- Creating a barrier to water vapor

- The composition of the roofing cake

- Creating conditions for the operation of insulation

- Composition of the pie

- Stages of attic insulation from the inside

- Roof insulation in the attic

- Wall insulation in the attic from the inside

- Floor insulation in the attic

- How to insulate the attic from the outside?

- How to properly insulate structural laying schemes

- Budget option: interrafter insulation

- Full attic insulation

- Why insulate?

- Preparatory work - where to start

- The device for steam and moisture insulation of the attic during insulation.

- What is the best material to use

- Proper completion of work

- Results

- About ways of warming

- Video - Test for heat retention of heaters

- Voting for the best insulation for the attic roof

- glass wool

- General technology for reducing heat loss

- Conclusions and useful video on the topic

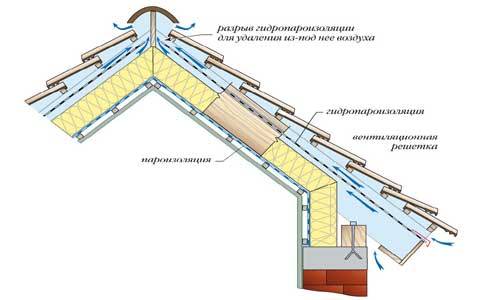

Creating a barrier to water vapor

Even a very high-quality vapor barrier film will only perform its function when it is properly laid and waterproofed, otherwise the vapors will penetrate into the thermal insulation.

The joints of the vapor barrier sheets are glued with adhesive tape made of butyl rubber, but even in this case absolute tightness cannot be guaranteed. The fact is that after a while the adhesion of the adhesive layer decreases, and the strips begin to diverge.

For this reason, if it is necessary to perform an exterior finish, when it is planned to lay drywall on the vapor barrier, an additional crate is made. It is created not only for smooth installation of the finish, but also to press the tape (sealant) with rails having a thickness of no more than 3 centimeters.

The crate allows you to lay electrical wiring directly under the skin, and not through the insulation. Such a decision is considered technically competent. At the same time, the places where the vapor barrier material adjoins the walls and laid pipes must be insulated with sealants or tapes without fail. When installing a vapor barrier, the canvas cannot be stretched, they should be fastened with a small margin.

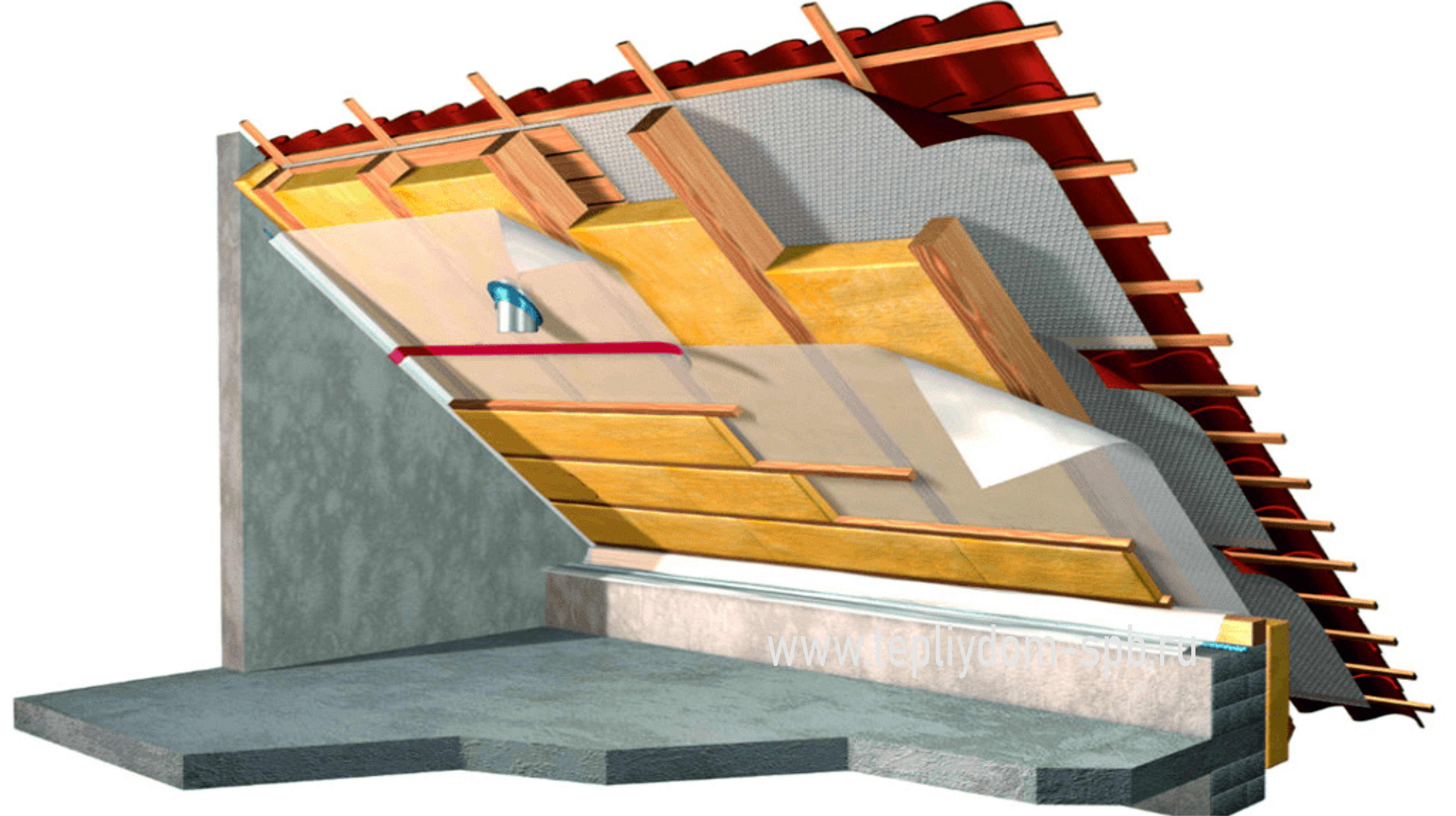

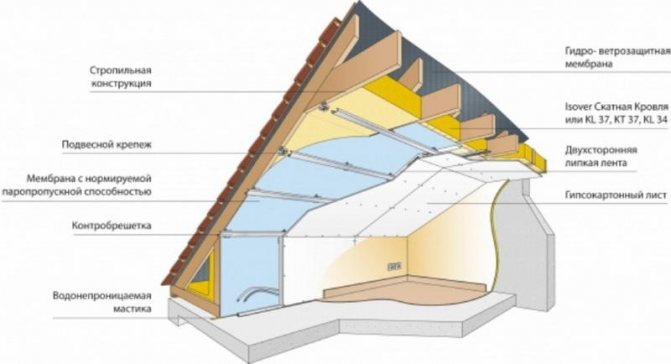

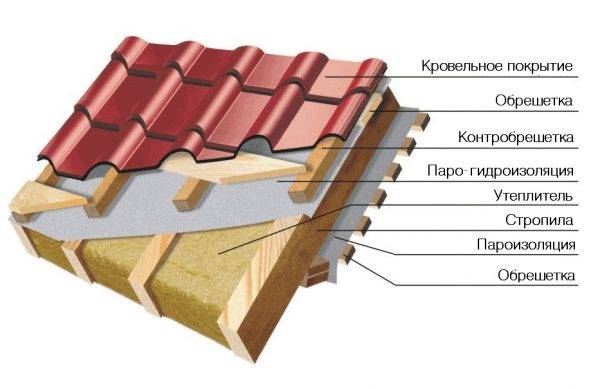

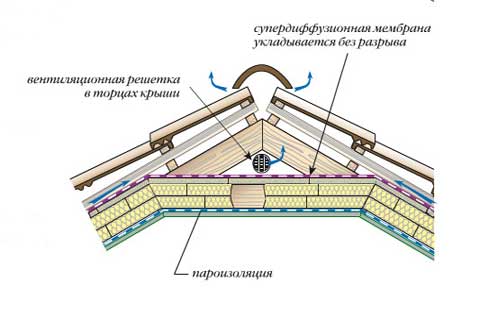

The composition of the roofing cake

Insulation of a residential attic with mineral wool requires mandatory compensation for the weaknesses of this material: the ability to absorb moisture from the room, as well as high airflow and low resistance to precipitation. Therefore, two, and sometimes three membranes are introduced into the composition of the roofing cake, provided that fibrous insulation is used. In the direction from the room to the outside, the layers are arranged in the following order:

Scheme of attic insulation with mineral wool

- Ceiling finish. The warmest material for this layer is drywall and a layer of putty (taken into account separately in the thermal calculation).

- An air gap formed by a crate for fixing the finishing cladding. Equal to the thickness of the laths (or galvanized profiles) of the crate. This gap is not necessary for the operation of the heat-insulating system.

- Vapor barrier film. Protects the insulation from the ingress of steam rising from the room.

- The main insulation (2 - 3 layers of mineral wool).

- High diffusion membrane (waterproofing). Its peculiarity lies in the one-way passage of water. Moisture coming from below (evaporated by mineral wool) should freely penetrate through the membrane, and water entering from above (precipitation and condensate) should drain under the roofing down to the street. Films of this type combine the functions of a hydro-barrier and wind protection. In domestic practice, isospan three-layer membranes have proven themselves well. It is better to use Izospan AQ proff for the attic, which is characterized by high strength and a good steam transmission rate (1000 g / m2 per day). The gap between isospan and mineral wool is not needed.

- Ventilation gap between the membrane and the roof deck. It is formed by battens of lathing, located perpendicular to the rafters in the plan. The thickness of the crate is usually 4 - 6 cm.

- Roof decking.

Creating conditions for the operation of insulation

For any material used for insulation, it is necessary to create appropriate operating conditions, because otherwise it will not be a source of heat, but rather cold, dampness and mold.

The main requirement for all heaters is low thermal conductivity, which assumes that the heat-insulating layer will separate the warm air inside from the cold outside.

It is not enough to insert the material into the rafters, you still need:

- Qualitatively waterproof the insulation from moisture from the outside.

- Make a vapor barrier so that a minimum of steam penetrates through the heat insulator.

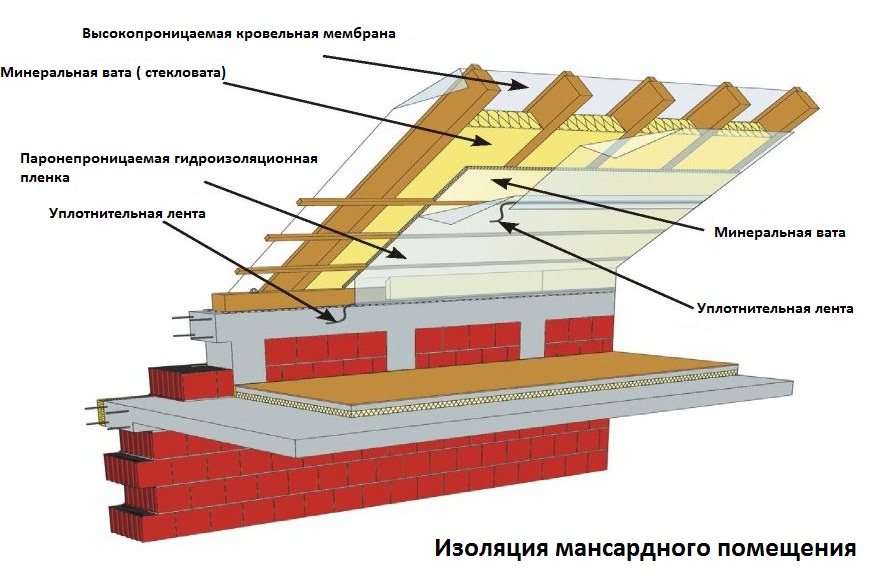

Composition of the pie

No, we will not talk about the preparation of a confectionery product. Pie in construction is called a multi-component system that is used to ensure indoor comfort.To put it simply, what layers should the surface consist of, be it a wall, a roof or a floor.

Considering the composition of the pie, we will move from the inside out to find out how to properly insulate the attic from the inside.

Finishing. Usually it is drywall or MDF. Less often - OSB boards, which are then puttied and wallpaper glued. We will not dwell on this, because. the type of finish does not particularly affect the thermal insulation index, more on the aesthetic component of the process.

Vapor barrier. It is necessary so that moisture does not get into the heat-insulating material (in our case, it is mineral wool). Otherwise, it loses its thermal insulation properties. Layers of vapor barrier are laid with an overlap of at least 10 cm. Joints must be glued with special adhesive tape

It is important to pay special attention to the joints. The vapor barrier will only work if there are not even the slightest gaps into which moisture can seep in the form of steam. To remove moisture, it is important to organize high-quality supply and exhaust ventilation

To remove moisture, it is important to organize high-quality supply and exhaust ventilation. crate

For it, you can use a beam or rail with a thickness of at least 20mm. Fasten across the truss system with a step of 600mm. A vapor barrier is attached to the crate using a construction stapler. It also allows you to form a ventilation gap between the insulation and the vapor barrier. Or it makes it possible to add another layer of mineral wool laid across the first layer. This minimizes the presence of cold bridges in the form of rafters.

Crate. For it, you can use a beam or rail with a thickness of at least 20mm. Fasten across the truss system with a step of 600mm.A vapor barrier is attached to the crate using a construction stapler. It also allows you to form a ventilation gap between the insulation and the vapor barrier. Or it makes it possible to add another layer of mineral wool laid across the first layer. This allows you to minimize the presence of cold bridges in the form of rafters.

Insulation. The most important part of the pie. Fits into the distance between the rafters by surprise. This means that if the distance between the rafters is 600mm, the width of the mineral wool slab or roll must be at least 620mm. In this case, it will be possible to avoid gaps through which cold will penetrate or vice versa, heat. When to be held insulation of attic walls from the inside the minimum layer should be 100mm

At the same time, it is important to lay the plates in a checkerboard pattern, overlapping the joints

Waterproofing. The use of a membrane is recommended. It is necessary in order to protect the heat insulator as much as possible from the penetration of water during precipitation, while at the same time allowing moisture that penetrates through the insulation to freely escape. Mounted across the rafters with a stapler with overlapping layers. Start the installation from the bottom, moving up. The membrane must be fixed with a slight sag. In this case, a kind of gutter is created, allowing the water to flow down and out of the house. It is necessary to fix the waterproofing along the entire length of the rafters, thereby bringing it outside the walls of the house.

Control grid. The key element is to properly insulate the attic. Allows air to circulate freely between the waterproofing membrane and the roofing. This removes moisture that appears and accumulates on the membrane.The height of the counter-lattice is at least 25 mm for corrugated roofing material (ondulin, tiles, metal tiles, slate, corrugated board) and at least 50 mm for flat.

Roofing material. Finishing coating of the attic roof, which will provide reliable protection from precipitation. The more accurately the installation is made, the longer the heat-insulating layer will last. It will be protected from moisture - the worst enemy of mineral wool insulation.

The photo shows a diagram of an exemplary roofing pie.

So, if you make the insulation according to the steps described above, you can be sure to get an excellent result.

Compliance with these principles will make the result of the expected quality. But, as in any work, the question of how to insulate the attic with your own hands has its own nuances.

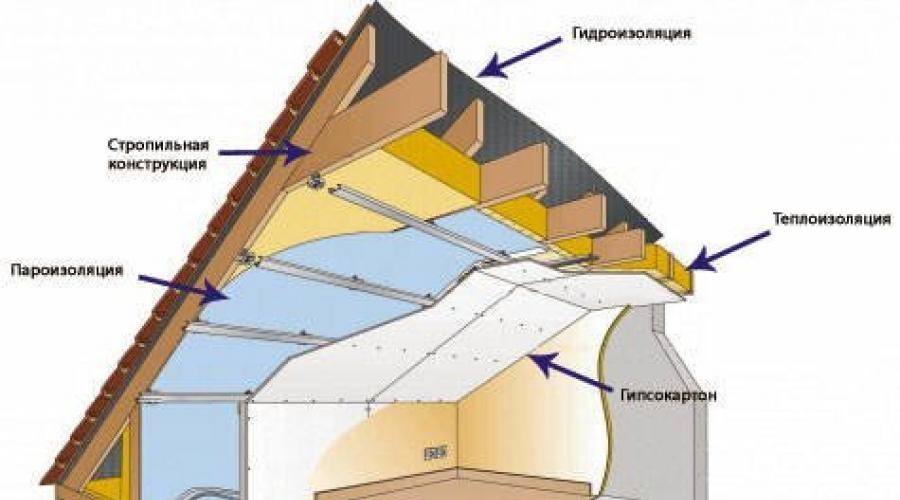

Stages of attic insulation from the inside

The process of work on the insulation of the attic takes place in several stages, in addition to the choice of material:

The procedure for thinning the attic

- roof insulation;

- Wall insulation;

- Floor insulation.

Roof insulation in the attic

First, it is worth telling what the process of insulating a mansard roof from the inside should consist of. Stages of work:

When insulating the attic, do not forget about steam and waterproofing

- Basic roof covering;

- Waterproofing device;

- Thermal insulation laying;

- Vapor barrier;

- Finishing work.

The initial stage, after the existing main roof covering, is waterproofing, which is laid along the entire height of the supports, from the bottom to the very ridge of the roof. Before starting the laying of the material, all wooden elements of the roof are treated with an antiseptic.In the presence of rotten and moldy parts, it is necessary to replace them. Knowing the coefficient of thermal conductivity, a decision should be made to exclude possible heat losses, whether one layer of insulation will be enough or whether it is still worth laying the second layer. In the place where the insulation is laid to ensure ventilation, when installing this material, a gap is left between it and the roof. If the roof material is undulating (tiles, metal tiles), then the layer is left at least 2.5 cm. And if the roof is made of flat-form material (steel sheets, rolled materials), the space between the insulation and the roof should be doubled.

Thermal insulation is carried out by laying the selected material on top of the waterproofing layer.

The next step is vapor barrier. The material is a special film, which in appearance can be like a regular film, or it can be in the form of a membrane, foil or perforated film. The film is attached to the rafters with a construction stapler.

Room decoration. At this stage, the following happens: fixing plastic, drywall, lining, moisture-resistant chipboard, fiberboard or plywood sheets. At the same time, you need to fasten close to the vapor barrier, or you can on a thin type crate from individual rails. Then you can, if necessary and desired, stick wallpaper, varnish or paint.

Wall insulation in the attic from the inside

Insulation of the attic walls is carried out when the roof does not reach part of the floor. So, when insulating walls, several steps should be taken to achieve the final result:

Wood treatment with antiseptic

- Treatment of walls with an antiseptic, removal of dust, dirt;

- Lathing of the roof surface from the inside with the help of beams or raw boards;

- Waterproofing;

- Laying a layer of the selected insulation;

- Vapor barrier layer;

- Wall decoration.

A distinctive feature of wall insulation work is the absence of battens, unlike the roof. The rest of the process takes place according to the same method as the insulation of the attic roof.

After treating the walls with an antiseptic, a vertical frame is arranged on the surface of the walls from a bar or raw board. The beam is attached to the wall with metal corners or dowels.

Plasterboard finishing insulated attic

Wall waterproofing means laying material in the frame cells. After that, the first layer is formed from the selected insulation.

The vapor barrier layer is fixed on top of the first layer of insulation. The vapor barrier material is a film, as mentioned above, which should fit snugly, without any sagging.

Wall decoration is carried out using facing materials: OSB boards, drywall, which are mounted on a frame made of a metal profile or wooden bars.

Floor insulation in the attic

Basically, the attic floor is made in the form of a wooden structure. And to create complete and final comfort in the room, the floor must also be insulated. And the floor insulation also takes place in several stages:

- Removing the old floor covering;

- Inspection of logs, detection of damages and defects, elimination of defects;

- Fixing the vapor barrier film;

- Laying the first layer of insulation;

- Laying the second layer of vapor barrier;

- Log sheathing.

The design of the insulated attic floor

The vapor barrier film is mounted along the entire length and width of the insulated surface. The film is attached with a construction stapler. In this case, the film must exactly repeat all the lines of the lag system, closely adjacent to the beams.

The first layer of insulation must be laid between the lags. This is followed by the stage of laying the vapor barrier layer, which will become the second layer. Accordingly, the vapor barrier material is laid on top of the insulation.

And the final stage will be facing the log with the help of front coverings made of OSB boards, or wooden boards.

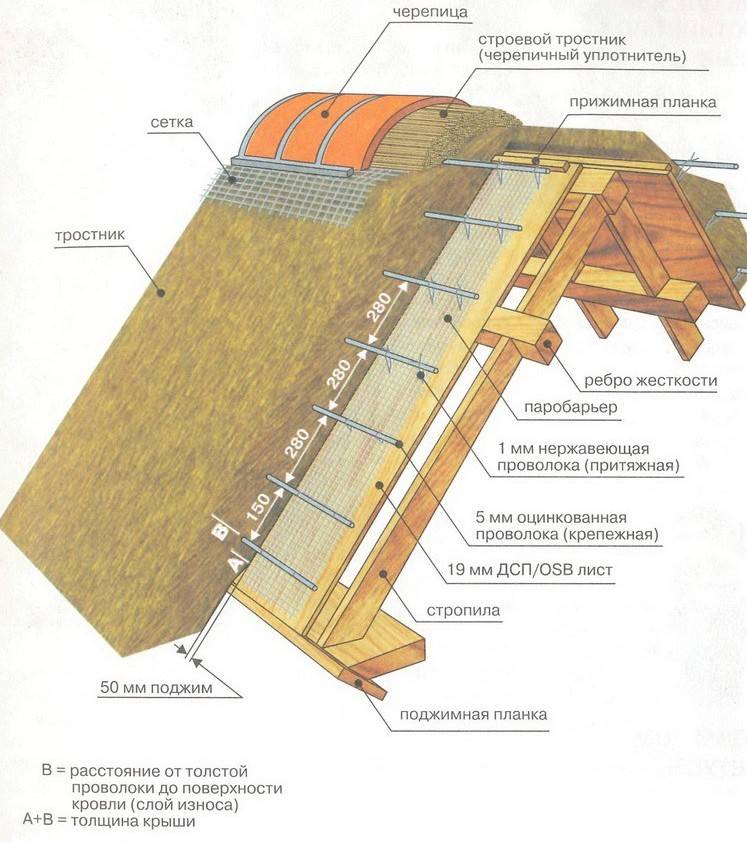

How to insulate the attic from the outside?

Before you start, you need to do some preparation.

For example, it is very important to pre-treat the wooden elements of the roof with special antiseptic substances. The metal parts of the roof should be painted

In the lower part of the roof, it is necessary to provide openings, the function of which is to ventilate the heat insulator.

Note! There must be a gap between the roofing material and the thermal insulation system. Its optimal width is 2 cm

In this case, ventilation will be most effective.

Consider step by step the process of external thermal insulation of the attic room. It should be noted that the technology of work varies depending on the type of roof and the type of heat insulator. For example, it is easiest to insulate the attic with foam, however, in regions with harsh winters, it is better to choose a different material for work.

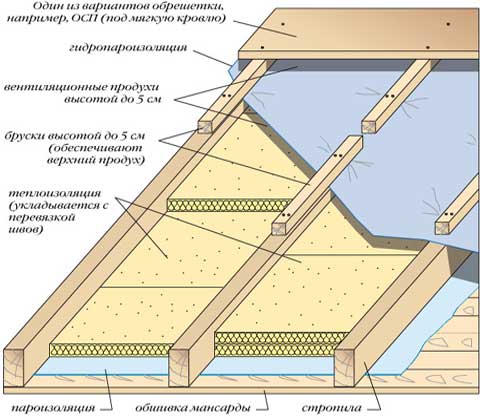

To insulate corrugated board or metal tiles, you first need to assemble a crate from wooden boards. It is done from the inside. Further, the vapor barrier membrane is fixed to the elements of the crate, as well as to the rafters.A heat-insulating material is installed on the membrane and covered with a waterproofing film.

Then, the bars will need to be fixed to the rafters in order to fill the gap between the insulation and the roofing material. At the end, the crate and the roof covering itself are installed.

The technology for installing insulation for soft types of roofing looks a little different. First you need to assemble a crate of wooden boards from the inside. Then a vapor barrier is applied to the entire structure. The next layer is insulation. It is followed by a waterproof film. After installing the waterproofing membrane, it is necessary to sheathe the structure with OSB boards and lay the flexible roof.

Thus, it is quite possible to insulate the attic with your own hands, but it is worth considering a lot of little things, without which it will not be possible to adapt the room under the roof for winter living.

What tips will come in handy when preparing the attic for winter?

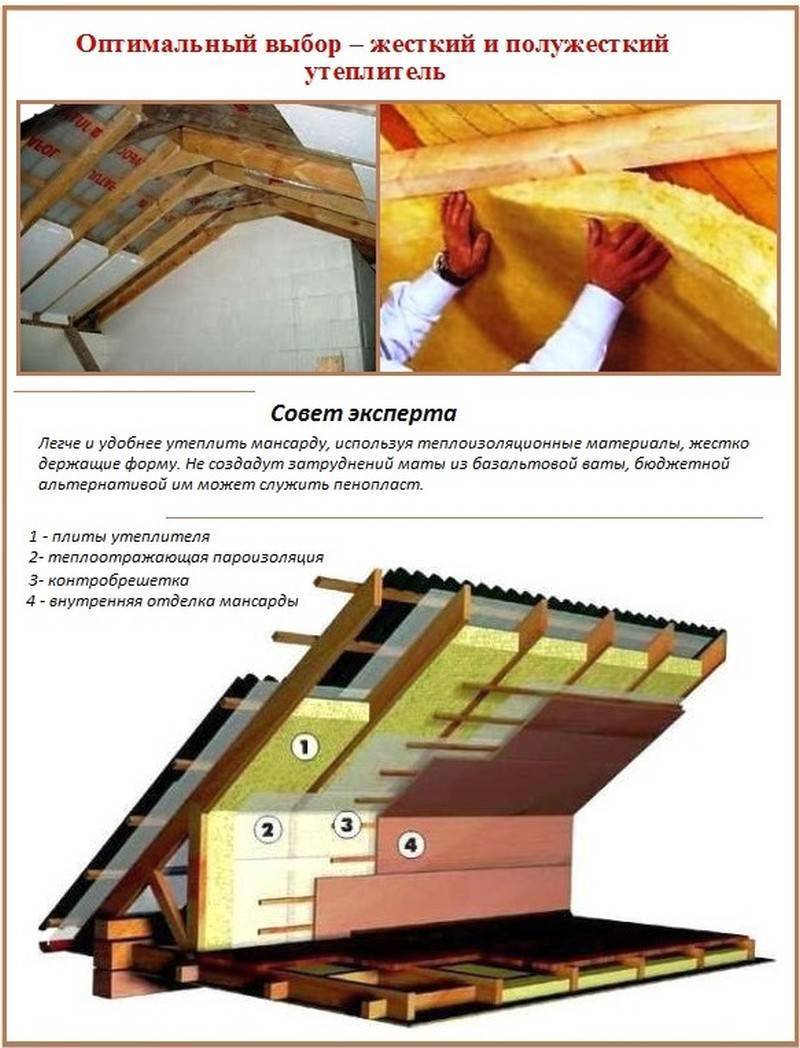

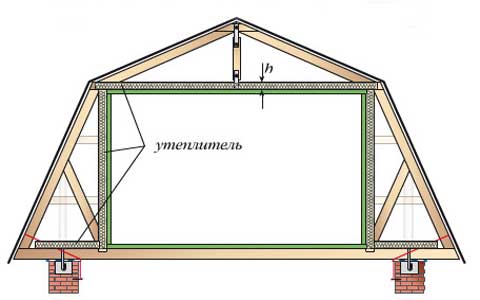

How to properly insulate structural laying schemes

Attic roof insulation is an issue that requires the most careful consideration, since insulating a sloping roof is one of the most difficult procedures, since it requires simultaneous insulation of several planes. In addition to the internal living space, remote balconies and windows can be provided on its lower slopes, which, in turn, further complicates the thermal insulation procedure. Thus, before insulating the attic, it is necessary to evaluate the design features and the actual state of the attic space.

Let's look at several options for attic insulation.

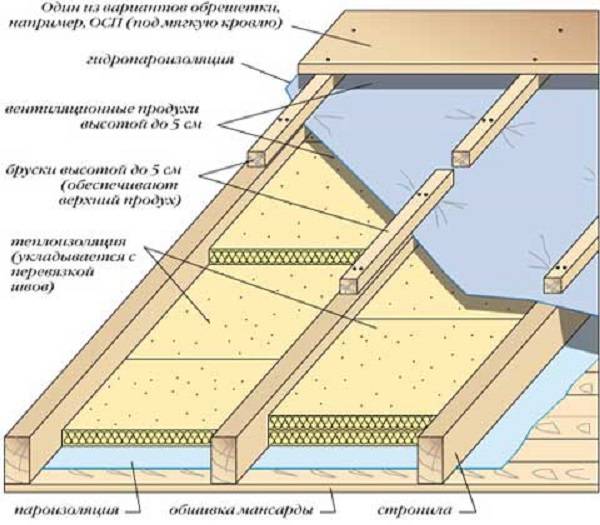

Budget option: interrafter insulation

- Mineral wool is an elastic heat-insulating material, and it is precisely due to this that it is held between the rafters.

- The insulation is pre-cut into slabs 4-5 cm shorter than the height of the rafters. Its thickness is chosen based on the climate of the construction area and the material of the inner lining.

- In the space between the rafters with attic sheathing, it is separated by a layer of vapor barrier. And on top of the roofing "pie" a hydrovapor barrier film is stretched (along the rafters). which is pressed with bars.

- Obtained between these layers: thermal insulation - film and film - roofing, two ventilation gaps must be left open at the ridge and eaves assembly to allow free movement of air. To do this, in particular, the film near the ridge cannot be overlapped onto another slope, on the contrary, it does not reach 5-10 cm to the ridge.

- The waterproofing film can break from temperature changes at the attachment points, so it is fixed to the rafters with a sag - about 2 cm.

- The airflow should be at least 2 cm higher than the sagging film and insulation. However, this insulation technology has a significant drawback - the likelihood of “cold bridges” forming along the rafters.

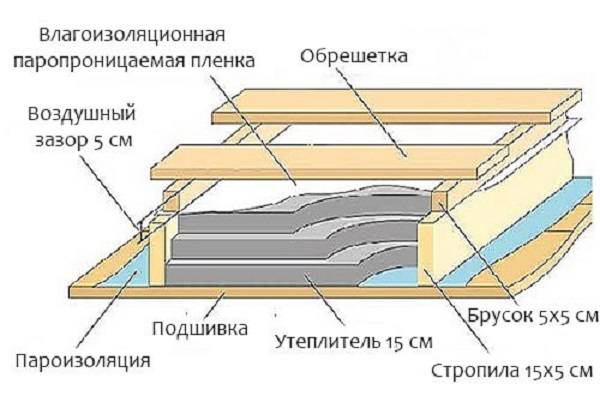

Full attic insulation

- Work begins with the first option, with the only difference being that the inter-rafter space is completely filled with mineral wool, to the very top. Next, wooden bars are sewn across the rafters. Their height should reach the estimated height of the mineral wool.

- A second layer of heat-insulating material is inserted into the resulting frame, and it should cover both the rafters and the joints of the mineral wool of the first layer. That is, in this way all possible "cold bridges" will be removed.

The insulation must completely fill all the space provided for it. It should not leave depressions and cavities - loopholes for the passage of air.

After laying the insulating layer, a superdiffusion membrane is laid directly on top of it, which is pressed with wooden bars. The height of the bars should correspond to the height of the ventilation gap, which should be at least 5 cm. After that, the crate and roof are mounted along the bars of the counter-lattice.

- The super-diffusion membrane is laid along the entire plane of the roof and, unlike the waterproofing membrane, with an overlap through the ridge and without any gaps for ventilation. This method assumes the presence of a single vent, which is located above the superdiffusion membrane.

- The second layer of insulation is laid from the inside of the room using the same technology as on top of the rafters. Across the rafters, bars of counter-lattices are sewn and mineral wool is laid between them. Next is the vapor barrier: depending on its type, they either shoot it with brackets to the rafters, or press it with wooden blocks.

If a foil vapor barrier is used, then it must be installed with foil inside the room. The reflective layer will only work if there is a gap of 2 cm, otherwise the thermal infrared rays will not be reflected from the foil.

Attic sheathing, of course, depending on the type, is attached either directly to the transverse or to additional bars that hold the vapor barrier.

2017

Mansard roof insulation: how to do it correctly Roof insulation device: what and how to insulate Roof insulation from metal tiles: we make a reliable roofing cake

Why insulate?

A good, warm attic has a number of advantages over an uninsulated floor:

- Can be used as a living space all year round.

- An uninteresting shape is suitable for interior decoration in an unusual style.

- The upper floor, due to its isolation and unusualness, can serve as a bedroom, study or children's room. Especially in the attic like, of course, children.

- Skylights are arranged differently than usual and let in a lot of light. This is useful if a children's room is located there, and is also suitable for other purposes, because natural lighting is always better than artificial.

- When transferring the function of any room in the house to the attic floor, a lot of usable space is freed up.

At the same time, attic insulation, despite the name, works in the opposite direction. Summer stuffiness and heat, concentrated under the roof of the house, are not the best companions of comfort. So that the air in the space of the attic floor does not heat up because the sun heats the roof all day, thermal insulation is needed.

Many people forget about this, choosing to insulate the attic from the inside, and instead of a room for all-season use, they get an option for wintering. In summer it is impossible to be there because of high temperatures and stuffy air.

Why insulate the attic is understandable: to increase the useful area of \u200b\u200bthe house by turning the attic into a living space. What specific type this room will be depends on the individual needs of the family. It can accommodate a greenhouse, a dining room (which is very convenient, since it will be easier to arrange an exhaust hood, and the smells of food will definitely not penetrate into other rooms), a children's room, a bedroom, an office, a pet room, a dressing room, a guest room.

Preparatory work - where to start

Before starting the arrangement of thermal insulation, it is necessary to properly prepare the attic: clean, take out things and objects, close up all holes and cracks, seal the butt sections of the window opening, etc. Small cracks and holes on the floor and in the walls should be covered with putty; larger defects can be first filled with foam particles, and then sealed with cement mortar.

In addition, it is necessary to process all wood structures with an antiseptic and fire retardant. The preparatory work also includes priming the walls, checking the quality of the roofing and the safety of its waterproofing properties.

After all the preparatory work is completed, you can proceed directly to the insulation of the attic.

The device for steam and moisture insulation of the attic during insulation.

In front of the mineral wool from the inside of the room, after laying the heat-insulating layer, a vapor barrier is performed to protect against vapors, condensate and moisture that appear due to moist warm air coming from the room.

All vapor barrier overlaps must be glued to each other and to the gables to prevent moisture from penetrating into the insulation layer.

From the outside, the insulation is covered with a waterproofing layer to protect the insulation from moisture penetration, for example, with thick polyethylene, about 5 mm thick, a diffuser membrane or vapor barrier. Also, do not forget about overlaps.

The insulation to the rafters is fastened with wooden slats, a counter-lattice.

Do not forget about the ventilation space between the underside of the roof and the top side of the insulation layer, that is, between the heat insulator and the roofing. This is necessary to create natural ventilation, in order to avoid the appearance of condensate and to remove flows of warm, moist air, which inevitably occurs during the operation of the attic and will penetrate through the thermal insulation.

The ventilation space must be made at least 5 cm, for this a counter-lattice is made.

It should not be forgotten that warm air is lighter than cold air and because of this, the air under the ceiling is always warmer by 2 degrees, unlike the rest of the room.

Therefore, with the internal insulation of the attic with mineral wool with your own hands, you should pay special attention to the insulation of the roof, because the main heat loss will occur through the ceiling

At the end of the insulation of the mansard roof with mineral wool from the inside, depending on the type of roof chosen and the internal design, between the posts, if side vertical walls are expected with a gable roof, an internal crate is made, into which another layer of insulation will also be placed and to which plywood will be attached or finishing material (drywall, lining, etc.). If the roof is broken, that is, mansard, then the racks will already be installed during the construction of the mansard roof.

How to sheathe the walls with drywall, you can read in the article Installing drywall on the walls with your own hands. If your choice is on a clapboard, then I suggest you read the article Cladding walls with a clapboard with your own hands.

But not only the roof and walls are subject to insulation, but also gables built from any materials.To avoid the accumulation of moisture in the heat-insulating layer between the base and the insulation, it is necessary to make a ventilation gap of 2-5 cm, covering it with a waterproof material from the outside, for example, polyethylene and vapor barrier from the inside. Polyethylene should be laid with an overlap, gluing the joints with adhesive tape.

The attic floor also requires thermal insulation. To do this, you can fill it with expanded clay or lay mineral wool slabs between the beams and lay thick plywood. And on top of it is the finish coat. To choose a floor covering, I suggest that you familiarize yourself with the section Floor Finishing Options.

Now you can not be afraid that drafts will make their way through invisible cracks.

Soundproofing will also be created.

After taking measures to insulate the attic from the inside with mineral wool with your own hands, you can proceed to the Interior decoration

And in the end, I would like to add that you do not need to try to save money on warming the attic with mineral wool from the inside with your own hands. This can lead to a significant reduction in the life of the entire roof structure and, in addition, to an increase in energy costs for heating.

Watch the video: How to insulate the attic with mineral wool from the inside with your own hands from Rokwool

Source - Build your own house.

What is the best material to use

Now there are a lot of high-quality heat-insulating materials on the building materials market. The most popular are mineral wool and fiberglass. It is they who are most often used when the walls of the attic are insulated from the inside with their own hands.

Fiberglass is the cheapest material.Its main advantages are its incombustibility, the absence of harmful substances and organic components in its composition. If the fiberglass material adheres perfectly to the base of the roof, then it will perfectly retain heat. However, only those structures that are assembled in compliance with all technologies will have this property, since any material has its pros and cons.

However, attic insulation with mineral wool is accompanied by its drawbacks. Firstly, it is that it has a large amount of fine dust, which consists of fragments of fiberglass. And this is a health hazard, especially for the eyes. But for the skin, their hit will not be pleasant, if it hits, the skin will begin to itch a lot, and the abrasions will not heal for a long time. When fiberglass is suspended in the air in a room, it is a breathing hazard. When the attic is insulated from the inside with mineral wool with your own hands, a prerequisite is the use of a respirator or mask. Another disadvantage is that glass wool will not fit well on the walls at an angle. If at the beginning the material will fit snugly enough to the wall surface, then over time it will begin to lag behind and create voids

A snug fit to the wall surface will be important for any material. Therefore, be sure to look at how to align the walls

But it will be better to insulate the floor with wool from basalt mineral fibers than just glass wool. Natural components are successfully combined with synthetic ones, and as a result, an almost perfect ratio is obtained. This material has such advantages as lightness and the absence of harmful effects on human health.Therefore, for the insulation of a mansard roof, this heat insulator will be preferable to glass wool. In addition, mineral wool is excellent for soundproofing plasterboard structures. This is due to the fact that mineral wool retains noise much better than glass wool. Mineral wool is usually produced in the form of square slabs, or it can also be rolled up. Such canvases will perfectly insulate horizontal surfaces, and the plates will fit on vertical or inclined surfaces.

For an experienced builder, warming the attic from the inside with your own hands will not be a problem. The professional will say right away what is the best way to use cotton wool from basalt fibers. Despite the fact that it will be more expensive when buying, it will be much more reliable and safer. That is why it often happens to overpay a little, but choose the best option.

Proper completion of work

The insulation is installed, but the process should also be completed correctly. It must be protected from damp vapors from the room. To do this, a vapor barrier film is mounted. Moreover, the overall result strongly depends on the thoroughness of the implementation. Although each package is provided with instructions, we will briefly repeat:

- The subsequent canvas overlaps the previous one by at least 15 cm.

- Joints are glued with special adhesive tape.

However, the attic vapor barrier has a dual purpose. Oddly enough, but it also protects the residents themselves. The fact is that vapor-permeable heaters are not strong enough and are amenable to slight weathering.

Outside, this is not so important, plus it is protected by a roofing membrane. And inside it is necessary to exclude even the minimal possibility of releasing the components of the insulation into the air - securely cover it

The final stage is the sheathing of the insulation with canvases, on which the finish subsequently falls.

Of course, this does not apply to penoplex. But it is also recommended to protect yourself from it, the effective material is penofol.

As for heaters of any type. In addition to the vapor barrier device, it is often used, at first glance, an unnecessary, but effective technique. Before finishing, an intermediate, seemingly superfluous material is mounted. It can be OSB, GVL or GKL - it depends on the design. Moreover, the technology is fully observed - all joints are carefully sealed. This is an additional barrier against the undesirable effects of materials.

About warming the attic from the inside in the video:

Results

It turns out that roof insulation from the inside if the roof is already covered is quite possible to do with high quality. Moreover, not only having planned everything in advance, but also on a roof that was ready for a long time, completely unsuitable for this. Now, knowing the intricacies of the process, it is much easier to choose a good performer for such a responsible task.

About ways of warming

Regardless of how warm the walls in the attic are, the floor also needs to be insulated. Especially - if the room is used as a playroom or bedroom. Remember that this is how you also insulate the ceiling of the lower floor.

While insulating the attic, remember some important points.

Table. Important conditions for the process of warming.

Name

Short description

Ease

The insulation should not weigh a lot, otherwise an additional load on the floor will be created.

Quality

It is important that the insulation used has excellent thermal insulation properties.

All participants of our rating meet these requirements.However, it is not easy to answer which one should be used to insulate the attic roof. Here it is necessary to take into account the size of the room, the type and features of the roof structure, the characteristics of the roof, etc. In addition, the financial capabilities of the owner of the house are also important.

Video - Test for heat retention of heaters

What insulation material do you prefer? What can you say about this? Write a comment - share your opinion with site visitors!

Voting for the best insulation for the attic roof

What insulation for the attic roof would you choose or advise?

glass wool

2.43% ( 7 )

Save the voting results so you don't forget!

You must vote to see the results

General technology for reducing heat loss

If the building is covered with a roof, the attic room is insulated from the inside.

External wall insulation is used to save usable superstructure space. Styrofoam or liquid polyurethane foam is more suitable for this. After completion of the work, the wall is plastered or sheathed with wood boards (chipboard, OSB, etc.).

When insulating the attic space, the lag of the truss structure is provided with a sufficient height. It is selected based on the thickness of the material. If the existing height is not enough, wooden slats are stuffed onto the rafters from the underside. Also, after waterproofing, a ventilation gap of 2-5 cm is provided.

Under its own weight, cotton wool can move out, sag, so it is fixed.

To provide vapor barrier, special films are used. The insulation is laid with an overlap, attached to the rafters with a stapler. After that, they make a fine finish with drywall or clapboard.

Conclusions and useful video on the topic

An example of attic insulation with mineral wool:

Thermal wool blowing technology:

Universal material - stone wool. Full review from the manufacturer TechnoNIKOL:

When choosing a heater, do not forget that the attic is a living space that should not only be warm, but also safe. If possible, purchase materials that comply with sanitary standards, with an appropriate flammability class and the absence of toxins in the composition.

And the best characteristics of thermal conductivity, stability and hygroscopicity are a guarantee of comfortable use of the premises for a long time.