- Materials that are used to insulate sewer pipes

- Sewer pipe heating

- Pipe freezing problem

- Ways and methods of thermal insulation

- Warming on the street

- How to perform thermal insulation of polypropylene pipes

- Actions in case of sewer freezing

- How to choose the right cable?

- How to insulate sewer pipes in a private house

- Pipe laying

- Excavation work

- Pipe laying and assembly

- Backfilling

- Choosing a heater

- Styrofoam

- Styrofoam

- Foamed polyethylene

- foamed rubber

- Ways of warming the water pipe on the street (in the ground)

- 1. Creating high pressure in the water supply system

- 2. Heating cable for plumbing

- 3. Application of thermal insulation materials for pipes

- Do I need to insulate the pipeline?

- Insulation of the hood for sewage background riser

- How to insulate the background riser with your own hands

- Conclusion

- Conclusions and useful video on the topic

Materials that are used to insulate sewer pipes

As mentioned above, various materials are used to insulate sewer structures. In fact, these are the same means as for thermal insulation of water pipes and other types of pipes.

Mineral wool.This material has a fairly reasonable price and is one of the most popular in thermal insulation work. However, for the insulation of sewer structures, it is not preferable, because over time the wool becomes caked. In addition, it has a high coefficient of absorption of water vapor, which negatively affects its thermal insulation qualities.

Note! If a heater with foil is used during the installation of thermal insulation for the sewer line, then it is worth placing it with the foil side to the pipe. Be sure to fix the resulting design with adhesive tape

To improve the insulation, the pipeline can be covered with sand.

Foamed polyethylene. Installation of this material is carried out most simply. Foamed polyethylene has good water resistance, unlike mineral wool. The thickness of this insulating material is usually small, therefore, when carrying out insulation work, it is recommended to wrap the pipes in several layers. Foamed polyethylene is produced in the form of rolls and finished tubes.

Styrofoam. Polyfoam possesses good resistance to water vapors. For sewer insulation, it is a good option. It is produced in the form of sheets, which, during the installation of thermal insulation, are placed in a special box that protects the structure. However, experts advise purchasing polystyrene in the form of a shell - this will reduce labor costs during installation to a minimum.

Expanded clay. Insulation of the sewer line with expanded clay is considered the most preferable. However, this material may only be used in dry conditions, otherwise its protective functions will not work.Expanded clay insulation is very simple - it is poured into a trench with a pipe.

Folgoizol. It is produced in two types: SRF and FG (waterproofing). SRF consists of fiberglass and polyethylene film. Waterproofing foil is made from a bitumen-polymer layer and corrugated aluminum foil. Such material is produced in rolls. It is usually installed on external highways. It has a long service life.

Glass wool. The composition of glass wool includes molten glass and quartz sand. Has a low density. The popularity of this material is very low, as it is considered harmful and requires strict safety measures during installation.

Foamed synthetic rubber. Such a material is an elastic insulation with a closed-cell structure. Available in the form of tubes and sheets. It can be used to insulate highways of almost any diameter.

Each of the above materials has its pros and cons. The choice of material for the insulation of the sewer network should be carried out based on the specific case and the characteristics of the region.

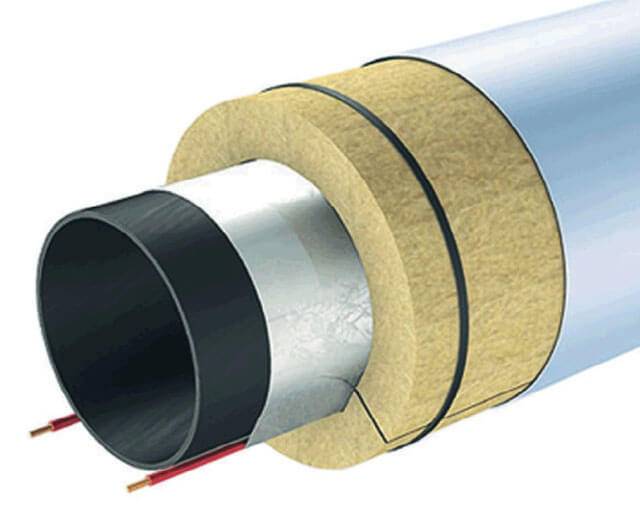

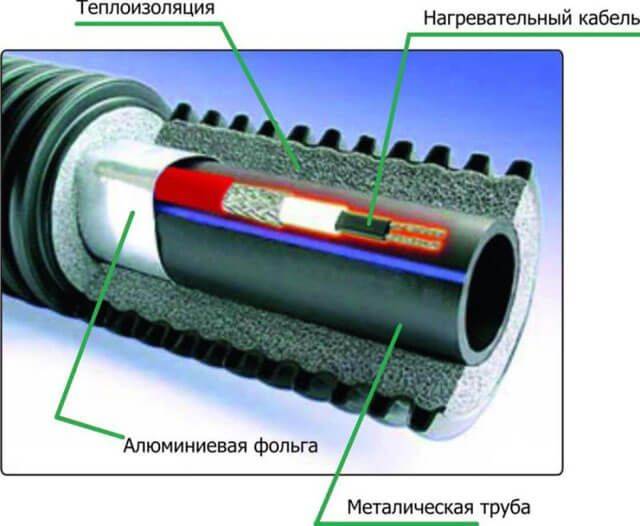

Sewer pipe heating

A good way to protect sewers from low temperatures is to equip the system with an electric cable. This method is considered the most effective, but also quite expensive. Installation involves not only installing the cable on pipes, but also connecting to a power source.

The heat-insulating cable must fit snugly against the walls of the pipeline so that it can be heated. Installation is carried out during the laying of the highway. If there is no insulating material, the heat generated as a result of heating will go to the environment.

For this reason, it is required to wrap the pipeline with a cable with insulation. This type of thermal insulation is suitable for individual sections of the sewer. The fact is that the cable may not be along the entire length of the pipeline. If necessary, it can be mounted on a problematic section of the sewer network, which is very convenient.

Pipe freezing problem

For the normal functioning of the sewer system, it is necessary that all its elements perform their duties efficiently and effectively. One of the most serious problems that can arise with sewer pipes is the problem of freezing. It is especially dangerous for those who live in cold regions.

Freezing pipes in winter is a problem that needs to be solved quickly and efficiently. If you do not pay due attention to it, you may encounter such troubles as:

- damage to sewer pipes;

- inability to transport wastewater;

- persistent unpleasant smell on the street and in the house;

- failure of the sewer system.

In order not to encounter such troubles, you should take care of how to perform the insulation of sewer pipes. There are enough options, you just need to choose the most suitable one, and make a little effort to complete the installation of the insulation.

Pipe freezing problem

Ways and methods of thermal insulation

Let's consider in more detail ways and methods of thermal insulation.

The choice of insulation to a large extent depends on the installation technology and design. plumbing. Work in the air is carried out only in dry weather. To install the shells on the street, an upper protective layer of roofing material or glassine is required.

_

protective layer - a roofing element that protects the main waterproofing carpet from mechanical damage, direct exposure to atmospheric factors, solar radiation and the spread of fire over the roof surface. (SNiP 11-26-76, VSN 35-77)

Installation - energy. conditional name of the object in power facilities for which the scheme is issued, for example, main circuits. (GOST 2.701-84)

Fastening cylinders made of basalt and foam:

When replacing unusable insulation, cylinders are used when laying new pipes. It is more convenient to take parts of a meter length with a protective foil coating for work.

- 10 - 15 cm one after the other, according to the existing shape of the cuts, the groove into the groove, fasten the halves of the shells.

- Installation should start from the flange connection of the pipe.

- With horizontal seams running apart, and not all in one line, install each cylinder close to the other.

- Wrap all joints tightly with special tape.

- For bends and turns, use special finished parts or shells cut from the material.

_

Detail - a product or its component part, which is a single whole, which cannot be disassembled into simpler components without destruction (reinforcing bar, washer, spring, window sill board, etc.).

PPU shell mounting technology

Clamps, adhesive tape, the larger the diameter, the more often fastening, fastening is carried out with ties.

The metal pipe must not be damaged by corrosion.

By tight matching in all grooves along and across, you need to install the shells in a clockwise direction.

The seams are sealed with a special polyurethane adhesive.

In the case of nearby sources of fire, it is important to treat the shells with a fire retardant.

_

fire protection - reduction of fire hazard of materials and structures by special treatment or coating (layer). (GOST 12.1.033-81)

Installation of polyethylene foam pipe thermal insulation on your own:

- When laying new pipes, they are first put on insulation.

- Weld water pipes.

- Glued with special glue along the length and end connections.

- Additionally reinforced with reinforced tape.

-

Glue flexible tubing.

Pipe insulation

- When laying on the ground, protective covers are put on the pipes.

- Put on the pipeline.

- To isolate the worker plumbing flexible materials are notched along the length.

Installation of roll materials:

- Wrap them around pipes.

- If necessary (on the street), they are reinforced with roofing material insulation.

- insulation cut into pieces of the desired size.

- Secure with construction tape.

Instructions for applying liquid thermal insulation:

- Apply a 1 cm layer with a brush or spray gun.

- Remove corrosion and dirt from pipes.

- Apply special primer to them.

- After 4 hours, periodically add the following. In total, 4 or 5 layers are needed.

- A day later, it is necessary to add treatment with a special primer - enamel with a metallized mirror coating.

Warming on the street

To insulate heating pipes on the street, it is necessary to take into account the possibility of contact with moisture. It could be rain or snow. Therefore, waterproofing must be provided without fail. The standard way to insulate heating pipes on the street:

- a layer of mineral wool;

- winding with silk threads;

- a layer of roofing material;

- winding made of corrosion-resistant metal wire (galvanized or aluminium).

Do heating pipes need to be insulated? You have probably seen the deplorable state of the insulation layer of heating mains in your city more than once. This directly affects the temperature in the apartments. For example, there is a temperature level of the supplied heat carrier determined by state acts. Based on this value, the average temperature in residential premises and the cost of utilities are calculated.

Calculations are made taking into account the serviceability of all elements of the heating system, including the insulating layer of heating pipes passing from boiler rooms to houses. With insufficient thermal insulation in the apartments, the temperature will be lower. It turns out that according to the documents, everything is in order, but in fact, the standard is not met and, as always, there is no one to blame. At the same time, people have to pay in full, although at home it is far from Tashkent.

How to perform thermal insulation of polypropylene pipes

Insulation for pipes can be of various shapes and designs: wound, glued, in the form of a shell - oval, etc. There is a wide range of insulation materials, linings and auxiliary insulation compounds available for use in hot water systems.

The list is constantly changing as new synthetic materials or application methods are developed. For example, the latest innovation in heat engineering is the use of antifreeze as a coolant for closed systems.

It does not make sense to consider any specific manufacturer of heaters, you need to pay attention to the types of materials used

Actions in case of sewer freezing

If you have not insulated the sewer pipes, or you have not insulated them enough, and they are frozen, first of all, you need to determine the damaged section of the pipeline in order to choose a method for solving the problem. Metal pipes can be heated with a blowtorch.

If the pipeline is made of plastic, open flames cannot be used. You can pour hot water into the sewer, in which you first dissolve salt (2 kg per 10 liters of water). You can direct a jet of steam or hot water to the revision closest to the frozen area.

If the damaged pipe is in the middle of the line, you can use a steam generator to warm up the soil. However, this process can take quite a long time. It is best to prevent the system from freezing, and when laying pipes, carry out their high-quality thermal insulation.

How to choose the right cable?

When choosing a suitable hot cable, it is necessary to determine not only its type, but also the right power.

In this case, it is necessary to take into account such parameters as:

- the purpose of the structure (for sewerage and water supply, calculations are performed differently);

- the material from which the sewerage is made;

- pipeline diameter;

- features of the area to be heated;

- characteristics of the heat-insulating material used.

Based on this information, heat losses are calculated for each meter of the structure, the type of cable, its power are selected, and then the appropriate length of the kit is determined. Calculations can be performed using a special formula, according to calculation tables or using an online calculator.

The calculation formula looks like this:

Qtr - heat loss of the pipe (W); - coefficient of thermal conductivity of the heater; Ltr is the length of the heated pipe (m); tin is the temperature of the contents of the pipe (C), tout is the minimum ambient temperature (C); D is the outer diameter of communications, taking into account the insulation (m); d - outer diameter of communications (m); 1.3 - safety factor

When heat losses are calculated, the length of the system should be calculated. To do this, the resulting value must be divided by the specific power of the cable of the heating device. The result should be increased, taking into account the heating of additional elements. The power of the cable for sewerage starts from 17 W / m and can exceed 30 W / m.

If we are talking about sewer pipelines made of polyethylene and PVC, then 17 W / m is the maximum power. If you use a more productive cable, then there is a high probability of overheating and damage to the pipe. Information about the characteristics of the product can be found in its technical data sheet.

Using the table, choosing the right option is a little easier. To do this, you first need to find out the diameter of the pipe and the thickness of the thermal insulation, as well as the expected difference between the temperature of the air and the contents of the pipeline. The latter indicator can be found using reference data depending on the region.

At the intersection of the corresponding row and column, you can find the value of heat loss per meter of pipe. Then the total length of the cable should be calculated. To do this, the size of the specific heat loss obtained from the table must be multiplied by the length of the pipeline and by a factor of 1.3.

The table allows you to find the size of the specific heat loss of a pipe of a specific diameter, taking into account the thickness of the heat-insulating material and the operating conditions of the pipeline (+)

The result obtained should be divided by the specific power of the cable. Then you need to take into account the influence of additional elements, if any. On specialized sites you can find convenient online calculators. In the appropriate fields, you need to enter the necessary data, for example, pipe diameter, insulation thickness, ambient and working fluid temperature, region, etc.

Such programs usually offer the user additional options, for example, they help to calculate the required diameter of the sewer, the dimensions of the thermal insulation layer, the type of insulation, etc.

Optionally, you can choose the type of laying, find out the appropriate step when installing the heating cable in a spiral, get a list and the number of components that will be needed for laying the system.

When choosing a self-regulating cable, it is important to correctly consider the diameter of the structure on which it will be installed. For example, for pipes with a diameter of 110 mm, it is recommended to take the Lavita GWS30-2 brand or a similar version from another manufacturer

For a 50 mm pipe, the Lavita GWS24-2 cable is suitable, for structures with a diameter of 32 mm - Lavita GWS16-2, etc.

Complex calculations will not be needed for sewers that are not used often, for example, in a summer cottage or in a house that is used only occasionally. In such a situation, they simply take a cable with a power of 17 W / m with a length corresponding to the dimensions of the pipe. A cable of this power can be used both outside and inside the pipe, while installing a gland is not necessary.

When choosing a suitable option for a heating cable, its performance should be correlated with the calculated data on the likely heat loss of the sewer pipe

For laying a heating cable inside a pipe, a cable with special protection against aggressive effects, for example, DVU-13, is selected. In some cases, for installation inside, the brand Lavita RGS 30-2CR is used. This is not entirely correct, but a valid solution.

This cable is designed for heating roofs or storm drains, so it is not protected against corrosive substances. It can only be considered as a temporary option, since with prolonged use in inappropriate conditions, the Lavita RGS 30-2CR cable will inevitably break.

How to insulate sewer pipes in a private house

Three main methods can be used to insulate sewer pipes in the ground:

Insulation of a sewer pipe in the ground with the help of a correctly selected laying depth. With this method, it is necessary to evaluate the statistics of winter temperatures in the construction region. Find out the maximum depth of soil freezing. And laying sewer pipes below this level.

The advantage of this method can be considered its relatively low cost. Only the cost of excavation is paid.

The disadvantages are significant limitations in the implementation of the method:

- too great a depth of freezing (in central Russia, this figure in recent years is 110 - 150 cm);

- groundwater is too high;

- the inability to organize the correct angle of 10 ° -12 ° inclination of the pipe over a considerable distance (the lower part of the pipe will then have to be deepened to 300 cm);

- insulation of external sewage by deepening will significantly reduce its maintainability.

Insulation of sewer pipes with a heating cable.In this case, there is virtually no sewer insulation, heating is used instead. The electric cable is connected through an automatic thermostat and heats up the pipe when it is cooled to temperatures close to 0 ° C, that is, to the freezing temperature.

In this case, it is necessary to provide a heat-insulating layer so that the heating is directed, that is, there are no inefficient losses towards the ground.

Cable - insulation for sewer pipes can be laid outside, or it can be built into special pipes for external communications.

The advantages of this method can be considered:

- high efficiency;

- small depth of laying sewerage;

- the ability not only to maintain the sewage system in working order, but also to defrost it if necessary;

- the possibility of using it for sewerage in houses of rare residence (country houses, gatehouses).

The main disadvantage is the high cost of operation. Although with rare use, the effectiveness of the method can offset the cost of electricity.

Insulation of sewer pipes of external sewerage with the help of heat-insulating materials. The most common method. Insulation of sewer pipes in the ground with various heat insulators allows you to save money during the operation of the sewer, and does not require such significant deepening.

Insulation of sewer pipes is produced by various materials. A specially designed thermal insulation for sewerage pipes with grooves for a standard diameter of 110 mm is used. Also, the insulation of sewer pipes is produced with universal heat-insulating materials.

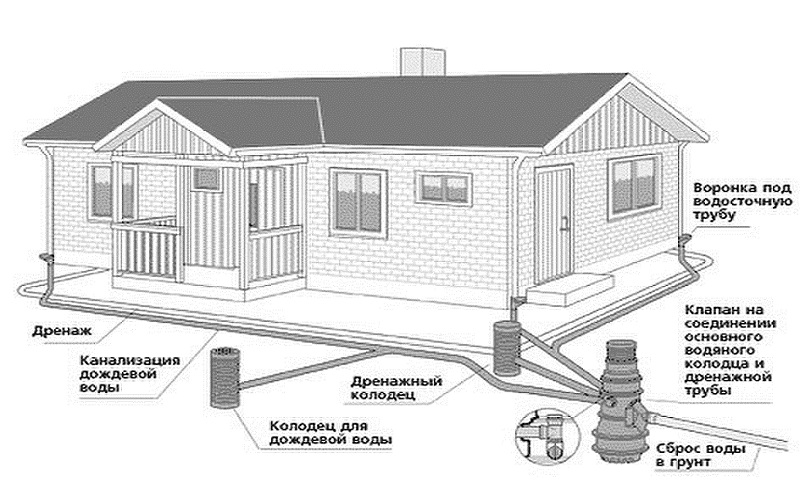

Pipe laying

Removal of the sewer pipe from the house

The pipe laying process can be divided into three stages:

- Excavation.

- Pipeline assembly.

- Backfilling.

Excavation work

Before laying sewer pipes, it is necessary to properly prepare the trenches. Rules for excavation:

- Trenches can be dug by hand or with earthmoving equipment.

- The width of the trench should allow the installer to work with the pipe from the bottom.

Advice! If the pipes have a diameter of 110 mm, then the width of the trench should be 60 cm.

Outdoor pipes laid in trenches

- It is more difficult to determine what is the optimal depth for laying sewer pipes. According to the regulations, it should exceed the depth of soil freezing in the area by half a meter. However, this condition is not always met in practice. If the pipes are laid at a shallower depth, then care should be taken to insulate them.

- Trenches need to be dug with a certain slope. As a rule, a slope of 2 cm per meter of pipeline is laid in the project.

- When digging trenches, they are made deeper than the designed pipe laying depth by 10 cm. This depth will be used to create a shock-absorbing cushion.

- The bottom of the dug trench should be well rammed, if there are large boulders or frozen clods of earth on it, then they will need to be removed, the resulting holes should be covered with earth and tamped there.

- Sand or fine gravel is poured at the bottom of the trenches. Sealing the pad along the entire length of the trench is not required. But in the places of the planned installation of revision wells, the poured sand will need to be compacted at a distance of two meters in each direction from the installation site of the well.

- In those places where the sockets of the pipes will be located, pits are arranged.

Pipe laying and assembly

Laying external sewer pipes in trenches

Consider the basic rules for laying sewer pipes:

- Installation of the pipeline begins from the place where the pipe exits the foundation of the house.

- Pipes should be laid along the trench, while the pipe sockets should be directed in the direction opposite to the flow of drains.

- We carry out pipe connections. To do this, you need to clean the bell well and make sure that the rubber o-ring is installed in it. The smooth end of the pipe, which will be inserted into the socket, is also cleaned no less thoroughly. A preliminary measurement is made of the entry of the pipe into the socket until it stops, putting a mark on the smooth pipe. To facilitate the introduction of the pipe into the socket, silicone grease is applied to the smooth end. If there is no lubrication, then you can use liquid soap or dishwashing liquid. The pipe is inserted into the socket, and in order to compensate for the linear deformations of the pipeline, the pipe is not inserted all the way, but a centimeter gap is left (when inserting the pipe, they are guided by the mark set earlier).

- If it is necessary to make a turn of the pipeline, it is necessary to use bends with an angle of 15 or 30. Use of bends with an angle of 90 degrees is prohibited.

- In addition, the technology for laying sewer pipes provides for the installation of revision wells. These devices are necessary to control the operation of the pipeline and carry out cleaning in the event of a blockage.

- If it is provided for by the project, then the pipes are insulated. For this purpose, it is recommended to use a heater based on foamed polyethylene.

Backfilling

Preparing to backfill pipes in trenches

- After the pipeline has been assembled and the slope of the pipes has been checked again, it will be possible to proceed with backfilling.

- The first 10-15 cm of the backfill height is recommended to be filled with sand. In this case, it is necessary to carefully compact the sand along the edges of the pipe, but it is strictly forbidden to ram the backfill on the pipe itself.

- Further, the pipeline can be covered with ordinary soil, which was taken out when digging trenches. You just need to make sure that there are no large stones in the ground.

The process of laying pipes in trenches is a simple job, but it requires accuracy and patience.

It is very important to follow the rules for preparing trenches and installing the pipeline, only in this case, the work carried out will be effective.

Choosing a heater

Let's try to figure out which insulation for external sewer pipes to choose.

Let's conduct a small comparative analysis of the two most popular options for heat-insulating materials: mineral wool and polystyrene foam:

| Mineral wool | Styrofoam |

| The composition includes phenol-formaldehyde resin, which is unfavorable for human health. | Environmentally friendly. |

| Short-lived. | Durable. |

| Under the action of mechanical loads, it "shrinks", which can lead to the appearance of "cold bridges" on the pipes. | Maintains constant dimensions during operation. |

| Relatively high moisture absorption. Additional insulation required. Cannot be used in high humidity conditions. | Does not absorb water. Can be used at any level of humidity. |

Insulation of pipes with mineral wool requires the mandatory use of additional waterproofing material

As a heater, mineral wool can be successfully used subject to certain safety requirements when working with it, in dry conditions and with a mandatory additional waterproofing layer.However, foam thermal protection due to its excellent performance in modern realities displaces it from practice.

Styrofoam

Modern insulation for sewer pipes - foam shell. It consists of two or even three parts, on the sides of which there are locks equipped with a simple device for fastening. The shells selected according to the diameter of the pipe are simply put on it and snapped into place.

Do not forget to provide overlaps when putting on the shell. Their overlap in length relative to each other should be at least 20 cm.

The service life of foam shells is more than 50 years. They can be used in any climate zone.

Styrofoam shell - effective in application and easy to install

Styrofoam

This material can be described as follows:

- Excellent thermal protection is provided for pipes located both in the ground and on the surface.

- For the consumer, the affordable price of heat-insulating material is important.

- Expanded polystyrene protection can be used repeatedly.

- The elasticity of the material due to the porous structure makes it possible to carry out work not only on straight sections of the pipeline, but also on bends.

- Expanded polystyrene shells are mounted quite simply:

- two halves of the required diameter, from which, when assembled, a “casing” for the pipe is obtained, are combined around it;

- the coating is additionally fastened with construction tape.

- Installation of such a thermal shell can be easily done by hand.

Foamed polyethylene

Modern heaters: expanded polystyrene and foamed polyethylene

The heat-insulating properties of this material are ensured by its peculiar structure - air bubbles in a polyethylene sheath. Foamed polyethylene has the following operational and other properties:

- good heat retention;

- providing protection against condensate and fogging;

- resistance to mechanical damage;

- resistance to oil, gasoline, cement, lime;

- high elasticity and flexibility;

- durability;

- preservation of characteristics during the entire period of operation;

- environmental Safety.

The thickness of the polyethylene foam protective coating varies depending on the outer diameter of pipes (7-114 mm) made of steel, copper or plastic, and can be from 6 to 20 mm.

Thermal insulation of large diameter sewer pipes, fittings and pipes with a non-circular section is made using sheets of foamed polyethylene with a foil coating.

Staples, glue or reinforced adhesive tape are used to fasten the insulation.

foamed rubber

This flexible synthetic material provides high quality and effective insulation due to its properties:

- good elasticity;

- low thermal conductivity;

- resistance to moisture absorption;

- durability;

- resistance to fire;

- ability to work in a wide temperature range: from -200 °C to +175 °C;

- good sound absorption;

- environmental friendliness;

- non-toxicity;

- economy.

Installation of synthetic rubber insulation is possible on pipes of any type (steel, plastic, copper). The outer diameter of the insulated pipes (6–160 mm) determines the thickness of the material layer: 6–32 mm.

Rubber has all the necessary insulation advantages

Ways of warming the water pipe on the street (in the ground)

- pressure increase in the water supply system;

- cable for heating a water pipe;

- thermal insulation for water supply pipes.

1. Creating high pressure in the water supply system

The water pipe will not freeze because the water will move at high speed. To implement this method, a pump is used to increase the pressure in the water supply system or a receiver that crashes into the pipe directly next to the pump.

2. Heating cable for plumbing

Cable power 10-15 W (average price - 15 USD / m.p.). Excellent for heating pipes in the ground with a small depth of their placement. According to the rules, it is not advisable to place any communications in the soil below the level of soil freezing.

Cable power 10-15 W (average price - 15 USD / m.p.). Excellent for heating pipes in the ground with a small depth of their placement. According to the rules, it is not advisable to place any communications in the soil below the level of soil freezing.

There are situations in which this requirement is ignored. In this case, simple pipe insulation will not give the desired result, because. the pipeline will in fact be in water (in a humid environment that freezes in winter). Most of the heaters are not suitable for this mode of operation and do not provide proper thermal insulation.

The use of a cable for heating water supply provides the possibility of laying pipes at a depth of up to 500 mm.

Cable for water pipe heating

Wiring diagram for installing a cable for heating a water pipe

Masters and users note that insulating a water pipe by heating a pipe with a cable is the most reliable method for protecting pipes laid in the freezing zone of the soil.

Cable heating makes it possible to avoid freezing of water in the pipe, and, no less important, to quickly defrost frozen pipes. Such a need may arise in the country, if it is intended for seasonal living.

In this case, you can quickly prepare the pipeline for operation, because in natural conditions you can wait for complete defrosting until May (when laying pipes at the level of soil freezing). The cable is located both inside and outside the water supply pipe.

3. Application of thermal insulation materials for pipes

This is the most budgetary and simple in terms of self-implementation way insulation. Let's dwell on it in more detail. Let's start with the better to insulate the water supply, what materials can and should be used better, depending on the specific conditions.

Do I need to insulate the pipeline?

The outer part of the sewer line in most cases is laid by a hidden method and is underground.

In warm climates, natural shelter is used. The pipeline is located below the freezing level of the soil, the entire system is simply covered with earth, which serves as a natural insulation.

But in the main part of the Russian territories, this method of insulation is not suitable. For trouble-free operation of drain communications in winter, when laying main sewer lines at a depth of more than 70 cm, care must be taken to insulate the outer part of the sewer.

Insulation of the hood for sewage background riser

Separately, it should be noted the need for insulation of external sewerage, which is understood as a ventilated background riser (exhaust) - a sewer pipe brought to the roof (or to the surface of the earth from a septic tank) and providing pipeline ventilation.

The background riser is designed to suck in air so that when the toilet is drained, the pressure in the system is equalized.And in the septic tank from the vital activity of bacteria, gases are formed, which are also removed through the background pipe.

The ventilation (background) pipe can freeze (condensate freezes and an ice plug forms) and needs to be insulated. Any material that is reliably protected from moisture and destruction by ultraviolet radiation is suitable for thermal insulation. For example, you can put a “stocking” Stenoflex on the pipe. The part of the pipe that is above the roof is insulated. And you can’t put a cap on top of the pipe, it must be free, otherwise it will freeze in this place.

How to insulate the background riser with your own hands

On the forum, one user suggested an interesting way to get rid of the buildup (freezing) of condensate in the background pipe.

You need to take a copper wire (necessarily from pure copper, without a braid, this is important), wind it into a voluminous, but at the same time “liquid” lump (so that air can easily pass through it). Push this wire ball from above into the pipe, and bend the ends of the wire so that you can fix the wire at the top of the pipe (otherwise it will fall inward). Push this wire ball from above into the pipe, and bend the ends of the wire so that you can fix the wire at the top of the pipe (otherwise it will fall inside)

Push this wire ball from above into the pipe, and bend the ends of the wire so that you can fix the wire at the top of the pipe (otherwise it will fall inward).

The meaning lies in the chemical properties of copper, it has a very high thermal conductivity. Warm air rises through the pipe, copper accumulates heat and melts the freezing condensate.

Conclusion

Sewer insulation in a private house is an important measure that will maintain the normal patency of sewer pipes in winter, prevent freezing of the pipeline and extend its service life.

Conclusions and useful video on the topic

This video covers the process of laying external sewerage in great detail, as well as the standard indicators that must be followed during installation:

This video shows how sewer pipes are laid in the ground:

Despite the apparent simplicity, the work of laying sewer pipes requires a competent approach and knowledge of the regulatory rules for laying. Only if the necessary indicators are observed and the work is done correctly, it is possible to equip a truly effective and durable sewer system.

Trying to lay sewer pipes yourself? Or maybe you don't agree with what is said? We are waiting for your comments and questions - the contact form is located below.