- How to do it yourself?

- Step one - slab laying schemes

- Step Two - Back Wall Insulation

- Step three - connecting the plates

- Step Four - Saving Spacing

- Step five - insulating stone or wood elements

- Step six - installation of steel profiles

- Step seven - compaction

- Step eight - selection of the pressure chamber

- Step 9 - Installing the ventilation grilles

- Materials for insulation of chimney ducts

- Why you need to insulate the chimney pipe

- Material selection

- Why does the structure collapse?

- Indications for warming

- How to avoid common mistakes - experts recommend

- Ways to insulate a gas chimney

- Insulation of an asbestos-cement gas chimney

- Insulation with brickwork

- Insulation of the chimney pipe with plastering

- Warming with mineral wool

- Steel chimney insulation

- Insulation of a brick chimney

- 2 Chimney insulation from metal pipes

- Features of the chimney insulation process

- Self-assembly

- Types and properties

- Bulk

- Cellular

- fibrous

- Liquid

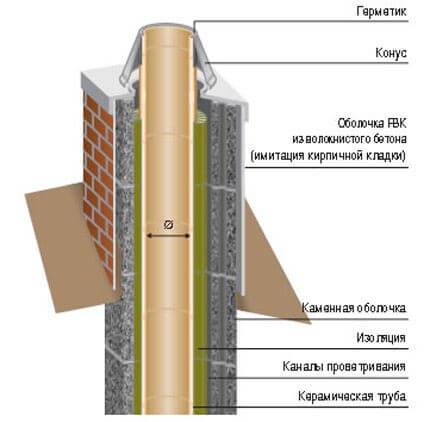

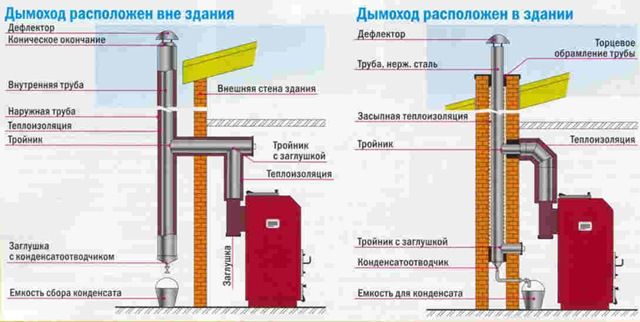

- Types of gas exhaust chimneys

- Chimney pipes made of stainless steel

- Brick chimney device

- Chimney from asbestos-cement pipes

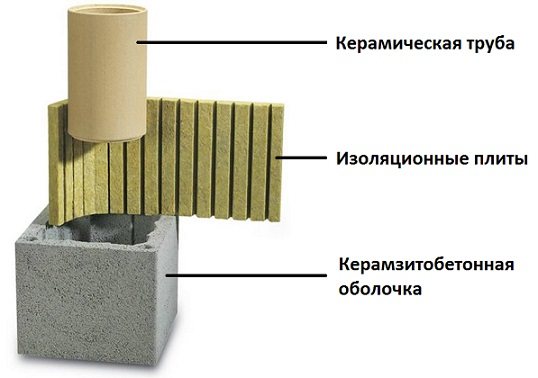

- Smoke channel from ceramic pipes

- Summing up

How to do it yourself?

- First, the required number of thermal insulation boards is taken, which are cut to the size of the fireplace insert.

- After that, a special heat-resistant adhesive (mineral, cement-based) is applied, and the application should be carried out pointwise.

- When installing foil material, glue is applied to the non-foil part.

- After that, the plates are mounted on the walls. Joints and other openings must be sealed with special heat-resistant aluminum tape, which can also be reinforced.

When the main heat-insulating part of the fireplace itself is finished, the installation process of the decorative portal (firebox) begins, but it is important to remember that between this frame and the thermal insulation layer there should be at least 4 cm, but not more than 10 cm. Then profiles are mounted, where additional thermal insulation boards in accordance with the dimensions

Making thermal insulation for boiler rooms or in the bath of a private house with your own hands is not difficult if you follow our recommendations.

Step one - slab laying schemes

It is important to carefully plan how the slabs will be laid. Knowing the exact dimensions helps to minimize the purchase of extra slabs and reduces the amount of waste.

Step Two - Back Wall Insulation

The back wall of the fireplace is often an external partition, and therefore also in contact with hot air, therefore it must be protected by plates with an aluminum screen. Due to this, more hot air will remain inside the fireplace body. Air - in the future will be distributed into the room. The board is mounted mechanically with stainless steel dowels or glued with a high temperature adhesive.

Step three - connecting the plates

To avoid gaps through which dirt can get inside and out of the fireplace, it is necessary to fold and connect the plates tightly. For this purpose, a high-temperature adhesive tape with aluminum foil is applied to maintain the continuity of the joints of the aluminum foil covering the boards. Plates are stacked with foil inside the fireplace.

Step Four - Saving Spacing

It is very important that the insulation does not lean against the fireplace or firebox. Between the fireplace and the stoves it is necessary to leave an air gap - at least 4 cm

Step five - insulating stone or wood elements

Stone and wood elements in the fireplace should also be insulated. There is a great risk that the lack of insulation on these elements will damage them.

Step six - installation of steel profiles

After installing the insulation, a drywall casing is made from steel profiles. In this case, the frame is built after installing the lower part of the fireplace.

Step seven - compaction

In order for thermal insulation to fulfill its function, special attention must be paid to two elements: the precise installation of panels and the sealing of all joints with aluminum tape

Step eight - selection of the pressure chamber

To reduce the undesirable effect of hot air from the fireplace on the ceiling, a decompression chamber is installed directly under the ceiling. Insulation is also installed in its interior. The next stage of work is the installation of drywall sheets to the grate.

Step 9 - Installing the ventilation grilles

The case is equipped with 2 ventilation grilles made of materials resistant to high temperatures. The grill for air supply is installed in the lower part of the housing, and for exhaust ventilation on the opposite side in the upper part.The decompression chamber must also have 2 ventilation grilles to keep the ceiling cool. Then all the necessary finishing work is carried out.

Materials for insulation of chimney ducts

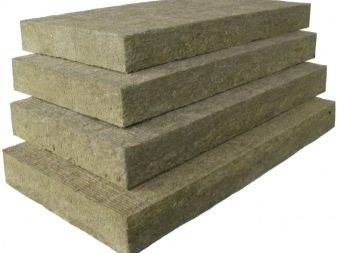

In order to produce high-quality insulation that will last more than one year, only refractory materials with a low specific gravity should be used. For this, the following materials are most often used:

- Various lukewarm (mineral).

- Basalt slabs.

- Glass wool.

- Refractory bricks (rubble or red).

- Galvanized sheet.

All of them are affordable, easy to work with and fireproof. They also have high durability and are absolutely neutral to almost any chemical environment. Due to the fact that all these materials are easy to bend, they can be used to work with objects that have a complex geometric configuration.

Of all the materials listed above, mineral wool basalt tiles are the most popular for insulating gas-fired or coal-fired furnaces. It has low thermal conductivity, and as a result, it is best suited for chimney insulation. Basalt tiles perfectly maintain the minimum temperature in the outer part of the casing. Among the advantages of this tile are the following factors:

- Basalt tiles are absolutely safe and are made from exclusively environmentally friendly materials.

- To work with this type of insulation, you do not need to use many tools. It is enough to get a hacksaw and a tape measure.

- This material is easy to adjust even to the most complex geometric configurations of the chimney. Basalt tiles are resistant to fungus and UV radiation.

- The service life of this heater is at least 50 years.

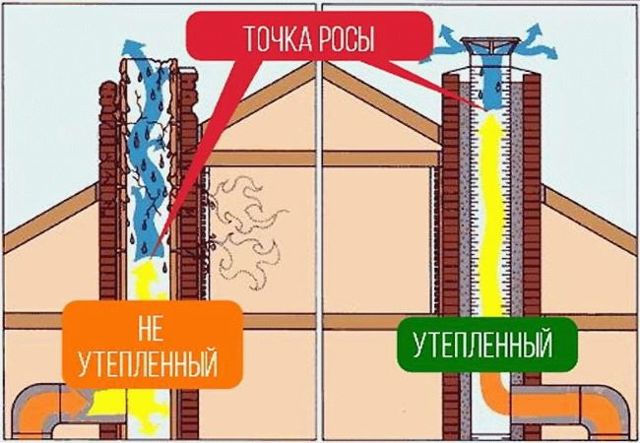

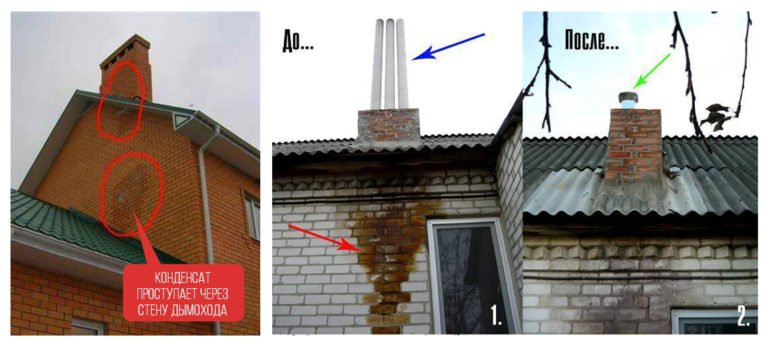

Why you need to insulate the chimney pipe

If you are concerned about the question of how to insulate a chimney pipe, then, first of all, you should find out why this needs to be done. It is necessary to insulate the chimney pipe for one simple reason - so that it serves for a long time and reliably. When we use a fireplace or stove, oxygen vapor accumulates in the pipe. This is due to the temperature on the surface of the chimney, which is several times higher than the temperature of the entire environment.

Oxygen steam is not only damp, but also a special substance that can act very aggressively on the pipe. When the chimney cools, the oxygen vapor permeates its walls. And if the temperature outside is below zero, then it becomes very dangerous. To avoid this destructive effect, it is just necessary to reliably insulate the entire structure of the chimney.

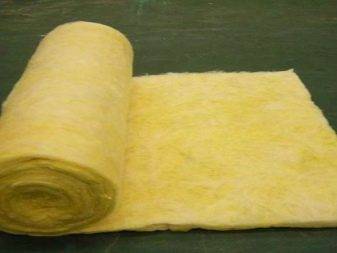

Material selection

In order to do the insulation with your own hands in compliance with fire safety regulations, it is necessary to correctly select the heat-insulating material.

The only material that meets these requirements is mineral wool. To insulate pipes, you can use a heat insulator, produced in the form of rolled mats, or special forms for pipes (not suitable for brick chimneys). Do-it-yourself insulation of the chimney with mineral wool should be carried out in compliance with safety regulations. Each worker must have the following personal protective equipment:

Effective heat insulating material

- mask or respirator;

- glasses;

- gloves;

- closed clothes.

This is necessary so that particles of the material do not get on the skin, eyes and lungs. Mineral wool fibers can cause serious irritation and itching of mucous membranes and skin.

The thickness of the insulation is selected based on the temperature of the resulting gases and outside air, as well as the location of the pipe:

- for outdoor - within 70-100 mm;

- for those located inside the building - within 30–50 mm.

Mineral wool can be used in the following types: basalt, glass wool, slag wool. Before use, read the manufacturer's instructions for the heat insulator. In addition to this effective material, bricks are sometimes used as an inexpensive alternative.

Why does the structure collapse?

The chimney is designed to remove smoke and other combustion products into the atmosphere. When burning a stove or fireplace, oxygen vapor accumulates, the amount of which increases in winter due to the intensity of heating. In addition, during the combustion of firewood or coal, several types of acids are formed, which also precipitate on the walls of the structure due to steam condensation.

The result is a chemically aggressive mixture of condensate and acid, which quickly destroys building materials. And this is not the only problem - the formation of steam inside leads to smoke in the oven: you need to constantly ventilate the room. If the amount of steam reaches a critical level and the pressure rises, an explosion may occur.

Insulation of the chimney will avoid such consequences. There are several options for insulating structures.

Indications for warming

The process of gas removal is accompanied by the accumulation of particles of combustion products on the walls of the smoke channel and the formation of condensate, which negatively affects the performance of heating equipment. Insulation of an asbestos, ceramic or metal chimney contributes to leveling problems with a decrease in the efficiency of the device, therefore it is recommended to perform high-quality thermal insulation of the chimney even at the construction stage. If necessary, the gas outlet channel is also insulated during operation, using a suitable version of the material with a low thermal conductivity.

What gives chimney insulation:

The risk of exposure to factors that cause damage to the surfaces of metal, ceramic or asbestos flue pipes is reduced. So, the presence of high-quality thermal protection helps to eliminate problems with condensate. In this case, a significant increase in the potential of the exhaust channel is observed.

Problems with traction deterioration are leveled. With reliable thermal insulation, the level of thermal conductivity of the pipe material decreases. This explains the decrease in the temperature difference between the flows of combustion products and the surface of the chimney line. As a result, the level of deposits on the walls is significantly reduced, and the risk of traction deterioration is leveled.

The energy efficiency of the heat generating device is optimized. An insulated chimney provides for the correct consumption of fuel resources, as energy costs are reduced to maintain the required temperature level in the combustion chamber.

Improved structural strength characteristics

With the help of a heat-insulating frame, a kind of reinforcement of the structure is performed, which is especially important when arranging the chimney section above the roof level. Reinforced with a reliable layer of heat-shielding materials, the smoke channel is not afraid of significant wind loads, temperature changes and other external factors.

High-quality thermal insulation is important not only when arranging thin-walled steel smoke exhaust pipes. Insulation with materials with a low thermal conductivity improves the efficiency of brick chimneys and purlins made of asbestos, metal and ceramics.

Chimney insulation with mineral wool

Chimney insulation with mineral wool

How to avoid common mistakes - experts recommend

Before insulating, especially an asbestos-cement or steel chimney, make sure that the structure is installed correctly. The exhaust pipe must comply with fire safety rules and other technological standards.

It is recommended to use heaters that breathe and do not accumulate moisture. In other cases, ventilation gaps of at least 25 mm must be left. Use materials that are available for self-laying. Follow the manufacturer's instructions.

Among mineral heaters, basalt wool is the most effective. It is somewhat more expensive than the usual mineral one, but with a small consumption, this does not play a significant role. But in reality there are significant advantages:

- ignition is possible at very high temperatures;

- has a high density;

- significant vapor permeability.

Basalt wool is good for thermal insulation both outside and in the attic

Even the highest quality thermal insulation does not prolong the life of the structure, when it is not previously brought to the proper state: cleaning is required, replacement of destroyed elements.

Work on the external insulation of the chimney is carried out immediately after its construction. A few years later, destructive processes begin that thermal insulation will no longer stop. It will need repair or a complete replacement of the structure.

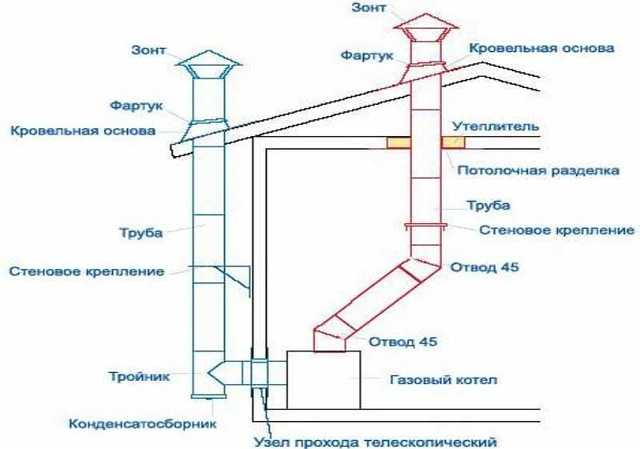

Ways to insulate a gas chimney

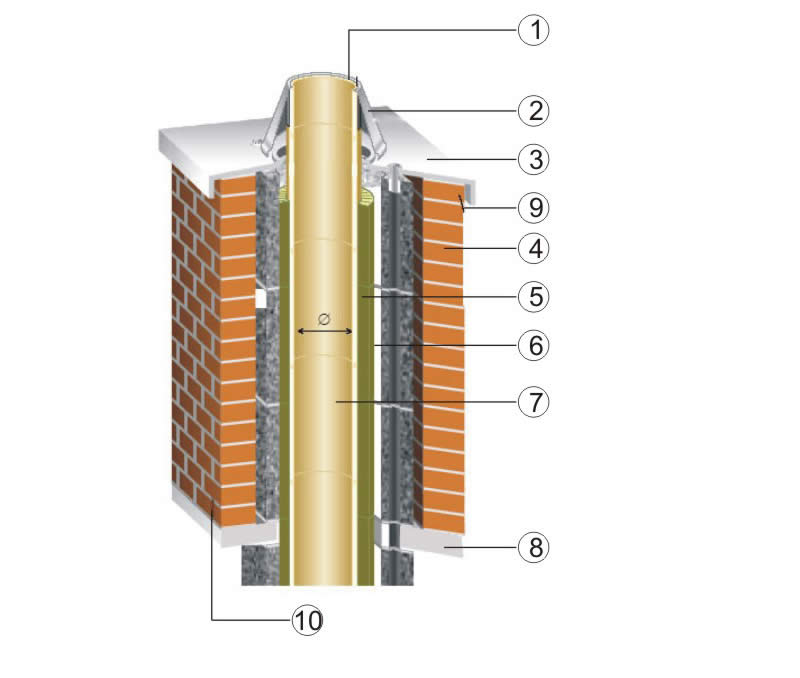

Insulation requires only that part of the chimney, which is located on the street or in an unheated attic. In this case, the pipes fixed on the facade of the building must be completely insulated, including the horizontal section passing through the wall.

The choice of insulation method is determined by the material from which the gas chimney is made. Work on the insulation of the chimney from a gas boiler depends not only on its design, but also on the material chosen.

Insulation of an asbestos-cement gas chimney

There are three fundamentally different ways to insulate an asbestos-cement pipe. Mineral wool, brickwork or plaster are suitable for their implementation.

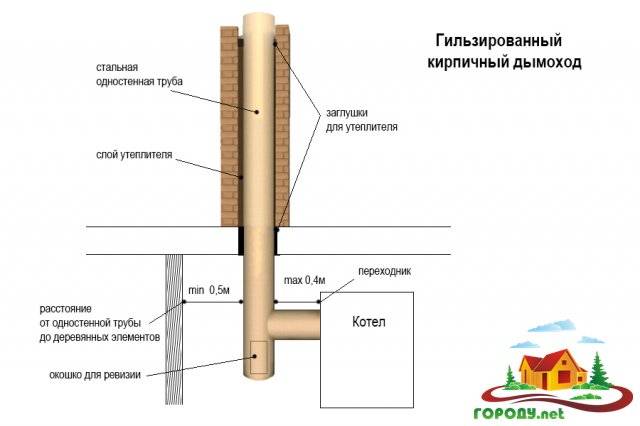

Insulation with brickwork

Insulation with brickwork with filling voids with loose insulation is allowed, but the process is quite laborious and time consuming.

This method is most often resorted to if there is already a brick chimney, and an asbestos-cement or galvanized steel pipe is used as a sleeve.

Insulation of the chimney pipe with plastering

The asbestos-cement pipe has high adhesion, so plastering can be used as insulation. Before performing work on the pipe, it is necessary to fix the reinforcing mesh.

The solution is prepared according to the following proportion:

- 3 parts of sifted slag;

- 1 part cement;

- 2 parts lime with water.

The solution should have a thick plastic consistency. The first layer is applied with a thickness of 20-30 mm. All subsequent layers are applied only after the previous one has dried. Before painting or whitewashing, the surface of the plaster must be sanded, and the cracks that have appeared must be puttied.

Warming with mineral wool

The work is reduced to fixing a layer of mineral wool on the outside of the pipe. Before starting work, the pipe must be cleaned of dust and the layer of rolled insulation must be fixed with clamps. Given that mineral wool is able to absorb moisture, it is recommended to hide it under a galvanized steel casing.

In order to save money within the attic, you can do without a steel casing, but under the influence of precipitation, the service life of mineral wool is unlikely to exceed 2-3 years.

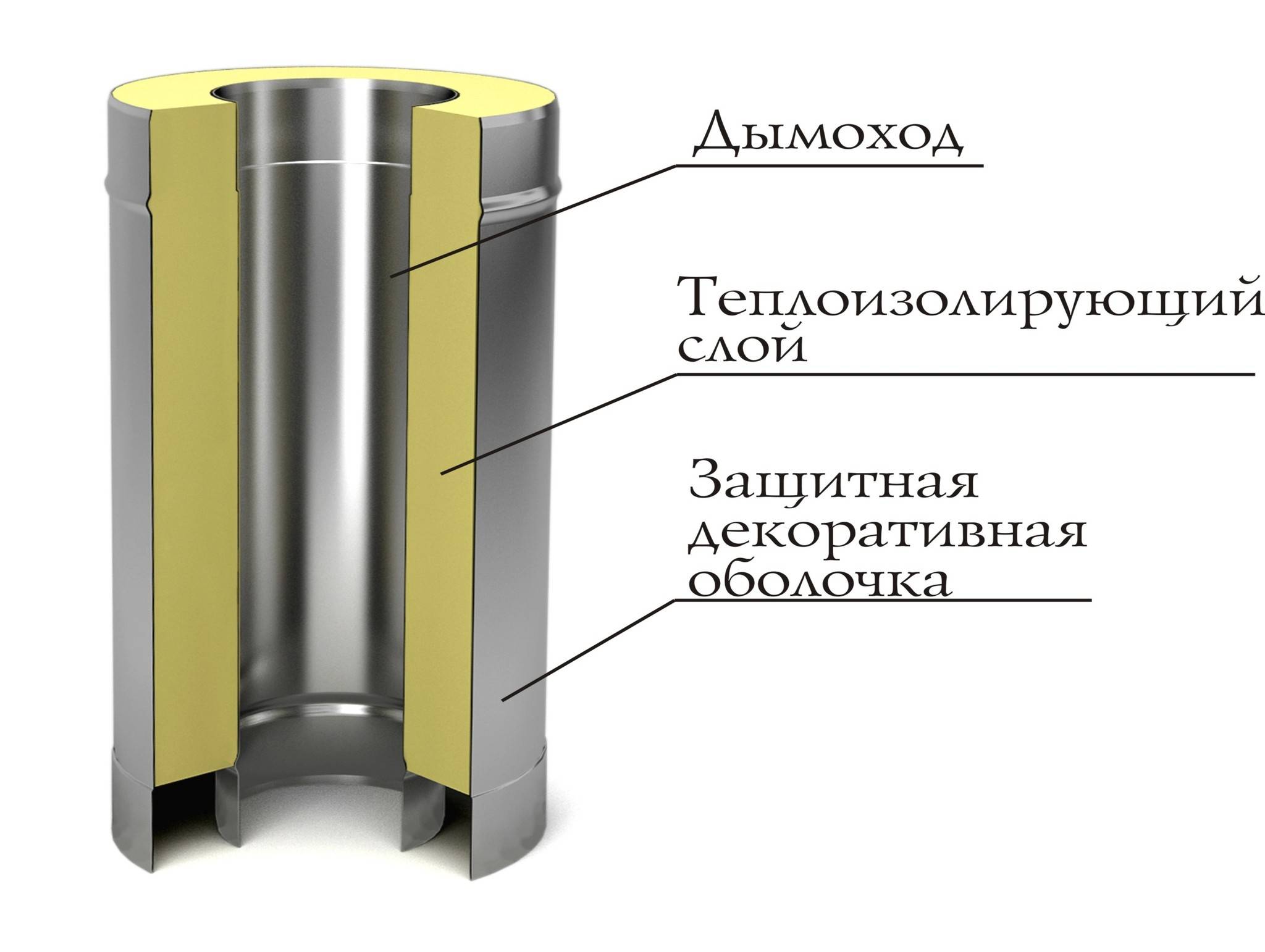

Steel chimney insulation

Stainless steel chimneys are essentially two pipes of different diameters, the space between which is filled with insulation. You can purchase a ready-made design in the form of a sandwich pipe. In this case, it is sufficient to carry out installation work without insulation, since the insulation has already been installed initially.

But the cost of sandwich pipes is high enough that you can save money by building a similar structure yourself. To do this, it is enough to wrap the inner pipe with a rolled mineral wool insulation or use ready-made shells or cylinders of the same material. Instead of stainless steel, the outer tube can be galvanized.

To fix the mineral wool on the inner steel pipe, it is best to use special clamps.

To fix the mineral wool on the inner steel pipe, it is best to use special clamps.

Another way to perform insulation within the attic is to install a wooden box using backfill. Slag, sand, expanded clay can be used as bulk materials.

It is easy to insulate a steel pipe with a wooden box with expanded clay backfill

It is important to avoid contact of combustible materials with heated surfaces. In places where the box comes into contact with the roof or crate, it is necessary to install protection from steel sheets to prevent fire

In places where the box comes into contact with the roof or the crate, it is necessary to install protection from steel sheets to prevent fire.

Insulation of a brick chimney

A brick chimney is traditionally insulated by plastering with preliminary fixing of the reinforcing mesh. The advantages of this method are low cost, the disadvantages are low efficiency. Heat losses are reduced by no more than a quarter.

Facing a plastered chimney with natural slate tiles will not only protect the chimney from destruction, but also give it an original aesthetic appearance.

You can increase the efficiency of brick chimney insulation with the help of mineral wool mats.

The insulation should fit snugly against the plastered chimney, so the appearance of cold bridges is excluded. Taking into account the fact that mineral wool easily absorbs moisture, it must be covered with a layer of vapor barrier film, followed by fixing with construction tape.

2 Chimney insulation from metal pipes

Thermal insulation of chimneys of fireplaces and stoves, which are not the main source of heating and are used periodically, and brick pipes are carried out quite simply - their surfaces are plastered. But if a gas boiler or a similar heating device using any other fuel is installed in the house, then sandwich chimneys are mounted. Their price is quite high, so they can be made by hand from stainless steel.

As a chimney insulation from a metal pipe, it is allowed to use any materials, but for a chimney made of asbestos pipes - mineral wool. Asbestos resists heat well, is not combustible, so it is enough to wrap it with insulation of the required thickness and cover it with galvanized sheets. The disadvantages of the material include the ability to absorb moisture and the rough surface of the walls, which increases the likelihood of deposition of formations.

The situation is somewhat more complicated when using bulk material for thermal insulation, since it will be necessary to mount a protective casing around the pipe, which will also be a frame, and then fill it with insulation. To prevent moisture from getting inside it, the gap between the casing and the pipe in the upper part is filled with cement mortar.

Do-it-yourself sleeves are carried out as follows:

- Prepare mineral or basalt wool and steel pipes (sleeves), preferably galvanized. Their diameter should exceed the dimensions of the chimney by several centimeters, but not more than 10.

- The chimney is covered with a layer of insulating material, the thickness of which should be more than 5 cm.

- Fix with foil tape or any soft wire.

- A protective cover is put on the heater.The edges of the sleeve, made of thin metal, can be fixed with self-tapping screws or use tightening straps.

- The gap in the upper part of the chimney, which was formed between the insulation and the protective casing, in order to prevent moisture from entering the structure, is filled with cement mortar.

Features of the chimney insulation process

Difficult, but possible. This is how you can describe the insulation of the chimney with your own hands - the process is quite complicated

It is important to follow the sequence of technological steps so that you do not have to redo it. Due to the lack of heat saving equipment is destroyed

Condensation (that is, moisture) affects this. Therefore, we insulate our favorite pipe without delay))

Condensation in the pipe destroys the chimney

Chimney pipe insulation:

- eliminates the appearance of condensate;

- protect from external influences and vagaries of nature (rain, snow, wind, temperature changes);

- protect against heat loss.

Before insulating the chimney iron pipe, check whether the installation of the structure is correct:

- height - at least 5 meters. This provides the best traction;

- to combustible elements of the roof - at least 25 centimeters;

- must have a spark arrester. This is a stainless steel mesh that encircles the structure from above.

Self-assembly

If a decision is made to independently carry out all the work, due attention should be paid to preparation, calculate the amount of material and what tools will be needed for work:

- Perforator;

- Nails;

- Felt pen or tape measure;

- Scissors;

- Profiles (metal);

- Vapor barrier film;

- A hammer;

- Basalt insulation;

- Glasses for eye protection.

To make calculations, you will need to take into account the material used and the fuel that is used for heating. This aspect affects the temperature readings inside the pipe. With 7+ 6+ and using solid type fuel, the thickness of the heat-insulating segment should be in the range of 50-100 mm, if the structure passes through the attic, then 30-50 mm

With 7+ 6+ and using solid type fuel, the thickness of the heat-insulating segment should be in the range of 50-100 mm, if the structure passes through the attic, then 30-50 mm.

If the appliance is operated with diesel fuel or gasoline, the thickness should be 20-30 mm. Measure the outer diameter, the length of the chimney channel, the section of the pipe that comes from the nozzle.

The scheme does not imply anything complicated for self-fulfillment:

- Carrying out the preparatory stage. It is necessary to cut holes in a diameter of 20-30 cm larger than the section of the prepared pipe;

- Installation of the crate;

- Installation work with insulation;

- Steam insulation;

- Facing the resulting structure;

- Closing the resulting hole in the roof.

All work requires mandatory calculations and measurements. Otherwise, you can damage the structure, make it less resistant to condensation or increase heat loss.

It is recommended to seek the advice of a specialist who will also help you choose a good option for thermal insulation material. With a successful choice, each owner of a private facility will be able to extend the life of the chimney, as well as ensure safe operation for himself and his family, which is no less important.

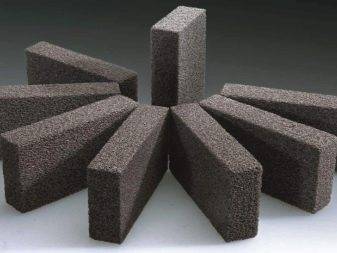

Types and properties

Insulation can have a different basis and production technology, which determines its appearance and technical characteristics. Consider the main types of non-combustible heat-insulating material.

Bulk

They are stones and formations of various fractions, which are poured into the space of a building structure. As a rule, for greater thermal efficiency, it is recommended to use bulk heaters of different sizes: larger ones provide thermal insulation, small ones fill the space between them.

Bulk types of non-combustible heaters include the following materials.

Expanded clay. Environmentally friendly material based on clay. Suitable for thermal insulation of hard-to-reach places. In addition to high thermal insulation characteristics, it has moisture resistance. Expanded clay is the best suited for insulating fire hazardous objects, it has long been used in the organization of industrial furnaces.

- Expanded vermiculite. The product is based on hydromicas subjected to high-temperature firing. Usually, this material is used for thermal insulation of low-rise buildings, as well as attics and external thermal insulation. Differs in environmental friendliness and improved indicators of biostability, among the shortcomings is the inability to withstand moisture. Leveling it allows only high-quality and properly installed waterproofing.

- Perlite. Material based on volcanic glass, which provides low thermal conductivity and low weight.Only 30 mm of perlite can replace a 150 mm layer of brickwork in terms of its thermal efficiency. Among the shortcomings - low rates of moisture resistance.

Cellular

Outwardly, such heaters look like frozen soap suds. The most common fire-resistant cellular heat-insulating material is foam glass. It is produced by sintering glass chips with coal or other gas generating agent. It is characterized by durability (service life reaches 100 years), mechanical strength, low thermal conductivity.

fibrous

Outwardly, the material resembles cotton wool, since it consists of randomly arranged finest fibers of a white or milky hue. Such heaters are called - "cotton wool". Release form - rolls or mats.

Mineral wool is also sheet. Sheet products have less rigidity compared to counterparts in mats. If we talk about fire-resistant fibrous insulation, then they include several types.

Glass wool. Withstands heating up to 500°С, retaining its technical characteristics. These include thermal efficiency, durability, low weight. However, the material is prone to shrinkage, and requires special protection during operation, since thin fibers prick, dig under the skin, and the smallest particles irritate the mucous membranes of the upper respiratory tract.

- Basalt wool. Basalt wool is based on fibers from rocks that are preliminarily heated to over 1300°C. This is due to the ability of wool to withstand high temperatures, up to 1000 ° C.Today, stone wool is one of the best thermal insulation materials: it has a low moisture absorption coefficient, is vapor permeable, does not shrink, is environmentally friendly and biostable.

- Ecowool. 80% recycled pulp, which has undergone a special flame retardant treatment. The material is environmentally friendly, has a low weight and low coefficient of insulation, but low moisture resistance.

Liquid

The raw material is sprayed with the use of special equipment, after hardening it forms a mass resembling polystyrene foam in its appearance and to the touch. The most well-known type of liquid fire-resistant insulation is liquid polyurethane.

It is characterized by environmental safety, and thanks to the application method and improved adhesive properties, it is evenly distributed over the surface, filling cracks and joints. This, firstly, ensures the durability of thermal insulation, and, secondly, guarantees its quality and the absence of "cold bridges".

Types of gas exhaust chimneys

Depending on the material used, gas chimneys are divided into several types, while brickwork is practically not used for venting gases.

However, brick is often used for tying the exhaust pipeline. This is not a simple facing brick - it has a square shape, and its inner part is a round section.

Chimney pipes made of stainless steel

Metal chimneys are the most popular. The most commonly used stainless steel, which is characterized by high corrosion resistance.

Chimney pipes made of stainless steel are easy to install and highly resistant to corrosion in any aggressive environment.

The main advantages of stainless steel structures:

- Resistance to condensed moisture;

- Resistance to precipitation;

- Chemical resistance to soot from gas combustion;

- Resistant to high temperatures;

- The smooth inner surface reduces the coefficient of friction, ensuring the unhindered passage of gases with minimal soot deposits;

- Light weight allows the use of standard fasteners;

- Simple installation eliminates the complexity of work with significant destruction of the walls;

- Pretty democratic value.

It is not recommended to use ordinary stainless steel pipes. This is due to the fact that it is the chimney pipes that are made of special grades of stainless steel, which, thanks to the introduction of alloying elements, are highly resistant to acids resulting from the formation of condensate.

Brick chimney device

Currently, a brick chimney is used much less frequently, because. is being built mainly for brick ovens, and they are being actively replaced by gas models. In addition, its device takes a lot of time.

Along with this, the brick chimney has the following disadvantages:

- Rough inner surface, contributing to the accumulation of soot and reduced traction;

- Not resistant to acid attack. Due to the hygroscopicity of the material, condensate is absorbed and quickly destroyed;

- Difficulty of construction. Masonry from piece building materials takes much more time than the assembly of metal or ceramic modules.

You can eliminate the negative qualities of a brick chimney by inserting a sleeve in the form of an asbestos or stainless steel pipe.

Chimney from asbestos-cement pipes

Previously, asbestos-cement pipes were very widely used in the construction of chimneys for gas boilers. Despite the porosity of the material, the roughness of the inner walls and the far from ideal cross section, the popularity of asbestos-cement pipes is due to their low cost.

The chimney made of asbestos-cement pipes is characterized by a low price, but for reliable operation it requires a strictly vertical arrangement

To avoid these shortcomings, the chimney made of asbestos-cement pipes should be as straight as possible with sealed joints. A simple cement mortar is not enough here, dried joints must be treated with a sealant or special sealed clamps should be used.

In general, the work is easy. With proper sealing of the joints, a chimney made of asbestos-cement pipes is in no way inferior to its stainless steel counterpart. However, during active operation, it will serve no more than 3-5 years, after which it requires mandatory replacement.

Smoke channel from ceramic pipes

Chimneys made of ceramic pipes are distinguished by reliability, durability, high corrosion resistance to aggressive substances and temperature extremes.

At device of a high chimney made of ceramic pipes require the construction of a reliable foundation, as they are erected according to the “root chimney” scheme

However, along with this, they have their drawbacks - a lot of weight, the mandatory construction of a separate foundation and high cost. But all these shortcomings of ceramic chimneys are covered by decades of reliable and stable operation.

Summing up

So, we learned how to insulate the chimney with our own hands. Conducted thermal insulation significantly extends the period.The thrust increases, the amount of condensate decreases, which means that the amount of soot deposited on the walls decreases.

If you need to extend the chimney (for example, when replacing the roof), trust it only to professionals. Otherwise, you can get what you can see in the video.

Therefore, be sure to insulate the brick pipe so that in winter there are no problems with heating the house.

At the end, be sure to watch the video in which the well-known builder blogger Andrey Terekhov explains the principles and methods of how to insulate a chimney pipe with your own hands.