- The process of insulating water pipes

- How to insulate with a heating cable?

- Secrets of proper insulation

- Applied thermal insulation materials

- glass wool

- Basalt insulation

- Styrofoam

- polyurethane foam

- Foamed polyethylene and artificial rubber

- Thermal insulation paint

- How to deal with insulation

- Installing filters

- We work with steel products

- About metal-plastic pipes

- Products with a polypropylene base

- Other methods of pipeline insulation

- Alternative insulation methods

- How to insulate water pipes yourself

- PPS insulation with shells

- Insulation of the water supply system with a self-regulating electric cable

- Foam insulation

- Heating of external water supply systems

- Organization of water circulation

- Using an electrical cable

- Conclusions and useful video on the topic

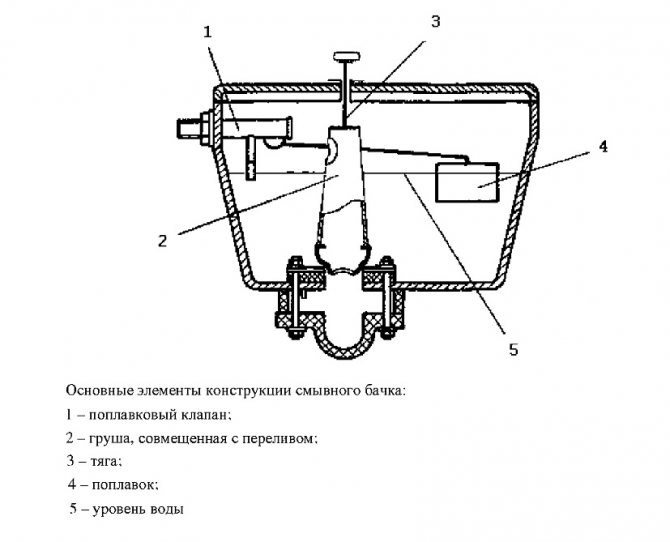

The process of insulating water pipes

How to insulate? Where to start insulating pipes in the ground? The most suitable material for insulating water pipes in the country is glass wool. Pipes are wrapped with this insulation, a special tape is used to fix it. Then waterproofing is provided with roofing material or other materials.

If a foam or basalt insulation is used, then half of the insulation is put on from the bottom side of the pipe, the second from the top.After that, for reliability, the seam is fastened with adhesive tape impregnated with waterproof glue. The next layer is protective material.

Insulation of a water pipe can be done using a shaped shell, it will close all turns and corners. The diameter of the shell is selected taking into account a snug fit to the water pipes.

How to insulate with a heating cable?

does not tend to freeze

If you decide to leave the cottage for an indefinite time, you should start the pump, than you set the working pressure to 3-5 atmospheres (this depends on the power of the device). These manipulations will create conditions under which freezing of water in the water supply system is excluded.

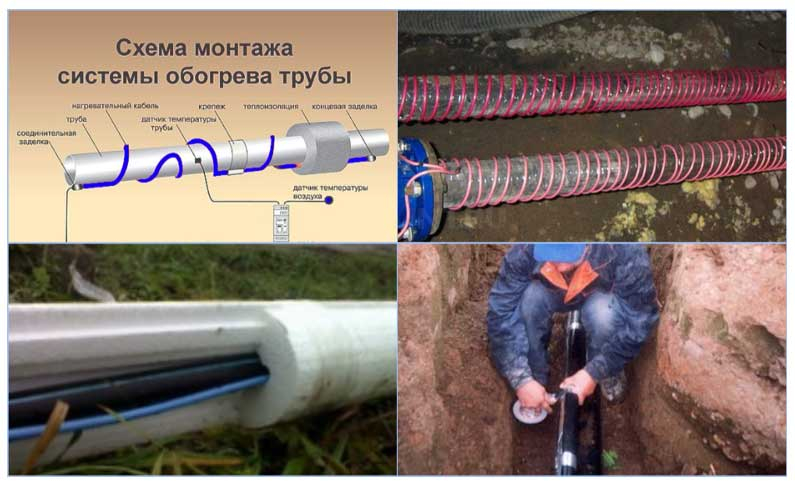

You will do the right thing when you decide to insulate the water pipe with a heating cable. Since this method is the most reliable for heating communications underground. Moreover, no matter how deep they are buried, they will be able to thaw on their own only by May, the heating cable will help thaw them in one day.

This method of insulating communications does not require deepening into the ground by 2 meters, it is enough to dig a trench 50 cm deep. At intervals of 10-15 cm, the water pipe is wrapped with a cable with a power of 10-12 W per 1 meter. Its location will not affect the performance of the system in any way, even though it is inside the water pipe, even outside.

One of the most problematic places when heating a water pipe is the place where it joins the wall. To avoid problems in this segment, you need to install a heating cable from the side of the house deep into the system for several meters.

The development of technology has also affected the water supply system. Nowadays, it is no longer a novelty to carry out heating cable installation with temperature sensors.Throughout the entire line, it will be enough to install 3-4 sensors that will notify you about the temperature of the water in the water supply. For example, if the temperature in the water supply drops to +5 degrees, then the heating cable automatically turns on, and the revolutionary system notifies the owner of the work done by a message on a cell phone or in another chosen way.

Secrets of proper insulation

chart

It is necessary to insulate and heat the entire pipeline line, which is exposed to negative temperatures. Therefore, areas included in the premises of the house also need protection, for example, unheated basements.

It is important to know that a warm pipeline in winter is subject to increased attention from various rodents and other living creatures. They are able to gnaw through insulation, plastic and asbestos pipes.

To protect the pipeline from the invasion of animals, it is necessary to plaster it with a composition with the addition of broken glass, wrap it with a metal mesh, or a metal sleeve.

Thus, the article dealt with how to insulate a water pipe in the ground. You can use this material when deciding whether to conduct a water supply system to ensure its uninterrupted service through insulation. Even in the most adverse climatic conditions, the above described methods of insulation will save you from freezing water pipes for many years.

Applied thermal insulation materials

When deciding how to insulate a water pipe in the ground and inside the house, it is necessary to ensure that the following requirements for thermal insulation are met:

- minimum coefficient of thermal conductivity of the material;

- stable shape retention under mechanical action;

- inability to absorb moisture or the presence of protection against it;

- easy installation work.

Especially for the insulation of pipelines, manufacturers of building materials produce assembly heat-insulating elements in the form of tubular shells, half-cylinders and segments. Sheet insulation is still considered a traditional material, with which pipes are simply wrapped.

glass wool

Fiberglass thermal insulation is used for warming water pipes only in dry rooms. The durability of this material, good thermal insulation properties and low cost lose their significance due to the ability of glass wool to actively absorb moisture. Therefore, the insulation of a water supply system in a private house requires the mandatory presence of a waterproofing layer, which increases the cost of insulation and complicates installation.

Basalt insulation

They are made in the form of flat mats, semi-cylinders and segments. The ability to absorb moisture is present, but it is much lower than that of glass wool. Recommended for insulation of pipes in dry rooms. Basalt heaters are not used for insulation of underground pipeline lines.

To insulate pipelines, manufacturers manufacture products with a protective layer of foil isol or glassine already glued. The complex manufacturing technology of the material increases its cost. As a result, the insulation of small diameter pipes often becomes uneconomical.

Selection of the diameter of thermal insulation for pipes.

Styrofoam

A dense, strong and durable material with excellent thermal insulation properties is best suited for insulating a water pipe in the ground. It is produced in the form of split tubes and semi-cylinders.There may be a surface protective coating of polymeric materials or foil.

polyurethane foam

This type of insulation is used for the manufacture of pre-insulated PPU pipes in the factory. Such systems are considered the best protection against heat losses and all types of external influences. But the main disadvantage for private developers is the need to attract specialists to carry out installation work.

Foamed polyethylene and artificial rubber

Especially for the thermal insulation of pipelines, tubular casings of various diameters are made from these materials. They are put on the pipe during installation work or on already installed pipelines. To do this, a longitudinal incision is provided along the length of the casing, which allows you to open the shell and put it on the pipe, performing the installation yourself.

Tubular insulation made of polyethylene foam and artificial rubber:

- has good thermal insulation properties;

- does not pass or absorb moisture;

- easy to mount;

- durable and affordable.

However, the low mechanical strength of these materials does not allow their use in underground laying. The weight and pressure of the soil will lead to compaction of the layer and loss of thermal insulation properties. Therefore, use is only allowed with open pipe laying.

Thermal conductivity of materials.

Thermal insulation paint

This innovative material is a thick paste-like composition that is applied to the surface of the pipeline. A layer of paint 4 mm thick corresponds in its properties to 8 mm mineral wool insulation.

The coating is characterized by high strength, wear resistance and high resistance to moisture. The main disadvantage is the high cost - more than $ 150 for a bucket of 10 liters.

How to deal with insulation

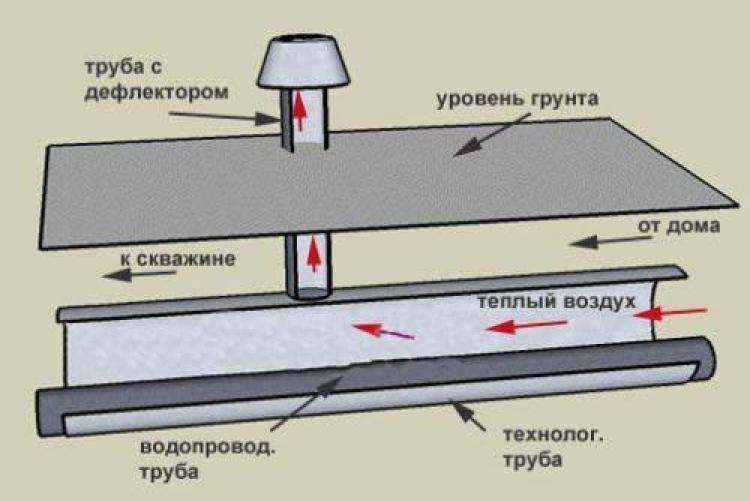

For this, for example, special cases are used. The existing water supply is laid inside another pipe, with a small diameter. This contributes to the formation of an air cushion between the walls of different products. This keeps the heat in the water.

Or the pipeline is simply poured using polystyrene concrete or foam concrete. This is a monolithic layer, with a base in the form of concrete with a low weight and a porous structure.

Plumbing is sometimes wrapped with insulation. Or heating cable. The latter is laid both inside and outside the structure. Laying is recommended in two available ways:

- Two lines parallel to each other.

- Spiral around the plumbing.

Not every system is designed in such a way that it builds pressure without problems. But this method of protection is able to boast of efficiency.

When high pressure is maintained inside, the liquid does not freeze. Even if there is no physical thermal insulation.

When installing external non-pressure types of sewage, the so-called socket connection is used. The main thing is the absence of pollution on the plastic, then the connections will acquire high tightness. Silicone or liquid soap lubricates parts that require connection.

Sealant treatment will provide additional protection during work such as laying water pipes from polypropylene pipes in the ground.

Only compliance with all requirements and technologies will allow you to get a water supply system that will function for a long time.And it will help reduce operating costs.

Installing filters

If there is no scale or sand in the water, then elements such as fittings on toilet bowls, automatic washing machines, and ceramic faucets live much longer.

Do not give preference to filters that are disassembled manually. Inside such structures are rubber seals, whose durability leaves much to be desired.

The preparation process depends on which type of pipes you have chosen. If it is galvanized, then we use a grinder to cut the blanks of the sizes we need with our own hands. You can also do this with a hacksaw.

It is more convenient to cut metal-plastic or polypropylene products immediately in place. Even small misses in size will not be terrible.

When connecting, preference is given to two methods. For example, through a collector, which plays the role of wiring for individual devices, when each of them has its own fittings. Or through a simple tee.

We work with steel products

With the appropriate tools at hand, such as welding, for example, it is used to connect a metal structure.

It is easy to use for welding threads. Or bends that were bent on a special machine, the so-called pipe bender.

You can use dies or holders and do the work manually. Threaded connections are made in the same way as in the case of valves.

About metal-plastic pipes

In this case, the connection is made using fittings, which are supplied with union nuts. After cutting off the pipe section, proceed to chamfering from the inside with a knife.The union nut is put on the pipe together with the split ring.

Watch the video

We place the fitting from the fitting inside the pipe

The main thing is to act carefully, otherwise the rings with sealing characteristics will shift. The nut is tightened just as carefully, without sudden movements.

Products with a polypropylene base

To do the job, it will be enough to purchase an inexpensive soldering iron. Heat is applied to the inner fitting surface by selecting the desired nozzle.

We do the same with the end where the polypropylene pipe is located. We insert one part into another, wait until everything cools down.

Other methods of pipeline insulation

It is worth considering how to insulate a water pipe without the use of insulating materials. There are the following ways to do this:

- pressure support;

- heating cable.

To use the first method, a receiver is installed in the pipeline, and a check valve is installed after the pump. The valve in front of the receiver is closed and the pump is started. Thus, the water supply system will not freeze during the winter period and the residents of the house can use the water freely without fear that it will freeze.

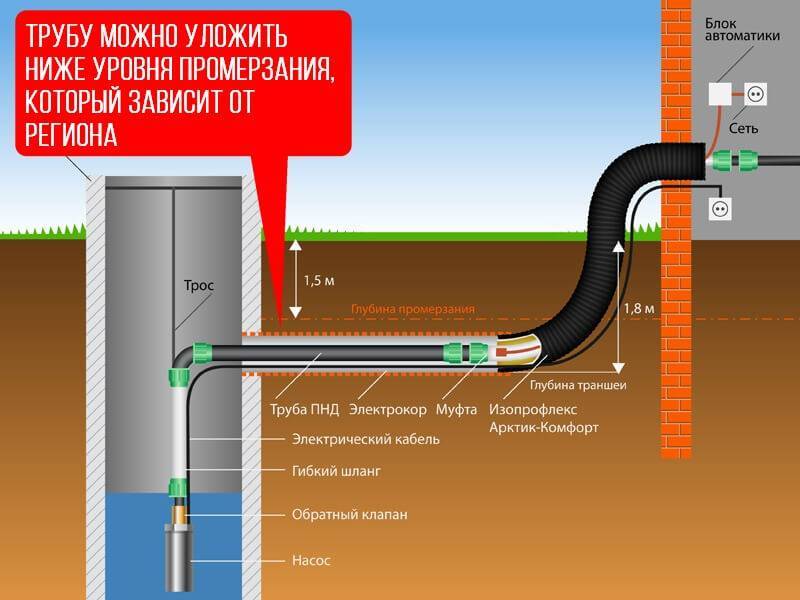

When installing an electric heating cable, it must be remembered that it can be placed both inside the pipes and outside. In this case, the laying of the water supply in this case is carried out at a shallow depth. Instead of 2 m, it is enough to dig trenches 0.5 m deep. But this method has a drawback - dependence on electrical energy.

Now about how to insulate the water supply in the country with this method. There are 2 types of laying: longitudinal and spiral. Installation steps:

- a layer of insulating material is wound around the pipeline;

- applying a protective film or coating;

- connected to the mains.

One of the problems is considered to be a section in the wall of the building - the introduction of water into the house. In order for the problem not to make itself felt in the winter, you need to:

- Create high pressure in those pipes that are responsible for bringing water into the house. The water supply system is supplemented by a receiver. When leaving the country house, it is turned on, and the pressure is set at around 3 atmospheres. This method will make it possible to insulate the input, while the water will not freeze. Arriving at the summer cottage next season, the owner relieves pressure and brings the water supply back to normal. In order to apply this method, it is necessary to make sure that the pressure in the system is uniform, that the pipes are strong (so that they are not damaged under increased pressure).

- Warming of water pipes is possible by heating the inlet pipes with an electric wire. In problematic places, they are wrapped with a cable and connected to the mains. But this method has disadvantages - additional power consumption and the impossibility of warming up during a power outage. But there is a way out of this situation, which is to buy a generator.

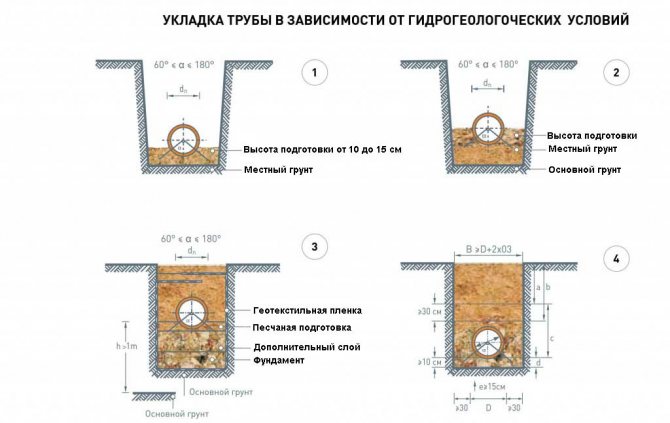

- Now about how to insulate a pipe with cold water with air. When deepening the water supply system into the soil, it is taken into account that the earth heats it from below, and cold (air masses) acts on it from above. If the pipes are insulated all around, they will be protected not only from the cold, but also from the natural heat coming from the soil. Therefore, in this embodiment, an insulating casing is used, its shape resembles an umbrella.

- The pipe-in-pipe method involves placing smaller products into larger ones in size or diameter, and the gap between them is filled with heat-insulating material: expanded clay, polystyrene, mineral wool, polyurethane foam, etc.Sometimes the annular space is filled with hot air. In this case, laying is carried out in the ground, and if the soil is wet or loose - in a brick tray.

In order for the sewer to be insulated, in addition to these methods, there is another way - the location of the pipes 0.1 m below the freezing point of the soil.

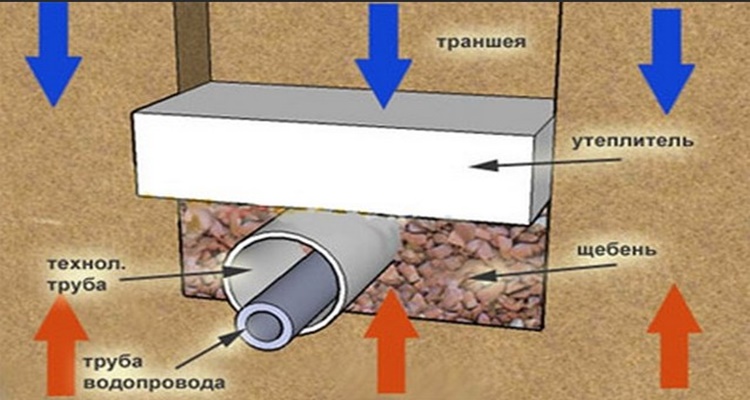

When laying the external sewage system, earthworks are carried out, trenches are prepared, a pit for a septic tank is prepared. If the freezing level is 1.7 m, then the minimum depth of the pipeline will be 1.8 m. And since the water supply system requires a slight slope, it will eventually lie at a depth of 2.6-3 m. If it is necessary to repair the system, this will complicate work. Therefore, do-it-yourself plumbing in the country house is mounted according to the instructions:

- trenches are prepared with a width of 0.6 m, a depth of 0.1 m more than the freezing point of the soil;

- trenches should have a slope of up to 2% of the total length of the pipeline;

- a sand cushion (0.1 m) is laid in the trenches and compacted;

- all elements of the plumbing system are laid out along the dug grooves;

- make connections and strengthen everything with sealant or silicone, while using cuffs (for sealing);

- put heat-insulating material on the pipe and fix everything with adhesive tape;

- everyone is covered with sand, and tamping is done on the sides;

- then everything is covered with soil (knoll), after a while it will settle.

Now there will be no questions about how to insulate pipes yourself. After all, every reader can.But if there are no installation skills, then it is better to invite specialists who will not only carry out the correct installation of the water supply system, but also calculate the required amount of material, which means that the consumer will save his budget and will not make unnecessary costs.

Alternative insulation methods

Not always the use of one insulation is able to provide effective protection. In very cold weather, additional insulation may be needed. Heating with a special cable or pressure is perfect for this.

Any liquid has a certain pressure at which it cannot freeze. Water pipe insulation can also be done according to this principle. Why just produce inserting the receiver into the water pipe.

The optimum pressure is 3-5 atm. The main point here is that the system is able to withstand this pressure. Then it will not freeze at high sub-zero temperatures.

Also, the insulation of underground pipes can be carried out with electric cables. The wires are placed on the pipes spirally or longitudinally, and then closed with a heater. This method is reliable and can heat pipes in a few hours, but it requires constant access to electricity.

How to insulate water pipes yourself

Before insulating a water pipe in the ground, they choose the appropriate option, taking into account the financial costs for the purchase of materials and the implementation of work, they often stop at using cheap high-density foam shells. Some homeowners use a sheath of 110 mm sewer pipes, placing a HDPE pipeline in them - air is the best heat insulator.

Recently, the method of heating the outer or inner shell of pipes with a self-regulating electric heating cable has become popular; Thus, the highest efficiency of work on heating the water supply is achieved.

PPS insulation with shells

Due to its low price, availability and suitable physical characteristics, a foam shell is the best option for solving the problem than insulating an underground water pipe on the street. Do-it-yourself installation of a shell on a HDPE pipeline does not present any particular difficulties for any owner and is carried out in the following sequence:

- A foam shell is put on the pipeline raised from the trench, snapping the locks and shifting each segment by approximately 1/3 in relation to the opposite element. Elements are fixed on the surface with adhesive tape or plastic ties.

- After fixing the PPS segments, the pipeline is lowered into the trench on a pre-prepared sand cushion 150-200 mm thick - this will prevent the heat-insulating shell from being skewed with a possible kink.

- Then the trench is covered with soil raised to the surface, the removed sod is laid out.

Installation of PPS shells

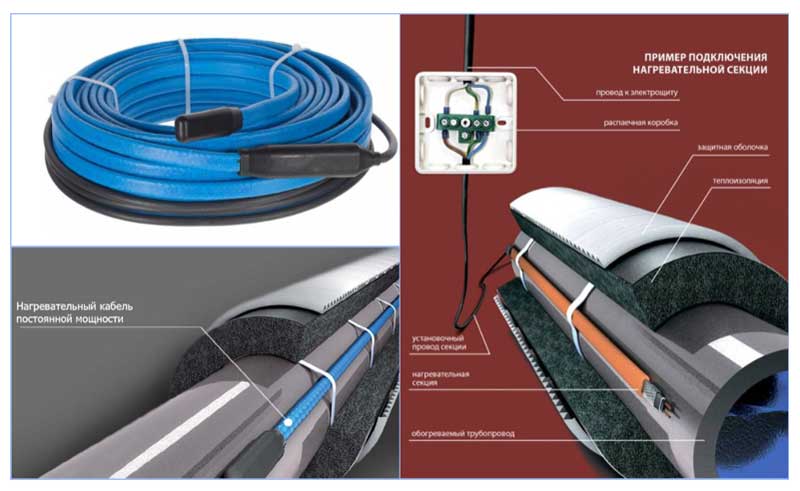

Insulation of the water supply system with a self-regulating electric cable

Insulation of an underground water supply by heating a pipe with an electric cable is one of the effective methods of combating freezing with a shallow location of the water supply line. The heating cable can be used along the entire length of the pipeline or in a separate section, it can also be immersed inside the pipe shell or left outside, on the surface of the pipe.The construction market sells electric cables with fittings for entering the pipeline, equipped with sealing rubber glands, the wire itself is short and is usually placed at the outlet of the pressure well pipes. In this place, the efficiency of its use is the highest - heated water will flow along the entire line from the well to the house, preventing pipes from freezing. In addition, laying the cable at the junction of the pressure pipeline from the electric pump with the water line is technically easier to implement than in any other more inaccessible place, which is usually absent throughout the entire water main.

Kit with self-regulating cable for installation in pipeline

Pipe insulation, when the water supply is in the ground, and it needs to be heated with an electric cable from the outside, is carried out as follows:

- The HDPE pipeline is located on the surface of the earth next to the trench, and the area in the places where the electric cable is laid is cleaned of dirt.

- They wrap the pipe surface at the point of contact with the electric cable with aluminum foil tape - this increases the thermal conductivity of the shell at the point of contact. If the wire is placed in a straight line along the length of the pipe, one or more straight strips of foil tape are glued, with a spiral placement of the cable, the entire pipe is wrapped with tape.

- After laying the heating wire, it is screwed with the same foil tape to the surface of the pipe along the entire length.

- To reduce heat losses, it is imperative to use an outer shell made of PPS foam, PPU polyurethane foam, which is put on top of the heating wire and fixed with adhesive tape or plastic ties.

Installation of a heating cable on a pipe

For insulating plumbing pipes for individual water supply more often than others use an inexpensive foam shell and a self-heating electrical cable, often both methods are combined. Carrying out installation work on the placement of a heat-insulating shell and a heating wire does not cause any particular difficulties and does not require high qualifications; with knowledge of the technology, all actions can be performed in a short time without much labor by one person.

Foam insulation

Penoplex

When using this material, the least amount of time will be spent. It, like the previous method, can be used for pipes that are laid in various conditions. The degree of moisture absorption is minimal. This means that penoplex can be in the ground without harming it. Products from it usually represent the so-called shell. These are two half-cylinders. In order for them to fit well together, a special spike-groove lock is provided at the ends. The radius of the inner circle is equal to the outer one on the nozzle for which a particular sample is intended. During installation, they can be coated with a suitable adhesive or reinforced tape. In this case, there is a guarantee that moisture will not seep inside and will not destroy the pipe.

Heating of external water supply systems

For water supply, pipelines partially located above the ground or in an unheated basement can be used.In this case, the owner of the house needs to know how to insulate the water pipe on the street. For protection, a special material is used or heat is supplied from external sources (for example, from the electrical network).

Organization of water circulation

To increase the temperature of the water in the pipe on the ground surface, the technology of supplying small portions of liquid to the supply tank is used. For example, water from a well in winter has a temperature in the range of 7-10 ° C, for pumping portions of the liquid, the pump is periodically turned on (manually or by signals from a sensor installed in the pipeline).

Water enters the supply tank or drains back into the well. But if the lines are made of steel pipes. That periodic draining of the water supply leads to corrosion of the metal.

There is a technology of protection with the help of excess pressure, which is created by the pump. A pump with a check valve supplies water from the well to a storage tank designed for high pressure. The liquid is injected into the section of the pipeline located on the soil surface.

A pressure regulator is installed in the line, which does not allow water to be supplied under excessive pressure to the located plumbing inside the house. Due to the increased pressure, it is possible to reduce the crystallization temperature of water by several degrees.

Using an electrical cable

To increase the temperature of the pipelines, an electric cable located inside or on the outer surface of the pipeline can be used. The internal cable provides an increase in the efficiency of the heating system, but is difficult to install.The outer cord is attached to the surface of the water pipe with aluminum tape, which provides additional thermal insulation.

An adjustable thermostat is introduced into the circuit, which allows maintaining the temperature in a given range while reducing the load on the electrical network. Insulation of the water supply at the entrance to the house can be carried out with a self-regulating cable.

With a correctly selected cord, installation of an additional controller is not required. The owner of the premises can independently assemble a line with electric heating or use a ready-made solution.

The screen is displayed in a heated room (for example, the technical floor of a residential building), hot air enters as a result of convection. The technique is used in residential buildings that are operated on an ongoing basis and are equipped with heating systems.

The forced airflow system provides for the installation of 2 boxes along the highway, into which hot air is injected. The channels fit snugly to the surface of the pipeline, it is recommended to seal the joints.

The resulting structure is covered with an insulator layer and installed in a protective tube. Hot air is supplied by a fan with an electric heating element, it is possible to install a control unit with temperature sensors.

Conclusions and useful video on the topic

Video #1 Laying a pipeline in the ground from a well to a house with its insulation and the nuance of freezing near the foundation:

Video #2 Insulation of a water supply system based on a plastic pipe and a method of insulating a knee using a cylinder of a larger diameter:

Video #3 Detailed instructions for fixing an external heating cable, taking into account the correct bypass of fasteners and taps:

High-quality insulation or heating of the water supply system located underground will ensure its uninterrupted supply in the winter. If the rules of installation and protection from the cold are neglected, a complicated defrosting procedure and expensive plumbing repairs can follow.

Want to talk about your own experience in the device thermal insulation of water pipes in the countryside? Would you like to share useful information with us and site visitors? Please write comments in the block below, ask questions, post photos on the topic.