- What should be the thickness of the insulation layer of the underground section of the pipe

- Varieties of heat insulators

- Insulation of water pipes inside the building

- Styrofoam

- Fiberglass materials

- Basalt materials

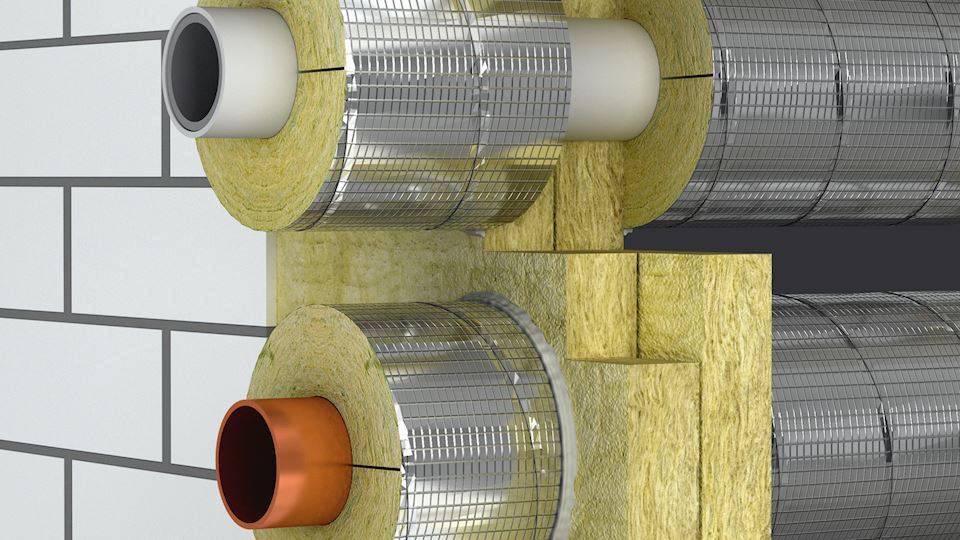

- Installation of shells made of basalt or expanded polystyrene

- Do I need to insulate the plumbing?

- How to choose a thermal insulation material: quality indicators. Liquid polyurethane foams and expanded polystyrenes

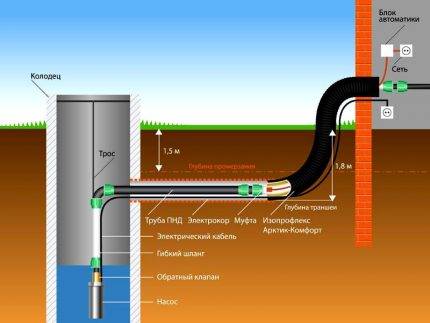

- How to insulate a water pipe in the ground with your own hands

- Insulation installation

- Heating

- Types of materials for thermal insulation of heating pipes

- Mineral wool

- Styrofoam and expanded polystyrene

- polyurethane foam

- Foamed synthetic rubber

- Foamed polyethylene

- Heat insulating paint for pipes

- Earth insulation

- Laying of external sewerage process overview

- Determine the slope of the sewer pipe

- We carry out earthworks

- Laying sewer pipes in a trench

- Commissioning

- Ways to insulate external water supply

- Application of simple techniques

- Types and forms of materials

- Thermal insulation paint and polyurethane foam spraying

- Ready-made complex solutions

- How to insulate a water pipe at the entrance to the house

What should be the thickness of the insulation layer of the underground section of the pipe

The exact method for calculating the required thickness of the insulation layer is given in the set of rules SP 41-103-2000 "Design of thermal insulation of equipment and pipelines." The manual contains formulas for calculating pipeline insulation and summary tables, taking into account thermal conductivity and design characteristics of materials.

On the Internet, you can find various online calculators for calculating the thickness of the heat-insulating layer, which take into account the peculiarities of laying each water pipe.

Tip: insulation of external pipelines, laid at a depth of 1 meter, is carried out with an insulating layer of 50 mm, and a water pipe laid at a depth of 50 mm is insulated with a layer of insulation of 100 mm.

Varieties of heat insulators

Below are the main materials for thermal insulation of communications:

cotton wool

Thorough insulation of heating pipes

To insulate heating pipes on the street, special mineral wool is used. Mineral wool for heating pipes can be of several types:

- Basalt - made from rock with a high content of basalt. A feature of this insulation is its high resistance to heat, the operating temperature reaches 650 degrees Celsius. Basalt wool does not react with chemical compounds and does not emit toxic substances when heated.

- Fiberglass - the main component is quartz sand. It is used not only in its pure form. Glass is made from sand, which is also part of this insulation. This material can only be used for insulation of external pipes, since their operating temperature is less than two hundred degrees, about 180.

The disadvantage of such insulation of heating pipes is the tendency of the material to absorb moisture, which negates all its thermal insulation characteristics. How to insulate heating pipes on the street to avoid wetting mineral wool? It is for this purpose that waterproofing is used in tandem with basalt or glass wool.

It should exclude contact of the insulation with moisture, since the insulation of heating pipes on the street is possible due to the porous structure of the wool. And when water fills the air cavities, the temperature of the coolant through the best conductor, water, is transferred to the air

Therefore, it is paramount to protect the insulation layer from moisture.

The easiest way is to wrap the insulated line with roofing felt, which can be fixed with wire. Cheap and cheerful, but a method proven by many years of practice. At the same time, any waterproof material that has sufficient resistance to mechanical stress can be used as waterproofing;

Styrofoam.

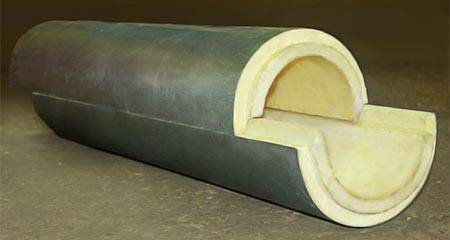

Styrofoam

For communications, special forms are made that repeat their geometry. Usually, this is a ring consisting of two parts. Each part has a groove connection, which creates an additional barrier to moisture.

Although there is a special type of expanded polystyrene, which is called "extrusive". It is denser than regular foam and completely waterproof.

Polyurethane foam can also be attributed to this group of heaters. They are close in composition. Such materials can be both separate elements of insulation, and parts of a single design of a multilayer pipe for heating. It is also possible to apply the above compositions in liquid form.For this, special compressors are used, with the help of which the insulation is sprayed onto the working surface. In this case, the advantage is the complete tightness of the insulation layer;

foam insulation for heating pipes.

These are products in the form of a cover. As a material used: rubber, polystyrene foam or polyurethane. Their inner diameter matches the standard dimensions of heating circuits. In order to put on such a cover, a longitudinal section is provided, which is then glued together. To do this, a special adhesive is applied to the end of the cut;

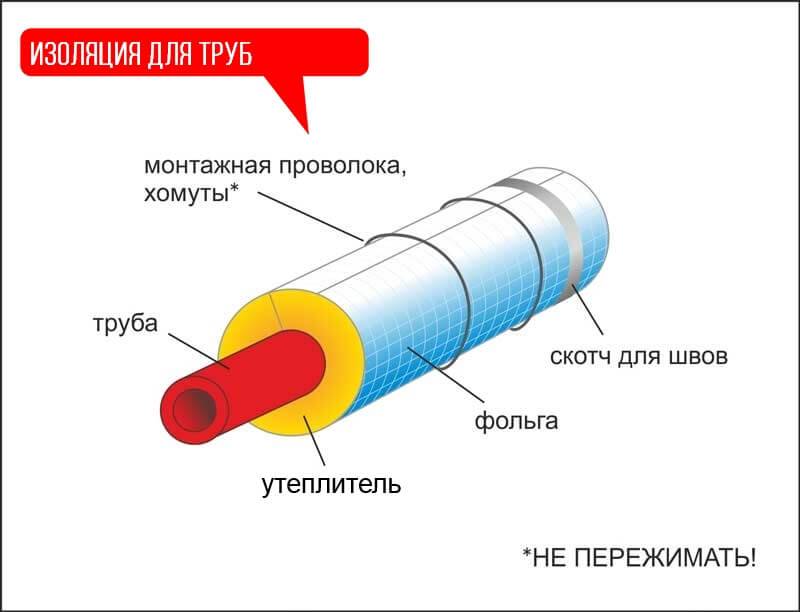

reflective winding of heating pipes.

Penofol - reflective insulation

The name speaks for itself. The bottom line is the reflection of warm streams due to the mirror surface of the insulation. To do this, use aluminum foil. It is wound over the main insulation and fixed with metal wire, or clamps. Heaters for heating pipes with foil perform several functions at the same time:

- reflects warm currents back to the contour;

- does not let the cold outside;

- protects from wind and moisture.

Also, the foil is used in tandem with foamed polyethylene or polyurethane. For example, penofol, which consists of a synthetic layer of foamed insulation and a layer of foil glued to it. It is produced in rolls of different widths and is used not only to isolate communications, but also to create the effect of a "thermos" when insulating rooms;

dye.

A fairly new type of insulation. It was first applied to space modules. The designers were faced with the task of creating an effective heat insulator with a minimum weight, since every gram matters when launching spacecraft and satellites.A few millimeters of such paint is enough to replace a thicker layer of other heaters. It is widely used for insulation of heating mains.

Insulation of water pipes inside the building

When it is necessary to insulate pipes indoors, polystyrene foam, fiberglass or basalt materials are used for this. All of them heat the system due to the ability to accumulate air inside.

Styrofoam

Expanded polystyrene is the most common insulation for water pipes. It is possible to use it not only for thermal insulation inside the building, but also for underground external insulation.

Expanded polystyrene is produced in the form of insulating shells from two semicircles. From above, such insulation is covered with a protective layer, which is fixed at the junction of the shells.

Fiberglass materials

Fiberglass materials are usually used for insulation of metal-plastic pipes. The need to use additional funds such as roofing felt or fiberglass due to the low density of glass wool leads to significant monetary costs when using them.

Basalt materials

Insulation for water pipes made of basalt can be used without trays. Due to their cylindrical shape, such materials are easy to install. The protective layer is made of roofing material, foil insulation, glassine. The only drawback of basalt heaters is their high cost.

Now you know how to properly insulate the water supply both outdoors and indoors, and we hope that you can easily cope with the task.

Installation of shells made of basalt or expanded polystyrene

Insulation for water pipes made of basalt or expanded polystyrene is mounted using the following technology:

- halves of the shells of the corresponding inner diameter are put on the pipe, while an offset for an overlap of 10-20 cm relative to each other is necessary;

- pre-fixing can be done with adhesive tape;

- in places of pipe outlets, segments specially selected or cut from straight sections of the shell are used;

- for thermal insulation of outdoor areas, roofing material or foilzol can be used as a protective material;

- final fastening on the pipe is carried out by tightening;

- if dismantling is necessary, it is carried out in the reverse order.

Do I need to insulate the plumbing?

Often the question of whether it is necessary to insulate the water supply arises on a frosty morning, when it is already late - the water from the tap does not flow. It is in such a situation that the homeowner has no doubts about the need for this event.

Indeed, pipe insulation is not always necessary. It all depends on the location of the house, climatic conditions, the time of residence of the residents and the features of laying water communications.

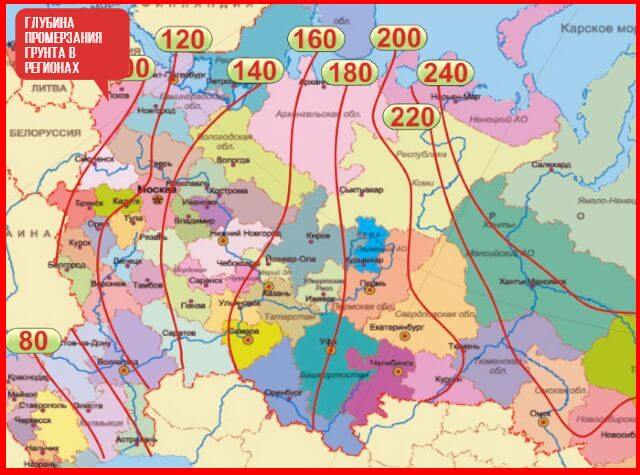

When it is decided to deepen the water pipes to the level of freezing, then there is no need to save on an additional depth of 0.5 meters. Otherwise, you should take care of thermal insulation

When it is decided to deepen the water pipes to the level of freezing, then there is no need to save on an additional depth of 0.5 meters. Otherwise, you should take care of thermal insulation

If family members come to rest only in the warm season, then there is no need for warming. To prevent accidental rupture of pipes due to frozen water in cold weather, when there is no one in the country, you just need to properly preserve the system, preparing it well for the winter.

Insulation is not required and the water supply, stretched at a sufficient depth.According to the norms, water pipes should be correctly laid to the following depth: 0.5 meters + the depth of soil freezing in a particular region

This is an important condition that must be observed so that you do not have to redo everything anew after the first winter.

If the water supply is not insulated and not deep enough, then there is a danger of freezing of the entire layer of soil and the formation of ice inside the pipe

For residents of the northern regions, the level of freezing is 2.5 m or more. This greatly complicates the process of deepening the pipeline to the desired level. Yes, and the cost of such an event will not be cheap. Here you can not do without warming.

It happens that it is not possible to make a trench of the required depth for laying water pipes. In such cases, insulation is a necessity. Another point is the entrance of the water pipe to the house

This area in cold weather often enjoys increased attention from many homeowners. Therefore, you need to take care of the insulation in a timely manner by choosing the right material.

If the water in the pipe is frozen, then in the best case, users will be left without water, and in the worst case, the pipe will break and costly repairs are ahead to find this area and fix the problem

Another place in the pipeline that you need to remember is the entrance of the pipe to the well / well. It all depends on the characteristics of a particular water supply and the method of arranging this site. If this is a well and the pipe is immersed in it, then we must not forget about its insulation by choosing a material that is resistant to ultraviolet rays and precipitation.

How to choose a thermal insulation material: quality indicators. Liquid polyurethane foams and expanded polystyrenes

Let's move on to the section: how to choose a thermal insulation material: quality indicators.

- Resistance to the effects of an aggressive external environment: elevated temperature, frost, sudden changes in temperature, humidity.

- Low thermal conductivity.

- Ease, accessibility for installation by a non-professional master.

- Convenience, ease of disassembly and reassembly.

- Durability: elasticity, strength, the material must have wear resistance.

- Low cost.

- Fire safety: as a result, the insulator cannot have a combustible base; pipes are often laid in close proximity to wooden structures.

- The tightness of the structure in the assembly.

Now let's look in detail liquid polyurethane foams and expanded polystyrenes.

Finely dispersed substances in the form of aerosols easily and tightly close the pipes with soft, uniform, durable layers that protect against heat loss. The main indicators of such coatings:

- Durable. Almost forever.

- Excellent protection against corrosion and damage.

- Safe.

- They weigh almost nothing.

- Their price is quite high.

- They are homogeneous, without joint joints.

- They have zero density and thermal conductivity.

- Waterproof, impervious.

- Beautiful appearance.

- Easy installation and repair.

_

Repair - a set of operations to restore the serviceability or operability of an object and restore the resource of a product or its components. (GOST R 51617-2000)

Price - the price of the product without a premium for quality, established by the price list or other relevant document; at the design stages - the limit price. (GOST 4.22-85)

How to insulate a water pipe in the ground with your own hands

Choosing what insulate a water pipe on the site, take into account the material of its manufacture, the outer diameter, the cost of the insulation and the complexity of the installation work.

Insulation installation

Usually, low-pressure polyethylene pipes (HDPE) with a diameter of 1 inch are used to supply water for individual water supply; installation of the insulation shell is carried out in the following way:

- A shell made of glass wool, mineral wool or polystyrene, foamed polyethylene is installed, fixing it with adhesive tape. When installing mineral or glass wool, it is necessary to monitor the tightness of the joints - otherwise water will get into the joint and the wool will nourish it, while the heat-insulating properties of the insulation will significantly decrease.

- After installation, a soft heat insulator can be protected from squeezing by soil with a more durable material, roofing material is usually used, wrapping the shell with it several times and fixing it with tape. The advantage of its use is hydrophobicity, which protects the insulation from moisture saturation.

- The insulated pipeline is lowered into the channel and covered with a light bulk composition to reduce pressure, expanded clay is usually used.

It should be taken into account that the installation of plastic segments must be carried out by fastening to each other with a slight shift of 20 cm, as an overlap connection.

Figure 12 Insulation of a plastic water pipe in the ground with a foam shell

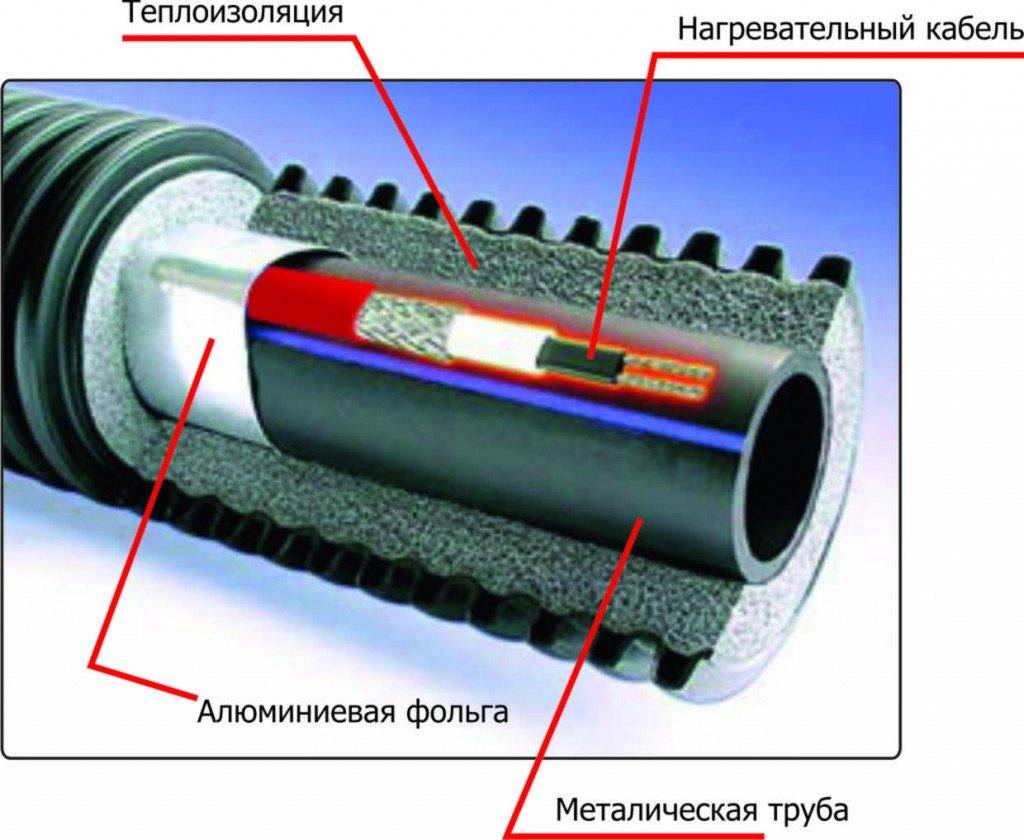

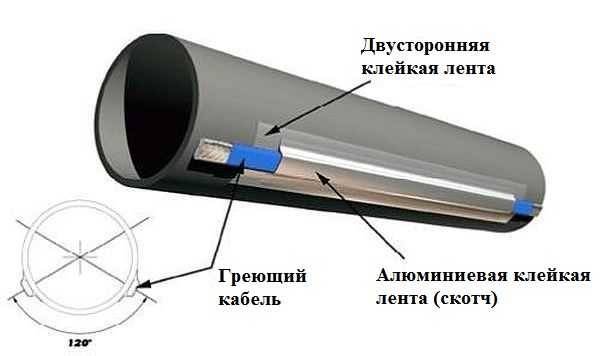

Heating

When planning a winter water supply system, you need to keep in mind that insulation only helps to reduce heat loss, but cannot heat. And if at some point the frosts turn out to be stronger, the pipe will still freeze. Particularly problematic in this sense is the section of the pipe outlet from the underground sewer to the house, even if it is heated.All the same, the ground near the foundation is often cold, and it is in this area that problems most often arise.

Way of fixing the heating cable to the water pipe (the cable must not lie on the ground)

The heating cable is good for everyone, but it's not uncommon for us to have power outages for several days. What will happen to the pipeline then? Water will freeze and can burst pipes. And repair work in the midst of winter is not the most pleasant experience. Therefore, several methods are combined - and the heating cable is laid, and insulation is placed on it. This method is also optimal from the point of view of minimizing costs: under thermal insulation, the heating cable will consume a minimum of electricity.

Another way to attach the heating cable. To make electricity bills smaller, you also need to install a heat-insulating shell on top or fix rolled thermal insulation

Laying a winter water supply in the country can be done using this type of thermal insulation, as in the video (or you can take the idea into service and do something similar with your own hands).

The development of a scheme for laying a water supply system in a country house is described here.

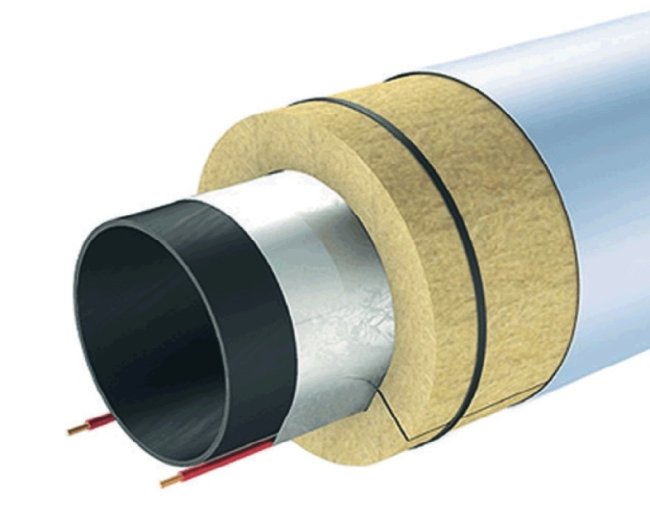

Types of materials for thermal insulation of heating pipes

Technical solutions for pipe insulation differ in design, materials and characteristics.

Mineral wool

Technical insulation from stone wool basalt rocks for insulation of high-temperature pipelines is produced in coiled cylinders, plates and mats, including those with one-sided foiling. It is chemically inert, bioresistant, non-combustible, has a thermal conductivity of about 0.04 W / m * K and a density of 100-150 kg / m3.

Styrofoam and expanded polystyrene

Heat-insulating materials from extruded polystyrene foam and polystyrene are made in the form of plates, segments in the form of half-cylinders. They are used to protect in-house heat pipelines, to assemble a closed or U-shaped box when laying a pipeline in the ground.

The insulation has a density of 35-40 kg/m3, a thermal conductivity coefficient of about 0.035-0.04 W/m*K, and low water absorption, does not rot, and is easy to install. The disadvantages include combustibility, a narrow range of operating temperatures from -600 to + 750C. Pipes must be treated with an anti-corrosion compound before installation in the ground; with open laying, the insulation must be protected from UV rays.

polyurethane foam

For insulation of heating pipes, PPU shells with and without foil coating are used. The material is characterized by low thermal conductivity of 0.022-0.03 W / m * K and water absorption due to the closed cellular structure, high strength, long service life, does not rot, is quickly mounted. Uncoated shells are used only indoors, as polyurethane foam is destroyed by UV rays.

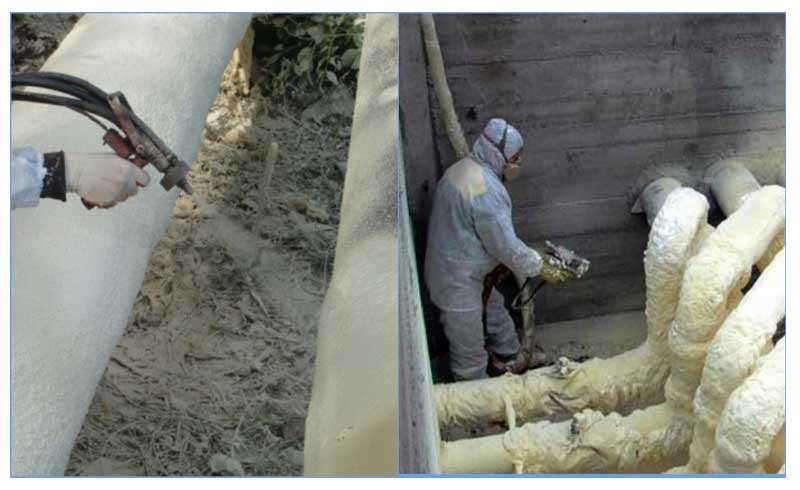

Insulation of large diameter pipelines can be performed using sprayed polyurethane foam insulation. It has an increased density and fire resistance, significantly reduces heat loss due to a continuous coating without "cold bridges".

Foamed synthetic rubber

Rubber technical thermal insulation is produced in rolls and tubes. It is non-combustible, environmentally friendly, resistant to chemical and biological influences, has a density of 65 kg/m3 and a thermal conductivity of 0.04-0.047 W/m*K.

The materials are used to insulate pipelines in rooms laid aboveground and underground; they can have an aluminized coating to protect against mechanical damage and UV rays. The main disadvantage is the high cost.

Foamed polyethylene

Thermal insulation for heating pipes made of foamed polyethylene with an elastic porous structure is used in any conditions, does not absorb water, maintains a low thermal conductivity of 0.032 W / m * k with temperature changes. It is available in the format of tubes, rolls, mats, easy and quick to install.

The material is used indoors, heating points, when laying pipes in the open air, in the ground. For above-ground installation, it is necessary to provide a cover layer, for underground - a casing.

Heat insulating paint for pipes

This method of thermal insulation should be discussed separately. It is the latest development of Russian scientists in the field of thermal insulation.

The paint is made from the following components: ceramic microspheres, foam glass, perlite and other heat-insulating substances.

Coating the pipe with heat-insulating paint gives the same effect as insulating it with several layers of polystyrene foam or mineral wool.

The paint is non-toxic, safe for humans and nature, practically odorless, therefore, its application does not require ventilation.

It is resistant to heating to high temperatures, and also protects the metal from corrosion. The paint can be used both in household and in production and industrial conditions.

Such a heater is produced in the form of an aerosol, which makes it as easy as possible to apply and allows you to cover with paint even the most inaccessible sections of the pipeline.

Earth insulation

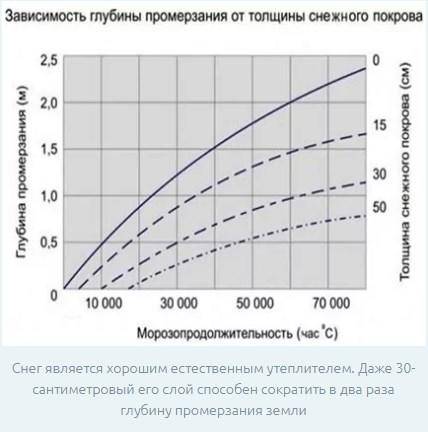

The main heat-insulating material at the dawn of the arrangement of engineering networks of settlements was the earth. Additional pipe insulation was used only for open laying. Subsequently, it turned out that such insulation did not live up to expectations. When the earth becomes wet more than 5 times, its specific thermal conductivity coefficient changes, from 0.2 to 1.1 units.

Soil freezing depth

Soil freezing depth

In addition, laying pipelines in the ground without insulation has a number of disadvantages:

- it is necessary to carry out a large amount of work to prepare a trench with a depth of 20-30 cm more than the depth of soil freezing;

- the presence of moisture and active elements in the ground accelerates the corrosion processes taking place in pipes;

- a large layer of earth exerts increased pressure on the pipe walls, causing its deformation and destruction during long-term operation.

When laying pipes underground, in order to increase the level of thermal insulation, it is necessary to carry out layer-by-layer compaction of the laid soil. In some cases, laying pipes at great depths is simply not possible or not economically feasible. He hopes that a lot of snow will fall on time, and frosts will not exceed the climatic norm in the presence of insulating materials, the height of carelessness. It is necessary to carry out thermal insulation in order to increase the service life of pipelines and reduce energy consumption.

Laying of external sewerage process overview

The very procedure for laying a sewer network of any type involves the consistent implementation of the following work plan:

Choosing sewer pipes for laying in the ground

Plastic sewer pipes

At this stage, you need to choose the diameter and length of the pipe.Everything is simple with the length - it is equal to the distance from the fan outlet to the input to the collector or septic tank. The diameter of the pipe is selected based on the estimated volume of effluents. However, in reality, you will have to choose between 110 millimeters and 150 (160) millimeters. These are typical sizes of household sewer pipes. If you plan to build an industrial highway, then the diameter will start from 400 millimeters.

In addition, you need to select the type of "pipe" material. Usually it is polyvinyl chloride (smooth pipes) or polypropylene (corrugated pipes). PVC products are less durable, but will cost less than PP pipes.

Determine the slope of the sewer pipe

Such a slope guarantees the flow of liquid through the pipeline under the influence of gravitational forces. That is, the system will divert effluents in a non-pressure mode.

We carry out earthworks

The depth of the trench for the sewer should correspond to the level of soil freezing. Otherwise, the system will freeze in the winter.

Laying sewer pipes in the ground

Therefore, the input to the sewer main (outlet from the fan pipe) is immersed in the ground by 1.2-1.5 meters. The withdrawal depth is determined based on a 2-centimeter slope (per linear meter of the pipeline).

As a result, at this stage, a trench is being dug, the bottom of which goes to the catchment point under a slope. Moreover, the width of the trench is 50-100 millimeters. And its walls, after deepening to the mark of one meter, are reinforced with shields and struts. The selected soil is stored in a special area, it will come in handy for filling the trench after the installation of the pipeline.

sewer well

Long sections of the sewer line are equipped with wells, the walls of which are reinforced with concrete rings. The bottom of the well coincides with the depth of the trench or falls below this mark (the missing part of the soil can be poured).

At the same stage, a pit is dug for a septic tank or a waste storage bin. The selected soil is removed from the site and disposed of. It will not be used for bedding. After all, the selected volume will fill the design of a septic tank or bunker.

In addition, at the same stage, you can start laying trenches for the drainage system of an autonomous sewer.

Laying sewer pipes in a trench

Laying sewer pipes

The installation of the pipeline is carried out in measured segments (4, 6 or 12 meters each), which are connected into a socket. Moreover, it is better to lay a layer of sand at the bottom of the trench, 10-15 centimeters thick, it will save the line from possible ground vibrations provoked by heaving deformation.

Laying is carried out with bells upwards, that is, the bell should be the first on the flow path, and the smooth end should be located under a slope. Therefore, the assembly is carried out from the outlet of the fan pipe towards the septic tank.

After completing the assembly, the pipe is covered with coarse sand, after which the trench is filled with selected soil, leaving a tubercle on the surface, which will “sag” next spring, after the soil “settles down”. The rest of the soil is disposed of.

Commissioning

Before backfilling the trench, it would be a good idea to check the tightness of the joints and the throughput of the pipeline. To do this, you can wrap the socket sections with newspaper and drain several buckets of water into the toilet.

If there are no wet spots on the newspapers, the system functions without compromising the tightness of the pipeline.Well, the throughput can be estimated by comparing the volumes of "introduced" and "discharged" fluid. If the same bucket of water “reached” the exit, then there are no stagnations in the sewer, and you will not have problems with system maintenance.

Ways to insulate external water supply

For thermal insulation of water pipes located on the street, the following are used:

- laying materials of natural origin;

- application of roll coating;

- spraying a liquid material onto a previously prepared pipe surface.

Application of simple techniques

Basic techniques are used when laying highways at the boundaries of the freezing zone and depend on the climatic zone.

To insulate water supply pipes in a private house, a method of increasing the soil layer can be used, which makes it possible to divert the border of the freezing zone from the main. A layer of earth or sand is poured along the laying line; snow is allowed in winter.

The width of the soil or snow shaft exceeds the depth of the pipes by 2 times. Methods do not require financial costs, but violate the appearance of the infield.

Types and forms of materials

Insulation of water pipes in a private house with cotton wool is carried out only in dry rooms. To protect the material from moisture in the basement, it is necessary to install concrete trays, the pipes covered with an insulator are covered with a layer of expanded clay.

Insulation of water pipes in a private house with cotton wool is carried out only in dry rooms. To protect the material from moisture in the basement, it is necessary to install concrete trays, the pipes covered with an insulator are covered with a layer of expanded clay. The elements are laid on the pipeline with overlapping edges by 150-200 mm (to ensure uniform protection). There is a heater for pipes, made in the form of segments with an angle of 180 ° or 120 °. The parts are laid on the highway, a special lock (protrusion and groove) is used to connect the sections.

The elements are laid on the pipeline with overlapping edges by 150-200 mm (to ensure uniform protection). There is a heater for pipes, made in the form of segments with an angle of 180 ° or 120 °. The parts are laid on the highway, a special lock (protrusion and groove) is used to connect the sections.

The surface is wrapped with a layer of sanitary tape, which holds the insulator and provides protection from external factors. The bends of the highways are closed with shaped elements of a standard type.

The surface is wrapped with a layer of sanitary tape, which holds the insulator and provides protection from external factors. The bends of the highways are closed with shaped elements of a standard type.

Thermal insulation paint and polyurethane foam spraying

This technology is distinguished by the absence of seams and provides protection for highways of complex geometric shapes. Polyurethane foam is applied with a spray gun, after crystallization, the material provides increased protection against cooling. Application requires the use of special equipment, which increases the cost of the work and does not allow you to insulate the pipes yourself.

Therefore, the insulation of a water supply system in a private house is carried out on its own using a special paint, which can be aerosol or liquid (for example, Alfatek materials). Metal pipes are cleaned of corrosion, the paint is applied with a spray gun or a paint brush.

The composition of the paint includes a binder and additives based on ceramics. The material has a low coefficient of thermal conductivity, but the paint layer may not be sufficient to reliably protect the water supply.

Ready-made complex solutions

The owners of the premises need to know how else to insulate the water pipes on the street. There are complex solutions that allow you to build a branched pipeline of complex configuration.

Flexible or rigid lines for water are produced, enclosed in a layer of elastic insulating sheath. There are designs with 2 parallel pipes to provide hot and cold water at the same time.

Insulated plastic pipes are supplied in coils of length up to 200 m (depending on the diameter of the pipe, the thickness of the insulating layer and the manufacturer), steel lines are made in the form of straight segments or shaped connectors.

The outer surface is protected by a corrugated plastic cover, which allows bends with a small radius. Plastic piping allows you to lay a line without connections, which improves frost protection.

How to insulate a water pipe at the entrance to the house

The owner of a cottage built on a strip foundation needs to know how to insulate the water pipe at the entrance to the house. To protect the pipe, synthetic and natural materials are used, as well as heating systems from external heat sources are installed.

If the house is built on a basement floor located below the freezing level. That insulation is installed directly in the basement. A box is built around the pipeline wrapped with basalt wool, which is filled with sawdust or expanded clay.