- The best bimetal radiators with non-standard distance between the axes

- TIANRUN Rondo 150 – durable and reliable heating device

- SIRA Gladiator 200 - compact battery

- Device and principle of operation

- 1 Rifar Monolit 500

- Calculation of the number of radiator sections

- Cast iron radiators

- The best cast iron radiators

- STI Nova 500

- RETROstyle DERBY M 200

- Viadrus Style 500/130

- Iron Lion Azalia 660

- Whether to believe, touting vacuum heating appliances

- Do-it-yourself technology and rules for installing vacuum radiators

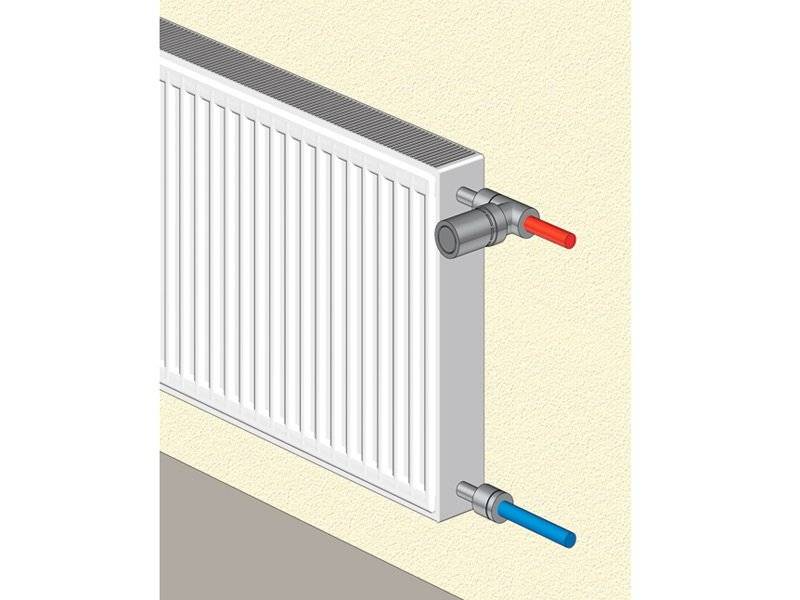

- Implementation options in the heating system

- Radiator installation rules

- Instrument installation sequence

- Positive traits

- Bimetallic heating radiators which is better selection instructions

- The positive aspects of using bimetallic radiators

- The negative aspects of using bimetallic radiators

- Advantages and disadvantages of bimetallic radiators

- Cast iron radiators

The best bimetal radiators with non-standard distance between the axes

Such models can have an extremely intricate design, which affects the center distance, heat transfer parameters and supply options.

TIANRUN Rondo 150 – durable and reliable heating device

4.9

★★★★★

editorial score

93%

buyers recommend this product

See review

This compact floor model withstands pressures up to 25 bar at coolant temperatures up to 135°C. This strength is achieved through the use of a solid steel frame. The absence of leakage between sections is guaranteed by high-strength forged steel nipples and special silicone gaskets.

Despite the extremely compact dimensions with an interaxal distance of only 150 mm, the radiator has a good thermal power (95 W at a coolant temperature of 70°C).

Advantages:

- High strength and reliability

- Good technical and operational characteristics.

- Sophisticated geometry of the body ribs.

- Light weight.

Flaws:

Floor bracket not included.

Tianrun Rondo is a good solution for heating rooms with a large glass area.

SIRA Gladiator 200 - compact battery

4.7

★★★★★

editorial score

82%

buyers recommend this product

The wall-mounted bimetallic radiator with a classic lateral inlet received a design focused on safety during operation. The main feature of this model is its small dimensions - as a result of the center distance reduced to 20 cm.

Despite its compactness, the bimetallic radiator has a very good operating pressure (35 bar) and perfectly tolerates temperatures up to 110 ° C. However, the dimensions affected the modest heat transfer - only 92 W per section.

Advantages:

- Reliability.

- Compactness.

- Light weight.

- High working pressure.

- Elegant design.

Flaws:

Average heat dissipation.

SIRA Gladiator is a very suitable model for heating small spaces.

Device and principle of operation

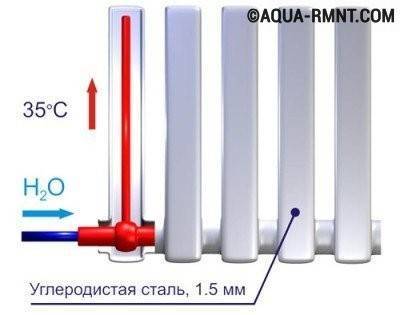

The difference between vacuum radiators and bimetallic and aluminum counterparts can also be seen during their external examination. In the former, the distance between the sections is greater. This heater consists of a housing, a horizontal channel and vertical sections.

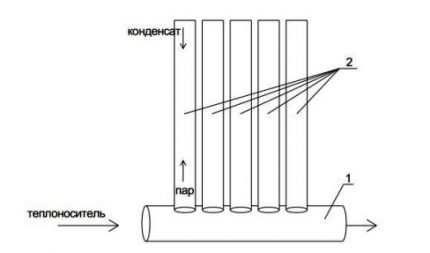

Simplified diagram of a vacuum radiator. Its main elements are the collector (1) and vertical sections (2), in which the secondary coolant is located.

Simplified diagram of a vacuum radiator. Its main elements are the collector (1) and vertical sections (2), in which the secondary coolant is located.

The first of these elements includes two sections made of 1.5 mm steel. The horizontal channel is the primary circuit located at the bottom and connected to the heat source. A coolant passes through it, transferring heat to the liquid located in sections that are located perpendicular to this channel.

The vertical sections are filled with a secondary coolant - a heat transformer. They are completely isolated from the primary circuit. Their number is directly proportional to the degree of heating of the room. The rate of liquid heating affects the pressure inside the cavities. The larger it is, the lower the pressure.

The secondary coolant is a liquid based on bromine and lithium. In the circuit, it is in a small volume and tends to boil and evaporate quickly at a low, about 35 ° C, temperature.

The circuits are well insulated against each other and the environment.

The process that takes place in vacuum batteries looks like this:

- Antifreeze or water heats the horizontal channel.

- Heat from the horizontal channel is sent to the vertical sections.

- The heat transformer boils, as a result of which the entire secondary circuit is filled with steam.

- The walls of the secondary circuit heat up and release heat into the room.

To ensure efficient transmission of heat rays from the lithium bromide liquid to the radiator walls, the state of the working substance must be as close as possible to the fog stage. Then the heat will be transported by drops of warm liquid.

To achieve this, the main condition must be met - the inlet in the pipes must have a temperature of at least 40 and maximum 60 ° C.

Vacuum devices provide room temperature 2-3 degrees lower than traditional batteries. But the cost of heating a house is reduced by an average of 17%

In the case of an autonomous system, it is difficult to achieve such indicators. In areas of the heating system remote from the source, the coolant will cool very quickly. Yield in the use of pyrolysis boilers with optimal temperature conditions from 45 to 60 °C or from 50 to 70 °C.

In another way, the problem is solved by installing one mixing unit in front of a group of vacuum radiators. In this case, the low-temperature level will ensure the connection of heated water with chilled water from the return. The working cycle in the vacuum radiator is repeated after the condensate is lowered down along the inner walls.

1 Rifar Monolit 500

The main advantage of the bimetallic heating radiator Rifar Monolit 500 is its low cost on the market with characteristics identical to its main competitors in the rating. The maximum heat output can reach 2744 W, which is enough to heat rooms up to 27-29 square meters

An important feature of the heater is the ability to operate at a pressure of 100 bar, which allows the sections to survive water hammer and maintain operating conditions for a long time.

Reviews of the Rifar Monolit 500 often include statements regarding a 25-year factory warranty. It is worth saying that this information is true, and Rifar is very scrupulous about the quality of its entire range of products. Other advantages of the model include 135 degrees of permissible operating temperature, a pleasant design, as well as a minimum of 210 milliliters of water per section for normal operation.

Calculation of the number of radiator sections

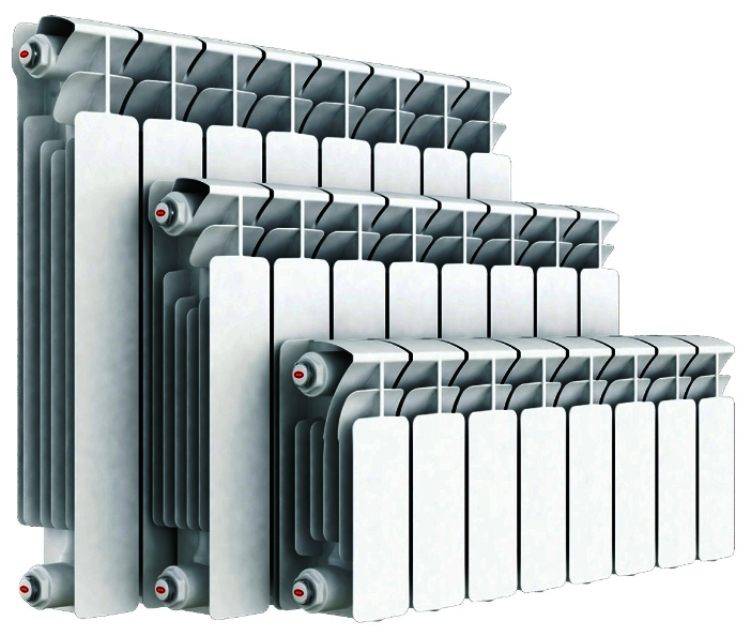

The thermal power of the radiator section depends on its overall dimensions. With a distance between the vertical axes of 350 mm, the parameter fluctuates in the range of 0.12-0.14 kW, with a distance of 500 mm - in the range of 0.16-0.19 kW. According to the requirements of SNiP for the middle band per 1 sq. meters of area, a thermal power of at least 0.1 kW is required.

Given this requirement, a formula is used to calculate the number of sections:

where S is the area of the heated room, Q is the thermal power of the 1st section and N is the required number of sections.

For example, in a room with an area of 15 m 2, it is planned to install radiators with sections of thermal power of 140 W. Substituting the values into the formula, we get:

N \u003d 15 m 2 * 100/140 W \u003d 10.71.

Rounding is done up. Given the standard forms, it is necessary to install a bimetallic 12-section radiator.

Important: when calculating bimetallic radiators, factors that affect heat loss inside the room are taken into account.The result obtained is increased by 10% in cases where the apartment is located on the first or last floor, in corner rooms, in rooms with large windows, with a small wall thickness (no more than 250 mm). A more accurate calculation is obtained by determining the number of sections not for the area of \u200b\u200bthe room, but for its volume

According to the requirements of SNiP, a thermal power of 41 W is required to heat one cubic meter of a room. Given these rules, get:

A more accurate calculation is obtained by determining the number of sections not for the area of \u200b\u200bthe room, but for its volume. According to the requirements of SNiP, a thermal power of 41 W is required to heat one cubic meter of a room. Given these rules, get:

where V is the volume of the heated room, Q is the thermal power of the 1st section, N is the required number of sections.

For example, a calculation for a room with the same area of 15 m 2 and a ceiling height of 2.4 meters. Substituting the values into the formula, we get:

N \u003d 36 m 3 * 41 / 140 W \u003d 10.54.

The increase is again carried out in the big direction. a 12-section radiator is required.

The choice of the width of the bimetallic radiator for a private house is different from the apartment. The calculation takes into account the coefficients of thermal conductivity of each material used in the construction of the roof, walls and floor.

When choosing sizes, the requirements of SNiP for battery installation should be taken into account:

- the distance from the top edge to the window sill must be at least 10 cm;

- the distance from the bottom edge to the floor should be 8-12 cm.

For high-quality space heating, it is necessary to pay attention to the choice of sizes of bimetallic radiators. The dimensions of the batteries of each manufacturer have minor differences, which are taken into account when buying. Correct calculation will avoid mistakes

Correct calculation will avoid mistakes.

Find out what the correct dimensions of bimetallic heating radiators should be from the video:

Cast iron radiators

The level of heat transfer of batteries depends on the material of its manufacture. Many consumers do not know how to choose heating radiators, because each type has its own advantages and disadvantages.

Well-known cast-iron heating radiators have:

- acceptable cost;

- the ability to function at high carrier temperatures;

- resistance to aggressive environments;

- high strength;

Cast iron batteries

The heat dissipation of these radiators is higher than that of the others. Along with the advantages, it should also be noted the disadvantages of cast iron radiators:

- unattractive appearance,

- significant dimensions and weight,

- susceptibility to water hammer,

- the need for periodic painting.

Cast iron vertical heating radiators are relatively cheap appliances. They are more suitable for gravity systems. The design of cast iron batteries consists of separate sections interconnected by casting.

The best cast iron radiators

Cast iron-based heating appliances are a time-tested Soviet classic, which is represented today by the most modern design. They have sufficient resistance to corrosive changes, high pressure in the system, as well as the presence of impurities in the coolant. Cast iron radiators have a very high thermal inertia, are durable and reliable in use.

STI Nova 500

9.3

Rating Based on customer reviews (2019-2020)

Design

10

Quality

9

Price

9.5

Reliability

9

Reviews

9

The modern model from a series of cast-iron radiators combines the advantages of material and stylish appearance.Such batteries are successfully used in water heating systems for urban apartments and private households, industrial facilities and public buildings. The equipment, developed taking into account all the requirements of GOST, is fully adapted to the most difficult operating conditions. If the installation rules are observed, the service life is 30 years.

Cast iron radiator dimensions (H×D×W): 580×80×60 mm. The mass of the heating battery is 4.2 kg. The maximum power level is 124 watts. The volume of the heat carrier is 0.52 l, and the operating pressure does not exceed 12 atmospheres.

PROS:

- manufacturer's warranty;

- durability;

- reliability.

MINUSES:

relatively long warm-up.

RETROstyle DERBY M 200

9.0

Rating Based on customer reviews (2019-2020)

Design

9.5

Quality

9

Price

9

Reliability

8.5

Reviews

9

The cast-iron heating radiator, made in the old English style, has a center distance of 200 mm, and is distinguished by a lateral type of connection to the system. By default, models of this series of sectional radiators are equipped with durable legs. Before shipment, all radiators undergo a pressurization test procedure under overpressure conditions. At the request of the customer, the surface of the equipment can be painted in accordance with the RAL scale. The effect of artificial aging of the battery also looks very original.

The standard dimensions of a sectional cast-iron radiator (W×D×H) are 174×1638×360 mm. The maximum operating temperature of the battery does not exceed 110°C. The level of heat output is within 1430 W.

PROS:

- stylish design;

- strength;

- high power.

MINUSES:

significant mass of the radiator.

Viadrus Style 500/130

8.8

Rating Based on customer reviews (2019-2020)

Design

10

Quality

9

Price

7.5

Reliability

8.5

Reviews

9

Models of this series are fully adapted for use in domestic heating systems. Radiators Viadrus Styl 500/130 are covered with high-quality heat-resistant paint that does not crack or fade during long-term operation. Design features allow the batteries to easily withstand fairly high operating pressures (within 8 atmospheres). In addition to practicality, cast iron radiators have a rather beautiful design, completely devoid of unnecessary details and overly complex elements. The warranty for Viadrus Styl 500/130 is five years.

The dimensions of the cast-iron radiator (W × D × H) are 120 × 60 × 80 mm, with a heat output of 70 W, a mass of 3.8 kg and a coolant volume of 0.8 liters.

PROS:

- energy efficiency;

- ease of maintenance;

- durability.

MINUSES:

insufficient heat output.

Iron Lion Azalia 660

8.7

Rating Based on customer reviews (2019-2020)

Design

9.5

Quality

9

Price

7.5

Reliability

8.5

Reviews

9

The retro radiator with a laconic and stylish design has medium dimensions, so it can be mounted in small rooms. The maximum operating temperature is 110 ° C at a pressure of no more than 15 atmospheres. These parameters allow you to install Iron Lion Azalia 660 when arranging the heating system not only in cottages, but also in apartment buildings. The base color of the surface of the sold radiators of this series is Black Ground.

The design feature is represented by a relief ornament and miniature decorative "ears". Intercenter distance - 500 mm. The dimensions of one section of the radiator (W×D×H) are 140×70×110 mm, with a thermal output of 90 W and a weight of 8 kg.

PROS:

- high wear resistance;

- long-term maintenance of heat;

- ease of installation.

MINUSES:

not a very modern look.

Whether to believe, touting vacuum heating appliances

We will try to approach this issue as scrupulously and objectively as possible, taking as a basis only proven facts. At the same time, we will consider each of the advantages of these radiators indicated by the manufacturer. So, we started.

1. The lightning-fast warm-up time characteristic of vacuum radiators is constantly advertised. Okay, let's say. However, the whole house does not warm up so quickly. After all, it contains not only air, but also walls, internal partitions with furniture, a ceiling with a floor. They take a certain amount of time to heat up.

And therefore it is not at all so important whether the radiator itself will warm up for a minute or five.

2. Now about a small amount of coolant, which is supposedly very economical. The only question is where exactly this savings manifests itself.

If in the central heating system, then this is a real bluff - it is not so important here, more hot water will flow through the pipes or less. If you take a country cottage, then the savings in it are also in question, given that the same modern panel radiators also require not so much coolant. 3

Air locks cannot appear in vacuum-type radiators. He talks about it with enthusiasm. But after all, radiators are not the entire heating system, but only part of it. By the way, traffic jams appear only when this system is assembled illiterately. Otherwise, they will not be with any radiators

3. Air pockets cannot appear in vacuum-type radiators. He talks about it with enthusiasm. But after all, radiators are not the entire heating system, but only part of it.By the way, traffic jams appear only when this system is assembled illiterately. Otherwise, they will not be with any radiators.

4. Two more fat pluses that manufacturers trump. This is the impossibility of clogging radiators and the absence of corrosion. Perhaps, for autonomous heating systems, these advantages are unlikely to be so fat. If the hot water in the heating is clean, its acidity level meets the standards, and it does not drain from the system, then there will be no corrosion. And there is no place for blockages to come from.

5. As for the low hydraulic resistance, which supposedly sharply reduces the cost of heating, let's say so. For centralized heating, it is not at all clear whose costs are meant. Unless the owners of boiler houses, hundreds of kilometers distilling tons of hot water. It turns out that there can be a benefit only when used in an autonomous heating system, and it is still a question whether it can be. And for an autonomous system in their home, many use the natural circulation of the coolant, so this issue is irrelevant.

6. The next point will be to save energy by half, or even four times. With this, the error came out, since the law of conservation of energy is still valid. Radiators, even the most innovative ones, cannot generate energy. They only pass it on, and there is no need to talk about savings. How much heat is spent, so much must be replenished - the only way.

7. Now let's touch on the heat transfer of vacuum tubes, which, according to manufacturer's certificates, is not stable. This indicator can have deviations of up to 5 percent up and down. It turns out that this depends on the speed of the water in the heating system, and on its temperature.So it is hardly possible to adapt automation to such a radiator. And two radiators with an equal number of sections can have different parameters.

8. Separately, let's talk about heating systems in private homes, where water circulates naturally. Here the hydraulic pressure is important, which is created due to the difference in the height of hot water in the boiler and radiator. So, for vacuum-type devices, this height is much less, so they work with problems in such a system.

9. Now imagine that a crack has appeared in the radiator case. Even if it is tiny, you can forget about the vacuum. He will leave forever, and normal atmospheric pressure will be restored. And it, in turn, will lead to an increase in the boiling point of the coolant. The result will be disastrous - either the liquid will hardly evaporate, or steam will not appear at all. In short, the radiator will stop heating.

10. By the way, this wonderful (according to sellers and advertisers) lithium-bromide liquid is also poisonous, it turns out. Therefore, the fact that the radiators become cold when the coolant leaks is only half the trouble. It is worse if the battery leaks, for example, at night, poisoning the sleeping residents of the apartment.

So, perhaps, it is not always worth believing, so convincing at first glance.

Do-it-yourself technology and rules for installing vacuum radiators

The first step is to choose a convenient connection method in accordance with your own capabilities and environmental conditions. After preparing the tools and materials, you can proceed to the sequential installation of equipment.

Implementation options in the heating system

Installation of equipment corresponds to the type of communications used in the house:

- to connect the radiator with an autonomous system, the standard method is suitable - the battery is installed using couplings to the inlets and outlets of the hot coolant,

- if electricity is used as fuel, a stationary or portable heater can be equipped to heat the lithium-bromide environment (the first option is more reliable),

- if you plan to connect the radiator to a solar source or central heating, you can use the first method.

Both the bottom and vertical wiring are equally functional.

Radiator installation rules

First of all, you need to choose the optimal area for fixing the battery. When fixing the device, it is desirable to maintain a distance of at least 5 cm from the nearest wall, the fixation height relative to the floor should be at least 2-5 cm from the bottom edge

It is also important that the upper edge of the radiator does not reach the window sill by about 10 cm.

Immediately before installation, you need to chill the battery, that is, create such conditions that the easily evaporating working composition stack down

The section of the wall that will be located directly behind the vacuum radiator should preferably be insulated with a reflective material. Construction foil, isolon can come in handy here. Immediately before installation, you need to chill the battery, that is, create such conditions that the easily evaporating working composition stack down. During installation, you can use the plugs commonly used for aluminum heaters. If the walls were previously thermally insulated, elongated brackets must be selected for mounting the equipment.

Instrument installation sequence

To facilitate the work, in addition to the radiator and brackets, it is advisable to prepare materials and tools:

- Ball Valves,

- impact drill,

- wrenches,

- roulette,

- pencil and hydraulic level,

- sealant, tow,

- victorious drills,

- screwdriver

Steps for installing a vacuum radiator:

- If necessary, in the reconstruction of the old heating system, the batteries are dismantled, the walls are leveled.

- Create markup in accordance with the above recommendations regarding the placement of equipment.

- Fix the brackets at the given points.

- They are mounted on the brackets of the vacuum radiator section.

- Ball valves are introduced, strengthening the joints with sealant and tow.

- The main pipelines are attached to the cranes, the connections are sealed.

Installed vacuum heating radiator

Next, you can fill the system with coolant to check the integrity of the structure, the absence of leaks.

Positive traits

Manufacturers of a new type of heater point to a number of advantages over traditional products:

- The need for the main coolant is reduced - it circulates only in the boiler and pipeline (it is not in the sections). On average, the heat carrier saving is 80%.

- Ease of installation combined with low consumption of pipes.

- Duration of operation - up to 30 years (however, the warranty for the product is not more than 5 years).

- There is no need to carry out antiseptics of radiators.

- Safety - if the product meets the requirements of p.p. 5.2 and 5.9 GOST 31311 - 2005).

Sellers go even further: they claim that their heat dissipation is higher than conventional batteries

They focus on the rapid heating of the radiator surface.

Bimetallic heating radiators which is better selection instructions

The first heating radiators made from two metals (bimetallic) appeared in Europe more than sixty years ago. Such radiators quite coped with the assigned function of maintaining a comfortable temperature in the room during the cold season. At present, the production of bimetallic radiators has been resumed in Russia, while the European market, in turn, is dominated by various aluminum alloy radiators.

Bimetal heating radiators which are better

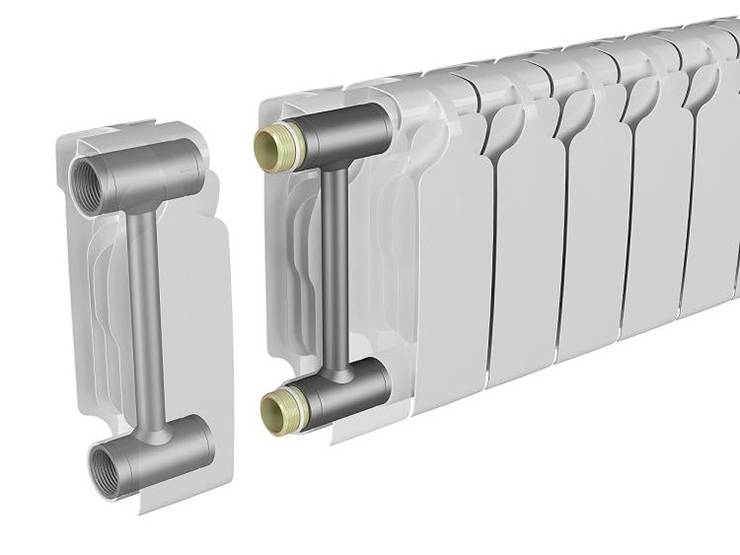

Bimetallic radiators are a frame made of steel or copper hollow pipes (horizontal and vertical), inside which the coolant circulates. Outside, aluminum radiator plates are attached to the pipes. They are attached by spot welding or special injection molding. Each section of the radiator is connected to the other by steel nipples with heat-resistant (up to two hundred degrees) rubber gaskets.

The design of the bimetallic radiator

In Russian city apartments with centralized heating, radiators of this type perfectly withstand pressures up to 25 atmospheres (when pressure tested up to 37 atmospheres) and, due to their high heat transfer, perform their function much better than their cast-iron predecessors.

Radiator - photo

Externally, it is quite difficult to distinguish bimetallic and aluminum radiators. You can verify the correct choice only by comparing the weight of these radiators. Bimetallic because of the steel core will be heavier than its aluminum counterpart by about 60% and you will make an error-free purchase.

The device of a bimetallic radiator from the inside

The positive aspects of using bimetallic radiators

- Bimetal panel-type radiators fit perfectly into the design of any interior (residential buildings, offices, etc.), without taking up much space. The front side of the radiator can be one or both, the size and color scheme of the sections are varied (self-coloring is allowed). The absence of sharp corners and too hot panels makes aluminum radiators suitable even for children's rooms. In addition, there are models on the market that are installed vertically without the use of brackets due to the additionally present stiffeners.

- The service life of radiators made of an alloy of two metals reaches 25 years.

- Bimetal is suitable for all heating systems, including central heating. As you know, low-quality coolant in municipal heating systems adversely affects radiators, reducing their service life, however, bimetal radiators are not afraid of high acidity and poor quality of coolants due to the high corrosion resistance of steel.

- Bimetallic radiators are the standard of strength and reliability. Even if the pressure in the system reaches 35-37 atmospheres, this will not damage the batteries.

- High heat transfer is one of the main advantages of bimetal radiators.

- The regulation of the heating temperature using a thermostat occurs almost instantly due to the small cross section of the channels in the radiator. The same factor allows you to halve the amount of coolant used.

- Even if it becomes necessary to repair one of the radiator sections, thanks to the well-thought-out design of the nipples, the work will take a minimum of time and effort.

- The number of radiator sections needed to heat a room can be easily calculated mathematically. This eliminates unnecessary financial costs for the purchase, installation and operation of radiators.

The negative aspects of using bimetallic radiators

- As mentioned above, bimetallic radiators are suitable for operation with a low-quality coolant, but the latter significantly reduces the life of the radiator.

- The main disadvantage of a bimetallic battery is the different expansion coefficient for aluminum alloy and steel. After prolonged use, creaking and a decrease in the strength and durability of the radiator may occur.

- When operating radiators with low-quality coolant, steel pipes may quickly become clogged, corrosion may occur, and heat transfer may decrease.

- The contested disadvantage is the cost of bimetal radiators. It is higher than that of cast iron, steel and aluminum radiators, but considering all the advantages, the price is fully justified.

Advantages and disadvantages of bimetallic radiators

Unlike aluminum, a bimetallic radiator is made not from one, but from two types of metal - aluminum and steel (or sometimes copper).

Given this, it is possible to unequivocally answer the question of which heating radiator is better to choose for an apartment - aluminum or bimetallic. Of course, in the conditions of a central heating system, a bimetallic radiator demonstrates the best performance parameters, since:

- The steel channels through which the coolant moves are inert to increased acidity and alkalinity of the coolant.That is, the coolant, which contains aggressive substances, circulates only through steel internal channels that are resistant to their effects, and at the same time they do not come into contact with the aluminum case, which is not resistant to them.

- Steel parts ensure the immunity of the device to the high operating pressure of the heating system, as well as possible water hammer.

- The aluminum body, which has a smooth surface and several convection channels, is an excellent heat emitter.

Cast iron radiators

Cast iron batteries heat up for a long time, but cool down for a long time. The residual heat retention number is twice that of other types and is 30%.

This makes it possible to reduce the cost of gas for home heating.

Advantages of cast iron radiators:

- Very high resistance to corrosion;

- Durability and reliability that have been tested over the years;

- Low heat transfer;

- Cast iron is not afraid of exposure to chemicals;

- The radiator can be assembled from a different number of sections.

Cast iron radiators have only one drawback - they are very heavy.

The modern market offers cast-iron radiators with decorative design.