- Attic ceiling insulation

- Features of the use of other materials

- Materials for hydro and vapor barrier

- External waterproofing

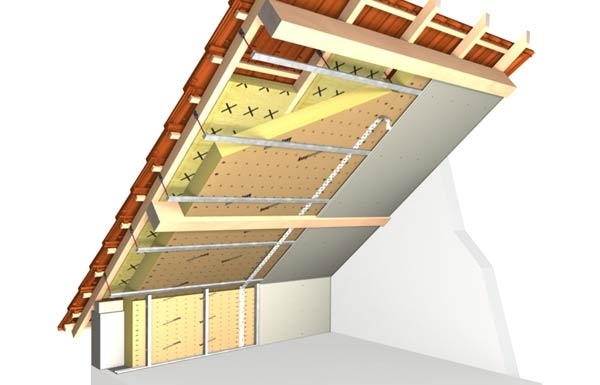

- Insulation between rafters

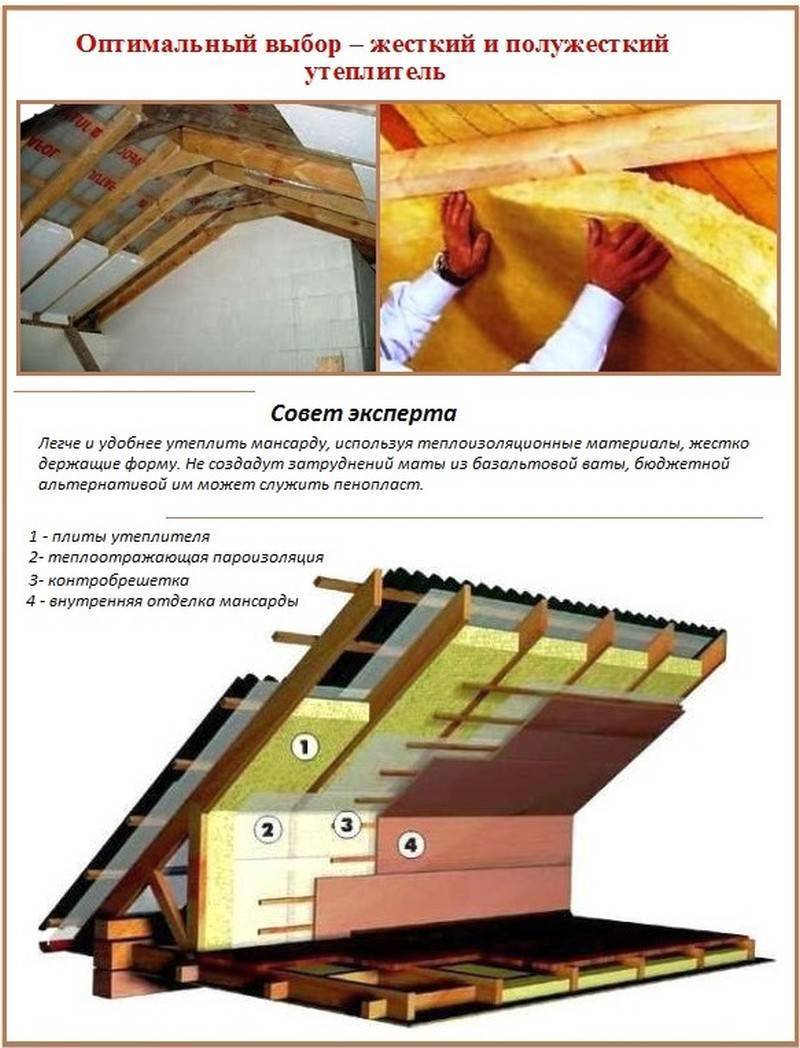

- The choice of the type of insulation

- General technology for reducing heat loss

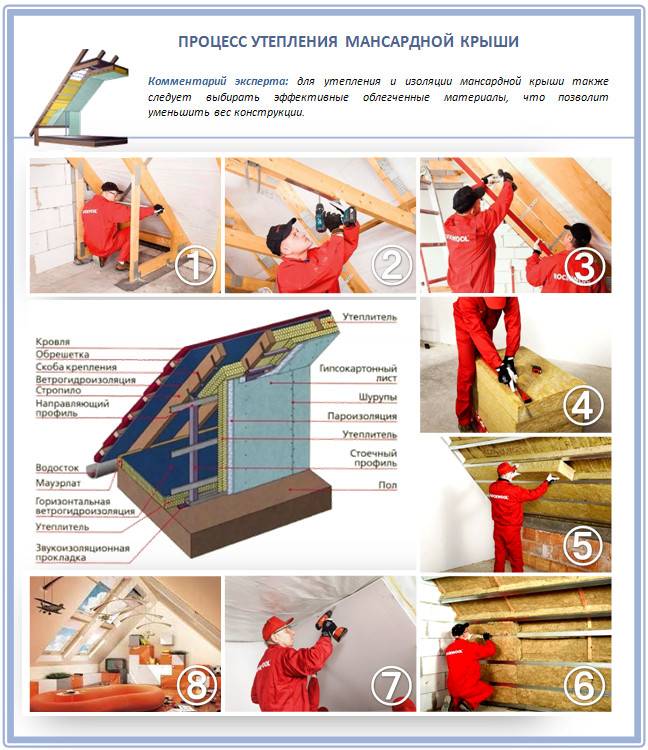

- Step-by-step instructions for warming the attic from the inside

- Floor insulation methods

- What vapor barrier to choose for the attic

- Do-it-yourself attic insulation rules

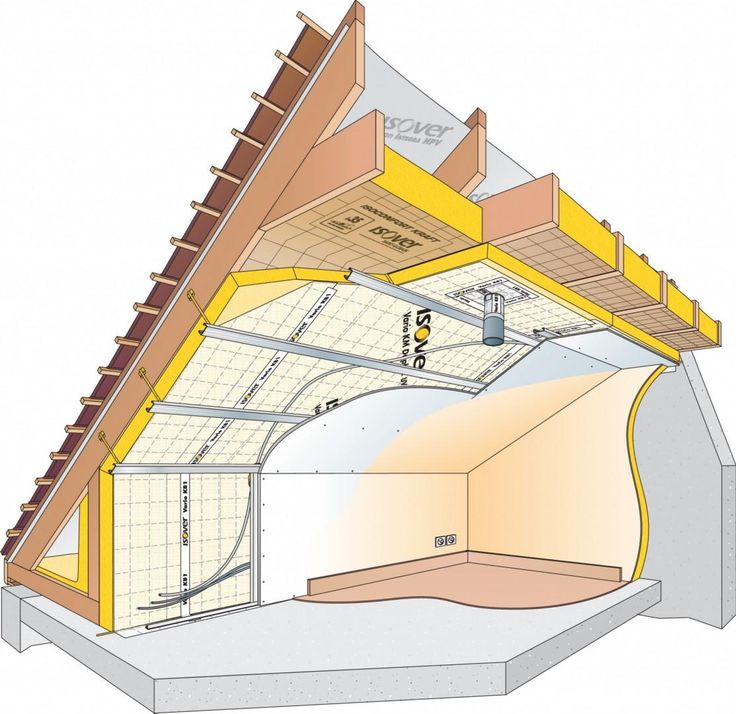

- How to properly insulate the attic from the inside

- Waterproofing

- vapor barrier

- thermal insulation

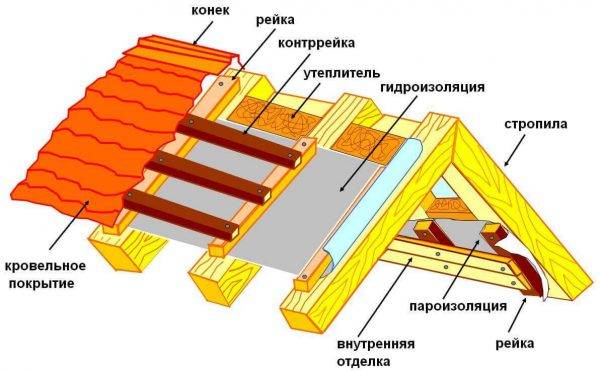

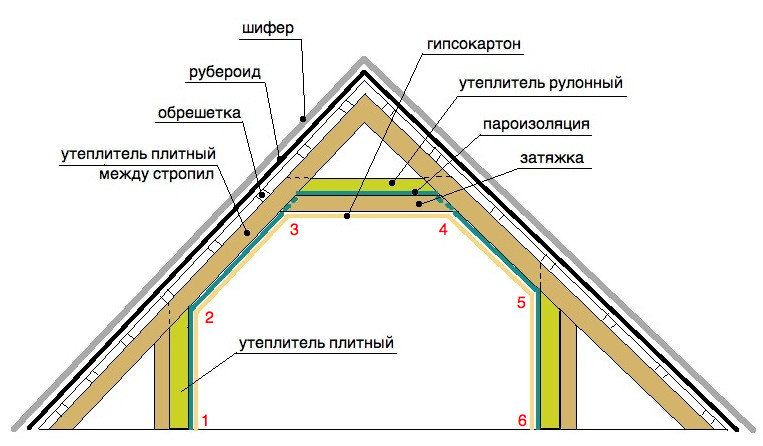

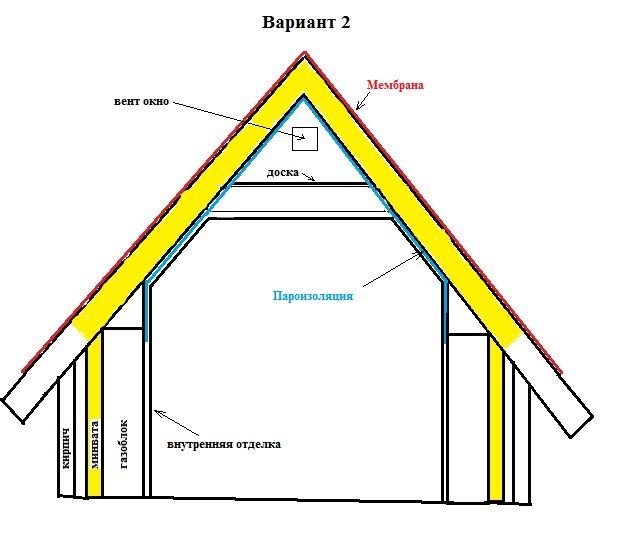

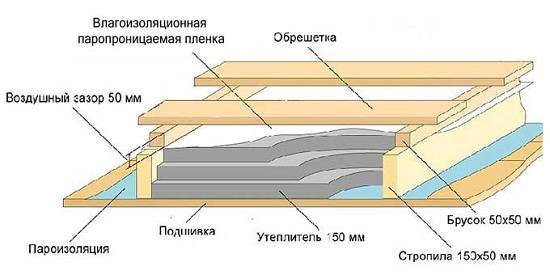

- mansard pie

- The procedure for working with foam

- Insulation "pie" for thermal insulation of the attic

- A little about choosing tools

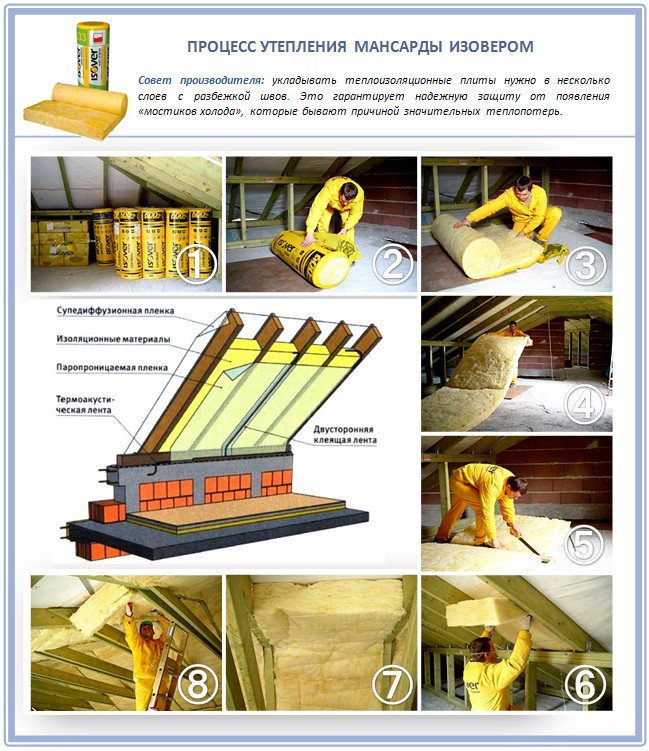

- Mineral wool: definition and manufacturing technology

- How to install insulation for a mansard roof with your own hands

- What materials are included in the insulation system?

Attic ceiling insulation

Insulation in the attic of the ceiling, mounted additionally, should be a single whole with the thermal insulation of the walls. Then the heat loss at the points of contact of the roof bevels with the ceiling is significantly reduced (read: “How insulate mansard roofwhich material to choose).

When using ecowool, a crate is specially mounted on a hemmed ceiling, which is covered with a vapor barrier film (for more details: “How to hem the roof with your own hands”).If polyurethane foam is used, then it is applied to the mounted roof from the inside, and the hemmed ceiling, if necessary, is insulated with mineral wool or glass wool (read: "Insulation of the roof with mineral wool, methods of laying insulation").

Features of the use of other materials

Extruded polystyrene foam is a good but more expensive replacement for styrofoam. It is available in slab form. You can purchase elements with a stepped end, which will provide an exceptionally tight connection.

Plates of extruded polystyrene foam are not placed between the rafters, but are mounted on top of them. The material is fixed using various adhesives or self-tapping screws with an enlarged telescopic cap.

Simple installation helps to reduce the time of work, but you should be aware of the flammability of polystyrene foam when installing electrical wiring.

Ecowool is an environmentally friendly heat insulator with decent characteristics. It is made of paper, which brings the quality of this material closer to natural wood.

Ecowool is an environmentally friendly heat insulator with decent characteristics. It is made of paper, which brings the quality of this material closer to natural wood.

Glass wool in terms of installation technology is similar to mineral wool insulation. But working with such a material is more difficult, since protective clothing will be needed to keep the skin from the irritating effect of the glass fiber. You will also need a protective face mask, contact of glass wool with mucous membranes is undesirable.

Ecowool is an interesting option for warming. It is a safe and effective material that is applied to the space between the rafters. But the work will be quite expensive.

Foamed polyurethane foam provides exceptionally reliable insulation. It is applied in a continuous layer without seams.But it is difficult to carry out such work on your own, since this requires equipment and trained personnel.

Materials for hydro and vapor barrier

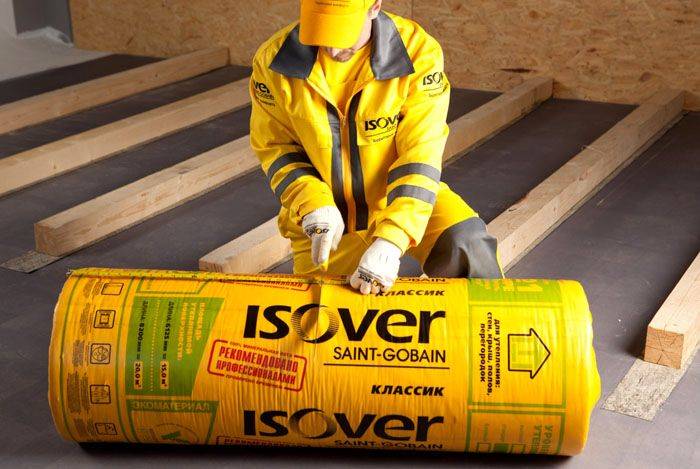

For attic roof insulation from the inside, mineral wool is mainly used with their own hands, which tends to accumulate moisture. If you do not protect the material with films for vapor and waterproofing, it will quickly get wet and cease to perform its functions.

To isolate the material for insulation use:

- Izospan is a two-layer membrane for vapor barrier, the rough surface of which allows condensate to be retained.

- Polyethylene - a film that performs a waterproofing function, but does not let steam through - is the cheapest of the materials.

- Waterproofing membrane. Quite often you can find roofing membranes that serve as waterproofing and are vapor-permeable at the same time.

- Penofol. Insulating material with a foil waterproofing layer.

External waterproofing

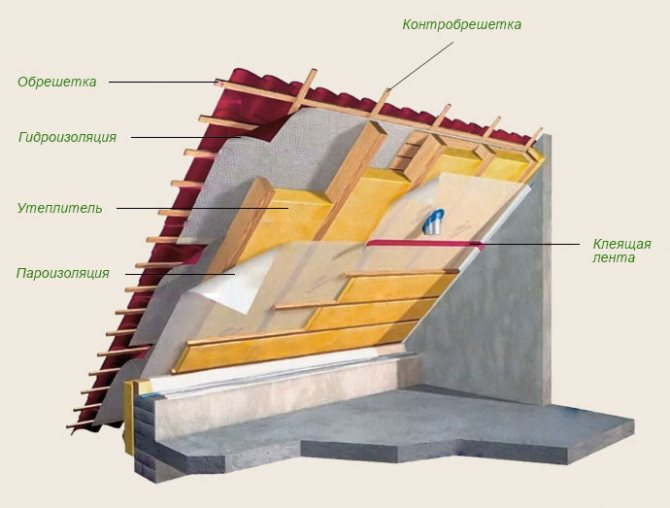

When a vapor barrier is laid on the warm inner surface of the insulation, which prevents the penetration of moist air from the room, then it is necessary to fix the waterproofing material on the colder outer surface, which will protect the thermal insulation under the roofing pie from possible leaks.

If an inexpensive waterproofing agent is purchased, then the moisture that has entered the thermal insulation will evaporate for a long time and with difficulty, as a result of which dampness will soon destroy the insulation. An excellent solution is to purchase a modern vapor-permeable membrane with a well-thought-out structure that does not let moisture in, and brings water vapor out.

When installing a diffuse material, it must be positioned as tightly as possible to the insulation without the slightest gap.Otherwise, the membrane will cool more strongly, and its temperature will become lower than that of the steam migrating through the heat insulator. As a result, ice will appear on the surface of the vapor barrier, and the membrane will lose its vapor-tight qualities.

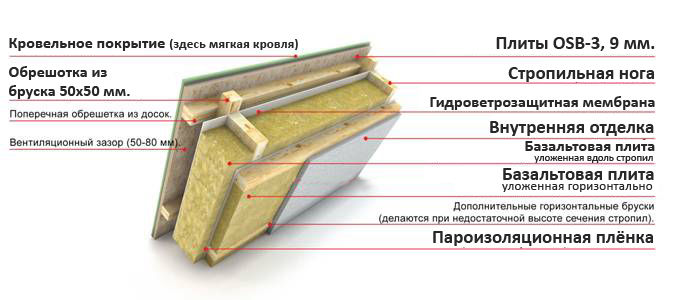

Insulation between rafters

The traditional way to insulate a sloping roof is to place the insulation between the rafters. In this case, you can arrange a flat ceiling of the attic room.

Before starting the insulation, you need to mount a waterproof film over the rafters. It will protect the room from possible precipitation and will allow you to work in any weather. It is better to choose a diffusion membrane. When installing a micro-perforated or anti-condensation coating, a two-sided gap is arranged. Condensation often forms on films. His hit on the heater:

- increase the coefficient of thermal conductivity;

- lead to damage to the insulation;

- contributes to the development of mold;

- reduce the bearing capacity of roofing elements.

The insulation is not laid to the full height of the rafter leg. A gap of 2-3 cm is enough to ensure the flow of air and natural drying.

With this technology, low-density insulation is often used. For proper operation, such heaters need to be additionally fixed, which leads to an overrun of the frame material.

Often soft insulation shrink during operation. Deformations occur both in width and in height. As a result, some areas are exposed, becoming defenseless against the cold.

It is not recommended to use insulation in the form of dense materials: polystyrene foam, polyurethane foam. Due to the instability of dimensions, gaps form between the rafters and the slabs. The use of mounting foam does not save the situation.Blowouts are formed.

Mineral wool thermal insulation Stone (basalt) wool Glass wool

Mineral wool of a slab type is best suited for insulation inside the rafters. When laying, the joints of the plates are shifted by half the width of the product. In this case, the appearance of cold bridges is prevented.

The dressing of the seams is also important with multi-layer styling. The next product should overlap the seams of the previous flooring. For multi-layer laying, products of maximum thickness are used. For example, for insulation with a layer of 150 mm, it is better to take a material of 100 and 50 mm than three plates of 50 mm each.

With a slope angle of less than 30 °, an additional frame is arranged under the insulation. It will prevent the plates from slipping and caking. The frame holds the boards in their mounting position during their entire service life.

The accepted width of the slabs should be 1-1.5 cm more than the clear distance between the rafters. In this case, a tight fit will be ensured. With a smaller width, gaps will occur due to defects in the wood or oversight of the builders. Large thickness contributes to the deformation of the plate and its bending.

Inside the insulation of pitched roofs on wooden rafters, there should be no air gaps and cracks. Layers should adjoin each other tightly. This also applies to interlayer spaces and joints. Professionals lay the plates, cutting them into two trapezoidal parts.

Polyurethane foam (PPU)

Another innovative way of insulation is polyurethane foam. It is possible to arrange the coating both after the waterproofing device and after the installation of the roofing.

The application process is sputtering. The work is carried out using special equipment.Mandatory protection for the employee in the form of:

- suit;

- masks;

- respirator.

Foam is applied both in the gap between the rafters and on the supporting elements of the roof. They must first be treated with antiseptics or an anti-corrosion solution. Foam:

- clogs the smallest purges and cracks;

- hides holes from bolts;

- covers all metal elements, protecting them from corrosion.

The continuous layer excludes penetration of drafts and moisture. Low thermal conductivity reduces the cost of heating the under-roof space.

Ecowool is the second innovative solid coating material. The name itself speaks of environmental friendliness and safety of use.

Ecowool

The composition includes flame retardants and antiseptics. The former prevent the layer from igniting, the latter from the spread of fungi and mold inside. The bulk of the composition is waste paper and cardboard production waste.

Laying is done in a dry and wet way. When dry laying, the rafters are sewn up from the inside with facing material. Material is placed in the formed boxes. In the wet method, wet cotton wool is applied to the surface under pressure. High adhesion of the material allows you to cover the surface with a dense uniform layer.

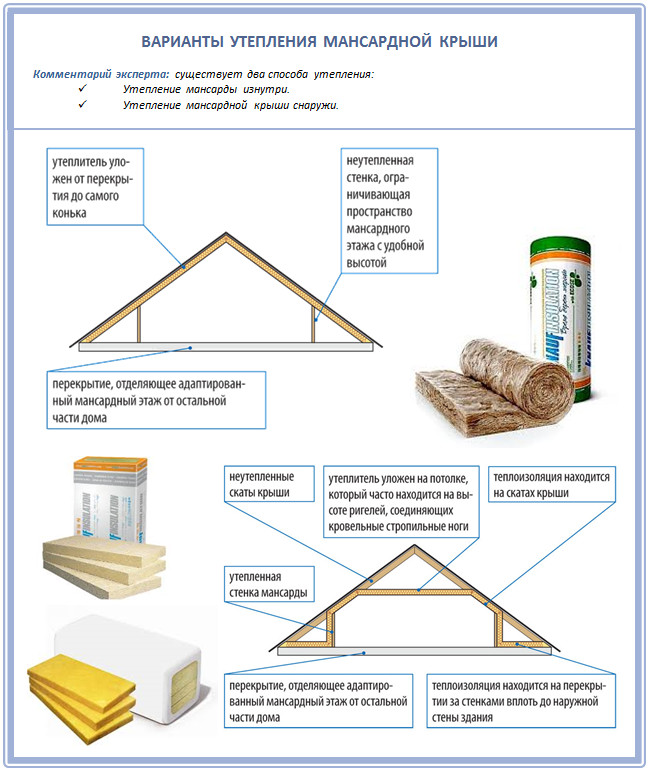

The choice of the type of insulation

Modern industry offers three types of heat-insulating materials: slab, roll, shapeless (foam). We do not consider bulk insulation in this case, since the insulation of inclined and vertical surfaces with bulk materials is extremely inconvenient.

The material for attic insulation should be chosen in accordance with the design and necessary parameters of the heat-insulating layer, namely density, thermal conductivity and vapor permeability.

Density affects the weight of the material - it is undesirable to make the truss structure too heavy, especially if it was originally calculated "back to back", without a margin of safety. Insufficient thermal conductivity will significantly increase heating costs, and poor vapor permeability will lead to increased humidity in the room.

Accordingly, the best choice for the attic would be:

-

when sheathing with plasterboard or other similar materials - mineral wool. Slabs or pieces of roll (depending on density) are laid in the gaps between the rafters. The spacer beams remain in sight, the inclined elements of the attic are sewn up with sheet material;

-

polystyrene foam, plain or extruded, as well as polystyrene foam - for plastering or plasterboard finishing, in the event that the finish is not afraid of high humidity;

-

polyurethane foam for complex roof geometry and in the presence of additional elements that make it difficult to insulate with plates or a roll.

If, in addition to the walls and ceiling of the attic, it is also necessary to insulate the floor (in fact, the overlap between the first and attic floors), it is permissible to use any of the listed heat-insulating materials, as well as bulk insulation. More on this later.

General technology for reducing heat loss

If the building is covered with a roof, the attic room is insulated from the inside.

External wall insulation is used to save usable superstructure space. Styrofoam or liquid polyurethane foam is more suitable for this. After completion of the work, the wall is plastered or sheathed with wood boards (chipboard, OSB, etc.).

When insulating the attic space, the lag of the truss structure is provided with a sufficient height. It is selected based on the thickness of the material.If the existing height is not enough, wooden slats are stuffed onto the rafters from the underside. Also, after waterproofing, a ventilation gap of 2-5 cm is provided.

Under its own weight, cotton wool can move out, sag, so it is fixed.

To provide vapor barrier, special films are used. The insulation is laid with an overlap, attached to the rafters with a stapler. After that, they make a fine finish with drywall or clapboard.

Step-by-step instructions for warming the attic from the inside

Consider how you can insulate the attic using only your own hands, without involving expensive construction teams for this. We will insulate the attic room with mineral wool, the amount of which we carefully calculate in advance. First, we prepare all the materials and tools necessary for work (do not forget about protective gloves, a suit and a face mask, since cotton wool gives a lot of dust during installation). We will need:

Types of fixing insulation.

- mineral wool;

- a hammer to align individual sheets from the inside;

- mallet, chisel and chisel;

- wooden counter rails, nails and wood screws;

- to work with wooden elements, you need to take a plane, an ax, a sherhebel;

- waterproofing membrane, vapor barrier.

Insulation with mineral wool will be carried out between the roof rafters, but before starting work, it is necessary to provide waterproofing of the roof. First, we lay the waterproofing film, starting from the bottom edge of the roof. This should be done with an overlap, we fasten the edges with adhesive tape. At the walls, the film should have a small margin, all excess is cut off after the end of the insulation.After that, we nail the counter-rails to the rafters, which allows not only to ensure that the film adheres to the roofing material, but also makes a ventilation gap. Now we lay the insulation from the inside in such a way that it fits snugly against the rafters, leaving no gaps.

Floor insulation methods

The floor of the attic is the ceiling of the lower floor. Its insulation has, rather, a noise-insulating function than a heat-insulating one. Depending on the material from which the ceiling is made, the method of insulation is also selected.

If the floor is wooden and there are beams on it, then the space between them is filled with insulation, after taking care of the vapor barrier layer.

Boards or OSB boards are laid on top of the beams. As a heater, mineral wool or polystyrene is perfect.

If the floor is a reinforced concrete slab, then a cement screed device will be required:

- the surface of the plate must be cleaned of dust and all cracks must be sealed;

- a vapor barrier material is laid, and a heater on top;

- a cement screed reinforced with mesh or reinforcement is poured over the thermal insulation;

- after the cement has completely dried, a decorative coating is applied.

Expanded clay floor insulation is very common. This is a bulk material with excellent heat and sound insulation properties and at the same time has a low cost compared to other heaters.

Expanded clay is suitable both for warming wooden floors (it is poured between beams) and for cement screed, but since it is a porous material that absorbs moisture, it is necessary to take care of high-quality vapor and waterproofing.

I think this should be rounded off, the material turned out to be quite voluminous anyway.And even in such a volume it is impossible to fit all the nuances, so be sure to ask questions - I will be happy to share my experience.

What vapor barrier to choose for the attic

As a vapor barrier, modern developers use various materials:

- Polyethylene film. The material is laid in the process of creating the roof. A prerequisite for installation is the creation of ventilation gaps that prevent the formation of condensate. Evaporation of vapor particles occurs when laying with the rough side out.

- Polypropylene films. The material has high strength. When choosing a vapor barrier of this type, it is worthwhile to additionally lay a layer of cellulose or viscose on the upper side of the layer. This is necessary to absorb drops of condensate.

- reflective membranes. For such insulation, it is not necessary to create ventilation gaps - due to the special structure, the material allows air to pass through and retains moisture. The membrane has high reliability and quality.

The method of fixing the vapor barrier layer depends on the type of surface. To bricks, concrete or foam blocks, the material is attached to a double-sided tape. On wooden surfaces, the membrane is fixed with a stapler or nails.

It is important to lay the vapor barrier with the smooth side into the room.

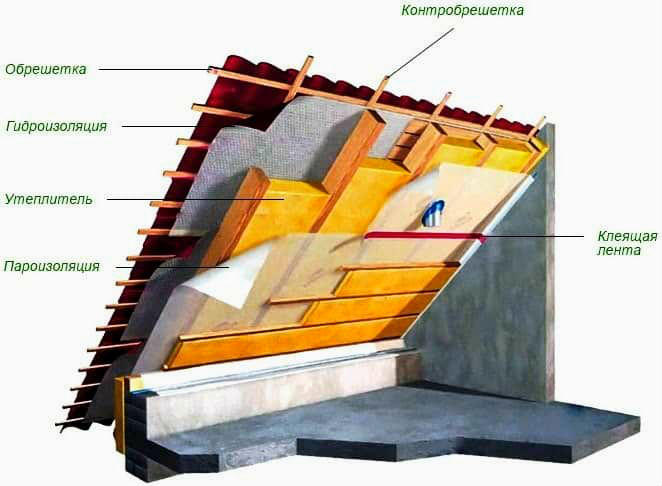

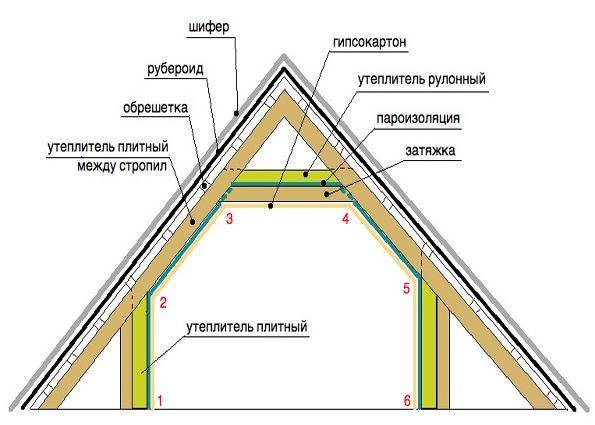

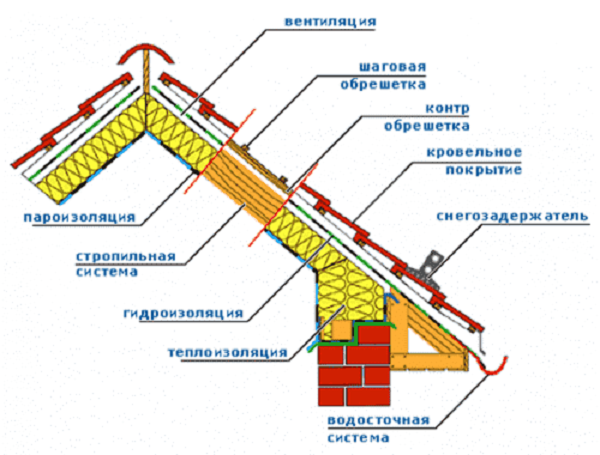

Do-it-yourself attic insulation rules

• Before proceeding with the insulation, it is necessary to determine the suitability of the attic for living space. The height and design of the rafters of some roofs allows the operation of the area only for household needs. According to building codes, the height from the ceiling to the ridge should be 2.5 m or more, and the vertical height of the racks should be 1.5 m.If the parameters are lower, the room cannot be called an attic. A semi-attic is considered to be an under-roof space with a height of vertical racks of 50-70 cm or in their complete absence.

• An important aspect is the construction of a roofing pie. Further work depends on the contents of its layers. The correct sequence for roof decking includes:

- roofing;

- crate;

- bars located along the rafters;

- superdiffusion membrane (or waterproofing);

- counter crate, vapor barrier material.

• The roof structure is made mainly of wooden elements

It is important to treat the wood with an antiseptic and flame retardant before sheathing. The antiseptic solution has an antimicrobial effect, protects the material from microbiological processes and insect damage. A flame retardant reduces flammability

A flame retardant reduces flammability.

• The attic is a place of vapor accumulation, so it is better to opt for a heater with good vapor permeability.

• Finishing the attic should include new wiring and ventilation systems.

• Dormer windows can be cut into the roof to create good natural light. Some designs of such windows can increase the space.

How to properly insulate the attic from the inside

In the photo, the insulated attic:

If the roof is already covered, the attic can be insulated from the inside at any time of the year and day. The disadvantage is the presence of hard-to-reach places that must be processed.

Waterproofing

The roof must be protected from moisture: atmospheric influence, condensate, steam, evaporation.Waterproofing must be of high quality - the life of the entire roof depends on it.

The material should be laid directly under the outer layer of the roof covering, leaving a gap between them for air circulation.

Waterproofing must meet two requirements: prevent moisture from getting inside the building and serve for a long time.

Ordinary polyethylene film is not suitable - it contributes to the appearance of condensate and is not durable. It is better to use perforated film or "breathing" membranes. Rolls should be overlapped and glued together.

vapor barrier

There is warm damp steam in the living room. To prevent it from penetrating into the insulation layer, a vapor barrier material is used. It isolates cold and warm air from each other. If you do not use a vapor barrier, then the condensate will wet everything and it will lose its insulating properties.

A vapor barrier cloth is applied to the material from the side of a residential warm room

It is important to combine it into a single whole

thermal insulation

When insulating the attic from the inside, thermal insulation is necessary to retain heat in the room. It depends on the thermal conductivity of the material used. The lower the thermal conductivity, the better the material retains heat. The thermal conductivity depends on the density and the presence of air bubbles.

To achieve the goal (preservation of heat), the thickness of the layer should be maintained. The greater the thermal conductivity, the larger the layer required.

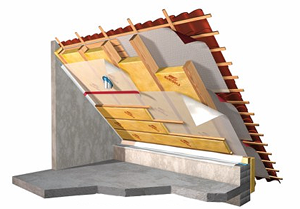

mansard pie

Before proceeding with roof insulation work, it is worth understanding the structure and thickness of such a structure. Otherwise, it is called "mansard pie."

Considering all the nuances of such a structure, the requirements that apply to the insulating layer are special.

This is explained by the fact that, according to the construction of the structure, the walls are represented by the slopes of the roof and the gables of the building, in some cases there is a tight fit to the slopes.

This causes the air masses in the room to heat up quickly in the summer and cool down quickly in the winter.

As for the structure of the structure, it is as follows:

- A layer of vapor barrier material;

- insulating layer;

- ventilation gap;

- waterproofing material;

- Roof covering.

More attention is paid to ventilation systems and the heat-insulating layer, it depends on them how convenient and comfortable it will be to be in the room.

The procedure for working with foam

The following series of operations can serve as a description of how to insulate a mansard roof with foam plastic:

- Cut sheets of insulation in accordance with the size of the space between the rafters.

- The foam is put in place and fixed with foam.

- Perform the installation of the second layer of foam.

- All joints are re-treated with mounting foam.

After that, you can start laying communications and finishing the room. Although the scheme looks simpler compared to attic insulation with mineral wool, increased requirements are placed on the quality of work.

The dimensions of the piece of foam should be about 5-10 mm larger than the space between the rafters, so that the insulation fits exactly into the space allotted to it

The dimensions of the piece of foam should be about 5-10 mm larger than the space between the rafters, so that the insulation fits exactly into the space allotted to it

It is very important to use mounting foam correctly. It is blown into the junction of the insulation to the rafters, as well as at the joints between the individual sheets

After application, you need to wait about five minutes, only then press the next element.

If there is already a layer of vapor barrier on the bottom of the roofing cake, you can not press the foam directly against it, you will need a gap of 25 mm

If there is already a layer of vapor barrier on the bottom of the roofing cake, you can not press the foam directly against it, you will need a gap of 25 mm

The foam that comes out after solidification is cut off with a knife. Before laying the next layer of foam, all edges and joints on the already installed insulation are treated with mounting foam.

After waiting for the necessary time, the second layer is simply pressed against the first. Sometimes additional foam is applied to improve the adhesion of the layers.

The foam layers should be as tight as possible, and the joints should not overlap to prevent heat leakage and condensation.

After that, all joints around the piece of foam are re-blown with foam. Good sealing is the main requirement for foam insulation.

The Mauerlat at the junction with the rafters deserves special attention. Here it is recommended to use foam generously to ensure that this moving element is properly sealed.

The foam responds well to seasonal changes in size in the place where the rafters are adjacent to the Mauerlat, while the tightness of the connection is not violated

The foam responds well to seasonal changes in size in the place where the rafters are adjacent to the Mauerlat, while the tightness of the connection is not violated

Styrofoam is easier to work with than with mineral wool. The use of mounting foam allows you to perform all work on the insulation of the mansard roof of a private house much faster. But do not rush to the detriment of quality.

If there is a gap between the layers of insulation, moisture will penetrate there, and this can eventually lead to damage to the truss structure.

Insulation "pie" for thermal insulation of the attic

Only by observing the correct sequence of the insulating "pie" from the inside of the attic roof, you can achieve comfort and coziness in the room at any time of the year.In this case, this design has the following layers:

- finishing layer;

- ventilation with crate;

- vapor barrier layer;

- insulation ball - different types of mineral wool;

- waterproofing layer;

- finishing material used for roofing.

A vapor barrier layer is a mandatory requirement for laying cotton wool insulation. Thanks to this, it is possible to qualitatively protect mineral wool from steam and condensate. In the case of using polyurethane foam, a vapor barrier is not required.

A waterproofing layer is needed in all situations and the high-quality protection of the wooden elements of the roof structure will depend on its use. As a waterproofing, it is advisable to use diffusion-type membranes, which freely let vapors out and do not let moisture into the room.

Be sure to leave an air ventilation gap of at least 50 mm between the layers of the heat insulator and the waterproofing material. Its main purpose is to remove excess moisture from the insulation.

A little about choosing tools

If you ask an experienced roofer what tools are needed to insulate the mansard roof of a private house, he will shrug his shoulders and say: a hammer, a knife, a head and hands. For the most part, this is true, but there are professional secrets that not everyone is willing to share.

The biggest trick is choosing a knife. If you take a simple construction and assembly knife, then throughout the entire process you will suffer, unevenly cutting the insulation. The blade of such a tool is too short, it does not cut through a thick layer of insulating material.In addition, the mounting knife will quickly become dull on mineral wool or foam.

You can get by with an improvised cutting tool (a hacksaw) or use a wide kitchen knife for cutting bread with a serrated sharpening.

The professional cutting tool is a wide, long blade made of carbon steel. Blade length - 35 centimeters, handle made of durable plastic is very comfortable to use

In addition to a good knife, you really need a hammer, as well as self-tapping screws and a screwdriver, a strong cord, protective clothing, a respirator and goggles.

Tips for cutting insulation:

- the room in which you will cut the mineral wool should be well ventilated;

- hands, head and, especially, eyes and respiratory tract must be protected from the penetration of volatile fibers;

- after working with a heater, you need to take a shower, wash your hands and face thoroughly;

- the material must be cut across the fiber - so there will be less flying dust;

- in order not to be mistaken in the size of the pieces, you should carefully measure their locations.

It is better not to unwind the rolled insulation, but to cut it directly in the roll

Mineral wool: definition and manufacturing technology

Among the existing methods of attic insulation from the inside, mineral wool is in the first place, as an economically viable and technically convenient material. Its price is much lower than other heaters, and installation is easy and simple.

Mineral wool is a fiber obtained as a result of the melt of volcanic rocks, glass and blast furnace waste. The insulation, depending on the base, is divided into basalt, slag or glass wool.

To obtain it, the same technology is used:

- Glass, rock melt or blast-furnace slag is loaded into a shaft-type furnace.

- At temperatures above 1500ºС, it is heated to a liquid state. By blowing or centrifugal method, the fibers are obtained directly. They form the structure of the material.

- The fibers are fastened with phenol-formaldehyde resins, followed by polymerization.

- Heat treatment.

- Package.

Mineral wool is hygroscopic, with prolonged contact with water it loses its thermal insulation properties. To prevent moisture ingress, the material is sealed in a plastic film.

How to install insulation for a mansard roof with your own hands

To insulate the roof of the attic, you need to carry out the following work in the following sequence:

- prepare the attic space for the installation of insulation;

- lay a heat-insulating layer;

- fix the material.

Above the level of thermal insulation, between the rafters and the crate, a waterproofing layer should be laid with an overlap, starting from the lower edge of the slope. After that, install counter rails made of wood. Their thickness should create the necessary clearance for ventilation. Reiki can be attached to the rafters with nails or self-tapping screws. To a pre-prepared structure inside between the rafters, you need to lay and fix the insulation.

When insulating the attic, it is not necessary to stop only at installing a heat-insulating layer between the rafters, but it is better to additionally lay a continuous layer of heat-insulating material on top of the laid insulation mats or slabs. For laying out a continuous layer, it is recommended to choose a thin insulation, this will significantly improve the quality of the insulation of your attic.

But this method also has its drawbacks.For example, the rafters are hidden and in the future it will be extremely difficult to use them to fasten other structural elements. It is advisable when working to correctly mark where the rafters are located.

Of course, our advice is not a complete instruction on how to insulate the roof in the attic. Re-read the special manuals, watch the training video, consult with your friends about this, and only then get to work.

We have introduced you to the recommendations regarding the insulation of mansard roofs, and how to choose the right insulation material and install it. Your comfort during your stay in the attic at any time of the year depends on how well you do this.

What materials are included in the insulation system?

Thermal insulation of the attic is made using various materials. The insulation system, which is most often used by specialists, includes three layers. Let's consider them in more detail:

- vapor barrier;

- heat-insulating;

- waterproofing.

The vapor barrier film performs a very important function, namely: it prevents the penetration of water vapor into the room. Without it, unwanted condensation will occur on the inner walls. The waterproofing material is represented by a moisture-proof membrane.

The thermal insulation layer is the main one. There are many materials that can be used for high-quality insulation of the attic. For self-installation, experts recommend choosing the most environmentally friendly of them. According to this indicator, ecowool and mineral wool are in the lead. The second option is more preferable, since the cost of mineral wool is lower.

Note! The structure is best insulated from the outside. This will protect the attic room from freezing, as well as condensation on the walls. In no case should outdoor work be carried out in rainy weather.

Roof inspection should be carried out prior to installation. It is also strongly recommended that you familiarize yourself with the training video material, which reveals the topic of attic thermal insulation in more detail.

Outdoor work should never be carried out in rainy weather. Roof inspection should be carried out prior to installation. It is also strongly recommended that you familiarize yourself with the training video material, which reveals the topic of attic thermal insulation in more detail.