- We insulate the wall of the house from the outside with polystyrene foam

- What properties should a heater for a frame house have

- Thermal conductivity

- Water absorption

- fire safety

- Insulation shrinkage

- Environmental friendliness

- 8 Expanded clay

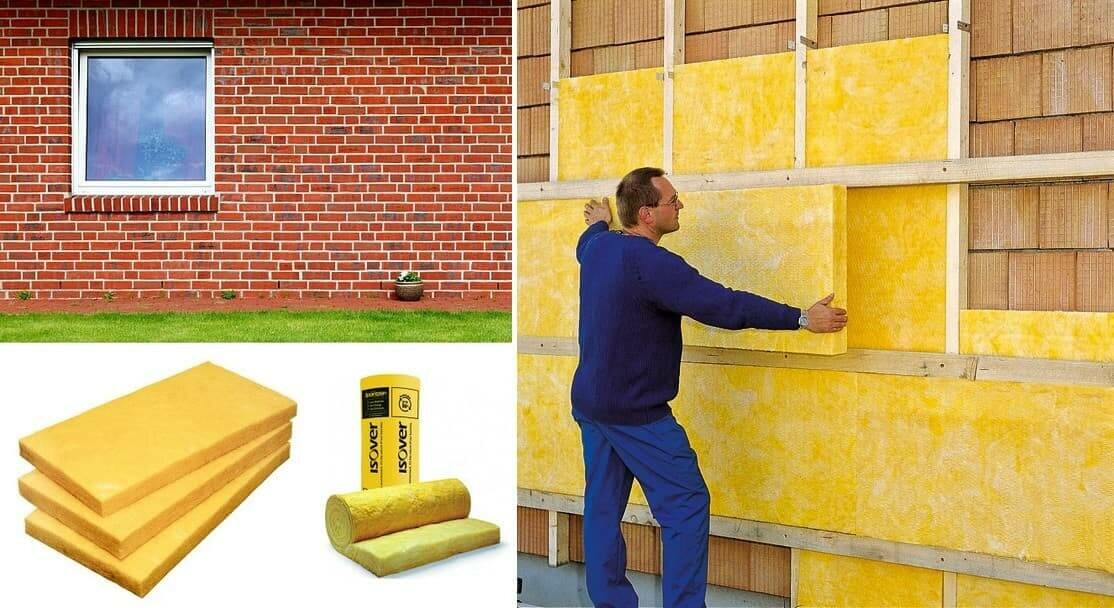

- The best fiberglass insulation

- Isover Warm House

- Advantages

- Ursa Geo

- Advantages

- No. 5. Polymer heaters

- Styrofoam

- Extruded polystyrene foam

- PVC foam

- No. 6. Polyurethane foam for insulation of a wooden house

- The main mistakes of insulation

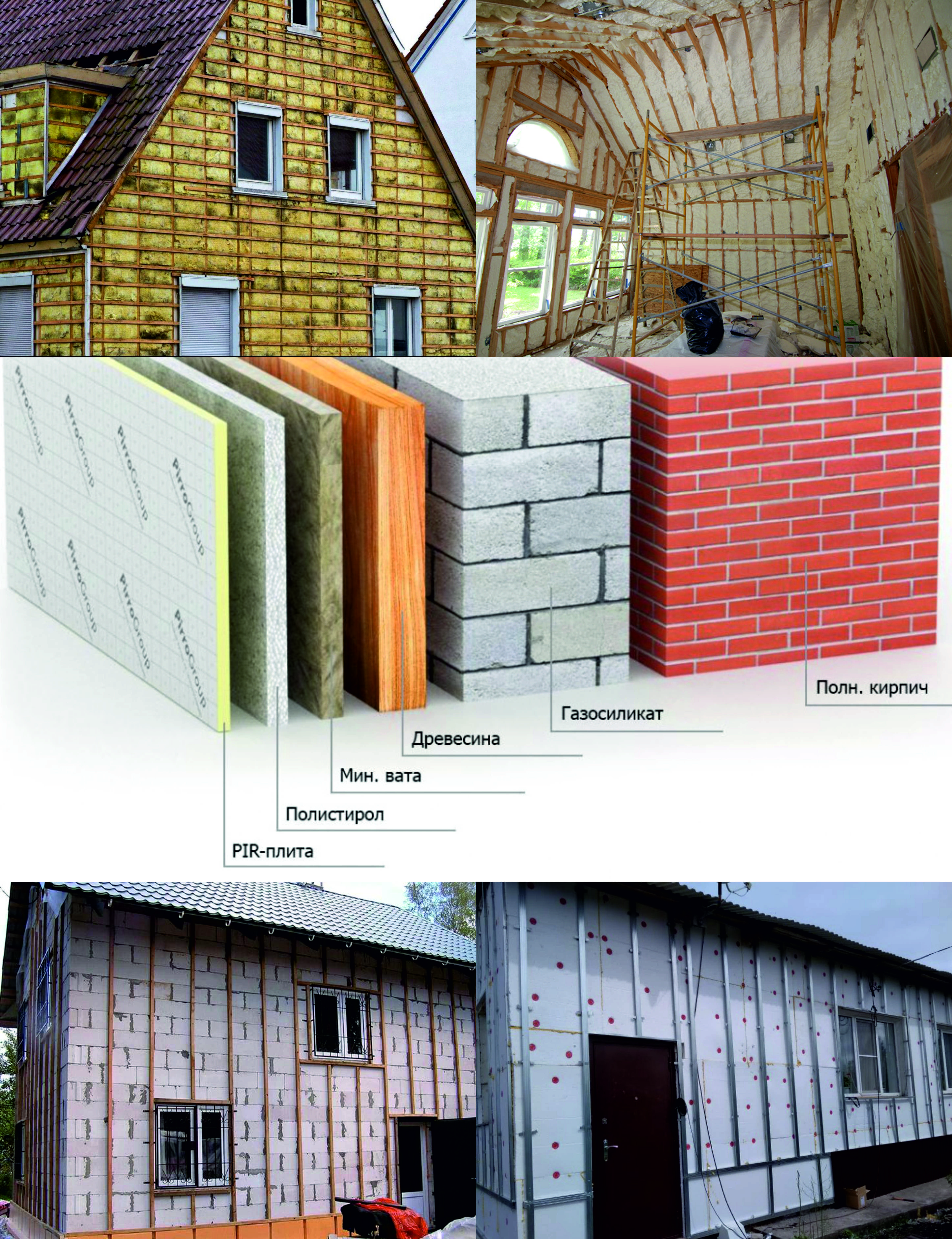

- Facade insulation methods

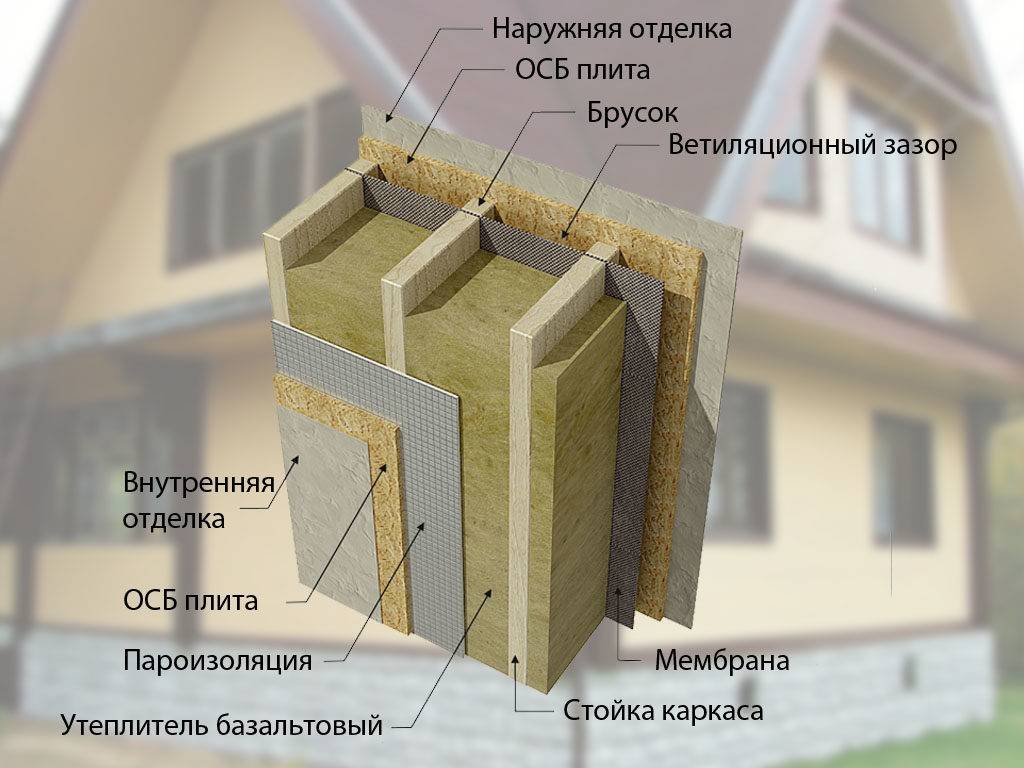

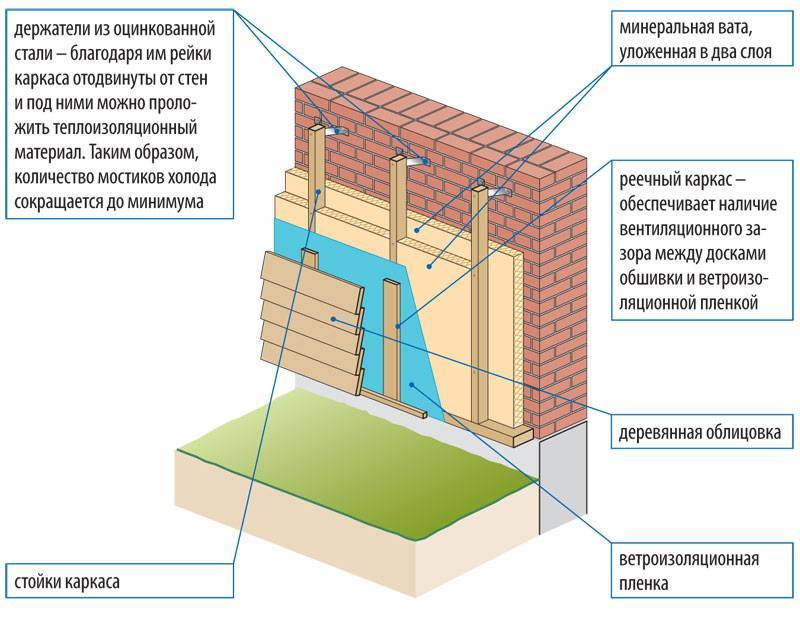

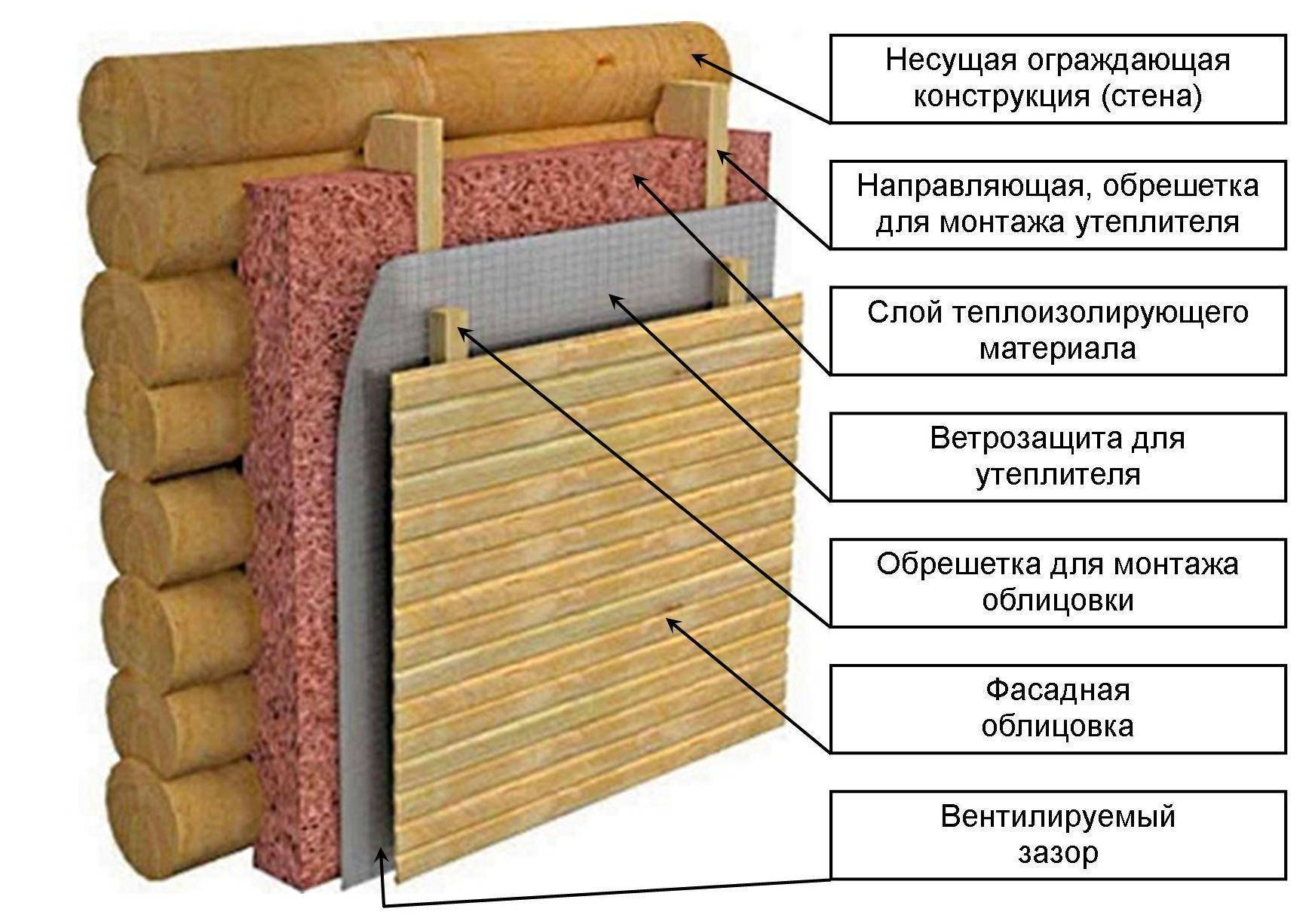

- Ventilated facade technology

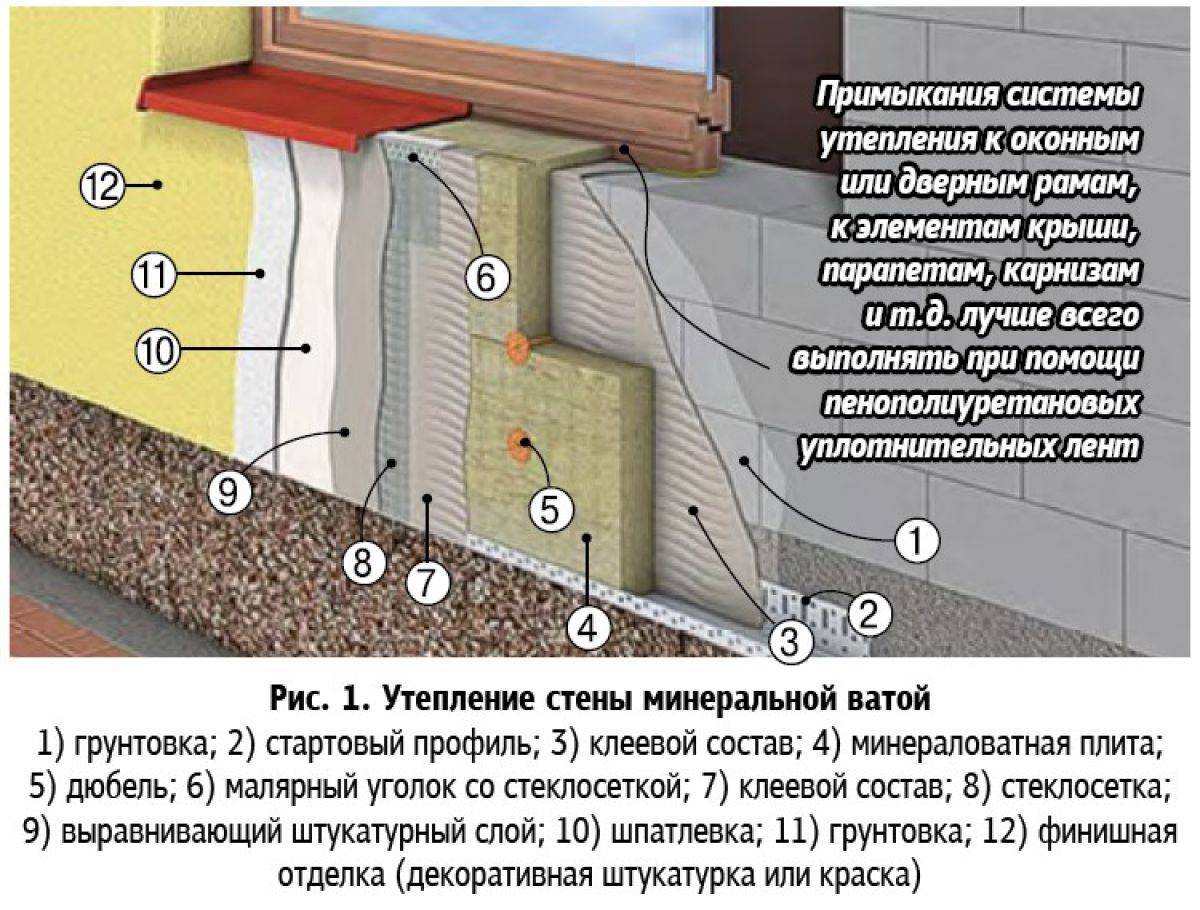

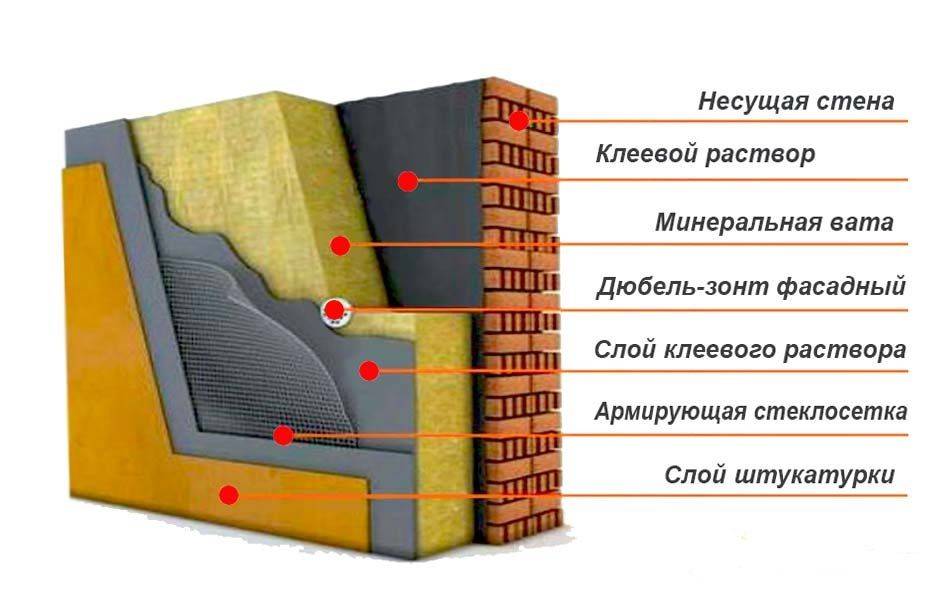

- Wet facade technology

- About vapor permeability and dew point

- polyurethane foam

- Material selection

- Expanded polystyrene insulation

- Extruded polystyrene foam

- Features of polyurethane foam

- Mineral wool

- Liquid thermal insulation

- stone wool

- Differences in the insulation of aerated concrete, wooden, brick houses

- Wall preparation

- What material to choose for external insulation of a brick building?

We insulate the wall of the house from the outside with polystyrene foam

Insulation sheets are attached to the wall with adhesive and additionally fixed with dowels. The reliability of the dowels will directly affect the quality of the insulation retention under strong wind loads. In this case, there are two main types of dowels with a standard and extended spacer zone.At the same time, standard fasteners are used to fix polystyrene foam on concrete and brick walls. In turn, it is advisable to use elongated dowels for walls made of porous material - foam block, lightweight concrete, etc.

Plates of polystyrene insulation have one significant drawback - the high combustibility of the material. Although manufacturers have been able to solve this problem through the use of new technologies in the manufacture

Therefore, it is the resistance of the material to fire that should be given special attention when choosing

After the adhesive composition is applied to the surface of the wall, proceed to fixing the plates. Glue is applied in sufficient volume so that the composition completely fills all the irregularities. The insulation plate is tightly pressed against the wall surface, while excess adhesive solution comes out from under it, falling under the adjacent plate, due to which the joints become more reliable. After that, the plate is additionally fixed with dowels in the corners and in the center of the product. Neighboring joints of plates, as well as dowel caps, are smeared with mastic.

After laying the outer insulation, the resulting structure is reinforced. To do this, use a fiberglass mesh, and, if necessary, metal products. The plates are opened with adhesive compositions, on which the mesh is laid, by pressing against the heat insulator. For greater reliability, the mesh is fastened with an overlap. After the adhesive composition dries, it is sanded and proceed to the application of the finish. The most popular is decorative plaster, which, after drying, is opened with a layer of weather-resistant paint.

What properties should a heater for a frame house have

Heaters used to insulate the walls of a frame house must have the following properties:

- low thermal conductivity;

- fire safety;

- low water absorption;

- lack of shrinkage;

- environmental friendliness.

Thermal conductivity

The ability of a material to transfer heat reflects the coefficient of thermal conductivity. The lower its value, the less heat passes through this material. At the same time, in winter, the room does not cool down so quickly, and in summer it heats up more slowly. This allows you to achieve savings on cooling and heating. For this reason, when choosing a heater, be sure to take into account the value of the thermal conductivity of the material during operation in specific conditions.

Water absorption

The next important indicator that affects the ability of the insulation to retain heat is its water absorption. It is the ratio of the amount of water absorbed by the insulation to the mass of the insulation itself. This characteristic demonstrates the ability to absorb and retain moisture in the pores in case of direct contact with water.

Due to the fact that wet material conducts heat well, the smaller this value is, the better. This is due to the fact that when wet, the air pores of the insulation are filled with water, which has a greater thermal conductivity than air. In addition, too wet material can simply freeze, turning into ice and completely lose its function.

fire safety

The fire safety of materials means the ability to withstand exposure to high temperatures without breaking the structure and igniting.This parameter is regulated using GOST 30244, GOST 30402 and SNiP 21-01-97, which subdivide them into combustibility groups from G1 to G4, while completely non-combustible substances are designated NG. For frame residential buildings, heaters belonging to the NG group are most preferred.

Insulation shrinkage

When choosing a heat insulator for a frame building, it is imperative to take into account such an indicator as the ability to shrink. This value should be minimal, otherwise, during operation, material subsidence will appear at the places where the insulation is laid, which will lead to the appearance of cold bridges and an increase in heat loss.

Environmental friendliness

The basis of the walls of the frame house is a heater. Since the insulating material will surround you everywhere in the frame house, you need to be sure that this is a really high-quality insulation and that it does not emit harmful substances.

8 Expanded clay

When concrete bases (floor, ceiling) are used in a wooden house, it is possible to cheaply and effectively perform thermal insulation using expanded clay. This material is a small pebbles of a certain size (10-20 mm). Previously, a crate is made on a concrete base (in the case of a plank floor), a hydro- or vapor barrier is laid, and then expanded clay with a thickness of at least 20 mm is scattered in an even layer. Calculating the required amount of heat insulator is quite simple. For insulation 1 sq. m layer of 10 mm will require 16 liters of expanded clay. Also, the heat insulator can be added directly to the concrete when installing the screed.

Builders call expanded clay the best insulation for concrete foundations. But you should work with the material carefully to prevent damage to the granules.Otherwise, the thermal conductivity coefficient will increase significantly.

The best fiberglass insulation

This type of product in the rating is popularly called glass wool. It is produced by melting soda, sand, borax, limestone and cullet. This results in thick fibers of various orientations that effectively delay heat transfer. The material costs less than analogues, but it hurts the hands a lot during installation.

Isover Warm House

Rating: 4.9

In the first place in this category of the rating is a product known to the whole world. Glass wool for the home is produced in rolls with a cross section of 5 cm and a width of 55 cm. In the production, the company uses the patented TEL technology, which is highly environmentally friendly. The insulation is suitable for use in a house on a pitched and straight roof, in floors and wall partitions. The product complies with ISO9001 and EN13162 standards. In addition to insulation, heat contributes to noise protection. In terms of thermal conductivity, the substance has an indicator of 0.040 W / (m * K). Buyers in the reviews note the affordable price and long service life with proper protection from water.

Our experts have added insulation to the rating due to the convenient form of release in rolls from 5.5 to 7 meters long. This is practical when filling walls in drywall partitions to immediately close the space from floor to ceiling and get by with a minimum of cuts. The thickness of 50 mm is well suited to the width of the profile.

Advantages

- meets hygienic standards (can be used in childcare facilities);

- does not burn;

- completely from natural materials;

- elastic and does not require exact dimensions when cutting;

- lets steam out of the house.

- does not hold its shape well;

- properties deteriorate when wet;

- uncomfortable to lay;

- average thermal conductivity.

Ursa Geo

Rating: 4.8

In second place in the rating of the glass wool category is the domestic brand, which is often used as a common noun when indicating the type of insulation. Now these products are known throughout the CIS and are in high demand. The thickness of the insulation for the house varies from 5 to 10 cm, and the width of the roll is 120 cm. A square meter weighs 1 kg (with a cross section of 10 cm), which is convenient for calculating the mass for supporting structures. Glass wool is allowed to isolate not only the walls, floor and roof in the house, but also the pipes of the chimney, heating, ventilation. The product belongs to the fire hazard class KM0. The masters in the reviews like the vapor permeability, which is 0.64 mg / mchPa, but its thermal conductivity loses to its counterparts and is in the range of 0.040-0.046 W / (m * K).

The product is rated as the best for pitched roofing and floor insulation in the house, since it is also available in convenient rolls. The choice of the buyer can be two rolls of 6 m in one package, or one, 10 m long. When installed in the floors along the logs, this allows you to stretch one roll immediately along the length of the room and save time.

Advantages

- glass wool does not burn;

- light weight simplifies transport and installation;

- does not have a serious impact on the foundation;

- high sound insulation;

- compatible with wood, aerated concrete, foam blocks, bricks.

No. 5. Polymer heaters

The hand does not rise to recommend this group of materials for warming a wooden house. Polymer materials do not breathe, which means that all the advantages of wooden walls go down the drain.When using such heaters, you will need a serious ventilation system. It is justified to use them when insulating concrete slabs and stone plinths.

Styrofoam

It is popularly called foam. The material consists of a mass of balls that are interconnected to form small cavities.

Pros:

- low weight and ease of handling;

- good thermal conductivity (0.036-0.051 W / m * C)

- low price;

- durability;

- soundproofing.

Cons are more significant:

- combustibility;

- vapor tightness;

- rodents like to make minks in polystyrene foam;

- water can accumulate in the cavities between the foam balls. The water absorption index by volume for 24 hours is 2%, for 30 days - 4%. Not so much, but the accumulated moisture during freezing can destroy the structure of the insulation.

Too much work will have to be done to protect the material from fire, rodents and moisture, and to provide ventilation in the house, so it’s better not to insulate wooden walls in this way - the low price of foam plastic is not justified by other expenses.

Extruded polystyrene foam

This is already a more advanced insulation, a material related to foam, but the production method is completely different, hence the difference in properties.

Pros:

- low thermal conductivity (0.028-0.034 W / m * C). If the house is beyond the Arctic Circle, then this is the best solution;

- light weight;

- ease of installation;

- moisture resistance;

- sufficiently high strength.

Of the serious disadvantages are vapor tightness, flammability and high price.

PVC foam

The insulation is made on the basis of polyvinyl chloride (PVC). The result is a lightweight cellular material with an impressive set of advantages:

- high strength, higher than that of extruded polystyrene foam;

- low coefficient of thermal conductivity (0.035-0.07 W / m * C)

- resistance to burning;

- good vapor permeability, the highest in this class of materials;

- biostability.

Everything would be fine, if not for the price. The material is very expensive, and when burned, although it is prone to self-extinguishing, it emits hydrogen chloride, which, when combined with water, gives hydrochloric acid.

No. 6. Polyurethane foam for insulation of a wooden house

This type of insulation has recently been used more and more often, and it is its sprayed version. There is another option in the form of plates. Sprayed polyurethane foam requires the use of special equipment, but fills all the cracks well, creates a solid coating.

Pros:

- low coefficient of thermal conductivity (0.019 W / m * C);

- resistance to temperature extremes, durability;

- resistance to fire, rodents, decay;

- light weight;

- water resistance.

The main disadvantage is vapor permeability, according to this indicator, the material is 50 times worse than mineral wool. In addition, for spraying you will need special equipment, which must be managed by a professional, and this affects the price. Polyurethane foam is afraid of sunlight. Frankly, it is not very suitable for wooden houses, but if the goal is not to maintain the ability of the structure to breathe, then this insulation can be used.

The main mistakes of insulation

External insulation of the walls of a country house must be carried out in accordance with the requirements and rules for the installation of materials. Errors that most often occur during insulation contribute to improper circulation of air flows and the formation of moisture inside the cake, which leads to a weakening of thermal insulation qualities:

- incorrect calculation of heat resistance;

- in the absence of a basement rail at the bottom of the wall, the insulation may come into contact with the ground;

- polystyrene foam during installation should not be left in the sun for a long time;

- gaps between the insulation plates lead to the appearance of cold bridges;

- at the corners of the building and around doors and windows, expansion dowels should be installed to securely fasten the material.

In addition, you should not save on materials, since in addition to their correct installation, the poor quality of the material should not cause poor-quality insulation.

Thus, when insulating the walls, the living area is preserved, a careful study of the details is required to calculate the amount of materials and determine the order of installation work.

Facade insulation methods

It should be said that for the insulation of a wooden house from the outside, there are two technologies for external insulation:

- ventilated facade;

- wet facade.

The first technology is suitable for frame houses. The frame is mounted on the walls, after which it is sheathed with siding, clapboard or some other finishing material. In this case, the insulation is placed between the finishing material and the wall. This technology is very good in that it excludes wet work, and the facade itself in this case will be more durable and durable.

In the second case, the walls of the house are simply pasted over with insulation, after which they are plastered using a technology specially developed for this.

Now let's talk in more detail about the features of each of the methods.

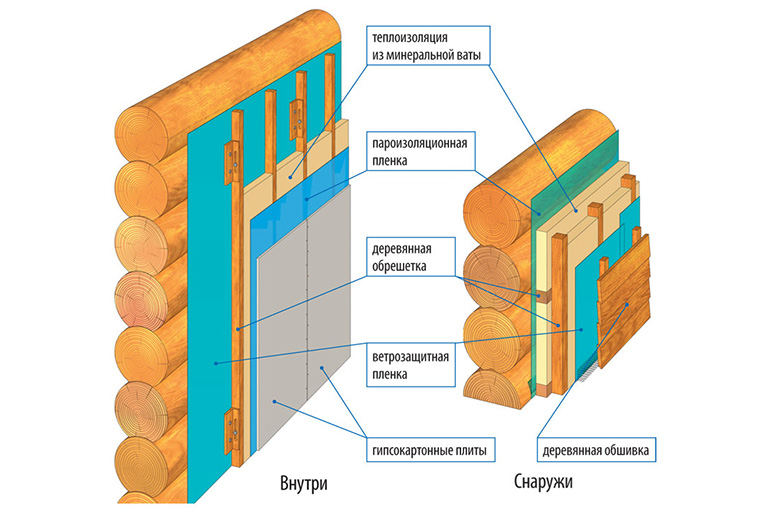

Ventilated facade technology

The process of creating a so-called ventilated (or hinged) facade includes several parts:

- facade preparation;

- arrangement of the ventilation gap and installation of the frame;

- frame sheathing.

And, in principle, with this method, its use is also allowed. It is only necessary to remember that the foam plastic resists the effects of fire very poorly, and also does not allow steam and moisture to pass through. And this can negatively affect the microclimate inside the house. Therefore, in this case, it is better to give preference to mineral wool.

If we talk about racks for the frame, then either bars or boards are used for it. They can be attached to the walls using brackets or metal corners. By the way, as an option, you can apply a profile that is used to install drywall. In addition, you will need a vapor barrier film that will protect the insulation from getting wet, the material that will be used for finishing: siding, lining, block house, or some kind of facade material.

Also, to implement this method, you will need an interventional heater. Usually, jute tow is used in this capacity, which acts as an excellent protection for seams, but you can use special foam or any other materials that work. You will also need a wood preservative so that it can resist moisture. It is usually applied under plaster.

Now let's talk about the features of another method.

Wet facade technology

It consists of the following parts:

- facade preparation;

- installation of insulation;

- reinforcement;

- painting.

Speaking a little more, in this case it is also better to give preference to such material as mineral wool.In addition to insulation, in this case it will also be necessary to purchase a special glue for mineral wool, dowels in the form of umbrellas, a special reinforcing mesh made of fiberglass, perforated corners, a primer, paint for the facade, as well as decorative plaster. After all these materials are purchased, you can begin to work.

About vapor permeability and dew point

There is a lot of conflicting information on the internet about this topic. There are heated discussions on construction forums about the terrible dew point, because of which water appears and freezes inside the walls, mushrooms grow, bacteria multiply. Let's try to clarify the situation.

In winter, indoor humidity is higher than outdoors. This means that the air is more saturated with water vapor, respectively, their partial pressure is higher. What happens at the border of 2 zones with different pressure, separated by the wall of our house:

- Vapors from the zone with high partial pressure (room) tend to flow into the second zone with low pressure (street), because the partition is not hermetic.

- As the thickness of the wall passes from the inside to the outside, the temperature decreases. The cooling air is no longer able to hold a large amount of steam, at a certain point condensation begins. The same dew point arises - the temperature at which saturation occurs, excess vapor passes into a liquid state, and condensate.

- The condensation zone and the dew point are constantly moving depending on the difference between the external / internal temperature, the vapor content in the air of the room.

- When the walls of the house are properly insulated, only a small part of the moisture condenses, this is a normal process.The dew point falls on the heat-insulating layer, the condensate is safely vented due to the vapor permeability of the material.

- If an impermeable barrier (for example, a polyethylene film) arises in the path of evaporation, which coincides with the condensation zone, moisture falls out at the interface of 2 materials. There is nowhere for her to escape, the wall is damp. A similar effect is observed in the absence of ventilation - air supersaturated with steam condenses in a cold wall without any insulating barriers.

Preliminary conclusion: for ceilings, floors and exterior walls of the house, you can choose any insulation, the main thing is to follow the insulation technology. Remember, the dew point always occurs in the walls, the problem lies in the amount of condensate and the way it is brought out. An exception is full-fledged external insulation with extruded polystyrene foam, inside which condensation is impossible.

For thermal insulation of the outer wall, you need to select polystyrene foam of the required thickness so that condensation does not form in the brick

Hence 3 recommendations:

- Insulators that are poorly permeable to moisture are best used outside and not fastened back to wood.

- For internal thermal insulation, use polymers, but provide effective supply and exhaust ventilation in the rooms that removes humid air.

- Materials with open pores (mineral wool) need to be ventilated with outdoor air, which will remove excess steam and condensate from the thickness of the insulation.

Note that ventilation of residential premises is needed in any case. A good hood will save you from problems with wet corners and “weeping” windows.

polyurethane foam

Popularly called foam rubber insulation.In everyday life, it is found as furniture upholstery, but it is soft. In construction, polyurethane foam is rigid. It is possible to insulate the house from the outside with foam rubber in the standard way - in the form of plates, but spraying has recently become popular. Using the option involves preparing the material directly at the construction site in the form of foam. It is convenient that an integral coating is created, there are no joints and cold bridges.

Advantages of a heat insulator:

Low thermal conductivity. Compared to foam, the thermal conductivity is 50% better and 100% lower than mineral wool.

Resistant to moisture penetration. Polyurethane foam is a better external insulation than polystyrene, as it has a 10 times lower level of water absorption.

High temperature resistance. Among the other options considered earlier, it withstands the widest temperature ranges, the lowest up to -70 ° C, and the largest up to + 110 ° C.

Long service life

At least there will be no complaints about insulation for 30 years, if it is properly installed, then even longer.

It is not subjected to deformation effects during the entire period of operation.

Resistant to rot and fungus formation, which is important for external insulation.

When we insulate with polyurethane foam, an additional layer of sound insulation is created, and it is quite high quality.

At this stage, you can call it the best insulation, but in fact there are also disadvantages:

- The high price of the material.

- Installation of spraying is quite complicated and expensive.

- Polyurethane foam cannot be used to insulate houses without additional protection, as it is susceptible to UV radiation. In addition to simple failure, it can emit harmful substances from the sun.

Polyurethane foam has higher performance than mineral wool and polystyrene, but requires large investments, which narrows the scope of its use.

Material selection

It is from the correct choice of heat-insulating material that the quality and efficiency of the insulation of the walls of the house will depend.

With external insulation, it is necessary to pay attention to the following factors, on which the choice of material used will directly depend:

- Chemical resistance.

- Fire safety and fire resistance.

- Ecological purity.

- Sound absorption indicators.

- Minimum vapor permeability and moisture absorption.

- Low thermal conductivity.

- Durability and strength.

- Resistance to biological factors and mechanical influences.

- A light weight.

- Ease of installation.

Having correctly selected the insulation used, all work on wall insulation can be done independently, subsequently cladding the facade of the building with siding panels, a block house, plastering and painting the walls of the house.

The most commonly used types of insulation for walls outside:

- Liquid insulation.

- basalt materials.

- Mineral wool.

- Polyurethane foam.

- Extruded polystyrene foam.

- Styrofoam.

Each of these thermal insulation materials popular with homeowners has its own advantages and disadvantages. The technology of working with one or another insulation also differs, which must be taken into account when performing home repairs.

Expanded polystyrene insulation

Expanded polystyrene (polystyrene) is an inexpensive polymer insulation for house walls, which is efficient and affordable.This material is characterized by low thermal conductivity, minimal water absorption and resistance to chemical and biological influences. Modern polystyrene is an environmentally friendly, inexpensive and durable material, the service life of which exceeds 50 years.

The use of expanded polystyrene does not present any difficulty, you can fix the sheets of insulation with glue or dowels with mushroom caps. Of the advantages of this material, we note the ease of working with it: insulation with polystyrene foam can be performed even without arranging an additional crate, there is no need to use steam and waterproofing materials.

Extruded polystyrene foam

This is the latest generation of insulation, which differs from foam plastic in improved strength and excellent thermal insulation characteristics. Extruded polystyrene foam is resistant to chemicals, is not subject to mold, is not eaten by rodents and insects, being at the same time an excellent sound insulator. Excellent environmental friendliness of this insulation allows you to use it for external and internal insulation.

Features of polyurethane foam

Polyurethane foam is an inexpensive and easy-to-use insulation that has a cellular-foam structure. Excellent adhesion of polyurethane foam to metal, wood, brick and concrete surfaces ensures high-quality thermal insulation and good sound and thermal insulation performance.

Polyurethane foam is an inexpensive and easy-to-use insulation that has a cellular-foam structure. Excellent adhesion of polyurethane foam to metal, wood, brick and concrete surfaces ensures high-quality thermal insulation and good sound and thermal insulation performance.

The application of polyurethane foam on the walls of the house is carried out using a compressor with a hose, which ensures the uniformity of the coating and the absence of seams.The excellent elasticity of the material during its application makes polyurethane foam one of the best heat insulators for insulating the walls of buildings of complex shape, when it is not possible to use conventional plate and roll insulators.

Mineral wool

Mineral wool is a natural environmentally friendly insulation, which is obtained from dolomite, basalt or by processing waste from the metallurgical industry. This insulation is durable, environmentally friendly, durable, good sound and heat insulation of the room. Mineral wool is used for internal and external insulation. In the latter case, it will be necessary to provide high-quality protection of the coating from moisture, for which moisture and vapor barrier membranes are used.

Liquid thermal insulation

Liquid heat insulators are new generation materials that can be used with equal success for private houses built of wood, blocks and bricks. Such liquid thermal insulation can be applied using rollers or brushes, spray guns or high-pressure compressors. It takes 5-6 hours for the material to dry, after which the coating acquires the necessary strength and resistance to mechanical stress.

stone wool

Despite the generally accepted belief that stone wool is a synthetic material, this material is a natural product. The idea for production was the principle of a volcanic eruption, in which molten rock under the influence of high temperature turns into lava and is thrown out of the vent. The production process of basalt wool is very similar.

Stone wool production

In the likeness of a natural process in the factory, using industrial furnace equipment, basalt rock or limestone is heated to a temperature of 1500 degrees. As a result, a straightened mass is obtained, from which threads of fibers are made. Of these, already with the help of a pendulum spreader, an insulation sheet of the desired density and size is made with the help of synthetic binders. The result is a material without a clearly directed structure. At the final stage, the insulation mats are subjected to heat treatment up to 200 degrees for hardening. After the end of the web, they are cut to standard sizes and packed for transportation. As a result of the fact that various raw materials are used in the production, the following types of heaters are obtained at the output:

- basalt wool;

- glass wool;

- slag wool.

The material may have a different density. Depending on it, the type of packaging can be of two types: in plates and in rolls.

Stone wool in rolls

Roll refers to soft insulation and has a density of 10 to 50 kg / m3. The material of medium rigidity, or semi-rigid, is made in the form of plates and has a density of 60 to 80 kg / m3. The most rigid plate basalt heaters have a density of 90 to 175 kg/m3. The advantages are:

- high rates of thermal insulation;

- the ability to pass steam;

- environmental friendliness;

- good soundproofing properties;

- resistance to bacterial and fungal infection;

- fire safety - heaters do not ignite and do not burn;

- long time use.

Installation of stone wool for internal wall insulation

The main disadvantage of this material is that during cutting and installation, small particles of basalt enter the air, which can enter the respiratory tract. In order to protect yourself from harmful effects, it is strongly recommended to use personal protective equipment during installation. Also, due to the fact that stone wool is not a closed-circuit insulation and has the ability to pass vapors, it is necessary to additionally arrange a vapor barrier layer during installation. If this is not done, then over time the insulation may become damp, which will lead to subsidence and deterioration in thermal insulation ability. It is also impossible not to note the cost of stone wool, which significantly exceeds the cost of PPS insulation. In addition, the need to purchase a vapor barrier further increases the estimate for the purchase of materials for insulation.

Foam insulation

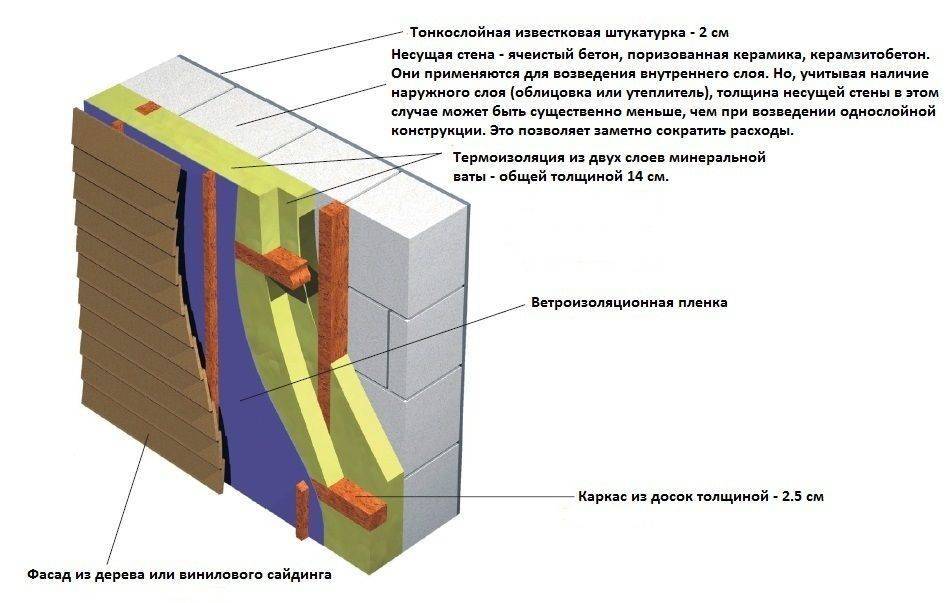

Differences in the insulation of aerated concrete, wooden, brick houses

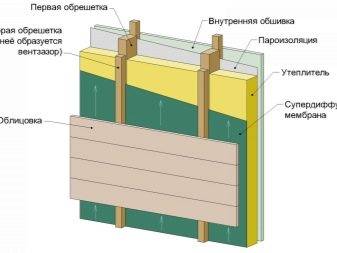

From what material the walls of the house are made, the method of insulation depends. If we compare houses made of wood, brick and aerated concrete, we can highlight the following points that deserve attention:

- unlike brick walls and houses made of aerated concrete, a prerequisite for the installation of insulation in a wooden house is the installation of a crate to provide ventilation. Installation of the lathing of block walls is carried out only under siding or other hinged cladding;

- the most suitable heaters for aerated concrete and brick walls are materials with a high moisture resistance index (penoplex, expanded polystyrene), while for wooden houses, breathable mineral wool slabs are ideal insulation;

- the thermal conductivity of a brick wall is higher than that of aerated concrete, so the wall must either be insulated with a thicker layer of insulation, or the thickness of the brickwork must be increased;

- with external insulation of a wooden house, the surface should be carefully prepared by treating it with antiseptics;

- most often, fastening the layers of a wooden wall pie requires the installation of chipboard or OSB sheathing.

In addition, one should keep in mind all the indicators of the materials from which the walls are built, such as moisture resistance, thermal conductivity and thermal resistance.

Wall preparation

The formation of batten knots on wood is the simplest and easiest, compared with the processing of walls made of other materials. At the same time, the layout design of the material should take into account the basic properties of wood: its high vapor permeability and the likelihood of fungal infection. The frame can be formed from a wooden bar or an aluminum profile. Special fixing points for heat-shielding material and a crate for front trim should be provided. Roll insulation is attached to the walls of the beam on the slats.

A two-layer thermal insulation coating must be mounted on a double crate (simple or supplemented with brackets). You can get a wooden frame using an electric jigsaw (if you choose the right blade), but it is recommended to cut aluminum structures with metal scissors. You should not try to speed up the process using angle grinders, it damages the anti-corrosion layer, reduces the shelf life of thermal insulation. Screwing screws, bolts and self-tapping screws into wooden walls is best done with a screwdriver with a set of nozzles.The battery version of the device is best suited, because then there will be no always interfering wire.

It is advisable to adjust the parts made of wood and drive in dish-shaped dowels with a hammer or a rubber mallet. If you need to mount membrane films, the best solution is to use a stapler with a set of staples. When preparing the crate, each part of it is verified according to the building level: even minor deviations, imperceptible to the eye, often lead to improper operation of the insulation. Of course, even before starting the installation, wooden walls must be impregnated with several layers of an antiseptic composition. The use of a spray gun will help speed up this impregnation.

What material to choose for external insulation of a brick building?

Some materials are better suited for interior wall decoration, and some are specially made. for external thermal insulation. Below is a list of the most suitable options for insulating a brick house from the outside:

- Mineral wool. It is the most commonly used heat insulator and has good water absorption and thermal insulation properties. But it is preferable to use it for interior work, since its main disadvantage is the deterioration of technical characteristics when moisture enters.

- Styrofoam. No less popular material that is perfect for insulating walls from the outside and from the inside. Moisture resistant material that has excellent thermal insulation qualities. Among the shortcomings are flammability and poor steam transmission.

- Extruded polystyrene foam. It has the same qualities as ordinary polystyrene foam, but has a higher level of strength.It is an excellent option for wall decoration outside and inside.

- Warm plaster. It has many advantages, including high sound insulation, excellent vapor permeability and resistance to fire, while there is a low level of moisture absorption. Among the minuses is the need to apply a layer, the thickness of which should be no more than five centimeters. If the house is insulated with this type of plaster, a sufficiently large weight will be noted, which becomes the reason for strengthening the foundation.

No less effective and often used for thermal insulation is also foam and thermal panels. Styrofoam is a fairly cheap material that has most of the advantages, and does an excellent job with its basic functions.

The basis is polyurethane foam, as well as the decorative part, which is most often made of ceramic tiles. This option of thermal insulation is one of the most suitable for exterior wall decoration of brick houses, as it is very resistant to moisture, frost, easy and quick to install and does not need any additional finishing.

Separately, it should also be said about polyurethane foam. This is one of the varieties of plastic that has a foamy texture. Among the advantages of this material are:

- excellent adhesion to any wall material, therefore it is suitable for both brick and concrete, stone and even wood;

- there is no need for additional surface treatment of the walls;

- increases the strength of walls and partitions;

- does not react to temperature fluctuations;

- when finishing, one single solid structure is formed without any seams and gaps.

But such material does not have the best wear resistance, so experts recommend covering it with plaster on top. Polyurethane foam does not burn, however, under the influence of high temperatures it tends to melt, so it is not suitable for use in production.