- Advantages and disadvantages of using sawdust

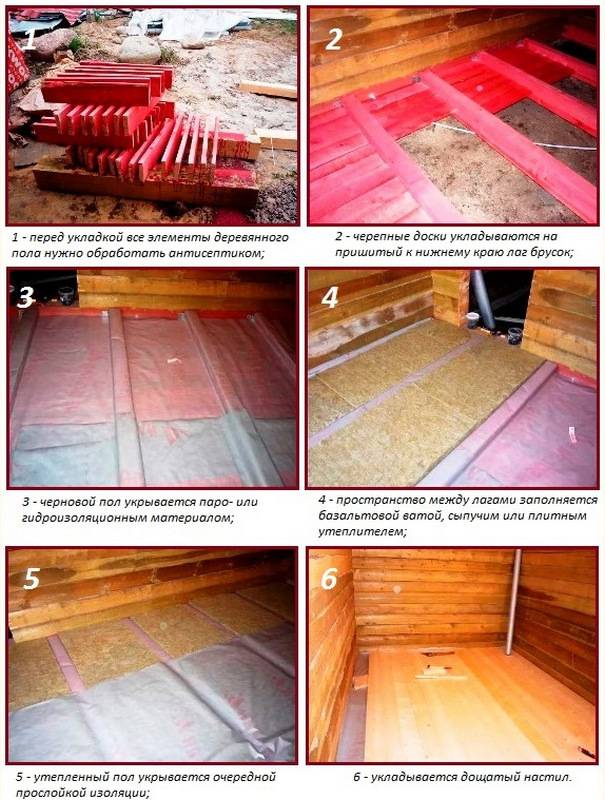

- Installation technology: how to do it yourself?

- Laying thermal insulation

- Marking and installation of pipes

- Screed installation

- Checking the performance of the heating system

- pouring cement

- concrete floors

- concrete floor insulation

- Option number 1 - insulation + screed

- Option number 2 - insulation along the lags, without the use of wet processes

- Peculiarities

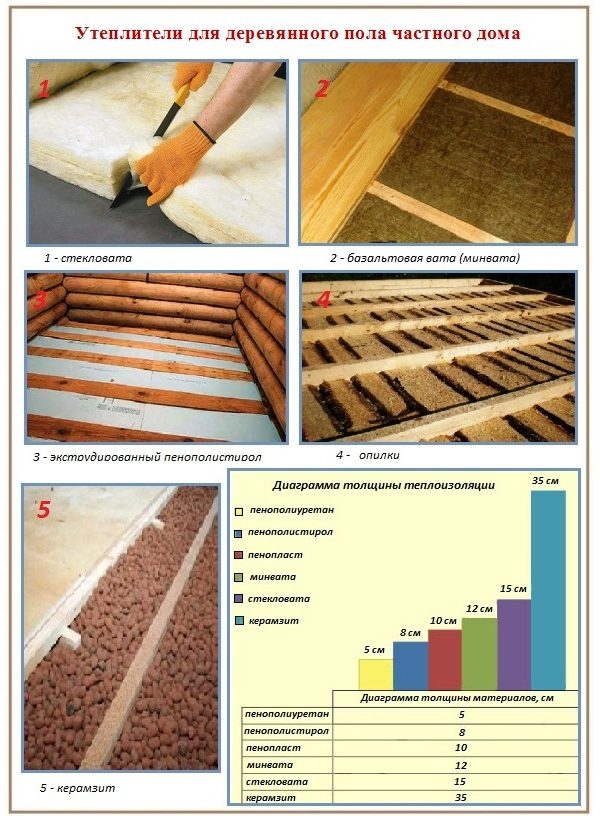

- Types of insulation for wooden floors

- What materials are used?

- The choice of insulation

- How is the repair of floors in a house where there are wooden floors?

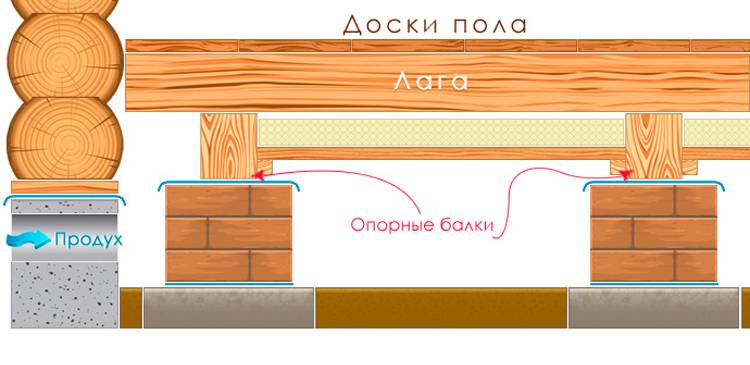

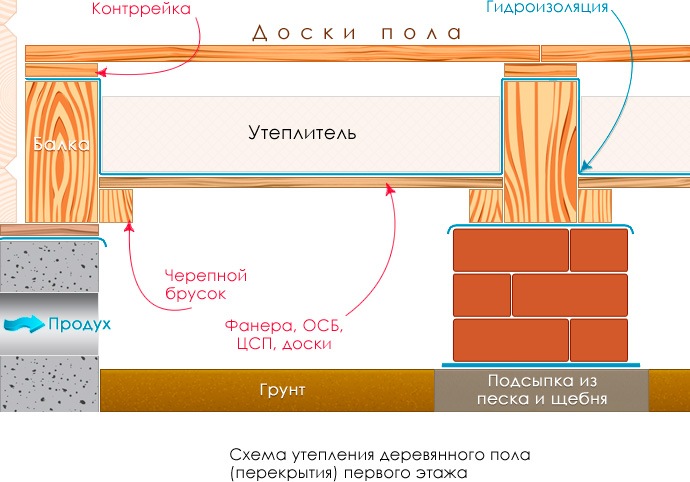

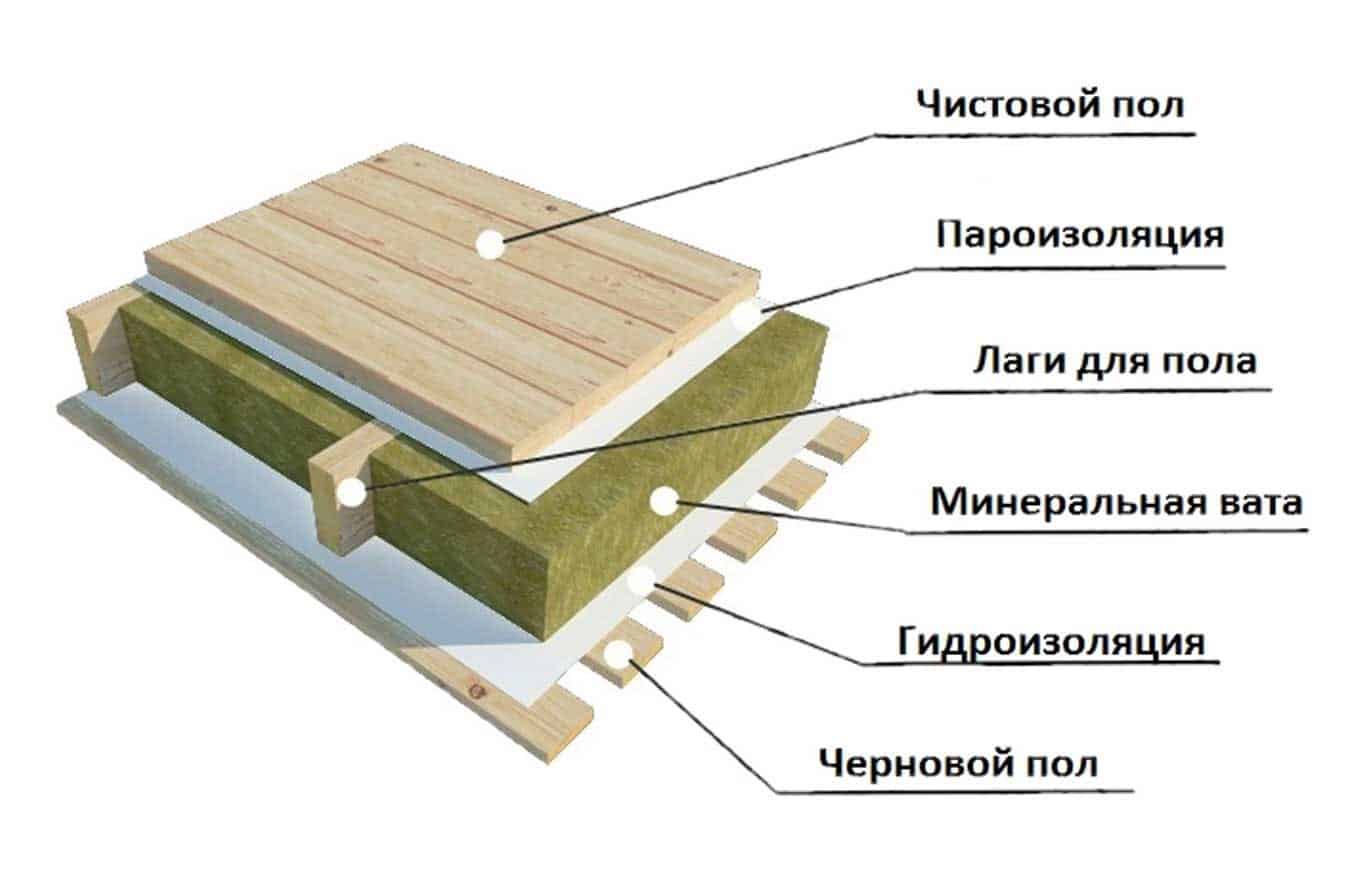

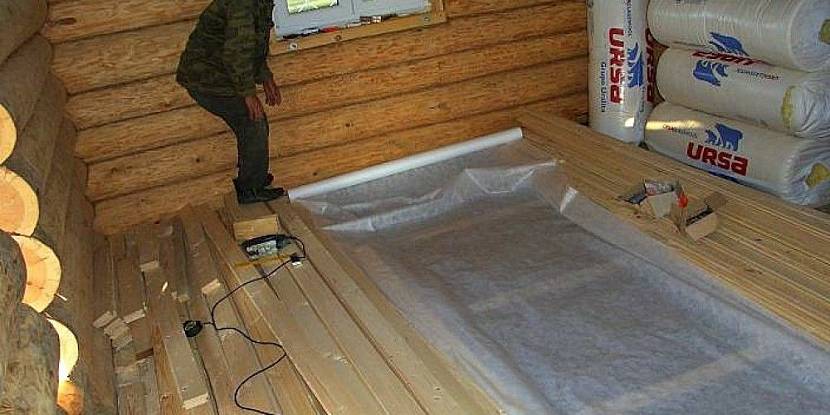

- Floors on joists

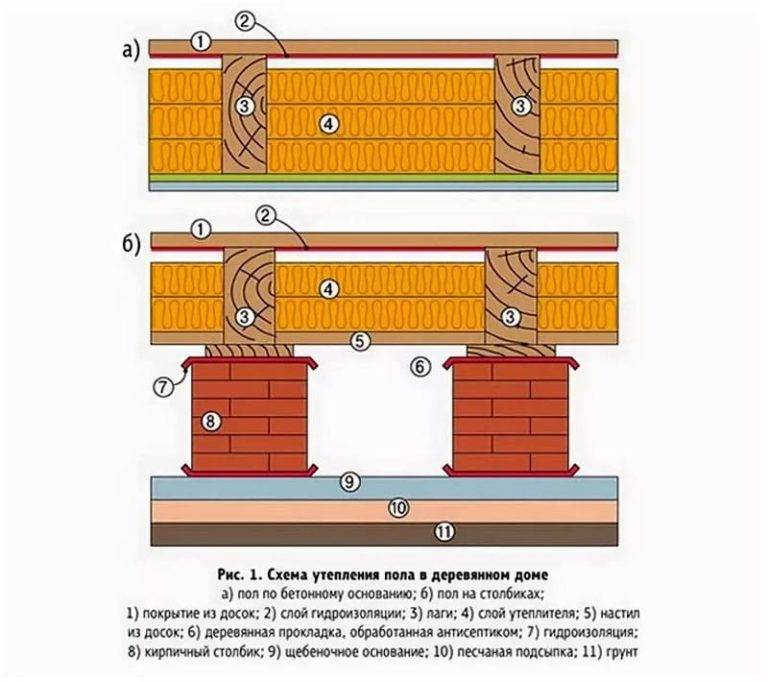

- Concrete

- floating screed

- Warm screed

- Warming along the lags

Advantages and disadvantages of using sawdust

Sawdust is one of the most "ancient" options for floor insulation. The main advantages of wood shavings include:

profitability, since sawdust is cheaper than any other products;

environmental friendliness and non-toxicity, which is very important for people who suffer from allergies;

high thermal insulation properties of the material;

the ability to fill hard-to-reach places with sawdust, where it is impossible to lay with other material.

But it was not without drawbacks:

- the process of warming is quite laborious, long, not mechanized - that is, all work in the house will have to be done by hand;

- sawdust is flammable - dry products light up like a match;

- if the chips are not processed, it is likely that insects or mice will settle in them.

sawdust insulation

By the way, when insulating a house, you can use both clean sawdust and materials that consist of shavings. These are special granules, wood blocks and material such as sawdust concrete. Wood blocks are a mixture of sawdust, blue vitriol and concrete. The heat insulator in the form of granules includes glue, shavings and an antiseptic. Due to this, the granules have a high level of biological stability, thermal conductivity and fire resistance, which makes them a completely safe insulation.

Installation technology: how to do it yourself?

After drawing up the project, you can proceed directly to the installation of the heating system. To do this, you need to prepare the base so that it is even. After that, you can proceed to the next steps.

Laying thermal insulation

Of great importance is what the room is located above, where it is planned to install a warm floor.

- When it is mounted on the ground floor, the thickness of the heat-insulating layer should be 60–80 mm.

- If the room is located above a warm room, then 3-5 mm is enough.

- An insulator with a thickness of approximately 20 mm must be installed above the cold room.

Marking and installation of pipes

- Next, on the canvas of the heat insulator, it is necessary to mark the location of the pipes. You can do this with a marker or electrical tape, which is then removed. Marking will greatly simplify the laying of pipes and help to avoid mistakes.

- Then, a mounting mesh with 10 by 10 cm cells is laid on top of the heat-insulating layer. The mesh can be plastic or metal.

- Next, the pipes are installed directly. They are laid out according to the scheme and fixed with clamps.

Instead of mesh, you can use polystyrene mats, which simultaneously hold the pipes and act as a heat insulator. This is an inexpensive option that simplifies installation.

Although the pipes are elastic, you should try to bend them to a minimum. Do not install damaged ones, pull them in order to reduce consumption. Do not cut them in advance or make up one contour from several segments.

Important

If serpentine laying is selected, then installation must begin from the window or outer wall. In other cases, this will not play a role.

Screed installation

With a large area of \u200b\u200bthe room, it is recommended to install beacons before pouring. This will simplify the process and help to make the base even. Beacons are located at a distance of 50 cm from the wall, and a little less from each other. You need to start pouring the screed from the far corner, gradually moving towards the door.

Checking the performance of the heating system

To check the installed system for structural strength, it is necessary to carry out hydraulic tests:

- pipes must be filled with water;

- increase the pressure to 5 bar and maintain it;

- check the system for leaks and eliminate them;

- it is necessary to reduce the pressure to 1-2 bar, leave it in this state for 24 hours;

- if after a day the pressure has not dropped, you need to set the heating system to the maximum temperature in order to drive the coolant through all circuits;

- test the system for a day in this mode.

If the system is working, you can start filling.

pouring cement

In order for the screed to finally harden, you must wait at least 30 days and only then start using the heating system.

The underfloor heating installation technology may seem complicated, but by following the steps and paying maximum attention to the process, you can do the installation yourself without the help of specialists.

concrete floors

In modern construction, wooden floors are used very rarely; they have long been replaced by concrete floors. The main advantage of a concrete floor is low cost, ease of installation, high strength and durability, as well as environmental friendliness and fire resistance.

But there is one big “BUT”, the concrete floor has a high thermal conductivity, which is why even on the hottest days it blows cold. Therefore, it is necessary to cover the concrete floor with a special insulation. You can use the same materials as for the wooden floor on the logs.

A well-dried concrete floor must also be covered with a waterproofing film before laying the thermal insulation layer. The technology for laying thermal insulation with lags is the same as for a wooden floor. It should be noted that when warming along the logs, the floor height will increase by 10-15 cm.

Another good way to insulate concrete floors is to use chipboard. This material is in no way inferior to mineral heaters and is quite often used for insulation in private houses and suburban buildings. Organic insulation materials include wood shavings, moss and sawdust. You can also add straw, small dry grass, reeds, hay, sedge or peat chips.

To protect the chipboard from moisture, the concrete is covered with a polyethylene film with high waterproofing. Then chipboards are laid. In this case, the slabs do not need to be laid close to the walls, keeping a distance of about 1.5 cm.This is necessary so that the plates do not warp with strong changes in temperature and humidity.

The plates are firmly fixed with dowels. After fixing the plates, all joints must be reinforced with a construction mesh and covered with putty, which is mixed 1: 1 with oil paint. Then a plinth is mounted around the perimeter. Linoleum or carpet is laid on the finished structure.

You can insulate the floor in the house with your own hands using "warm" linoleum. This material consists of two layers - a warm substrate and polyvinyl chloride, resistant to chemical and mechanical damage. The substrate of such linoleum is made on the basis of natural felt or synthetic non-woven material. Its thickness is about 3-4 mm.

When laying insulated linoleum, it is cut in such a way that there is a small distance between it and the wall, otherwise after a few days it will warp due to an increase in size as it is trampled down.

The concrete floor can also be insulated with a technical cork, which is practical and durable. It is made from the bark of a cork oak, which is glued together with the resin contained in the cork mass. Such material is 100% environmentally friendly, does not pass water, has high heat resistance and does not burn. But there is also a significant drawback - the high cost.

Isolon is also considered one of the best and most effective heat insulators. It is very easy to insulate the floor with it - you need to roll it out on a well-dried concrete floor, and then proceed with laying the floor covering.

Warming the floor in the country is a necessary measure by which you will make your home even more comfortable.It's so nice to sit down on the warm floor with the whole family, when the weather is "non-flying" outside the window, and play, for example, monopoly or twister.

concrete floor insulation

In most cases, the floors in the apartments of urban high-rise buildings are reinforced concrete slabs. The concrete floor itself is very cold, but if you add to this the gaps between the slabs, insufficiently tight joints between the walls and the floor, then it becomes truly icy. Therefore, the insulation of the concrete surface is a top priority for residents of high-rise buildings who seek to increase comfort in their apartments.

Each master involved in insulation derives his own formula for the ideal insulating "pie" on concrete slabs. Consider the most popular of the possible options.

Option number 1 - insulation + screed

It is possible to significantly improve the thermal insulation properties of a concrete floor by laying insulation between the floor slab and the cement leveling screed. In this case, the floor insulation in the apartment is performed as follows. The first step is to remove the old floor covering, remove the screed. The surface of the slab is cleaned of debris, dust, and irregularities from the remnants of the cement screed are eliminated.

Insulation of the floor in the apartment with the help of heat-insulating material and reinforced screed

Then perform vapor barrier. A polyethylene or polypropylene film is laid on a concrete base, overlapping strips by 15-20 cm and leading 3-5 cm onto the walls. The overlap joints are insulated with special adhesive tape. A foam plastic with a minimum thickness of 50 mm and a density of 25 mm is laid on the vapor barrier film. Instead of foam, you can use expanded polystyrene, mineral wool, etc.Insulation sheets are laid as close as possible to each other so that cold bridges do not form in the seams. After that, another layer of vapor barrier is laid. If foam or polystyrene foam was used as a heater, then this step can be skipped.

Now a metal mesh with square cells is laid (cell side - 50-100 mm). The mesh will act as a frame for the cement screed, making it more durable. A cement screed with a minimum thickness of 50 mm is poured over the mesh. A thinner screed will be unreliable - after a while it will begin to crack and crumble. The cement screed should dry, it will take about two weeks. After that, to strengthen the top layer, it is necessary to cover it with a primer. After all this, any decorative coating is laid on the screed.

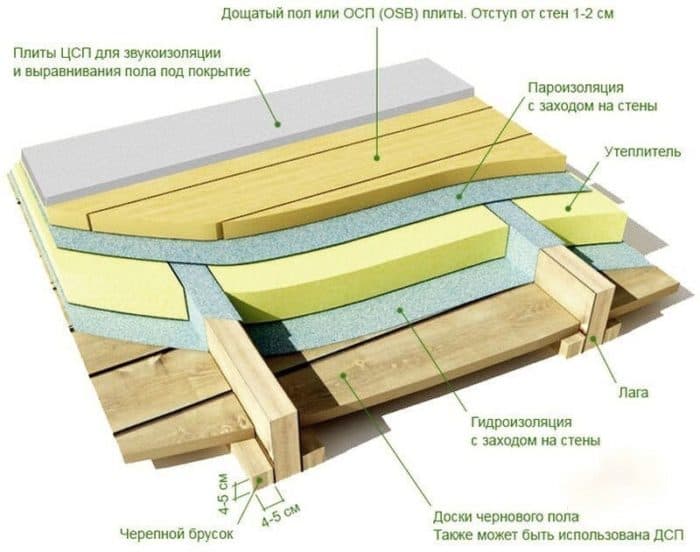

Option number 2 - insulation along the lags, without the use of wet processes

This option is similar to the insulation of a wooden floor. The difference is that logs are initially provided in the thickness of the wooden floor, between which it is convenient to lay any type of insulation. In the case of concrete floors, these logs will have to be designed independently.

Insulation of the concrete floor along the logs eliminates wet processes and does not weigh down the floor

The technology of concrete floor insulation along the logs:

1. First of all, they clean the concrete slab from the old screed, debris and dust.

2. Arrange waterproofing. It is convenient to use ready-made waterproofing polymer-bitumen solutions, which are applied to the concrete surface with a roller or brush. Another option is to use a vapor barrier film for these purposes, which is laid out on the floor with an overlap, leading to adjacent walls.If you want to save money, then the most acceptable material for hydro and vapor barrier will be ordinary polyethylene film.

3. Lags are installed at a distance of no more than 0.9 m from each other, if you take a step more, then the floors will sag. Instead of a log, if bulk material is supposed to be used for insulation, metal beacons are attached to the floor.

Installation of wooden logs on a concrete floor

4. Lay the selected insulation. Suitable for both mineral wool and polystyrene, and any variant of loose thermal insulation materials. Insulation in the form of sheets or rolls, laid out tightly, without gaps between the lags. Bulk material (for example, expanded clay) is poured between beacons and leveled to one level with a metal rule.

Insulation is laid in the space between the lags

5. Lay the floor. To do this, you can use sheets of plywood, GVL, OSB, chipboard with a thickness of 10-15 mm. It is safer to lay them in two layers so that the seams of the lower sheets overlap with the panels of the upper sheets. Thus, the floor covering will be seamless, which will eliminate the possibility of cold bridges. After laying, the layers of sheets are connected to each other and to the lags (beacons) using self-tapping screws.

Laying sheets of dense material (plywood, GVL, etc.) on logs

6. Suitable for any floor finish.

Installing laminate flooring on underfloor heating

In a short video, you will clearly demonstrate the process of warming along the lags:

Peculiarities

Wooden floors, unlike concrete, are much warmer. Wood is a capricious material and when building a house it is not always possible to achieve the desired effect.The ratio of thickness and thermal conductivity is often disproportionate, so floor insulation in a house made of wood is simply necessary.

The possibility of floor insulation is not only in new houses, but also in long-built ones.

Floor insulation helps to maintain an ideal microclimate in the room and serves as a guarantee against such undesirable problems:

- dampness;

- the appearance and reproduction of mold;

- the appearance of microorganisms and fungi that adversely affect the health of those living in the house;

- high consumption of thermal energy for heating the house;

- building damage and destruction.

Insulation of structures involves different types of work:

- insulation of floors above the basement;

- insulation of interfloor ceilings;

- insulation of the ceiling between the living room and the attic.

In each case, materials are used not only to maintain optimal temperature conditions, but also for sound insulation. A well-insulated first floor is a guarantee that the house will become comfortable for living.

Types of insulation for wooden floors

A wooden house was previously considered a very warm structure that did not require any additional insulation work. True, not all modern developers know that the floors in old houses were made from logs cut in half, and the thickness of such coatings reached 20–25 cm. The walls of the log house were assembled from round timber Ø 55–60 cm. and for floors, boards with a thickness of no more than 2.5 cm are used. Such thin lumber cannot in any way comply with the requirements of current regulations.

According to the existing standards for heat conservation of residential buildings (SNiP II-3-79), in order to achieve energy saving R = 3.33 ° C m2 / W, the thickness of the timber in the Moscow region should be 50 cm. In order not to install such thick walls, modern insulation materials must be used . 12 cm of expanded polystyrene has the same heat saving effect as a 53 cm thick wood or a 210 cm brick wall.

The construction industry offers consumers a wide range of thermal insulation materials that differ in structure, manufacturing technology and thermal conductivity parameters.

Table. Varieties of floor heaters

| Type of insulation | Brief description of physical and operational characteristics |

|---|---|

| Rolled | In terms of cost, they belong to the middle category, quite technologically advanced and effective heaters. Rolls make it possible to cut materials exactly to the size of the niches, due to this feature it significantly reduces the number of unproductive losses. To insulate floors in a wooden house, rolled mineral wool insulation is most often used. There are also rolls of cork bark, but such materials are recommended to be used during the arrangement of underfloor heating only as additional lining insulation, since their thickness does not exceed a few millimeters. For basic insulation, this is very little. Often, rolled heaters have a foil coating. This is a reliable protection against moisture penetration, in addition, it is possible to slightly reduce heat losses due to infrared radiation. |

| Pressed | On special equipment, light and porous heaters are pressed into plates with standard dimensions.Plates, unlike rolled materials, can retain their geometry, which simplifies and speeds up the installation process. The dimensions of the slabs are taken into account at the design stage of the house, taking into account their dimensions, the distance between the floor lags is selected. Most often, mineral wool and glass wool are pressed, but ecowool slabs can be found. The price is slightly higher than rolled ones, the thermal conductivity parameters are almost the same. Separately, pressed polymer foam-based insulation is located. Modern technologies make it possible to make them safe for health and do not support open combustion. Such operational properties make it possible to use these materials for floor insulation in wooden houses. |

| Liquid | The main difference is that the materials harden or polymerize after being applied to the surface. The insulation layer has no gaps, the technology makes it possible to isolate the most inaccessible places of complex configuration. In liquid form, polymer thermal insulation and ecowool are applied. The disadvantage is the complexity of the technology of polymer insulation. According to the actual characteristics, these materials occupy the last places and are not recommended for use by professional builders. |

| Bulk | Traditional and cheapest heaters, most often - expanded clay and slag. The main advantage is that they are absolutely non-flammable. In terms of thermal conductivity, they occupy the last place among all existing heaters. |

Many types of insulation are used to insulate floors in wooden houses, but not all are equally common. Mineral wool and polymeric materials are considered the most common, expanded clay is less commonly used and, in very few cases, sprayed liquid insulation.

Most often, floors are insulated with foam.

What materials are used?

The most commonly used heat-insulating materials made on the basis of fiberglass. This type of thermal insulation is available in the form of plates of various sizes.

A wide selection of plate sizes allows you to arrange thermal insulation of a log house with virtually no waste. The insulation is fixed on the walls of the house. To exclude moisture of the thermal insulation material, after installation, another layer of vapor barrier film is usually laid on top.

Today, heat-insulating materials are produced, covered with a vapor barrier film on both one and both sides. Information about this can be found on the packaging. In this case, an additional layer of vapor barrier is not required!

The choice of insulation

The question of choosing a heater for a house made of timber largely rests on financial opportunities. You can use both expensive imported materials and cheap domestic ones. The latter have proven themselves well in housing construction.

However, keep in mind that it is not recommended to use when insulating residential buildings and cottages from a bar:

- Styrofoam;

- expanded polystyrene;

- large-sized heat-insulating materials.

All of them after a while begin to release harmful, carcinogenic substances that can cause various diseases. The use of these materials without well-equipped ventilation can nullify the entire environmental friendliness of a house made of timber.

How is the repair of floors in a house where there are wooden floors?

Step 1. First of all, as mentioned above, you need to completely dismantle the entire structure of the old floor, leaving only the floors and support beams in place. All rubbish must be removed immediately so that it does not interfere with the work.

First you need to dismantle the floor

Step 2In this case, the craftsmen will install a system of adjustable floors, that is, adjustable logs will be mounted. They will be mounted on plastic bushings and bolts. Plywood 12 mm thick will be laid on top of the logs. Insulation and vapor barrier material will also be used without fail. You will need a board-beam 100x50 mm, logs 60x40 mm. All this must be purchased in advance in the required quantity.

Materials needed for work

Step 3. Even before the start of work on the installation of a new floor, it is required to lay all communications that may be under the floor. It can be electrical wiring and water supply pipes.

Communications need to be laid in advance

Step 4. All work must be performed, focusing on the desired height of the final floor

In order not to make a mistake with the level of laying the lag, it is important to use the building level. The fulcrum for the new floor will be load-bearing wooden beams, on which new support beams will be laid, which will be boards measuring 100x50 mm

They need to be laid at an equal distance from each other on the main support beams and secured with reliable bolts.

Using the laser level

Step 5. Next, on the laid logs-boards 100x50, you need to start installing an adjustable floor, which is supported by a beam of 60x40 mm. It will turn out, as it were, the second level of the lag, a kind of crate. The step between the lags of the second level is 30-40 cm.

Adjustable floor installation

Another photo of the process

Step 6. In each board 60x40 mm, you need to make holes for plastic bushing bolts with a diameter of 24 mm and immediately make a thread inside them, into which you want to insert the bushings themselves. The length of the bushings is 10 cm.Thanks to the presence of such elements, the floors can be adjusted in height to the required level.

Holes for plastic bolts

Bushings are inserted into the holes

The floor is adjustable in height

Step 7 Under each bushing on the log, you need to lay a metal washer, which will not allow the tree to be washed over time under the influence of the load on the floor. A long bolt must be inserted inside the sleeve, which is screwed into the lower support lag.

Metal washers are placed under the bushings

Inside the sleeve you need to get a long bolt

Step 8. The protruding parts of the plastic bushings need to be cut off.

Remove excess bushings

Step 9. Next, you need to lay a vapor barrier. The material is spread in accordance with the instructions attached to it, until the insulation is laid. They cover all the free space between the lags and the lags themselves

It is also important to lay individual strips of material overlapping.

Vapor barrier installation

Step 10. After that, the free space between the lags must be filled with sheets of insulation, adjusted to size. The insulation must lie tightly enough so that cold bridges do not form in the future.

Insulation is placed between the lags

Insulation laying

The material must be tight enough

Step 11 The vapor barrier layer can be attached to the joists using a construction stapler. This will ensure a secure fixation of the material.

Construction stapler used

Step 12. Next, you can mount a plywood layer on top of the lag system. So, sheets should be laid with a small distance (a few mm) from each other and at some distance from the wall. All sheets of plywood, if necessary, can be easily adjusted to the desired dimensions.

It is important to remember that the joints of plywood sheets in adjacent rows should not match, the sheets should be laid with a slight shift

Plywood is being laid

There should be a small gap between the plywood and the wall

Sheets are trimmed if necessary

Step 13. Sheets of plywood need to be screwed to the logs with self-tapping screws in increments of about 20-30 cm.

Screwing plywood sheets

Step 14. When the floor is ready, you need to use a long rule to check the level of the floor, see if it turns out even. The error is allowed, but small - no more than 2-3 mm. In general, it is now possible to install almost any type of flooring and enjoy the updated floors.

Checking the evenness of the finished floor

Floors on joists

Properly calculated and arranged floor insulation in a wooden house is an important component of its energy efficiency. In order not to open the floors after the first winter, it is necessary to think about thermal insulation before making the foundation.

The most common of them are tape, columnar, pile and pile-screw. As a rule, the base is made with an underground space. Perfume is a must. Their task is ventilation, the removal of moist air that can penetrate the heat-insulating floor cake.

The source of increased moisture is soil and condensate on the inside of the foundation at low temperatures. Reduce its amount by insulating the basement, covering the soil with a vapor barrier film, followed by backfilling with a 5-10 cm layer of sand.

However, ventilation holes are required. Clause 9.10 of SNiP 31-01-2003 (SP 54.13330.2011) establishes the total area of the vents: 1/400 of the technical underground area. In areas with increased radon release, their area is 4 times larger.

Is it a lot or a little? Let's calculate: 0.018 - the area of \u200b\u200ba sewer pipe with a diameter of 150 mm. For a house of 100 m2, 0.25 m2 is needed. These are 14 products, evenly distributed around the perimeter. Additional holes are made in the inner tapes.

In practice, designers do not lay such a number of ventilation holes. And if they are, then the desire to decorate them reduces the efficiency by half. Fine wire mesh for protection against rodents is the best solution.

If the soil is covered with a film (more on this below), some of the vents can be closed after the first frost. Cold air contains little moisture, air draft through open channels will only remove moisture from the insulation.

Why is such a seemingly insignificant detail described in such detail? Because it will not be possible to insulate the floor in a private house with a wet underground.

The opposite case: in a frame house on stilts, the plinth is closed at best in the second year. The wind walks under the floor, ruffles the windproof film, and with it the heat-insulating cake. If there is no such film, then you need to know that the blown thermal insulation does not insulate anything.

Decided to build a house? Just think about the floors. Correcting the errors of their device is very expensive.

Concrete

Concrete base means the use of floor slabs or concrete screed on top of the ground or other type of floor. The result is still the same concrete that provides the strength and durability of the floor, but does not protect against heat loss and is even colder to the touch.

Warming is carried out in two main ways, which allow you to actually use any heat-insulating material.

floating screed

In the first case, a floating screed is formed.On top of the leveled concrete surface, waterproofing is spread and a heat insulator is laid.

The material needs to be durable, moisture resistant and preferably with minimal vapor permeability. Next, sheet material (MDF, plywood, drywall, etc.) is laid on top of the insulation and another layer of screed is formed, only so that it does not touch the walls, for which a damper tape is used.

For this option, the following heaters are suitable:

- Styrofoam;

- extruded polystyrene foam;

- rigid stone wool slabs;

- foil insulation, Penofol.

Expanded polystyrene is one of the most used insulation under the screed

The first three heaters are almost equivalent in terms of characteristics and thermal insulation, however, mineral wool boards have high vapor permeability and even taking into account the treatment with hydrophobic compounds, moisture can accumulate over time, so they are not recommended for use in rooms with high humidity.

Foil insulation is a base made of foamed polyethylene or polypropylene with aluminum foil or a polymer composition applied on top that can reflect heat. Their main task is not to delay the penetration of heat, but to turn most of the radiant energy back into the room. They do not significantly increase the thermal resistance of the floor, but they are able to separate the cold base and the warm floor in the room. Most often, penofol and similar materials are used in combination with other heaters.

Warm screed

Separately, it is necessary to consider expanded polystyrene concrete and expanded clay concrete. In fact, these are concretes in which granular heat-insulating materials are used as a filler.A simple and effective way to insulate the floor without losing strength and without using complex multi-layer structures at all.

These materials are able to replace both a rough screed and a final screed for laying any floor covering or installing a self-leveling floor. If you only need to slightly increase the thermal resistance of the floor, then expanded polystyrene concrete and expanded clay concrete will be the best solution.

Warming along the lags

It is possible to use almost any heat-insulating material on top of concrete when forming a subfloor along the logs. Logs are installed on the floor slabs - beams from 50x50 to 150x50, leveled to the level and subsequently covered with a floorboard that forms the subfloor.

Niches are formed between the lags, in which heat-insulating material can be laid. It can actually be any option from the table.

Mineral wool in rolls or in the form of slabs is a versatile option. Given the mandatory presence of a ventilated gap to remove moisture from the underground space, ideal conditions are created for the use of this material.

Foamed polyurethane, liquid polystyrene foam, ecowool are able to fill niches of any shape and provide good thermal insulation without gaps and cold bridges. They are perfect for floor insulation on an uneven concrete base, which is often found in old buildings.

Preference is given to breathable materials with high vapor permeability: mineral wool, expanded polystyrene (not extruded), ecowool. When using wooden logs, effective ventilation with removal of excess moisture will be required.

The use of expanded clay or dry screed is justified only if only minor insulation is required or there is a large space that can be taken under the screed. Expanded clay is relevant only for warming the first floor to separate the floor in the room from the basement or ground surface.