- Vapor barrier and waterproofing of the wall

- Insulation with expanded polystyrene

- Prices for Ceresit glue

- Prices for building levels

- Insulation of pipes using special thermal insulation

- Heating of external water supply systems

- Organization of water circulation

- Using an electrical cable

- Types of insulation - which is better?

- Pipe insulation materials

- How to insulate a water pipe: insulation options

- Other frost protection methods

- Insulation of water pipes inside the building

- Styrofoam

- Fiberglass materials

- Basalt materials

- Other insulation methods

- Heating cable

- High pressure

- Warming with air

- Types of heaters

- Mineral wool

- Styrofoam

- Penoplex

- polyurethane foam

- Ceiling insulation

- How to choose the thickness of the insulation?

Vapor barrier and waterproofing of the wall

With internal wall insulation, it is necessary to install a vapor barrier and waterproofing layer.

Vapor barrier materials can be:

- polypropylene films;

- foamed polymer films;

- foil films;

- diffusion membranes.

The vapor barrier layer is made taking into account the specifics of its installation:

- fasten the film to the crate with an overlap stapler, glue the joints with adhesive tape;

- the crate on which the vapor barrier is attached should be no more than 5 cm;

- the vapor barrier layer is laid using the continuous contour method around the entire perimeter.

Vapor barrier installation

A waterproofing layer that protects against moisture coming from outside is laid on the wall. Styling nuances:

- the waterproofing film is attached to the crate, leaving space for ventilation;

- a profile is attached to the film;

- a heater is laid between the profile, and then a vapor barrier layer.

Wall waterproofing

The most popular waterproofing material is roofing material. Vapor barrier and waterproofing must be installed to prevent condensation and keep the wall cake dry. Now let's look at ways to insulate walls from the inside.

Insulation with expanded polystyrene

Step 1. The first step is to do the preparatory work. That is, the walls must be cleaned of dirt and debris.

First you need to clean the walls

First you need to clean the walls

Step 2. Next, you need to apply a deep-penetrating primer, which will increase the level of adhesion of other materials, as well as save the walls from dusting. It must be applied over the entire surface of the walls with a brush or roller.

Primer application

Primer application

Step 3. After that, you need to mount the starting bar. It is fixed above the basement of the building with dowels, having previously carefully aligned, focusing on the building level. The starting bar will allow you to properly glue the polystyrene foam.

Installation of the starting bar

Installation of the starting bar

Step 4. Next, you can start gluing insulation panels

It is important to use specialized formulations. The adhesive solution must be prepared immediately before use strictly according to the instructions.

Preparation of the adhesive solution

Preparation of the adhesive solution

Prices for Ceresit glue

Glue Ceresit

Step 5The adhesive solution must be applied to the expanded polystyrene plate using the “side-flat cake” method - a strip of glue is applied around the perimeter of the plate, and then 3-5 glue cakes must be placed in the middle. In this case, the adhesive will cover about 40% of the board surface.

Applying glue to insulation

Applying glue to insulation

Step 6. Next, the panel with glue must be placed on the starting profile and then attached to the wall, pressing it firmly.

The plate is attached to the wall

The plate is attached to the wall

Step 7. Whether the panel is evenly glued can be determined using the building level. You need to check the evenness of the panel in three planes - on the sides and on top.

Checking the evenness of the slab

Checking the evenness of the slab

Prices for building levels

Building levels

Step 8 Now you can glue the rest of the panels in the first row. By the way, in subsequent rows, the panels are glued in a checkerboard pattern.

Panel bonding process

Panel bonding process

Step 9 After installing the boards, wait 12 hours for the adhesive to set, and then fill the wide gaps between the boards with mounting foam.

Filling gaps between tiles

Filling gaps between tiles

Step 10 After drying, excess foam must be cut off with a sharp knife, and the panel joints must be sanded.

Removing excess foam

Removing excess foam

Joint grinding

Joint grinding

Step 11

When installing polystyrene foam in the area of window and door openings, it is important not to forget to reinforce the corners of the insulation with strips of reinforcing mesh. This will strengthen them

The mesh should be laid at an angle of 40-45 degrees. Such a measure will allow in the future to avoid cracking the walls in these places.

Installation of expanded polystyrene in the area of window openings

Installation of expanded polystyrene in the area of window openings

Strengthening the corners

Strengthening the corners

Step 12. At the corners of the house, the panels still need to be laid in a checkerboard pattern, joining the sections from different sides of the house (shown in the image). Here, by the way, you also need to use a mesh for reinforcement.

At the corners of the panel are stacked in a checkerboard pattern

At the corners of the panel are stacked in a checkerboard pattern

The use of reinforcing mesh

The use of reinforcing mesh

Insulation of pipes using special thermal insulation

Multifunctional can be considered the insulation of the water supply of a private house using mineral wool or tow. Absorbing a certain amount of moisture from the air, the material is able to swell significantly over time and seal the gaps in the pipes. So, to ensure optimal conditions for the functioning of pipes in winter, a layer of insulation of 5 cm is sufficient.

Scheme of pipe insulation using special thermal insulation.

The service life of tow is 8-12 years, and with the use of natural oil paint, it can be increased by 2 times. Mineral wool or tow must be covered with an additional layer of waterproofing (roofing material) or waterproofing compounds.

The disadvantages of this method of insulation include the complexity of the work performed and, as a result, the high cost of the entire insulation system.

One of the newest ways to insulate water pipes in a private house is the use of polyethylene foam. This is one of the best thermal insulators today. In addition to ease of use, the low price is also pleasing. A heater of such a plan will last a very long time: it tolerates temperature extremes well, does not rot and is not affected by moisture. The term of its operation varies within 25-50 years. You can insulate the system with polyurethane. It should be laid according to the tenon-groove system to avoid the formation of cold bridges. Due to the low weight of the structure, there is no pressure on the water pipes in a private house and on the street.

Installation of heating pipes.

The stable structure of the insulation allows you to achieve high strength.Such a heater is able to successfully withstand the pressure exerted on it by soil masses poured from above.

Heating of external water supply systems

For water supply, pipelines partially located above the ground or in an unheated basement can be used. In this case, the owner of the house needs to know how to insulate the water pipe on the street. For protection, a special material is used or heat is supplied from external sources (for example, from the electrical network).

Organization of water circulation

To increase the temperature of the water in the pipe on the ground surface, the technology of supplying small portions of liquid to the supply tank is used. For example, water from a well in winter has a temperature in the range of 7-10 ° C, for pumping portions of the liquid, the pump is periodically turned on (manually or by signals from a sensor installed in the pipeline).

Water enters the supply tank or drains back into the well. But if the lines are made of steel pipes. That periodic draining of the water supply leads to corrosion of the metal.

There is a technology of protection with the help of excess pressure, which is created by the pump. A pump with a check valve supplies water from the well to a storage tank designed for high pressure. The liquid is injected into the section of the pipeline located on the soil surface.

A pressure regulator is installed in the main line, which does not allow water to be supplied under excessive pressure to the water supply network located inside the house. Due to the increased pressure, it is possible to reduce the crystallization temperature of water by several degrees.

Using an electrical cable

To increase the temperature of the pipelines, an electric cable located inside or on the outer surface of the pipeline can be used. The internal cable provides an increase in the efficiency of the heating system, but is difficult to install. The outer cord is attached to the surface of the water pipe with aluminum tape, which provides additional thermal insulation.

An adjustable thermostat is introduced into the circuit, which allows maintaining the temperature in a given range while reducing the load on the electrical network. Insulation of the water supply at the entrance to the house can be carried out with a self-regulating cable.

With a correctly selected cord, installation of an additional controller is not required. The owner of the premises can independently assemble a line with electric heating or use a ready-made solution.

The screen is displayed in a heated room (for example, the technical floor of a residential building), hot air enters as a result of convection. The technique is used in residential buildings that are operated on an ongoing basis and are equipped with heating systems.

The forced airflow system provides for the installation of 2 boxes along the highway, into which hot air is injected. The channels fit snugly to the surface of the pipeline, it is recommended to seal the joints.

The resulting structure is covered with an insulator layer and installed in a protective tube. Hot air is supplied by a fan with an electric heating element, it is possible to install a control unit with temperature sensors.

Types of insulation - which is better?

For proper internal insulation of a wooden house,  heaters, which, while maintaining thermal insulation properties, do not cause an unpleasant odor over time, are fireproof and environmentally friendly.

heaters, which, while maintaining thermal insulation properties, do not cause an unpleasant odor over time, are fireproof and environmentally friendly.

The most common options for internal insulation are:

- mineral basalt wool. It is the most popular material for wall insulation. The features of this material are: good thermal insulation properties, high level of sound insulation, fire resistance, strength, high hygroscopicity, due to which it is necessary to install a strapping of vapor barrier films;

- foam boards. Due to the fact that the material can release styrene, extruded polystyrene foam is used, which requires a fencing system. The material has good thermal insulation, has soundproof properties, however, it is rather fragile;

- glass wool. It has greater thermal conductivity than mineral wool, but the price of the material is much lower than basalt slabs. The material crumbles a lot, so it should be laid in protective equipment: material crumbs are harmful to health. In addition, it is necessary to mount enclosing structures;

- isoplat. Insulation, which consists of compressed linen fibers and wood board. An ideal heat-insulating material in terms of environmental friendliness, and also strong enough that it does not require the installation of enclosing systems;

- polyurethane foam, which is installed by spraying it onto the surface, is installed using special equipment. Modern and quite expensive material.

Comparative characteristics of thermal insulation

The type of insulation should be chosen based on the characteristics of the building, climatic conditions, and the purpose of the building.

Pipe insulation materials

Long gone are the days when the plumbing was insulated with quilts, clothing and other household materials. Now in the construction markets you can find a large number of different materials for thermal insulation.

It is important to be able not to get confused in them and choose what you need. It is necessary to buy material for thermal insulation of a water pipe, based on ease of installation and basic characteristics.

When choosing a pipe insulation, you need to compare it with the following requirements:

- Durability, resistance to biological and chemical influences of the environment.

- Good heat-saving properties, low thermal conductivity.

- Work at high temperature without losing its own physical properties and structure.

- Low water absorption, because the moisture of the insulating material leads to an increase in the thermal conductivity.

Having learned the basic properties of the material and the features of the location of the water supply in your area, it is easy to make the best choice for pipe insulation. Mostly they are recommended to be used for insulation of pipes indoors.

glass wool

Among the heaters for water pipes are:

- Glass wool. This type of heat insulator is mainly used for the insulation of metal-plastic pipes. Of the well-known manufacturers of glass wool, Knauf, Ursa and Isover can be distinguished. Fiberglass material has a low density, when using it, it is necessary to additionally lay an external insulator, for example, fiberglass or roofing material, which is fraught with unnecessary costs.

- Basalt insulation. This type of heat insulator is produced in a cylindrical shape, so its installation is quite easy.For additional protection, the material is covered with a layer of foil isol, roofing felt or glassine. Despite a lot of advantages, the cost of this material cannot be called democratic.

- Styrofoam. This heat-insulating material is often chosen by those who independently insulate water pipes. Expanded polystyrene is produced with or without an outer layer, it is designed for reusable use for insulating water pipes, both indoors and outdoors.

- Heat insulating paint. This heat-insulating material appeared on the construction market relatively recently. It is a white or gray paste, and is made on the basis of water or varnish with the addition of various fillers and acrylic dispersion. It is best to apply heat-insulating paint with a spray gun. The result of the work depends on how thick the paint layer will be, it perfectly withstands low and high temperatures, and prevents the development of corrosion. One layer of heat-insulating paint can replace glass wool or polystyrene foam.

How to insulate a water pipe: insulation options

To prevent freezing of water in the pipeline during cold weather, before insulating a water pipe, you need to carefully consider the technology for performing thermal insulation, taking into account a number of factors.

When arranging a pipeline for year-round use, it is laid below the freezing mark of the soil, where the temperature is always stable close to +50C. But in some cases, the freezing depth is 2 meters, which makes the thermal insulation of the water supply system by this method very laborious.

However, there are alternative ways to insulate water pipes, avoiding laying communications at great depths. You will learn about them from our article.

Other frost protection methods

Insulation of the water pipe on the street can be replaced by work to prevent freezing. The two most popular methods other than deep burying are:

- thermal cable;

- forming a constant high pressure receiver;

- the second circle of pipes, constantly keeping the fluid in motion.

The principle of the receiver, which holds the pressure that does not allow water to freeze, is actively used in the private sector water supply system. The columns that supply water to residents both in winter and summer are arranged exactly according to this principle: a pipe for a water supply system in the ground does not need to be insulated.

Laying a second duplicating row of pipes is a costly undertaking, but it also pays off: the stream constantly circulating in a circle cannot freeze either, so insulation for water pipes is not required in this case.

Duplication of the system with a thermal cable is a popular technique. With this method of preventing freezing of pipes, the cable is either laid along the pipe, or wrapped around it in a spiral. It is worth noting that both techniques have disadvantages: in the first case, this is uneven heating, in the second, a number of calculations of the permissible number of revolutions and the distance between the turns. It is worth noting that the insulation of the water pipe in this case is not canceled, but the insulator will act as a heat-retaining gasket, protecting the pipe.

Insulation of water pipes inside the building

When it is necessary to insulate pipes indoors, polystyrene foam, fiberglass or basalt materials are used for this.All of them heat the system due to the ability to accumulate air inside.

Styrofoam

Expanded polystyrene is the most common insulation for water pipes. It is possible to use it not only for thermal insulation inside the building, but also for underground external insulation.

Expanded polystyrene is produced in the form of insulating shells from two semicircles. From above, such insulation is covered with a protective layer, which is fixed at the junction of the shells.

Fiberglass materials

Fiberglass materials are usually used for insulation of metal-plastic pipes. The need to use additional funds such as roofing felt or fiberglass due to the low density of glass wool leads to significant monetary costs when using them.

Basalt materials

Insulation for water pipes made of basalt can be used without trays. Due to their cylindrical shape, such materials are easy to install. The protective layer is made of roofing material, foil insulation, glassine. The only drawback of basalt heaters is their high cost.

Now you know how to properly insulate the water supply both outdoors and indoors, and we hope that you can easily cope with the task.

Other insulation methods

In addition to traditional methods of insulating underground water pipes, there are several alternative methods that avoid the need to lay pipes to great depths.

Heating cable

With this method, the pipeline is heated with a cable with a power of at least 20 W per 1 m of pipe. Insulation is carried out both from the outside and the inside of the pipes. This prevents them from freezing at the entrance to the house.Heating by this method is carried out only in frosts, so that in the warm season electricity can be saved.

The advantage of this method is that when using a cable, pipes can be deepened by only 50 cm. Another positive side is the ability to defrost a pipe that has caught frost.

The main disadvantage of this method is its high cost. And in the absence of special skills for installing the cable inside the pipe, you will have to involve specialists, which will also affect the cost of heating. You can also run the cable over the pipe with your own hands, since such work is much easier to do. The work is carried out using a self-regulating insulation cable, which can be purchased already installed in the pipe.

High pressure

It is possible to insulate water supply pipes by maintaining high pressure inside them, to create which you will need:

• Embed a receiver in the pipe, capable of creating pressure within 3-5 atmospheres.

• Pressure is maintained by submersible pumps. For this purpose, pumps are installed that pump pressure in the range of 5-7 atm.

• After that, you will need to install a non-return valve, while the valve must be closed in front of the receiver.

To start such a system, you just need to bring the pump into working condition. Air is bled from the system to bring the pipeline back into operation.

Warming with air

Freezing of the soil in winter occurs from its upper layers. At the same time, the lower layers of the earth, despite the severe frost outside, remain warm. This natural feature can also be used to heat the pipeline in private homes.To do this, you can put tubular thermal insulation on it, or make thermal insulation in the form of an umbrella. In the latter case, heat enters from below and is retained by an impromptu umbrella at the level of the pipeline.

Air insulation can also be done by laying one pipe inside another. For the outer layer, it is best to use a sewer pipe made of propylene. This method has the following advantages:

• In the event of an emergency, a polypropylene manifold can be used to route the emergency hose. To this end, it is recommended to equip the pipe with a cable or wire in advance.

• It will be possible to replace a damaged pipe without digging a trench.

• This method will guarantee heating of the pipeline under any conditions. If a high-pressure cable or system periodically requires repair, then the propylene manifold can serve uninterruptedly for a long time.

• In the event of a pipe freezing, warm air can be blown into the collector to melt the frozen water.

As you can see, different methods can be used to insulate water pipes. Properly carried out work will ensure the life of the pipeline even in the most severe frosts

It is important to remember that the issue of water supply insulation should be addressed in a timely manner, without waiting for the pipes to burst from frozen water.

Types of heaters

There are many insulation materials on the market. Consider the most popular heaters in detail.

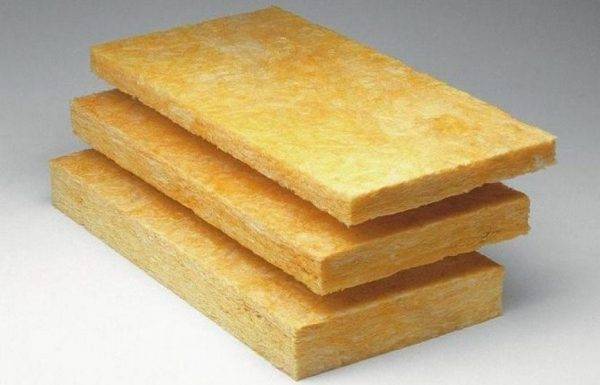

Mineral wool

One of the most successful options is stone (basalt) wool.Usually, when it comes to mineral wool, they mean stone, although the term denotes a wide group of materials, which include slag wool, glass wool and other types of similar insulators. Basalt wool is more convenient to use, has a good set of operational and technical characteristics. It does not burn, does not emit harmful substances and is not subject to decay. It is produced in different forms - from rolled to more rigid slab. The disadvantage of mineral wool is the ability to absorb water, which makes installation somewhat difficult and requires additional operations.

Mineral wool slabs are one of the most popular insulation for walls and other surfaces.

Mineral wool slabs are one of the most popular insulation for walls and other surfaces.

Styrofoam

This insulation is a confident leader among all other types in terms of popularity. The reason for this is the low price of the material, low weight, ease of installation and processing. The material is resistant to water, has stable dimensions and geometry of the plates, impervious to water vapor. For internal insulation, this is the most preferred option, budgetary and not time-consuming.

Styrofoam is suitable for both internal and external insulation

Styrofoam is suitable for both internal and external insulation

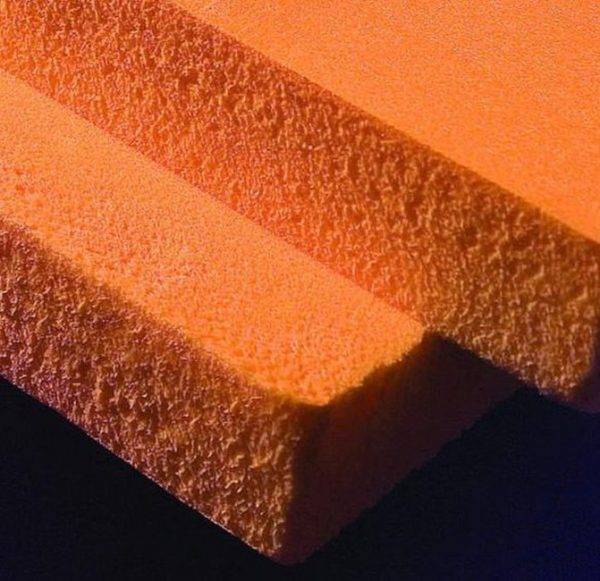

Penoplex

From a chemical point of view, this material is a complete analogue of polystyrene - both of them are variants of expanded polystyrene. But unlike polystyrene, which is expanded polystyrene granules connected during heat treatment, foam polystyrene (extruded polystyrene foam) is a monolithic material, hardened foam. It is stronger and heavier than foam, has a higher price.

Penoplex does not crumble during processing, it is completely resistant to moisture or water vapor.

Penoplex does not crumble during processing, it is completely resistant to moisture or water vapor.

polyurethane foam

A specific heat insulator, sold in liquid form and applied by spraying onto the surface to be treated. In air, the material foams and hardens, as a result, an airtight layer is formed, resembling mounting foam. Polyurethane foam is ideal for insulating walls with complex geometry, the presence of small defects or protruding parts. The price of the material is quite high, in addition, special equipment is used for application. These factors somewhat limit the use, although the performance of the insulator is very high. It is completely impervious to moisture, sealed and perfectly covers the surface without gaps or gaps.

Wall insulation with sprayed polyurethane foam

Wall insulation with sprayed polyurethane foam

There are other materials that can be used for internal insulation. It is not advisable to list them all, since they are noticeably inferior to the named species in terms of operational and technical characteristics or are expensive.

Permeable types of heat insulators require the installation of a vapor barrier film, which increases the number of installation operations and requires additional costs. Permeable types of insulation include mineral wool and polystyrene, foam or polyurethane foam are impervious to steam or water.

Ceiling insulation

Do-it-yourself ceiling insulation

Do-it-yourself ceiling insulation

How to insulate a wooden house, namely its ceilings, is a question that should be asked long before the start of work. Ceiling insulation in a wooden house is an important step in thermal insulation of the whole house. Work with ceilings is best done before the roof is fully assembled, otherwise it will interfere with the dense laying of the insulation. Consider the order of work using the example of thermal insulation of the ceiling of a house with mineral wool:

- A vapor barrier is pulled onto the ceiling beams, a board, plywood or sheets of oriented strand board are stuffed over it.

- Now mineral wool is laid on top of the entire ceiling, tightly and without voids, with overlapping seams by 15-20 cm.

- For a non-residential attic, there is no need to cover the insulation with a membrane. It is enough to sew it up with plywood, a board so that you can walk on it.

- There are situations when it is impossible to insulate the ceiling from above, then the work is carried out indoors. This is painstaking work, during which you need to tie up the insulation so that it does not fall.

On a note! The heated air rises, so if the ceiling is not properly insulated, the house will intensively rub the heat.

How to choose the thickness of the insulation?

To reduce heat loss and ensure an acceptable temperature in the premises during insulation, the thickness of the walls, their heat-insulating properties, the type of foundation, the climate of the area and the prevailing wind loads are taken into account. With sufficient thickness of walls made of materials with high heat-insulating properties (for example, made of bricks or logs), facade insulation is not necessary.

The thermal insulation of a house assembled from cinder blocks should be maximum - this material is not able to retain heat for a long time. When calculating the wall thickness, the thermal conductivity of the insulation itself is taken into account. Materials such as polyurethane foam, polystyrene, mineral wool have the best characteristics.

For example, a 50 mm layer of polyurethane is able to retain heat in the same way as a 1720 mm brick.

Thermal conductivity of materials

Professional builders use rather complex formulas to calculate the thickness of the insulation.When choosing a heat insulator for a private house, it is convenient to use online calculators. You only need to indicate the region of residence, the size of the building, the types of basement and attic floors, the thickness and material of the walls, the type of roof.

Even with a significant wall thickness, a small layer of insulation along the facade is still worth laying. Indeed, upon contact with cold air and temperature changes, cracks form on their surface over time, leading to premature destruction.

Veranda attached to the house - expanding the living space: projects, tips on how to create your own hands (200 original photo ideas)