- External insulation methods

- Insulation of walls under plaster

- Non-ventilated 3-layer system

- Ventilated facade

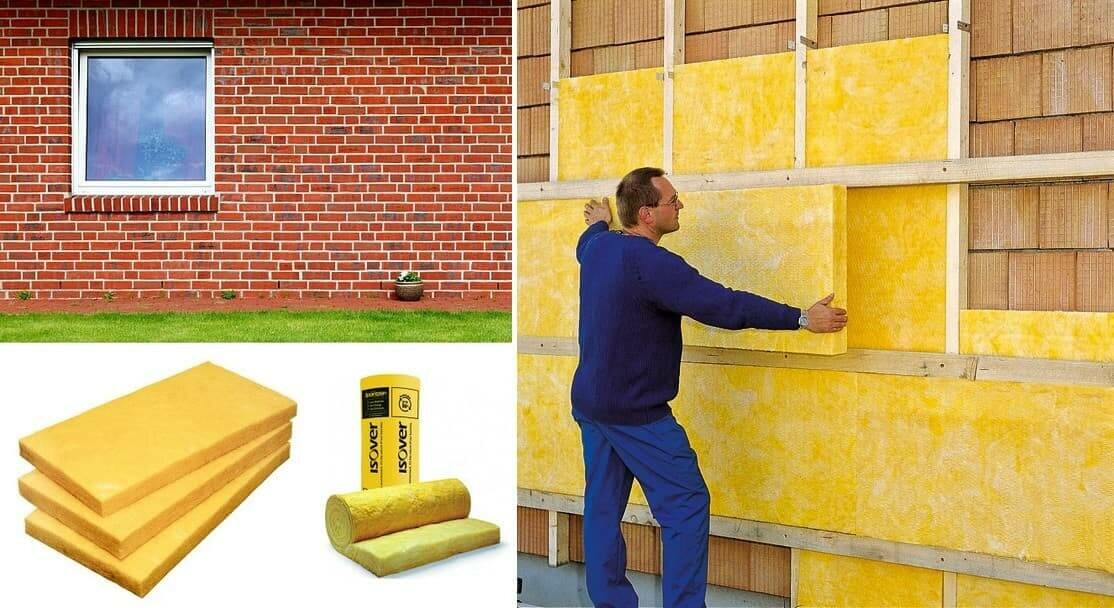

- How to insulate houses from the outside with mineral wool

- Helpful Hints

- Material selection

- Conclusion:

- Conclusion:

- Why vapor barrier and wind protection of heaters are important

- Which brand of wall insulation is better to choose?

- How to insulate a wooden house with foam plastic

- Features of a hinged facade

- As a result - what other options can be considered

- Mistakes that are made when insulating wooden walls

- No. 1: installation of insulation without wood preparation

- No. 2: neglecting the caulk

- No. 3: the wrong side is chosen

- No. 4: the wrong insulation is chosen

- No. 5: improper transportation and storage of insulation

- No. 6: using roll insulation instead of slab

- #7: Wrong Calculations

- popular vote

- Styrofoam

External insulation methods

The materials used to insulate the house from the outside are for the most part universal and suitable for wall structures built from any materials.

But it is important to understand how insulation will affect the wall's ability to "breathe" with a particular installation technology.

Pay attention to the exterior finish on the outside of the insulation. As a rule, plaster, facade panels, siding, facing bricks are used.

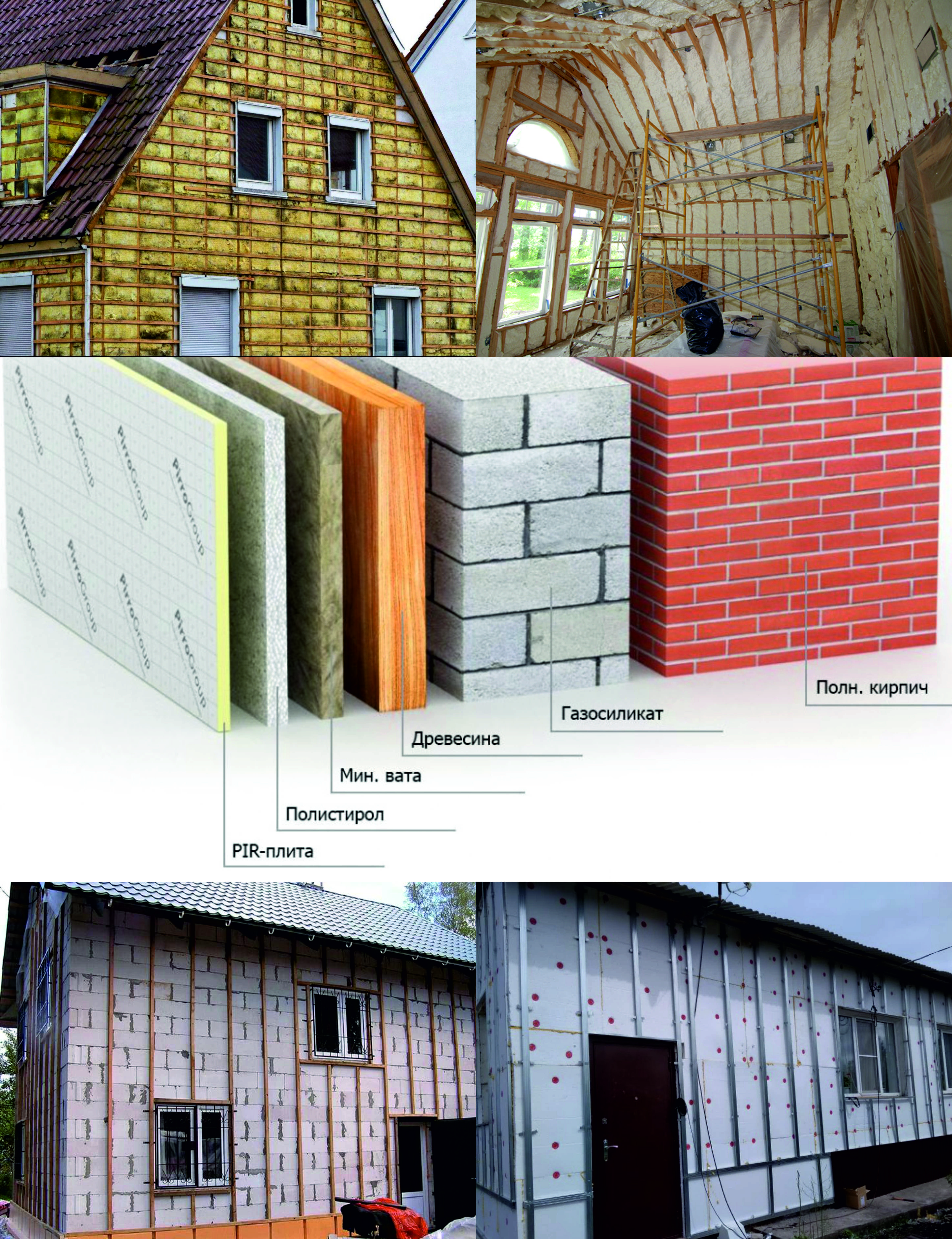

There are three main ways to insulate a building from the outside:

- fixing the heat insulator under the plaster;

- arrangement of a non-ventilated three-layer system;

- installation of a ventilated facade.

The application of a liquid heat-insulating composition has not yet become widespread.

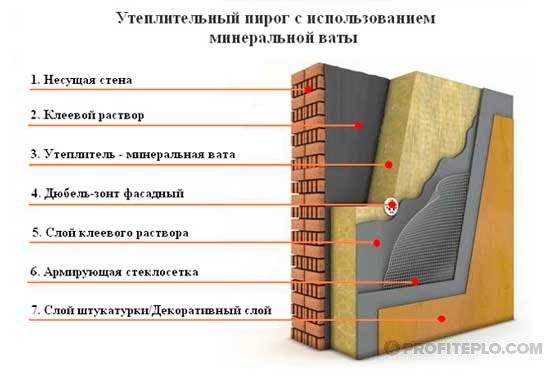

Insulation of walls under plaster

"Pie" of the wall with thermal insulation with mineral wool

"Pie" of the wall with thermal insulation with mineral wool

For installation under plaster, slab heaters are used for the exterior walls of the house. The material is attached with special glue and “umbrella” fasteners to aligned walls (wooden structures are pre-treated with an antiseptic). The cladding elements are mounted "in a run-up" so that there are no long butt joints.

Then plaster is applied with the obligatory use of mesh for reinforcement. To prevent the plaster layer from falling off the polymer insulation over time, it is recommended to treat its smooth surface with an abrasive for better adhesion and use a plaster material with high adhesion.

When choosing a heat insulator, it is important to consider:

- If foam plastic or extruded polystyrene foam is used as an insulating material, the house turns into a thermos, as these materials are vapor-tight. To prevent the walls from dampening from the inside, effective exhaust ventilation must be provided in the house.

- By using mineral wool, you will maintain the vapor permeability of the wall, but provided that the plaster is not painted with acrylic paint, as it creates a film.

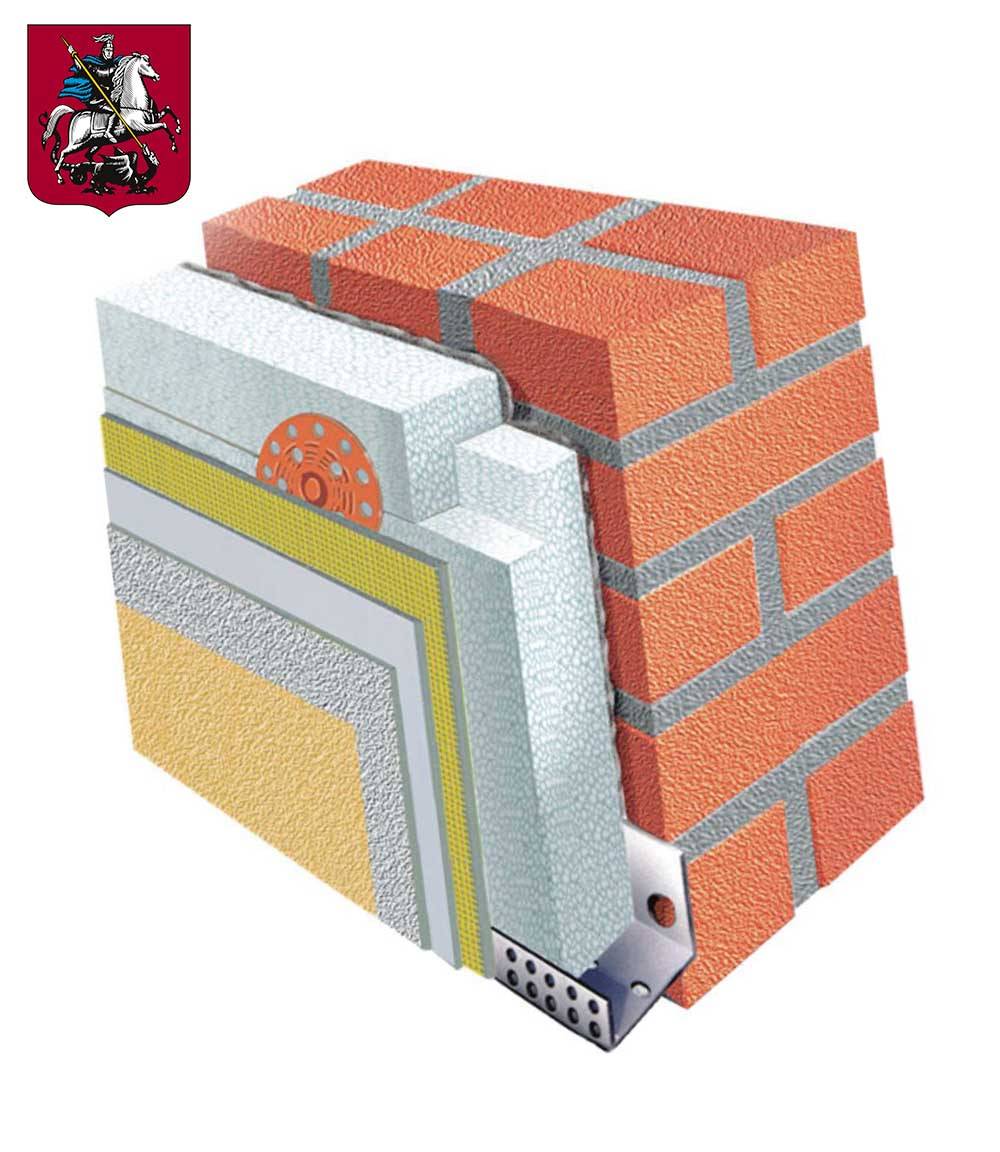

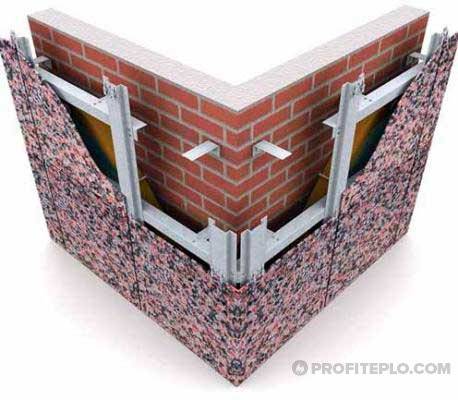

Non-ventilated 3-layer system

Wall section when installing a non-ventilated three-layer system

Wall section when installing a non-ventilated three-layer system

- a heat insulator of any type is attached to the wall with glue or spraying;

- with an indent for the air gap, the outer cladding of the house is made of decorative bricks.

If you insulate a house using this technology with a foamed polymer, you need to take care of good ventilation, since the walls stop "breathing". The advantages of the technology include the ability to make a beautiful brick facade of the house. It is also possible to mount facade panels.

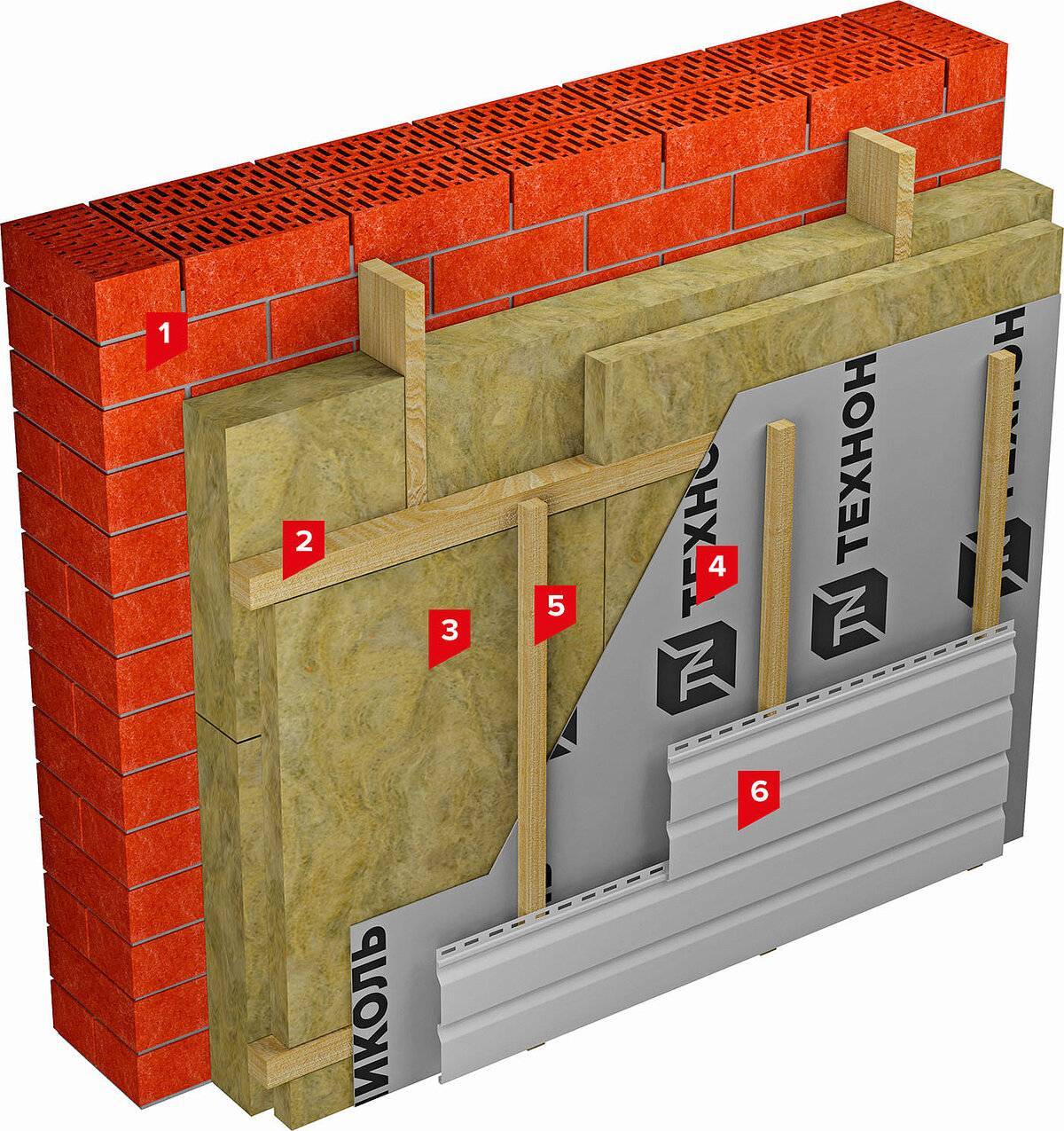

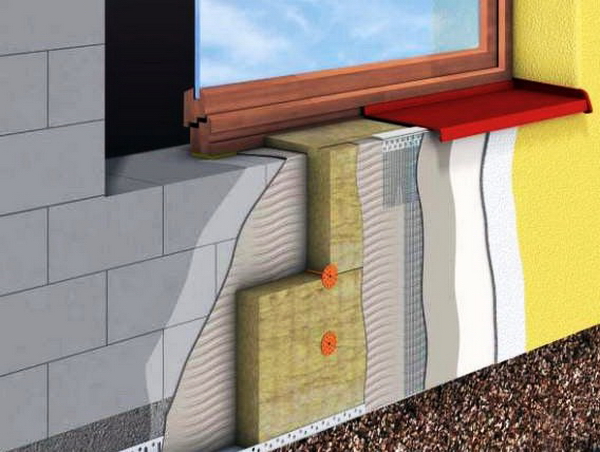

Ventilated facade

Wall insulation with a ventilated facade

Wall insulation with a ventilated facade

The most common option provides for the possibility of sheathing the house with siding, decorative panels, lining. The material for thermal insulation of the facade can be mineral wool, XPS boards, foam plastic.

The construction of the "pie" is as follows:

- crate of boards to create a ventilation gap;

- fastening of hydro-vapor barrier;

- crate (on boards) for laying a heat insulator;

- insulation in the resulting sections;

- windproof film;

- counter-lattice to create an air gap;

- finishing cladding with selected material.

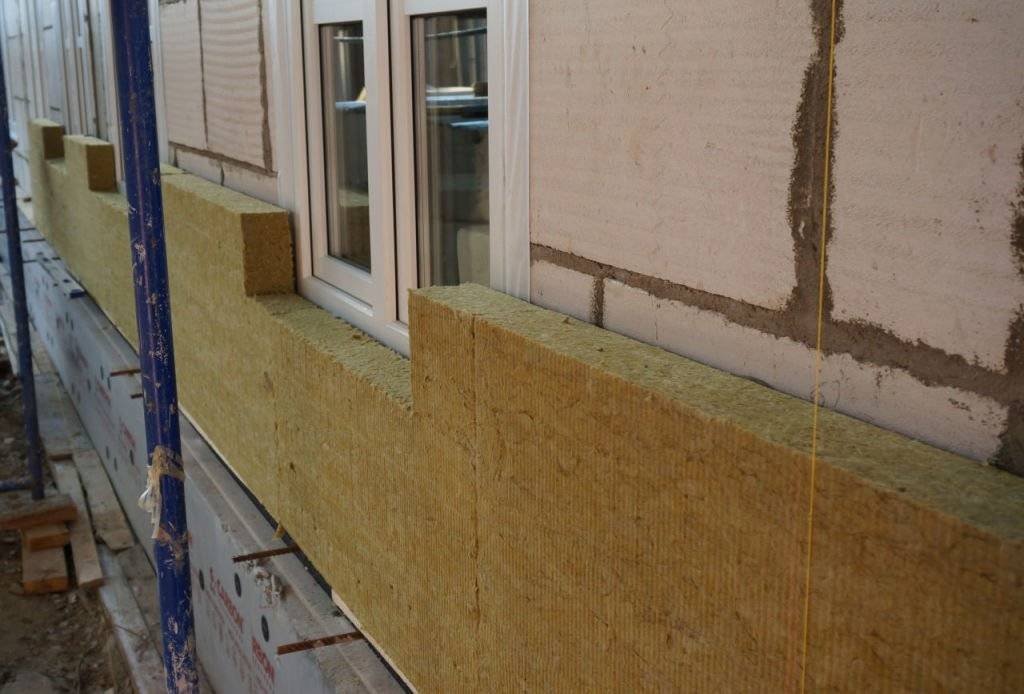

How to insulate houses from the outside with mineral wool

Many people use mineral wool for thermal insulation. This type of insulation is suitable for a house whose walls are built of blocks, bricks or wood. In order for the fastening of the insulation to be of high quality and reliable, a frame made of rails is used. Here, the spreading method is also used, i.e. the distance between the laths of the crate should be slightly less than the width of the mineral wool slab. This can achieve a tight entry of the insulation between the racks of the frame.

If you insulate a log house from the outside, the walls of which have an uneven surface, use two-layer mineral wool slabs with different layer densities. Looser layers of insulation provide high-quality adhesion to the uneven surface of the logs.For the arrangement of wind and hydro protection when insulating walls with mineral wool, you can use a plastic film. As a facing material, decorative brickwork, siding and other materials are used.

Helpful Hints

Professionals insulate houses from reinforced concrete slabs as carefully as possible. This material, not only does it transmit a lot of heat by itself, but it is also designed in such a way that the thermal efficiency is significantly reduced. Developers strive to make reinforced concrete products light and compact by construction standards, so it is recommended to take into account the information from the accompanying documentation.

Foil insulation is a fairly new and practical solution that combines three valuable properties at once:

- curbing the flow of heat;

- blocking the wetting of the insulating layer and its substrate;

- suppression of external sounds.

Modern versions of foil materials allow you to simultaneously insulate both the wall and the partitions in the house, and pipelines, and even auxiliary buildings. Mineral wool, covered with foil on one side, is recommended for use mainly in non-residential premises. Regardless of the type of material, it is attached in such a way that the reflector "looks" into the building.

Industrial waste has become quite widespread in the thermal protection of private houses; many people use metallurgical slag for this purpose. More than others, nickel and copper smelting wastes are in demand, since they are chemically stable, and the limit strength starts from 120 MPa. Using slags with a specific gravity of less than 1000 kg per 1 cu. m, you need to create a heat-shielding layer of 0.3 m. Most often, blast-furnace waste is used to insulate floors, not walls.

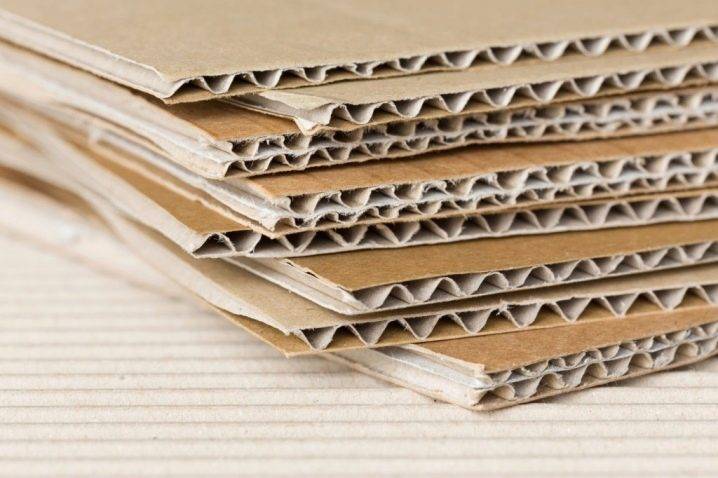

Sometimes you can hear statements about insulation with cardboard. Theoretically, this is possible, but in practice there are a lot of problems and difficulties with this. The only option that meets the necessary requirements is corrugated cardboard, which has air gaps that retain heat.

The paper itself, even if very dense, protects only from the wind. Corrugated material is supposed to be laid in several layers with mandatory gluing of the joints. The fewer connections between individual layers, the better.

The best grades of cardboard:

- hygroscopic;

- smells very bad when wet;

- conduct too much heat compared to other options.

It is much better to use kraft paper: it is also thin, but much stronger than a cardboard sheet. Such a coating effectively protects the main insulation from the wind (in most cases, mineral wool is located below). In terms of thermal protection, kraft paper is identical to natural wood, and it also passes steam well.

The advantages of thermal insulation with ecological wool are at least indicated by the fact that products for it are produced on an industrial scale and even using different technologies. The dry method of applying cellulose involves filling the granules into designated niches

It is important to consider that ecowool is produced in the form of a fine fraction and can “dust”. A number of reagents contained in this insulation can provoke local allergic reactions.

Therefore, all work is carried out using rubber or fabric gloves and respirators (gas masks), and a layer of ecological wool is surrounded by a kraft paper barrier (it cannot be replaced with cardboard!).

How to insulate the walls of the house outside with your own hands, see the next video.

Material selection

Each insulating material has its own characteristics. There are several popular heaters for facade work.

Styrofoam. Insulation of the facade of the house with foam plastic is used very often, as it is one of the lightest and cheapest materials. It is practically impervious to moisture.

It is important to choose the right type. The most popular is the material with a density of 25 kg / m3, it is both durable and warm. There are options with a density of 15 (brittle foam) and 35 (expensive)

High-quality insulation of the facade of the house with foam plastic can only be carried out with the correct calculation of the amount and thickness of the material

There are options with a density of 15 (brittle foam) and 35 (expensive). High-quality insulation of the facade of the house with foam plastic can only be carried out with the correct calculation of the amount and thickness of the material.

Extruded polystyrene foam (EPS) in terms of thermal conductivity is much better than foam plastic - it is 0.029–0.032 W / (m * K). When the facade is insulated with extruded polystyrene foam, due to the interlocking joints of its plates (no seams), there are no cold bridges. Also, XPS is much stronger than polystyrene, does not crumble, and the chance to break off a corner or edge is minimal.

The standard dimensions of a polystyrene plate are 120x60 cm (area - 0.72 m²), and the thickness is 1, 2, 3, 5 and 10 cm. The material is inert to chemical compounds, except for solvents and acids. XPS moisture resistance is achieved due to its closed-cell structure, so it is vapor-tight and durable. Drawing a parallel with simple foam, XPS is an improved version of it.

But the price of this material is much higher than the foam.For comparison, an extruded polystyrene slab 120x60x5 cm in size costs about 80–85 UAH per piece, which is almost 4 times higher than the price of a foam plastic slab of approximately the same size.

Combustibility of the material - G4 and G3, supports combustion, emitting acrid smoke. More expensive flame retardant versions are prone to self-extinguishing.

Conclusion:

Thermal insulation of the facade with polystyrene is an excellent, but expensive option. It is also worth considering that when the EPS is insulated, the walls will become vapor-tight, which means that the humidity in the house will increase - a good ventilation system becomes mandatory.

Mineral wool. Warming the facade of the house with mineral wool is an excellent option, given fire safety and rodent control. This material is practically incombustible. It withstands high temperatures up to six hundred degrees. Rodents really do not like mineral wool, so when using it, the owner of a private house can stop worrying about its safety and the quality of home insulation. It is easy to insulate the facade of a house with mineral wool, because it is flexible and does not require special surface preparation.

Mineral wool (mineral wool, it is also basalt wool, stone wool) is made from the melt of rocks, therefore it is considered an environmentally friendly insulation. The material is fireproof, class - NG (not combustible). In terms of thermal insulation, it is inferior to XPS and is 0.04 W / (m * K).

For wall insulation, mineral wool slabs are used, the size of which depends on the specific manufacturer. Most of them produce standard plates in the size of 100x60 cm, differing in thickness (5, 7.5, 10 cm).

In addition to thermal insulation, mineral wool perfectly absorbs sound, so it is often used as sound insulation.

When buying, you need to pay attention to the density of the material, since for the subsequent finishing of the surface of the insulation, its high density is required - about 145 kg / m³

The material is vapor-permeable, which means that you do not need to pay special attention to the ventilation of the house and the air

What is also important - rodents do not start in the mineral wool

The price of one plate, for example, 120x60 cm (area - 0.72 m²) and 10 cm thick, is about UAH 58–66 (UAH 345–400 per pack). Sold in packs, the number of plates depends on the thickness.

The disadvantages of mineral wool can be called non-moisture resistance. When moisture enters the structure of the material, its thermal insulation properties are greatly reduced. And if the cotton wool is of poor quality, then over time it can crumble / shrink.

Conclusion:

Insulation of the facade with mineral wool in terms of thermal insulation is comparable to insulation with foam plastic, but higher in price. But the material is universal and suitable for both houses that cannot tolerate excess moisture (frame, wooden, adobe / clay), and "classic" buildings (brick, concrete, shell rock, stone). Mineral wool is the choice of careful owners who prefer the safety of insulation instead of its high performance.

Why vapor barrier and wind protection of heaters are important

Vapor barrier is necessary to protect the thermal insulation layer of mineral wool from the influence of moisture and fumes coming from inside the room. The efficiency of the entire thermal insulation system largely depends on the quality of the device and the performance of the vapor barrier. It is advisable to entrust its implementation to professionals or, at least, exactly follow all the recommendations of manufacturers of steam and heat insulation materials.

Mineral wool insulation needs protection from the outside as well. A thick woolen sweater cannot always protect its owner from the wind. But it is worth putting on a windbreaker made of thin, but not blown fabric over it, it immediately becomes warm and cozy.

Similarly, a layer of insulation will reliably retain heat only when it is protected by a reliable hydro-windproof membrane fixed on the outside. At the same time, wind protection not only helps to save heat inside the building, but also prevents the fibers of the heat-insulating material from weathering, and also protects it from atmospheric moisture.

The material used for wind protection must not only retain moisture and cold air coming from outside, but also freely pass water vapor from inside the insulation. In other words, it must simultaneously be vapor permeable and airtight. After all, moisture, getting inside the insulation, significantly reduces its thermal insulation characteristics, and when negative temperatures appear outside, the insulation also begins to freeze.

In order to protect against these factors, multilayer modern hydro- and windproof membranes are used. They create the most favorable conditions not only for the functioning of the insulation, but also for the people living in the building.

At the same time, it is very important to observe the technology of their installation. It is unacceptable to use polyethylene or any other film that contributes to the occurrence of a “thermos effect” inside the building.

In addition, their use in addition to non-professional installation may lead to the loss of mineral wool insulation in all dimensions of the structure.

Which brand of wall insulation is better to choose?

The rating includes products from well-known manufacturers among builders, as well as from little-known companies. To better navigate the brands, you should take the time to get to know each of them:

- Penoplex is a Russian company founded in 1998. One of the country's largest manufacturers of polymeric materials for decor and interior decoration. All procedures for the manufacture of materials are carried out at our own production sites.

- Tsmceramic is an international group of companies. It has become widely known for its innovations in the field of energy saving and the production of protective coatings for all surfaces. The main direction of production is heat-insulating materials that meet advanced standards.

- Isover is part of a French concern with a long history. It is world famous, as it includes one of the largest industrial enterprises on the planet. The production of thermal insulation materials began in 1937.

- Izovol is a domestic manufacturer that has appeared relatively recently. The company's products are of high quality, confirmed by international certificates.

- Green Board - belongs to Construction Innovations LLC and is the only manufacturer of fiberboard materials in Russia and the CIS. The highlight of the company is the environmental friendliness of products, achieved by a special manufacturing technology.

- Teploknauf is an international company founded in Germany in 1932. A significant part of the brand's production enterprises is located on the territory of the CIS countries. Long-term development has allowed the organization to become one of the most advanced in the world.

- Ursa occupies a leading position among European manufacturers of building materials.Offers technological solutions for heat and sound insulation. The brand's products are used in all areas due to the unique set of characteristics that make them optimal in various situations.

- Bronya is a Russian company that produces liquid wall insulation. Its products are practically unparalleled. The convenience and efficiency of materials allowed the brand to quickly gain recognition and fame.

- TechnoNikol is a domestic manufacturer of materials for roofing, hydro- and thermal insulation. Founded in 1992. The company's factories are located in Russia, Belarus, European countries. It is one of the five largest European manufacturers of insulating materials.

- Izospan is a pioneer in the production of vapor-moisture protective materials. The company's products have been manufactured since 2001. During its existence, the company has become one of the most famous in the CIS. Products are manufactured at our own production base: all stages are controlled by the company's specialists, which ensures high quality materials.

- ShelterEcoStroy - produces thermal insulation without the use of carcinogens. This is the first Russian brand that manufactures such products. Due to the ease of installation and comfort in operation, the company's products quickly became popular in the CIS countries.

- Euroblock is a Russian company founded in 1995. The brand's products are constantly evolving: experts make materials not only better, but also more convenient to use. The emphasis is on the functionality of the insulation, which is constantly being expanded.

How to insulate a wooden house with foam plastic

If you wish, you can find examples of using foam to insulate a wooden house from the outside.Moreover, there is a technology that does not impair the "breathing" properties of the walls and the level of comfort, which is ensured by natural gas exchange between the premises and the street. This is achieved by creating a ventilated gap between the insulation and the wall. Moreover, in this case it does not matter what the walls are made of - from a bar or a log.

In order not to impair the "breathing" properties of a wooden house, a ventilated gap must be created between the foam and the wall

In our video, we will look at how polystyrene is produced, is polystyrene harmful and where is it used?

What happens if it is wrong to insulate with polystyrene - in the video:

Features of a hinged facade

In this case, the requirements for the peel strength of the insulation surface are not as high as for the "wet facade", so the density of the mats can be less than 125 kg/m³, but higher than 80 kg/m³.

There are ready-made systems of hinged facades with their own fastening subsystem, a set of panels and fasteners. The only drawback of such systems is the need for individual adjustment to the specific geometry of the house and walls. As a rule, these systems are designed for houses made of brick or building blocks, and aluminum sandwich panels, artificial stone, porcelain stoneware are used as cladding.

For facing wooden houses, imitation of timber, block house, planken, siding are usually used. That is, those materials that are more in line with the aesthetics of a wooden house.

If you want to change the decorative qualities of a wooden house, you can use facade panels made of artificial stone when cladding

The most common practice is the manufacture of lathing from a wooden beam - it is easy to adapt to the surface of the walls, it is easier to fix, it does not change size with temperature changes and does not serve as a "cold bridge".

Wooden crate is the easiest option

The only drawback of wooden structures is low resistance to moisture. Therefore, both the elements of the crate and the finishing panels made of natural wood must be treated with an antiseptic before installation.

As a result - what other options can be considered

The article described only the two most common ways to insulate a wooden house from the outside. What is better in your case and other options should be discussed with the developer, who knows the local conditions. The use of eco-wool has not yet become widespread, although the technology is quite simple - mounting the crate to the wall, applying a “wet” insulation (mixed with glue) to the surface with the help of special equipment, sheathing with facade panels along the crate. Brick cladding on flexible connections follows the same rules as for a stone house, with the only restriction at the choice of insulation - use only mineral wool.

Despite the apparent simplicity of the whole process, when installing any type of insulation, there are a sufficient number of pitfalls that must be taken into account so that all the work is not done in vain. If there is no experience, then it is always better to invite a professional, especially since self-respecting developers perform all work under the contract and give a guarantee.

Mistakes that are made when insulating wooden walls

When carrying out facing work on your own and preliminary insulation of a wooden house, mistakes are often made, which we will discuss below. The result is the inefficiency of the insulation, dampness in the house, the destruction of wood and the loss of its performance properties. The following 7 errors can be considered typical - they are most common.

No. 1: installation of insulation without wood preparation

Often, old log houses are subject to external insulation. Years later, the log house gave the final shrinkage, and its parameters will no longer change, which means they will not affect the front finish.

But it is important to understand that the years of exploitation of wood "in the open air" could not pass without a trace.

Due to the fact that the insulation and sheathing will completely cover the walls, before starting work, an audit of the enclosing structures should be carried out in order to identify weak areas that need to be repaired and processed. It is necessary to treat the tree with antiseptics and antiperms

It is important not to leave untreated areas. The solution should be applied 2-3 times

Each layer must dry completely. Warming should begin when the wood is dry.

In order for the wood to serve for a long time without being biodegraded or damaged, it should be treated with a special antiseptic impregnation.

No. 2: neglecting the caulk

To prevent the log house from being blown, a caulk is used. At the same time, the structure is insulated. When examining walls before insulation, it is necessary to carefully examine all areas where caulking is used - whether it sticks out, how tightly it holds. It happens that protruding, loosely twisted material is pulled away by birds.

Insulation caulk

No. 3: the wrong side is chosen

Log houses are insulated exclusively from the outside. This is a rule that must be strictly observed. Only this method allows you to ensure the correct operation of wood and thermal insulation material. If you choose the other side and fix the insulation inside the house, then both the wood and the insulation will get wet. As a result, a violation of the microclimate in residential premises and an increase in humidity.

Log houses are insulated exclusively from the outside.

No. 4: the wrong insulation is chosen

Insulating material is presented on the construction market in a wide range of prices and performance characteristics. Of all the variety, meanwhile, only a few are suitable for insulating wooden houses: mineral wool (basalt and glass), as well as extruded polystyrene foam. The latter has excellent performance, except that, when melted, it releases substances that are extremely dangerous for humans. Therefore, the only alternative for warming a wooden house is mineral wool.

One of the best insulation materials is mineral wool.

No. 5: improper transportation and storage of insulation

It is important when buying to check the tightness of the packaging of the heat insulator. It must not be damaged and the contents must be dry.

If the insulation gets wet, then its thermal insulation properties will decrease significantly. It is recommended to remove the insulation from the package one day before installation. And after it is fixed on the wall, it is necessary to immediately continue work on wall cladding so that the insulation does not remain “open”.

Check the material carefully before buying

No. 6: using roll insulation instead of slab

Mineral wool is the best way to insulate wooden walls.On sale you can find plates and rolled material. Why are mats not recommended? Because, being in a vertical position, over time, sagging of the insulation will inevitably occur, gaps will appear through which cold air will rush into the house. Plate insulation keeps its shape throughout the entire period of operation, does not deform, does not sag.

Slab insulation keeps its shape throughout the entire period of operation

#7: Wrong Calculations

Too thick or thin layer of insulation will cause a violation of the microclimate in the room. Usually, the heat insulator is laid in two layers of 5 cm. In the south, one layer is enough, and in the north, three are required.

Correct calculations will help maintain the correct microclimate in the room

popular vote

And what material would you choose or advise for home insulation?

Styrofoam

16.67% ( 1 )

Save the voting results so you don't forget!

You must vote to see the results