- Foam insulation

- How to insulate the ceiling from the attic

- Expanded clay

- Ecowool

- Penoizol

- mineral wool

- Sawdust

- Attic for the summer

- Insulation of the ceiling in a wooden house with sawdust and penofol: a step-by-step diagram

- Helpful Tips

- Basalt wool insulation technology

- What is the best way to insulate the ceiling in a private wooden house

- Materials used for internal insulation

- Dealing with moisture

- Conclusion

- How to insulate the ceiling with sawdust

- Attic insulation

- How to properly insulate the attic floor

- Insulation of the ceiling and walls of the attic floor

- Peculiarities

- What to insulate?

- Drywall

- Technical wool

- Finally, backfilling the attic

- Internal wall insulation

- How to choose the right material for ceiling insulation

- flat roof insulation

- Insulation of a flat wooden roof

- Insulation of a flat roof on a concrete floor

- Preparatory stage

- Caulker walls

Foam insulation

Work with foam

The technology of wall insulation with foam plastic is no different from the operations described above. The only difference will be the replacement of mineral wool sheets with foam sheets.

The positive qualities of foam, as a heater, include:

- Convection disappears, there will be no loss of heat due to poor-quality caulking;

- Even if the thickness of the beam is very small, the walls, as well as the corners of the house, will never freeze. The appearance of frost is completely excluded;

- If such a wooden house is installed in a country house, then its warming up, after being insulated with foam plastic, will take only a few minutes;

- Styrofoam is an excellent sound insulator;

- Polyfoam is easy to process and install.

I would like to warn everyone who insulates their house with polystyrene foam that it does not meet environmental safety and is a low-combustible material

Therefore, you should always be very careful when choosing an insulating material, even if it has a low cost and low weight.

When insulating a house, for example, from foam, each owner develops his own scheme for installing insulation. Someone uses a metal profile for this, while someone likes wooden bars. But in any case, such a scheme always takes into account the requirements of the technological process of insulating the walls and ceiling of a wooden house.

How to insulate the ceiling from the attic

Insulation of the ceiling from the attic side allows the use of a wider range of thermal insulation materials, reduces the time spent on work and reduces material costs for the entire process. Today, there are many materials that allow for the insulation of the ceiling. Consider the best heaters, which are evidenced by the reviews of many homeowners.

Expanded clay

Among the advantages of expanded clay are:

- relatively low price;

- good thermal insulation characteristics;

- availability.

Minuses:

- due to the large weight, expanded clay cannot be used on weak wooden ceilings. It is preferable to use the material with a concrete floor;

- low moisture resistance requires mandatory laying of a vapor barrier as the first layer;

- to create high-quality insulation, you will need to pour expanded clay with a layer of at least 20 cm.

Experts recommend filling up expanded clay of small and large fractions, which will fill the voids.

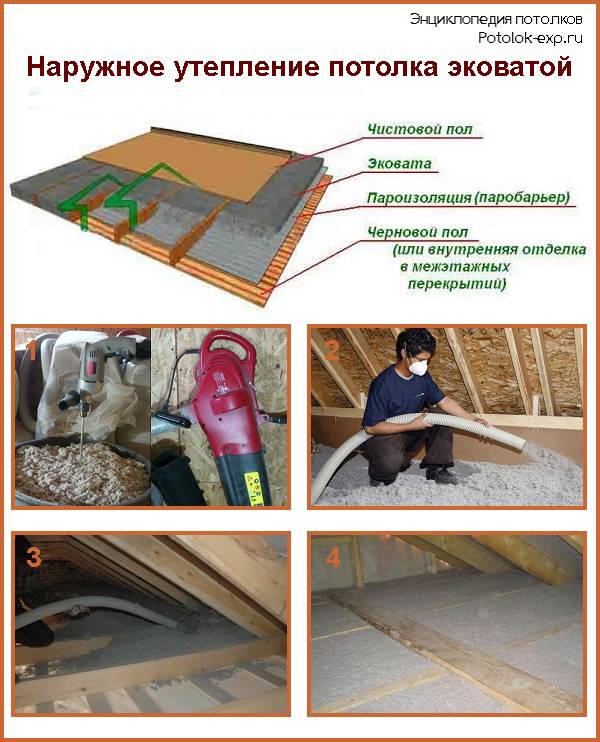

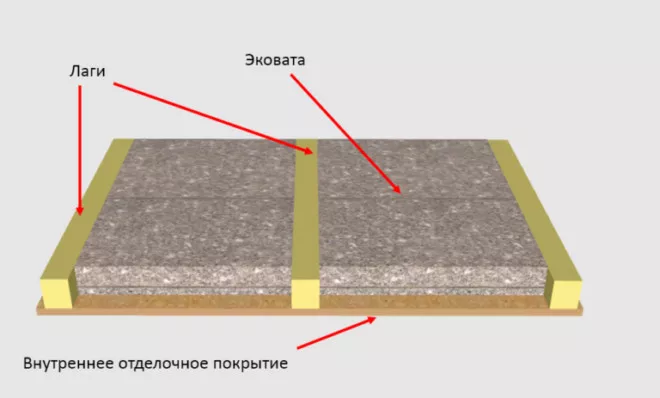

Ecowool

The material is made from cellulose with the addition of flame retardants to increase resistance to fire, as well as boric acid to protect against fungus and harmful microorganisms.

Advantages of ecowool:

- the material allows you to blow it into all the cracks, which significantly improves the quality of thermal insulation;

- the composition does not have compounds harmful to human health;

- to obtain good thermal insulation performance, a large amount of material is not required.

Flaws:

- the need for laying vapor barrier due to low resistance to moisture;

- requires the use of special equipment;

- since shrinkage is characteristic of ecowool, the material must be laid with a margin of 15%.

Penoizol

This insulation can be used in different ways, depending on the installation technique - sprayed or poured. However, thermal insulation of a house with foam insulation requires the involvement of specialists with appropriate equipment and equipment, as well as experience in work.

Advantages:

- penetrates well into all cracks;

- resistance to fire;

- environmentally safe for humans;

- not damaged by rodents;

- provides high quality insulation.

Among the shortcomings, one can single out the high cost and fragility of the material, which, under mechanical action, cannot restore its previous shape.

mineral wool

Warming the ceiling with mineral wool in a house with a cold roof has the following advantages:

- low cost;

- fast installation;

- high thermal insulation performance.

Of the minuses are:

- since cotton wool shrinks over time, when laying, the material should be taken with a margin of 15-20%;

- strongly absorbs moisture, as a result of which thermal conductivity deteriorates, therefore a waterproofing device is required;

- the heater should not be wrinkled. To do this, equip the wooden floor along the logs.

Many people have a question, what is the best way to insulate the ceiling, with mineral wool or clay? Since mineral wool is a modern material, preference should be given to it, and clay should be used for lack of a better one.

Sawdust

The most budgetary and easy-to-use material that must meet certain requirements:

- minimum moisture to prevent mold formation. To do this, sawdust is pre-dried, for example, in a dry room for a year;

- to reduce flammability, sawdust is mixed with flame retardants;

- to prevent the formation of fungus and protect the material from rodents, antiseptics, fungicides, and slaked lime are added to the sawdust.

Regardless of which material is preferred, for example, mineral wool or sawdust, the result will in any case be much better than without insulation at all.

Attic for the summer

True, in order to implement this option, it is necessary to cover the thermal insulation with a hard coating, which should lie on the logs.

Experts recommend insulating the ceiling of a wooden house with foam plastic, if there is a summer attic - due to the rigidity of the material for the floor, additional support is created. First of all, a vapor barrier layer is laid, for which the same glassine is used. A beam is selected on the logs with a thickness, as in the case of polystyrene.If they are laid at half-meter intervals, then there will be practically no waste of heat-insulating material. Sheets of plywood or OSB are placed on top, a layer of 15 millimeters thick will be enough (read: “Plywood ceiling: how to finish”).

Insulation of the ceiling in a wooden house with sawdust and penofol: a step-by-step diagram

From sawdust and cement, you can prepare a good insulation mixture. For installation work, you will need glassine. Instead, you can take any other insulating material. In addition to glassine, you will need a couple of bags of sawdust and cement mortar.

The scheme of insulation of the ceiling in the house with cement-sawdust mortar:

- First, treat the wooden ceiling with specialized antifungal agents.

- Lay a waterproofing layer over the entire floor area.

- Mix sawdust with cement.

- Lay the resulting mixture evenly over the entire area of the ceiling slab.

- Tamp the solution. To do this, you can just walk around the mixture a little.

Nowadays, penofol has become widespread, since this material is inexpensive and easy to install. In addition, penofol has high rates of heat and sound insulation.

The process of insulating the ceiling in a private house using penofol:

- First you need to attach penofol to the surface. To do this, you can use staples or screws. Sheets can be fastened end-to-end.

- Next, glue the joints of the sheets with tape.

- Then make a wooden frame with slats. This design will help to avoid condensation.

- Install drywall on the frame.

Helpful Tips

Experts recommend following the following useful tips when insulating the ceiling in a private house from the inside:

- in the attic, it is often necessary to mount a crate, which creates a space between the ceiling and the floor. Wood knots must be treated with an antiseptic primer;

- all concrete and wooden floors of the upper floor must be carefully insulated with a film, which is mounted according to the "overlap" principle;

- free areas are covered with expanded clay or laid with PVC panels;

- The heat loss of a wooden ceiling can sometimes reach 4 W/m²/K. Wood has good thermal conductivity; for brick or reinforced concrete, the figure is much higher;

- to insulate the ceiling, if there are warm rooms at the top, it makes no sense;

- in the hot season, the insulation plays the role of an insulator that protects the room from heating;

- at the beginning of the design of work, it is best to decide where the insulation will be located - from the inside or outside;

The prefix "eco" in the name of the insulation is an indicator of its environmental safety. For example, ecowool is a safe product that consists mainly of cellulose and natural additives. A very good material is foam glass due to optimal thermal conductivity, high strength and durability. The material does not burn and is not afraid of high temperatures. Foam glass is often poured between floors. Expanded clay is noticeably inferior in quality to PVC slabs or mineral wool.

How to insulate the ceiling in a private house, see the following video.

Basalt wool insulation technology

After the walls (ceiling) have dried after processing, proceed with the installation of insulation.

Stages of work when insulating walls with basalt wool:

- Determine the extreme elements of the crate. They are carefully checked using a level and a plumb line, since further installation work depends on their position.

- Fix the first vertical bar with screws and dowels.

- At a distance of 1 m, the following vertical strips are fixed, and so on, until the entire surface is covered with a crate. For the installation of rolled wool, the installation of the crate at this stage ends.

- If there are windows or doorways on the wall, separate bars are installed along their perimeter.

Sheathing near windows

- To install a lumpy heat insulator, a sheathing grid with horizontal elements is made. On the resulting vertical grid, horizontal strips are stuffed at an equal distance. The distance between the bars should correspond to the dimensions of the insulation. The result was a grid for the installation of thermal insulation.

- Cotton wool is placed in the cavity between the fixed planks. When installing the heat insulator on the walls, do not use glue or other means for fixing. If the crate is done correctly, then the cotton wool will fit snugly against the surface, but you must remember about the ventilation gap. If the ceiling is insulated, then the insulation will have to be fixed.

Any cotton has a porous structure, so it accumulates moisture. Therefore, when insulating a wooden house with cotton wool, it must be covered with a vapor barrier. When installing the roll material, cut off the required length and fix it on the wall. Before starting work, you should calculate how much material is needed to insulate a wooden house. Add 10% to the resulting number.

What is the best way to insulate the ceiling in a private wooden house

Undoubtedly, the best option for internal insulation are rolled materials.They have a low specific weight, are very practical and durable. As a roll material, it is best to use mineral wool or glass wool.

The process of warming a wooden ceiling using rolled material:

- First you need to nail the nails to the ceiling. At the same time, they should stick out a little.

- Pull string or string over the nails.

- Next, you need to lay the heater. It is desirable to carry out the installation with a partner, since it is very difficult for one to cope with laying the insulation layer and pulling the thread.

- Then attach a specialized film to the ceiling, which will serve as an anti-condensation material.

- Drive nails deeper.

- Attach drywall or other finishing material to the ceiling.

During installation work, try to avoid the appearance of cracks. Even small gaps can become a place for heat leakage. In addition, harmful condensation can form in large gaps.

Materials used for internal insulation

The materials that are used in the internal insulation of the house must meet certain requirements:

- Firstly, they must have low thermal conductivity in order to fulfill their main function - insulation.

- Secondly, these materials must meet the fire safety requirements for the premises.

- Thirdly, the material alone or in combination with the mounting structure must provide the required mechanical strength.

- And, finally, all materials used indoors must be environmentally friendly and not release any chemicals into the surrounding air that adversely affect the health of living beings.

Dealing with moisture

After performing work with insulation, humidity rises in timber houses.To ensure optimal humidity in the room, you will need to make forced ventilation.

For a blower, a medium-sized fan is best, with which you can maintain the desired humidity in the house, turning it on daily for a while. When the house from the timber is insulated from the inside, the ventilation works well, you can proceed to the finishing work. Another crate of thin bars is mounted on the second layer of the film. For wall cladding, it is best to use wooden lining or planken. Such materials will well emphasize the interior and give nobility to a wooden house, look at the photo. If you decide to stick wallpaper, then it is better to fix drywall on the insulation.

Conclusion

Using the instructions and watching the video, you can at no extra cost, with your own hands, insulate the house from the bar from the inside. Such work does not require special skills and is within the power of any person who owns a hammer and screwdriver.

In the process of working on the project of any wooden house, it is important to immediately exclude possible heat losses. This issue plays an important role in ensuring a high-quality microclimate in the future home.

To some extent, the interior design of the premises of the house also depends on it.

It is important to keep in mind that the insulation of a log house from the inside differs from those built of stone, brick, silicate blocks. Doing heat-insulating work with your own hands is quite simple, if you follow a few basic rules and work technology

How to insulate the ceiling with sawdust

This method is obsolete, but is still used to insulate ceilings.

Flaws:

- shrink, they need to be sprinkled

- fire hazardous

Sawdust insulation installation technology

First you need to replace the wiring, insulate it in metal pipes, and also insulate the chimney. To use sawdust as a heater you will need:

- sawdust

- lime

- cement

- blue vitriol

- water

Water is poured into a 10 liter watering can, several tablespoons of copper sulfate are poured as an antiseptic. Slowly, the contents of the watering can are poured into a barrel with sawdust mixture. If, with a clenched fist, the mixture stops emitting moisture, then it is ready for use.

Glassine is spread around the entire perimeter of the ceiling and fastened with adhesive tape or galvanized clamps. A sawdust mixture is laid out on the surface of glassine in an even layer. You don't need to push it too hard. Level the surface and let it dry for at least 2 weeks. Everything, the heater is ready. Only walking on it is not recommended, therefore, a room insulated with sawdust should not be used.

Attic insulation

Unlike a cold attic, the thermal insulation of which is done solely to minimize heat loss through the roof, the attic is a full-fledged living room, so the task is to insulate the room so that you can live in it.

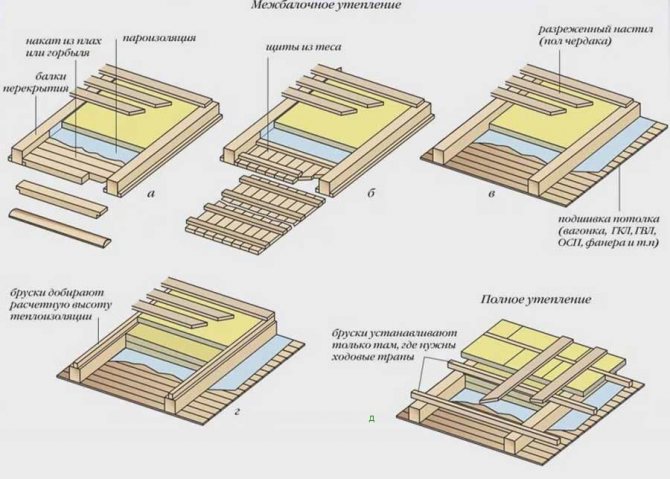

How to properly insulate the attic floor

- A vapor barrier material is laid on wooden beams, the canvases are overlapped on top of each other with a margin of 20-25 cm.

- On the vapor barrier from the side of the lower floor, boards are stuffed onto the beams, which will serve as the black floor of the attic and the basis for the ceiling of the second floor.

- Expanded clay of fine fraction is poured between the floors, which will act as a heater and at the same time soundproof the room.

- Another layer of vapor barrier is laid on top of the expanded clay, the film is fixed to the beams with the help of rails.

- Bars are mounted perpendicular to the beam ceilings, the distance between them should be equal to the width of the selected insulation.

- Between the bars, plates of insulating material are laid, bringing them as close as possible to each other. A vapor barrier layer is laid on top.

- If ecowool is used as thermal insulation, instead of wooden bars, a farm is made of metal profiles. Installation of a metal frame and insulation with ecowool are works that are difficult to do on your own. To do this, you need to have professional equipment and devices, so such thermal insulation is usually not done independently, but entrusted to specialists.

- Boards or thick plywood are laid on top of the insulation cake, which are attached to wooden blocks.

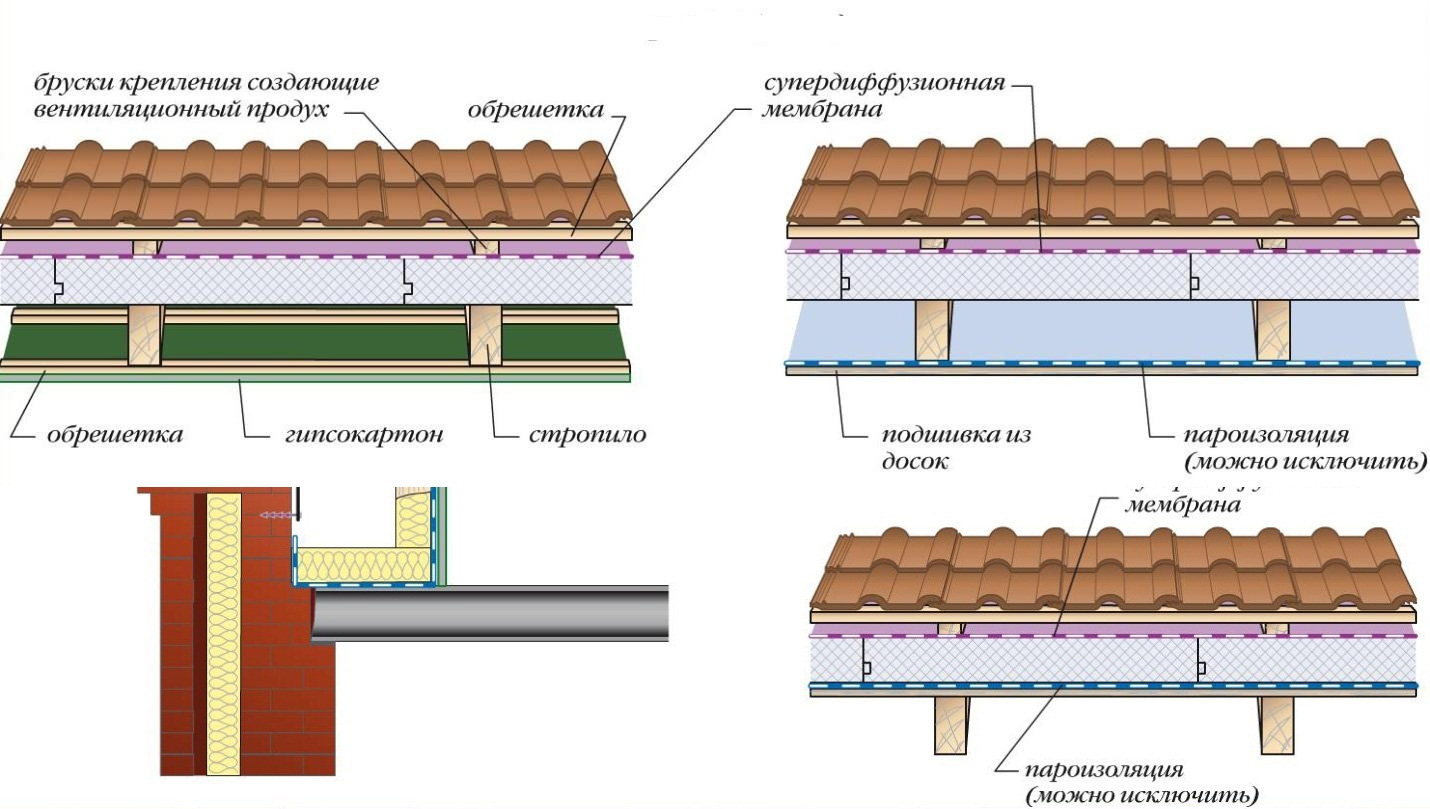

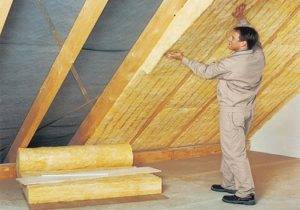

Insulation of the ceiling and walls of the attic floor

- From the floor itself, to the ridge, waterproofing is laid. The film should cover the entire surface, so that no open spaces form, it is necessary to overlap the canvases. The material is fixed on the rafters with a stapler.

- A crate is made of wooden slats, which are attached to the beams with a distance of 50-60 cm from each other.

- A heater is laid between the laths of the crate, its thickness should correspond to the width of the log. Plates are laid from the bottom of the room, moving to the top.

- From above, the cake is closed with a vapor barrier film, which is attached to the crate with thin slats, and the joints between the sheets are additionally glued with adhesive tape.

- A finishing finishing material is mounted to the crate, for example, lining or decorative panels.

If the ceiling and walls of the attic are separate parts of the room, then the walls are insulated as follows:

- Lay a layer of waterproofing.

- Make a wooden crate around the windows.

- At the bottom, along the entire length of the wall, a horizontal base beam is installed, and vertical racks are mounted from it in increments equal to the width of the insulation.

- A heat insulator is laid between the bars.

- Everything is covered with a vapor barrier film.

- A counter-lattice is made of thin rails to create a ventilation gap.

- Finishing is installed.

Peculiarities

The main feature of the ceiling insulation from the inside is the impossibility of organizing a condenser drain. The situation could be corrected by drainage walls. However, their cost is far from affordable for everyone. Depending on the season, the ceiling can quickly heat up and cool down. For this reason, the main ceiling insulation technology is focused on ensuring that condensation does not form in the finished structure.

In the people, such a heater is called glass wool. If this material is used in conjunction with a suspended ceiling, drywall will create an insurmountable barrier to escaping heat.

The installation of mineral wool should be divided into several stages:

- Assembly and installation of a frame on a metal or wooden base. For this process, it is worth using an electric drill and dowels.

- Filling the free space between the parts with mineral wool. As a fastener, a special glue for tiles is used. It instantly hardens and creates a reliable fastening of the material. Do not forget about the additional installation of vapor barrier.

- At the final stage of work, drywall is installed on the ceiling. It is recommended to use self-tapping screws made of hardened steel as fasteners (they have high strength and are able to withstand maximum loads).

To an ordinary person it will seem that the installation technology is quite simple. However, any installation process has its own nuances. It is strictly forbidden to press mineral wool. The main effect of heat retention is that the bubbles located in the inner part of the material do not provide heat exchange between the ceiling and the attic.

Spotlights can also create a certain problem. It is known that energy-saving lamps get very hot. The installed insulation will prevent the removal of heat from the lamps, which will lead to their rapid breakdown. An alternative option is to create an additional gap between the lamps and the insulation (obstruction of heat removal and air circulation).

What to insulate?

In order to insulate a room inside, several types of materials are used. Most often, a special heat-insulating material is used, which is called glassine. It has the following advantages:

- economically beneficial;

- practical;

- resistant to temperature extremes;

- resists moisture well.

And also popular heaters with similar characteristics. Among them are such as:

- nenofol;

- expanded polystyrene;

- isolon;

- penoplex;

- technical wool;

- cork.

As a waterproofing, PVC film is most often used, which reliably protects against leaks. Its service life is several decades. It is beneficial to use the film, because it is inexpensive.

Drywall

Drywall is good because it provides a perfectly flat surface without seams, it can be used to make any kind of ceiling. To work with drywall, two types of crates are used, such as:

- from wood - it is easier to work with such material, it costs less;

- from a galvanized profile - is more durable, does not deteriorate under the influence of temperature changes, is not affected by mold or fungus.

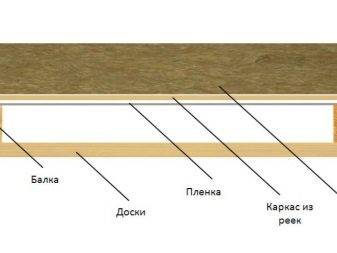

Technical wool

Insulation of the ceiling in a private household using technical wool is carried out in the following way:

- with the help of a stapler, a PVC film is mounted to the ceiling, which will reliably protect against moisture on the plates;

- a crate is stuffed from wooden bars in increments of 40–50 cm. The size of the bar should correspond to the thickness of the thermal plates, that is, have 5 cm;

- technical wool slabs are laid, they are fastened with special mounting rails. This design is reliable and simple, not subject to deformation.

Mineral wool has several important characteristics.

- Low thermal conductivity - 0.036 W / (m * K), a layer of no more than 10 cm is sufficient for insulation, which corresponds to the usual thickness of the supporting beams.

- The material has increased vapor permeability, for 50 kg of weight per cubic meter the coefficient is 0.7 mg / (m * h * Pa). This figure is higher than that of wood.

- Slight hygroscopicity, that is, upon contact with a liquid, the material will absorb no more than 2% of moisture from the total volume.

- Mineral wool boards have high fire safety. Such a heater does not ignite, does not contribute to the spread of fire.

- Mineral wool has good soundproofing characteristics, is able to effectively delay sound waves of very different frequencies.It is especially beneficial to use basalt insulation, because it does not deform, has a long service life. One package is enough to process about twenty square meters.

- The material is not susceptible to the harmful effects of fungus or mold, has antiseptic properties.

- The porous material, which has a low specific gravity, cannot be a burden on the supporting structures, which contributes to a long service life.

The condensate has a detrimental effect on technical wool, it inevitably loses its useful properties. PVC plates are not afraid of moisture, are not affected by erosion or the spread of fungus. The advantages of mineral wool are that it is not afraid of moisture, does not dampen. Mineral wool is cheaper than PVC boards, does not contain toxins, foam boards release harmful components.

Finally, backfilling the attic

The use of bulk materials is the simplest option for insulating the ceiling of a country house, although not the most effective. Thermal insulation is carried out on top of the floor in various ways:

- The space between the beams is filled with expanded clay, sawdust or vermiculite crushed stone to the maximum possible height. Floor boards are laid on top.

- Shavings and sawdust are mixed with pre-soaked clay. The solution fills the space between the lags.

- A screed made of sawdust concrete is arranged - the waste is mixed with cement and sand in a ratio of 5: 1: 1.

If you have an auger concrete mixer at your disposal, you can prepare a more modern ceiling insulation - polystyrene concrete. The cement-sand mortar is mixed with polystyrene beads and laid on the floor with a layer of 200-300 mm. You don’t have to lay the flooring - the monolith has sufficient strength.

Internal wall insulation

Before starting work, the wooden walls from the inside must be well cleaned of dust. Then they are covered with a special emulsion that protects the wood from the appearance of harmful insects. In addition, the wood is treated with a liquid that prevents it from rotting and turns it into a non-combustible material.

When the fire-retardant treatment is completed and the walls are cleaned from the inside, the cracks are caulked. Every builder knows well that after the construction of a wooden house, re-caulking can be done only after a year. During this time, shrinkage of the house will occur, new gaps will appear if no one lived in the house during this time.

Shrinkage is much slower if immediately after the completion of construction, the house was inhabited. Therefore, re-caulking from the inside is done in a couple of years. For caulking cracks from the inside, jute fiber is mainly used. It is pushed into the cracks with a thin chisel. Large gaps are covered with tape tow, which is pre-rolled into a miniature roller.

It is very important in a wooden house to create a vapor barrier from the inside. The fact is that the wooden base, consisting of beams, is closed with two heat insulators. That is, external and internal insulation material

As a result, increased humidity will be observed in the room, a “thermos effect” will appear. The walls just can't "breathe"

That is, external and internal insulating material. As a result, increased humidity will be observed in the room, a “thermos effect” will appear. The walls just can't "breathe".

The only way to deal with humidity from the inside is to create forced ventilation. It will not allow the wood to start to dampen. Otherwise, rot may appear on the walls of the house. In order for ventilation to have a positive effect, it is laid according to a previously developed scheme.

To protect the walls of the house from the inside from this phenomenon, before installation, the insulated surface is covered with a waterproofing film. It is laid with the rough side on the wooden surface of the timber.

How to choose the right material for ceiling insulation

Material content

Insulation of the ceiling will significantly reduce the cost of heating residential premises

The main heat leakage occurs through the upper and lower floors of the house, so you need to pay attention to both of them. It should be understood that the insulation of the attic floor requires a more careful approach than the interfloor

The fact is that the first will always be colder, since there is a roof next to it.

Materials for insulating the ceiling in the house

When choosing thermal insulation materials, the following characteristics should be taken into account:

- thermal conductivity (the lower it is, the better the insulation will be);

- water absorption coefficient (an important indicator that allows you to choose the least hygroscopic material);

- density and weight;

- flammability class (optimum G1);

- environmental friendliness.

In a private house, the floor can be either concrete or wood. In the first case, bulk materials, polystyrene, sprayed heat insulators, and dense mineral wool boards are used. To insulate a wooden floor, you can use any available materials with a low thermal conductivity.It is easier and easier to work with such ceilings. Methods of installation of the same materials for concrete and wood floors may be different.

In order to quickly determine the type of insulation, we recommend that you familiarize yourself with the table.

Table. Characteristics of the most popular thermal insulation materials.

| Material | Thermal conductivity coefficient (W/m*°С) | Flammability class | Density (kg/m3) |

| Styrofoam | 0,035-0,039 | G2 | 15-25 |

| Styrofoam | 0,025 | G2 | 35-50 |

| Mineral wool boards | 0,035 | NG (non-flammable) | 250 |

| Mineral wool | 0,041 | NG | 125 |

| Slag | — | NG | 1000 |

| Expanded clay | 1,148 | NG | 500 |

| Perlite | 0,041 | NG | 40 |

| Vermiculite | 0,05 | NG | 100 |

| Wood fiber boards | 0,09 | G2 | 250 |

| Sawdust | 0,090-0,180 | G2 | 25 |

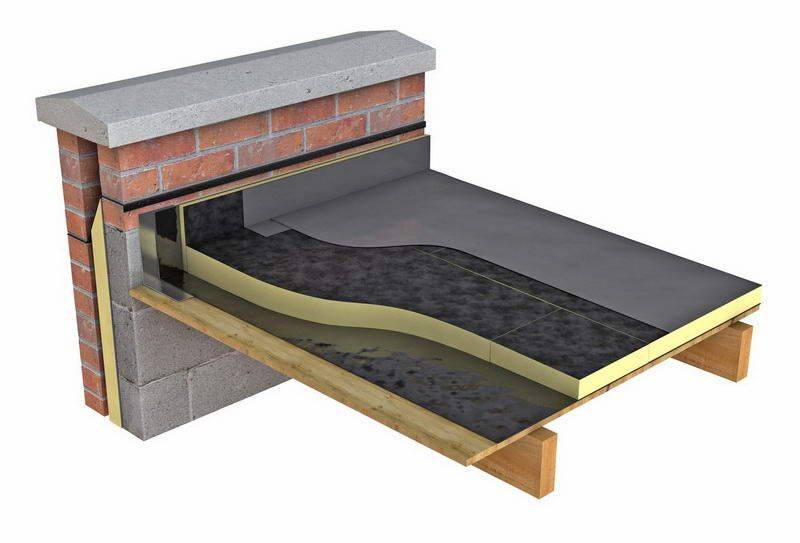

flat roof insulation

The technology for insulating a flat roof depends on the materials of the floor and the features of operation.

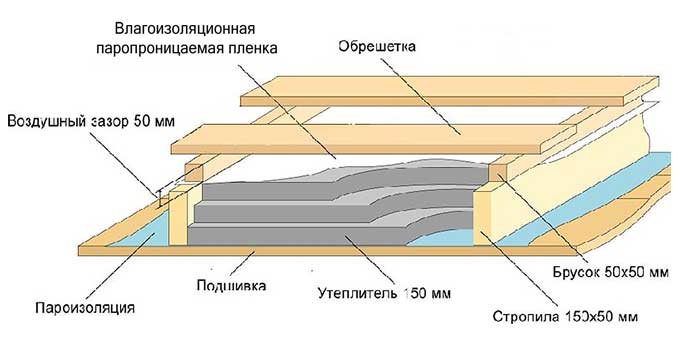

Insulation of a flat wooden roof

Usually, flat wooden roofs are considered as a "sign" of a frame house. It is this scope of application that is indicated even in the "proprietary" description of the roofing systems of the companies producing heat and waterproofing materials TechnoNikol. But even in brick houses, a wooden flat roof is not uncommon, since with a relatively small weight of the structure, sufficient rigidity and strength of the roof of a low-rise building can be ensured.

One of the possible schemes for warming a flat wooden roof

The wiring diagram looks like this:

- Base. Moisture resistant OSB board (class 3 or 4).

- Vapor barrier film. Spread with an overlap of strips by 15-20 cm along the long side and along the short side (when increasing in length). Along the perimeter, the vapor barrier should rise to the parapet and adjacent surfaces by the same 15-20 cm. Polymer-bitumen vapor barrier films are attached to the base with glue or telescopic fasteners (together with thermal insulation).A polypropylene or polyethylene film can be spread without fastening to the base, fixing it around the perimeter to the walls of adjacent surfaces using a self-adhesive vapor-tight tape.

- Insulation on the roof of the house. Three types of materials can be used for thermal insulation of a flat roof: stone wool mats, extruded polystyrene foam, rigid polyisocyanurate foam boards.

- Roof covering.

Perhaps the most common example of a flat insulated roof over a wooden floor is a terrace with access from the second floor. But in this case, the design of the roofing pie is closer in its structure to the insulated ceiling of a cold attic.

Insulation of the terrace floor on the second floor is carried out between the beams

As a roofing covering of flat roofs, rolled waterproofing materials are used, which make it possible to make a continuous and inseparable top layer. But, as with the insulation of a pitched roof, the waterproofing layer must be "breathable". There are two main options for a breathable flat roof:

- the use of polymer membranes with high mechanical strength and resistance to direct exposure to ultraviolet radiation;

- two-layer bituminous coating - welded roll insulation on top, substrate with ventilated channels on the bottom (for example, Uniflex Vent).

Two-layer bituminous roofing on an insulated flat roof

The advantage of a wooden flat roof is that a slight slope is arranged due to the position of the floor beams. And it is needed even at a flat roof to drain precipitation into the drain.

Insulation of a flat roof on a concrete floor

This type of insulated flat roof accounts for the most options for constructing a roofing pie.

To start with, there are unexploited and exploited flat roofs. Moreover, "operation" can be of a completely different nature - from the terrace as a recreation area to the arrangement of the so-called "green roof".

One of the options for the scheme of an operated flat roof with a Mauritanian lawn

If you do not take into account the different options for roofing, then the same order of layers is used on the concrete floor as on the wooden one, except for one nuance - the organization of a slope to divert precipitation into the external or internal drainage system. And several solutions can be used here:

- device for overlapping the screed with a slope;

- installation of a bulk slope-forming layer of expanded clay on a concrete base, separated from the insulated roofing pie with a reinforced screed;

- installation of a bulk slope-forming layer of expanded clay over a layer of extruded polystyrene foam or mineral wool, followed by laying a screed and roofing;

- the device of a slope-forming layer of special plates or mats of thermal insulation, in which one surface is located with respect to the other with a slope.

Sloping mats or thermal insulation slabs are laid as a second layer on top of thermal insulation materials with the usual "geometry"

Preparatory stage

It is necessary to start with an assessment of the condition of the walls, the quality of the previously performed work on the insulation of the log house. It is necessary to carefully examine all the joints, corners and junctions of the beams, evaluate the compaction of the entire surface of the walls of the log house. If any defects are found (for example, thinning of the caulking layer), they must be eliminated in advance.

Caulker walls

Any construction from a bar is distinguished by a large number of seams.After the building shrinks and the moisture content of the wood equalizes, voids can form in the grooves and seams, which reduce the ability of the entire structure to retain heat. That is why caulking is so important, which allows you to completely isolate interventional connections.

The implementation of such work requires compliance with several rules:

caulking must be carried out from below and one crown must be processed from all sides at the same time, otherwise the building may warp;

it is important to choose the right tool, because the chisel should not damage the tree;

taking into account the formation of a narrow groove between the timber, it must be processed “stretched”.

This type of caulking is carried out by stretching along the seam of fibers of tow, moss, jute or their analogues. Part of the material is left out and, after processing the groove, it is rolled up and pushed in, completely covering the space between the crowns.