- Choosing a machine for welding polypropylene pipes

- Butt welding machine

- Machines for socket welding

- Top 6 best soldering irons for plastic pipes

- The best soldering irons for home

- Caliber SVA-900T 00000045816

- ENKOR ASP-800 56950

- The best semi-professional soldering irons for pipes

- Black Gear PPRC 1500W

- Sturm TW7219

- The best professional soldering irons for pipes

- Rothenberger ROWELD P110E Set 36063

- Rotorica CT-110GF Medium

- The device of the soldering iron and the principle of its operation

- Tool power

- How to make a soldering iron for PPR pipes with your own hands

- Pros and cons of homemade

- Necessary tools and materials

- Assembly process

Choosing a machine for welding polypropylene pipes

Do not know which machine for welding polypropylene pipes to choose? Then the first thing you need to do is decide what type of connection you will use.

Butt welding machine

Machine for butt welding of polypropylene pipes

Usually, outwardly, such a device resembles a machine tool, the mechanism of which is assembled on a frame with guides along which blocks with clamps for two pipes move. They allow you to fix the pipes well.

Typically, the package of such clamps includes insert segments, which are designed for pipes with different diameters.Also in the design there is an electromechanical trimmer - this is a double-sided circular knife that brings the pipes to the required state. The trimmer can be either removable, presented as a separate unit, or folding, on a swivel joint.

After the products are well cleaned, the trimmer is removed and instead, a flat round heating element is placed in the middle of the two pipes, thanks to which the material heats up and melts. Next, we proceed to the compression phase - the heater must be removed, and the movable blocks with clamped pipes move towards one another. You can achieve the desired effort through hydraulics or mechanical transmission - screw, worm, lever, etc.

Welding machines for polypropylene pipes

If you do not know how to use a welding machine for polypropylene pipes, then you can always resort to the help of specialists, or practice simpler ones before making complex connections.

Butt welding machines differ in size, type of power drive. There are models that are universal or designed for a specific range of pipe diameters. Their main common characteristic is the high price, due to which their use in domestic conditions is absolutely unprofitable.

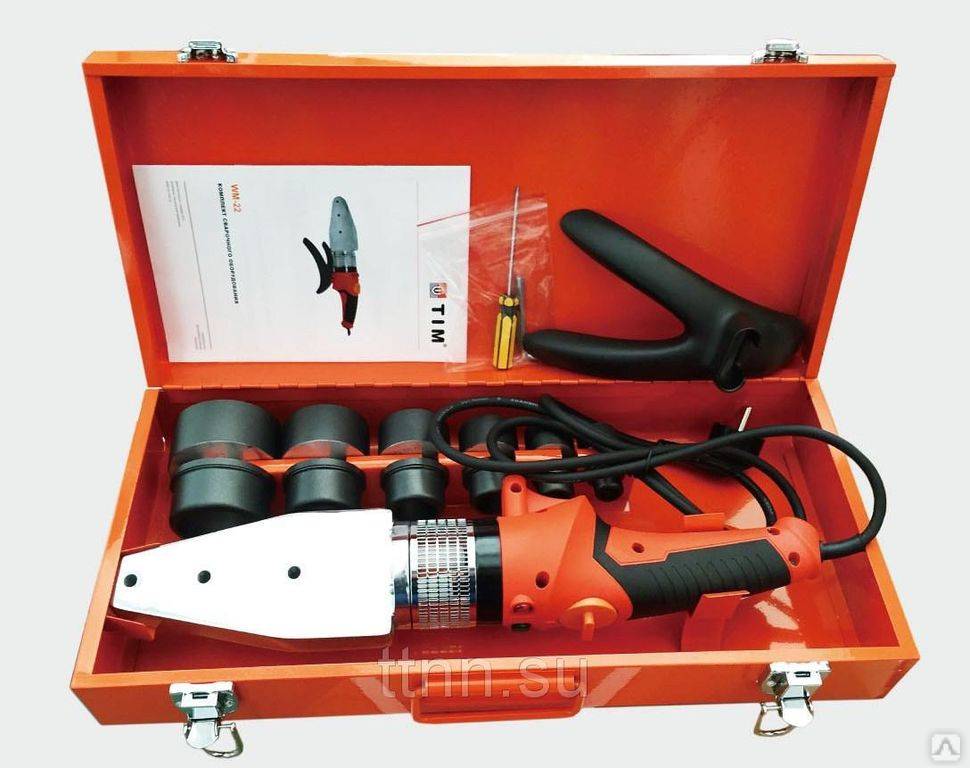

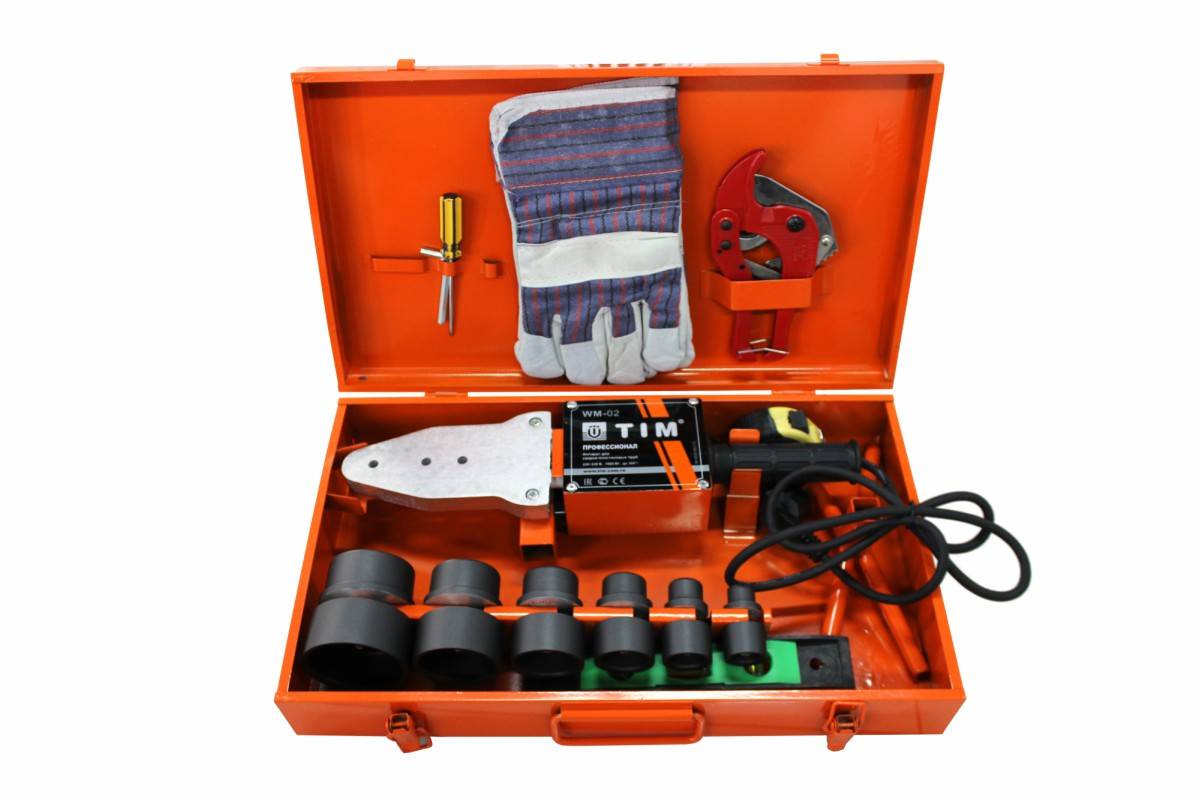

Machines for socket welding

Such devices, on the contrary, are most often used at home to create high-quality seams on polypropylene pipes.

Machine for socket welding of plastic pipes

There is no need for mechanical drives here; human power is quite enough. Therefore, the design of the device is very simple.

The package of any apparatus for socket welding includes a handle, which is necessary for the possibility of carrying out welding work on weight, in hard-to-reach areas. A cable usually comes out of the handle, thanks to which the device is connected to the electrical network.

On the body of the device there are control and management elements, which are the thermostat and heating indicators. Thanks to them, you can set the desired temperature mode of heating. The red indicator indicates the operation of the heating element, the green one indicates that the optimum temperature has been reached and the device is ready for operation. More modern models are equipped with a digital indication of the operating mode.

Top 6 best soldering irons for plastic pipes

Let's look at the best soldering iron models in different areas of use.

The best soldering irons for home

Caliber SVA-900T 00000045816

Soldering iron Caliber SVA-900T 00000045816 excellent tool tool for 1300 rubles and a power of 900 W, which can be used for welding polymer pipes. High power guarantees high-quality tight connection. The kit includes nozzles with a diameter of 20mm, 25mm, 32mm, 40mm, 50mm, 63mm and a stand for the heating element. The heating elements are Teflon coated. The soldering iron weighs only 3.6 kg, which ensures convenience during long-term work.

Price: ₽ 1 269

ENKOR ASP-800 56950

Soldering iron ENKOR ASP-800 56950 with a power of 800 W is additionally equipped with a thermostat for temperature control and costs about 1600 rubles. It is possible to install 2 nozzles at the same time, which will save time during work. Rubberized handle provides a secure grip, preventing slippage of the palm.Facilitates the work of light weight - only 3 kg.

Price: ₽ 1 600

The best semi-professional soldering irons for pipes

Black Gear PPRC 1500W

Soldering iron Black Gear PPRC 1500 W CN-005 20 × 63 IS.090786 with a power of 1500 W costs about 3000 rubles and provides quick heating of the nozzles and the pipes themselves. The unit is offered in a set that includes nozzles with diameters from 20mm to 63mm, a wrench for their installation, a stand, as well as scissors for cutting pipes, a level, tape measure, and a case. The heating elements have a high-quality Teflon coating. When used, polypropylene does not stick to the nozzles.

Price: ₽ 3 039

Sturm TW7219

Soldering iron Sturm TW7219 with a power of 1900 W has 2 heating elements that can be turned on separately, which allows you to choose the optimal operating mode for each specific case. Heating is carried out very quickly, in addition, the tool is equipped with a temperature controller. The diameter of the nozzles in the kit varies from 20mm to 53mm, which is quite enough for most of the work. The price of the device is less than 3000 rubles.

Price: ₽ 2 920

The best professional soldering irons for pipes

Rothenberger ROWELD P110E Set 36063

The Rothenberger ROWELD P110E Set 36063 unit is a professional device priced at almost 37,000 rubles, designed for manual welding of pipelines. The non-stick coating on the heating elements ensures that there is no problem of sticking of polypropylene. You can work with such a soldering iron with different materials: polyethylene, polypropylene, as well as PVDF and PB. This is an ideal device for professionals involved in the professional installation of internal communications of water pipes and heating systems. The device has a power of 1300 W and a set of nozzles with diameters of 75-90-110mm.The temperature controller has a liquid crystal display. The unit weighs only 2.2 kg, which is a big plus if long-term work is required.

Price: ₽ 35 689

Rotorica CT-110GF Medium

The Rotorica CT-110GF Medium socket soldering iron is designed for welding pipes and fittings made of polyethylene, polypropylene, PVDF, PB with a diameter of 75mm, 90mm, 110mm. The heating element has a high-quality anti-adhesive Teflon coating, so that work can be carried out quickly and cleanly. The design has digital temperature control. The built-in stand and clamp mount makes it possible to use the tool more conveniently in working conditions and compensates for the inconvenience of the large weight of the unit. The device costs about 9500 rubles.

Price: ₽ 9 500

The device of the soldering iron and the principle of its operation

The design of various models of soldering irons is almost the same, they differ mainly in the method of attaching nozzles to a heating surface. The soldering iron includes:

- case with handle;

- welding heater in a cast metal casing;

- thermostat;

- special nozzles.

The soldering iron is similar in design to a conventional iron. The difference lies only in the purpose of the device and its form. In a soldering iron, as in an iron, the main parts are a powerful heating element and a thermostat. The heating element in it is built into both a flat case and a round one. It is the shape of the body that determines the variety of designs for attachments for working nozzles.

The principle of operation of the soldering tool is quite simple: a heating element connected to the mains heats the stove to the desired temperature, which heats the nozzles. They then soften the polypropylene to the viscosity required for hermetic pipe connections. The optimum temperature of the nozzles (approximately +260°C) is maintained by a thermostat. He controls the welding process so that the polypropylene does not melt more than necessary. Indeed, with excessive heating of the working nozzle, the joint will be overheated, the polypropylene will “flow” and the diameter of the pipeline will significantly decrease or it will be damaged.

The thermostat is the main element of the soldering tool

It controls the heating temperature of the working nozzle, which is very important during the installation process. If the pipe is not heated enough, this will certainly affect the tightness of the connection. In addition, the thermostat protects the heating element, preventing the metal head of the tool from melting.

Inexpensive models of soldering irons are not equipped with a high-quality thermostat, therefore, during the soldering process, the pipes may melt or get an insufficient temperature for heating. As a result, the quality of the work of the master suffers.

In addition, the thermostat protects the heating element by preventing the metal head of the tool from melting. Inexpensive models of soldering irons are not equipped with a high-quality thermostat, therefore, during the soldering process, the pipes may melt or get an insufficient temperature for heating. As a result, the quality of the work of the master suffers.

If the pipe is not heated enough, this will certainly affect the tightness of the connection.In addition, the thermostat protects the heating element by preventing the metal head of the tool from melting. Inexpensive models of soldering irons are not equipped with a high-quality thermostat, therefore, during the soldering process, the pipes may melt or get an insufficient temperature for heating. As a result, the quality of the work of the master suffers.

A separate role in the work of the soldering iron is given to nozzles. Their quality determines the reliability of the joint obtained by soldering. Nozzles are produced with various coatings

When choosing a soldering iron, it is important to pay attention to the thickness of the non-stick layer. Teflon-coated nozzles are considered durable, as well as with metallized Teflon (an even more durable option), which are distinguished by uniform heating of the ends of polypropylene pipes

Tool power

The usual power of a soldering iron for polypropylene pipes is 1.5 kW. This is sufficient for soldering pipes with a cross section of up to 50 mm. In most cases, this is quite enough for domestic needs, but sometimes it is required to connect larger diameter polypropylene pipes. To do this, use tools that work with a power of 1.7-2 kW. Such soldering irons are more expensive and consume more electricity.

However, modern technologies make it possible to achieve greater energy efficiency and heat transfer when the device consumes less power. So, for example, a modern soldering iron Ditron TraceWeld PROFI blue consumes only 1 kW with the possibility of connecting pipes of almost any diameter.

How to make a soldering iron for PPR pipes with your own hands

Pros and cons of homemade

Homemade pipe connection tools have both advantages and disadvantages. Assembling such a device with your own hands is quite simple.In addition, a home-made installation can be adapted to any diameter of products.

However, a do-it-yourself soldering iron has its drawbacks:

- With it, it is impossible to change the temperature of the preheating of the workpiece.

- It is quite difficult to control such a device without experience in welding PPR products.

- Soldering large diameter structures with a homemade tool takes a lot of time.

Necessary tools and materials

To carry out the installation of a homemade soldering iron, it is necessary to prepare the following consumables and accessories:

- Gas burner. As it, you can use a compact device with piezo ignition.

- A piece of metal pipe. It should fit snugly against the burner nozzle and not loosen.

- A few tips from an old soldering iron.

The list of tools for work includes:

- electric drill;

- drill for metal processing.

Assembly process

To assemble a home-made device, you should prepare a piece of pipe where the nozzles will be placed. The optimal length of the workpiece is 20 cm.

Having cut the pipe, step back 5 cm from the edge and drill a through hole for the bolts and nozzles, install and screw them at the end.