- Independent flooring

- We prepare everything you need

- Phased reproduction of pouring works

- Materials for interior work: what is better to use

- What is the best insulation for the ceiling in a brick house

- Ceiling insulation with mineral wool

- The process of insulating the ceiling from the attic side with mineral wool

- Installation of wool from the inside of the house

- How to properly insulate the ceiling in the house with sawdust

- How to make ceiling insulation in a wooden house with expanded clay

- Insulation of the ceiling in the house with mineral wool

- Insulation in a wooden house with foam

- Why is it necessary to insulate the basement ceiling?

- On wooden beams

- Warming scheme

- The method of forming thermal insulation with sawdust

- How to calculate the layer thickness?

- Tips & Tricks

- Conclusions and useful video on the topic

Independent flooring

Before starting work, it is advisable to carefully study and calculate everything. Incorrect material calculations can cause serious costs for the preparation of the mixture and refilling the surface. For the first time, it is very difficult to accurately calculate the volume of ingredients and do everything correctly, so experts advise involving a master.

We prepare everything you need

The necessary tools and materials must be prepared in advance.You will need such equipment for the production of the mixture and installation of the floor: a building level, spatulas, a rule, a generator and a mixer, a solution supply unit (gerotor pump, hoses), technical film, fasteners for the frame, timber. Materials: cement without lumps, dry sand without debris, foam concentrate.

Phased reproduction of pouring works

First you need to choose the right foam concrete in accordance with the type of room and the intensity of the loads. For an ordinary living room, the arrangement of a combined foam concrete floor is carried out according to standard technology. The thickness of the screed layer can be different, but if it is laid on reinforced concrete floors, at least 5 centimeters will suffice.

Stages of laying a foam concrete floor:

1. Cleaning the base, laying waterproofing (if necessary), laying and testing the underfloor heating system (if this type of floor is being installed).

2. Installation of the crate - it is performed not only as beacons, but also for additional reinforcement. The wooden crate is mounted using planks along the thickness of the first layer (where the top point is), the width of the working strips is a maximum of 50 centimeters. It is possible to install logs on the base in increments of 2 meters and arrange metal beacons in increments of 1 meter.

3. Production of foam concrete - foam test to determine sufficient resistance and weight, performing the first batch. It is necessary to ensure that the temperature of the water in the solution, the air in the room and the water in the foam is the same. Due to sudden drops, the foam can be unstable, which will damage its structural walls.

4. Weighing the foam when it is fed into the mixture and determining the weight of the finished mixture itself to confirm the quality of the foam concrete.Mixes that differ greatly in density are best not to use at all.

5. Pouring concrete with ready-made mortar. Features of the fill depend on the size of the room and the thickness of the layer. Usually they are poured in several stages, trying to prepare a solution with the most similar characteristics in order to avoid density drops.

6. Smoothing concrete - fast and easy, without vibrators, etc. You need to take a rail and spatulas, align the layer with beacons. When the first layer is ready, it must be covered with a film, allow the screed to harden under current environmental conditions.

7. After the first layer has hardened, the second layer is poured with a screed mixture of the required grade and density, a self-leveling mixture can be poured. It is necessary to set beacons and fill the floor surface. Additional waterproofing is not required.

8. Finishing - carried out a month after the screed. When installing the floor on the roof or attic, it is imperative to lay a layer of roll insulation.

- To protect the composition more effectively and make it more durable, it is advisable to impregnate the base with an antifungal drug.

- To obtain a perfectly flat surface at the exit, you can pre-prepare a fixture from a corner (according to the dimensions of the room) and a special handle welded to it in the form of an arc.

- When buying ready-made foam concrete mixtures, it is necessary to strictly observe the conditions specified in the instructions, proportions, hardening time.

- Foam concrete is best suited for the installation of insulation of the "warm floor" system. The foam concrete floor warms up faster, it is several degrees warmer than the similar concrete floor, it has excellent heat-insulating properties, which can significantly reduce the cost of heating the room.

- During the hardening process, the floor must be periodically watered with water by spraying to prevent it from drying out and to avoid cracks.

With the correct selection of the characteristics of foam concrete and the calculation of the layers of the screed, it is possible to produce a high-quality, durable, warm coating that meets all operational requirements. Such a floor will cost much less than other filling options, it will make it possible to do everything easily and quickly, achieving the best result.

Materials for interior work: what is better to use

Most often, ceiling insulation from the attic is impossible due to the low roof slope or too thin beams. Often the reason is the elementary lack of access. In this case, you need to mount a heater inside the room. This complicates the work, increases their cost. We have to think about the presence of vapor barrier, make a new "finishing" ceiling. The impossibility of using the most common, cheap, easy-to-use heat-insulating materials, such as expanded clay and sawdust.

For interior work, not every material is suitable. The main condition is compliance with the following requirements:

- high fire resistance;

- environmental friendliness, at room temperature the material should not emit substances harmful to humans;

- durability, resistance to fungus;

- adequate price;

- sufficient efficiency with a minimum thickness, which is especially critical for low ceilings;

- low specific gravity, so as not to load the structures of wooden floors.

First of all, it is:

- Styrofoam;

- expanded polystyrene;

- polyethylene foam;

- mineral wool.

The quality of the materials used directly determines how effective and durable the insulation will be.Accordingly, this issue requires detailed consideration.

What is the best insulation for the ceiling in a brick house

For effective insulation of the ceiling in cold roof house outside and inside the following types of material are used:

- Monolithic - has a high density and water resistance, while the dew point goes in any direction without deteriorating the properties of the insulation. These include extruded polystyrene foam.

- Fibrous or porous - produced in the form of rolled material or mats. They are highly exposed to moisture saturation and lose their characteristics, therefore they are used only in conjunction with a vapor barrier. There are such types: mineral wool, slab and sheet polyurethane foam.

- Bulk or sprayed - the first option is laid manually, and the second only with the help of special equipment.

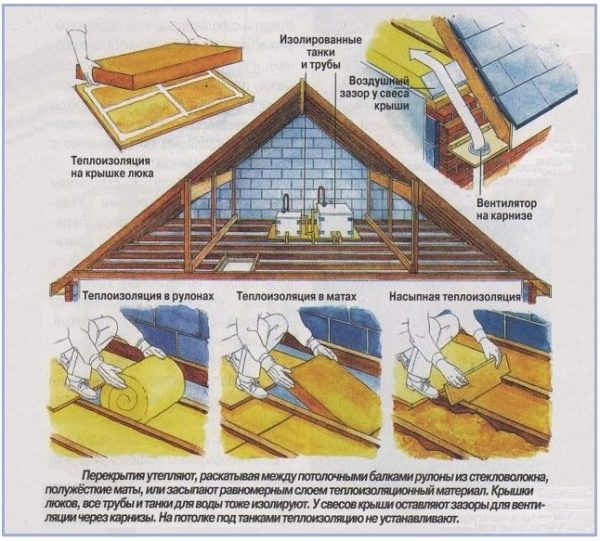

From the outside, insulation along the wooden beams of the attic floor is carried out using light rolled or bulk materials (sawdust, leaves). For concrete slabs, dense monolith, slabs or heavy bulk material (expanded clay) can be laid.

Ceiling insulation with mineral wool

Mineral wool is one of the most popular materials for ceiling insulation with a cold roof. Among its positive qualities are affordability, environmental friendliness, incombustibility, and ease of installation.

The thickness of the mineral wool layer for insulation depends on the type of building. If in multi-storey buildings it is possible to insulate the ceiling with a layer of 5 centimeters, then for a private house it is sometimes not enough and 15 cm. For cottages, you need to choose high-density mineral wool, which will guarantee good thermal insulation properties.

In general, high-density mineral wool should also be chosen for cold winter conditions, as it is able to cope with significant temperature fluctuations without losing its thermal insulation qualities.

Cotton wool is resistant to fungus, mold, rodents. As an added bonus, when using it, good sound insulation can be noted. Therefore, if you insulate the ceiling with mineral wool, in a private house it will be not only warm, but also quiet.

One of the annoying minuses of mineral wool is its hygroscopicity. It absorbs moisture well, so when using it, it is imperative to use hydro and vapor barrier.

If the waterproofing properties of the material are important, it is better to insulate the roof with basalt wool. This is a kind of mineral wool, which is absolutely not afraid of water. In addition, insulating the ceiling in a private house with slab basalt wool will require a minimum of effort. With installation work on their own, one person may well cope.

It should be noted that work on insulation both outside and inside will be carried out according to a single scheme. If it is decided to insulate the ceiling from the side of the attic, then it is better to take basalt wool in rolls. For interior work, plates with a density of about 50 kg / m3 are more convenient. The thickness of the material should ideally be about 60 mm.

Many experts argue that basalt wool is preferable to other types of mineral wool for ceiling insulation. In addition to waterproofing properties, basalt insulation has plasticity and at the same time has good rigidity, which increases its service life up to 15 years.

A significant drawback of basalt wool is the unevenness of the seams within the material itself, due to which gaps can form.And this, in turn, can negate all its positive qualities.

The process of insulating the ceiling from the attic side with mineral wool

- From the side of the attic, it is necessary to create a cellular frame.

- A vapor barrier layer (foil material or polyethylene film) is laid between the beams.

- Next, mineral wool is laid. The recommended installation technology must be observed: the distance between the frame elements is made smaller than the mineral wool slabs. Thus, mineral wool is laid close to the structure, gaps are almost not formed, and the insulation efficiency increases.

- The beginning of laying cotton wool is the far corner of the room (if you navigate from the door). To remain able to walk on the attic floor, you can lay plywood;

- They lay waterproofing (if the attic room itself is not planned to be insulated). If waterproofing was taken into account when creating the roof, this item can be skipped.

- Mount the elements of a clean floor in the attic.

Attention! The organization of a warm ceiling structure in a concrete, block or brick house is carried out in a similar way. In the presence of a chimney, the material is applied to the surface of the device, up to a level of 400-500 mm in height, after which the plates are fixed

Installation of wool from the inside of the house

- You need to make a metal frame. The recommended pitch between frame profiles is 400 mm. The average size of mineral slabs is 500-1200 mm (in width).

- The installation of cotton wool is carried out in the "accordion" method, that is, the material is placed in the space between the elements.

- A film for vapor barrier is laid (from inside the house).

- Drywall sheets are mounted on an insulated base.

How to properly insulate the ceiling in the house with sawdust

When the ceiling is insulated with sawdust, the house turns out to be warm and environmentally friendly. For this process, well-dried clean sawdust of medium or large size is purchased. From below, sheet or rolled parchment is used. Lime and copper sulfate are used as an antiseptic and protection against rodents. The average layer of insulation of a wooden house, bathhouse or cottage is 25 cm.

To prepare a heater with your own hands, take:

- 10 buckets of sawdust;

- lime bucket,

- 250 grams of copper sulfate;

- a bucket of cement;

- 10 liters of water.

Lime and blue vitriol are mixed with dry cement. The mixture is poured into sawdust and kneaded, then water is slowly poured in. The resulting mixture should form a homogeneous dense structure.

The chimney is insulated with fire-resistant material, and the wiring is closed with a metal pipe. The parchment is spread, then the sawdust mixture is poured and rammed. After this flooring remains to dry for 2 weeks.

How to make ceiling insulation in a wooden house with expanded clay

Expanded clay is environmentally friendly, refractory, does not rot, is not exposed to various temperatures

Rodents do not start in expanded clay, which is important for owners of wooden houses. Steam and waterproofing is spread in the upper part of the ceiling. Pipe, wiring are insulated with refractory materials (sheet metal or iron pipes)

Pipe, wiring are insulated with refractory materials (sheet metal or iron pipes).

Waterproofing or parchment is spread, while the width of the material should be 10 centimeters greater than the distance between the beams of the house. Laying is carried out with an overlap on beams, walls. The roofing material is fixed with rubber-based mastic.When using simple adhesive tape at the joints, aluminum plates are additionally installed.

With an overlap of 15 cm, there is a vapor barrier, and the exit to the walls after backfilling with expanded clay is also 15 cm. A 50 mm layer of clay is laid out, then there is a layer of expanded clay. The minimum thickness is about 15 cm. A screed of sand and cement is poured onto it. To use the attic, chipboard or plank flooring is made from above.

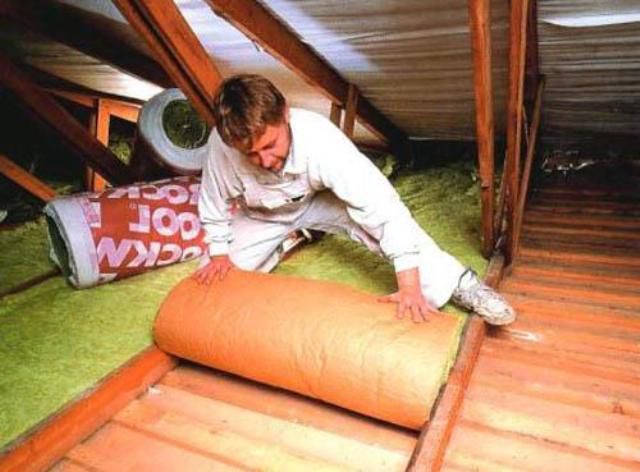

Insulation of the ceiling in the house with mineral wool

Basalt and mineral wool reduce the thermal conductivity of the ceiling. These types of insulation are easy to install and environmentally friendly. They cost a little more than previous analogues, but they allow you to insulate the outside and inside of the ceiling. Plates are used outside.

When insulating the ceiling in a wooden house, the vapor barrier is laid out with an overlap of 15 cm. The overlap lies on the walls, the beams and are fixed, and mineral wool is laid between the beams. When using rolls, keep in mind that they must fit the openings. Rolling is carried out along the location of the beams. The mats are tightly packed. Another layer of insulation is laid across the top.

Beams, joints are hidden, and the gaps are sealed with mounting foam. A vapor barrier is laid with an overlap of 15 cm. The seams are glued with adhesive tape. From above there is a screed of cement with sand. In a residential attic, boards or laminate are laid on the screed.

Insulation in a wooden house with foam

The most reliable type of insulation for the home is the use of polyurethane foam or polystyrene foam boards. These materials are the most expensive. Installation, in comparison with the previous view, is more time-consuming from the inside, but at the same time, the attic area in this option is the least lost.The insulation lies more tightly than others during the insulation of the ceiling in a wooden house.

A rolled vapor barrier is mounted on the inside of the ceiling of the house. Styrofoam is tightly inserted between the bars. To do this, it is measured and cut to size. Then comes another layer of vapor barrier material with an overlap of 15 cm. The seams are closed. A crate of wooden or iron bars with a cross section of 5 by 5 centimeters is installed on the beams. A ceiling made of GKL or GVL is attached to it.

All these materials can be used for insulation in a private house, bathhouse or cottage. Knowing how to insulate the ceiling in a wooden house with your own hands, you can complete repair or construction work in a short time without involving specialists. Insulation not only allows you to keep warm in the house, but also becomes a good option for soundproofing.

Why is it necessary to insulate the basement ceiling?

First, it is worth understanding whether it is so necessary to have insulation in the basement of a private dwelling. The basements of suburban real estate are most often not heated. Because of this, cold air from the street gets inside through the cracks in the interfloor ceilings and reduces the temperature in the rooms on the first floor. Therefore, you have to thoroughly spend money on heating your home.

The main functions of thermal insulation of the ceiling surface in the basement:

- protection of load-bearing structures from the harmful effects of low temperatures and high humidity;

- reduction of heat losses in the dwelling by 20 percent;

- ensuring that the floor covering of the first floor of the building maintains an optimal temperature.

On wooden beams

Produced from the side of the attic or from below. The latter option is extremely inconvenient, noticeably "eats" the height of the room.Modern internal insulation on the ceiling in a private house - Paroc lamellas.

Panels with decorative bevel. The material is hard stone wool.

Before choosing a heater, we recall that the combination of wood and any foam in terms of combustibility is not much inferior to gunpowder. And in terms of the toxicity of combustion products, plastic has no analogues.

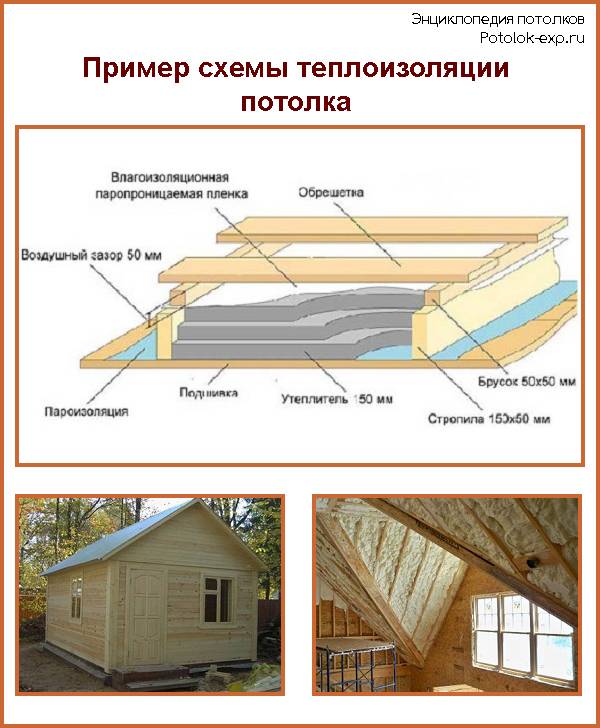

Warming scheme

On the left in the figure, the insulation is in one layer, on the right - double. From below, a vapor barrier film goes along the beams, from above - a waterproof vapor-permeable film.

Ceiling insulation for a cold attic will work better if the logs / beams in contact with it are sharpened.

The best insulation is mineral wool. The choice between rolled or slab depends on the construction budget. You should decide before laying the beams: the distance between them should be 2-4 cm less than the width of the roll or mat. In this case, the consumption of insulation will be optimal.

A good option is ecowool. Before use, it is fluffed with a construction mixer in a large container. This method is used in the construction of their own. Involved specialists fluff up the material in special installations and deliver it to the work site with a hose.

In order for the insulation for the ceiling not to be blown out, the fibers do not fly around the attic, the surface is protected by a wind barrier. It is a synthetic, capillary inactive material. When moisture is released by the insulation, it will condense (and accumulate, since there is no way out) on the lower surface of the film.

Capillary active paperboard (used instead of non-vapor permeable film) will absorb this moisture. Then from its surface it will evaporate into the under-roof space.

For the same reason, ecowool after installation is recommended to be moistened with water from an aerosol spray. After drying, a thin paper layer forms on the surface. It will keep the cotton from flying apart and will work just like cardboard.

A profile for drywall is attached to a beam or crate that holds the weight of the insulation. Sheets of moisture - and fire-resistant GKLVO for kitchens and bathrooms, GKLO for other rooms. Thickness 12.5 cm. Ideal - in two layers. This increases the level of fire safety.

A wooden ceiling for vapor barrier also has the right to life.

The thermal insulation cake will look like this.

- Ceiling filing from the inside of the room: edged board, lining, plasterboard.

- Vapor barrier fixed on floor beams, glued at the joints with an overlap on the walls.

- Insulation of design thickness. If the beam is below the insulation layer, a bar or board is stuffed on top of it in such a way that the insulation will be 40-50 mm lower than the beam.

- Wind - waterproof film.

- Roof revision deck.

Part of the cake should be the insulation of parapets to a height of 500 mm.

A mandatory element of the attic is a visiting hatch. It is arranged between the beams, it opens only upwards.

If wooden beams or logs are left as an element of the decor of the interior space, a wooden flooring, a frame is arranged on top of them, insulation is already laid on it.

The most common material for flooring and bottom filing is OSB boards. Thickness 9 - 10 mm. Durable, lightweight material for quick installation.

The method of forming thermal insulation with sawdust

To make the sawdust more fire resistant, it is necessary to treat it with slag, especially in the chimney sections. Nothing needs to be laid on top. If necessary, you can put boards. Another way to insulate is to carry out protective procedures to prevent moisture from entering. You can walk on the surface of the clay. Mix sawdust with cement as follows:

- sawdust (10 parts);

- cement (2 parts);

- water (1.5 parts).

In order for the sawdust and cement to firmly converge, they need to get wet properly. This mixture should be spread over the entire floor of the attic surface with a thickness of at least 20 cm.

How to calculate the layer thickness?

To calculate the thickness of the required layer of insulation, special calculations should be carried out. It will not be difficult if you use an online calculator. In general terms, the calculation scheme is based on the physical parameters of substances and established building codes.

For example, in Moscow, SNiPs established that the insulation of all types of floors should give resistance to heat transfer, R = 4.15 m2C / W. When a foam with a thermal conductivity of 0.04 W / mS is used, the required coating thickness is calculated as follows: 4.15 x 0.04 \u003d 0.166 m. Polyurethane foam will require a layer thickness of 125 mm, and expanded clay should be taken 415 mm in height.

Tips & Tricks

Ceiling insulation is a very important process. Through this space in the house, up to a quarter of all heat is lost. The process itself can be carried out by dry and wet methods. The second option involves the presence of a wet mass, which adheres to the surface and forms a layer of sound insulation.

It is advisable to check the moisture content of the material in summer and winter in several places.If an increase in humidity is not noted inside the insulation, then you should not worry about the quality of work.

The easiest way to check is to inspect the roof in the winter.

Everything that was supposed to stay inside the house goes outside.

If the appearance of moisture is noted, then it is necessary to increase the air flow in the gap for ventilation. This is done by connecting to a common air exchange system and bringing it to the roof. The second way is to blow the room with outside air. In such a situation, the presence of drafts in the attic is a very useful thing.

From the above, it follows that the process of insulating the ceiling is quite simple. This is within the power of both a novice master and an amateur builder. The main thing is to properly lay the insulator, bring lumber, make a counter-groove, put insulation and close it all with a board. But still, some materials are best applied using special tools. To do this, you still have to turn to professionals.

The mass of material poured by hand retains heat much worse. Such savings on the work of specialists in the future will cost the owner of the premises much more.

In the case when the distance between different floor elements is greater, it is recommended to use roll-type mineral wool. Depending on the manufacturer, it is usually one meter wide.

Fans of natural materials should be aware of a few features. In the absence of sawdust, you can use straw. In this situation, water is added to the clay until a wet mass is formed. Then wet straw is added to the composition and everything is thoroughly mixed with hands or feet.

It is important to remember about fire safety.The material for insulation must comply with the standards

Its technical characteristics should include holding the fire for a quarter of an hour in a private and an hour and a half in an apartment building.

In any case, before starting work, you need to carefully study the instructions for thermal insulation. It would be useful to consult with experienced craftsmen and study all the nuances of the upcoming work in order to choose the material that is suitable for a particular roof and perform the work at a high-quality level.

For information on how to properly insulate the ceiling in the attic room, see the following video.

Conclusions and useful video on the topic

Mineral wool floor insulation technology:

Thermal insulation of the ceiling of a private house with sawdust:

Insulation of the ceiling with a cold roof is one of the conditions for comfortable and economical operation of the house

When arranging a heat-insulating layer, it is important to choose the right material. The method of installation is important, as well as the obligatory formation of a reliable cut-off of condensate

Do you want to share your own experience in arranging the thermal insulation system of the ceiling? Do you have information that will be useful to site visitors? Please write comments in the block below, ask questions and publish photos on the topic of the article.