- Basalt (stone) wool

- Mounting

- What can be used

- Ways to insulate water pipes

- Warming the water supply system to the house: alternative approaches

- Pipe heating

- Insulation

- Pipe in a pipe

- Ways to protect pipelines from freezing

- Water supply insulation

- Organization of streaming modes

- Heating of the water main

- Ways to insulate external water supply

- Application of simple techniques

- Types and forms of materials

- Thermal insulation paint and polyurethane foam spraying

- Ready-made complex solutions

- How to insulate a water pipe at the entrance to the house

- Which heater to choose?

- Ways to insulate water pipes

- Installation of galvanized PPU protection

- Criteria for choosing a heat insulator

Basalt (stone) wool

Thicker than glass wool. The fibers are made from a melt of gabbro-basalt rocks. Absolutely non-combustible, briefly withstands temperatures up to 900 ° C. Not all insulating materials can, like basalt wool, be in long-term contact with surfaces heated to 700 ° C.

The thermal conductivity is comparable to polymers, ranging from 0.032 to 0.048 W/(m K). High performance indicators make it possible to use its thermal insulation properties not only for pipelines, but also for the arrangement of hot chimneys.

Available in several versions:

- like glass wool, rolls;

- in the form of mats (stitched rolls);

- in the form of cylindrical elements with one longitudinal slot;

- in the form of pressed cylinder fragments, the so-called shells.

The last two versions have different modifications, differing in density and the presence of a heat-reflecting film. The slot of the cylinder and the edges of the shells can be made in the form of a spike connection.

SP 61.13330.2012 contains an indication that the thermal insulation of pipelines must comply with safety and environmental protection requirements. By itself, basalt wool fully complies with this indication.

Manufacturers often resort to tricks: to improve consumer performance - to give it hydrophobicity, greater density, vapor permeability, they use impregnations based on phenol-formaldehyde resins. Therefore, it cannot be called 100% safe for humans. Before using basalt wool in a residential area, it is advisable to study its hygiene certificate.

Mounting

Insulation fibers are stronger than those of glass wool, so it is almost impossible for particles to enter the body through the lungs or skin. However, when working, it is still recommended to use gloves and a respirator.

The installation of a roll web does not differ from the way in which glass wool heating pipes are insulated. Thermal protection in the form of shells and cylinders is attached to pipes using mounting tape or a wide bandage. Despite some hydrophobicity of basalt wool, pipes insulated with it also require a waterproof vapor-permeable sheath made of polyethylene or roofing felt, and an additional one made of tin or dense aluminum foil.

What can be used

In principle, any material that will be listed below can be used to insulate a water pipe. But the choice should fall on the one that will be most suitable for specific conditions. It may not meet absolutely all the requirements listed above, and this is not always necessary.

Mineral wool and polyethylene foam

One of the options that has been used for a long time and is constantly being improved is mineral wool. There are several varieties of it. Glass wool is made from glass, its share is about 35% (usually recycled glass containers, etc.), soda ash, sand and other additives. Therefore, it can be called sufficiently environmentally friendly. Its positive aspects are:

- minimum thermal conductivity;

- ease of installation;

- light weight;

- ease of transportation;

- not food for rodents;

- noise protection.

Of the minuses can be noted:

- poor resistance to moisture, which leads to loss of thermal insulation properties;

- the need to use personal protective equipment during installation;

- the fiber is easily damaged and torn with little effort;

- shrinkage may occur over time;

- resistance to fire.

Basalt wool

A peculiar subspecies is basalt wool. It is made from stone battle. In addition to all the above advantages, one can single out resistance to high temperatures, as well as immunity to moisture.

foamed rubber

Foamed rubber is a synthetic product that has appeared on the market not so long ago. It was developed specifically for the insulation of pipelines indoors and outdoors. Its characteristics:

- high elasticity;

- resistance to high temperatures;

- moisture resistance;

- ease of installation;

- vapor tightness;

- self-extinguishing when exposed to an open flame.

If we talk about the minuses, then this is most likely only the complexity of delivery, because it takes up a fairly large volume with a low weight.

Insulation for pipes polyethylene foam

Polyethylene foam is often used as a substrate for various floorings. But some of its types are designed specifically for pipeline insulation. The choice of masters falls on him because he:

- does not support the development of bacteria and fungi, which is very important for a humid environment;

- easy to install;

- has a small weight;

- UV resistant;

- fireproof;

- does not require special skills during installation.

With prolonged use, the material may shrink to a certain extent, which reduces its initial performance. In addition, there are certain problems when sealing seams. It is very difficult to achieve a perfect fit in some cases.

Styrofoam

Penoplex and polystyrene foam have a lot of similar properties. They are derivatives of the polymer component. This means that they practically do not interact with organic substances. These materials:

- are easy to install;

- have a small weight;

- have zero heat capacity;

- resistant to moisture;

- characterized by compressive strength.

At the same time, the products are very unstable to open fire. Rodents are very fond of harming such heaters.

Foamed polyurethane

The shell made of foamed polyurethane is a product in the form of semicircles, which are put on like a cover on a pipe. Usually on top it is covered with a protective layer of waterproofing. Use it based on:

- ease of selection for a specific diameter;

- lack of thermal conductivity;

- light weight;

- assembly in the form of a constructor;

- the possibility of multiple use;

- the possibility of carrying out work on insulation even in winter.

The negative aspects are: sufficient transport costs, as well as a maximum temperature limit of 120°C.

Insulation paint

A relatively new, but quite interesting development is insulation with a special paint. Even a small layer of it has good insulating properties. If it is increased several times, then the losses will be significantly reduced. This product:

- easy to apply on surfaces of any shape;

- has excellent adhesion to metal;

- not affected by salts;

- endowed with anti-corrosion properties;

- eliminates the formation of condensate;

- no additional load on the pipes;

- after coating, all valves or revision units remain freely available;

- ease of repair;

- high temperature resistance.

Of the negative sides, one can single out the need for additional insulation in case of severe freezing of the soil or the external location of the water pipes.

Ways to insulate water pipes

So that the frost does not damage the water pipes in a private house / cottage / cottage, you have to worry about their thermal insulation in advance.

It is important even at the stage of laying communications to consider options for insulating pipes, and not only water pipes. If this is done in a timely manner, the costs will be minimal.

There are a lot of options for pipe insulation - it is important to choose high-quality material among the mass of offers, not focusing too much on price. The cheapest option is money thrown to the wind. Among the methods of insulating a pipeline for supplying water to a house among homeowners, the most popular are:

Among the methods of insulating a pipeline for supplying water to a house among homeowners, the most popular are:

- stretch the pipeline 0.5 m below the freezing level;

- use a heating cable;

- insulate with heat-insulating material;

- provide an air gap;

- buy a finished factory pipe;

- apply multiple methods.

Most often, more than one method is used. So, if the water pipes are deep, then the area responsible for the entrance to the house still needs to be insulated. Therefore, the most optimal option is selected for it in order to secure the local water supply system.

The depth of the pipeline depends on the region. To find out, you can use special reference tables by finding your region or check it empirically

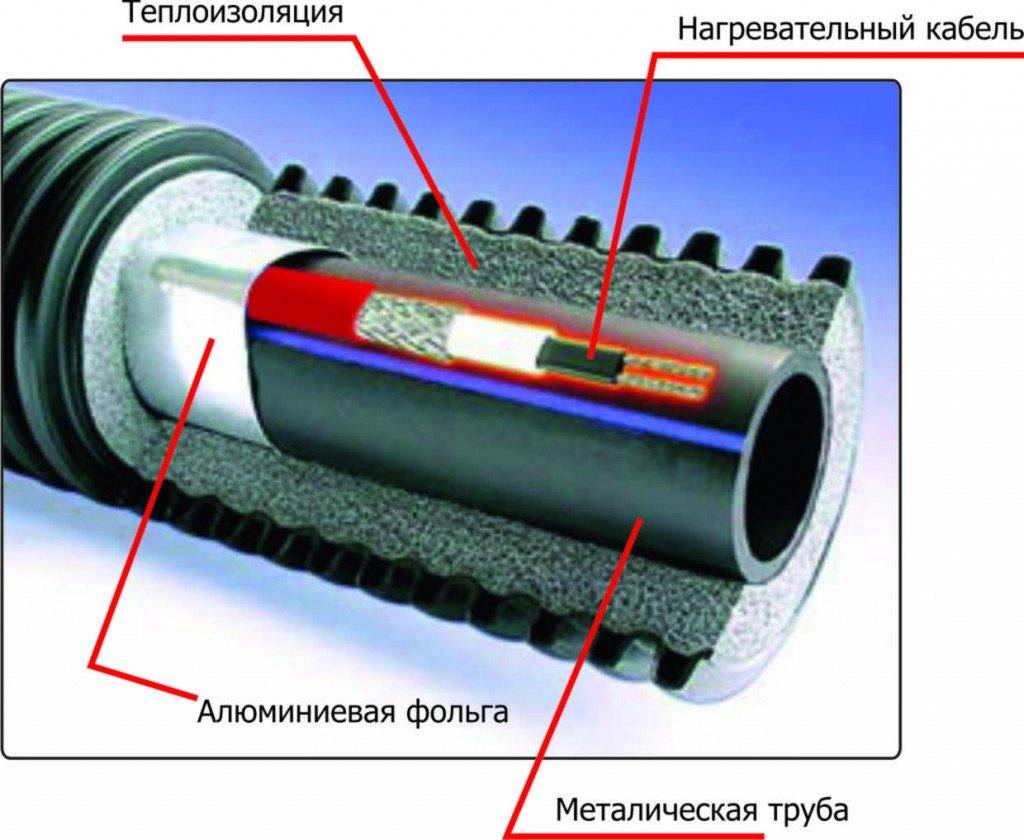

The heating cable is widely used due to the ease of installation and the high-quality performance of the functions assigned to it.

Depending on the type of installation, there are 2 types of cable:

- outer;

- interior.

The first is mounted on top of the water pipe, and the second - inside. It is securely insulated and made of safe materials. It is connected through a heat shrink sleeve to a regular cable with a plug or to a machine. Read more about heating cable for plumbing.

The heating cable comes in different capacities. Most often found between 10 and 20 watts

There are a lot of thermal insulation materials on the market. They all differ in their properties, quality, price, complexity of installation and service life.

Which one to choose depends on the specific situation.

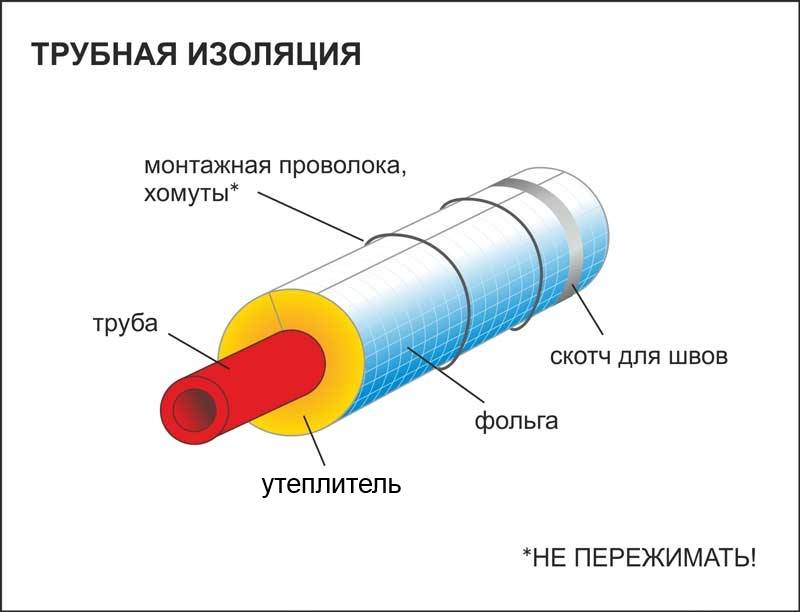

Among the heaters, polyethylene and polyurethane foam semi-cylinders - shells are especially easy to install.

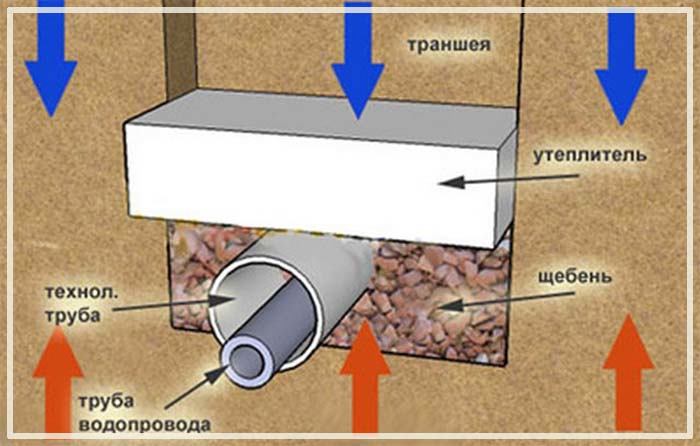

The air gap method is also often used. It is a water pipe placed in a cheap smooth plastic or corrugated pipe of a larger diameter.

Inside there is free space for the circulation of warm air coming from an insulated basement or heated in another way.

Warm air perfectly protects the water pipe from freezing. Although often it is additionally insulated with polypropylene or other material

Another option is to buy ready-made insulated pipes of factory origin. They are sold fully assembled.

They are 2 pipes of different diameters placed inside each other. Between them is a layer of insulation. Often this method of insulation is called pre-insulation.

The option with ready-made pipes does not always satisfy the needs of a particular user - the diameter, type of material and cost can become a real problem for their purchase

The use of several methods of thermal insulation of pipes is due to the fact that all methods are imperfect and it will not be possible to apply them in all cases. The conditions of use in various households located in all regions of the country are radically different from each other. Therefore, you have to choose the option that suits your specific requirements.

Warming the water supply system to the house: alternative approaches

Create high pressure in the pipes that supply water to the room. As you know, water under pressure does not freeze when the temperature drops. In this regard, it is recommended to supplement the system with a receiver - a device that maintains constant pressure in water pipes.

When using this method, pay particular attention to the uniformity of pressure throughout the system, and also make sure that the pipes have the necessary strength to withstand the increase in pressure without ruptures or other damage.

Pipe heating

Equip the heating of the pipes that provide the house with water using an electric wire. To insulate the water supply in this way, it is necessary to wrap the problem areas of the pipes with an electric cable and connect it to the mains. Under voltage, the cable will heat up, heat the pipe, which means that the water inside it will not freeze.

The main nuances of this method of warming the water inlet are an increase in electricity costs and the impossibility of heating pipes in the absence of voltage in the network. Speaking about the first “but”, it should be noted that the overpayment for electricity will be much less significant than the laboriousness of the process of defrosting an icy water supply. The solution to the second problem can be the purchase of an autonomous generator.

Insulation

Insulate the pipes supplying water to the house with air. When water pipes are deepened into the ground, they are affected by different temperatures: from above - cold air penetrating into the soil from its surface, from below - heat from the depths of the soil.

If the pipeline is insulated from all sides, then it will be insulated not only from the cold, but also from heat, therefore, in this case, insulation with an umbrella-shaped casing would be a more suitable option so that the heat coming from below naturally heats the pipe.

Pipe in a pipe

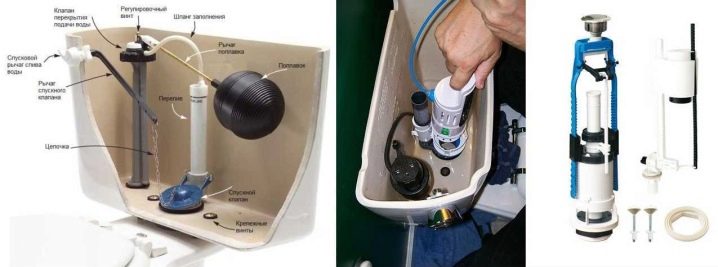

Use the pipe-in-pipe method. To insulate in this way, water pipes should be placed inside other pipes of large diameter, and the voids should be filled with expanded clay, foam plastic, mineral wool, polyurethane foam or other heat insulator.

Hot air can also be pumped into the space between the pipes. With this method of plumbing equipment, your financial costs will not increase too much, since polypropylene pipes are inexpensive. The pipe in the pipe is laid directly into the ground or into a specially prepared brick tray (if the soil is loose or excessively wet).

Ways to protect pipelines from freezing

It is possible to ensure the safety of the water main in a country cottage without burying it to a great depth underground. To do this, you need to reduce the possibility of freezing of water flowing through the pipes in one of the following ways.

Water supply insulation

All pipes passing outside the house are lined with thermal insulation. The thickness of the layer depends on the location of the pipes. For underground utilities, it is less than for those located on the street. But they also require enhanced insulation for areas that come to the surface. In addition, the material itself must be protected by waterproofing from the deterioration of its thermal insulation properties when wet.

Methods for applying thermal protection to water pipes:

- laying the line in boxes, followed by filling the free space with insulation and sealing with plates laid on top;

- wrapping pipes with various heat-insulating materials and applying the top layer of moisture insulation;

- the use of ready-made insulating structures worn on water pipes - long cylinders or segment blocks (shells);

- application of liquid heat insulators to the surface of the pipeline, which, when solidified, form a continuous protective layer.

Organization of streaming modes

You can increase the resistance of tap water to freezing by changing the conditions of its flow or state:

- Increasing pressure. By installing a receiver near the pipeline pump, they achieve an increase in pressure in the line up to 5 atm in the absence of water movement. In this state, water freezes more slowly. But this method requires the reliability of pipes and connections that can withstand excess pressure.

- Creation of circular circulation. When moving in the highway and replacing cold water with warmer water, the pipes do not freeze. But this will require a closed loop with forward and return pipes, as well as a pump for pumping in the absence of consumption. You don't have to run water all the time. It is enough to turn on the pump for a few minutes for an hour. This can be achieved by setting a simple timer.

- Heating with warm air. Pipelines of short length can be enclosed in a casing, between the walls of which and the pipe itself, let air out of the house. The air circuit can be open or closed. The flow movement is created by a pump or hair dryer.This method is good for insulating pipes passing under the floor in the basement.

Heating of the water main

Heating of pipelines with a cable

Heating of pipelines with a cable

Simple insulation is not able to withstand severe frosts. Reliable protection can only be obtained by maintaining the required temperature with additional devices. An effective way is to insulate the water supply by heating the pipe with a special cable. It is superimposed along the entire length of the highway and is connected to the power supply of the house.

Ways of laying the heating cable:

- Longitudinal. Heating plates are glued in one line on the outer surface of the pipe.

- Screw. The cable is also wound on the outside, but in a spiral with a step calculated from its power. The higher it is, the less often winding takes place.

- Interior. The heating wire is located inside the pipeline itself.

It is impossible to insulate a water pipe above the ground from frost with a simple winding of protective material. The only way is to organize heating with a cable. It is not his task to maintain a high temperature of pipes and flowing water. Enough to prevent them from freezing. Sensors installed along the line allow you to control the degree of heating and turn on the device only when the pipe temperature approaches zero.

Ways to insulate external water supply

For thermal insulation of water pipes located on the street, the following are used:

- laying materials of natural origin;

- application of roll coating;

- spraying a liquid material onto a previously prepared pipe surface.

Application of simple techniques

Basic techniques are used when laying highways at the boundaries of the freezing zone and depend on the climatic zone.

To insulate water supply pipes in a private house, a method of increasing the soil layer can be used, which makes it possible to divert the border of the freezing zone from the main. A layer of earth or sand is poured along the laying line; snow is allowed in winter.

The width of the soil or snow shaft exceeds the depth of the pipes by 2 times. Methods do not require financial costs, but violate the appearance of the infield.

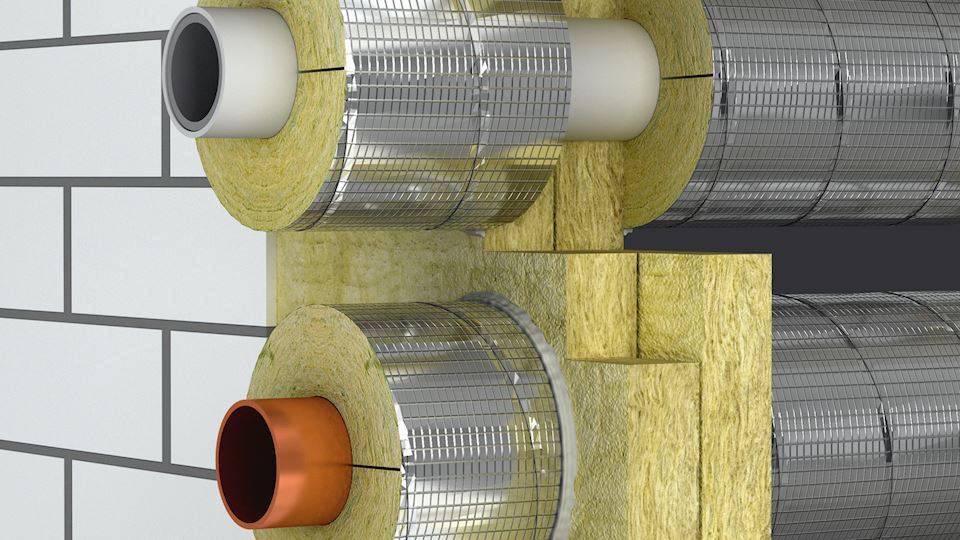

Types and forms of materials

Insulation of water pipes in a private house with cotton wool is carried out only in dry rooms. To protect the material from moisture in the basement, it is necessary to install concrete trays, the pipes covered with an insulator are covered with a layer of expanded clay. The elements are laid on the pipeline with an edge overlap of 150-200 mm (to ensure uniform protection). There is a heater for pipes, made in the form of segments with an angle of 180 ° or 120 °. The parts are laid on the highway, a special lock (protrusion and groove) is used to connect the sections.

The surface is wrapped with a layer of sanitary tape, which holds the insulator and provides protection from external factors. The bends of the highways are closed with shaped elements of a standard type.

Thermal insulation paint and polyurethane foam spraying

This technology is distinguished by the absence of seams and provides protection for highways of complex geometric shapes. Polyurethane foam is applied with a spray gun, after crystallization, the material provides increased protection against cooling. Application requires the use of special equipment, which increases the cost of the work and does not allow you to insulate the pipes yourself.

Therefore, the insulation of a water supply system in a private house is carried out on its own using a special paint, which can be aerosol or liquid (for example, Alfatek materials). Metal pipes are cleaned of corrosion, the paint is applied with a spray gun or a paint brush.

The composition of the paint includes a binder and additives based on ceramics. The material has a low coefficient of thermal conductivity, but the paint layer may not be sufficient to reliably protect the water supply.

Ready-made complex solutions

The owners of the premises need to know how else to insulate the water pipes on the street. There are complex solutions that allow you to build a branched pipeline of complex configuration.

Flexible or rigid lines for water are produced, enclosed in a layer of elastic insulating sheath. There are designs with 2 parallel pipes to provide hot and cold water at the same time.

Insulated plastic pipes are supplied in coils up to 200 m long (depending on the diameter of the pipe, the thickness of the insulating layer and the manufacturer), steel lines are made in the form of straight segments or shaped connectors.

The outer surface is protected by a corrugated plastic cover, which allows bends with a small radius. Plastic piping allows you to lay a line without connections, which improves frost protection.

How to insulate a water pipe at the entrance to the house

The owner of a cottage built on a strip foundation needs to know how to insulate the water pipe at the entrance to the house. To protect the pipe, synthetic and natural materials are used, as well as heating systems from external heat sources are installed.

If the house is built on a basement floor located below the freezing level. That insulation is installed directly in the basement. A box is built around the pipeline wrapped with basalt wool, which is filled with sawdust or expanded clay.

Which heater to choose?

The operation of the water supply system outside the premises, that is, on the street, is carried out in extreme conditions. Two requirements are set for its insulation: low thermal conductivity and low water absorption.

Being in the ground, the main is simultaneously in contact with cold on the one hand, and heat on the other, so condensate appears on its surface. The material must be resistant to the formation of fungi and mold, malleable to the mount and have the longest possible service life.

There are the following heaters for water pipes:

- glass wool;

- basalt wool

- expanded polystyrene.

Glass wool used for mounting the heat-insulating layer is produced in rolls. They are characterized by a soft structure, therefore they are widely used to isolate elements of complex configuration: taps, gate valves, etc. The material is used for insulation of metal-plastic pipes. Works only with roofing material or fiberglass.

Basalt wool is produced in the form of cylinders. Builders call them shells. These are ready-made joints 1 m long. They can be easily cut into smaller pieces to insulate small sections. Some types of basalt are produced with an aluminum surface. It is designed to protect the material from mechanical damage, so it lasts longer than the rest.

Expanded polystyrene, similar to basalt wool, is produced in the form of shells. It is characterized by ease of installation, therefore it has become widespread among private developers. From expanded polystyrene, shaped insulation with angular turns is produced. Can be used multiple times.

Styrofoam insulation of a water pipe

The material meets all the requirements for insulating gaskets, however, it is combustible, therefore it is not used in places with an increased risk of fire.

Ways to insulate water pipes

In addition to the materials mentioned, there are ways to effectively insulate pipes from the cold in places where deep laying of highways is not required. Among them:

- Heating cable.

- Insulation of water pipes with air.

- High pressure insulation.

It is not necessary to wrap the pipe line with heat-insulating material. You can heat the space around it with a heating cable. The power of its work per 1 m of running pipe is 10-20 watts.

The second way is to create a kind of thermal shield in the way of cold air. Warm streams emanate from the lower part of the highway, which are preserved around it, thanks to the umbrella effect. It is mounted in this way: a pipe is placed in a cylindrical insulating material so that in practice a “pipe in pipe” system is obtained.

The third method involves connecting a receiver, into which pressure is pumped. It is effective in the arrangement of submersible water supply pumps, as they are characterized by the optimum pressure for the system - 5 atmospheres. The operation of the pump requires the installation of a check valve, which allows you to pressurize the entire system.

Installation of galvanized PPU protection

Installation of pipes is carried out by welding, for sealing joints, a polyurethane foam mixture is used, which is poured into an empty space using a formwork made of galvanized sheet. To connect galvanized pipelines, a two-component composition of polyurethane foam is used, a cover cuff from a zinc sheath segment and a bitumen-rubber adhesive tape, the work is carried out in the following sequence:

- After checking and examining the quality of the weld, a workplace is prepared to ensure free access for the worker to the joint, a temporary shelter is constructed from precipitation, the air temperature should not fall below -25º C.

- The surface of the zinc sheath is cleaned, washed and dried, the pipe is cleaned from dirt, paint, traces of scale and rust with a stiff brush to a metallic sheen, the inner surface of the casing and the galvanized sheath in the contact zone are degreased with solvent brand No. 646.

- Remove the waterproofing from the ends of the pipes to a depth of 15 - 20 mm, when wet, remove the layer until a dry surface appears.

- Connect or pair together the conductors of the operational remote control system (SODK) of adapters and pipes.

- Cut out two strips of adhesive tapes with a pipe circumference of 50 mm, heat the pipe ends with a gas burner to 80 - 90º C and stick the strips on the surface, which melt slightly upon contact with the metal.

- In the same way, a strip is glued to the longitudinal surface of the metal casing after heating the contact point with a gas burner.

- Install the protective cover on the surface of the pipes with an overlap so that one edge goes from top to bottom, fix it along the edges with tightening straps.

- Gas burners heat the surface of the casing along the edges and in the place of the longitudinal connection, gradually tightening the belts, the procedure is continued until the steel casing begins to tightly fit the joints and squeezed out adhesion appears at the edges. To bleed air and fill in the upper part, a hole with a diameter of about 10 mm is drilled.

- Using a screwdriver and self-tapping screws, the edges of the casing are connected along the entire length and along the circumference with a step of 100 - 250 mm, a distance of 10 -15 mm retreats from the edges. Fig. 9 Adhesive tape, which is installed at the joints of the PPU pipeline

- The joint is poured at its temperature of 20 - 25º C, if the ambient temperature is below -10º C, the casing is heated with a burner in the range from 20 to 40º C, two drainage holes with a diameter of 3 mm are drilled along the edges of the cuff.

- PPU components are mixed at a temperature of 18 - 25º C in the amount necessary to cover a given volume, first pour the contents of the container with composition A and add a normalized amount of B, mix for 20 - 30 seconds until a homogeneous composition is obtained using an electric drill and a mixing nozzle.

- The composition is poured through the upper 10 mm hole of the metal casing, and the entrance is closed, previously cut with a small metal plate (140x50 mm).

- The appearance of foam in the drainage holes indicates the complete filling of the volume, after 20 - 30 minutes the cover is removed and excess PPU is removed from it, drainage 3 mm channels are cleaned of polyurethane from above.

- The casing is heated in the area of the filler hole to a temperature of 80 - 90º C, an adhesive tape is applied to it and then a cover, the lining is pressed with a tie-down strap and fixed at the corners with four self-tapping screws (rivets).

- Pieces of tape 40x40 close the drainage 3 mm external outlets along the edges, applying them to a surface preheated by a gas burner, after which the holes are closed with plugs using self-tapping screws or rivets.

Rice. 10 Galvanized pipe insulation example of installation at joints

Criteria for choosing a heat insulator

Giving preference to one of the types of insulation, the following nuances are taken into account:

The method of laying the plumbing system

It is important to understand here that depending on the place of laying: underground or on the surface, different methods of insulation and materials used are used.

Permanent or seasonal use of plumbing construction. If the plumbing is made in the country, then it will require a heater to prevent pipe rupture or install a receiver

For a permanent residence, serious thermal insulation of the entire pipeline system will be required.

The coefficient of thermal conductivity of the material from which the pipes are made. Plastic retains heat longer, metal is stronger and heats up faster.

Material resistance to UV rays, heat, moisture, burning. These technical indicators are taken into account when understanding what kind of protection the pipeline requires.

Durability. This criterion affects the frequency with which the insulation material will have to be changed.

Price.