- Insulation materials

- Internal heating of pipes

- steam generator

- Homemade boiler

- Hot water

- Need

- Warming for seasonal and permanent residence

- We use glass wool

- Who should pay for the replacement of pipes in the basement -

- How does a heating cable work?

- How to insulate a water pipe on the street

- Do I need to cover the pipes from the cold

- Insulation of pipelines according to SNiP

- Basic norms and rules for thermal insulation

- The main tasks of thermal insulation, features of the choice of materials

- Types of heaters

Insulation materials

To insulate a do-it-yourself water pipe in a country house, several options for special materials are used. The first variety, which is called "pipe shell", is a shell in the form of a pipe.

The second variety is a variety of insulating materials made in rolls of various widths and lengths.

"Pipe shells" are made from polystyrene foam, extruded polystyrene foam and polyurethane foam. It is a product in the form of a semi-rigid cylinder, which consists of two halves. It is put on the pipe, and fastened with overlaps, special glue, clamps and foil tapes.

Typically, the length of such a "shell" is one meter, but can reach two meters.Such products can be produced with additional coatings of foil, fiberglass or galvanized. This type of insulation material is quickly and easily mounted, as well as removed and replaced during repairs. "Shell", covered with fiberglass, can be used for all types of water pipes or pipelines that are placed in the ground, outdoors and indoors.

It will be useful to read:

Water well drilling methods

Water has always been and is one of the essential elements of life. And even the very first settlements tried to create on ...

Styrofoam is called foamed plastic in the form of small white balls (known to absolutely everyone), which, in the manufacture of the “shell”, are pressed into the shape of a pipe and then steamed. Interestingly, this material is almost 97-98 percent air. The advantages of polystyrene are lightness, practicality and low cost. And the disadvantages include fragility and fragility.

Extruded polystyrene foam is a type of polystyrene foam that uses pressure and heat to produce it. The result is a stronger material than foam. This material is liked for its resistance to environmental influences (does not rot). It does not absorb moisture, has a long service life, low weight and is easy to install.

Polyurethane foam is a plastic foam material consisting of numerous gas-filled cells.

It attracts attention with the best sound insulation characteristics, good mechanical strength, ease of use and low weight.

Of the insulating materials that are produced in the form of rolls, it is worth mentioning stone wool, polyethylene foam and glass wool.

Glass wool is a material for insulation, consisting of glass fibers.

It attracts attention with its noise and heat insulation characteristics, durability and price. The disadvantages include the fact that when working with glass wool, it is imperative to observe safety precautions, since this material is prickly. During isolation work, the respiratory organs and skin are protected by protective equipment (special work suits, gloves and masks)

During isolation work, the respiratory organs and skin are protected by protective equipment (special work suits, gloves and masks).

Fibers of stone or basalt wool are produced from molten rocks of volcanic origin, slag and silicate materials

This insulating material attracts attention with its high resistance to various loads and impacts, incombustibility, as well as the fact that products of various shapes and densities are made from it.

Foamed polyethylene is obtained by processing ordinary high-pressure polyethylene using propane and butane. It is an elastic porous material consisting of a large number of cells. Foamed polyethylene stands out among other insulating materials with its highest resistance to water, and it is also not affected by fungi and bacteria. It tolerates well the effects of petroleum products, alkalis and acids.

Internal heating of pipes

Consider what to do when water froze in a pipe underground. With a shallow depth and low hardness of the soil, it is worth digging a trench and applying some of the methods described above.If this is not possible, internal heating should be carried out. The main methods are based on the application:

- steam generator;

- homemade boiler;

- hot water.

All methods assume the possibility of penetration into the pipeline. If it is missing, you should disassemble or cut out part of the structure, after cutting off the water supply.

steam generator

To defrost the pipe, you will need a steam generator - a device that produces hot water vapor under pressure. Stages:

- Pour water into the tank.

- Connect a heat-resistant hose with a small diameter to the steam generator.

- Insert the hose as far as it will go (up to the ice plug) into the water pipe. At the same time, there should be free space in it for the flow of melt water.

- Turn on the steam generator. Wait until the ice begins to defrost. This usually takes 5-15 minutes. The amount of water in the steam generator tank must be monitored.

When solving the problem of how to heat water in a plastic pipe underground, if there is no steam generator, you can use an autoclave. The heat-resistant hose must be connected to the fitting of the appliance.

Homemade boiler

You can warm up the plastic water supply using a homemade electric boiler. This method is not suitable for metal structures.

It involves working with high voltage, so you need to be careful

Action algorithm:

- Take a copper wire with two insulated cores (section - 2.5-3 mm).

- Separate the wires and spread apart.

- Remove the winding from one wire. Bend the second core in the opposite direction along the wire.

- Tightly wrap the "bare" part 3-5 times around the fold. Cut off the rest.

- Retreat from the turns of 2-3 mm. Strip the end of the bent wire.Wind it around the insulated wire 3-5 times. Trim off the excess. The turns of the first and second wires must not touch.

- Connect the plug to the other end of the wire.

- Insert the "boiler" into the water supply until it stops.

- Plug in the plug. Under the influence of heat, the ice should begin to melt.

- As the cork decreases, the "boiler" should be moved deeper.

A mobile steam generator will help to warm the pipe in the ground in a fairly quick time

Hot water

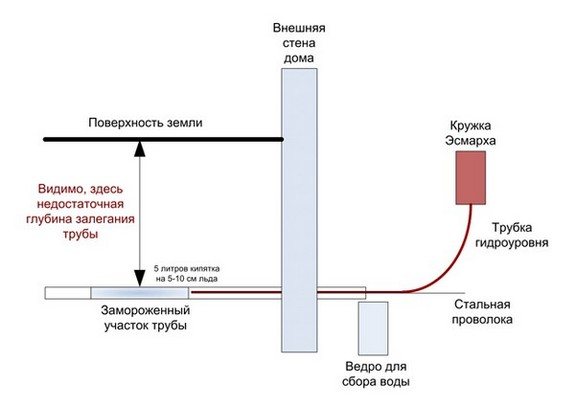

The essence of this method is reduced to the impact on the ice in the pipe with hot water. For its "delivery" to the cork, you can use:

- hydro level and Esmarch's mug;

- pump.

The first option is suitable if the question arose of how to warm up a frozen pipe underground when the plug is far from home, and the system has turns and bends. Required:

- building hydraulic level;

- Esmarch's mug (device for enemas);

- hardened steel wire.

Stages:

- Connect the length of the hydraulic level tube and the wire, making a loop at its end for greater rigidity. The edge of the tube should protrude 1 cm beyond the end of the wire.

- Attach the second end of the hydro level to Esmarch's circle.

- Push the device into the water supply as far as it will go.

- Place a bucket under the pipe hole.

- Pour hot water into a mug. It must flow through the hydraulic level tube to the ice and heat it. In this case, defrosted water will pour out of the hole in the pipe.

Defrosting a water pipe with an enema This method of heating requires a lot of time and effort. To thaw 5-10 cm of ice, you need up to 5 liters of hot water. The whole process can take 5-7 hours depending on the length of the cork.

If there is a pump, then it should be installed in a container in which water is constantly heated, and a heat-resistant hose, insert it into the water supply and supply hot water under pressure. The diameter of the hose must be such that there is a gap for the release of melt water from the pipe. It can be reused for heating.

Defrosting the water supply with a pump

Need

At a depth of 1.5 and even 2 meters, the earth freezes in winter to -15 C. In different regions of Russia, this figure reaches -20 C. Turning into ice, water stops flowing into the house. Without any insulation, or if it is insufficient, you will have to wait until the water itself thaws. Naturally, under the influence of temperatures, when the weather and season change, this will not happen until April. No one wants to be left without water for so long! Even 2 days without supplies for a modern civilized person is already a disaster.

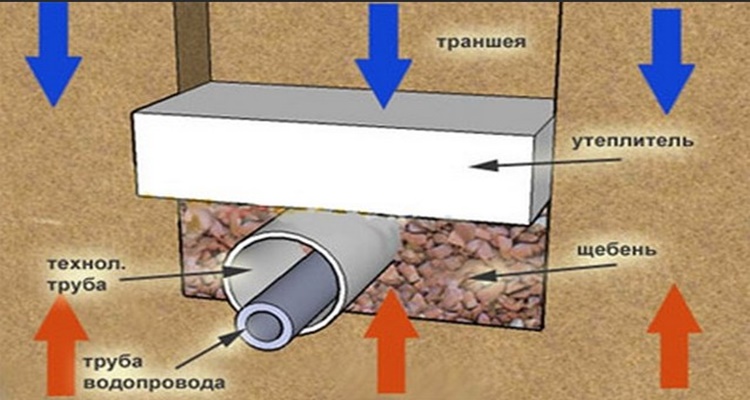

- firstly, you need to take care of the maximum possible depth of the trench;

- secondly, to additionally insulate the water flow underground;

- thirdly, if it is not possible due to hard ground or for other reasons to “dip” 2 meters, take care of maximum insulation.

There are many building materials with thermal insulation properties. But not many of them are made specifically for the insulation of water pipes.

At first, the water supply system was insulated with the help of wadded blankets, sweatshirts - everything that came to hand. Today we can choose more reliable and comfortable materials.

Your choice will depend on the characteristics of the water supply system in a private house or apartment, on the place where the insulation is made (indoors, underground).

To make it easier to make a choice, let's turn to the main criteria:

- low thermal conductivity;

- high heat-saving properties;

- durability;

- resistance to influences (mechanical, chemical, biological);

- ability to repel water;

- temperature resistance.

So, the insulation of water pipes in the ground is carried out using:

- polystyrene foam - inexpensive, convenient to mount on a water channel (there are special joints that are firmly connected to each other), it is not damaged underground and lasts quite a long time;

- basalt wool - more expensive, but it is convenient (cylindrical, which is conveniently put on a pipe and gently wraps around even at corners of 90 C), protected from damage by a layer of roofing material or other similar material (glassine, foilizol);

Glass wool insulation for pipes

glass wool is an inexpensive way, it is easy to put on through a single cut and sealed tightly with “adhesive tape”, while it has high thermal insulation, the material is ideal for warming plastic and metal-plastic water ducts.

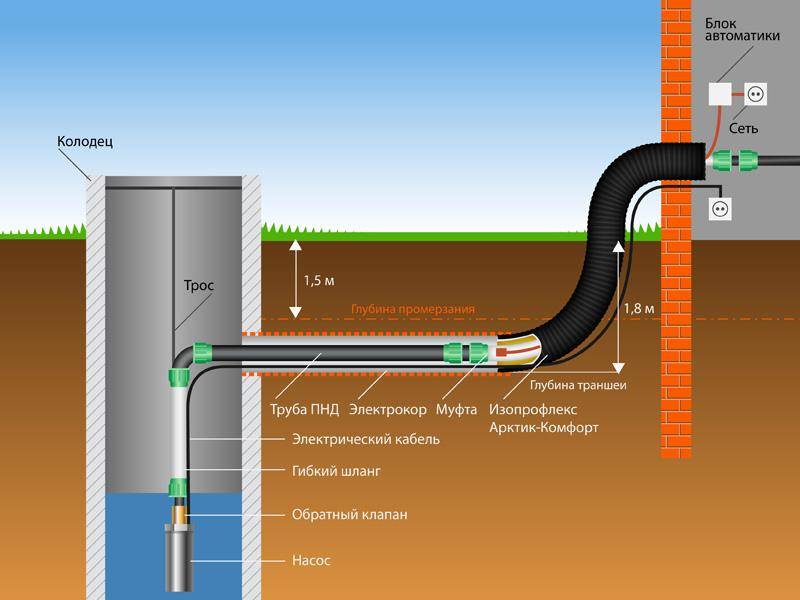

For greater reliability, a heating cable was invented to automate the system. This is an expensive pleasure. But it's worth it. Equipped with sensors, the cable starts to be heated from the mains (requires low power, obtained from the 220 W mains, but through a 36 W transformer) as soon as a low temperature is registered. Limits can be set independently. The heating system can also be equipped with a warning device to signal the owner of the house about a change in temperature in the soil, about turning the heating on and off.

Warming in unheated rooms, in bathrooms, bathrooms and in the kitchen, where water pipes are connected. made with the same materials.Sometimes foamed polyethylene or expanded polystyrene is also used - it is convenient, durable and suitable for both outside and inside insulation (indoors and underground).

It is also worth learning about a new product - heat-insulating paint. Its basis is varnish, less often water, the remaining ingredients are dispersion (acrylic) and various fillers. Easy to apply by hand with a sprayer. Try to make the layer thicker. The thicker the layer applied to the pipe, the more heat it will retain. The new paint is able to withstand temperature changes, its composition prevents corrosion (and this is a good property, useful when using any non-plastic pipes). This insulation is superior in its characteristics to the common expanded polystyrene and even glass wool (basalt).

So, having considered the materials and fixtures, we can highlight the main methods of insulating water pipes:

- heater installation. Here, insulation also occurs due to air: it protects the warm air coming from below from freezing, and from above the material closes the pipe from cold air. To do this, it is placed in a cylindrical insulation.

- installation and connection of the heating cable, sensors and warning equipment.

But there is another technology: high pressure insulation. In this case, a receiver is used - a "receiver", into which pressure is pumped from a submersible pump. A check valve is required. The receiver crashes into the water supply.

Warming for seasonal and permanent residence

Of course, in each case, a different heater will be used. For example, in a country house where water is needed only once a season, experts advise insulating pipes with glass wool.But for temporary housing, automatic or semi-automatic heating systems are still more suitable: heating cable, pressure. When you return, you can always warm the water by heating, and in the second case by first turning on the pump.

So, for warming home plumbing, you need:

choose good material;

choose the appropriate method of insulation depending on the frequency of use of the water supply (seasonally or permanently);

carry out the work carefully, with special attention to detail, clearly following the instructions and advice of the masters.

Insulating water pipes in the ground is a task that requires attention to detail, a meticulous choice of materials and methods, but is quite feasible for every home craftsman (whatever method you choose).

- Blockage in the dishwasher: causes, remedies, prevention

- The principle of operation, features and device of a drain tank with a button

- Do-it-yourself repair of a single-lever mixer: stages of work

- Calculation of the throughput of the pipe - methods, determining the optimal diameter

- Installing a shower cabin with your own hands

- Do-it-yourself shower cabin assembly

- Do-it-yourself glass shower enclosures without a pallet

- Shower enclosure sizes

We use glass wool

Glass wool insulation was very popular, but the emergence of new heaters is gradually pushing it out of the market. Its ease of use and low price cannot outweigh its shortcomings:

Glass wool insulation was very popular, but the emergence of new heaters is gradually pushing it out of the market. Its ease of use and low price cannot outweigh its shortcomings:

- low environmental cleanliness;

- insufficient physical density.

When laying, maximum protection of the skin and respiratory organs from contact with the material is necessary.A protective cover is required in order to prevent the reduction of the insulating layer under the weight of the earth. It will also be required when insulating a pipe laid in an open way in order to prevent the destruction of the insulation under the influence of water and wind, as well as to ensure the necessary safety of people.

Before insulating the pipe on the street (if the pipe is made of metal), it is necessary to paint it.

When laying in a trench, the pipe is wrapped with material, pre-fixing it with clamps. Then they wrap it with a layer of waterproofing, fixing it with turns of knitting wire, clamps. For this, roofing felt, roofing felt, metallized foil, fiberglass are used.

Provide protection of the insulation against compression by:

- laying it in a large-diameter pipe that is slightly susceptible to corrosion;

- covering with U-shaped or semicircular elements made of asbestos cement or concrete.

To separate thermal insulation from soil water, it is recommended to provide for the arrangement of a waterproofing layer of sand and gravel.

Who should pay for the replacement of pipes in the basement -

Hello, I live on the ground floor, the apartment is divided into three rooms, a hot water pipe burst in our basement (that is, there is no water only in our apartment, there is water in the whole house), the management company says that the tenants must replace it themselves. Such a question, should we pay money for replacing the pipe, or should the management company do it?

Victoria Dymova

Support Officer

Similar questions

- Who should, after replacing the pipes of the in-house heating system, eliminate the consequences (if the wallpaper was damaged during gas welding)? 23 August 2016, 14:56, question #1354083 5 answers

- Replacement of pipes and mixers in a communal apartment June 14, 2015, 20:38, question No. 871057 2 answers

- At whose expense should there be a replacement of the pipe from the central water supply to the column in the private sector? July 28, 2017, 13:34, question #1708933 1 answer

- Who should pay for the repair of heating pipes? 10 February 2017, 21:20, question #1534698 1 answer

- Do we have to pay for the replacement of the pipe or should the housing department replace it for free? 16 July 2016, 13:56, question #1316494 1 answer

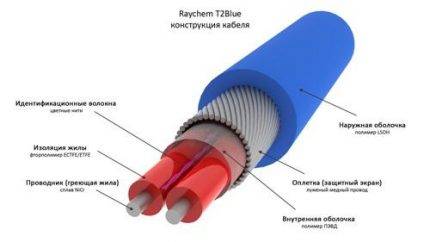

How does a heating cable work?

A heating or hot cable is a heating system for pipes laid in the ground. The electrical cable in the insulating sheath is fixed on the pipe and connected to the power supply. The pipe heats up, as a result, the wastewater acquires a consistently high temperature, which reliably protects it from freezing.

There is a cable for external heating of a pipe or internal. The first is laid outside the structure, and the second - inside. It is believed that outdoor installation is easier to produce than internal, so it is more in demand. In addition to the external cable, a heating film is also used.

Heating with a film for sewer systems is not often used. The material has to be wrapped around the entire pipe, which complicates installation, but ensures uniform heating

This material is completely wrapped around the structure, then it is fixed. The film gives a more uniform heating of the pipe than the cable, it has less power, which allows you to somewhat reduce operating costs.

Three types of cable can be used for heating pipes:

- self-regulating;

- resistive;

- zonal.

A self-regulating cable is considered an extremely convenient option, since it can automatically change the heating temperature depending on climatic conditions. Cable resistance decreases if the ground heats up more and increases as the temperature drops.

Self-regulating cable is most in demand in modern conditions, since it is easy to lay, it is more reliable and does not require additional elements for installation.

This change in operating mode reduces the overall power of the system, i.e. allows you to save energy. Moreover, the change in resistance may be different in individual sections of the pipeline. The result is a better heating quality, the self-regulating cable itself will last longer, and there is no need to install thermostats.

A resistive cable does not have such abilities, but differs in comparison with self-regulating systems by a more reasonable price. When installing this type of cable, you will need to install a set of temperature sensors and thermostats to ensure that the operating mode of the system changes when the weather changes.

Resistive cable costs less than self-regulating counterparts. If this option is selected, a suitable power density must be carefully calculated to prevent overheating.

Resistive cable costs less than self-regulating counterparts. If this option is selected, a suitable power density must be carefully calculated to prevent overheating.

If this requirement is neglected, the risk of overheating of the cable and its breakage increases. The zonal cable also does not have the ability to regulate resistance, but this system does not generate heat along its entire length, but only in certain sections. Such a cable can be cut into separate fragments, which is convenient when installing pipelines of complex configuration.

It is also widely used in the installation of metal sewers or for heating tanks. It should be noted that the heating of structures buried in the ground is not the only area of \u200b\u200buse of a heating cable. It is also used to heat pipes laid on the surface or in rooms that are not heated.

Sometimes the cable is used only for certain sections of the pipeline, for example, parts that go to the surface. Systems that are mounted inside the pipe are used relatively rarely. Most often they are used if the pipeline is already laid in the ground, and the installation of an external cable would require extensive excavation.

So installing an internal cable will be much cheaper. But such cables are usually recommended to be used only inside small diameter pipes, since their power is low.

It varies between 9-13 W / m, which is usually not enough for large sewer pipes. The length of such a cable, for obvious reasons, should be equal to the length of the pipe. The internal heating cable is made only of a self-regulating type.

How to insulate a water pipe on the street

It often happens that it is not economically feasible to lay the water supply of a summer house or a private house underground due to the climatic characteristics of the region of residence.

With a deep level of soil freezing, the cost of excavation increases significantly, and laying the highway in an open way with a correctly selected and correctly laid insulation in this case will be the best solution.

As such, the same types of material are used, which is what insulates the water pipe in the ground. But technological progress does not stand still.Therefore, today the insulation of water pipes with the help of an electric cable is very popular.

Especially in regions with harsh winters, when the engineering communications of a private house or cottage are laid on the street in an open way. You can learn how to insulate a water pipe using such a heating device by studying its instruction manual.

But one point is important here. There are models of a self-regulating cable on the market that do not turn off the power when the ambient temperature rises, which results in a significant waste of electricity. For economical use in this case, it is necessary to install a thermostat.

For a private house, the problem of how the water pipe is insulated under the floor is very relevant. After all, most engineering communications, including water supply systems, enter the living quarters from the basement.

And under the floor in severe frosts, the temperature can drop below 0˚С. In this case, it is enough to use a special thermal insulation paint. It can also be used to insulate a water pipe on the street.

It has the form of a paste-like mass, which is applied to the surface of engineering communications. This is the cheapest option for resolving the issue of how to insulate water pipes in a country house and in a private house with your own hands.

In conclusion, it is worth noting that there is another option for how to insulate water pipes on the street. This can be done using a liquid thermal insulation material - keramoizol.

Do I need to cover the pipes from the cold

The coolant that enters the radiators of our apartments comes with a temperature slightly lower than it was in the boiler room. If the boiler room is located at a remote distance from the house, this heat loss is even more noticeable. According to statistics, a quarter of the total amount of heat that comes from the boiler room to the radiator is lost along the route of the pipeline. Most of the pipeline is in the open air and is not always insulated. Street heating is undesirable for any consumer. Therefore, protecting the pipeline from the cold is a vital necessity.

The warm water that flows inside is able to protect the pipeline from freezing, but the heat loss is significant. Pipe insulation will help maintain the temperature of the coolant inside the pipe, heat loss will be significantly reduced, and the pipes themselves will be protected from atmospheric influence: temperature and humidity changes. Corrosion processes in insulated pipes will be insignificant, this will lead to long-term use.

It will be especially important to carry out thermal insulation work in areas where the pipeline runs along the street, or in basements. Timely insulation will reduce the financial costs of heating an apartment or house.

Installing your own boiler house in a multi-storey building will not solve this problem, because the pipeline is located in the basement, where cold air is present, and heat loss is inevitable.

The use of high-quality thermal insulation materials will allow the consumer to obtain a comfortable air temperature in the apartment, regardless of which radiators he has: cast iron, aluminum or bimetallic.

So, the purpose of warming the heating pipeline is as follows:

- increase the temperature in the consumer's room;

- save money on the purchase of this coolant;

- exclude pipe freezing and, as a result, repair work;

- protect pipes from adverse environmental influences.

Insulation of pipelines according to SNiP

When performing work on equipment and installation of pipelines, it is necessary to comply with the norms of SNiP.

What is SNiP? These are building norms and rules for the organization of construction production, for compliance with standards, specifications and regulatory departmental acts.

Basic norms and rules for thermal insulation

Heat networks are one of the main elements of district heating. It is necessary to strictly adhere to the norms and rules when drawing up a project for the thermal insulation of pipelines.

Subject to SNiP, thermal insulation of pipelines will be carried out qualitatively without violating standards.

Thermal insulation of pipelines SNiP is provided for linear sections of pipelines, heating networks, compensators and pipe supports.

Insulation of pipelines in residential buildings, industrial buildings requires strict compliance with design standards and a fire safety system.

The quality of materials must comply with SNiP, thermal insulation of pipelines must be aimed at reducing heat loss.

The main tasks of thermal insulation, features of the choice of materials

The main purpose of thermal insulation is to reduce heat loss in heating systems or pipelines with hot water supply. The main function of the insulation is to prevent condensation.

Condensation can form both on the surface of the pipe and in the insulating layer.

In addition, according to safety standards, the insulation of pipelines must provide a certain temperature on the surface of the insulation, and in case of stagnant water, protect it from freezing and icing in the winter.

Insulation of pipelines also increases the life of pipes.

According to the norms of SNiP, thermal insulation of pipelines is used both for centralized heating and reduces heat losses from in-house heating networks. What to consider when choosing thermal insulation:

- Pipe diameter. It depends on what type of insulator will be used. Pipes can be cylindrical, semi-cylinders or soft mats in rolls. Insulation of pipes of small diameter is mainly carried out using cylinders and half-cylinders.

- Heat carrier temperature.

- The conditions under which the pipes will be operated.

Types of heaters

Consider the most popular and commonly used materials for thermal insulation:

- Fiberglass. Glass fiber materials are often used for above ground pipelines because they have a long service life. Fiberglass has a low application temperature and is characterized by low density. High-quality fiberglass has high vibration, chemical and biological resistance.

- Mineral wool. Thermal insulation of pipelines with mineral wool is a very effective heat insulator. This insulating material will be used in different conditions. Unlike fiberglass, which has a low application temperature (up to 180ºC), mineral wool can withstand temperatures up to 650ºC. At the same time, its heat-insulating and mechanical properties are preserved. Mineral wool does not lose its shape, has a high resistance to chemical attack, acid.This material is non-toxic and has a low degree of moisture absorption.

In turn, mineral wool comes in two forms: stone and glass.

Insulation of pipelines with mineral wool is mainly used in residential buildings, public and domestic premises, as well as to protect surfaces that are heated.

- Polyurethane foam has a wide range of applications, but is a rather expensive material. According to the norms of SNiP, thermal insulation of pipelines is environmentally friendly and does not affect human health. Polyurethane foam is resistant to external factors, non-toxic and quite durable.

- Styrofoam. In some areas of industry, foam is an indispensable material, as it has low thermal conductivity and moisture absorption and a long service life. Expanded polystyrene is difficult to ignite, and is an excellent sound insulator.

- In addition to the above materials, the insulation of pipelines can also be carried out using other less well-known, but no less practical heaters, such as foam glass and penoizol. These materials are strong, safe and are close relatives of Styrofoam.

Corrosion protection and high thermal insulation of pipes can also be provided by heat-insulating paint.

This is a relatively new material, the main advantage of which is that it penetrates into hard-to-reach places and is able to withstand high temperature differences.