- concrete floor insulation

- Option number 1 - insulation + screed

- Option number 2 - insulation along the lags, without the use of wet processes

- Glass wool and mineral wool

- What properties should a heater for a wooden house have?

- Thermal conductivity

- Vapor permeability

- fire safety

- Insulation shrinkage

- Water absorption

- Features of wall insulation from timber outside

- 1 stone wool

- 9 Penoplex

- The choice of insulation

- The use of mineral wool

- Criteria for choosing the optimal insulation for a house or apartment - what to look for

- Thermal conductivity

- Vapor barrier and hygroscopicity

- Combustibility of a heater

- Safety in terms of ecology

- The period of effective operation

- Manufacturer

- Floor types

- Floor heaters in a wooden house

- Expanded clay and sawdust

- polyurethane foam

- Styrofoam

- Penoplex

- Mineral wool

- Conclusions. Is the installation of floor insulation relevant in 2019?

concrete floor insulation

In most cases, the floors in the apartments of urban high-rise buildings are reinforced concrete slabs. The concrete floor itself is very cold, but if you add to this the gaps between the slabs, insufficiently tight joints between the walls and the floor, then it becomes truly icy.Therefore, the insulation of the concrete surface is a top priority for residents of high-rise buildings who seek to increase comfort in their apartments.

Each master involved in insulation derives his own formula for the ideal insulating "pie" on concrete slabs. Consider the most popular of the possible options.

Option number 1 - insulation + screed

It is possible to significantly improve the thermal insulation properties of a concrete floor by laying insulation between the floor slab and the cement leveling screed. In this case, the floor insulation in the apartment is performed as follows. Take off first old floor covering, remove the screed. The surface of the slab is cleaned of debris, dust, and irregularities from the remnants of the cement screed are eliminated.

Insulation of the floor in the apartment with the help of heat-insulating material and reinforced screed

Then perform vapor barrier. A polyethylene or polypropylene film is laid on a concrete base, overlapping strips by 15-20 cm and leading 3-5 cm onto the walls. The overlap joints are insulated with special adhesive tape. A foam plastic with a minimum thickness of 50 mm and a density of 25 mm is laid on the vapor barrier film. Instead of foam, you can use expanded polystyrene, mineral wool, etc. Insulation sheets are laid as close as possible to each other so that cold bridges do not form in the seams. After that, another layer of vapor barrier is laid. If foam or polystyrene foam was used as a heater, then this step can be skipped.

Now a metal mesh with square cells is laid (cell side - 50-100 mm). The mesh will act as a frame for the cement screed, making it more durable.A cement screed with a minimum thickness of 50 mm is poured over the mesh. A thinner screed will be unreliable - after a while it will begin to crack and crumble. The cement screed should dry, it will take about two weeks. After that, to strengthen the top layer, it is necessary to cover it with a primer. After all this, any decorative coating is laid on the screed.

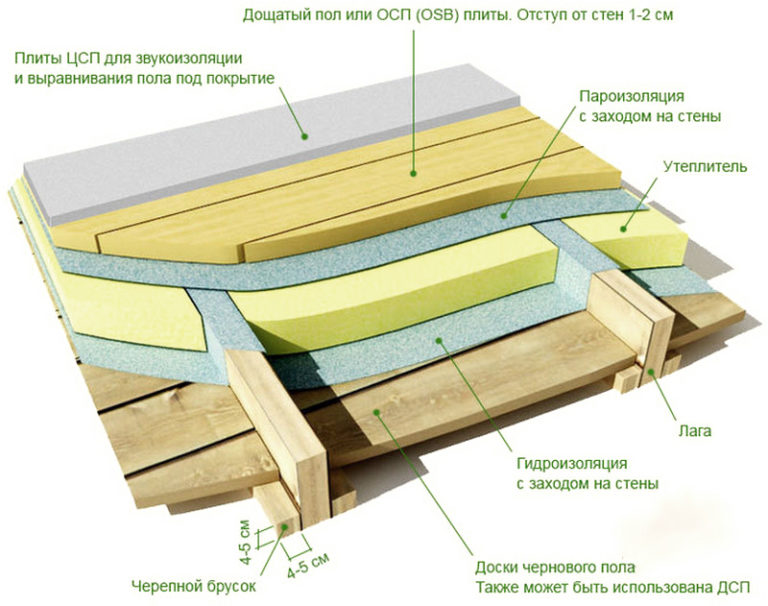

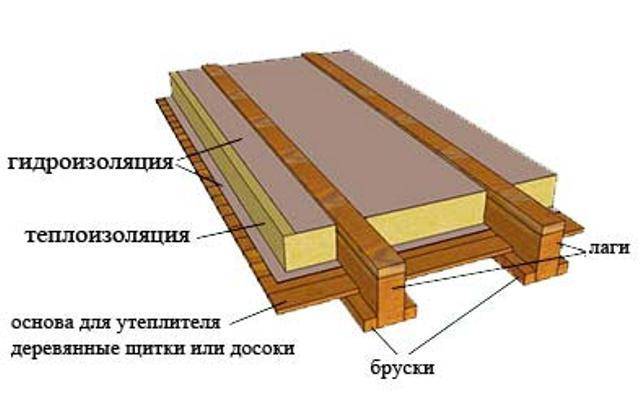

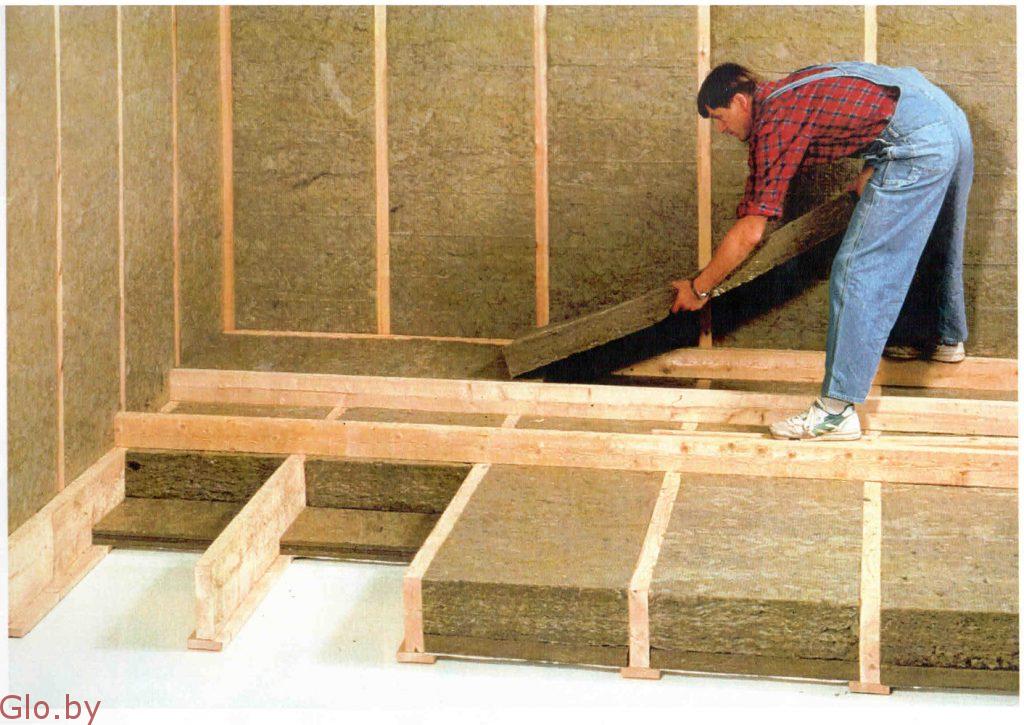

Option number 2 - insulation along the lags, without the use of wet processes

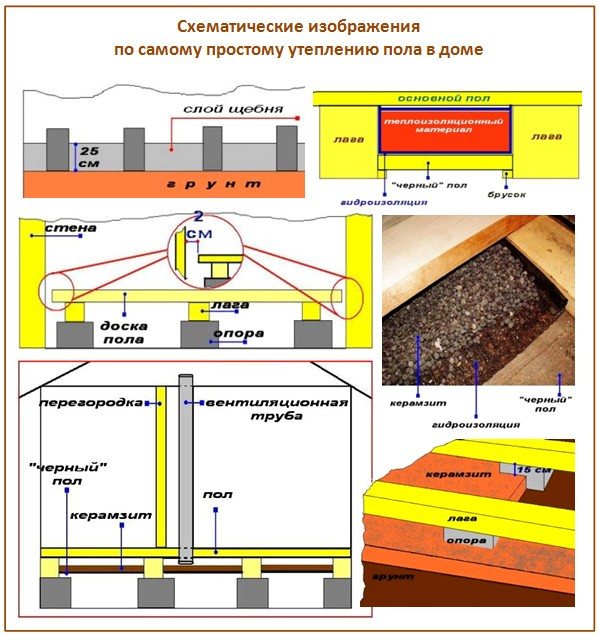

This option is similar to the insulation of a wooden floor. The difference is that logs are initially provided in the thickness of the wooden floor, between which it is convenient to lay any type of insulation. In the case of concrete floors, these logs will have to be designed independently.

Insulation of the concrete floor along the logs eliminates wet processes and does not weigh down the floor

The technology of concrete floor insulation along the logs:

1. First of all, they clean the concrete slab from the old screed, debris and dust.

2. Arrange waterproofing. It is convenient to use ready-made waterproofing polymer-bitumen solutions, which are applied to the concrete surface with a roller or brush. Another option is to use a vapor barrier film for these purposes, which is laid out on the floor with an overlap, leading to adjacent walls. If you want to save money, then the most acceptable material for hydro and vapor barrier will be ordinary polyethylene film.

3. Lags are installed at a distance of no more than 0.9 m from each other, if you take a step more, then the floors will sag. Instead of a log, if bulk material is supposed to be used for insulation, metal beacons are attached to the floor.

Installation of wooden logs on a concrete floor

4. Lay the selected insulation.Suitable for both mineral wool and polystyrene, and any variant of loose thermal insulation materials. Insulation in the form of sheets or rolls, laid out tightly, without gaps between the lags. Bulk material (for example, expanded clay) is poured between beacons and leveled to one level with a metal rule.

Insulation is laid in the space between the lags

5. Lay the floor. To do this, you can use sheets of plywood, GVL, OSB, chipboard with a thickness of 10-15 mm. It is safer to lay them in two layers so that the seams of the lower sheets overlap with the panels of the upper sheets. Thus, the floor covering will be seamless, which will eliminate the possibility of cold bridges. After laying, the layers of sheets are connected to each other and to the lags (beacons) using self-tapping screws.

Laying sheets of dense material (plywood, GVL, etc.) on logs

6. Suitable for any floor finish.

Laying laminate on insulated floor

In a short video, you will clearly demonstrate the process of warming along the lags:

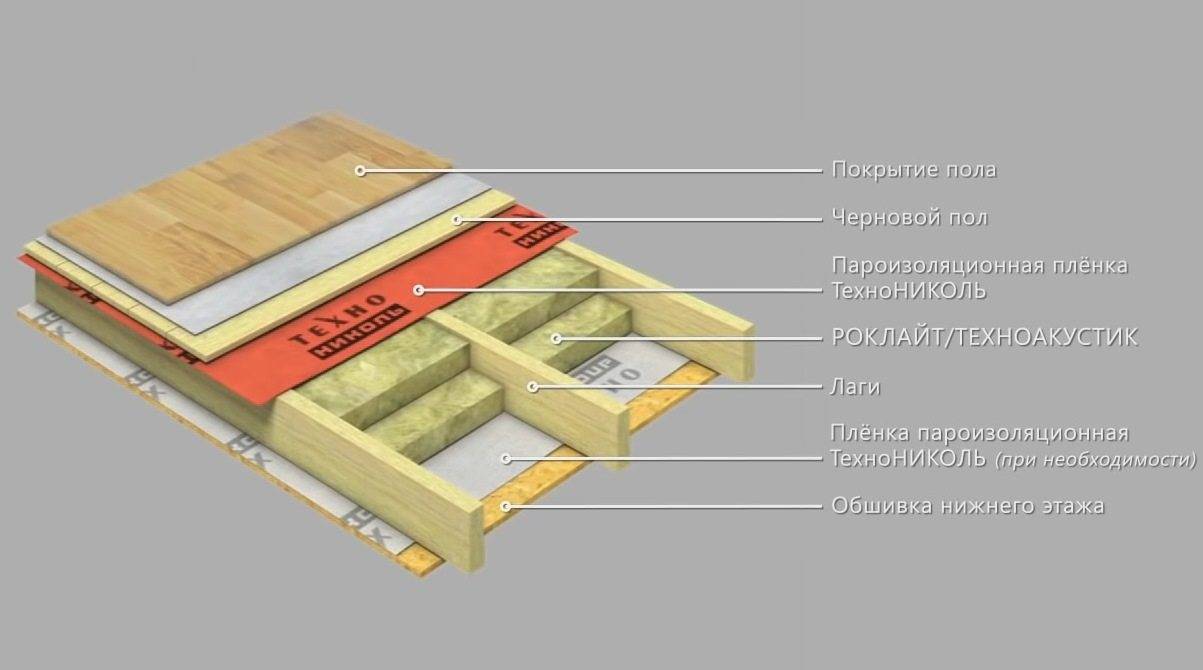

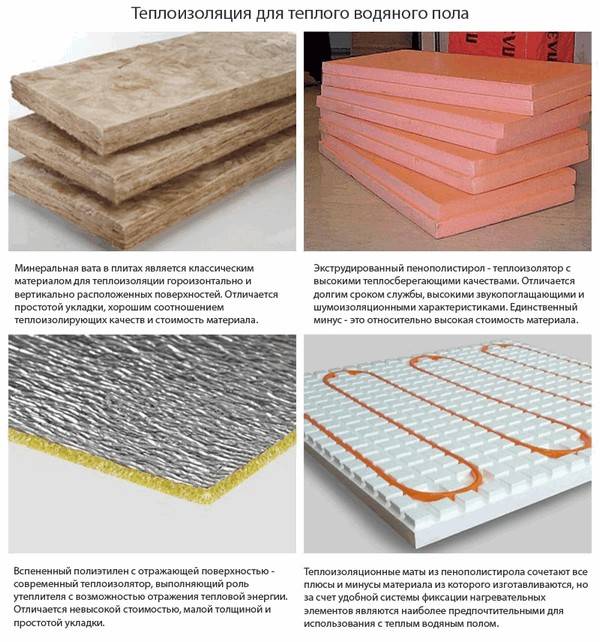

Glass wool and mineral wool

An example of floor insulation with mineral wool

Perhaps this is one of the most budget options for thermal insulation. In addition to the low price, cotton wool does not burn at all and has good vapor permeability, so it is great for warming wooden floors. On this, the advantages of this material end. The disadvantages include the fact that cotton wool tends to accumulate moisture in itself and this causes rotting and mold growth, the second disadvantage is that over time, cotton wool crumbles if the thermal insulation layer under the floor is not closed tightly enough, as a result, fiber particles can through the finish coating be airborne and cause respiratory irritation.Also, cotton wool has a very low strength, it is easily torn and deformed, which makes it impossible to use it under a concrete screed.

For floor insulation on the ground, rigid mineral wool slabs are recommended.

Despite the disadvantages, mineral wool is widely used as a heater, usually in wooden floors.

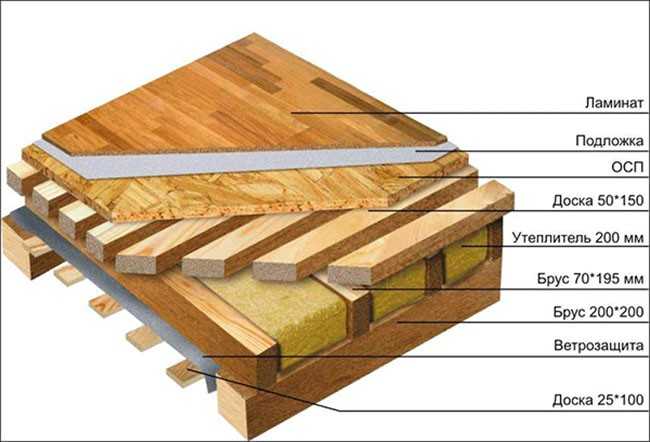

Most manufacturers produce glass wool and mineral wool in rolls or sheets, with a thickness of 50 to 200 mm. Sheets can be laid in several layers with offset joints for better thermal insulation.

Insulation thickness

The use of mineral wool on ground floors above ground requires very good waterproofing. Cotton wool instantly absorbs moisture, after which it loses its thermal insulation properties. For this reason, it is better to use polystyrene foam for thermal insulation of the first floors. If for some reason it is still necessary to use mineral wool, then its layer should be at least 400 mm.

Multi-layer insulation

If there is a basement under the floor of the first floor, then a layer of mineral wool 300 mm thick is sufficient.

When insulating wooden floors between floors of a private house, the wool layer should be at least 200 mm, and in the wooden floors of apartment buildings, a thickness of 100 mm is sufficient.

| Name | Advantages | Minuses | Thermal conductivity |

|---|---|---|---|

| Sawdust | Cheap, eco-friendly material, light weight | Flammability, susceptibility to decay | 0.090-0.180 W/mK |

| Expanded clay | Eco-friendly, durable material, does not rot, non-combustible | Heavy weight, fragility | 0.148 W/mK |

| Styrofoam | Does not rot, waterproof, lightweight and easy to install | Low vapor permeability, does not withstand high temperatures, releases toxins when melted | 0.035-0.047 W/mK |

| Mineral wool | Low thermal conductivity, easy to install, environmentally friendly, fireproof | When moistened, it shrinks and loses heat-insulating properties. | 0.039 W/mK |

What properties should a heater for a wooden house have?

Timber houses look neat, they are beautiful even without exterior decoration. But if the homeowner is faced with the task of reducing heat loss, making the building heat-efficient, then the log house needs to be insulated from the outside. This issue is especially relevant in the conditions of the Russian climate. A heater that is suitable for solving this problem must have the following properties:

- Be vapor permeable. This indicator for the insulator should not be less than that of the timber from which the house is built.

- Good to keep warm.

- Do not absorb moisture, as when wet, the thermal insulation properties of the insulation deteriorate.

- Be incombustible.

With all the abundance of thermal insulation materials on the construction market, only a few types are suitable for insulating wooden houses. For insulation, which is used for thermal insulation of wooden houses, there are special requirements. The material must have such properties that, according to all technical parameters, a residential building made of wood complies with the building codes adopted in the Russian Federation - SNiP 31-02-2001.

Thermal conductivity

The thermal conductivity coefficient shows how much thermal energy a material is able to pass in a certain period of time. The lower this indicator for the insulation, the better, since the heat loss of the building will be lower. The thermal conductivity standards for insulation for wooden houses are regulated by SNiP 23-02-2003.Insulation should be selected taking into account thermal conductivity, and the thickness of the insulation layer depends on the region in which the house is being built.

Vapor permeability

Wood is a vapor-permeable building material. This means that when the temperature difference in the street and in the house creates a pressure drop, as a result of which wet vapors move through the walls from the inside to the outside. To ensure the exit of moisture from building structures, used the heater must have the same vapor permeability properties as wood.

In this case, all the moisture from the house will go outside, providing natural drying of building structures. If a non-vapor-permeable material is installed along the contour of a wooden house, then water will accumulate in the timber or logs, causing their accelerated decay.

fire safety

Fire resistance is one of the most important parameters when choosing materials for insulation and wall decoration of a wooden house. The log house itself was made of combustible material, so everything possible is done in construction to reduce the possibility of ignition of wooden structures.

In the regulatory documentation, it is customary to classify building materials according to the degree of flammability into several types: from non-combustible (NG) to flammable with a combustion class from G1 to G4. Insulation for siding for houses made of timber or logs must be non-combustible NG. Basalt wool is suitable for this parameter - made of stone, it can withstand heating up to 1000 degrees Celsius.

Insulation shrinkage

The heat-insulating material must be dimensionally stable - retain its shape throughout the entire life of the building, do not shrink.Otherwise, gaps appear between the individual elements of the insulating layer (plates, mats, rolls), through which heat escapes. As a result, the amount of heat loss increases, the effectiveness of the thermal insulation of the building decreases.

Water absorption

When absorbing wet vapors from the environment, any insulation loses its heat-preserving properties. Water conducts heat better than air, freezes when the temperature drops below zero, turning the heat insulator into a piece of ice. So that the heat-preserving properties of the walls do not decrease during operation, it is necessary to carry out external insulation with a heater with a low water absorption coefficient.

The water absorption of the material is indicated as a percentage - this is the amount of water that it absorbs when completely immersed. The lower the water absorption coefficient, the better.

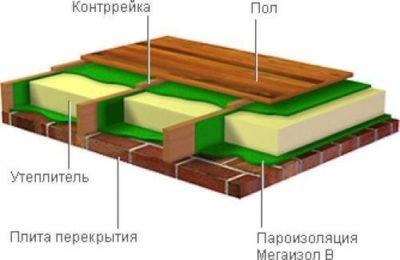

Features of wall insulation from timber outside

To choose a good material with which it would be possible to insulate a wooden house with high quality, you need to study all these features. The standard size of a beam for walls is 200x200 mm, but not less than 150x150 mm. The very technology of building residential buildings from glued laminated timber came to us from countries with a warmer climate, so such construction is not used in its pure form. In order to make it comfortable to stay and live inside a wooden house, it must be insulated.

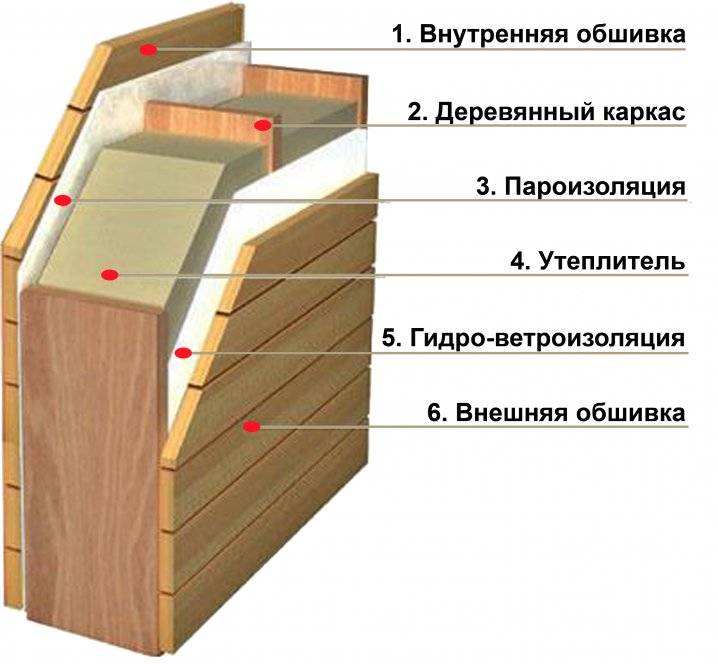

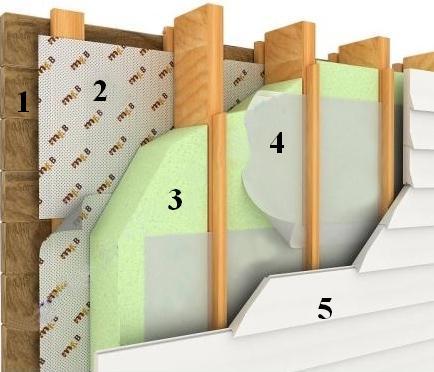

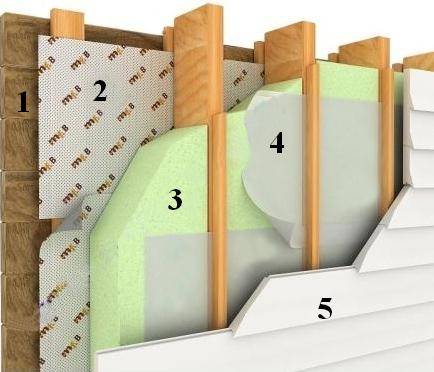

The technology of warming the walls of a wooden house from the outside: 1. The wall of the house; 2. Vapor barrier; 3. Insulation; 4. Hydro-windproofing; 5. Facade cladding.

Cheap construction of a house from a bar allows you to further save on heating.And if you wish, with certain skills and financial security, the heat losses of a house from a bar can be minimized, it is enough just to spend a certain amount on once. Work on the outside comes down to 4 main stages:

- a heater is selected;

- a complete calculation of the thermal characteristics, cost, quantity and other properties of the heat-insulating material is carried out;

- the heat insulator is laid and fastened;

- external finishing of the facade is carried out.

Efficiency in the absence of proper insulation of facades is markedly reduced. Due to the higher moisture content inside the building than outside, vapors and water droplets form on the walls of the house. Further, water can enter the thermal insulation and increase its thermal conductivity, thereby increasing the heat output to the outside. Therefore, for quality, a mandatory device of a ventilated air gap is required, through which moisture will be removed.

Various materials can be used to insulate the ceiling: sawdust, expanded clay, mineral wool, etc.

In addition to the walls, it is necessary to insulate the ceiling and floor. The ceiling accounts for up to 40% of heat loss, so it is better to start warming a house from a bar with it. Finding a gap through which it blows is quite difficult, you can not even try to do this. It is better to insulate the entire ceiling at once, so it will be warmer and more reliable. To do this, you can use any insulation, even sawdust. The main thing is that the heat-insulating layer be at least 15 cm. The insulation is evenly distributed throughout the attic, compacted a little, and filled into all voids.

The floor of a house made of timber can be insulated by simply covering it with a carpet.Of course, this is only a temporary solution, but it will allow you to determine whether the cold actually comes from the floor. However, it is better to carry out this work more thoroughly: insulate all floors, lay waterproofing material, thermal insulation, and maybe a new floor on top.

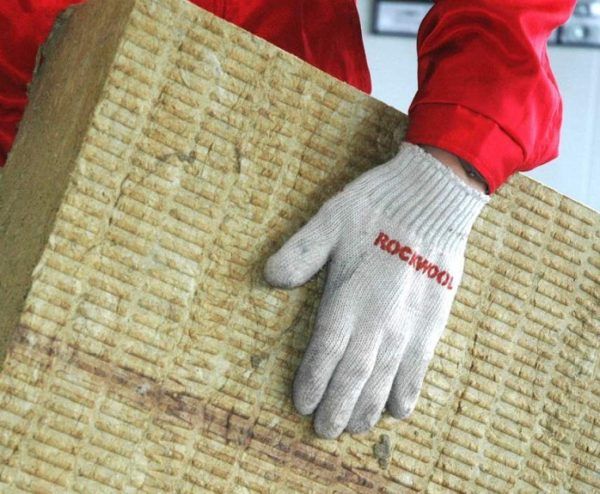

1 stone wool

Stone wool becomes an excellent universal heat insulator for a wooden house. It is made by melting rocks such as basalt. Water-repellent components are added to stone fibers, as well as urea and formaldehyde resins. The material is most often used for thermal insulation of walls from the outside, although internal insulation is also possible with stone wool. Experts note such strengths of the heat insulator as incombustibility (600 ° C), high vapor permeability and low thermal conductivity. Manufacturers compress stone fibers into rectangular slabs or mats. Some modifications are additionally equipped with a fiberglass or foil coating.

Builders call stone wool the best insulation for its density and rigidity, the material retains its original shape throughout its entire service life. The heat insulator is not damaged by microorganisms, and during installation it does not cause irritation to workers.

Attention! The above information is not a buying guide. For any advice, you should contact the experts!

9 Penoplex

Penoplex, like polystyrene, is made from expanded polystyrene, but manufacturing technologies, like properties, are seriously different. Insulation of a wooden house with foam plastic is the most effective option. Even in the northern regions of the country, this material is used as a heat insulator.The advantages of a synthetic heat insulator experts include high strength, the ability to apply plaster and paint. Thanks to this, the horizon for finishing work is expanding. The undoubted advantage of penoplex will be low weight, ease of installation, as well as a long service life of insulation.

But specialists have an ambiguous attitude to low vapor permeability. The breathing ability of a wooden house is deteriorating, so you will have to take care of the ventilation system. The disadvantages include the high price and combustibility of the material (class G4).

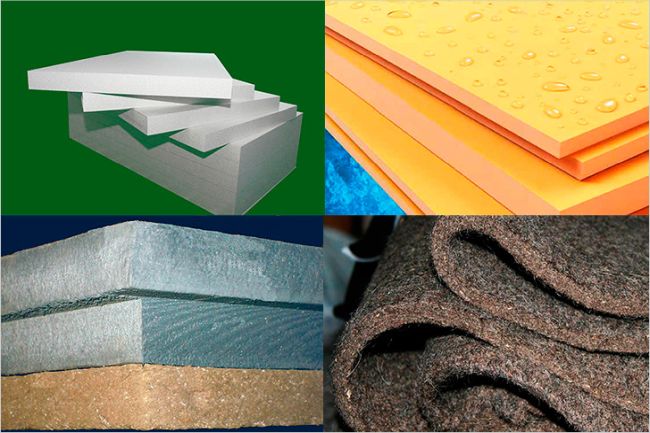

The choice of insulation

Many materials are used to insulate the floors of a wooden house. The simplest and most inexpensive can be called expanded clay or sand, which is poured between the rough and finish coating. They are hygroscopic and protect the boards from rotting, the spread of fungus and provide ventilation. However, bulk non-metallic heaters have their own drawback - over time, their hygroscopicity decreases.

Today on the market you can find many materials for warming a wooden house. In addition to good thermal insulation, it must meet the basic requirements:

- ecologicaly clean;

- be safe for residents of the house;

- long service life.

For insulation, fiberglass, mineral wool, foam plastic, polystyrene foam, etc. are used. Each of them has its own advantages and disadvantages:

o Mineral wool. It can be slag, stone and glass. The release form is also diverse - plate, roll, mat. Mineral wool has a high density, does not burn, conducts heat poorly and is quite economical. The main disadvantage is considered low moisture resistance.

When using mineral wool, the vapor barrier system and ventilation should be well thought out.The non-foiled side of the plate should be on the bottom.

When buying mineral wool, carefully read the composition, since the impregnation often contains substances dangerous to the body. The more saturated the yellow color of the material, there it is more dangerous.

In construction stores are more in demand:

- Isovol is a mineral fiber product. A distinctive feature is high hydrophobic efficiency in comparison with conventional mineral wool. Additionally, it has low thermal conductivity, non-combustible, biologically and chemically resistant.

- Rockwool is a basalt miner. Its peculiarity is that it does not cake, does not give in to deformation and shrinkage, like mineral wool. Rockwool resists mechanical loads well. The material is additionally used for sound insulation, since the porous structure absorbs noise of any frequency well. Like Izovol, Rockwool does not conduct heat well, does not burn and is resistant to biological and chemical attack.

- Expanded polystyrene - has a high rate of thermal insulation. It is resistant to moisture and does not absorb water, keeps its shape well with temperature changes, is strong, environmentally friendly, durable and is not exposed to the damaging effects of microorganisms. Styrofoam is easy to handle and use.

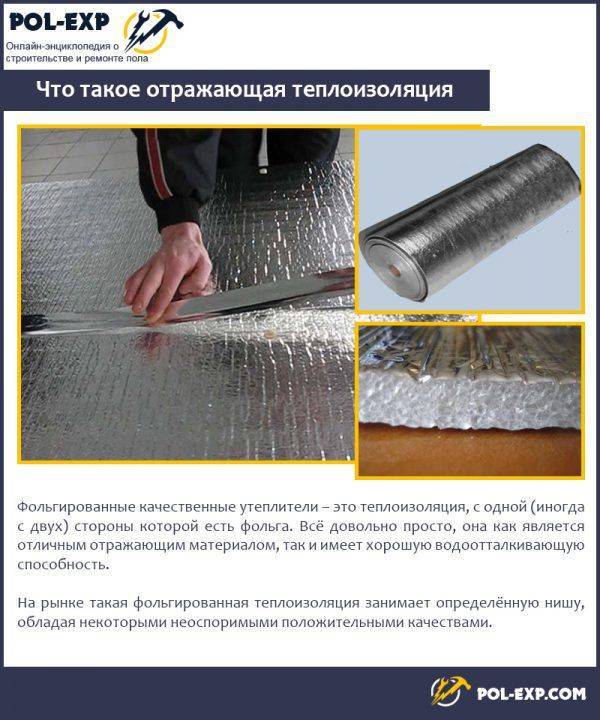

- Penofol is a modern heat insulator. Sold in rolls, is a heater with a layer of foil. The thickness and weight are small. The base may be different, but in most cases it is penofol (polyethylene foam). Thermal insulation properties are maintained under high mechanical stress. Laying occurs with an overlap or butt. The seams must be glued with metalized adhesive tape. Penofol does not require an additional layer of hydro and vapor barrier, since the foil already performs these functions.

- Ecowool is a natural heat insulator made from cellulose. Bind fibers with boric acid and lagnin (an organic antiseptic). The uniqueness of the material is that it does not absorb water and brings it out. The composition does not contain components hazardous to health. Ecowool is fire and bioresistant, absorbs sound well and does not conduct heat. A special sprayer is used for application, but the material consumption then increases by 40%.

- Izolon is a new material in construction. With a thickness of 2-10 mm, it is well heat and sound insulating, has high moisture resistance, does not rot and is durable.

For insulation, ordinary sawdust can be used. This heat insulator has been used for many centuries. Natural material is quite cheap and completely safe for the body. Sawdust often remains after building a house. This is the most affordable insulation for a wooden house.

Sawdust is added to some building materials:

- sawdust concrete consists of sawdust, cement, sand and water;

- granular heat insulator - sawdust, glue and antiseptic flame retardant;

- wood concrete - sawdust with cement and chemical additives;

- wood blocks - sawdust, cement and copper sulfate.

The use of mineral wool

Also, mineral wool has many advantages:

- the use of mineral wool for insulation makes heat loss in the house minimal, because it has a low thermal conductivity;

- can be used in rooms with high humidity;

- is a non-combustible material;

- does not lose technical properties during the entire period of operation;

- environmentally friendly product;

- high sound insulation;

- water resistance;

- resistance to temperature fluctuations, chemical and other adverse effects.

The joints of the vapor barrier coating must be sealed.This provides for the technology of floor insulation in a wooden house. Its observance will ensure the protection of the mineral wool from the effects of moisture on it.

If it became necessary to change the floors in the apartment, and it was decided to insulate the floor in a wooden house with your own hands, then this option is the most convenient in execution and financially cheap.

Criteria for choosing the optimal insulation for a house or apartment - what to look for

We suspect that many of our readers are already shocked by the abundance of available options for floor insulation in their homes.

But what aspects should be focused on first of all? The Homius editors are in a hurry to help you in this matter! Follow our guidelines below

Thermal conductivity

This is logical and follows from the title of our topic

It does not matter whether the floor is wooden or concrete, the rule is the same - the lower the thermal conductivity, the better. Otherwise, all the heat that is in the room will gradually be transferred outside, leaving you cold and damp.

As a rule, the heat transfer coefficient is indicated on the product packaging.

Vapor barrier and hygroscopicity

The first parameter has a high value if you have a wooden house. The bottom line is that evaporation in the process of heat release tends to get out by any means. And steam is a direct path to condensate, which is fraught with the destruction of structures and the growth of various unwanted "guests" (mold, etc.) In the case of concrete, such situations are extremely rare, but wood, alas, is afraid of dampness - that's why it is needed great vapor barrier.

The high value of hygroscopicity is harmful under any circumstances - the presence of liquid in the material leads to the deterioration of all its properties and rapid failure.

When the floor begins to dampen and rot, the risk of its unforeseen collapse at the most inopportune moment increases. Well, if there are no casualties

When the floor begins to dampen and rot, the risk of its unforeseen collapse at the most inopportune moment increases. Well, if there are no casualties

Combustibility of a heater

Also, do not discard such a characteristic as the risk of ignition from the scales. In the event of a fire, any element of the room can catch fire, so it is better to exclude even the smallest possibility of such a development of events.

Mineral heaters have the least flammability, and wood-shaving, on the contrary, have the maximum

Mineral heaters have the least flammability, and wood-shaving, on the contrary, have the maximum

Safety in terms of ecology

Everything is also quite simple here - it is better to give preference to products that do not emit toxic substances, do not violate environmental rules during operation and disposal, and also do not affect the body of the owner of the house under any circumstances.

If you have to carry out the installation work with gloves and a respirator, you got a non-ecological sample of floor insulation

If you have to carry out the installation work with gloves and a respirator, you got a non-ecological sample of floor insulation

Related article:

The period of effective operation

In the process of construction or repair, each owner wants his building to function as long as possible and without breakdowns.

Therefore, it is worth paying close attention to the service life of the heater. This information can be found on the packaging or on the manufacturer's website.

Please note that durable options are available both among wood or polymer, and among mineral types of products.

Manufacturer

Finally, it is worth noting that when choosing, products from well-known manufacturers should be a priority, since only they can give at least some kind of quality guarantee.The most popular in Russia in 2019 are the following brands:

| Manufacturer | Homius editorial score, score |

| Ursa | 8,7 /10 |

| rockwool | 9,0 /10 |

| Isover | 9,1 /10 |

| Knauf | 9,5 /10 |

| Paroc | 9,7 /10 |

The main distinguishing feature of such products is the presence of specialized packaging.

The main distinguishing feature of such products is the presence of specialized packaging.

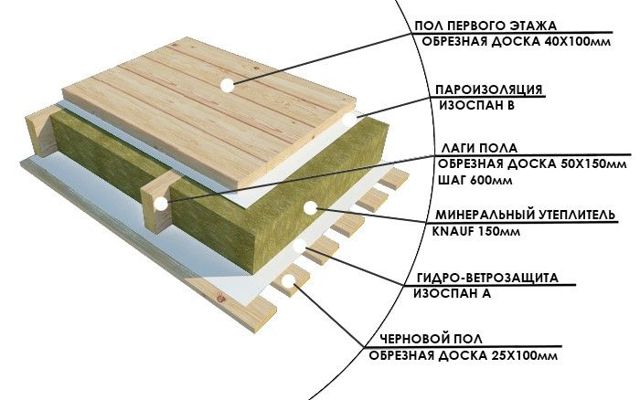

Floor types

In houses made of wood, two types of floors are used: concrete and wood.

The second option is divided into two

- floor board, glued wood;

- parquet board and laminate.

The concrete floor can be made by hand without the involvement of specialists. There are two options for laying concrete: on the ground and on logs. The most common is the first option.

All work is carried out in several stages:

- priming;

- sand;

- thermal insulation;

- waterproofing.

The next step is to fill the floor with concrete screed. If a warm floor is installed, then it must be installed at this stage.

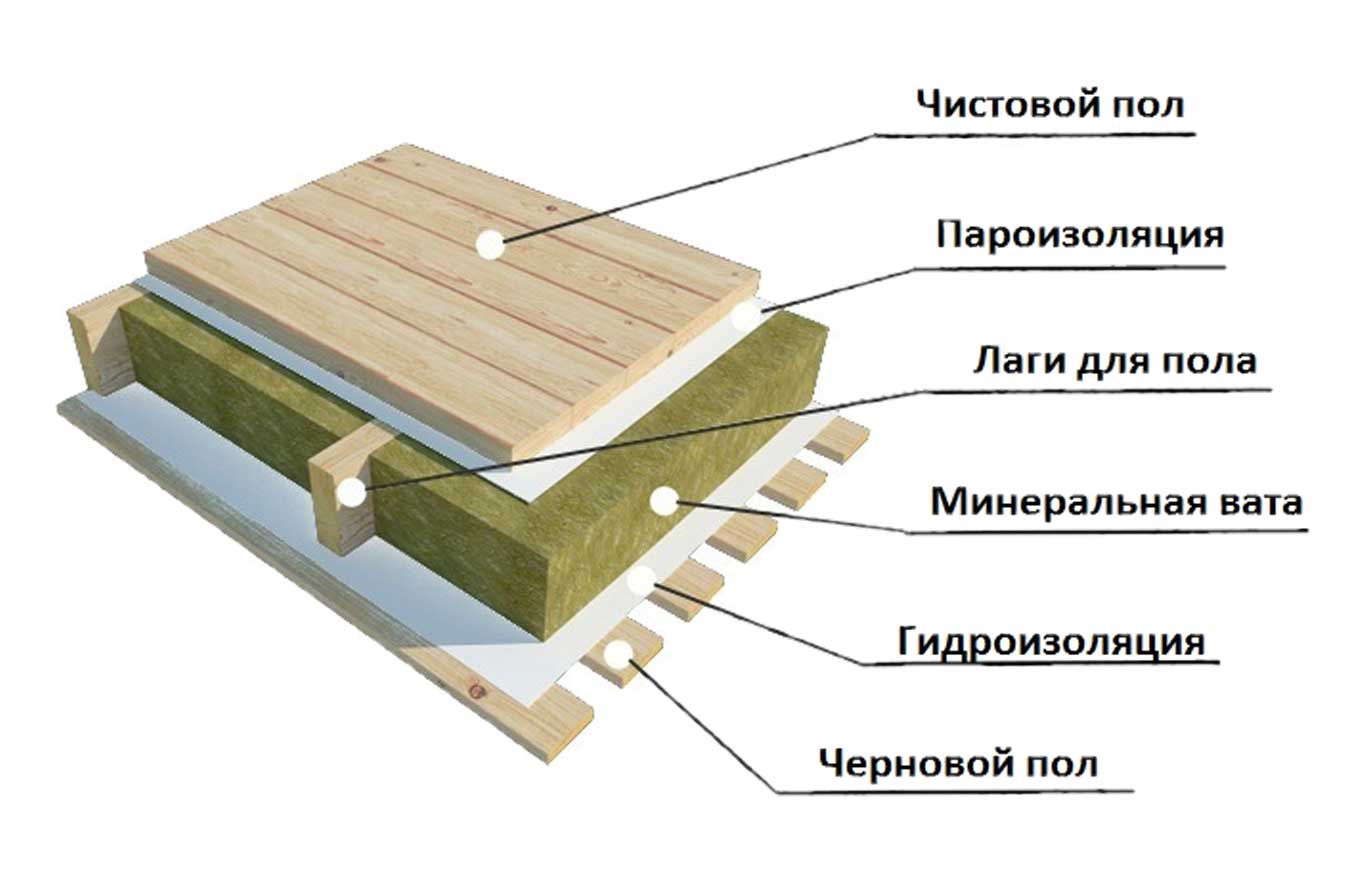

The wooden floor, like the concrete coating, also has several layers:

- bulk floor (rough);

- waterproofing layer;

- thermal insulation layer;

- clean coverage.

Floor heaters in a wooden house

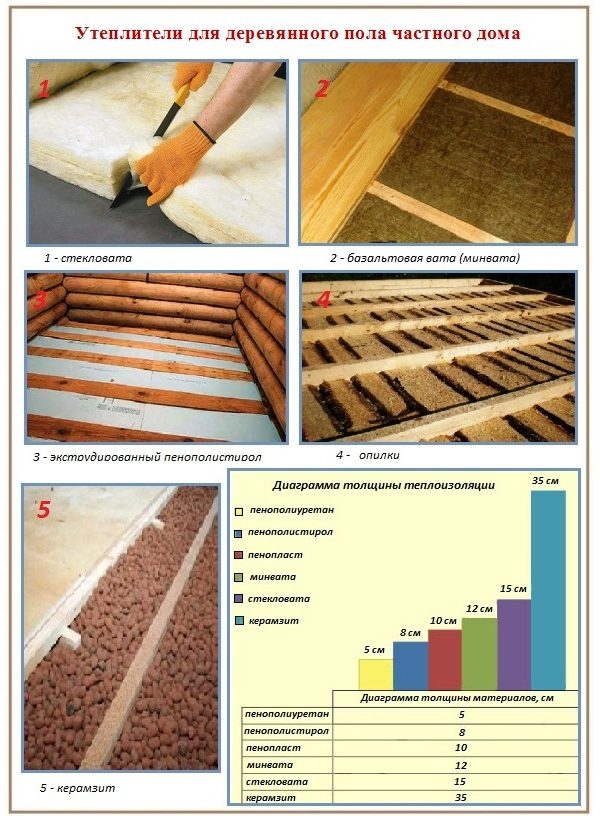

The range includes a number of products with which you can insulate the floor. It is divided into 4 types:

- Wood chipboard - chipboard, clean sawdust, plywood, ecowool, wood concrete, sawdust concrete, wood blocks;

Arbolite - slabs made on the basis of sawdust

Mineral - mineral wool and expanded clay;

Polymer (plastic) - foam, as well as similar products (polystyrene foam, foam plastic, etc.). This category also includes polymer foil products (roll type);

Silicate - glass wool.

Expanded clay and sawdust

Many craftsmen refuse to work with sawdust and expanded clay, citing the fact that other materials (penoplex, mineral wool and polyurethane foam) are more modern and, as a result, more efficient. However, a significant part of the owners strives to make their housing environmentally friendly to the end, so expanded clay and shavings are still in demand.

Moreover, they are also very cheap, which is important.

Expanded clay insulation

Modern materials are also in demand. Let's consider them.

polyurethane foam

Pros:

- practicality;

- fire safety;

- low thermal conductivity;

- immunity to aggressive environments.

Polyurethane foam - sprayed material

Minuses:

- the high cost of the material;

- high installation cost.

Styrofoam

Pros:

- resistance to temperature extremes - from -80 to +180 ° С;

- repels water;

- low density;

- strength;

- resistance to biological factors;

- low cost.

Floor insulation wooden house with styrofoam

Minuses:

- combustion toxicity;

- combustibility;

Penoplex

It is created from simple foam using extrusion technology.

Pros:

- durability;

- low thermal conductivity;

- min indicators of moisture absorption;

- strength.

Penoplex insulation

Minuses:

- lack of resistance to high temperatures (under such conditions, the foam is deformed);

- damaged by rodents;

- high price.

Mineral wool

These products are manufactured both in the form of flexible mats and in the form of solid boards.

Mineral wool insulation

Of the pluses - cheapness, of the disadvantages - when wet, it loses its thermal insulation properties.

The insulation of a log house has its own characteristics, compared with a frame house.

Conclusions. Is the installation of floor insulation relevant in 2019?

Our work for today is completed. We revealed to Homius readers all the secrets of choosing a thermal insulation material and compared them. The verdict is unequivocal - floor insulation work should become an obligatory part of your construction or repair, regardless of the conditions.

Almost forgot! The editors of Homius will be interested to read stories about how our readers installed the insulation, what problems you encountered or interesting life hacks. Leave comments and share your opinion. In the meantime, we wish you good luck with your plans!

Watch this video on YouTube

Watch this video on YouTube

Previous RepairStretch two-level ceilings - aesthetics and practicality

Next RepairHow to choose a drill bit for metal cutting