- Attic floor insulation options

- Should ceilings be insulated in a wooden house?

- Ways to insulate the ceiling

- How to insulate the ceiling in a private house: modern materials

- Recommendations for insulation work

- How to correctly calculate the thickness of the insulation for the ceiling?

- How to insulate the ceiling of the bath: first, decide on its type

- Why is it important to calculate correctly?

- Warming methods

- Mineral wool

- Types and materials

- Mineral wool

- Polyethylene foam

- Styrofoam

- Styrofoam

- Styrofoam and polystyrene

- Which to choose?

- Peculiarities

- Loose types of heaters

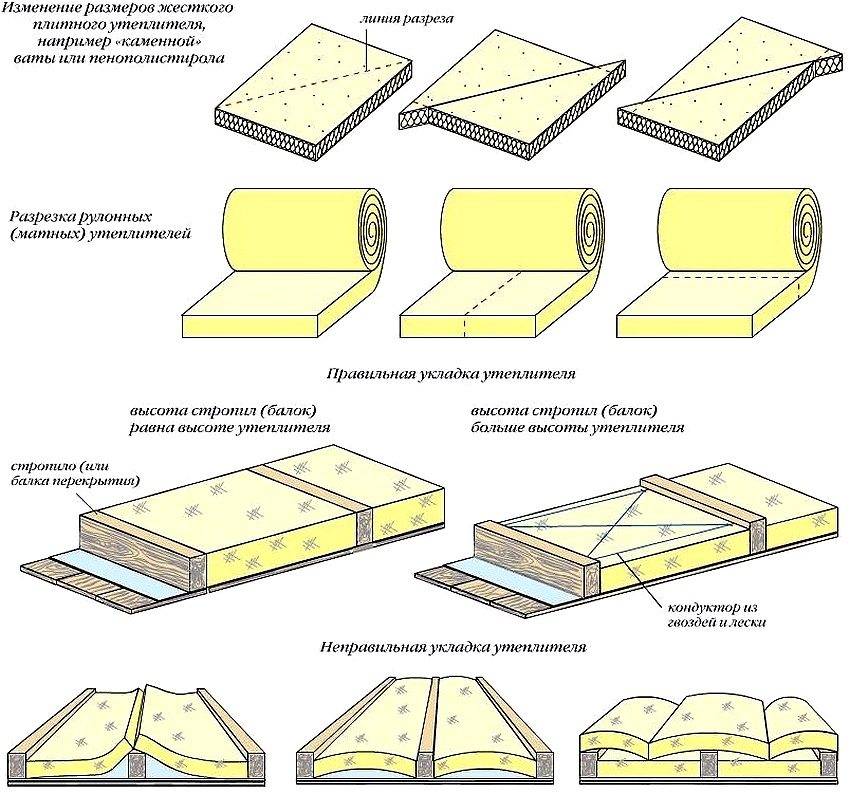

- The specifics of the installation of mineral wool boards

- Calculators

- Expanded polystyrene technology

- Table: Comparison of the properties of ceiling insulation

- The better to insulate the ceiling of a private house

- Insulation calculation

- Conclusions and useful video on the topic

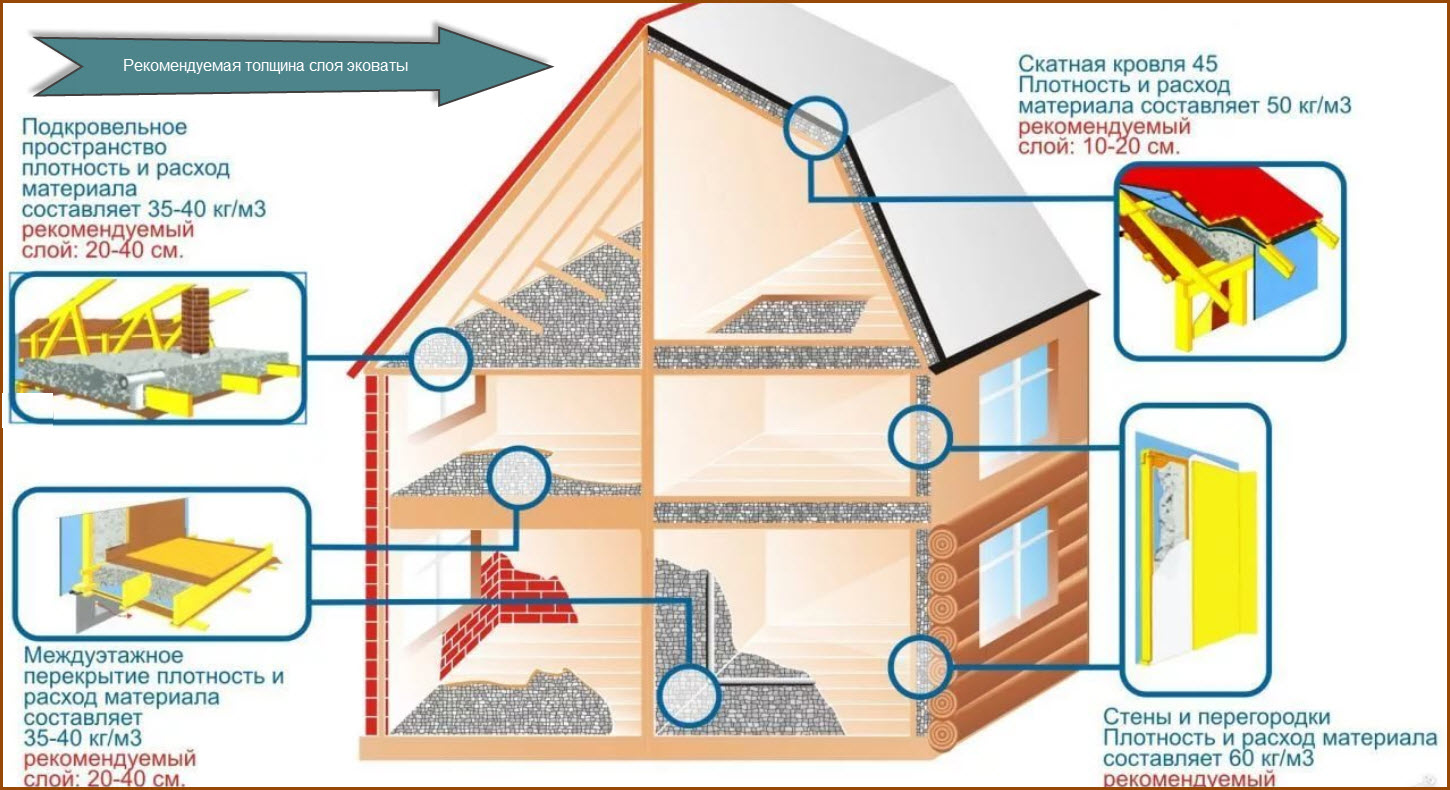

Attic floor insulation options

With an external version of insulation, thermal insulation is laid in the attic. If the attic space is not used, then the insulation does not need decorative trim, which distinguishes this option from the previous one. In addition, it is much more convenient to work with external insulation.

Internal insulation involves fastening heat-insulating materials to the inner surface of the ceiling and mounting suspended structures made of drywall, plastic, wood, etc. It should be borne in mind that with internal insulation, 15-20 cm of the height of the room is lost. Therefore, if your ceiling is at or below 2.5 m, then you should give preference to insulation from the attic.

Should ceilings be insulated in a wooden house?

Wood is a building material with good thermal conductivity. This property affects the loss of heat in the room, especially if its ceiling is also made of wooden materials. Experts have calculated that heat loss through the ceiling in a wooden house (without proper thermal insulation) can be 20%. The reason for this lies in the laws of physics: the warm air inside the room rises and flies out through a poorly insulated ceiling with all kinds of cracks. Therefore, insulation is a necessity, especially in a private house, and helps to avoid significant energy costs.

Ways to insulate the ceiling

Material content

First you need to talk about ways to insulate the ceiling. In our case, this will be the ceiling of the last floor, above which there is only an attic and a roof - it is through it that the main heat losses occur.

The first method of insulation is external. If you do not plan to make an attic under the roof, then this method is suitable for you. A frame is mounted on the floor of the attic with the help of a wooden beam and boards, the inner space of which is filled with heat-insulating material. The design of the frame depends on what kind of insulation you use.

Scheme of external insulation of the ceiling in the house

If you want to arrange an attic or a small warehouse in the attic, then the ceiling should be insulated from the inside. In this case, in the rooms of the last floor, the above-mentioned frame is formed on the ceilings, fixed with dowels-nails. After laying the heat-insulating material, it is closed with drywall, plastic panels or clapboard. This method of insulation is very time consuming and also reduces the height of the dwelling. Therefore, at the stage of building a house, this moment should be taken into account and the walls of the last floor should be made a little higher.

Scheme of internal insulation of the ceiling in the house

How to insulate the ceiling in a private house: modern materials

In a private house, thermal insulation of the ceiling is far from the last issue. The main thing is to insulate the ceiling cheaper and make the room warm.

To date, there are a large number of materials that can be used for thermal insulation of the ceiling in a private house.

List of materials for ceiling insulation:

- Expanded clay;

- Mineral wool;

- Ecowool;

- Styrofoam;

- Penoizol;

- Stone wool.

Expanded clay is a loose insulation. This is a non-combustible material. It is environmentally friendly, has good thermal insulation and is not liked by rodents and pests. Expanded clay easily absorbs water. For insulation, it is very heavy and it needs a strong substrate. Thermal insulation of the ceiling with expanded clay will cost you inexpensively. One of the most popular materials for ceiling insulation is mineral wool. It is an excellent thermal insulator, but it has a drawback. It is hygroscopic. Ecowool is also used as a material for ceiling insulation. This is an environmentally friendly material. It has good thermal insulation characteristics.Ecowool production technology is based on the processing of cellulose. Styrofoam is also used to insulate the ceiling. It is very easy to use, light in weight, fireproof. You can also insulate the ceiling with stone wool. This is a fibrous insulation.

Recommendations for insulation work

Insulation work is best done in the summer, when air humidity is minimal.

Walls for insulation in the room must be perfectly dry. You can dry them after additional plastering, finishing work on leveling surfaces using building hair dryers and heat guns.

Stages of surface insulation:

- Surface cleaning from decorative elements - wallpaper, paint.

- Treatment of walls with antiseptic solutions, priming the surface with deep penetration into the layers of plaster.

- In some cases, when installing polystyrene foam and electric heating elements, the walls are pre-leveled with waterproof plaster for bathrooms.

- Installation of insulation must be carried out in accordance with the instructions prescribed by the manufacturer for this type of material.

- Mounting a protective partition for applying the final finish, or covering the surface with a construction mesh, plastering it.

- Creation of a single composition with the overall design of the room.

Wall insulation inside the house is one of the most effective ways to protect your home from the penetration of cold and the negative effects of condensate, the main thing is to follow the technological sequence of stages. You can read more about the technology of home insulation from the inside in this material.

How to correctly calculate the thickness of the insulation for the ceiling?

If, after taking measures for the thermal insulation of the ceiling structure, the result is not satisfactory, there is only one reason - the incorrectly selected thickness of the Rockwool Roof Butts insulation, whose characteristics are stable. Also, incorrectly processed joints with external walls, and the appearance of cold bridges due to errors in the installation of the frame, and other shortcomings will also necessarily affect.

Mineral wool boards

The thickness of the insulation must be calculated based on several indicators:

- coefficient of thermal conductivity of the insulation;

- the thermal resistance of the ceiling, which is determined by two indicators: the thickness of the material and its thermal conductivity (in the event that different materials are used, their thermal conductivity indicators are summed up);

- calculated temperature indicators of the external and internal surfaces of the ceiling;

- design features;

- climate regulations.

The calculation is based on the value according to which the coefficient of thermal conductivity of the material should be maximum 0.24 W / m² K, which corresponds to 10-20 cm of a layer of thermal insulation made of mineral wool. When choosing a heater, experts recommend focusing on a thermal conductivity equal to 0.04 W / m² K.

After the required thickness of the heat-insulating layer is determined, it is recommended to add 50% to this value - in this case, the effectiveness of using the selected type of insulation can be fully guaranteed.

How to insulate the ceiling of the bath: first, decide on its type

Equally important is the type of ceiling used in the bath. ON A NOTE

The ceiling is laid only after the roof is laid (read about roof insulation in a separate article), otherwise there is a high risk of damage to materials!

ON A NOTE. The ceiling is laid only after the roof is laid (read about roof insulation in a separate article), otherwise there is a high risk of damage to materials!

There are several ways to lay the ceiling:

- hemmed (intended for solid baths with a large area);

- flooring (used in the construction of small baths);

- panel (has a wide scope).

For a false ceiling, any heat-insulating materials are suitable. The most convenient installation will be tiled synthetic or rolled foil materials. For a floor ceiling, we recommend all types of loose or mineral insulation.

ATTENTION! Do not forget to make protective sides along the edges of the flooring to prevent the heat-insulating material from spilling. The height of the sides must be equal to or greater than the layer of loose insulation.

The design of panel ceilings is suitable for any type of insulation, voluminous synthetic insulation and foil material will be a good choice.

Why is it important to calculate correctly?

In the modern world, thermal insulation is necessary not only for greater comfort, but also for savings. The cost of heating is constantly growing, which hits the pocket more and more, and the task of the heater is also to save money by retaining heat.

In winter, heat is retained indoors for much longer, and in summer, on the contrary, it retains excess heat from the street.

It seems to many that the greater the thickness of the slab of thermal insulation material, the greater the savings. But this is far from the case: it will be cooler in summer, and much hotter in winter, but the wall structure may undergo deformation and destruction. A smaller thickness can lead to an additional increase in energy consumption.

Insulation of the house structure (ceiling, walls, floor) is a necessary part during repair or construction (both in a residential building and in buildings intended for people to work). The selection of high-quality materials for thermal insulation is an important point in this matter, but much more important is the competent selection of material thickness. Factors such as: the durability of the structure and technical characteristics during the direct operation of the building depend on this.

If we compare the thermal conductivity of different raw materials, we can see that the mineral wool slab conducts it better than the construction of expanded clay concrete blocks.

Warming methods

Reducing heat loss depends on the correct selection of material, as well as on its location on the building. There are several ways to insulate walls, which differ in their properties, having both advantages and disadvantages.

There are the following ways to insulate walls:

- Wall. It is an ordinary brick partition with SniPovskaya thickness from 40 cm.

- Multilayer insulation. It is a wall covering on both sides. This is done only at the time of the construction of the structure, otherwise, part of the wall will have to be dismantled.

- External insulation. The most common method is performed by insulating the outer side of the wall, after which a layer of finishing is applied. Among the disadvantages of this method is the need for additional hydro and vapor barrier.

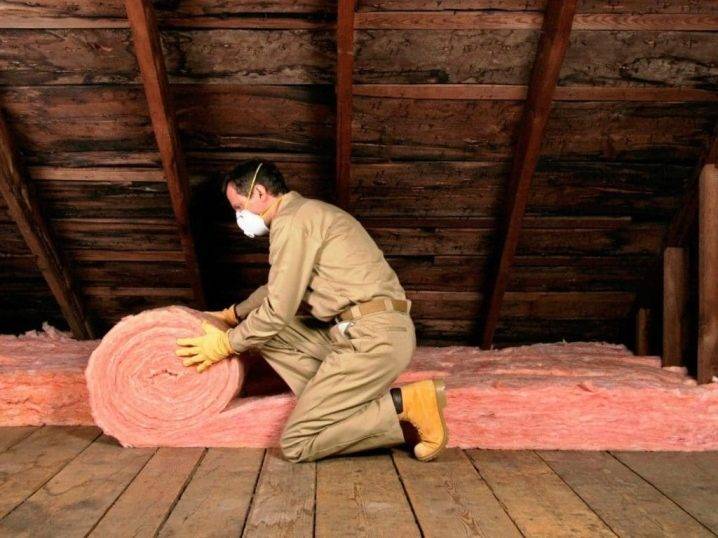

Mineral wool

One of the best options in terms of price and performance. Suitable for laying on the roof side and on the side of the room. You can choose from two varieties - rolls or plates. The latter are easier to install, but more operations are required and the insulating lining will be less uniform. In cases where the ceiling is insulated from inside the room, its height will decrease quite noticeably, since it will be necessary to lay a layer of 10 - 20 centimeters. Therefore, laying is best done from the attic.

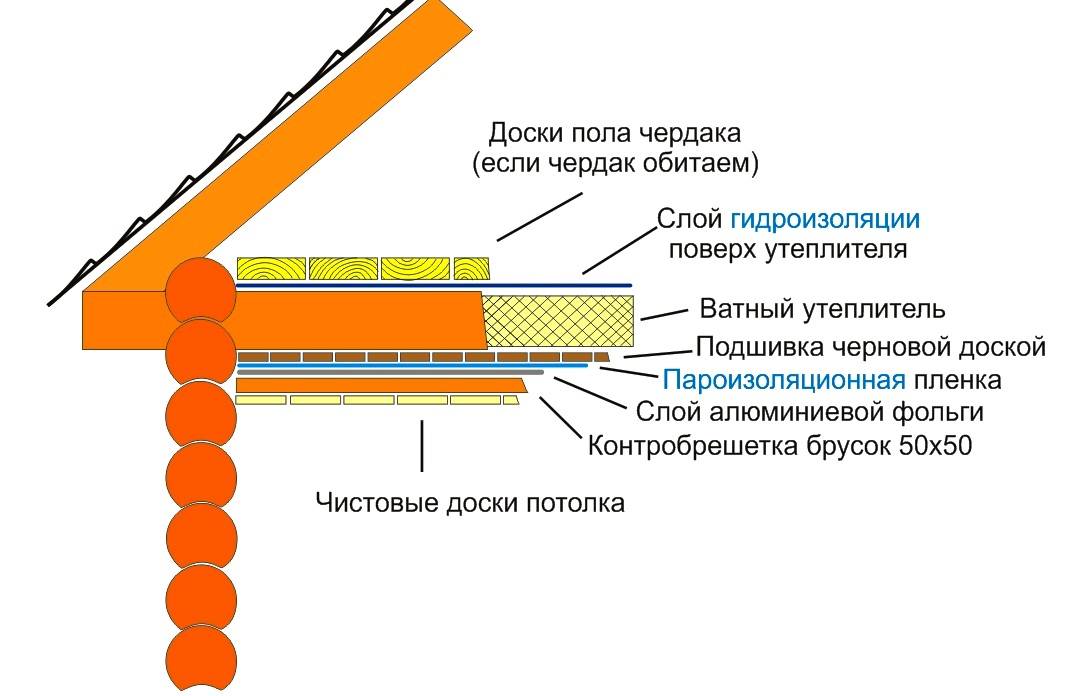

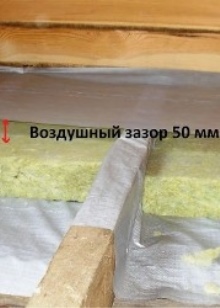

Laying from the outside is carried out as follows: a layer of vapor barrier film is laid between the floor beams, which will prevent moisture from penetrating into the insulation, then mineral wool is laid and again covered with a layer of an insulating membrane or film. After that, if necessary, the floor is laid or ladders are laid from the boards, on which it will be possible to walk.

Types and materials

Various shops and building materials markets offer a large selection of heaters. Against this background, several varieties stand out.

Mineral wool

Mineral wool is a common textile fiber obtained by various methods. Fiber made from volcanic materials is called stony. Slag wool is created on the basis of blast-furnace slag. Glass wool is a raw material created on the basis of glass melt. As for the thickness of the insulation, the indicator ranges from 2 to 20 cm.

Polyethylene foam

Polyethylene foam in the form of a roll on a foil basis is a new generation of insulation. The thickness of such material is from 3 to 20 mm. Polyethylene foam is the most effective material used for ceiling insulation.The small thickness makes it easy to install it in a private house and apartment.

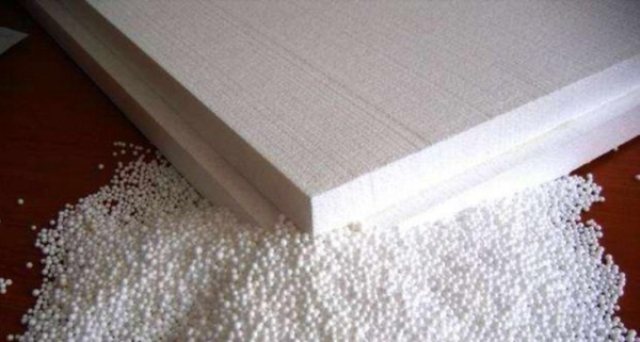

Styrofoam

Styrofoam is a material made from plastic mass in the form of cells. It is produced in the form of squares measuring 1 x 1 m. The thickness of the sheet is from 2 to 10 cm. The density of the material varies between 15-25 kg / m2 (foam 25 kg / m2 is often used to insulate the ceiling). Styrofoam is often used to insulate suspended frames, walls and other coverings of a private house. It has good reviews.

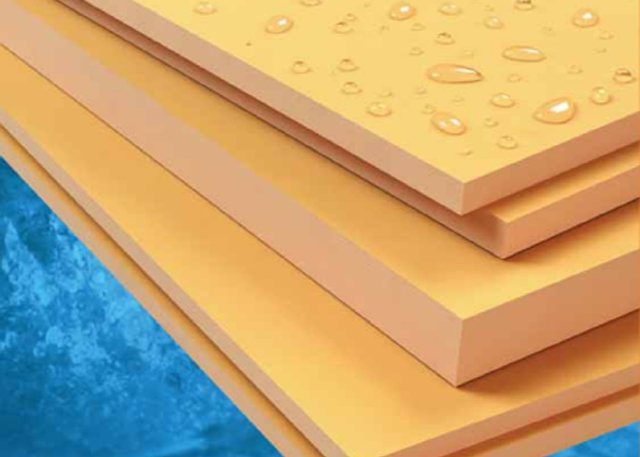

Styrofoam

Extruded polystyrene foam is formed by the production of special polymers: the finished insulation is created by extruding the material through a special mold measuring 120 × 60 cm. The thickness of the finished sheet ranges from 10 to 200 mm. For insulation of ceiling structures, a material with a density of 25-45 kg / cm2 is more often used. In simple terms, this is foam plastic made using a different technology. Its main difference is the higher strength of the material.

You can insulate the ceiling with loose expanded clay. This material is often used for insulation of attic floors. In addition to the basic materials, insulation can be carried out with isolon, penofol, penoplex

It is important to fix the insulation material correctly. The materials are suitable for insulation on the top floor, veranda, basement, attic

Styrofoam and polystyrene

These heat insulators are also classified as inexpensive. Styrofoam is a little cheaper, and polystyrene is more convenient to work with, as it does not crumble. With both heat insulators, it is possible to insulate the ceiling under a cold attic from the side of the living rooms, as well as from the outside.

If the work is done from the inside, sheets of foam or polystyrene are simply glued to the ceiling.Upon completion of the work, the ceiling is given a presentable appearance with the help of a suspended ceiling composition or in another way. It is worth remembering that some types of these heaters can emit harmful substances, as well as that both of them are very flammable.

Which to choose?

Below are some recommendations that will help you decide on the right choice of insulation for the attic in a private house:

- If you plan to deal with thermal insulation on your own, then you should give preference to expanded clay, polystyrene foam or mineral wool. Working with ecowool and polyurethane foam requires specialized equipment and some technical training - these materials are best left to professionals.

- If the attic floor is made using reinforced concrete slabs, then it is optimal to use expanded clay as a heater, but it is more expedient to protect wooden floors with mineral wool or cellulose wool, since these materials are considered "breathable", and they prevent the formation of condensate, as well as the destruction of wood.

- It also significantly affects the choice of material and the planned budget. For example, if the owner of the house has access to sawmill waste, then you can simply use sawdust and shavings - this will be the most environmentally friendly and at the same time cheap way of thermal insulation.

Peculiarities

Thermal insulation of the ceiling will save heating costs in a private house. For residents of apartments, this will help increase the room temperature during the heating season. An additional insulating layer will get rid of mold and fungus on the ceiling.

When building your own house, you need to remember the importance of keeping warm and initially lay the height of the ceiling, taking into account the parameters of the insulation. Depending on the use of the attic space, choose a method

When the attic does not involve intense load, then thermal insulation of the attic floor itself is used. If the roof is used as an attic, then it is advisable to insulate the ceiling from the inside.

For installation on top of the ceiling, a vapor barrier must first be laid to protect the structure from moisture. As a vapor barrier, polyethylene or anti-condensate films, glassine and modern membranes are suitable. If bulk insulation is used, then the vapor barrier will also have a protective function, preventing its particles from entering through the seams of plates or boards into the interior.

Apartment owners living on the upper floors should also think about self-insulating the ceiling from the inside. In a panel nine-story building, taking into account the deterioration of the housing stock, it becomes necessary to protect the outer walls and ceiling. To do this, you can use different types of materials. The main goal of proper installation is to create a monolithic layer of insulation to prevent leakage of warm air.

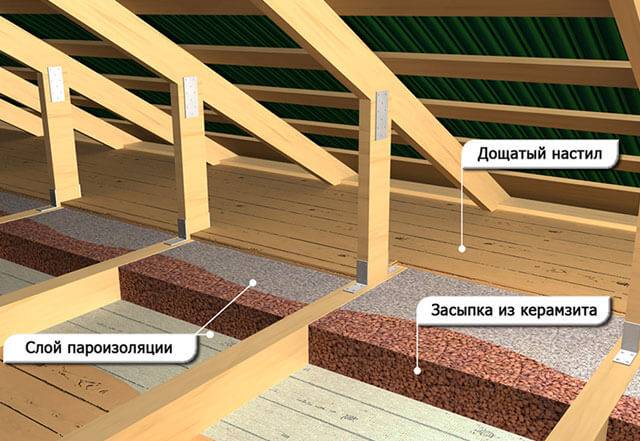

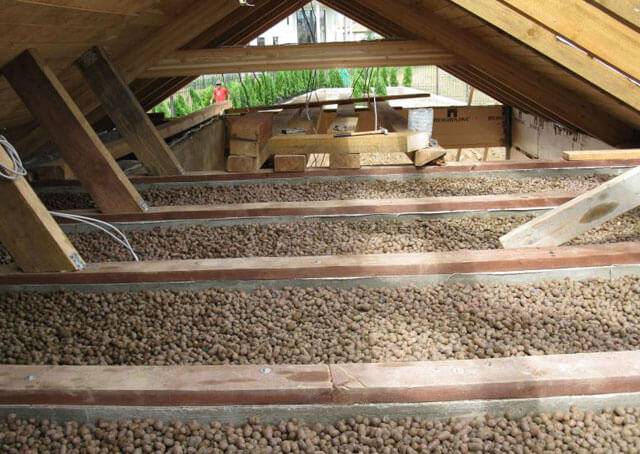

Loose types of heaters

Such heat-insulating materials are used only for warming attic floors from above. The most popular among them is expanded clay.

Granules of this bulk material come in three fractions:

- The smallest of them is called sand, since expanded clay does not exceed 5 millimeters in diameter.

- Larger and most popular granules differ in diameter up to 20 millimeters. They are also called gravel.

- Expanded clay crushed stone has a diameter of 20 to 40 millimeters.

In terms of their qualitative characteristics, the fractions are the same, and their difference lies only in size. The cost of expanded clay is affordable. Compared to other types of bulk materials, there is much less dust from expanded clay. The great advantage of this

insulation for the ceiling lies in the indifference to it of rodents. But, like any loose heat insulator, expanded clay is afraid of a high degree of humidity, since it is able to absorb moisture.

Sawdust is also considered to be a fairly effective insulation, given that the price for them is more than affordable. But there is an important nuance here - they are not used when they are fresh or in their pure form.

So that rodents are not found in this loose dumping, it must be kept in a dry room for about a year. Then it is mixed with "fluff" - the so-called powder of slaked lime, observing the proportion of 8 parts of sawdust and 2 parts of lime. From already aged sawdust, you can make plates for insulation, which have a fairly high efficiency.

The manufacturing technology of such a heat insulator is simple:

- Sawdust, lime and cement must be mixed in a ratio of 9:1:1.

- The resulting mass is moistened and then poured into pre-prepared forms and rammed a little.

- After about 7 days at room temperature, they dry out and are ready to use.

The specifics of the installation of mineral wool boards

For this, one of two finishes is usually used:

- Installation of wooden bars with a thickness slightly larger than the insulation using anchors on the floor. The optimal distance between individual jumpers is up to 70 cm. Further, the voids between the bars are filled with slabs cut to size.A great way to quickly insulate a flat horizontal plane. If curvature is detected, the lintels can be lifted with wedges. This usually takes a lot of time.

- Floor curves can be insulated in a faster way. After applying the same markings as in the previous case, the installation of metal suspensions with “wings” bent down is carried out. The distance between the individual suspensions is approximately 1 m. After gluing the insulation to the ceiling, holes are made in the thermal insulation directly under the wings bent down (any sharp knife is suitable for this). In this case, gypsum boards or lining are used as finishing sheathing. To do this, you need to install wooden planks or ceiling CDs on the suspensions.

Calculators

For those who do not want to learn these formulas by heart or do not have the opportunity to calculate everything on their own, remembering various clarifications, there are a huge number of online calculators.

They are specially designed to select the optimal thickness and take into account a variety of factors and characteristics of both insulation and walls. Some of them have a built-in range of products in which you do not need to enter additional values - it will be enough to select the type of insulation, its brand and model, as well as the type of material from which the wall is made.

Very popular among such calculators is ROCKWOOL, which was developed by experienced construction professionals. This calculator also calculates the energy efficiency of the insulation, giving all the necessary values in the report.Also, for those who do not want to understand the functionality, the website of this calculator provides a simple step-by-step instruction that is easy to understand: just click on the "Start Calculation" button and follow the prompts.

It should be remembered that when ignoring the calculations of the thickness of the heat-insulating material, a number of problems may appear, including damage to the structure of the structure itself, which is almost impossible to fix, and if possible, this will require additional, much higher costs (you will have to wait for an urgent or overhaul from the management company).

How to calculate the thickness of the insulation, see the following video.

Expanded polystyrene technology

Polymers are usually used for insulation of reinforced concrete floors and ceilings, and on both sides. In order to isolate the structure from the inside, the surface must be prepared - seal the joints of the plates, level with mortar and carefully treat with a primer.

The second stage of internal thermal insulation is the installation of a subsystem of wooden bars or metal profiles. The frame plays the role of a platform for the finishing device - drywall, suspended ceiling, and so on. Polystyrene boards are attached directly to the concrete surface with an adhesive mixture and dowels-umbrellas.

How to insulate a reinforced concrete ceiling in a private house from the inside:

- After preparing the surface and assembling the frame (or without it), prepare the adhesive mortar according to the instructions on the container.

- Apply glue to the foam board and press it to the surface, hold for a while.Fasten the next element end-to-end with the previous one, do the next row with a shift relative to the first.

- When the mixture hardens, additionally fix the polymer plates with dowels in the form of umbrellas. It is advisable to blow the joints with mounting foam.

- Cover the ceiling with a vapor barrier, observing the overlaps and gluing the joints. The film or "Penofol" is aimed at the subsystem with a stapler.

- Lay the edges of the film on the walls and glue with building sealant. Install the slats of the crate and proceed to the finish.

External insulation of reinforced concrete slabs with polymeric materials is used on flat roofs and exploited attics. The "pie" on the roof is formed like this:

- The prepared surface is covered with a vapor barrier film in accordance with all the rules.

- Expanded polystyrene is tightly laid on top, fixed to the ceiling.

- A cement screed is poured, which plays the role of waterproofing and a solid foundation so that you can walk on the roof.

- A built-up waterproofing with roofing material with weather vanes is installed to remove air and water vapor from under the "pie".

The technology for mounting polystyrene insulators from below to the ceiling is shown in detail in the video:

Of course, you can insulate reinforced concrete from the inside with mineral wool, and the ceiling of a log house with polystyrene foam. Then take additional measures: carefully isolate the mineral wool from the room, and blow mounting foam between the polymer and wood - it allows air to pass through and prevents decay.

Table: Comparison of the properties of ceiling insulation

| Characteristics | Light Butts Scandic | Acoustic Butts | Roof Butts N Extra |

|---|---|---|---|

| Density, kg/m3 | 35–45 | 45 | 115 |

| Dimensions, mm | Length 800, width 600, thickness 50 - 100 | Length 1000, width 600, thickness 50–70; 75; 80–200 | Length 1000/1200/2000/2400, width 600/1000/1200, thickness 40–200 |

| Flammability group | NG. Fire hazard class - KM0 | NG | NG |

| Thermal conductivity | λ10 = 0.036 W/(m K) λ25 = 0.037 W/(m K) | λ10 = 0.034 W/(m·K) λ25 = 0.036 W/(m·K) | λ10 = 0.037 W/(m K) λ25 = 0.039 W/(m K) |

| Water absorption at partial immersion, no more | 1.0kg/m² | 1.5 % | 1.0% |

| Acidity modulus, not less than | 2,0 | 2,0 | 2,0 |

Also, when calculating the thickness of the insulation, the selected option should be taken into account. thermal insulation works, which could be:

- internal;

- external;

- complex.

Of course, there is no choice in a city apartment, but in a private house with an attic space, the option of insulation from the outside, that is, the attic side, is often used. The complex option must be used in cases where it is necessary to achieve the maximum effect: it is used mainly in baths or saunas.

The better to insulate the ceiling of a private house

In the conditions of severe Russian winters, the problem of high-quality insulation of a house is a matter of, if not survival, then at least the comfort of life and health of your family members. In a "cold" cottage without anyor thermal insulation heating costs will beat all conceivable records, and colds will become the norm for its residents.

But this will not happen if you make sound insulation of walls, floors and ceilings in the house. This is especially true for ceilings - heated air always tends to rise, and if it does not meet a barrier in the form of a layer of heat-insulating material on its way, it will simply go outside. And you end up with condensation on the ceiling and higher heating costs.

If you do not take care of the high-quality insulation of the ceiling, then condensation will form on it, and warm air will freely go outside

The quality of ceiling insulation strongly depends on what material would be used and how well it was installed. And at this point, the owner is faced with the question: what to choose? Today, there are many types of insulation on the building materials market, and each of them is presented as the best in its segment. This article should help you solve the problem of choosing thermal insulation materials, it will tell you about their features, installation methods, advantages and disadvantages.

Insulation calculation

The attic floor requires one and a half times the thickness of the heat-insulating material than the walls. And this is understandable: warm air tends to rise. The partial pressure of the water vapor that is in it also helps to find the smallest cracks. They are always found: expensive heat flies into the sky.

Before you insulate the ceiling in a private house, you need to imagine how much it will take. A certain standard for the thickness of the insulating layer has always been the height of the floor beams. The maximum size of a beam or cut log is 200 - 240 mm. This may not be enough.

Knauf booklet for England:

The average annual temperature in London is +11.9°C, in Moscow +5.8°C. The conclusion is obvious: the thickness of the insulation for the ceiling of a cold attic should be - depending on the type of insulation - from 300 to 400 mm.

Another indicator: a layer of expanded polystyrene in factory SIP panels: 200 mm. They block the first floor with a cold attic.

The thickness of the floor insulation (based on thermal calculation) should be 1.5 times greater than that of the wall insulation.The thicknesses given as an example should be used as a guide for calculations. The house is built to last for centuries, so additional insulation will not be superfluous.

They independently carry out the calculation, guided by SP 50.13330.2012. The methodology is described in great detail on 139 pages, all reference materials are available. As a result of calculations, the thermal resistance of the element of enclosing structures is determined.

The total conditional resistance to heat transfer Ro is the sum of these indicators for all layers. If it is less than the standard, the design needs to be changed.

You can try your hand at such a calculation, while the correct result is not guaranteed. The right decision is to trust the experts. If not, you can recommend a fairly reliable online calculator SmartCalc. It will calculate the impedance of a user-specified design, show where the dew point is.

Conclusions and useful video on the topic

Interesting ideas for ceiling insulation:

Nuances of ceiling insulation from timber:

If there is no residential or insulated attic in a wooden house, you cannot do without ceiling insulation. The ideal case is the insulation of the floor during the construction process.

Installation of an insulating layer in an already built house is somewhat more difficult, but still possible.

It is important to follow the technology and take into account the features of the selected heat insulator

Do you have personal experience ceiling insulation in a wooden house? Do you want to share your accumulated knowledge, talk about the nuances of the work or ask questions on the topic? Please leave comments and participate in discussions - the feedback form is located below.