- Alternative ways of warming

- Durability of thermal insulation

- How to perform floor insulation in the country with your own hands without removing the old one

- Ways to insulate the floor without its preliminary installation

- Mineral wool floor insulation

- Expert advice

- The choice of insulation

- Popular floor insulation schemes

- Reinforced thermal insulation

- The usual scheme of insulation

- Peculiarities

- Principles of installation work

- Optimal insulation for wooden floors

- Heaters for economical owners

- Modernized expensive heaters

- How to choose floor insulation

- Inexpensive heaters

- Expensive modern materials

- Manufacturers

Alternative ways of warming

If the heat loss through the floor is small, then you can use simpler methods of insulation. Their essence is to use a material with a low coefficient of thermal conductivity as a floor covering.

The simplest thing is to lay carpet or carpet on the existing floor. Products made of natural wool with a long pile have the greatest warming properties.

Another option is to use thickened linoleum on a warm substrate (felt, jute) or on a foam base.Similarly, you can “insulate” the laminate by laying a thickened cork, polyethylene or expanded polystyrene underlay under it.

Thus, in order for the floor to maintain a comfortable temperature even in winter, it is not necessary to use additional heating systems and “warm floor” structures. In most cases, to increase the floor temperature by several degrees, it is enough to properly insulate it with the help of available materials.

Durability of thermal insulation

Various qualities have to be taken into account when choosing a particular material. For example, with a certain load on the heat-protective layer, it will no longer be able to restore its original volume - some of the fibers will simply break. That is why such raw materials do not adhere tightly to the logs and floor beams. As a result, cold bridges are inevitably created on structures. Condensation can also appear where the thermal insulation does not fit snugly.

In order not to miscalculate the choice and buy a good quality insulation, press on a small piece of it (for example, step on it). If after such a test it takes its former shape, then it suits you. If it remains crumpled and flat, then it is best to refuse such a product.

Is it possible to improve thermal insulation qualities? When warming, you can not do with mats alone. Insulated finishes are often used: heat-insulating linoleums, two-layer carpets. For example, he advises laying wood-fiber boards or tiles under the parquet. Other materials can also not be neglected. The first floor can be made warmer by insulating the foundation. Basements should be carefully checked and all cracks sealed.

How to perform floor insulation in the country with your own hands without removing the old one

Underfloor heating in a country house is a prerequisite for a comfortable stay in the winter. The funds invested in insulation are compensated by lower heating costs and the absence of colds in the family.

Almost all technologies prescribe the dismantling of the top coating and the laying of mineral fiber or polystyrene foam insulation between the joists of the floor frame. What if the need for thermal insulation of the floor fell on the heating season? The traditional sequence of thermal insulation work with the removal of the coating can create many problems for the owners living in the house.

On construction forums, the owners of problematic cottages offer their options, from which you can choose the most acceptable one.

For floor insulation along the logs, our experts recommend

| Rockwool Light Butts | Baswool Light 35 | URSA GEO M-11 |

Ways to insulate the floor without its preliminary installation

In temperate climates, flooring with oriented strand boards (OSB) is practiced. The coating structure is characterized by low thermal conductivity. For decoration, several layers of colored varnish are applied to the surface. Naturally, the base must be fairly even. As a waterproofing, you can use a fairly dense polymer film, sealed at the seams by heat welding.

In a region with difficult climatic conditions, hydrophobized mineral wool panels of increased density are recommended for floor insulation. In the budget version extruded polystyrene foam 30 mm. The insulation can be closed with any sufficiently strong and moisture-resistant panels; linoleum, laminate or material with identical properties can be used as a front cover.

Mineral wool floor insulation

- Panel stone wool, the thermal conductivity of which is sufficient for the implementation of the most complex projects, is characterized by the stability of working properties, chemical inertness, and a long service life.

- The material is environmentally friendly, so there are no restrictions on the internal insulation of residential premises. It is possible to use semi-rigid panels for insulating concrete screeds under floor tiles.

- Moisture-repellent impregnation of mineral wool panels works quite effectively, but the presence of a damp basement determines the need for film or mastic waterproofing.

More affordable polystyrene foam and expanded polystyrene retain their insulating properties even in a damp environment. To seal the system, it is enough to seal the seams and interfaces with moisture-resistant putty or glue with construction tape.

When choosing a heater, this disadvantage should be taken into account in the first place.

For floor insulation under the screed, our experts recommend

| Penoplex Geo | URSA XPS N-III-L | Ravatherm XPS Standard G4 |

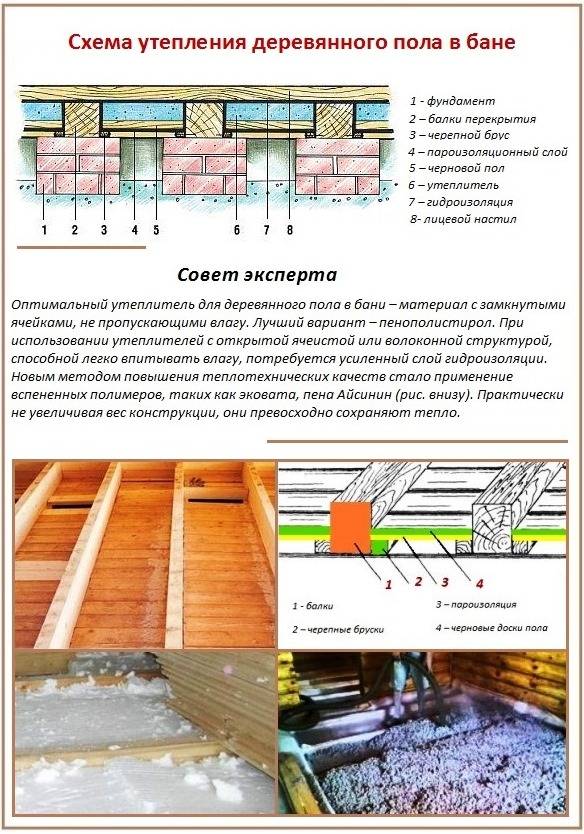

Expert advice

Indeed, the proposed schemes are workable and can be used in the budget version of floor insulation. It should be noted that manufacturers of cheap facing materials continue to use old technologies using phenol-containing components. Savings take place, but it is better to refrain from purchasing cheap panels and heaters at the selection stage.

How thick should modern floor insulation be? It is difficult to recommend volumetric coatings, since raising the floor by only 80 mm significantly affects the reduction in the volume of the room.The low thermal conductivity of both heaters allows the use of plates with a thickness of 20-30 mm. Even with panel cladding, the floor height will increase by only 40-45 mm.

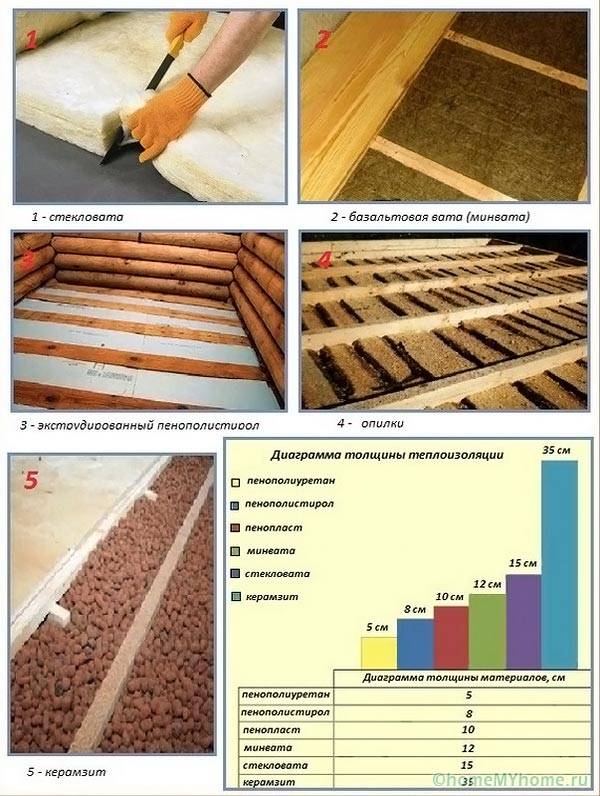

The choice of insulation

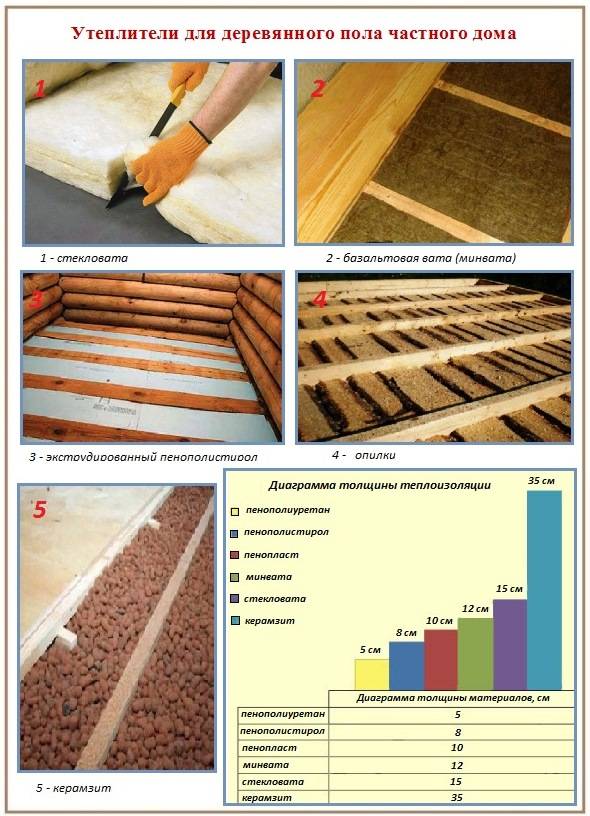

Many materials are used to insulate the floors of a wooden house. The simplest and most inexpensive can be called expanded clay or sand, which is poured between the rough and finish coating. They are hygroscopic and protect the boards from rotting, the spread of fungus and provide ventilation. However, bulk non-metallic heaters have their own drawback - over time, their hygroscopicity decreases.

Today on the market you can find many materials for warming a wooden house. In addition to good thermal insulation, it must meet the basic requirements:

- ecologicaly clean;

- be safe for residents of the house;

- long service life.

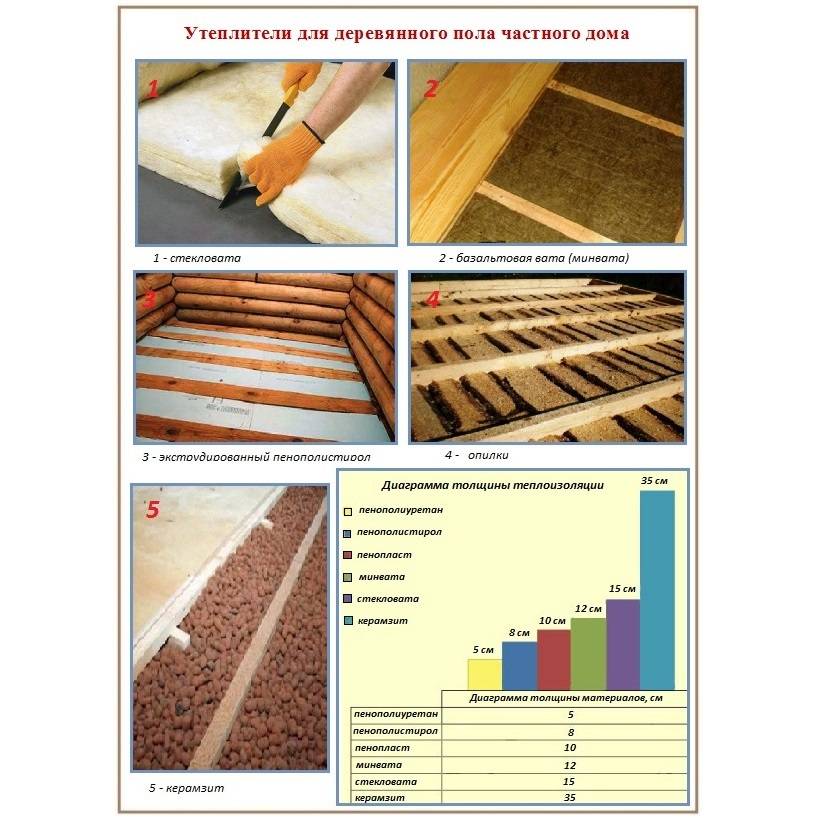

For insulation, fiberglass, mineral wool, foam plastic, polystyrene foam, etc. are used. Each of them has its own advantages and disadvantages:

o Mineral wool. It can be slag, stone and glass. The release form is also diverse - plate, roll, mat. Mineral wool has a high density, does not burn, conducts heat poorly and is quite economical. The main disadvantage is considered low moisture resistance.

When using mineral wool, the vapor barrier system and ventilation should be well thought out. The non-foiled side of the plate should be on the bottom.

When buying mineral wool, carefully read the composition, since the impregnation often contains substances dangerous to the body. The more saturated the yellow color of the material, there it is more dangerous.

In construction stores are more in demand:

- Isovol is a mineral fiber product. A distinctive feature is high hydrophobic efficiency in comparison with conventional mineral wool. Additionally, it has low thermal conductivity, non-combustible, biologically and chemically resistant.

- Rockwool is a basalt miner. Its peculiarity is that it does not cake, does not give in to deformation and shrinkage, like mineral wool. Rockwool resists mechanical loads well. The material is additionally used for sound insulation, since the porous structure absorbs noise of any frequency well. Like Izovol, Rockwool does not conduct heat well, does not burn and is resistant to biological and chemical attack.

- Expanded polystyrene - has a high rate of thermal insulation. It is resistant to moisture and does not absorb water, keeps its shape well with temperature changes, is strong, environmentally friendly, durable and is not exposed to the damaging effects of microorganisms. Styrofoam is easy to handle and use.

- Penofol is a modern heat insulator. Sold in rolls, is a heater with a layer of foil. The thickness and weight are small. The base may be different, but in most cases it is penofol (polyethylene foam). Thermal insulation properties are maintained under high mechanical stress. Laying occurs with an overlap or butt. The seams must be glued with metalized adhesive tape. Penofol does not require an additional layer of hydro and vapor barrier, since the foil already performs these functions.

- Ecowool is a natural heat insulator made from cellulose. Bind fibers with boric acid and lagnin (an organic antiseptic). The uniqueness of the material is that it does not absorb water and brings it out. The composition does not contain components hazardous to health.Ecowool is fire and bioresistant, absorbs sound well and does not conduct heat. A special sprayer is used for application, but the material consumption then increases by 40%.

- Izolon is a new material in construction. With a thickness of 2-10 mm, it is well heat and sound insulating, has high moisture resistance, does not rot and is durable.

For insulation, ordinary sawdust can be used. This heat insulator has been used for many centuries. Natural material is quite cheap and completely safe for the body. Sawdust often remains after building a house. This is the most affordable insulation for a wooden house.

Sawdust is added to some building materials:

- sawdust concrete consists of sawdust, cement, sand and water;

- granular heat insulator - sawdust, glue and antiseptic flame retardant;

- wood concrete - sawdust with cement and chemical additives;

- wood blocks - sawdust, cement and copper sulfate.

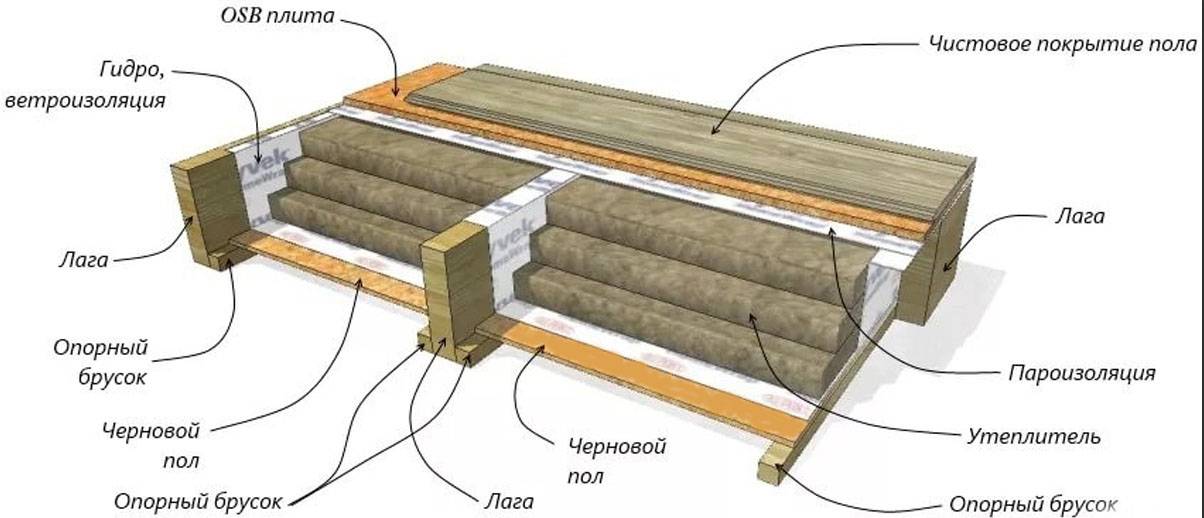

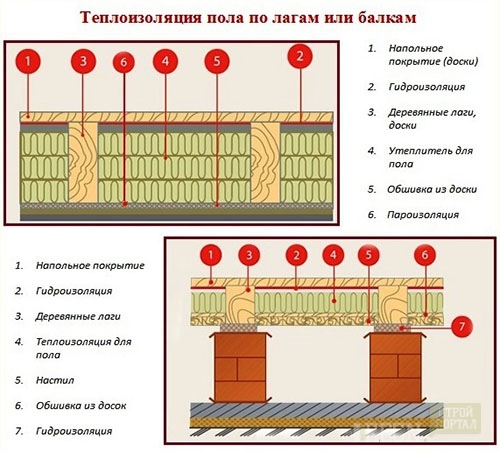

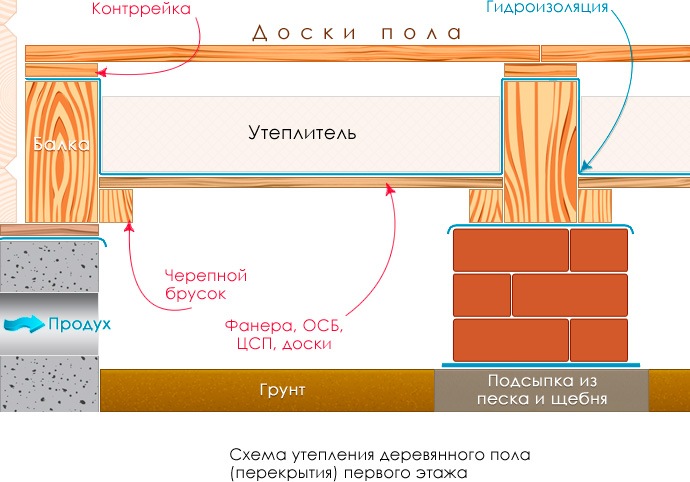

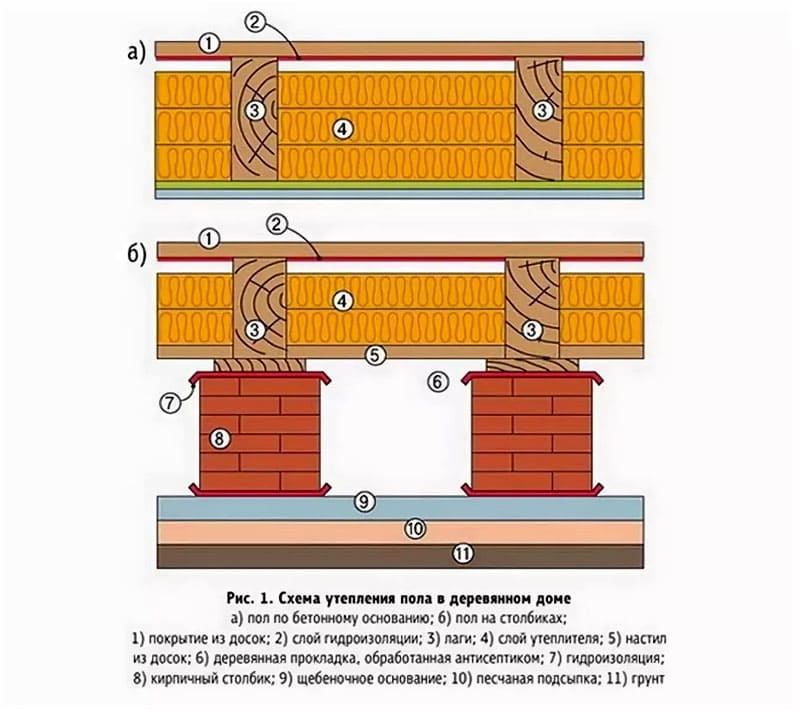

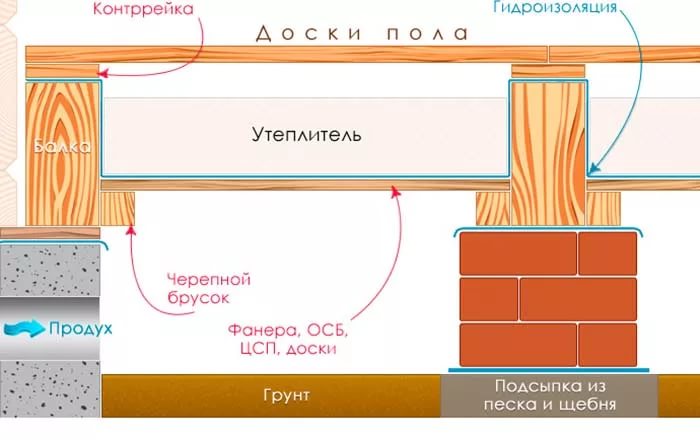

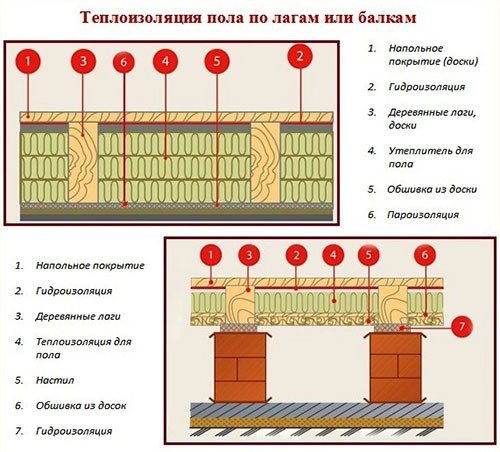

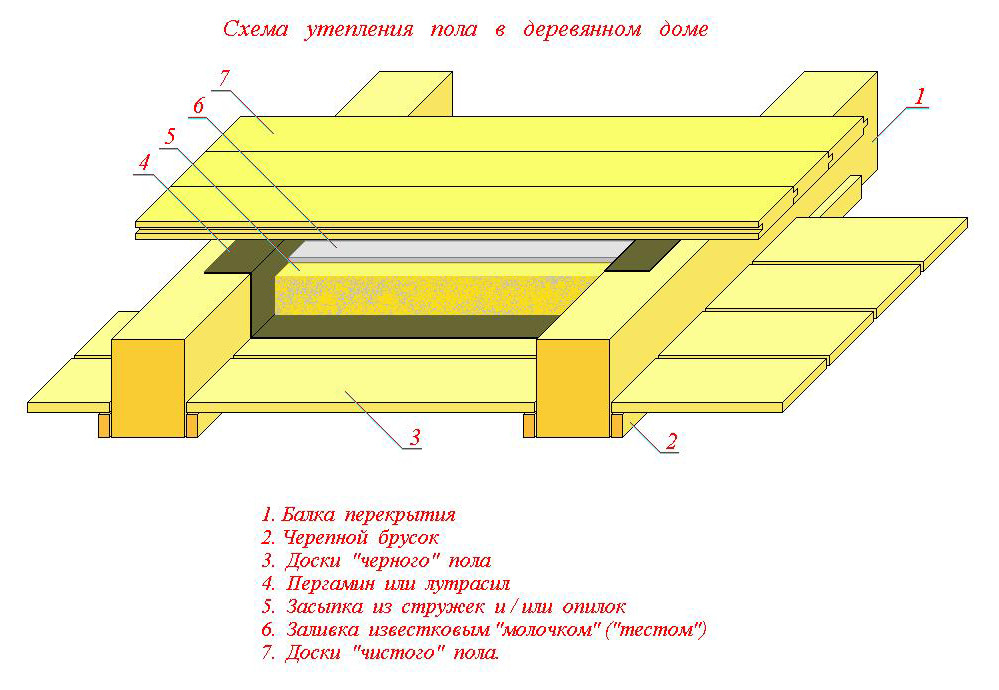

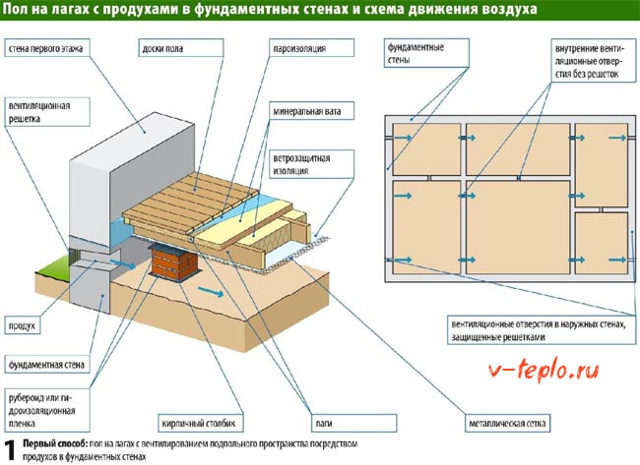

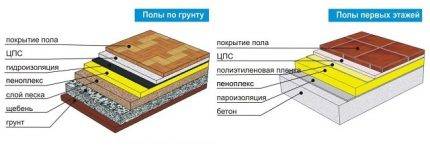

Popular floor insulation schemes

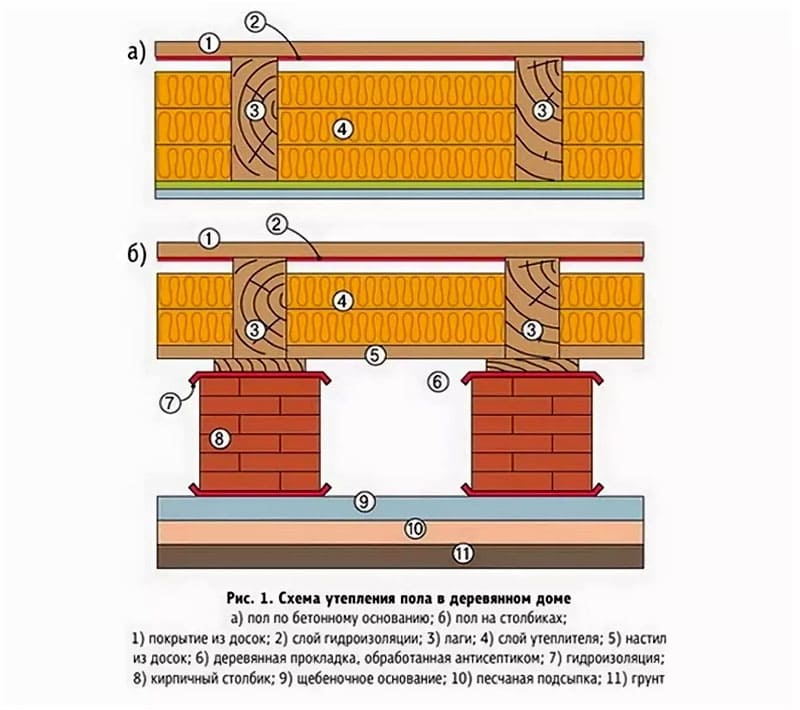

In practice, most often, two schemes for insulating the floor of the basement / lower floor are used. The first is the most reinforced when the insulation is present both under the logs and between them. Such thermal insulation, as described in the first case, is used only in northern latitudes, where the earth freezes quite noticeably in winter.

But most often, on the ground floor of the building, the logs are mounted on top of the screed, and in some cases on top of well-planned soil.

Consider both examples suitable for the basement floor, and then we will talk about the insulation of the floor of the upper rooms.

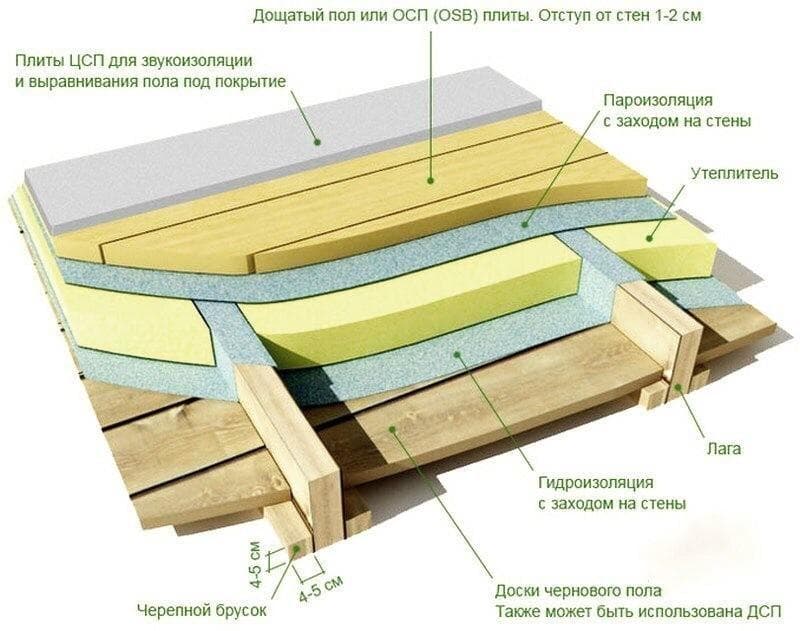

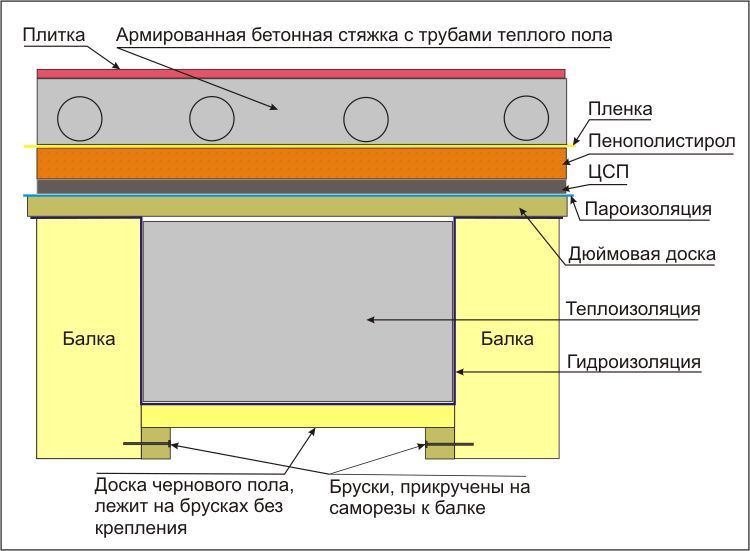

The scheme provides options for floor insulation for the lower floors. The DSP layer can be simplified, which most owners prefer to do

The scheme provides options for floor insulation for the lower floors. The DSP layer can be simplified, which most owners prefer to do

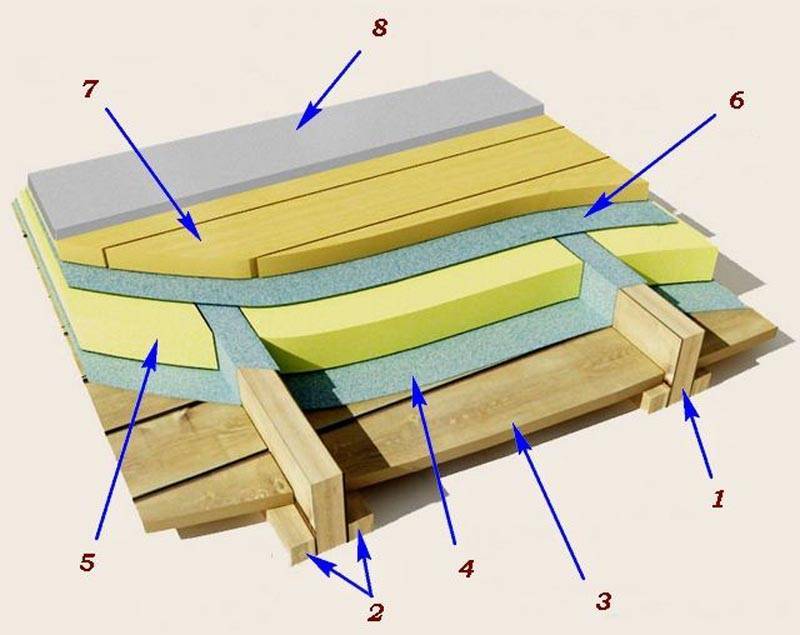

Reinforced thermal insulation

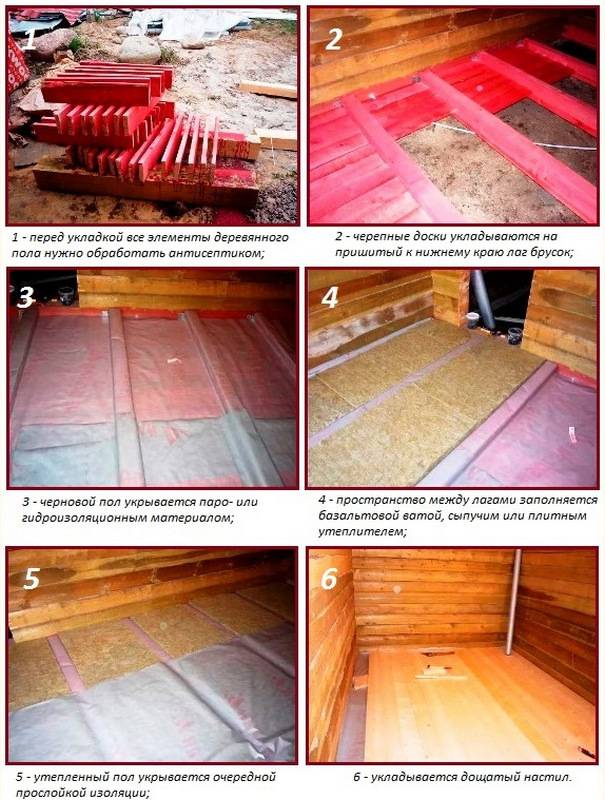

According to this scheme, at first, even before the installation of the log, it is required to plan the soil and insulate it with the bottom layer.

As a heater for the first layer, builders can choose:

- expanded clay concrete;

- planned layer of expanded clay;

- extruded polystyrene foam;

- a firmer and more dense variety of penoplex.

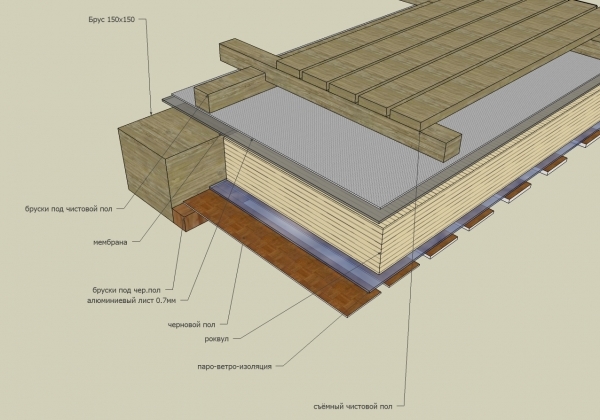

Logs are already mounted on top of it, after which the space between them is also carefully filled with insulation. This time, the same penoplex or one of the varieties of wat can act as it.

In this case, people often resort to double waterproofing - one is laid between the upper and lower layers of insulation, the other is laid on top of the top, on which the counter-rails for ventilation and, directly, the floorboards will be attached.

In this variant, penoplex was chosen as the bottom layer of insulation. The top layer material does not have to be identical to the bottom layer.

In this variant, penoplex was chosen as the bottom layer of insulation. The top layer material does not have to be identical to the bottom layer.

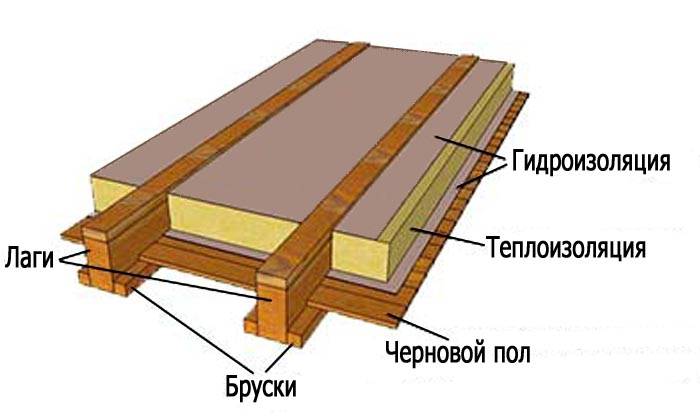

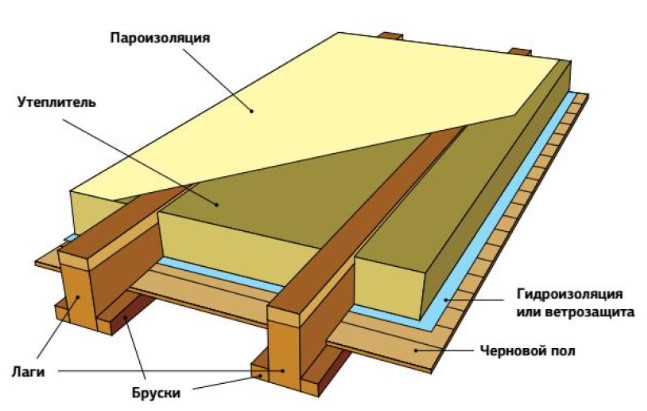

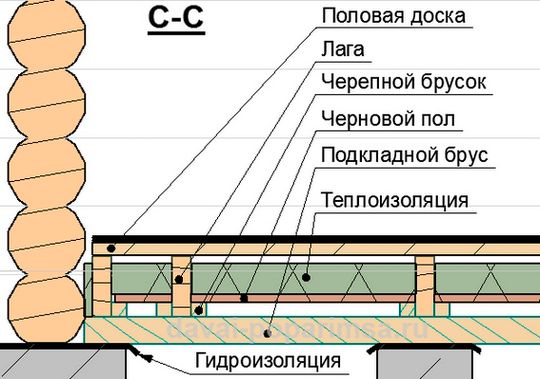

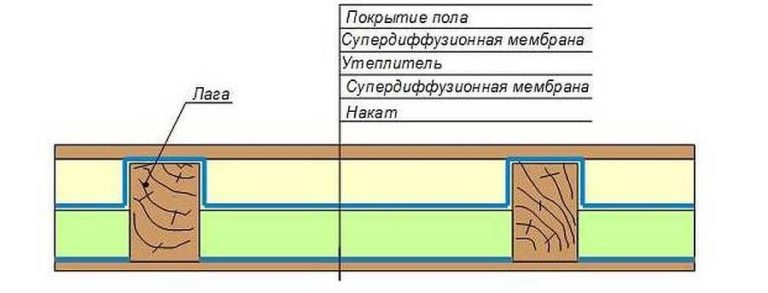

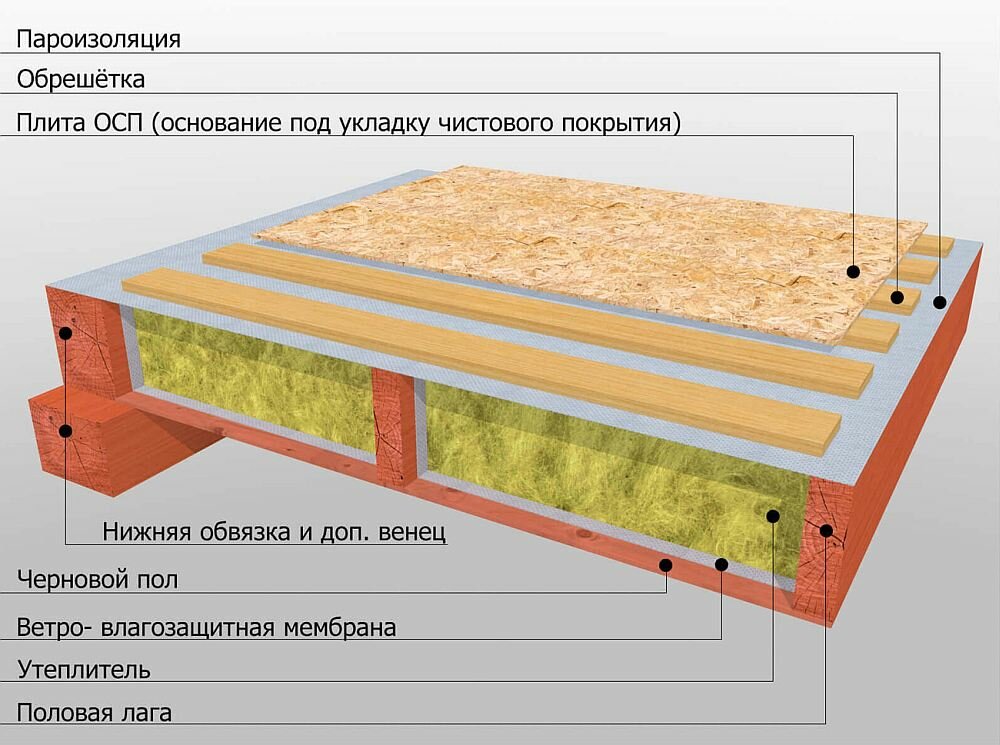

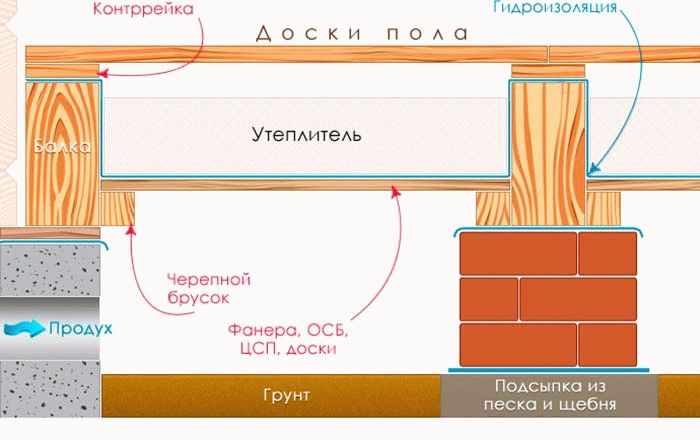

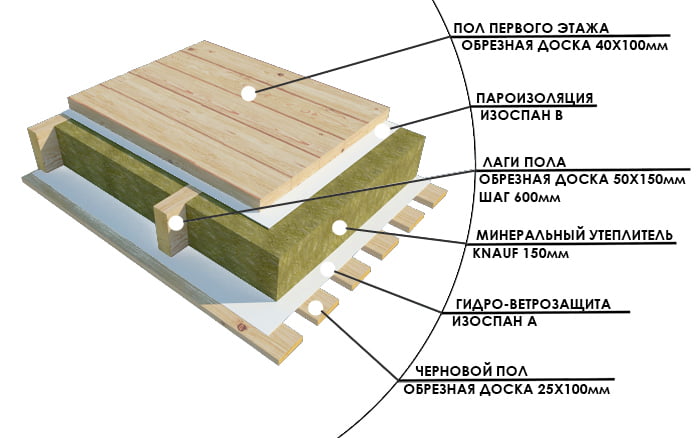

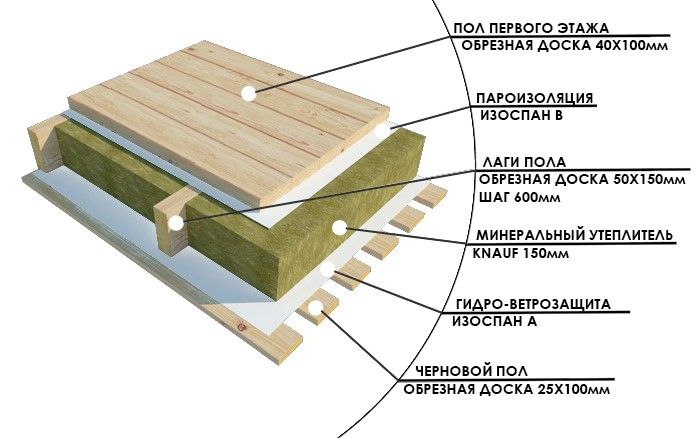

The usual scheme of insulation

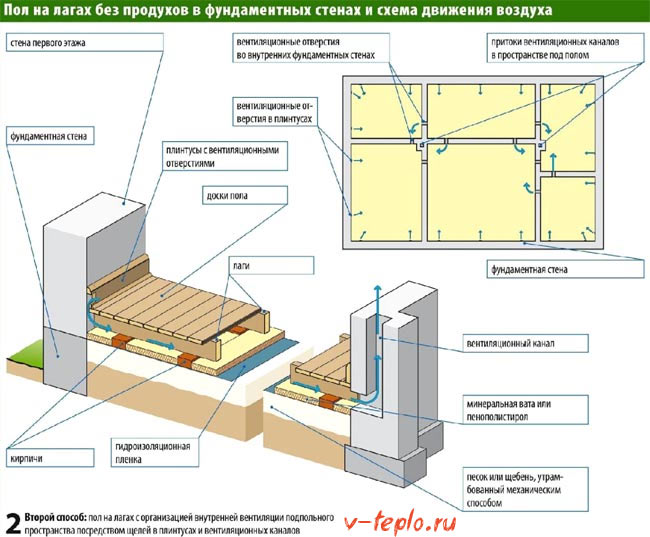

Everything is clear here. Logs are mounted directly on top of the planned ground surface or, in the case of a screed, on it.

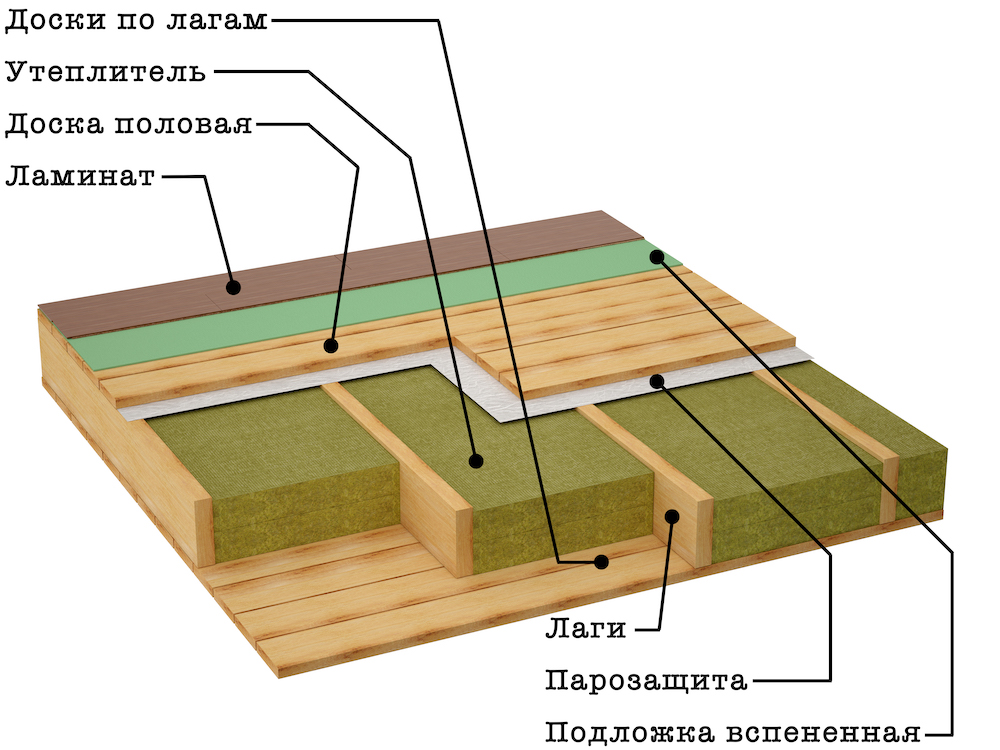

Next, a layer of insulation is laid on them. On the insulation - a layer of vapor barrier, which, as a rule, is an ordinary thick plastic film. Then, thin counter-battens are nailed over the logs (some may neglect them), after which a fine floor covering is laid.

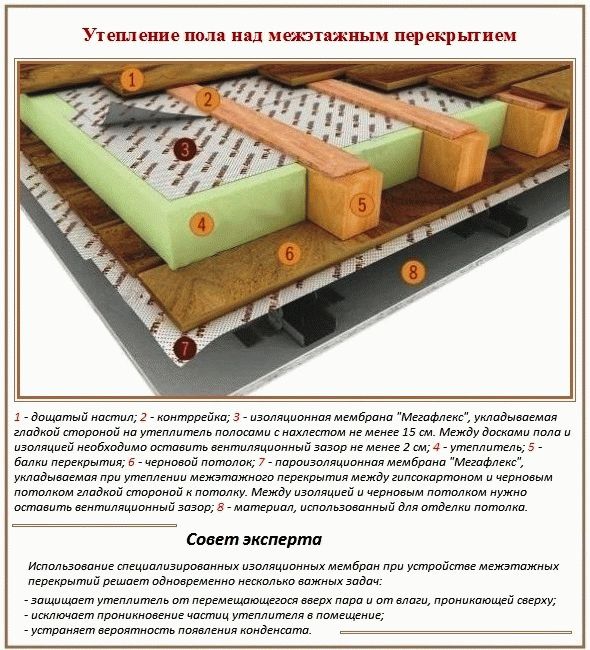

If you want to insulate the floor on the upper floors, then you will have to act a little differently. Here, a vapor barrier layer is first laid on the floor material - the same film, then the logs are only mounted.

Often in this case, builders lay a kind of draft floor on top of the soil - the basis for insulation. Here is how it will look on the diagram

Often in this case, builders lay a kind of draft floor on top of the soil - the basis for insulation. Here is how it will look on the diagram

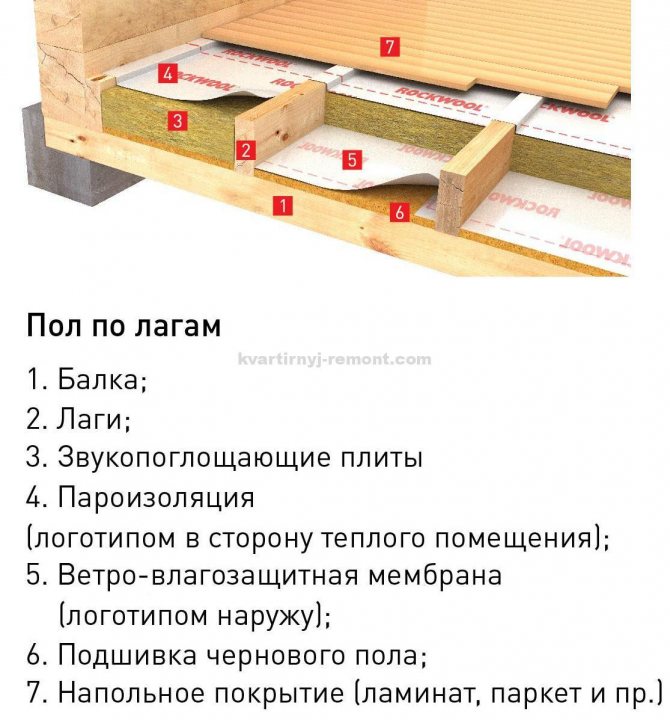

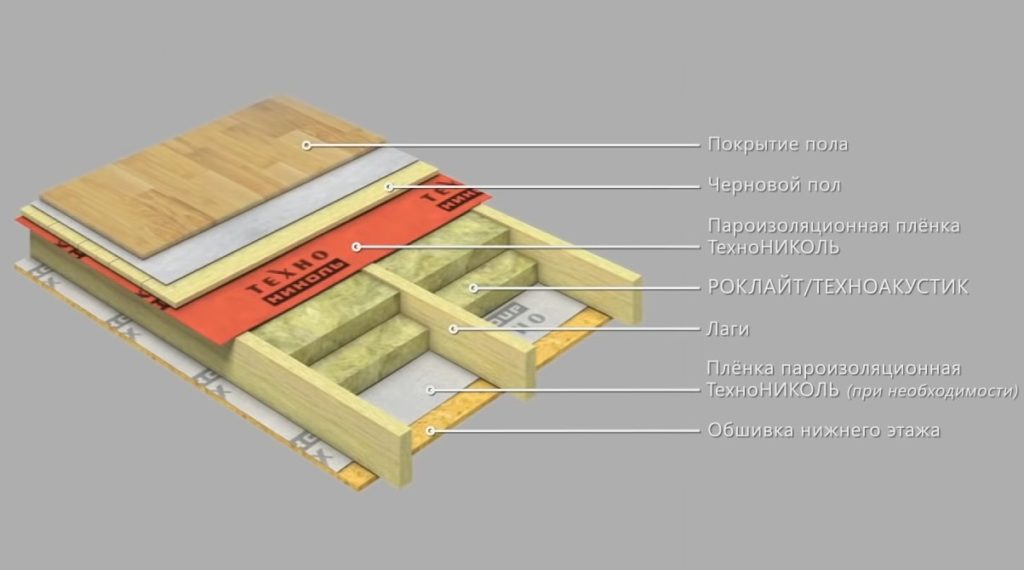

When insulating the floor with mineral wool or ecowool, the lower layer of vapor barrier must be present. This is especially true of the second and all subsequent floors.

The space between the lag is sealed with insulation, after which everything is again covered with a film. Counter rails are screwed onto the logs with a screwdriver, onto which the finishing floor is laid.

We also recommend reading the article, where we described in detail how to put into practice the insulation of a wooden floor.

Peculiarities

Wooden floors, unlike concrete, are much warmer. Wood is a capricious material and when building a house it is not always possible to achieve the desired effect. The ratio of thickness and thermal conductivity is often disproportionate, so floor insulation in a house made of wood is simply necessary.

The possibility of floor insulation is not only in new houses, but also in long-built ones.

Floor insulation helps to maintain an ideal microclimate in the room and serves as a guarantee against such undesirable problems:

- dampness;

- the appearance and reproduction of mold;

- the appearance of microorganisms and fungi that adversely affect the health of those living in the house;

- high consumption of thermal energy for heating the house;

- building damage and destruction.

Insulation of structures involves different types of work:

- insulation of floors above the basement;

- insulation of interfloor ceilings;

- insulation of the ceiling between the living room and the attic.

In each case, materials are used not only to maintain optimal temperature conditions, but also for sound insulation. A well-insulated first floor is a guarantee that the house will become comfortable for living.

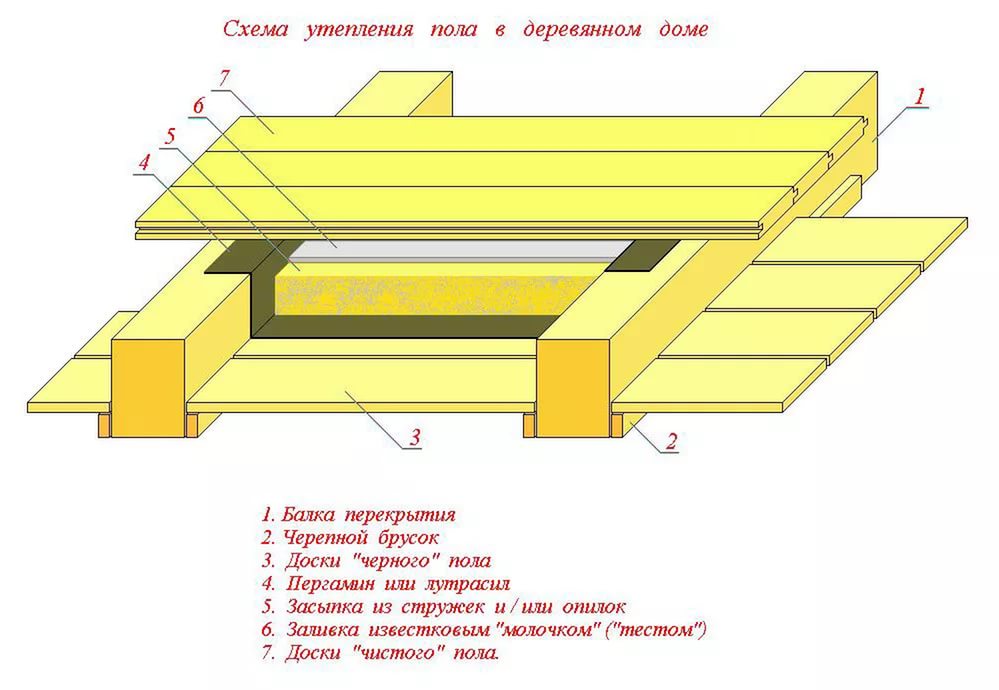

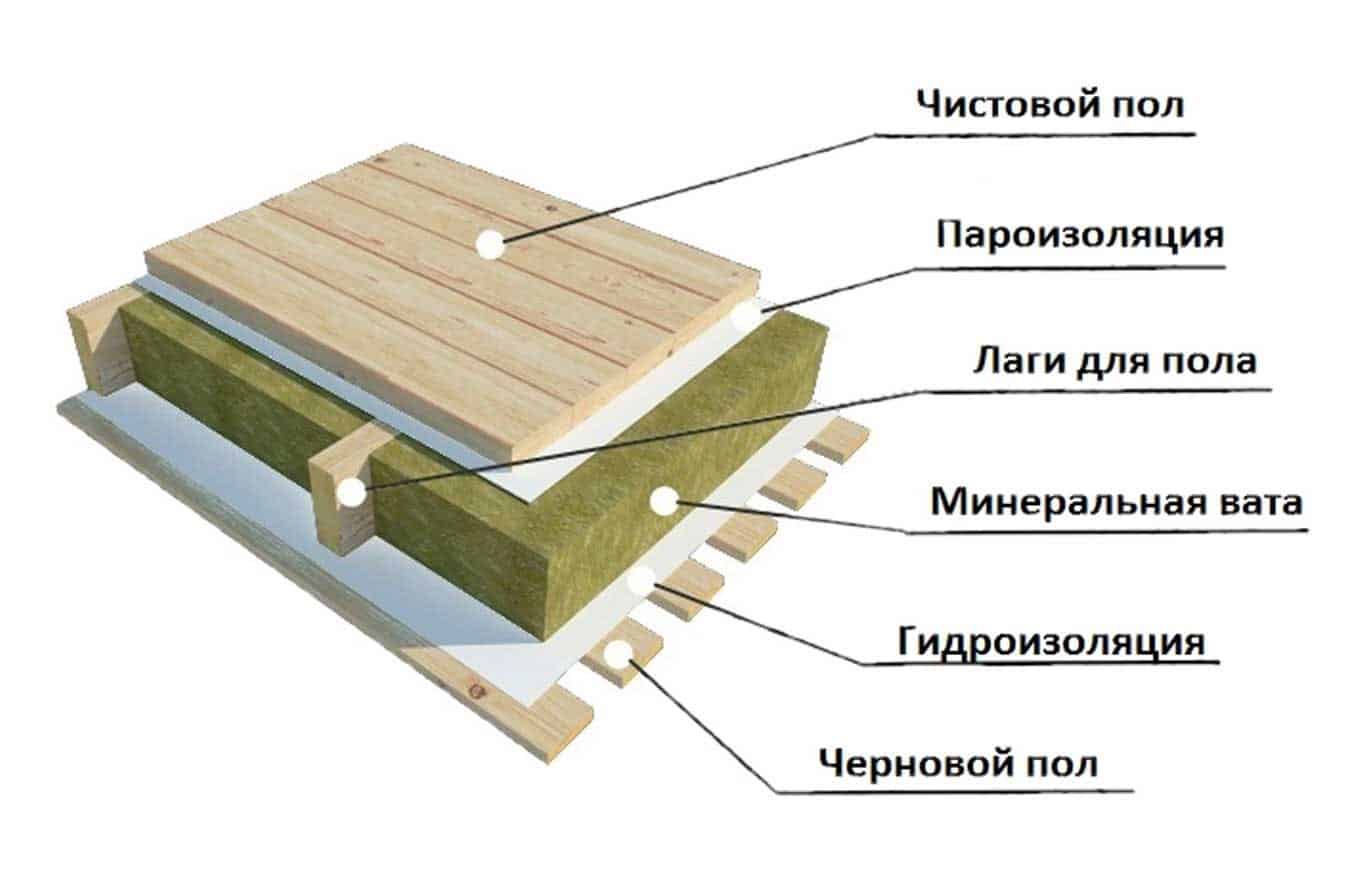

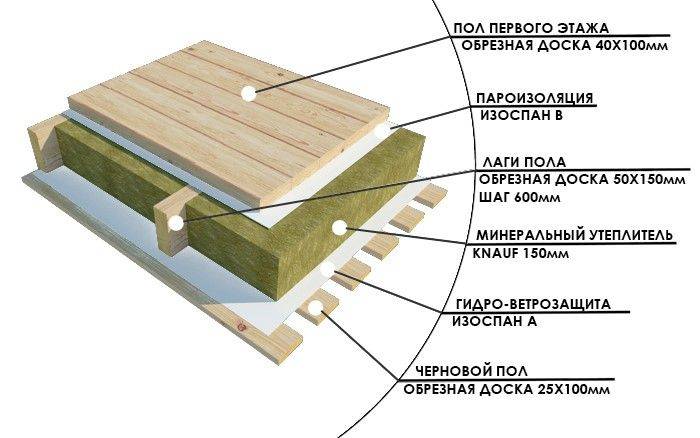

Principles of installation work

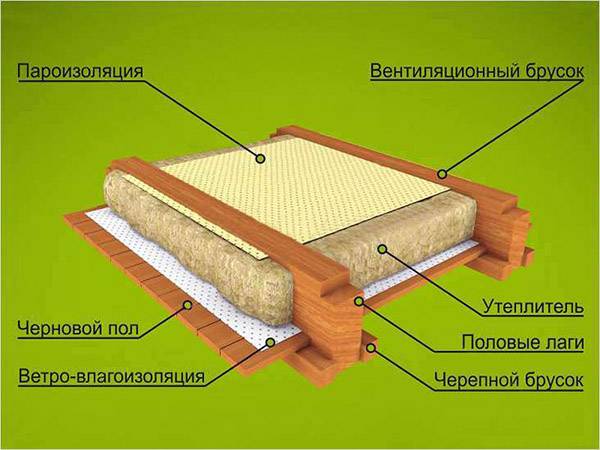

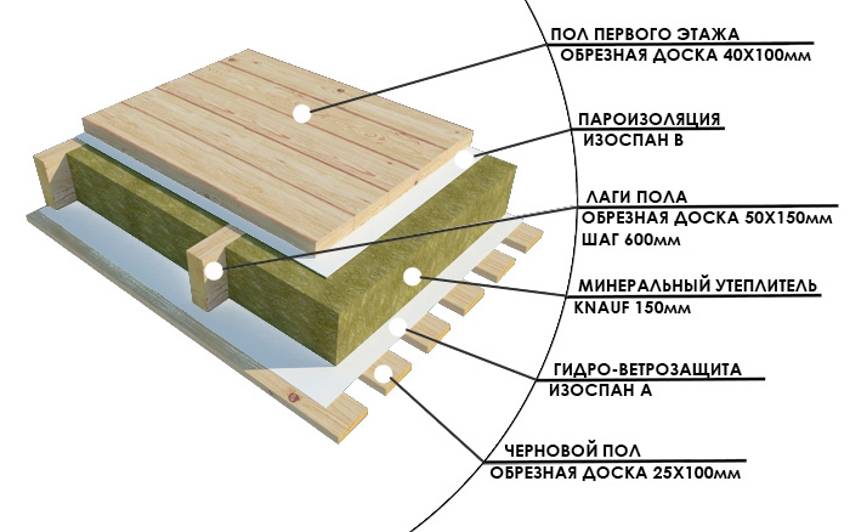

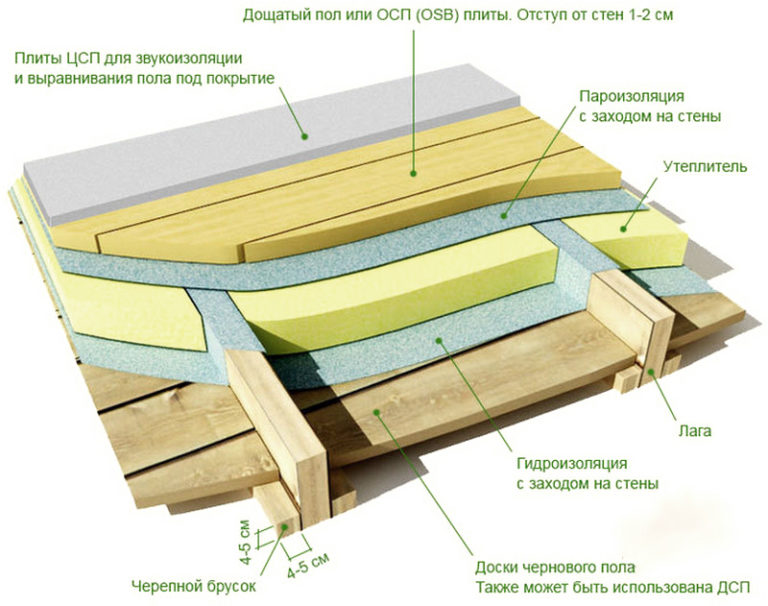

Regardless of the choice of type of thermal insulation, it is necessary to follow the sequence of work performed for proper insulation. Considering the structure from the bottom up, it will look like this:

- waterproofing layer;

- thermal insulation layer;

- vapor barrier layer;

- construction for floor installation;

- floor.

The easiest way to lower insulation is along the lags. They are bars measuring 5x10 cm or more, on which the floor is subsequently laid.

The scheme of floor insulation along the lags

After their installation (the recommended distance between adjacent lags is 1 m), plywood sheets, chipboards or beams are hemmed from below, on which a waterproofing layer is laid. This is a measure to combat condensation, which can reduce the performance of the thermal insulation layer. Approximately this technology is used in the insulation of the house "Stanislav Chalet".

Next, the heater is installed. Its thickness should not exceed the thickness of the lag, but it is better to be several centimeters less. The next stage is the laying of a vapor barrier, which will prevent moisture from entering the insulation from inside the room. And at the end floorboards are laid.

If it is necessary to insulate the finished floor in a wooden house from below, there may be problems fixing the insulation, which can be solved in one of the following ways:

- Adhesive fastening. Almost any insulation can be glued to the floor surface (and the ceiling in the basement) using special adhesives.

- Rail fastening. To support the insulation, bars, slats, etc. are nailed to the logs.

- Docking in size. Tight joining of heat-insulating material with lags using, if necessary, spacer wedges.

When laying the insulation end-to-end with the lags, it is necessary to strictly maintain the size

In any case, it is necessary to lay a vapor barrier, and after insulation, hem the basement ceiling with boards. This will prevent the insulation and its particles from falling down.

Optimal insulation for wooden floors

There is no point in discussing the best material for thermal insulation of a wooden floor. Almost everything is applicable, from old-fashioned dry foliage to expensive vermiculite. They insulate the floors in wooden houses with loose thermal insulation options, mats and slabs.

Since the list of requirements for any insulation consistently includes lightness, minimum water permeability, durability, operational safety, all these qualities are quite satisfactory for builders and owners of wooden houses.

The choice mainly rests on the financial capabilities of the owner, on the type of foundation and on the method of laying. Owners who are not limited in funds will be able to purchase progressive, easy-to-fit materials with detailed instructions on how to insulate the floor in a private house without the involvement of builders and with an accurate indication of the thermal performance of the factory product on the package. If you want to save money, you will have to tinker a lot with traditional insulation schemes.

Heaters for economical owners

Independent home craftsmen who do not want or are not able to invest significant amounts in insulation can use as a heat insulator:

- dry sawdust, pleasing with a minimal price, but requiring a reliable waterproofing device on both sides of the insulating layer due to the tendency of the material to actively absorb moisture;

- sawdust granules, which are a more practical option, treated with an antiseptic and fire retardant;

- slag, attractive in cost, but used mainly in floor insulation schemes on the ground;

- expanded clay, used to create a heat-insulating layer of considerable power, since its optimal thickness for our latitudes is 30 cm;

- simple mineral wool without foil and corrugated shells that increase thermal performance;

- roll insulation, created on the basis of fiberglass, slag;

- polystyrene foam, which needs to be carried out to protect it from the encroachment of rodents and from fires.

Subject to the rules for thermal insulation using the listed materials, heat leakage through the lower ceiling will be excluded. However, laying them will require impressive labor efforts.

Modernized expensive heaters

If the owner of a country property does not have the main task of how to insulate the floor in a wooden house with little expense, then at his disposal:

- Vermiculite is a product of the processing of hydrated micas with excellent insulating properties and operational durability;

- Penoplex - extruded polystyrene foam produced in plate format with increased strength and excellent waterproofing properties;

- Various modifications of heaters with the brands Ursa, Thermolife, Isovent, Penofol, Isolight, etc., which are mats and plates with bases made of foamed polystyrene, glass wool and basalt analog, optimized by increasing wear resistance, minimizing water permeability, applying foil shells for reverse reflection of heat rays and other methods.

It is possible to isolate a wooden floor in case of minor heat leaks with ecowool or polyurethane foam, but it is impossible to blow these materials without special equipment.

This is a significant minus, and the plus is the creation of a dense water-repellent layer of insulation that does not require a device to protect the insulation from steam.

How to choose floor insulation

Professional builders have been arguing for a long time about the best thermal insulation material for the floor in the country, but in most cases, the owners of their own houses are interested not only in the effectiveness of the insulation, but also in its cost, and it is desirable that it be as low as possible. A warm floor in the country can be made using inexpensive bulk materials, heat-insulating mats or slabs, and if funds allow, you can organize polyurethane foam spraying and forget about drafts forever. There are a lot of heaters on the market, but almost always the choice is based on financial capabilities.

There are a number of requirements for floor insulation:

- Light weight so as not to create an additional load on the foundation.

- Waterproof - the insulation should not pass or pass water minimally, not damp and provide additional waterproofing (ideally).

- Durability - you must admit, no one wants to start such large-scale work to change the insulation every 3-5 years.

- Fire safety - insulation should not easily ignite or support combustion.

- Ecological purity.

If the financial situation allows, you can purchase modern heaters that are easy and quick to install without the help of specialists. There is also a solution for economical owners - traditional insulation schemes using cheap materials, but you will have to tinker with their installation. Consider all options.

Inexpensive heaters

If you want to save on building costs without sacrificing quality, there are several thermal insulation materials that provide reliable protection from the cold and at the same time are inexpensive. For example, our ancestors also insulated floors with dry sawdust. They can be purchased at a minimal price or even obtained for free at a woodworking production. However, in this case, it will be necessary to strengthen the waterproofing, because the sawdust easily absorbs moisture, and when they become damp, they no longer retain heat.

A more practical option is sawdust pellets - this is a product of modern production, the raw material for which is woodworking waste. The sawdust is pressed under pressure into small, hard granules that are not so easily succumbed to moisture and last longer. The granules are treated with flame retardants (means that do not easily catch fire) and antiseptics. Basically, this material is used for thermal insulation of the floor on the ground. In addition, untreated pellets are an excellent economical fuel for stoves and boilers. They are also used as fillers for cat litter, which speaks in favor of their environmental friendliness and safety.

Expanded clay has excellent thermal insulation qualities and is a favorite insulation material for economical builders.These are clay granules foamed under the influence of high temperature, which practically do not absorb moisture and are able to give the house warmth for many years and even decades.

The only drawback of expanded clay is its fragility, so care should be taken during transportation. For high-quality thermal insulation of the floor in the middle latitudes of Russia, it is recommended to pour a layer of expanded clay with a thickness of about 30 cm. Another inexpensive insulation is mineral wool in rolls without a corrugated sheath or foil layer

However, for it, as well as for sawdust, reinforced waterproofing is necessary. The same applies to roll materials based on fiberglass, stone wool, slag wool.

Another inexpensive insulation is mineral wool in rolls without a corrugated sheath or foil layer. However, for it, as well as for sawdust, reinforced waterproofing is necessary. The same applies to roll materials based on fiberglass, stone wool, slag wool.

Foam boards are also inexpensive, but they are very fond of spoiling rodents, which sooner or later start up in any private house. In addition, the foam should be protected from fire - and although it does not burn on its own, it emits acrid smoke when melted, which can lead to suffocation.

Expensive modern materials

If you want to conduct high-quality floor insulation in the country and are not constrained by funds, you have a lot of options, one is better than the other.

The most popular modern heaters:

Manufacturers

Many companies are engaged in the production of materials for floor insulation. Among them are world-famous brands and those who are just starting their journey. Most companies have almost a century of history.In order to help you in your choice, below is a ranking of the most popular manufacturers. All of them represent materials with proven quality.

Knauf. An international manufacturer with over 90 years of experience. Insulation materials are popular all over the world. Products are made from natural raw materials using the latest technologies. All heaters are environmentally friendly and harmless. Knauf has been a market leader for many years.

- rockwool. The company works on modern technologies and specializes in basalt heat-insulating materials. The advantage of this raw material in high performance and affordable price. In Russia, branches are located in the Moscow, Chelyabinsk and Leningrad regions. The company is in second place in the ranking of manufacturers of insulation materials.

- Paroc. The company also specializes mainly in the production of mineral wool. Time-tested quality. The manufacturer focuses on saving thermal energy for heating a living space and excellent sound insulation. But the disadvantage of this company is that all heaters have a fairly high price. That is why the company is ranked third.

- isover. The manufacturer focuses on the production of mineral wool and offers two solutions - glass wool and stone wool. This is a distinctive feature of the manufacturer, since both options are often used in construction. The materials have high elasticity and strength. According to its characteristics, the mineral wool of this brand is the best. The price-quality ratio is well maintained here.

- Ursa. The company works on new technologies and offers both mineral wool and fiberglass.Product prices are affordable. The company has recently entered the Russian market, so it is not yet very common. But, thanks to prices that are significantly lower than the prices of other market representatives, there is a demand for products.