return flows by 100%. It also has 100% forward passability. It is impossible to jam such a system. The standard non-return valve is made in a rugged body, with a massive cast iron cap, and the ball itself is coated with nitrile, EPDM, etc.

Another positive quality of the ball valve is its excellent maintainability.

If the ball needs to be cleaned or replaced, the sewer ball valve can be easily and quickly disassembled by simply removing 2 or 4 bolts on the valve cover.

PVC check valve

The non-return valve is very useful for owners of apartments on the lower floors. It can be installed on both internal and external sewers. This shut-off valve serves to block the return flow of sewage water and well delays the ingress of various insects and rodents through the sewer system.

If an emergency occurs and a backflow occurs, the valve will automatically shut off the entire sewer system. In such a valve, it is possible to block the return flow forcibly. To do this, simply turn the valve knob to the OFF position.

AT check valve PVC for sewage, a locking element is built in, which moves back and forth, and perpendicular to the movement of wastewater in the sewer system. PVC lift check valve can be spring and springless.

Almost all check valves are designed so that they can be installed in both vertical and horizontal pipelines.

When doing this, the direction of wastewater flow must be taken into account - usually the direction is indicated by an arrow on the valve body. Non-return PVC valve does not react to ultraviolet radiation, does not give in to corrosion, does not react with aggressive chemical impurities

The duration of its operation corresponds to this indicator for plastic pipes

The PVC check valve does not react to ultraviolet radiation, does not corrode, does not react with aggressive chemical impurities. The duration of its operation corresponds to this indicator for plastic pipes.

If you properly operate the PVC check valve, then it is quite capable of lasting 50 years or more.

For pressure sewer

The non-return valve, which is installed in the pressure sewerage system, does not allow a change in the direction of the wastewater flow in the sewerage system. This safety valve only allows effluent to flow in one direction and stops the liquid from flowing in the opposite direction.

The check valve for pressure sewage works in automatic mode, and is called a direct-acting valve. This is an uninterrupted universal device, since the check valve can work both in normal mode and in an emergency.

For example, if several pumps are operating, and their pressure lines are combined into one common line, then one check valve (or several) is installed on each individual line, which protects each line from the pressure of the operating pump on any of them.

Thus, if the pressure drops on one line, then the pressure on the other lines will remain the same, and no accident will occur.

If the wastewater does not pass through the shut-off valve, then the check valve works like this: under the influence of its weight, the spool in the valve allows the movement of water through the valve seat. In order for wastewater to change direction, it must be suspended.

When the liquid flow stops, the pressure on the other side presses the spool, not allowing the backflow of sewage to form.

Conclusion of a fan riser in a private house

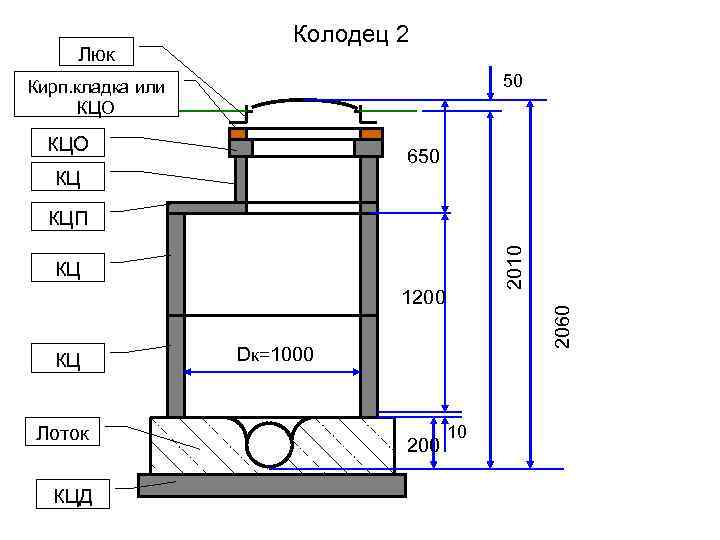

The ventilation outlet on the roof looks like a riser. The exit point is strictly regulated by building codes and regulations.

It is important to rely on this documentation in your work.

The riser should have the following height:

- On a pitched roof, 50 cm is enough;

- On a flat unused roof - 30 cm;

- On a flat exploited roof - 3 m.

Takes into account the interval from the riser to the windows and balconies. This distance is at least 4 m. But it is strictly forbidden to combine the exit with the chimney.

The exit of the pipe to the attic is also prohibited. Under the roof overhang, installation is also not carried out. Even with a cap in this case, the pipe will not last long.