- Equipment for vacuuming and refueling

- Carrying out the evacuation of the air conditioner

- Process to Avoid

- How long to vacuum?

- HEALTH REQUIREMENTS BEFORE STARTING WORK

- Pumps for evacuation of split systems

- Which is more profitable: professional installation or do-it-yourself installation of a split system

- Air conditioner installer mistakes

- SAFETY REQUIREMENTS DURING WORK

- How long to vacuum

- Vacuuming the refrigeration circuit

- Vacuum process

- Vacuum time

- Vacuum pump selection

- "Purge Freon"

- The nuances of vacuuming

- Hole tightness

- What you need for self-assembly

- Installation tools

- materials

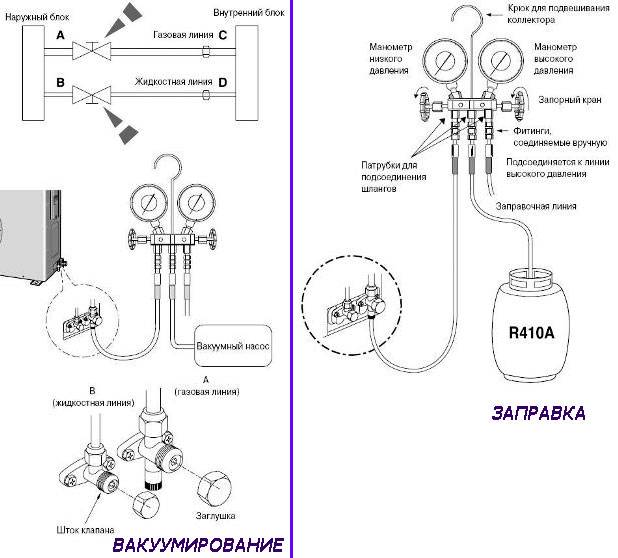

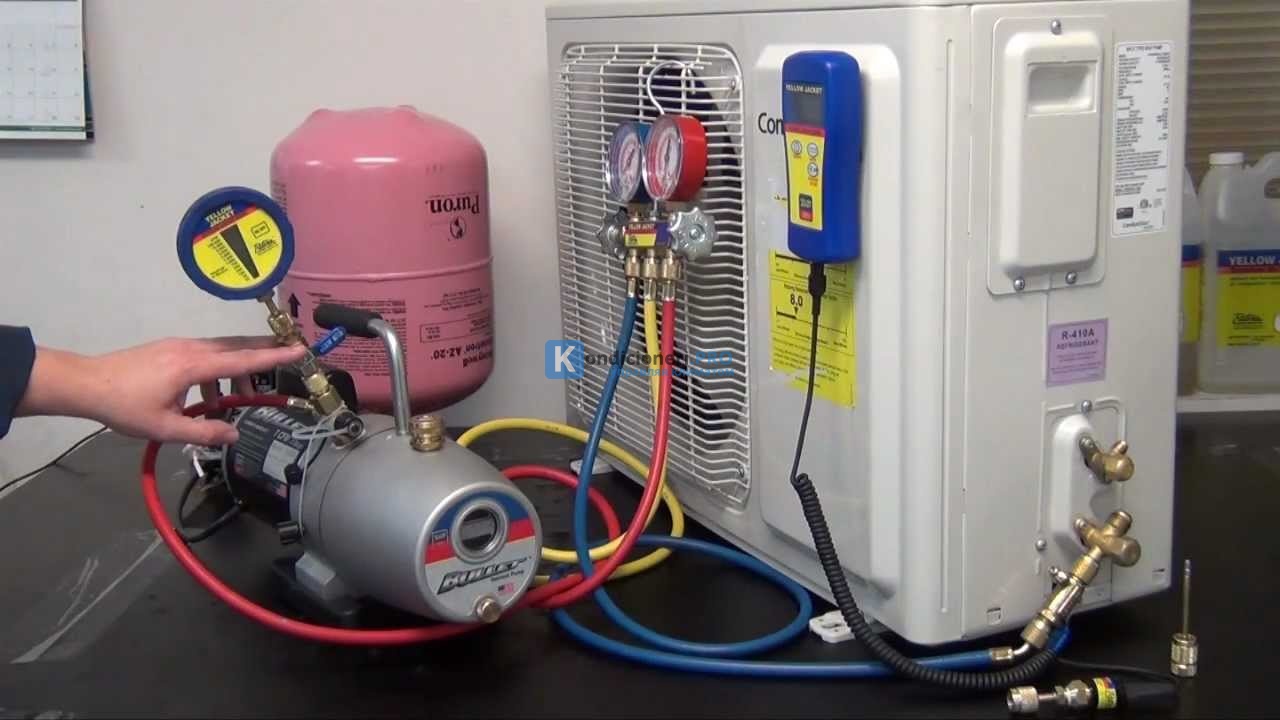

Equipment for vacuuming and refueling

To work, you need the following tools and devices:

To work, you need the following tools and devices:

- Vacuum station for air conditioners. Before charging the refrigerant, it is connected to the circuit and drains it. The pressure gauges on the instrument show the vacuum level. In the work of the wizard, two-stage models are used, which are economical in terms of energy consumption, easy to install. Heterion vacuum cleaners for air conditioners provide good cleaning, but are rarely used, as they are expensive.

- Manometric manifold.

- A set of screwdrivers and wrenches for working with fittings.

- Cylinder with freon for subsequent refueling.

The most important device is the pump, which will seal the pipeline. Ease of use is created by the weight of the device - the lighter it is, the simpler it is. Models that have a rubber mount to reduce vibration levels are more comfortable to operate.

During operation, the pump consumes oil, so the indication of its level is a useful feature for a person who constantly works with the device.

To remove vapors, a valve must be provided, as well as a set of fittings designed for the outdoor unit, through which air is evacuated.

The market is dominated by equipment from German, American, Swiss manufacturers of equipment for climate control equipment of various price levels. Some Chinese firms supply products that are not inferior in quality to European counterparts, but much cheaper.

Carrying out the evacuation of the air conditioner

Removal of air or moisture from the cooling system and its subsequent filling with freon is always done using special tools and equipment. Vacuuming the air conditioner cannot be carried out without:

- special pumping equipment;

- manifold equipped with pressure gauges;

- a cylinder with liquid freon for the operation of a split system;

- hand tools (wrenches, pliers and screwdrivers).

A lot of information is known about how to vacuum an air conditioner. There are several different algorithms of action. But, without the availability of tools and equipment can not do.

The outdoor unit of the air conditioner has a special port for servicing the cooling system. It is necessary to connect a collector with monomers to it. And the vacuum pump completes this chain. Vacuuming the air conditioner is carried out as follows:

- Open the pump ballast valve and close the gas valve on the manifold.

- Turn on the pump and look at the pressure gauge. After a few minutes, the pointer on the meter may change position. With accumulated air, the indicator will be equal to 1 atmosphere, and with moisture - less than one. The ideal score is 0.

- The pump is turned off and nitrogen is pumped in. This gas binds and bleeds foreign products through a valve on the air conditioner itself.

- After that, the vacuuming procedure is repeated.

If you neglect this sequence of actions, then the functioning of the air conditioner will not be as effective. With prolonged use of equipment with such a disadvantage, there is a risk that the condensing unit will fail. And repairing or buying a new device will be much more expensive than even calling specialists to vacuum the air conditioner.

Vacuuming should be carried out sequentially, clearly according to the scheme

Process to Avoid

Many installers ignore such an operation as vacuuming a split system. Instead, they expel some of the freon from the system. This is done in order to displace the air.

You can also use freon purge. Only this is strictly prohibited by the manufacturer. The method is initially wrong, and, accordingly, completely unreliable. It should only be used as a last resort, such as when a vacuum pump is not available.

For example, look at the tubes of several air conditioners that have already worked. They are an unpleasant blue-black color. This is the result of copper oxidation in the process of interaction with moisture and air.The same condition will have the insides of your air conditioner if you do not vacuum the system.

Of course, the loss of a small part of the refrigerant does not particularly affect the operation of the air conditioner. Danger must be sought from the other side. Air may remain in the system, which subsequently reacts with the refrigerant and causes equipment malfunction.

The air conditioner starts to cool the temperature in the room badly. The user of the equipment tries to lower the temperature using the remote control, attempts to turn the device on and off. As a result, the electric motor burns out and the split system needs repairs, which are quite expensive.

If the air conditioner is under warranty service, in case of failures in its operation, an examination of the equipment will be carried out, which can very accurately determine the cause of the breakdown. If this is a factory defect, the manufacturer will bear all repair costs. If the examination shows that the equipment was used at an unacceptably low temperature, or without a significant part of freon, the owner of the air conditioner will pay for expensive repairs.

Therefore, when deciding whether to vacuum the air conditioner yourself or trust the installer, carefully weigh the pros and cons. If the installation is carried out according to all possible rules, you will use the equipment strictly according to the instructions and maintain it on time, then your air conditioner will serve you faithfully for many years. Good weather to your home and a pleasant climate!

How long to vacuum?

The duration of the process depends on the capabilities of the vacuum equipment.An indicator of the degree of vacuuming is the power of the equipment, single-stage vacuum cleaners are less powerful, suitable for the corresponding split systems. The act of sealing can last about 30 minutes.

The two-stage pump is more powerful equipment, it can achieve vacuum even in a minute. The next 15-20 minutes are necessary to check the tightness of the system.

You can monitor the pressure level using a monometric manifold or a vacuum unit. More accurate indicators of the tightness of the circuit are achieved by high pressure crimping (40 bar).

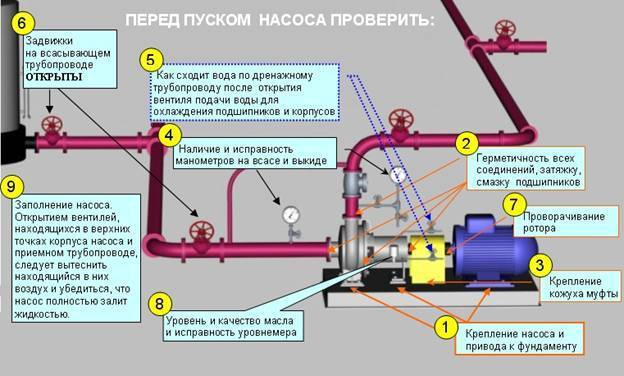

HEALTH REQUIREMENTS BEFORE STARTING WORK

2.1. Check the serviceability of overalls, safety shoes and other PPE for the absence of external damage, put on serviceable PPE appropriate for the work performed. Overalls must be buttoned up. Remove hair under the headdress. It is forbidden to keep sharp, breakable objects in the pockets of clothing. 2.2. Remove wedding rings and other jewelry. Shoes must be closed. It is forbidden to wear sandals, flip-flops and other similar footwear. 2.3. Obtain a task from the immediate supervisor, if necessary, be instructed. 2.4. Inspect the workplace, remove everything that may interfere with work or create additional danger. 2.5. Check the ventilation, sufficiency of illumination of the working area. 2.6.Prepare the workplace for safe work: - inspect it, remove all unnecessary items, containers, raw materials, without blocking the aisles; - check approaches to the workplace and evacuation routes for compliance with labor protection requirements; - check the availability of fire-fighting equipment, first aid kits; - establish the sequence of operations. 2.7. Check by external inspection: - the absence of hanging and bare ends of the electrical wiring; - the condition of the floors (no potholes, unevenness, slipperiness). 2.8. Check the condition and serviceability of the vacuum apparatus: - check the serviceability of fittings, pipelines, steaming and leakage of water at the junctions of pipes; — check the serviceability of the manometer; - check the presence of a seal on the safety valve; - check the serviceability of the unloading valves; - check the cleanliness, serviceability and tightness of the installation of viewing windows. - check the reliability of equipment fastening, protective covers and grounding. 2.9. The employee must personally verify that all the measures necessary to ensure safety are implemented. 2.10. If any malfunctions are found, report this to your immediate supervisor and do not start work until they are eliminated.

Pumps for evacuation of split systems

To remove a larger proportion of gaseous substances from the compressor and condenser unit that has been collected, but not yet filled with freon, a special device is required - a vacuum pump. The procedure for pumping air from a split system is capable of performing pumps of two main types - low-vacuum and high-vacuum.

For splits up to 7000 BTU, a single-stage vacuum pump is suitable, for more powerful ones, a two-stage vacuum pump is needed, and for multi-zone systems, only an ion-getter pump is needed. You will definitely need a manometric station with hoses and fittings for 410 freon

We repeat once again: evacuating the air conditioner with your own hands is possible, but this work cannot be done without a vacuum pump.

Types of low vacuum pumps:

- Rotary vane (single-stage). Characterized by low noise during operation, the ability to adjust the residual pressure, simple design. Their disadvantages are the need for periodic replacement of consumables (for example, oil);

- Two-rotor (two-stage). Equipped with two main rotors working synchronously. Economical, effectively “push” air to the drain pipe by increasing the pressure in the circuit of the device being evacuated;

- Water ring. Able to equally well remove both air and liquid. The disadvantages of such devices are the significant consumption of electricity and the need for water.

Of the types of vacuum pumps listed above, only water ring devices operate exclusively in the low vacuum range (105-102 Pa). For other types, the vacuum range is wider and reaches 10-3 Pa, i.e. high vacuum levels.

Types of high vacuum pumps:

- Diffusion. Highly efficient, provide fast vacuuming. But they cannot be used for the refrigeration circuit, because. the working fluid of these pumps are synthetic oils that pollute the evacuated circuit;

- Cryogenic. Their work is accompanied by the injection of nitrogen, which freezes and removes gases and liquids with an increase in the degree of rarefaction of the internal atmosphere of the circuit;

- Ion-getter.Equipped with a thin titanium film that traps the molecules of gases and liquids discharged from the refrigeration circuit during vacuum. The most effective - eliminate up to 97% of impurities.

Despite the advantages of ion-getter degassers, which turn off the provision of a high degree of vacuum (over 10-5 Pa), they are rarely used when installing split systems - these devices are expensive.

Which is more profitable: professional installation or do-it-yourself installation of a split system

The price of installing an air conditioner depends on the complexity of the work, on the power and size of the equipment. To make the comparison correct, the cost of professional services for the installation of a small power household appliance, for example, 3.5 kW, can be considered as a basis.

This service includes:

- installation and connection of both units;

- harness laying (up to 5 m);

- formation of through holes in the wall.

Also, the cost of installing an air conditioner includes the cost of consumables. On average, professional installation of low-power split systems costs the client 5500-8000 rubles.

Average prices for renting a tool and purchasing materials for installing an air conditioner in an apartment with your own hands:

- Perforator ("Makita") - 500 rubles per day.

- Two-stage pump - 700 rubles / day.

- Installation kit + communications (5 m) - 2500 rubles.

Independent installation of a split system saves from 1500 to 4000 rubles

In some cases, equipment is leased only on security. It is approximately 4000-8000 rubles. The amount of the deposit depends on the value of the equipment rented. If pipe rolling is required, then tool kits designed for this purpose will have to be added to the list. The cost of their rent is 350-500 rubles per day.

The total amount reaches 3700 rubles.To this value you need to add 10%, which will cover unforeseen costs and the purchase of consumables. The result will be about 4000 rubles. This means that self-installation of a split system saves from 1,500 to 4,000 rubles.

It is worth noting that the minimum amount for a professional installation does not always include a complete list of work. You may have to pay extra for some of them. With this in mind, we can conclude that the savings are about 2500-3500 rubles.

The cost of installing an air conditioner includes the cost of consumables.

Air conditioner installer mistakes

You can install a split system in no more than half an hour. Only those people who do not vacuum or do it incorrectly can say so. So, the main mistake of HVAC equipment installers is the displacement of air with freon. The process itself may be effective, but there is one big drawback. Manufacturers of air conditioners prohibit such interventions. Even if you manage to displace the air in this way, then later, this can lead to other problems. In the event of a breakdown of the device during the period of validity of the warranty card, the repair service workers will identify a lack of refrigerant in the system. It is unlikely that a lack of freon will be attributed to a gas leak.

SAFETY REQUIREMENTS DURING WORK

3.1. Obey the rules of the internal labor regulations, other documents regulating the issues of labor discipline. 3.2. Perform only the work for which training has been completed, instructions on labor protection have been received and to which the person responsible for the safe performance of work has been admitted. 3.3.Do not allow untrained and unauthorized persons to work. 3.4. Work in the established overalls, safety shoes, properly use personal protective equipment. 3.5. Strictly comply with the safety requirements set forth in the operational documentation of the manufacturer of the vacuum apparatus. 3.6. During the whole working day, keep the workplace in order and cleanliness, avoid blocking the approaches to the workplace, use only the established passages. 3.7. In the process of work, control the technological process. At the same time, be located in such a way as not to be exposed to hazardous production factors. 3.8. Maintain proper fencing and insulation. 3.9. Before starting the steam, drain the condensate from the steam jacket of the apparatus through a drainage device. 3.10. When purging, open the air valve and drain valve. Purging should be carried out for 1-2 minutes. 3.11. Check the function of the safety valve. 3.12. Watch for thinning. The vacuum should be 600-650 mm. rt. Art. 3.13. Avoid heating the vacuum pump above 45-50°C. 3.14

Unload the mass carefully. Work with gloves

3.15. Do not carry out any work under the unloading valve. 3.16.When working with a vacuum apparatus, it is prohibited: - to install and remove the plug with wet hands; - pull and twist the power cord; - remove parts of the body, safety devices during operation; - use the vacuum apparatus in an improper way and not for its intended purpose; - operate a faulty vacuum apparatus; - work in case of damage to the electric drive; - work on an ungrounded vacuum apparatus; - perform work without the use of the necessary PPE; - to carry out maintenance and repair of the vacuum apparatus in the switched on or running state. 3.17. When servicing a vacuum apparatus, it is necessary to comply with the requirements that ensure safe working conditions and the normal conduct of the technological process. 3.18. Do not use random objects (boxes, boxes, etc.), equipment and fixtures for sitting. 3.19. Timely maintenance of the vacuum apparatus. 3.20. Comply with the rules of conduct on the territory of the enterprise, in production, auxiliary and amenity premises. 3.21. Do not eat at work. 3.22. If you feel unwell, stop work, notify your supervisor and consult a doctor.

How long to vacuum

The duration of the process depends on the capabilities of the vacuum equipment. An indicator of the degree of vacuuming is the power of the equipment, single-stage vacuum cleaners are less powerful, suitable for the corresponding split systems. The act of sealing can last about 30 minutes.

The two-stage pump is more powerful equipment, it can achieve vacuum even in a minute. The next 15-20 minutes are necessary to check the tightness of the system.

You can monitor the pressure level using a monometric manifold or a vacuum unit. More accurate indicators of the tightness of the circuit are achieved by high pressure crimping (40 bar).

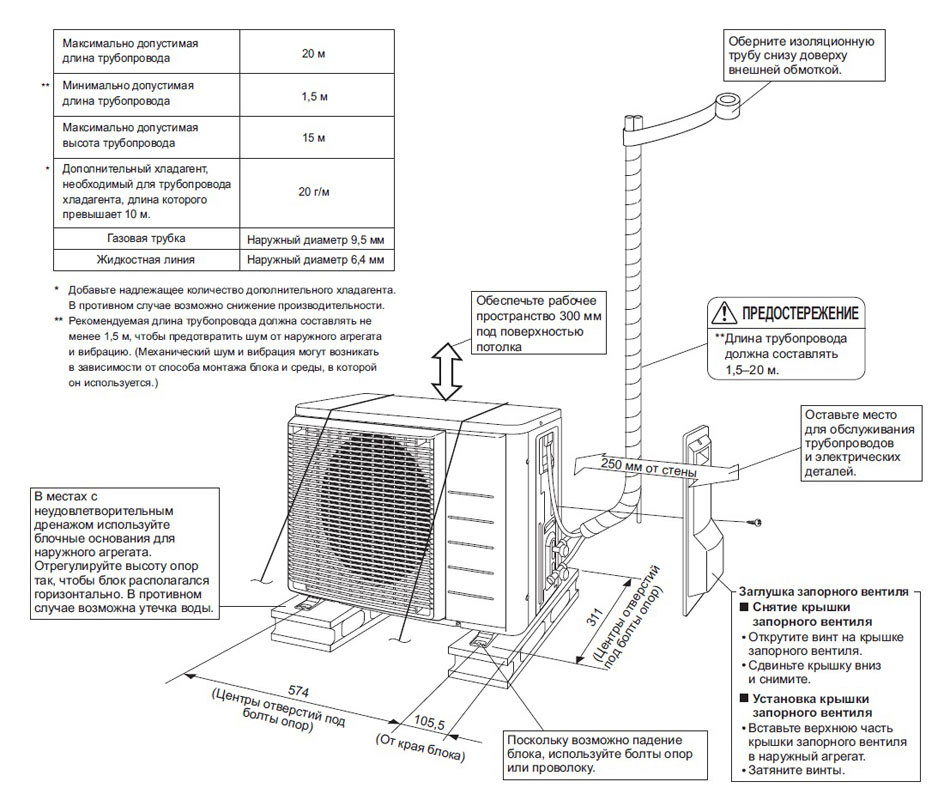

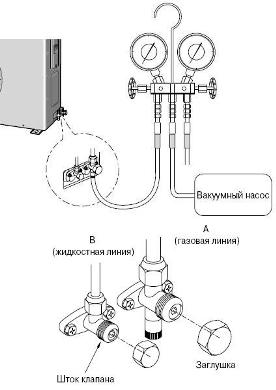

Vacuuming the refrigeration circuit

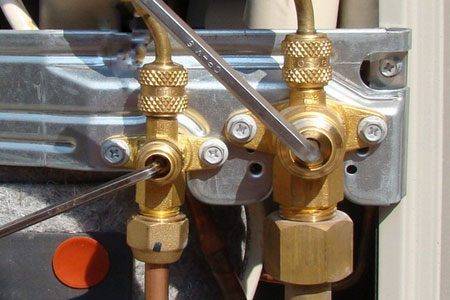

The external unit of the air conditioner comes from the factory charged, that is, it contains freon in the required amount. Closed three-way valves do not allow it to go out.

After installation, we get a system consisting of an indoor unit and connecting pipes filled with atmospheric air with impurities and moisture contained in it.

For normal operation, we need to remove air and moisture from the system, then open the valves by starting the freon.

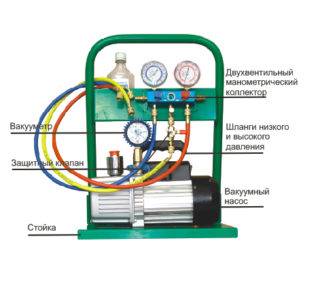

Vacuum process

We connect the manometric manifold to the valve on the air conditioner (low pressure hose-blue)

Connect the filling hose to the vacuum pump (yellow)

- Opening the low pressure valve

- Turn on the vacuum pump

- After the end of the process, close the valve on the manometric manifold

- Only then turn off the pump.

- We launch freon into the circuit by opening the valves on the air conditioner with a hexagon (both)

Vacuum time

To control the degree of rarefaction in the system, there is a device - a vacuum gauge, the scale of which is graduated in mbar - good vacuum gauges are initially equipped with vacuum gauges, but separate ones, for example, electronic ones, can also be used.

Some installers are guided by the pressure of the pressure gauge - as soon as the pressure drops below zero, they stop vacuuming, believing that the air has been removed and the process can be stopped.

But this is wrong.Any air contains moisture - it evaporates during vacuuming, so for 7 Btu / h air conditioners, the vacuuming time should not be less than 15 minutes (depending on the performance of the pump itself), for more powerful systems, respectively, more.

Vacuum pump selection

For different purposes, it is necessary to choose different equipment, for example, for the installation of household air conditioners, you will need a pump with a small capacity, which is quite enough for a small track. And when installing industrial, VRV systems, pumps with high performance and power are already needed.

- Productivity, l/h

- Residual pressure, Pa

- Engine power, W

The pumping speed from the refrigeration system depends on the performance, it is indicated in liters per hour.

Residual pressure characterizes the "quality of vacuum", the smaller this value, the better, measured in Pascals or miles Bars.

The time of continuous operation of the pump depends on the power of the electric motor; for long routes in RVV systems, this parameter is of great importance.

These are the most basic parameters, there are a number of other parameters, such as the number of stages, the type of pump - oil, oil-free, the number of engine revolutions and others.

"Purge Freon"

Many installers practice this procedure - they expel the air by opening the valve and unscrewing one of the nuts, air comes out from under it, after which it is twisted.

After such installation, moisture remains in the system, the consequences of this are oxidation of copper pipes, damage to the compressor, clogging of the expansion valve with moisture.And most importantly - a significant reduction in service life, so you can ruin any air conditioner, even the most expensive one.

The nuances of vacuuming

Vacuuming a split system does not always go without problems. So, pressure readings can jump. Such abrupt and frequent changes indicate a loss of tightness. This means that constant jumps are a sign of a hole, a loose hose nut, etc. The best diagnostic method is a soapy solution. This old but still effective method will externally show the problem area. If bubbles appear in some place, then you need to reconnect this element, or simply tighten the nut with a wrench.

Most often, all problems with vacuuming are associated with violations of the connections. So, nuts can be undertightened or overtightened. It is possible that the thread may be torn off.

This option requires additional actions on the part of the wizard. Connect the collector to the freon refueling valve, turn on the air conditioner and close the valve on the thin pipe. As soon as the readings on the pressure gauge begin to decrease, the adjacent valve should also be closed. After that, you can turn off the air conditioner and turn off the rest of the equipment.

After carrying out additional operations for pumping the refrigerant, it is necessary to carry out the evacuation again. The process of removing air and moisture is simple if you do it yourself. There is only one downside. If suddenly something does not go according to plan and certain measures are not taken to protect the device, then there is a risk that the cooling system may be damaged or become malfunctioning.And when the air conditioner is vacuumed by specialists, the risk that a problem situation may occur is minimal. An additional and important factor in commissioning carried out by specialists is a guarantee for the quality of work. For any problems that have arisen with KKB after that, the second repair will be free.

Hole tightness

Independent installation of a split system must be accompanied by careful sealing of all docking holes. It all starts with sealing the hole in the wall. For this, the usual standard putty is suitable.

The drainage pipe is usually tightly fixed with a special clamp. With regard to the electrical connection and the cable connecting the units for data transmission, they must be connected in accordance with a special diagram. Usually it is attached to the device passport. Depending on the type of installation and the manufacturer, the connection must also be made.

The cable and data line are connected to the appropriate terminals, which are usually marked with different colors. The cables connecting the two units must also be secured with a special clamp.

During the installation process, be sure to pay attention to the following factors:

- The electrical unit must be securely fixed and closed. If this condition is not met, the risk of electric shock or elemental fire increases, since dust, dirt or water can easily get inside.

- The electrical connection cable must under no circumstances be connected to the cold pipe. The cable through which freon passes heats up during the operation of the installation, so their contact should be excluded.

What you need for self-assembly

The main thing you need for self-installation of a split system is tools and materials. Specialists do not just set a high price for installing an air conditioner, because the equipment is expensive. Do not forget about the need for its armotization.

Installation tools

- Perforator (a tool for creating a hole in the wall through which communications are laid and split system blocks are connected);

- Drill and drills of different diameters, which will be needed to install the base (fasteners) for the air conditioner;

- Expander of copper pipes, with the help of which the pipe is deformed to the required diameter;

- Pipe cutter, which is used to cut copper pipes;

- Rimmer or a regular file, which are needed for stripping pipes and removing burrs.

materials

The list of materials for installing a split with your own hands is longer and includes the following objects:

- Copper seamless pipes exclusively for air conditioners. There is a difference between these and water pipes. For split systems, soft pipes are used, which successfully allow you to create good sealing. According to the diameter, this material is divided into large and medium size. The required length should be 20 cm longer than the length of the communication;

- Cable for connecting blocks of a split system. Often a 4-core wire with a cross-sectional thickness of 2-2.5 square millimeters is used. The length of the cable must match the length of the communication or be slightly longer;

- Drainage tube - spiral plastic hose;

- Insulation for pipes made of rubber;

- Brackets for mounting the outdoor unit. Dimensions depend on the dimensions of the block and the bearing capacity of the wall;

- Fasteners (dowels, anchors, bolts, screws, etc.);

- Plastic box in order to hide communications at the end of the installation of a split system.