- Floor insulation

- Video description

- vapor barrier

- Elimination of heat losses

- Conclusion

- Thickness calculation

- The technology of warming a wooden floor with mineral wool

- Thickness calculation

- Why is floor insulation worth it?

- In what cases and why is insulation from below correct?

- Floor insulation with tepofol

- Preparatory work

- Insulation laying

- What to choose?

- Sawdust with pellets

- Arbolit

- sawdust concrete

- The choice of insulation depending on the material of the walls and the method of finishing

- brick walls

- wooden walls

- Walls made of aerated concrete blocks

- Insulation forms

- Liquid heat insulator

- in slabs

- in rolls

- Bulk thermal insulation

- Thermal insulation of the floor in the house

Floor insulation

The concrete floor must be insulated. The wooden one is covered with a heat insulator as desired, but after insulation, the room will be much warmer.

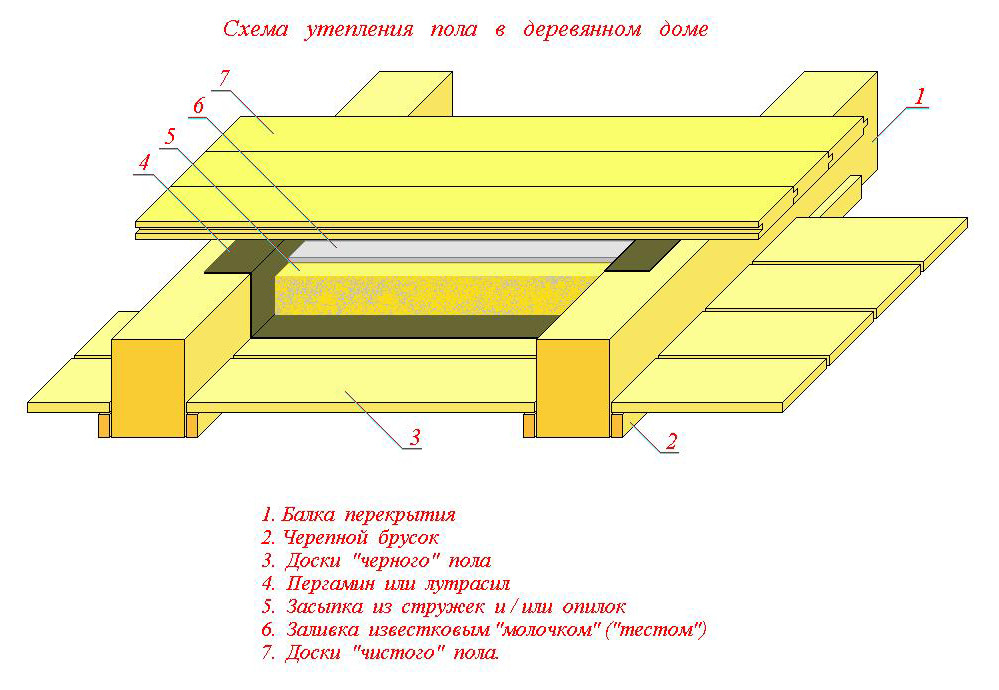

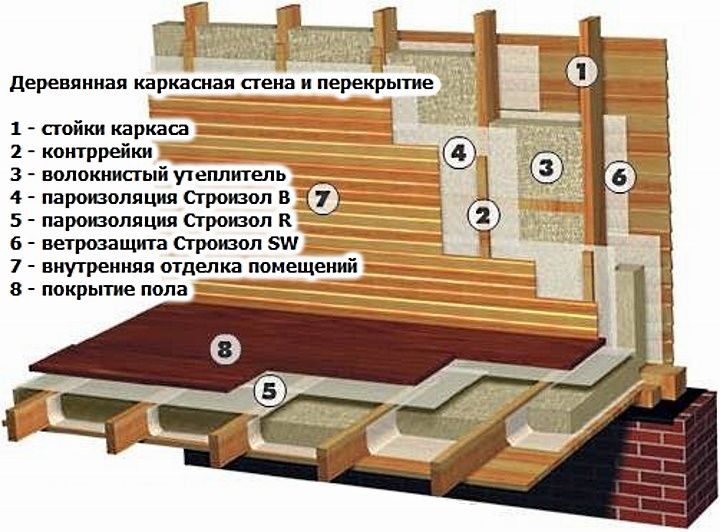

Scheme of floor and wall insulation

In wooden houses, insulation is laid on a rough coating, and a finishing floor is already mounted on top.

As a vapor barrier, a film with a membrane, polyethylene is used. Insulation using roofing is popular among the people. This material has been known for a long time, it is cheap, well protected from moisture, durable.

Mineral wool is used as a floor insulation.It is cheap, easy to install, durable, has good heat and sound insulation properties. In addition, a relatively new material is increasingly being used - expanded polystyrene, which is gradually replacing cotton wool from the building materials market.

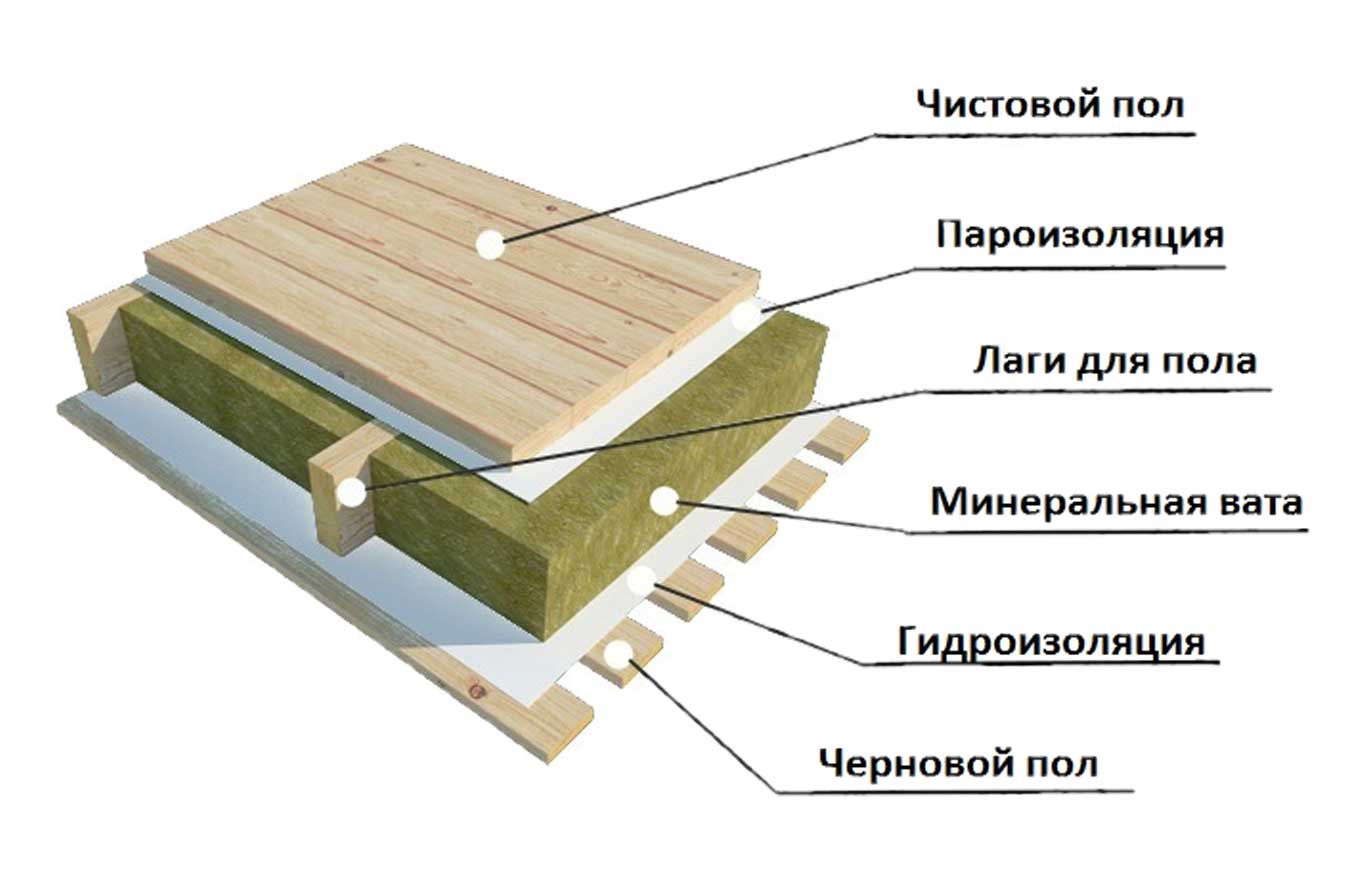

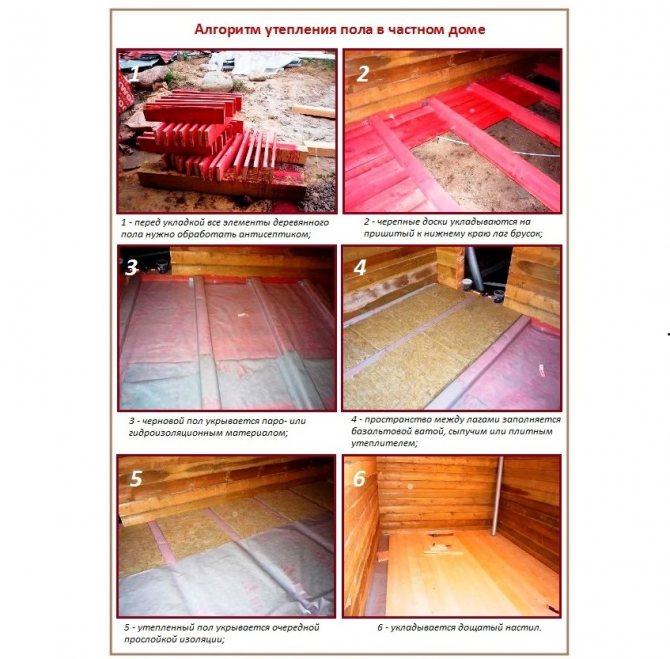

The sequence of actions when installing insulation on the floor of a wooden house.

The surface under the heater is leveled.

A waterproofing / vapor barrier is laid, the task of which is to prevent moisture from entering the insulation from outside

In regions with wet soil, this stage should be given special attention.

Install lags. The thickness of the lag must be at least 5 cm

Distance from the wall 30 cm. Distance between the bars 50 cm.

A heater is laid between the lags. The presence of voids between individual pieces of heat insulator is not allowed.

A vapor barrier film is laid on top of the insulation.

After the formation of all layers, the finishing floor is laid.

Video description

How the insulation is installed on the walls of a wooden house from the inside, see the video:

vapor barrier

If there is a need to install a vapor barrier, it is better to use a special film with a membrane.

It will allow the walls to pass air normally, and after installation, condensate will not accumulate inside the “pie”. To install a vapor barrier, a film or polyethylene is applied to the insulation. An allowance is made along the edges.

Film with membranes for vapor barrier

Elimination of heat losses

The weakest points in terms of cold penetration are the joints. There should be no gaps between the individual pieces of insulation. Insulating material is laid tightly to the crate. For floor insulation, an important point is the connection with the walls.In these places, the insulation is laid with a slight overlap on the walls and fixed.

When applying a vapor barrier, make sure that each layer of material overlaps the previous one with a slight overlap.

Insulating material is applied directly between the wooden beams before insulating the walls of a wooden house from the inside. For this, long-known materials are used - tow, linen rope, linen. It is possible to fill the joints of the bars with modern sealants - latex, acrylic, rubber.

Still, to reduce heat loss in a wooden house, the “warm seam” method is used.

Warm seam application

Conclusion

Despite the fact that it was previously believed that a wooden house should be insulated exclusively from the outside, modern materials allow high-quality insulation of the building from the inside. With such insulation, the external design is not violated and it will not be necessary to carry out work at height if the house is two-story or with an attic. The main thing is to choose the right material for insulation and entrust the work to professionals who know all the additional nuances. For example, they can calculate where the dew point will be after insulation so that condensate does not form right inside the wall.

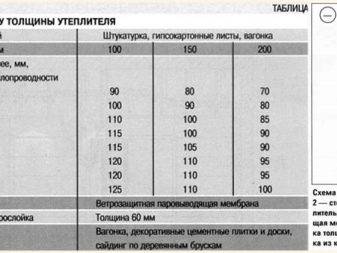

Thickness calculation

In an individual house there are no requirements for thermal protection of structures, so the thickness of the insulation can be selected approximately. It depends on the climate of the territory, for most cases it will be enough to protect with mineral wool 100-150 mm thick.

To calculate a more accurate value, you can use the help of a specialist or a simple Teremok program. It can be found online for free.

Mineral wool is a modern heat-insulating material that, if used correctly, will last a long time and reliably protect building elements. The material is suitable for work with all types of floors from basement to attic.

The technology of warming a wooden floor with mineral wool

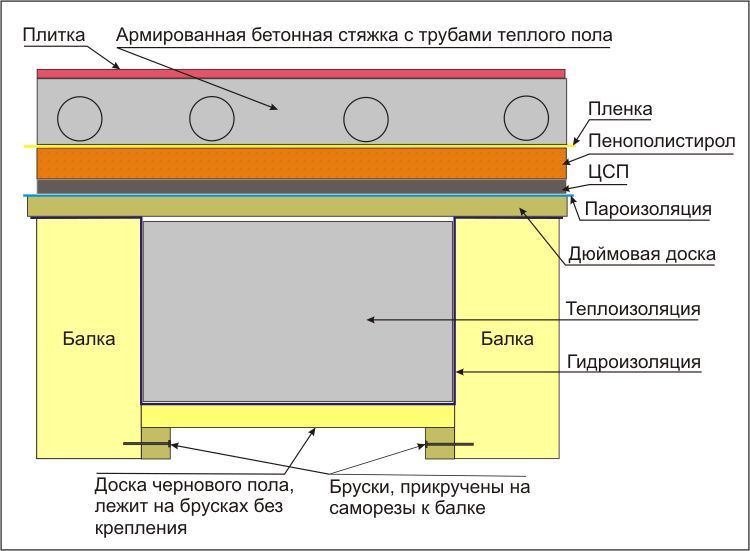

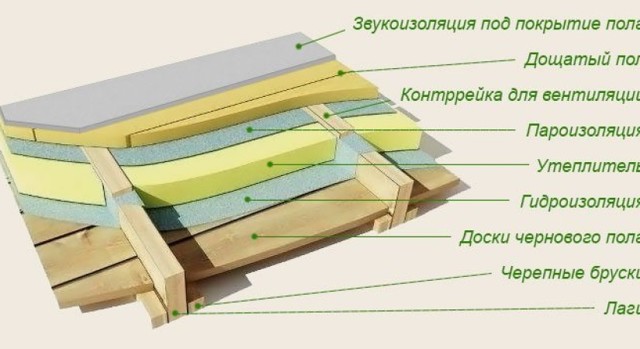

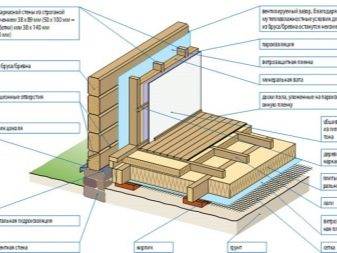

Waterproofing (membrane) is laid under the mineral wool.

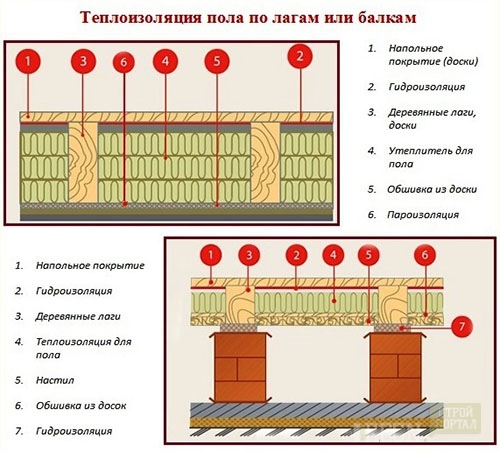

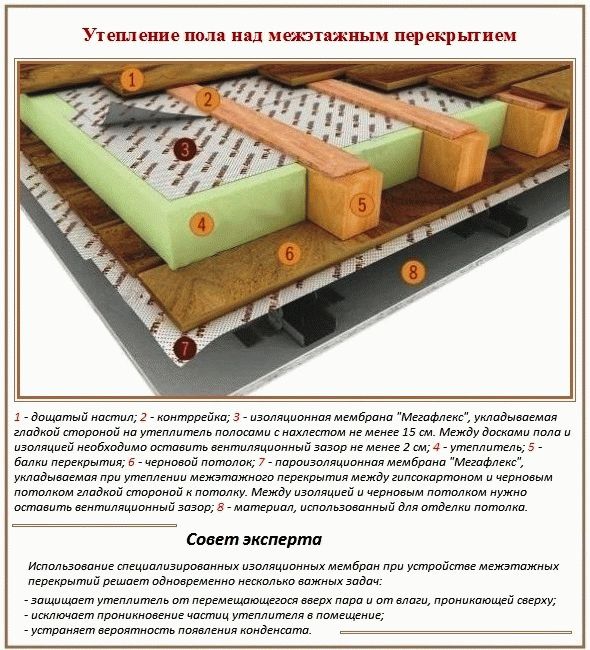

A wooden floor is a board stuffed onto load-bearing rails. Bars or logs can be used as guides, which are placed either on posts or in special wall niches. Guides are placed on the posts only when the floor is erected on the first floor, and bars or logs fixed in the walls can also be used as a ceiling between floors. The guides on both sides are sewn up with a board, which directly affects the method of floor insulation with mineral wool. The technology consists in laying thermal insulation in the voids between the subfloor and the finishing floor.

If the floor is laid on the interfloor ceiling, then the ceiling of the first floor will act as a rough coating. The board is stuffed from below directly onto the beams. If we are talking about the field of the first floor, then there are two methods for laying the rough coating:

- from below on the beams;

- on bars fixed along the guides.

In the second case, the boards can not even be screwed, which will allow, if necessary, with a little blood to open the layer of floor insulation with mineral wool. Thermal insulation installation technology involves the use of protective films. If they are placed incorrectly, then moisture will collect in the insulation. To dry the mineral wool, it must at least be opened, which is much easier if the draft floor is easy to dismantle. Also read: “Insulation of the ceiling of a private house with mineral wool“.

Glass wool is soft and light.

Which mineral wool is better for the floor? - by a combination of factors (environmental friendliness, thermal conductivity, features of installation and operation), unequivocally, glass wool. It is lighter, retains heat better, does not break and does not generate dust. For its production (many manufacturers, but not all) do not use phenol-formaldehyde resins.

To insulate the floor with mineral wool, you will need two types of films:

- vapor barrier - does not allow steam and moisture to pass through;

- waterproofing - allows moisture to pass in one direction, steam does not pass at all. It is called a diffusion membrane.

The vapor barrier is laid on either side, and the membrane must be laid correctly. The side where the drawing is applied should not come into contact with the insulation. The side that is rough or fleecy should be laid to the thermal insulation. Methodology floor insulation along the joists mineral wool:

- draft coating;

- waterproofing (advertising down);

- glass wool;

- vapor barrier;

- clean floor.

It also happens that a screed is poured onto a wooden floor. In this case, thermal insulation work can also be carried out, which we will describe below.

Thickness calculation

An important point is the calculation of the thickness of the insulation. It should be noted that the thickness of the thermal insulation layer depends on the thickness of the walls of the house, as well as climatic features. But to know how thick the insulation should be is simply necessary. If there is too much of it, then this can adversely affect the house, and an insufficient amount will cause the low efficiency of the insulation process as a whole.

In addition, this parameter significantly affects the design of the frame, since it is very important to know at what distance from the walls the guides for the outer skin should be placed. It is not difficult to make such calculations yourself, especially if you apply a certain calculation method.

Its essence is that the total heat transfer resistance of a wall of several layers of construction R should not be less than calculated for a certain climatic region.

To determine the specific required thickness of the insulation, it is necessary to know the thermal conductivity of each layer, as well as their thickness. The calculation will be carried out according to the formula: Rn = Hn / λn, where:

- Hn is the thickness of a specific layer;

- λn is the thermal conductivity of the material from which this or that layer is made.

As a result, the calculation formula will look like this: Hу = (R– H1/ λ1 – H2/ λ2 – H3/ λ3… ) × λу, where

- λу is the thermal conductivity coefficient of the specified thermal insulator;

- H is the thickness of the insulation.

It is quite easy to find such coefficients. Sometimes manufacturers even indicate them on the packaging. Measuring the thickness of the layers is also not difficult. If you do not want to calculate everything manually, then you can use an online calculator. It already has all the necessary basic and frequently used building, insulation and finishing materials.

Why is floor insulation worth it?

Warm flooring provides a comfortable stay in the house. The health of residents and their well-being depend to a large extent on the temperature values that are stored in living rooms.

To minimize heat loss, you need to figure out how to properly install the insulation, which materials have the best characteristics and the longest service life. It is also worth noting that the choice of thermal insulation material is influenced by many factors that cannot be ignored. For example, it is necessary to take into account not only the material from which the building was erected, but also the number of floors, as well as whether the building was built on the ground or a basement (basement) was built under it.

In what cases and why is insulation from below correct?

It is better to warm the floor above a cold attic from above, but it is technically more competent to perform thermal protection of the ceiling above the basement from below. This has its reasons:

- no reduction in the height of the room on the ground floor;

- there is no need to choose a dense hard insulation that will withstand the loads from residents, furniture and equipment;

- protection against freezing not only of the floor, but of the entire wooden floor;

- displacement of the dew point (the line on which condensate falls) to the floor surface from the thickness of the structure, which prevents decay.

But when carrying out work in a private house or in the country, there may be some difficulties associated specifically with working from below:

- the need for a more reliable fixing of the insulation;

- the complexity of work in a low subfloor;

- the need to work on the ceiling leads to rapid fatigue of workers;

- restriction on the types of insulation.

Therefore, if you are looking for easier ways to insulate, we recommend that you read the following articles:

- Floor insulation with foam

- Floor insulation "Penoplex"

- Insulation of the floor of a frame house

- Mineral wool floor insulation

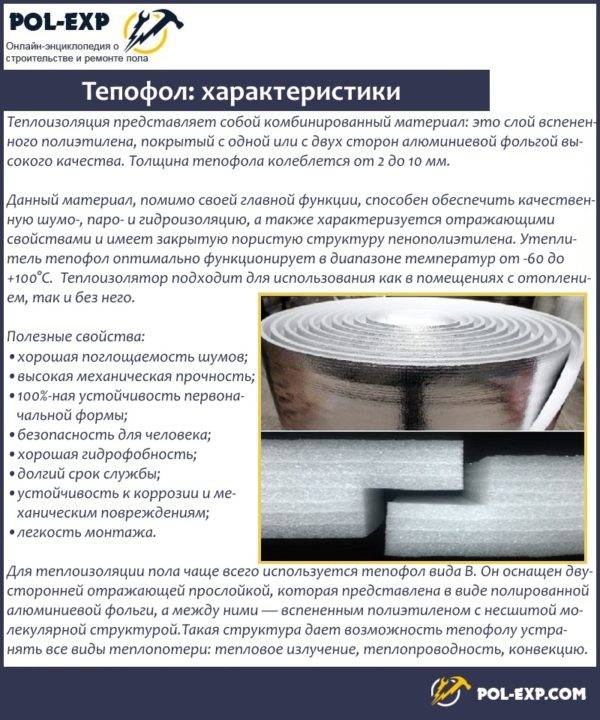

Floor insulation with tepofol

We have already mentioned that this is a new material, the technology of working with it is unknown to many.

Tepofol: characteristics

How to properly insulate wooden floors with tepofol?

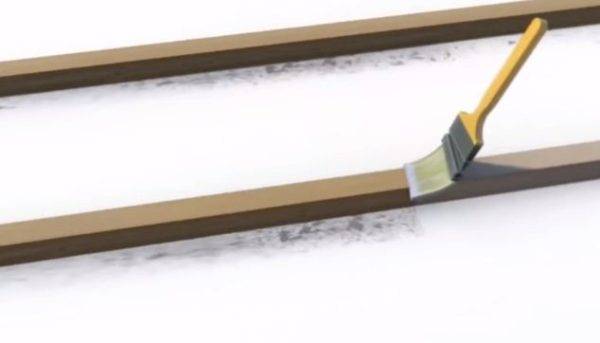

Preparatory work

Step 1. Cut the roll insulation into pieces, before that, measure the dimensions of the room. The fewer joints there are, the more airtight the coating, the more effective the thermal insulation.

Roll out the roll and cut the insulation into pieces according to the size of the floor

Step 2. Thoroughly impregnate all wooden elements of the floor structure with a protective solution. The tree must be dry, it is necessary to work in clear weather. If the solution is absorbed very quickly, then the treatment must be repeated.

Wooden elements are treated with protective compounds

Step 3. Lay at least two layers of waterproofing on the strip foundation of a wooden house, in practice roofing material is most often used, but more modern membranes can also be used.

The base is covered with a layer of waterproofing

Step 4. Assemble the first strapping row at home, in the lower part on the inside, fix special metal stops for the log. The distance between them depends on the load on the floor and the linear parameters of the log. But it is immediately recommended to keep in mind the technical characteristics of the floor insulation materials, it is advisable to make niches of such a width that nothing needs to be cut during installation. In this way, time is saved and the amount of waste of expensive building materials is reduced.

Mount logs

The strapping row should be at least 5 cm wider than the wall beams.

Step 5. For a strong connection of the thermal insulation joints, it is necessary to lay boards under them. They are also fixed on metal stops with self-tapping screws or cloves.Metal corners have many holes, but this does not mean that you need to screw a self-tapping screw into each. A large number of hardware can cause cracks in the lag. Holes are required so that during fixing, builders can choose places without knots on the logs. The distance between the boards should correspond to the width of the tepofol.

Planks are laid between the joists

The preparatory cycle of work is completed, it is carried out before the start of the assembly of the log house. Further insulation of floors should be done only after covering the house with a roof.

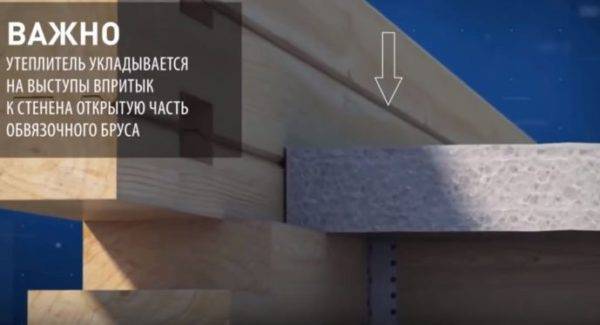

Insulation laying

Step 1. Cover the entire area of \u200b\u200bthe room with pieces of insulation prepared earlier along the length. The edge of the tepofol should be located on the ledge of the strapping beam, and the joints along the previously installed boards. The insulation is laid perpendicular to the lags.

Lay insulation on the boards

Step 2. Fix each individual piece of insulation to the lags, for this you need to use special plastic washers of large diameter.

Fix the insulation with self-tapping screws and plastic washers

Step 3. Nail slats 50 × 50 cm along the perimeter of the room to the walls, they will close the gaps between the crowns and the edges of the insulation. In addition, the floor covering is then laid on these slats.

Stuff the slats around the perimeter of the room

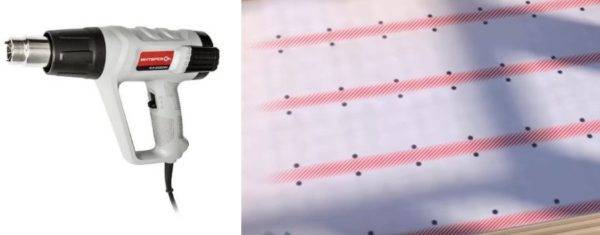

Step 4 Using a building hair dryer, weld the longitudinal joints on the insulation. This is a new mounting technology, such welding is not used in other systems. It is necessary to heat the material with a powerful building hair dryer, the temperature is regulated depending on the distance and speed of movement.

Heat the joints of the insulation with a building hair dryer until the material melts

If the technology for welding joints is violated, tepofol can melt strongly, the coating will lose its heat-saving abilities.

Step 5. Proceed to manufacture over the insulation of the crate under the floor covering. It is made from bars 50 × 50 mm in several stages.

-

Lay a bar over each lag, trim the dimensions along the length.

-

Drill holes for special screws. These fasteners are installed in pairs at an angle of 45°. For proper drilling, it is recommended to make a template from wood - cut off one side of the square with a saw at the right angle, the drill will rest against it when drilling holes for hardware. The distance between adjacent self-tapping screws is ≈100 mm, the pitch of pairs is 50–60 cm.

-

Screw the screws into the holes.

This method of fixation allows you to completely release the fragile insulation from loads. Efforts are taken by self-tapping screws, and due to their original position, they do not allow the beam to go down. The surface of the insulation is not deformed, the final quality does not deteriorate.

Step 6 Nail the floorboards to the timbers. If there is a desire or need, then you must first lay the subfloor, and then finish it on it. The decision is made on site by the master, taking into account the characteristics of the materials used and the wishes of the customer.

The final stage - the installation of floor boards

What to choose?

Often, buyers have a question about which material to choose if financial resources are limited.

Sawdust with pellets

Budgetary, but high-quality insulation of a wooden floor in a house can be done using sawdust, which, as already mentioned, is inexpensive and safe for human health.In order for the material not to be compressed and to last longer, several variants of sawdust-based heaters were developed not so long ago. For example, there is a mixture of sawdust with pellets. It is made by treating sawdust with a special disinfectant and glue.

Arbolit

Also, arbolite should be distinguished from inexpensive sawdust-based heaters. This is a block type of material with synthetic impurities, flexible and very durable. It does not burn, it is environmentally friendly, but when using it, it is necessary to lay a layer of a moisture-proof film.

sawdust concrete

If we are talking about warming only the first floor, you can use a material such as sawdust concrete. Outwardly, it looks like a cinder block, but is made from a strong mixture of sand, cement and wood shavings.

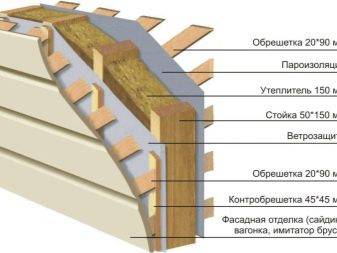

The choice of insulation depending on the material of the walls and the method of finishing

brick walls

For a brick house, any insulation for the exterior walls of the house is suitable. But for each type of finish there are recommendations for insulation technology.

Facing brick

If facing brick is chosen as the outer finishing layer, and the load-bearing walls of the house are also made of brick, then both foamed or extruded polystyrene foam and stone wool can be used as insulation. In the case of stone wool, it is necessary to provide a ventilated air gap so that water particles evaporate freely - this will help to avoid wetting the walls.

Pie for warming a brick house with stone wool with brick lining.

Wet facade

According to the construction and design rules (clause 8.5 of SP 23-101-2004), the layers must be arranged so that the vapor permeability of the inner layer is less than that of the outer one. i.e.the insulation should not interfere with the weathering of moisture from the walls of the room. If you follow this rule, then mineral wool is best suited in this case due to its high vapor permeability. However, brick walls do not have high vapor permeability, so expanded polystyrene can be used to insulate them, followed by the application of a plaster layer.

A pie for insulating brick walls with polystyrene foam, followed by the arrangement of a plaster layer.

Ventilated facade

If wall panels or large porcelain stoneware slabs are chosen as facing brick walls, which are mounted on a ventilated facade, then it is recommended to use stone wool as a heater.

Brick wall insulation pie when arranging a hinged ventilated facade.

wooden walls

Houses made of logs or timber are insulated both according to the technology of a hinged ventilated facade, and according to the technology of a wet facade. In both cases, it is recommended to use stone wool as a heater.

Insulation of wooden walls with stone wool.

Walls made of aerated concrete blocks

Wet facade

If you follow the rule that the vapor permeability of building structures should increase from the inside of the room to the outside, then it is best to use stone wool to insulate load-bearing walls made of aerated concrete blocks.

Pie of wall insulation from aerated concrete blocks with stone wool, with the arrangement of a plaster facade.

However, aerated concrete is not a tree, rotting cannot occur in it, and if the room is well ventilated inside, then expanded polystyrene can be used for external insulation of aerated concrete walls.

Pie of wall insulation from aerated concrete blocks with expanded polystyrene, with the arrangement of a plaster facade.

Facing brick

If a facing brick is chosen as the exterior finish of aerated concrete walls, then it is possible to use both stone wool and expanded polystyrene as a heater. In the case when the insulation is made with stone wool, it is necessary to provide a ventilation gap between the insulation and the brickwork. This will allow moisture to evaporate from the insulation.

Wall insulation cake made of aerated concrete blocks, followed by facing bricks.

Insulation forms

All existing types of insulation can be divided into groups based on the shape of the material. Each of them has its own advantages in certain conditions. Let's take a closer look at them:

Liquid heat insulator

Liquid thermal insulation are materials that are applied in bulk or by spraying. In air, they solidify or (more often) foam, forming a continuous hermetic web. The disadvantage of such materials is the need to use special equipment.

However, there is an important advantage - liquid materials can be applied to any surface, with a large number of small details, potholes or other flaws. The coating canvas will in any case be even and tight.

In addition, the thickness of the layer is relatively small and does not create an excessive load on the supporting structures.

Liquid types of insulation include:

- polyurethane foam;

- penoizol;

- insulating paint;

- liquid rubber.

The use of such materials is limited due to the complexity of installation and high cost.

in slabs

Plate types of insulation are convenient in that they are able to hold their shape during installation and do not need to install load-bearing structures. These include the following materials:

- Styrofoam;

- penoplex;

- stone (basalt) mineral wool;

- wood concrete;

- foam glass.

The disadvantage of slab forms is the need for careful preparation of the base. In a house without basement heating, the condition of the planes is rarely ideal. It requires leveling the plane, eliminating potholes, dents and other flaws. Installing insulation on uneven surfaces will not bring the expected effect. Moreover, water will gradually accumulate in the cavities of the dents, which will lead to a gradual peeling of the insulation. Before installation, you have to do thorough preparation, apply a leveling layer of plaster or sheathing to the subfloor.

in rolls

Roll types of heaters represent the most extensive group. These include:

- mineral wool;

- penofol;

- isolon.

The advantage of roll materials is the ability to install on convex or concave bases. They can be mounted on cylindrical walls, pasted over spherical surfaces, figures of complex shape. The disadvantage is the lack of self-supporting capacity. Before insulating the floor in a private house with rolled materials, it will be necessary to assemble additional support structures, use adhesives or other auxiliary materials.

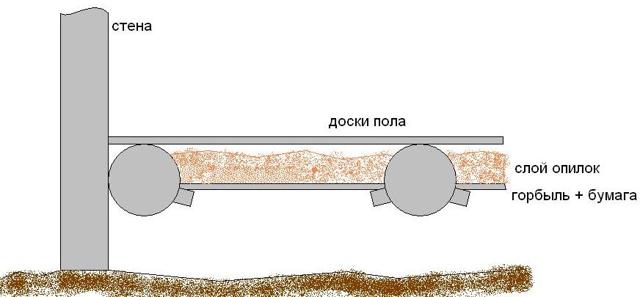

Bulk thermal insulation

Bulk materials are used only on horizontal planes - for floor insulation, attic, ceilings, ceiling tiles. This group includes:

- expanded clay;

- sawdust;

- expanded polystyrene granules;

- perlite.

The use of such heaters is limited due to the peculiarities of their structure.The best use case is floor insulation in a wooden house. The main advantage is the ability to extract and reuse the material. The disadvantages include the need to create a rather thick layer of backfill - the desired effect appears with a layer thickness of 25 cm or more. Because of this, they are most often used to insulate floors in a private house with a cold underground.

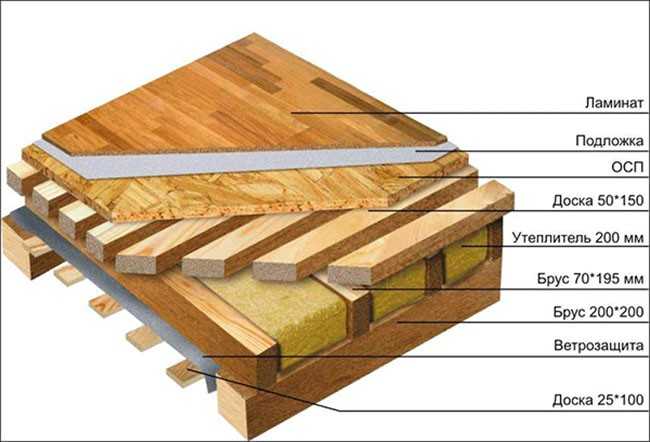

Thermal insulation of the floor in the house

Warming the floor in a wooden house is an extremely important and difficult task.

It should be remembered that for uninsulated floors, heat loss can reach up to 20 percent of the total heat loss.

It will be important not only to correctly insulate the floor area, but also to choose the right insulation itself.

Today, mineral wool is increasingly used for insulation work. This material is a classic in its niche. Everything is due to the advantages of mineral wool as a heat insulator. In a wooden house, this material is usually used, primarily because it is non-combustible, in addition, it will prevent the spread of fire, so its use as a heater allows for additional fire protection of the entire building structure. According to manufacturers, mineral wool fibers are able to withstand temperatures exceeding 1000 degrees.

Scheme of wooden floor insulation.

Mineral wool insulation has gained such high popularity for the reason that this material has excellent thermal insulation characteristics.

It is only important to comply with the insulation technology

Professional builders and home craftsmen also prefer this material for its excellent soundproofing characteristics, which is important, especially when comparing this insulation with some others. Thermal insulation of a house with the help of mineral wool is especially relevant for those buildings that are built in the northern regions, since the insulation has high frost resistance, and with sudden and significant changes in temperature, the insulation is able to demonstrate a complete absence of deformations. This insulation perfectly copes with the effects of chemical and biological reagents.

In addition, it is economical and its price is affordable.

This insulation copes well with the effects of chemical and biological reagents. In addition, it is economical and its price is affordable.

Thermal insulation of a house with the help of mineral wool is especially relevant for those buildings that are built in the northern regions, since the insulation has high frost resistance, and with sudden and significant changes in temperature, the insulation is able to demonstrate a complete absence of deformations. This insulation copes well with the effects of chemical and biological reagents. In addition, it is economical and its price is affordable.

Mineral wool, however, is not ideal, it has some disadvantages, among them high porosity, which gives the material low strength. Warming the floor of a wooden house with its use must be accompanied by waterproofing, since without this procedure the material will become wet, blown, losing its characteristics. If the insulation is not carried out correctly, the material will begin to form cold bridges, the pores will begin to accumulate condensate.That is why the insulation must be carefully protected.