- Features of installation of a typical design

- 6 Optimal location

- How to calculate the exact height

- What influences

- Roof structure

- Fire safety rules

- cross section

- Types of deflectors for ventilation systems

- Features of self-assembly

- Norms and requirements

- Installation of the ventilation passage through the roof

- Choosing a place for the node of the passage through the roof

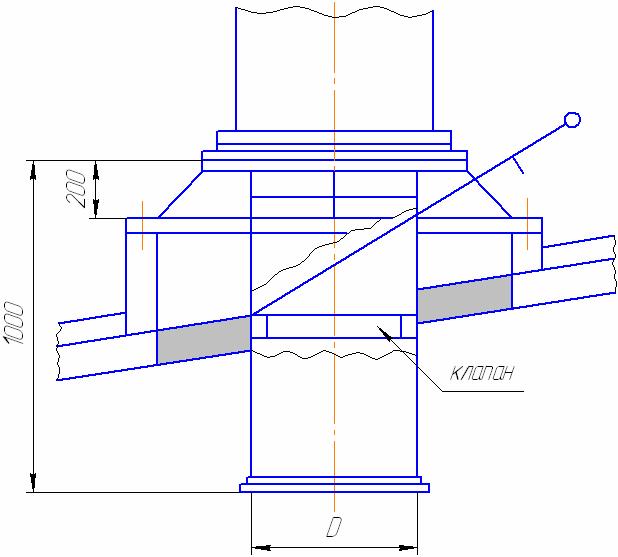

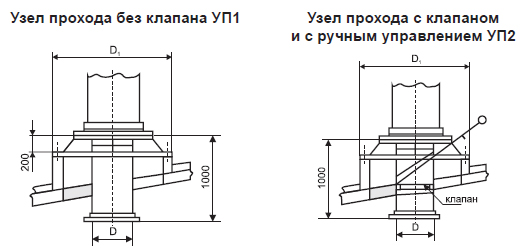

- Types of UE

- Size range of air ducts

- Classification of ventilation pipes for exhaust hoods

- General characteristics of roof ventilation units

- What is the principle of the structure of the ventilation passage?

- The Importance of Resistance in a Ventilation Duct

- Conclusions and useful video on the topic

Features of installation of a typical design

Penetration units for ventilation communications of industrial production are performed in accordance with the requirements of GOST-15150. It is believed that the air temperature inside the communication pipe should not exceed 80 degrees, and the flow humidity should be within 60%.

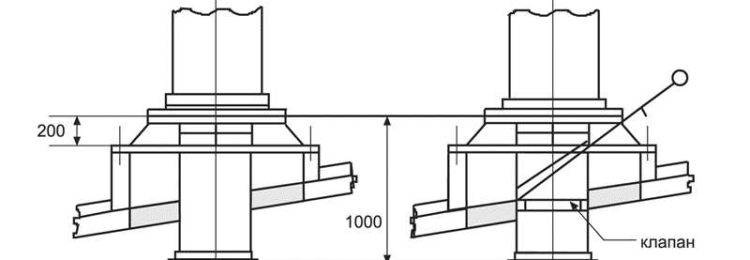

The place where the ventilation pipe passes through the roof usually has a square configuration, this must be taken into account when choosing the shape of the duct and the type of transition node

To calculate the passage node, one should take into account such indicators as the angle of the slope of the slope and the distance from the element to the roof ridge.

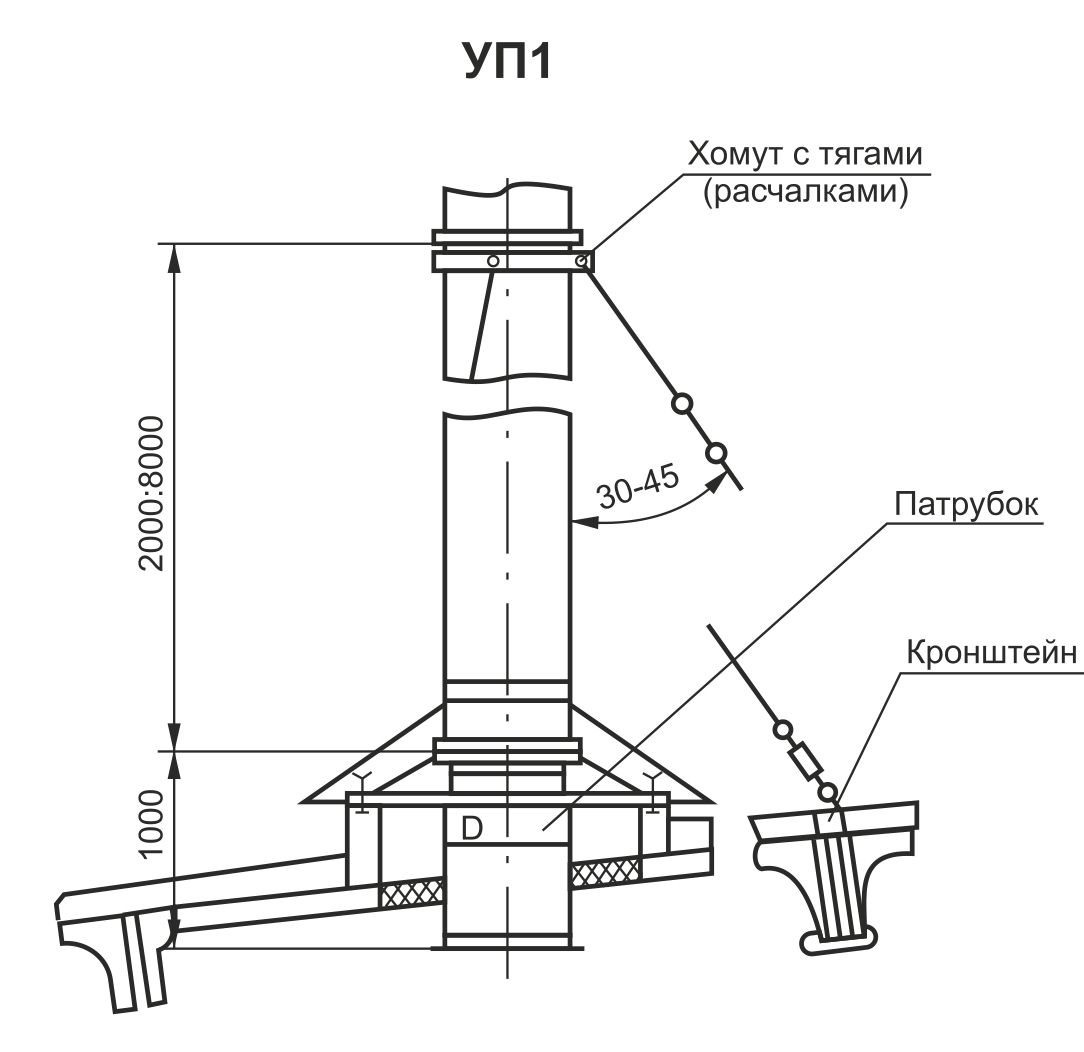

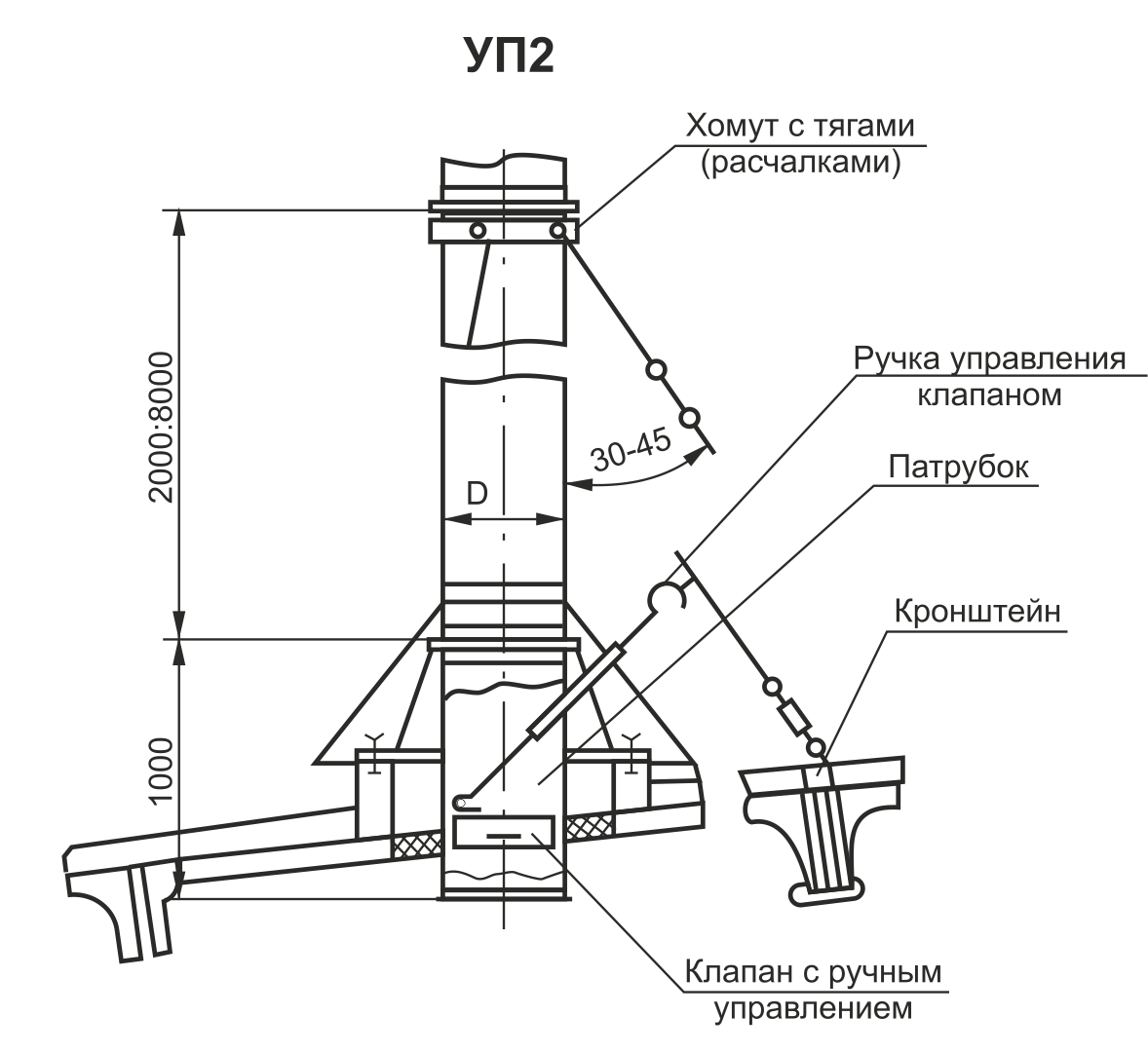

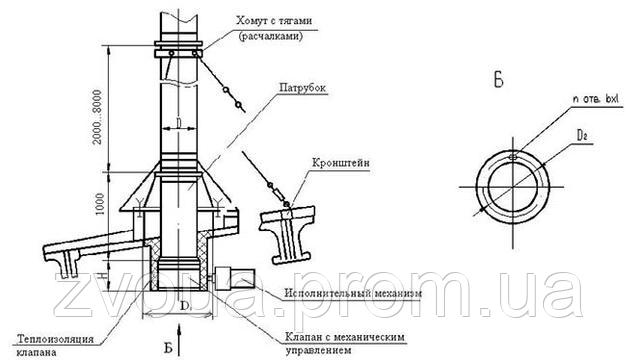

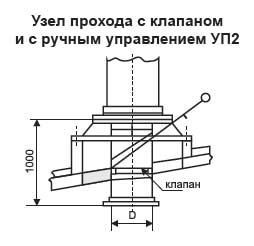

A typical transition node can be made in the following variations:

- with or without condensate ring;

- with insulated or conventional valve or without valve;

- with manual or mechanical control for the valve;

- with or without spark protection, etc.

The options listed may vary depending on the situation. For example, it is not necessary to install a mechanical valve if the system is stable and does not need constant adjustment. It is also possible to manufacture a penetration unit on order.

Typical units for penetration through the roof, made at industrial enterprises, are very diverse, they are selected depending on the size of the pipe and the characteristics of the roof

Structures of this type are made of polymers, stainless steel 0.5-0.8 mm thick and black steel 1.5-2 mm thick. The cross section of the finished transition node can be round, oval, square or rectangular. A specific model is chosen depending on the type of roofing material and the parameters of the ventilation pipe.

Although foreign-made passage assemblies are usually of high quality, they are not always adapted to local climatic conditions, so it does not hurt to carefully study the offers of domestic manufacturers.

They are usually labeled as follows:

- the letters UE with an index from 1 to 10 indicate a design without a condenser ring and a valve;

- indexes from 2 to 10 indicate devices with a manual valve, the ring is missing;

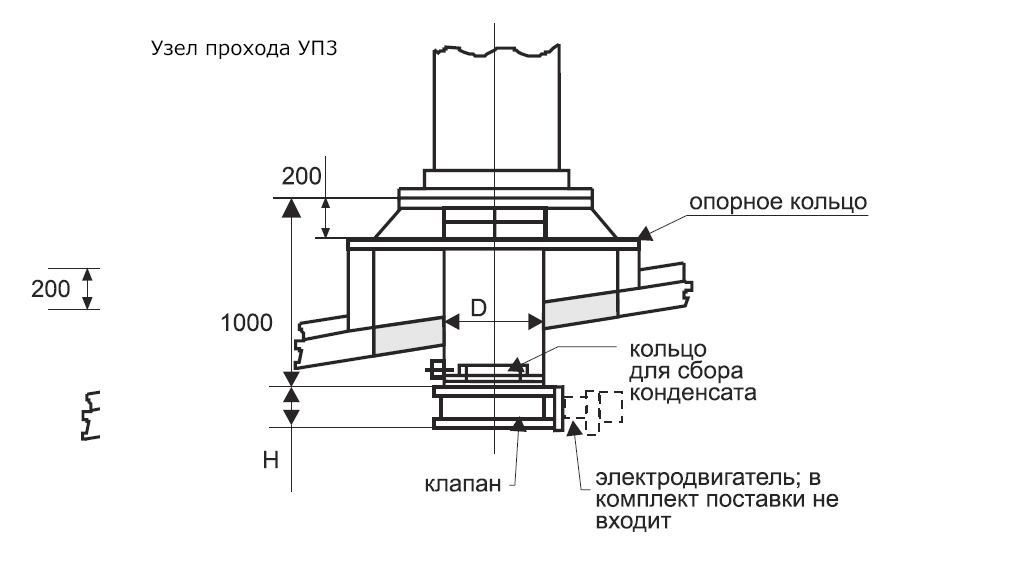

- the designation of the UPZ is assigned to devices with a special platform for the actuator for the valve, which is provided for by the design.

The complete set of ready-made models of transition nodes includes embedded bolts and nuts that are attached to wooden structures, reinforced concrete cups intended for installation. Mineral wool is successfully used for thermal insulation, which is recommended to be protected with a layer of fiberglass.

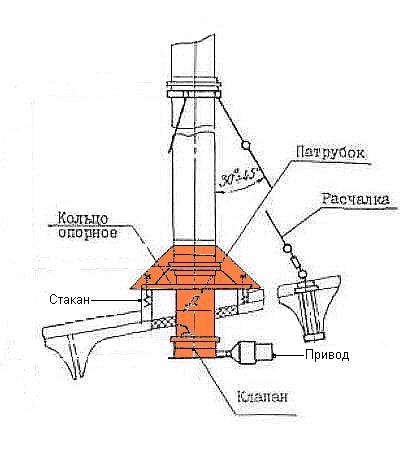

If it is necessary to install a ventilation unit with a safety valve, you should pay attention to the branch pipe intended for it. A valve must be attached to the bottom flange of this element.

The upper flange is designed to fix the position of the air duct. Clamps and brackets are used as fasteners for braces.

To further protect the ventilation riser from moisture, you need to use a skirt. The condensate collector is welded to the branch pipe.

It is designed to remove moisture from air massesthat move through the ventilation duct. To control the valve, a mechanical assembly is used, which should be installed on the shelf intended for it.

This element should not be installed next to the condensate collection ring in order to maintain the integrity of all penetration elements. Typical node models are usually mounted before the start of roofing work: first, the ventilation system ducts are mounted, then the passage, and the roof is placed after that.

It is recommended that at the end of the work, all joints be sealed, including the junction of the assembly elements to the roofing.

For this you should:

- clean the surfaces of the pipe and roof from contamination;

- seal the lower part of the duct and the adjacent section of the roof with foil paper;

- fill holes with sealant.

These measures will help protect the penetration from moisture and create additional thermal insulation of the structure.

The article recommended by us will acquaint you with the rules for installing the ventilation system directly, in which the nuances of design and organization are analyzed in detail.

6 Optimal location

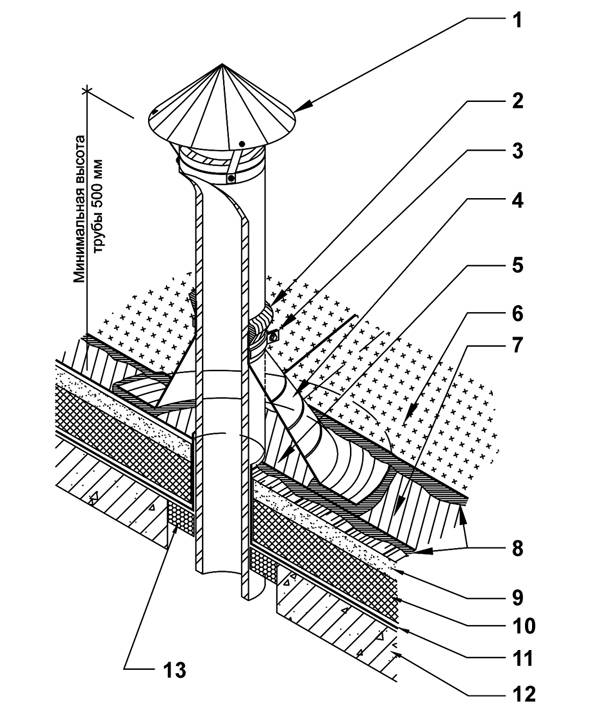

On a pitched roof made of metal, it is better to put a penetration near the ridge itself. So the long part of the pipe will be under the roof, insulated from external influences. The remaining short element will be able to withstand any wind blows and other processes.

At the installation stage, it is also important to consider the height of the shaft above the roof. Too low an indicator will negatively affect traction, and too high will be exposed to gusts of wind and quickly deform

In addition, it will have to be additionally fixed with braces and other fasteners.

According to current construction standards, the optimal height of the shaft above the sloping roof should be no more than 50 centimeters. If the roof is flat, the height indicator is 30 centimeters. When using the roof for arranging open areas for recreation, the ventilation outlet must rise at least 2 meters.

How to calculate the exact height

Even at the stage of building a house, you need to determine the height of the chimney. This will ensure natural draft, dispersion of combustion products and polluted masses in the atmosphere, and will not interfere with nearby buildings and people living in them. The height of the ventilation pipe above the roof is determined by the norms of SNIP. The calculation is made taking into account climatic conditions, the type of structure, its performance characteristics. If errors were made during installation, it will be difficult and expensive to correct them.

What influences

When designing a chimney, the following factors influence height calculations:

- environmental characteristics: air temperature in winter and summer, wind speed and strength;

- the configuration of the heating and ventilation system, the presence of complex elements and turns in the line, which contributes to an increase in the friction force inside the channels;

- proximity to the location of the chimney can lead to the suction of combustion products into the supply ventilation;

- moving away from the ridge reduces installation performance, which can cause a pipe that is too high to fall.

Roof structure

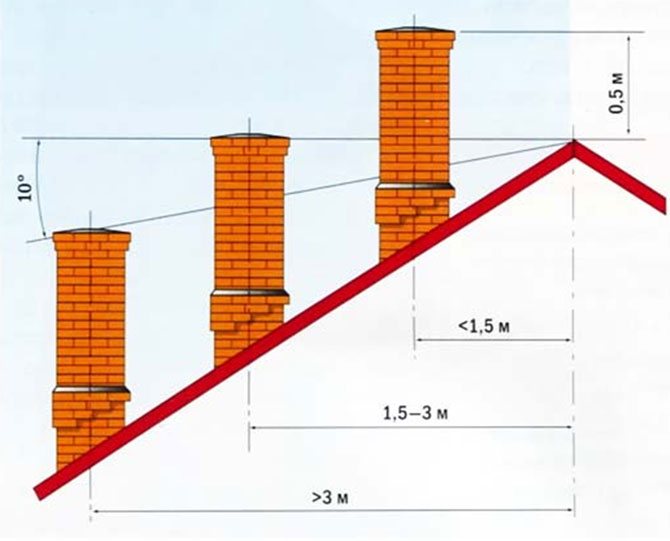

Influence on Height ventilation shaft renders design roofs. Installation on a flat roof will not cause difficulties - 50 cm is enough to provide traction. On pitched models, you must adhere to a number of rules:

- it is mandatory to take into account the relationship between the highest point of the ridge and the end of the pipe;

- when removed at a distance of 1.5 m, the upper boundary of the duct must exceed the roof level by 50 cm;

- the greater the distance, the higher the pipe to create good traction.

Fire safety rules

Ventilation and chimney pipes often run in close proximity to each other or are a single unit. For this reason, some fire safety measures are imposed on such highways:

- with separate structures, the distance between them must be at least 3 m;

- the height and dimensions of the ventilation pipe must be equivalent to the chimney;

- when arranging the heating of the outer part of the mine, fire safety rules must be taken into account;

- if the channels are close, they should be insulated with heat-resistant and insulating materials.

cross section

There are 2 types of duct section - round and rectangular.When designing, it is necessary to take into account not only the aesthetic component, but also the performance of the system. Air moves faster through round channels, turbulence and reverse flows are not formed. Rectangular adjoin close to the wall, do not "steal" usable area and look better.

The best option may be a combination of different sections. It is better to mount rectangular ones in visible places and residential premises, and place round ones on the rear walls of the house and in technical rooms.

Types of deflectors for ventilation systems

To date, the following types of deflectors are used:

- TsAGI with a diffuser - expansion of the ventilation duct: the most efficient design when the wind flow is more than 2m / s. The design consists of a bottom cup with an extension at the end, a cylindrical steel body, an umbrella-lid and lid fastening racks.

- The Volper-Grigorovich cylindrical fungus is a nozzle that successfully compensates for pressure losses at the outlet. It consists of a bottom cup, an upper cup with concave walls, a conical umbrella and fasteners. The Volper fungus protects the ventilation system better from the wind than TsAGI.

- The H-shaped pipe collector is an element of pipes in the shape of the letter H. This rather bulky design completely protects against wind blowing, moisture ingress, reverse thrust, and freezing. However, the design increases the traction force minimally.

- The wind vane always turns back to the wind during operation, which prevents it from blowing inward. A zone of low pressure appears behind the nozzle body and the air jet leaves the vertical channel faster.Effective for increasing traction, but poorly protected from rain.

- The turbo deflector is a spherical rotary deflector with many semi-circular blades that are rotated by the wind. A vacuum appears inside the sphere. Not effective in calm weather.

One of the improved varieties of the traditional fungus on the pipe is the static-dynamic device of the Astato type, which consists of 2 truncated cones, which are turned towards each other with their vertices. Above is an electric fan and an umbrella.

The system is effective even in complete calm. The only drawback is the high price.

When choosing a deflector, you need to consider:

- The size of the nozzle must be selected according to the diameter of the hood shaft. If the house has a rectangular shaft, you will have to use an adapter.

- TsAGI and the Volper deflector do not require maintenance.

- In the absence of traction, it is better to install dynamic cap options.

- When buying a rotating deflector, you need to choose more expensive models with a closed bearing that does not freeze in winter.

- In areas with strong winds, it is better to choose an H-shaped deflector or turbo reflector, for other climatic conditions - TsAGI.

If you have a budget in any region, you can install Astato. The device requires periodic maintenance.

The TsAGI deflector can be assembled with your own hands. It differs slightly from the usual Grigorovich umbrella. The difference is only in the shell attached around the fungus

Let's look at how to properly install a roof vent hood. After purchasing the model, you need to assemble and securely fix all fasteners. Then, when mounting the device on the pipe, you need to carefully drill holes for mounting. The device is fixed on screws or rivets.Additionally, you can put a clamp.

Features of self-assembly

Each model has instructions for installation, according to which the work is carried out

The set of penetration modules for ventilation through the roof includes hardware and embedded parts that allow them to be attached to wooden elements, reinforced concrete cups. The function of thermal insulation protection is performed by mineral wool, covered with a layer of fiberglass. When installing modules with a protective valve, the branch pipe designed specifically for it is taken into account. The valve mechanism is attached to the lower edge of the tubular element. Its upper flange serves to ensure a fixed position of air ducts or pipes. For fastening, use the clamps and brackets included in the kit.

Before choosing a passage node, the slope angle of the pitched roof, as well as the distance from it to the roof ridge, are taken into account

It is also important to determine the version of the valve and ring. All of these options vary depending on the operating conditions.

There is no need to install a mechanical valve, for example, when the system is already operating normally and no constant adjustment is required.

UE are made of the following materials:

- polymers of various classes;

- stainless steel 0.5-0.8 mm thick;

- black steel 1.5-2 mm.

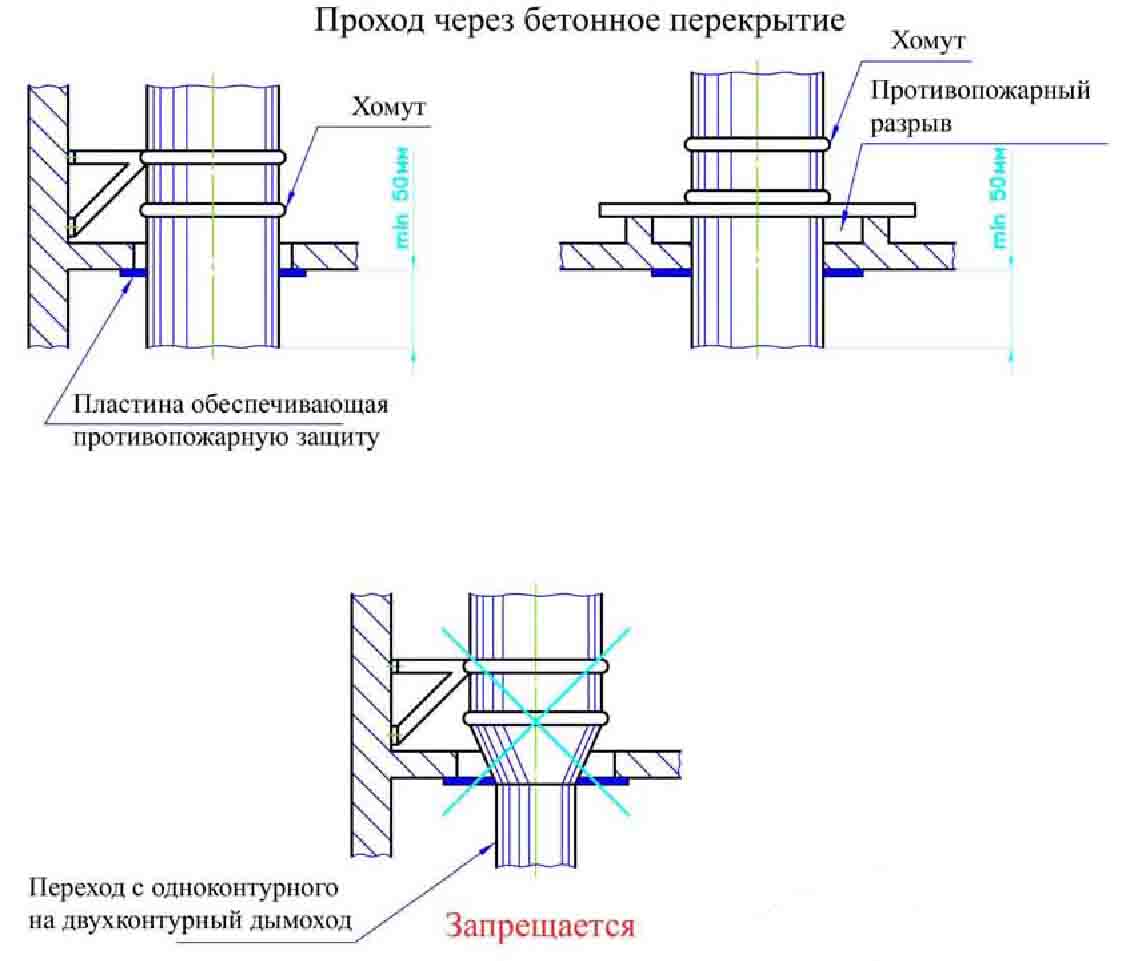

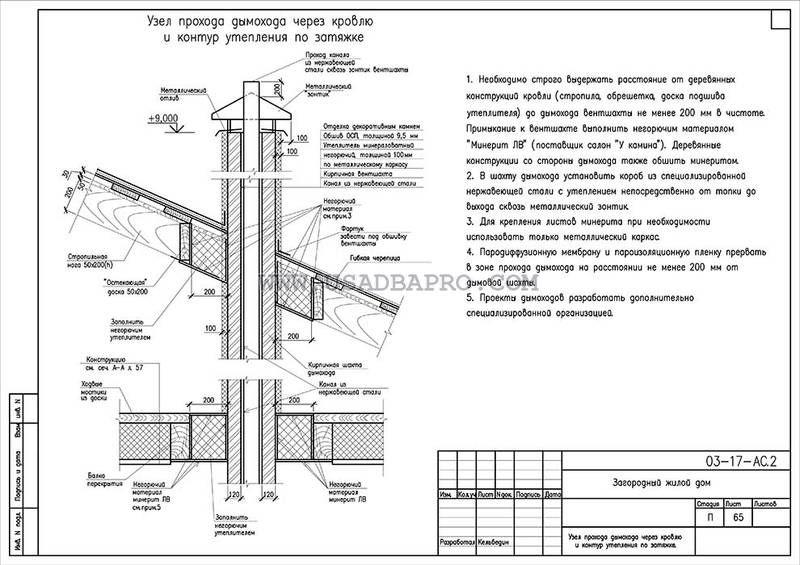

Norms and requirements

The high-quality installation of the chimney passage through the roof is so important for the safety of the building and residents that the state has officially fixed rules and regulations for its arrangement. A document that takes into account sanitary and hygienic, fire hazardous, corrosive and other loads on the structure and materials is called SNiP 41-03-2003 "Thermal insulation of equipment and pipelines".

Piping through the roof is planned at the construction stage.If the furnace is reconstructed, changed or repaired during operation, then the chimney is usually left in the old place. The fundamental condition for a high-quality chimney is the location of the pipe relative to the roof ridge.

To ensure optimal traction, the best place to bring the pipe to the roof is its highest point - the ridge. This allows you to lead the main part of the pipe through the attic, which protects it from moisture and cold. The difficulty lies in the fact that it is necessary to violate the integrity of the horizontal beam by installing additional supports on both sides of the chimney. More often, the pipe is brought out at a short distance, which makes it possible to limit the street part of the pipe to a minimum of fifty centimeters.

There is the following dependence of the height of the chimney on its distance from the ridge:

- the distance to the ridge does not exceed 1.5 m - the pipe rises 50 cm above it;

- distance from 1.5 to 3 m - it is enough to bring the chimney flush with the ridge;

- when the chimney outlet is more than 3 m away from the ridge, the height of the pipe may be lower than the top point of the roof (the difference should be an angle of 10 degrees).

The optimal height of the pipe is from 0.5 m to 1.5 m. The outlet is located between the rafters, so as not to violate their integrity and leave a distance of 15-25 cm from them.

If the direct vertical exit of the pipe falls on a similar merger of two roofs, then the roof penetration should be shifted half a meter to the side, adding a horizontal section (up to 1 m) to the chimney. In winter, snow and ice accumulate in the recess, which creates an additional threat for the occurrence of leaks.

An unfortunate location for the roof penetration for the chimney is the lower part of the roof.Here, the pipe can be damaged when masses of snow and ice come off. In addition, a large section of the pipe has to be taken outside to ensure normal traction, which contributes to its freezing and the formation of condensate on the inner walls.

Installation of the ventilation passage through the roof

Running the chimney to the roof is a task that for most homeowners may seem like a no-brainer. However, the ventilation passage assembly through the roof must be equipped very carefully in compliance with all technical norms and rules. Only under these conditions will the integrity of the roof pie be preserved, and the ventilation system will work efficiently.

Most often, in private housing construction, ventilation ducts from the bathroom, kitchen and living rooms are led through the ceiling to the roof. Roof venting, ending in a tube that rises above the roof, can provide efficient air draft. This method of arranging ventilation ducts makes the air in the house clean, since all unpleasant odors exit through the penetration into the street.

Taking into account SNiP, the exit of the passage node air duct through the roof required for:

- air exchange in the attic or attic room of the house;

- installation in the wall of the fan section of the sewer shaft (the fan pipe is connected to the sewer and ventilation to remove odors);

- supply of clean air enriched with oxygen.

Ideally, the development of a ventilation passage through the roof should be carried out at the design stage or during construction before the house contour is closed (roof, doors and windows).

But in practice, it is often necessary to reconstruct the roof passage assembly in an already constructed building and build on the existing features of the layout of the premises.

If there are errors in the arrangement of the passage unit, then this is fraught with a high concentration of unpleasant odors, carbon dioxide, and the appearance of reverse thrust.

The through-flow ventilation unit is a plastic, metal or combined pipeline. It is placed in a hole in the roof and fixed in a metal cup. After installation, the hole must be sealed and insulated. An air duct of the ventilation system is connected to the penetration from below, and a protective cap is placed on top.

To organize the passage of the pipe, you can also use a ready-made product, which is designed for ventilation on the roof. This is a pipe that consists of an outer polypropylene layer and a galvanized metal pipe inside. At the bottom of the product, where the air duct is installed, there is thermal insulation, and at the top of the structure there is a protective drip.

The design and installation of the node will depend on a number of factors:

- roof slope angle;

- type of roofing material - profiled sheet, ceramic or soft tiles;

- roof type.

Since for the installation of the pipe it is necessary to cut out a part of the roof, including the outer section, the layer of hydro- and thermal insulation after fixing the structure must be well sealed. If this is not done, then water will pass through the ventilation pipe into the house, and the temperature in the rooms will be disturbed.

There are certain requirements:

- it is not necessary to connect several ventilation passages into one, but for all parts (sewer riser, hood, attic, living rooms) make a separate exit to the roof;

- structures must be vertical without bends, so that it is possible to freely ensure the movement of air to the street;

- for the installation of mines, it is necessary to choose high-quality shaped products that can ensure tightness and unhindered movement of air masses;

- ideally, ventilation shafts must pass through the ridge in the middle of the structure or at a close distance near it.

Installing ventilation passages through or near the ridge is the best solution for a gable roof that is not equipped with a ridge rafter system.

The main element of the passage assembly is the outlet - a shaped product in the form of a branch pipe, which has a flat base corresponding to the type and coverage of the roof. For different engineering structures, various types of fittings are used: a passage for pipes, an outlet for a sewer riser and for an exhaust hood.

Separately, in stores you can find special ventilation units for the passage through the roof for corrugated board, metal tiles, for flexible and seam roofs, as well as universal products. Many types of passages correspond to the geometry of the roofing materials, due to this they provide a strong sealing of the assembly during installation.

Choosing a place for the node of the passage through the roof

All recommendations for choosing a passage through the roof come down to ensuring that its location allows the channel to be made with the least number of turns. In this case, the performance of the system will tend to the maximum.

Sometimes, due to objective reasons, bends are indispensable. Corrugated pipes will come to the rescue. The use of corrugated pipes makes it possible to install air ducts with the necessary turns.

As noted above, the passage through the roof with the truss system is performed as close as possible to the ridge. Then, the largest part of the pipe will remain in the attic space, protected from temperature changes and ultraviolet radiation. The whole pipe will not be afraid of a sharp wind, since only a smaller part of it will go outside.

Indicators of wind backwater must be taken into account for any location of the exhaust pipe through the roof. Strong wind can cause poor air flow or direct it into the system.

Types of UE

On sale there are a large number of varieties of passage nodes. They differ in their design and other parameters.

Round pass knot

Table. Types of passage nodes.

| Design features | short information |

|---|---|

|

valveless and with valves | Models without valves are cheaper, but they do not provide the ability to adjust the emission of air and shut off its flow. Often installed in private homes. Valve units are equipped with a damper, which, if necessary, can close the air flow, they are optimal for installing ventilation systems in administrative or industrial buildings - where constant ventilation is not needed. |

|

With insulation or without additional insulation | Insulated UEs can be equipped with a basalt or glass wool thermal insulation layer. Convenient for use in cases where the ventilation pipe is mostly outdoors or located far from the ridge.Insulation helps to get rid of a large amount of condensate that will form due to the difference between the temperatures outside and the flue gases. Non-insulated UEs are used if the building is located in a region with a mild climate or the ventilation pipe is located next to the roof ridge. |

|

Mechanical and automated | The mechanical model has a special cable that allows you to manually adjust the circulation of air flows. Suitable for arranging permanently operating ventilation systems. In automatic UE, a controller is provided that controls the system independently. |

Installation of ventilation passage nodes through the roof

All UEs have a special marking, which allows you to better understand the range of equipment. It looks like an alphabetic and digital designation - for example, UP1-01. The last two digits after the letter designation show the dimensions of the structure. They can vary from 01 to 10. As for the first digit, it shows the design features of the product. For example, a unit reports that the system is not equipped with a valve and a condensate ring. The deuce reports that there is also no condensate ring, but there is a mechanical valve. The three after the letters says that the design has both a ring and a mechanical valve. But in products of this type, the subsequent numbers will vary from 11 to 22, also reporting the dimensions of the structure.

Today, the industry produces eleven types of ventilators, including those for ventilation of seam roofing and corrugated board. For original designs of ventilation systems and aerators, non-standard versions of UE are manufactured

Square and rectangular knots on the roof

Size range of air ducts

According to the regulatory documents mentioned above, round galvanized steel air ducts are manufactured with diameters of 100, 125, 140, 160,180, 200, 225, 250-2000 mm. The parameters of rectangular elements vary from 100 to 3200 mm.

In one ventilation system, parts with different configurations and parameters can be used. To connect them, various shaped elements are used: tees, bends, adapters, diffusers

To select products of the right size, it is necessary to know the design value of the air velocity. In residential buildings with natural ventilation, this figure should not exceed 1 m / s, and with forced ventilation, it should be 3-5 m / s.

For each dwelling, you need to calculate the amount of air supplied. When calculating, you need to focus on the regulatory documentation - SNiP 41-01-2003 and MGSN 3.01.01.

There are also special diagrams compiled by experts that make it easy to find the right duct diameter for various options for standard systems.

Classification of ventilation pipes for exhaust hoods

The modern market offers the widest selection of ventilation systems and accessories required for installation. In this case, there is a certain classification of air ducts.

Pipes for ventilation can be round, square or rectangular.

Pipes for ventilation can be round, square or rectangular.

Exhaust pipes in a private house or apartment, intended for domestic ventilation, are conventionally divided into the following groups:

- Depending on the material of manufacture, there may be aluminum, plastic pipes for ventilation, as well as those made of galvanized steel.

- According to the shape of the duct, square, rectangular or round pipes are distinguished.

- Given the degree of flexibility, two types of products are distinguished - flexible and rigid boxes.

Flexible air ducts are usually made from corrugated aluminum or galvanized steel. Now rigid metal pipes are not used, since their installation is quite complicated, as is the manufacturing process itself. Such pipes should have a diameter of 100-150 mm. Aluminum products are much more expensive, although they do not have special qualities and advantages. Therefore, they are not used when installing a kitchen hood.

Plastic air ducts have a round, square or rectangular shape. Their surface can be either rough or smooth. Most often they are white, although they are often painted in other colors, which makes it possible to choose a plastic air duct for a kitchen hood that will harmoniously fit into the interior.

We will talk in more detail about each specific type of air ducts below, list their advantages and disadvantages, and also dwell on the installation features.

In addition, hood pipes can be rigid or flexible. Note! Plastic ventilation pipes are considered the most practical, because thanks to their smooth surface they are easy to clean, and much less fat and soot accumulate inside. The smoothness of the walls also helps to reduce air resistance, resulting in reduced vibration and noise.

In addition, hood pipes can be rigid or flexible. Note! Plastic ventilation pipes are considered the most practical, because thanks to their smooth surface they are easy to clean, and much less fat and soot accumulate inside. The smoothness of the walls also helps to reduce air resistance, resulting in reduced vibration and noise.

General characteristics of roof ventilation units

When installing various technical communications, ventilation pipes are traditionally installed on the roof. This approach has specific features and requires scrupulous adherence to the installation technology.

The ventilation units of the passage in many cases have a similar design for various models. They are used for the forced and natural process of removing exhaust air, condensate, and fumes outside the building.

All types of roof penetrations must be impeccably made and sealed so that atmospheric dust and water do not penetrate into residential and utility rooms. According to the schemes of roof passages, not only ventilation pipes are equipped, but also aerators, and chimneys, and antennas, and roof hatches

The ventilation pipe of the roof unit is positioned so that the exhaust air can escape unhindered.

For pitched roofs, a convenient solution would be to install a ventilation pipe next to the ridge. This design does not require additional reinforcement and the installation of a snow removal system.

With the close location of the exhaust pipes to the ridge ridge, the least wind pressure is exerted on the system. However, for the formation of normal draft, the ventilation pipe (shaft) must be at least 0.5 m higher than the ridge. This requirement does not apply to aerators and roof fans that solve the problem of draining the roof cake

The manufacture of passage systems complies with GOST 15150, namely:

- The thickness of the material exceeds 1.9 mm.

- The diameter of the circle is 10-12.7 cm. For nodes with a square section, the dimensions may vary.

- Treated with anti-corrosion compounds.

- The size of the support ring necessarily exceeds the diameter of the nozzles.

- The length of the structure must be a maximum of 1 m.

The node itself can be placed on a reinforced concrete glass or directly on the roof section.

The consumer is now offered a wide range of universal and specialized devices for hermetic and operational design of roof passages, both for the internal ventilation system and for drying roof layers.

The dimensions and shape of the outlet are affected by the type of coating, its thickness and the special characteristics of the material, as well as the characteristics of the entire ventilation system. Its choice depends on the conditions created inside the building: the degree of humidity; dusty rooms; gassiness, etc.

What is the principle of the structure of the ventilation passage?

The design features of the ventilation passage, in addition to the removal of dirty air, make it possible to ensure a strong sealing of the roof and protect against the penetration of atmospheric precipitation into the attic. Each node consists of an adapter of a certain diameter, which is inserted into a branch pipe fixed to a concrete sleeve.

Node systems are fixed with anchors, which are included in any standard kit. On a metal base, fastening is also carried out, however, instead of a concrete glass, a similar metal one is built in.

The support ring, which is part of the assembly structure, guarantees a perfect connection between the structure and the roof surface. Clutch flanges provide reliable fastening - the lower one is connected to the air duct, the upper one is the support of the ventilation umbrella, which protects the pipe from precipitation. A ring is placed inside the pipe, which guarantees the removal of condensate.

The Importance of Resistance in a Ventilation Duct

Ventilation pipe above the roof

The draft of air masses depends on another factor - on the roughness of the ventilation ducts from their inside.The friction created directly affects the air flow, and the smoother the material inside, the greater the thrust.

To reduce the resistance value, you can try to perform the following actions:

- all the elements that make up the channel shaft must match and fit together to form a flat surface;

- it is desirable to create seams without any protrusions or pits;

- if possible, maintain an identical cross-sectional size throughout the channel, if such a condition is not feasible, then the deviation angle should be limited to 30̊;

- the absence of horizontal sections in the canal shaft.

Among the important indicators on which the design of the entire ventilation system depends is the height of the ventilation pipe above the roof. If its location is too low, then the thrust will be low. There is also a possibility of a reverse draft process, when the hood draws in air and smokes the room. To prevent this unpleasant process, experts recommend using a variety of nozzles on the outlets of the ventilation pipe. They are not only able to increase the traction force, but also allow the ventilation to operate in the same mode even with the strongest gusts of wind.

Conclusions and useful video on the topic

On the presented video you can hear the opinion of a specialist on plastic air ducts and tips for their installation:

When choosing ventilation elements, you need to carefully consider the layout of the system. Based on the plan, it is necessary to determine the design features of the air ducts, their diameter, throughput, fastening methods and other factors.

It should be taken into account what types of communications have already been laid in the house, as well as the material of walls, ceilings or other parts of the structure along which it is supposed to lay a network that provides air circulation.

Do you have something to add, or do you have questions about the selection and installation of ventilation ducts? You can leave comments on the publication, participate in discussions and share your own experience in performing work. The contact form is in the bottom block.