- Popular types of thermal insulation materials

- Heaters in rolls

- Plate materials

- Liquid polymer thermal insulation

- Loose thermal insulation

- Floor insulation instructions

- Garage wooden floor insulation

- Working with a concrete base

- Wall insulation inside the garage

- What is floor insulation in the garage for?

- Follow-up progress

- Types and structure of sheets

- Optimal insulation for wooden floors

- Heaters for economical owners

- Modernized expensive heaters

- Mineral wool

- Why do you need to insulate your garage?

- Ways to insulate the floor in the garage

- Features and Benefits

- How to choose floor insulation

- Inexpensive heaters

- Expensive modern materials

- Gaps and slope of the screed

- Materials for floor insulation in the garage

- How to choose a heater?

- What heater to choose?

- How to choose material?

- Calculation

- Concrete floor

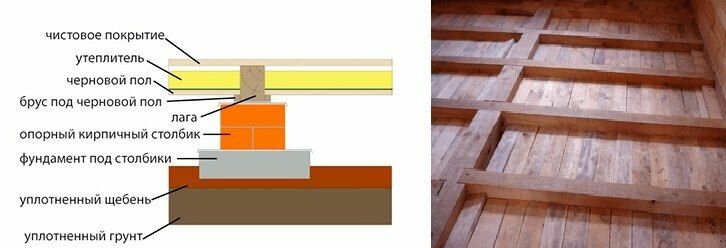

- Wooden floor

- Main varieties

Popular types of thermal insulation materials

Ease of use is one of the most important criteria for choosing materials. Some of them are solid and can only be used on flat surfaces, while others are also successfully used for thermal insulation of areas of complex shape. Before insulating the floor in a wooden house, you should choose the most suitable type of insulation.

When choosing a material, it is necessary to take into account the conditions under which it will have to be laid.

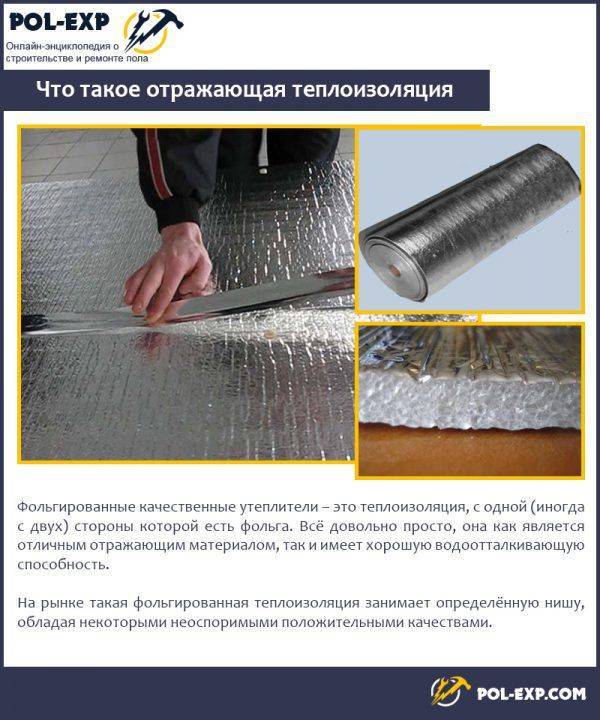

Heaters in rolls

In this form, heaters are supplied, the basis of which is cork or mineral wool. The physical characteristics of these materials (softness and reduced density) make it possible to lay thermal insulation without much difficulty, not only on a perfectly flat surface. Roll insulation can be laid with the least number of butt joints, which increases the degree of thermal insulation. In most cases, this type of insulation is afraid of high humidity, so when laying it, you should take care of waterproofing. Sometimes roll materials have an outer foil layer that protects the material from moisture.

Rolls are easy to unwind on a flat surface

Plate materials

These are lightweight slabs or insulation mats that can not change shape during installation. They are characterized by low thermal conductivity and low weight. Easily mounted on the surface with minor errors.

Tiles can be installed alone

Liquid polymer thermal insulation

This type is a special formulation that forms a solid foam structure when exposed to air. With the help of such thermal insulation, all hard-to-reach places and errors are filled. Among the well-known representatives of this type of insulation, penoizol can be distinguished, which is applied to the surface from a can using a special sprayer. The only drawback of liquid heaters can be called a high price.

Liquid insulation sticks to any surface

Loose thermal insulation

This type of insulation is represented by such bulk materials as slag, expanded clay or sawdust.They fill the prescribed volume quite tightly, while laying is possible both on a pre-equipped base and on ordinary soil.

When choosing a method of insulating wood flooring, one should be guided by the efficiency of the use of the material and the material benefit.

Least effort on flat surfaces

Floor insulation instructions

There are a lot of options to insulate the floor in the garage. In most cases, the method that is chosen depends on the type of floor.

It is recommended to install the insulation in the warm season - it will be easier to work, and the screed will be able to harden faster.

Starting work on floor insulation, it is important to take into account the base material, your own professional skills, and the size of the budget.

The insulation plan depends on various criteria. The main ones are: professional training, available budget, selected materials.

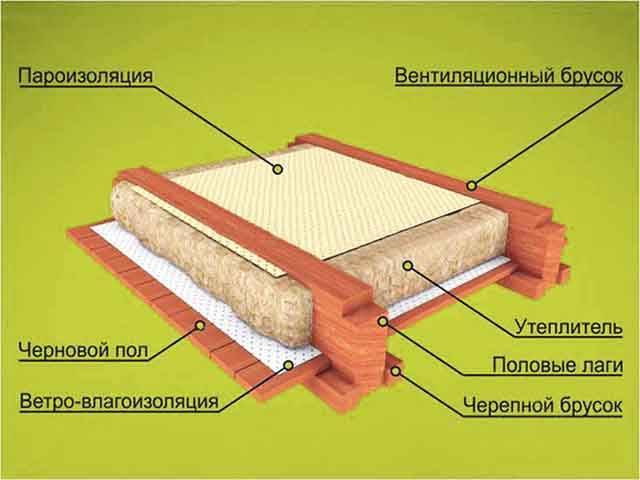

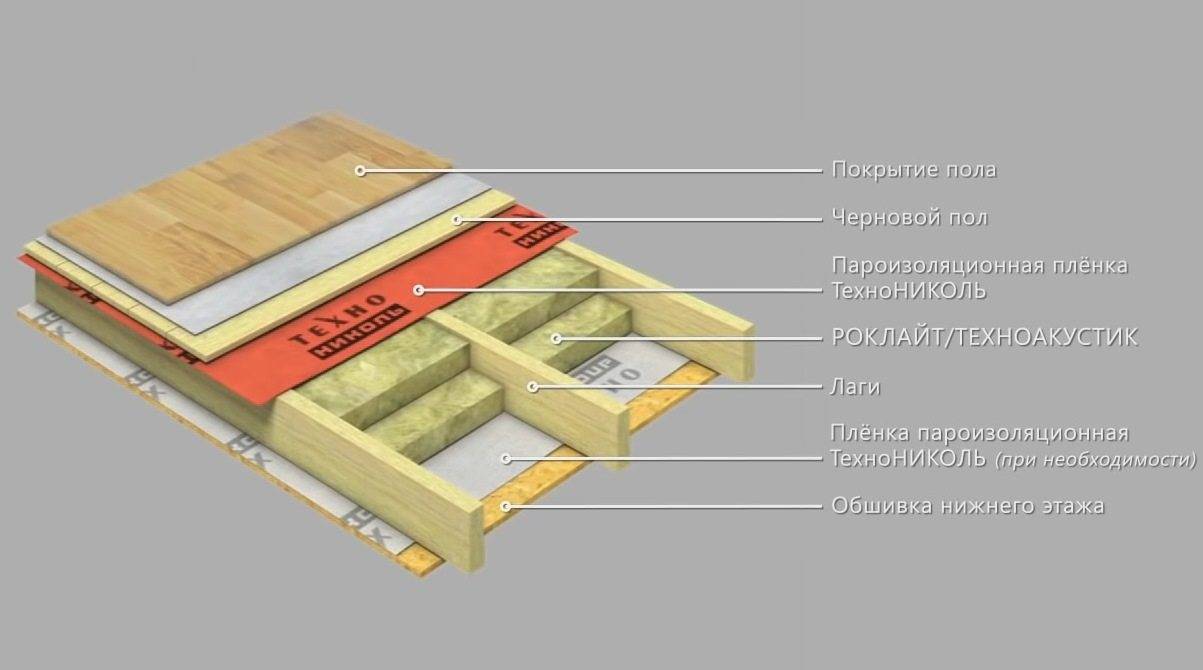

Garage wooden floor insulation

The most budgetary solution is the use of mineral wool. The material is inexpensive, and installation does not require professional skills, expensive tools.

The order of work is as follows:

level the soil, pour a layer of sand up to 10 cm thick on it;

pour concrete screed;

lay a layer of waterproofing using polyethylene, roofing material;

install wooden logs so that the distance between them corresponds to the width of the insulation roll;

lay mineral wool in the recesses;

cover the insulation with a layer of waterproofing;

install wood flooring.

Wooden logs can be installed on a base made of expanded clay. Often, instead of mineral wool, foam or extruded polystyrene foam is used.

Insulation of a wooden floor comes down to providing waterproofing, filling the space between the lags with an insulating material. When protection against cold is installed at the construction stage, the logs are mounted on an insulated base

The thickness of the insulating layer or sheets of material should be about 10 cm. If the work is done in a finished garage, insulation comes down to filling the space between the lags with a heat insulator, ensuring its protection from moisture.

Do you have not only a garage, but also a wooden floor in your house? And have you also thought about its insulation? We recommend that you familiarize yourself with the technology of thermal insulation work in more detail.

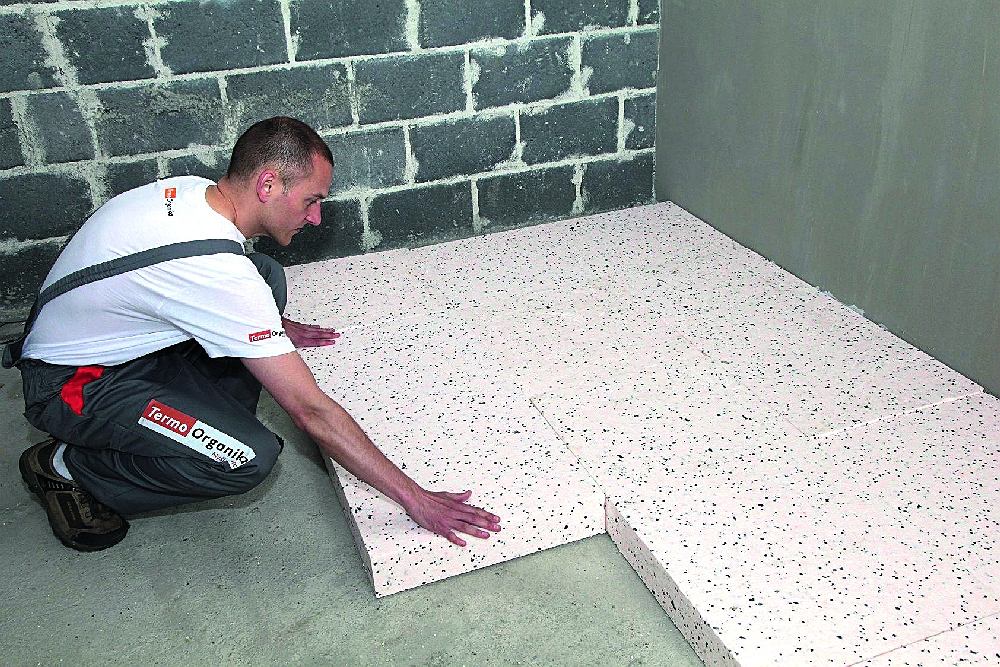

Working with a concrete base

A stronger concrete floor is preferred by owners of heavy vehicles. High-quality screed guarantees long-term operation of the surface. If cracks or insufficient insulation appear, an additional layer of insulating material can be laid on top of the old one, without dismantling.

To create an insulating layer, all the same materials are used, only the rules for their installation change. Expanded clay is poured onto a rough base with a layer of 25 cm or more, covered with a reinforcing mesh, poured with a solution.

When using expanded polystyrene, most of the load will fall on the foam layer.

To ensure the durability of the structure, it is necessary to adhere to the following recommendations:

- When preparing the base, carefully close up all the irregularities that can break the insulation layer.

- Lay the overlapping waterproofing film, do not forget about entering walls up to 15 cm high. Secure the joints with adhesive tape.

- Lay the foam sheets tightly, fix the joints with glue or mounting foam.

A film is laid on the insulation layer, which will prevent the penetration of moisture from the solution, then a reinforcing mesh. The structure is filled with mortar.

Styrofoam floor insulation is a simple, practical option for a garage. To create a monolithic structure, sheets are sometimes equipped with spikes and grooves or chamfers.

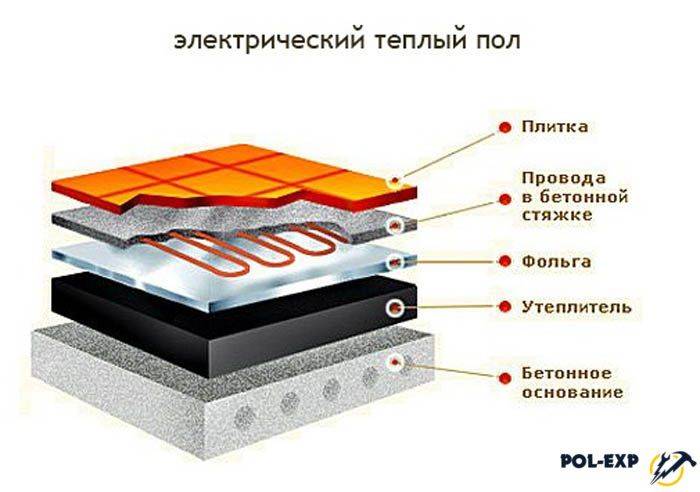

If it is necessary to heat the garage, in some cases a water-heated floor is installed. Foamed polystyrene foam is then used as a heater.

Pipes are additionally integrated into the design, through which the coolant circulates, providing heating.

We reviewed the best ways to heat a garage in the next article.

When planning floor insulation in the garage, it is worth considering the inspection hole - its presence facilitates the maintenance and repair of the car. However, it becomes a serious channel for heat leakage. When working with the floor, do not forget about its thermal insulation.

The complexity of the device of modern machines leads to the fact that the owners are less and less likely to carry out various work on their own, so the pits are not used for their intended purpose. As a result, they are closed with homemade plugs, insulated with improvised materials. If there is a difference in the quality of the thermal insulation of the floor and the pit, condensation may form at the place of temperature difference.

Wall insulation inside the garage

The instructions for properly insulating the garage inside are not too different from the previous one.

It is necessary to eliminate all surface defects and level the walls with putty. If the garage is metal, then you should clean its walls with large emery, a regular metal brush or a grinder with a cord brush. It is advisable to clean everything down to the metal, but if the paint does not go away, then you do not need to be too zealous.Next, you need to remove dust from the walls and degrease the surface.

A pre-prepared crate is installed on the walls, into which the foam will be placed. For crates, it is better to use a wooden beam. Its thickness is equal to the thickness of the insulation. But it must be remembered that the tree does not have fire resistance.

If the foam is tight, then you can do without glue. For a metal garage, you can not use the crate. In this case, the insulation is simply glued to the surface using liquid nails or mounting foam. But it should be borne in mind that then there will be nothing to attach the shelves to.

After installing the insulation, the walls can be brought into a more decent form - sheathe them with plywood or clapboard.

What is floor insulation in the garage for?

Floor insulation works increase the financial costs for the construction or repair of the operated facility, but nevertheless, these costs are justified, because. floor insulation allows you to achieve the following results:

- The ability to maintain the temperature inside the room within the specified parameters with minimal heat loss through the floor surface;

- Creation of comfortable conditions during the repair of various types of equipment and the performance of other works;

- Maintaining an indoor microclimate that will be optimal for storing equipment, spare parts and other materials.

Many users think about how to make a warm floor in the garage, and depending on the design of the floor, there may be several options for such an arrangement.

Follow-up progress

Pour the prepared mixture over the base. We focus it on the entire surface evenly.You need to act clearly and quickly, since the solution hardens within two hours. Here the question often arises - what should be the thickness of the floor in the garage? It all depends on the requirements for it. Usually the thickness varies from thirty to seventy millimeters. Here, a big role is still played by the fact how much materials were spent to eliminate the irregularities of the concrete slab or the ground on which the screed was laid, whether it is planned to install a “warm floor” heating system.

IMPORTANT TO KNOW: Filling must be done at one time. Due to this, the floor will turn out to be monolithic and as durable as possible.

The screed must be moistened after pouring - once every ten hours. This will prevent it from cracking while drying. It will take six to seven days for the concrete mixture to completely harden. If you used a self-leveling mixture for the screed, then its curing time is completely different - see the packaging. Usually it's twelve to twenty-four hours.

After the screed has completely cured, you may decide to use an additional concrete floor coating. Often competent persons cover the surface with epoxy or polyurethane compounds, or paint the concrete with special paint.

Some craftsmen put tiles on concrete. There are no restrictions. It all depends solely on your financial capabilities and preferences. The main thing is that the floor surface is rough - this provides excellent grip for the wheels of the car.

Types and structure of sheets

Boards of this thermal insulation material are produced in standard widths of 0.6 m and lengths of 1.2 m and 2.4 m.The thickness of the slab varies from 0.02 to 0.1 m, therefore, depending on the needs and the possibility of increasing the height of the floor cake, you can choose the right insulation.

In the production of plates, manufacturers maintain clear dimensions of the sheets, which makes it easy to mount the material. When determining how to insulate the floor with foam plastic, you need to familiarize yourself with the technical and operational characteristics of various grades of material.

Property Specifications

| Characteristics | Penoplex 31 | Penoplex 31C | Penoplex 35 | Penoplex 45 | Penoplex 45C |

|---|---|---|---|---|---|

| Density (kg/m3) | 28-30,5 | 25-30,5 | 28-37 | 35-40 | 38,1-45 |

| Compressive strength (MPa) | 0,20 | 0,20 | 0,21 | 0,41 | 0,5 |

| Flexural Strength (MPa) | 0,25 | 0,25 | 0,4 | 0,4 | 0,4-0,7 |

| Water absorption per day (%) | 0,4 | 0,4 | 0,4 | 0,4 | 0,2 |

| fire resistance category | G4 | G1 | G1 | G4 | G4 |

Expanded polystyrene for the floor is a modern technological building material that combines the properties of foam and plastic. Due to its specific cellular structure, penoplex perfectly retains heat and actually does not absorb moisture.

It is distinguished from similar sheet heat insulators by its high density and fracture strength. The rigid structure of the slab allows you to create a frameless floor insulation with polystyrene foam.

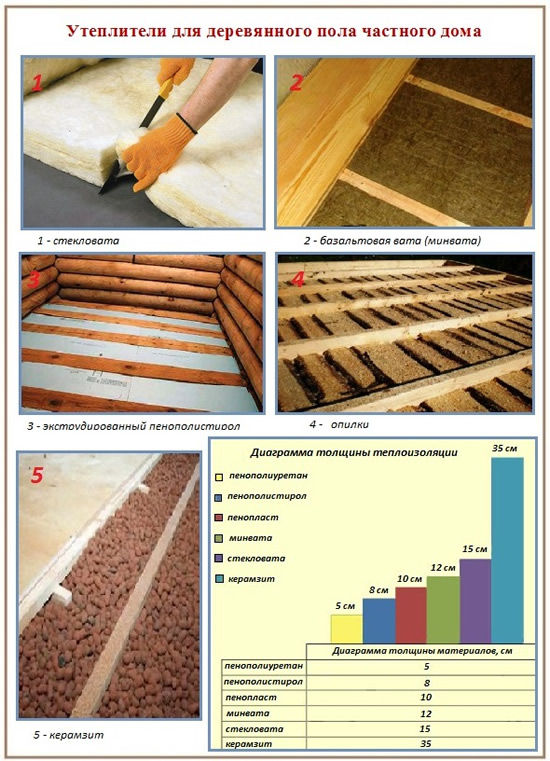

Optimal insulation for wooden floors

Discuss on a topic the best material for thermal insulation of a wooden floor is meaningless. Almost everything is applicable, from old-fashioned dry foliage to expensive vermiculite. They insulate the floors in wooden houses with loose thermal insulation options, mats and slabs.

Since the list of requirements for any insulation consistently includes lightness, minimum water permeability, durability, operational safety, all these qualities are quite satisfactory for builders and owners of wooden houses.

The choice mainly rests on the financial capabilities of the owner, on the type of foundation and on the method of laying. Owners who are not limited in funds will be able to purchase progressive, easy-to-fit materials with detailed instructions on how to insulate the floor in a private house without the involvement of builders and with an accurate indication of the thermal performance of the factory product on the package. If you want to save money, you will have to tinker a lot with traditional insulation schemes.

Heaters for economical owners

Independent home craftsmen who do not want or are not able to invest significant amounts in insulation can use as a heat insulator:

- dry sawdust, pleasing with a minimal price, but requiring a reliable waterproofing device on both sides of the insulating layer due to the tendency of the material to actively absorb moisture;

- sawdust granules, which are a more practical option, treated with an antiseptic and fire retardant;

- slag, attractive in cost, but used mainly in floor insulation schemes on the ground;

- expanded clay, used to create a heat-insulating layer of considerable power, since its optimal thickness for our latitudes is 30 cm;

- simple mineral wool without foil and corrugated shells that increase thermal performance;

- roll insulation, created on the basis of fiberglass, slag;

- polystyrene foam, which needs to be carried out to protect it from the encroachment of rodents and from fires.

Subject to the rules for thermal insulation using the listed materials, heat leakage through the lower ceiling will be excluded. However, laying them will require impressive labor efforts.

Modernized expensive heaters

If the owner of a country property does not have the main task of how to insulate the floor in a wooden house with little expense, then at his disposal:

- Vermiculite is a product of the processing of hydrated micas with excellent insulating properties and operational durability;

- Penoplex - extruded polystyrene foam produced in plate format with increased strength and excellent waterproofing properties;

- Various modifications of heaters with the brands Ursa, Thermolife, Isovent, Penofol, Isolight, etc., which are mats and plates with bases made of foamed polystyrene, glass wool and basalt analog, optimized by increasing wear resistance, minimizing water permeability, applying foil shells for reverse reflection of heat rays and other methods.

It is possible to isolate a wooden floor in case of minor heat leaks with ecowool or polyurethane foam, but it is impossible to blow these materials without special equipment.

This is a significant minus, and the plus is the creation of a dense water-repellent layer of insulation that does not require a device to protect the insulation from steam.

Mineral wool

The preparation of the base for insulation is carried out similarly to the previous option, but the insulation of the walls of the garage from the inside in this case will differ in technology. First, it is worth assembling a crate made of wood or metal parts. Usually, these are all familiar profiles intended for the installation of structures from gypsum boards.The installation step of the elements almost corresponds to the width of a mineral wool roll or a rigid mat made of the same material, but slightly less. So the insulation will be securely fixed in the cells of the frame.

Next, you should take care of protecting the insulator from moisture and lay a layer of waterproofing. Rigid mats of a cotton heat insulator are laid inside the cells or parts of rolled wool cut to size are inserted. On top of the resulting design is closed with a layer of vapor barrier and decorated to your liking. It should be noted that mineral wool will completely lose its properties when it gets wet and protect it as well as possible from water ingress.

Why do you need to insulate your garage?

The temperature regime, which has a positive effect on the condition of the car, is significantly different from the one in which it is comfortable for a person. If in residential premises the standard is to maintain the air temperature at the level of + 20-22 degrees Celsius, then +5 degrees is considered the most optimal for storing the car. At this temperature, almost no condensation forms on metal parts, causing destructive corrosion.

Therefore, to create a microclimate suitable for equipment in the garage, other approaches to insulation are used. After all, the desire to recreate room conditions in the garage with the help of insulation and heating devices will harm the vehicle. For example, in winter, getting into a heated room from frost, the car will instantly fog up, the air humidity will increase, and in such a warm-humid fog the car will stand all night.

How to properly insulate a garage? Let's figure it out.

Ways to insulate the floor in the garage

Insulation of the floor in the garage should begin with bulk modern materials. Expanded clay is the leader in such work.The relatively inexpensive bulk material is ideal for underfloor insulation work. Expanded clay belongs to the group of non-combustible building insulation, therefore, in addition to the insulating effect in the garage, you will receive a safe fire-resistant floor covering.

An additional and important property of such a substance is moisture resistance. Before starting work, dig a recess, up to 45 cm, where pour the insulation and level its surface. Previously, the very bottom of such a pit can be treated with roofing material. Place a reinforcing mesh on top of the loose mixture and pour the screed.

An additional and important property of such a substance is moisture resistance. Before starting work, dig a recess, up to 45 cm, where pour the insulation and level its surface. Previously, the very bottom of such a pit can be treated with roofing material. Place a reinforcing mesh on top of the loose mixture and pour the screed.

Expanded polystyrene is a high-quality insulation of any surface, has a high density, has good thermal conductivity and partially prevents the passage of moisture and steam through its surface.

For high-quality insulation, it is necessary to pay special attention to the cracks at the joints of the connecting plates. Their base is quite fragile, but it is easily cut with a knife.

Such a heater spreads already directly on the concrete surface, which is previously waterproofed with roofing material or resin. The final stage of work will be laying a wooden floor on top of the slabs.

Styrofoam is the cheapest and therefore very popular material for insulation. It has high thermal insulation properties, is durable, flexible and lightweight. Installation of such a coating does not require special skills, it is easily processed with a hand tool. Pre-level the surface, install a wooden crate, lay the foam boards end-to-end, apply a waterproofing layer. Then a non-rigid (most importantly, not very heavy) reinforcing mesh is laid and a thin layer of screed is poured. A wooden floor is laid over everything.

Features and Benefits

If there is an underground or basement in a wooden house, the process of warming must be started from there: as a result of cold air entering the top, which comes from the freezing ground, a large loss of heat is formed. Also, before warming, it is necessary to ensure total drying of the entire room where the work will be carried out, using special devices for ventilation.

The installation of thermal insulation coatings is not particularly difficult. The main thing is that the materials are of good quality with processing by special means: this will help reduce the impact on them of the severity of the boards, soil and low temperatures. Before purchasing insulation coatings, you should consider what the load on them will be, as well as the level of the lowest temperature indicator that this or that type of material can adequately withstand.

But in general, any insulation technology has several main stages:

- First, the logs are mounted, then dense sheets of wood are fixed on them, and only after that the laying of the insulation itself begins.

- After the insulation is laid, the base is sheathed with a material that has the property of insulating against steam and moisture: this ensures that the material will retain its original properties longer.

- At the end of the work, the rough base is ennobled with the help of finishing.

How to choose floor insulation

Professional builders have been arguing for a long time about the best thermal insulation material for the floor in the country, but in most cases, the owners of their own houses are interested not only in the effectiveness of the insulation, but also in its cost, and it is desirable that it be as low as possible.A warm floor in the country can be made using inexpensive bulk materials, heat-insulating mats or slabs, and if funds allow, you can organize polyurethane foam spraying and forget about drafts forever. There are a lot of heaters on the market, but almost always the choice is based on financial capabilities.

There are a number of requirements for floor insulation:

- Light weight so as not to create an additional load on the foundation.

- Waterproof - the insulation should not pass or pass water minimally, not damp and provide additional waterproofing (ideally).

- Durability - you must admit, no one wants to start such large-scale work to change the insulation every 3-5 years.

- Fire safety - insulation should not easily ignite or support combustion.

- Ecological purity.

If the financial situation allows, you can purchase modern heaters that are easy and quick to install without the help of specialists. There is also a solution for economical owners - traditional insulation schemes using cheap materials, but you will have to tinker with their installation. Consider all options.

Inexpensive heaters

If you want to save on building costs without sacrificing quality, there are several thermal insulation materials that provide reliable protection from the cold and at the same time are inexpensive. For example, our ancestors also insulated floors with dry sawdust. They can be purchased at a minimal price or even obtained for free at a woodworking production. However, in this case, it will be necessary to strengthen the waterproofing, because the sawdust easily absorbs moisture, and when they become damp, they no longer retain heat.

A more practical option is sawdust pellets - this is a product of modern production, the raw material for which is woodworking waste. The sawdust is pressed under pressure into small, hard granules that are not so easily succumbed to moisture and last longer. The granules are treated with flame retardants (means that do not easily catch fire) and antiseptics. Basically, this material is used for thermal insulation of the floor on the ground. In addition, untreated pellets are an excellent economical fuel for stoves and boilers. They are also used as fillers for cat litter, which speaks in favor of their environmental friendliness and safety.

Expanded clay has excellent thermal insulation qualities and is a favorite insulation material for economical builders. These are clay granules foamed under the influence of high temperature, which practically do not absorb moisture and are able to give the house warmth for many years and even decades.

The only drawback of expanded clay is its fragility, so care should be taken during transportation. For high-quality thermal insulation of the floor in the middle latitudes of Russia, it is recommended to pour a layer of expanded clay with a thickness of about 30 cm. Another inexpensive insulation is mineral wool in rolls without a corrugated sheath or foil layer

However, for it, as well as for sawdust, reinforced waterproofing is necessary. The same applies to roll materials based on fiberglass, stone wool, slag wool.

Another inexpensive insulation is mineral wool in rolls without a corrugated sheath or foil layer.However, for it, as well as for sawdust, reinforced waterproofing is necessary. The same applies to roll materials based on fiberglass, stone wool, slag wool.

Foam boards are also inexpensive, but they are very fond of spoiling rodents, which sooner or later start up in any private house. In addition, the foam should be protected from fire - and although it does not burn on its own, it emits acrid smoke when melted, which can lead to suffocation.

Expensive modern materials

If you want to conduct high-quality floor insulation in the country and are not constrained by funds, you have a lot of options, one is better than the other.

The most popular modern heaters:

Gaps and slope of the screed

When constructing a concrete floor, in no case should one forget about such an important condition as a slope. Only two percent is allowed, i.e.

two centimeters per square meter. The slope of the screed should lead to a drain grate or gate.

Compensation gaps should not be neglected either. They are needed near internal protruding parts (pipes, poles, ledges, etc.) and all walls. This condition is mandatory when the garage area does not exceed fifty square meters. At the time of the screed, it is most convenient to leave gaps. To work, you need to stock up on a strip of polystyrene foam (half a centimeter thick), expansion tape or a plastic profile from the same material.

Materials for floor insulation in the garage

Warming the floor in the garage requires an integrated approach. You should start with the choice of material and method of insulation. This will determine how long the work will take and how much you will need to spend on materials.

How to choose a heater?

Materials for insulation on the market is presented in abundance. It's very hard to choose

Therefore, we have compiled a list of characteristics that you should pay attention to when choosing:

durability - the material should not require replacement after a few years after the start of operation;

fire resistance - a garage room is an object with a high fire hazard, in addition, combustible substances are stored in it;

hygroscopicity - the insulation should not absorb moisture from the soil, if it is not waterproof, then waterproofing must be provided;

subtleties of installation - be sure to pay attention to the complexity of laying the selected material, whether you can handle the upcoming work yourself;

cost - consider your financial capabilities when choosing a material, especially since there is no fundamental difference between heaters.

What heater to choose?

We found out what characteristics a heater for the floor in the garage should have, now it’s worth figuring out what they are, modern heaters.

Most insulation materials can be divided into three categories. Let's talk a little about each of them.

1. Mineral fiber insulation.

These include mineral wool and glass wool. They are made from natural materials. Most often sold in the form of rolls or plates, fibrous in structure.

2. Polymer insulation.

The production of such materials is the foaming of a polymer with various additives. Such materials include: polystyrene foam, polypropylene foam, polyurethane foam and others. They are usually produced in the form of plates. Such heaters are the most popular. This is due to the low price and ergonomics. The material is lightweight and easy to install.

3. Others.

To others, in this list, we include such materials as expanded clay and roofing material. They are used for floor insulation much less often and have a number of specific characteristics.

How to choose material?

In search of an answer to the question of what is the best way to insulate the floor, do not forget about the norms of building heat engineering, which are different for each region of Russia. Thermal insulation will be more effective if you choose the best option for a particular floor covering.

Calculation

First of all, it is necessary to calculate the thickness of the material. For this, resistances are taken into account:

- acceptance of air by the floor - R1;

- heat passing through the floor - R2;

- heat transfer - R3.

All layers are taken into account, including the air gap. The density of a material is divided by its thermal conductivity coefficient. The result of the calculation is the value of the coefficient of heat transmission through the floor.

A product with a thickness equal to the sum of all resistances must be equal to the heat resistance standard for a particular region, determined by SNiP II - 3 - 1979 "Construction Thermal Engineering".

Concrete floor

For a concrete floor, wood-chip heaters are perfect, which are mounted on a plastic film for waterproofing. Mineral wool is also convenient for installation. Thermal insulating paint and foam work effectively.

Before starting work, inspect the concrete base. If you find gaps, then be sure to eliminate them with foam.

Wooden floor

For the wooden floor of a private house, mineral wool is perfect, which is convenient to lay under the boards. If you plan to replace the floor after insulation, then use foam or foam. It is not always possible to put a dense insulation, in this case, use cork or chipboard.

Floors play a huge role in keeping the heat in the room. Through cold floors, heat loss reaches 20% of the total volume. By insulating the floors in an apartment or a private house, you not only create an optimal microclimate for your family, but also save energy and money resources.

Main varieties

Modern expanded polystyrene is represented by the widest range of brands that differ in thickness and performance properties. However, they are grouped into five groups:

- non-pressed polystyrene foam (in particular, PSB-S, EPS, etc.);

- autoclave (Stirofoam);

- extruded ("Penoplex", XPS, etc.);

- extruded-autoclave;

- pressed (PS (from 1 to 4), other foreign brands).

Expanded polystyrene brand PSB-S-35.

If you want to insulate the floor on the first floor of the house, then it is better to use the material of the brand PSB-S-35. Such plates are characterized by low thermal conductivity (0.4 W / m²) and moisture absorption (maximum 2%).

With a heavy load, it is recommended to opt for the PSB-S-50 brand. This is an ideal solution for garages and other outbuildings.