- bottom insulation

- Thermal insulation methods

- How to insulate?

- Warm lid installation

- Sequence of work

- decorative house

- Work order

- Top ring insulation

- Work execution algorithm

- Special insulation and polyurethane foam

- Work procedure

- Foam insulation

- Applied thermal insulation materials

- glass wool

- Basalt insulation

- Styrofoam

- polyurethane foam

- Foamed polyethylene and artificial rubber

- Thermal insulation paint

- How to insulate a well

- Why you need to insulate the well

- Ways to insulate wells

- caissons

- Well ring insulation

- decorative house

- Hanging cover in the well

- Pipeline insulation

- Insulation for water pipes

- Why is freezing water dangerous?

- What if the well is still frozen?

- Method one. Cover insulation

- Laying pipes below freezing depth

- Causes of freezing wells

- Cover insulation

- Materials for processing

- Warming methods

- Cover insulation

- Insulation of the walls of the well

- External insulation

bottom insulation

During construction, a special plate with a protrusion is placed at the bottom of the concrete well, which guarantees the exact centering of the lower ring. The resulting joint is carefully sealed. This is done in several ways:

- In the place where the well will stand, before installing the first ring, a special waterproofing cord is placed, which, when the humidity rises, swells several times, thereby isolating the bottom of the well.

- Roll waterproofing is also effective here. The bottom of the well is thoroughly cleaned of dirt and debris, laid with bituminous mortar, covered with roofing material with a 20-centimeter overhang on the walls. To protect the bottom of the well for sure, the roofing material is placed in several layers. Additionally, it is recommended to smear the top layer of roofing material with mastic, pour a 10-centimeter ball of gravel on top.

- In drinking pools, the seams between the bottom and the first ring are sealed with MEGACRET-40 repair mortar. When the first layer is applied, a waterproofing tape should be glued on it. At the end, the joint in two layers is treated with AQUAMAT-ELASTIC.

Thermal insulation methods

How to insulate a well for the winter? There are several effective methods of thermal insulation of well shafts that help prevent freezing of water in it. The main ones include:

- Insulation of the head (base). In this case, the part of the well shaft, which is above the soil level, is insulated with wood. It prevents the flow of cold masses into the source, which prevents the decrease in water temperature;

- Insulation of the walls of the well shaft. This method of thermal insulation is more laborious than the previous one, since a trench is dug around the well shaft. The depth is chosen according to the level of soil freezing. After that, the outer walls of the structure are insulated with materials with low thermal conductivity;

- Cover insulation. Wells in the country often remain completely without covers or hatches.The construction of a heat-insulating cover in this situation will help to avoid freezing of water in the source.

How to insulate?

There are quite a few options for warming, each of which will be able to perform independently with due care. But the most popular ways of warming are only five.

Warm lid installation

This method is good not only for its high-quality thermal insulation, but also for the ability to protect the well shaft from accidental ingress of debris (for example, fallen tree leaves in autumn).

You will need:

- plywood sheet;

- polystyrene (5 cm thick);

- glue;

- mounting foam;

- a piece of plastic pipe for arranging ventilation (it is necessary to prevent the appearance of an unpleasant odor in the water).

Sequence of work

- Two circles are cut out of plywood, equal in diameter to the well rings (together with the walls).

- A foam circle is glued between the plywood circles.

- For ventilation, a hole with a diameter of no more than 6 centimeters is drilled, into which a prepared piece of plastic pipe is inserted. The tightness of the pipe fitting is ensured with the help of polyurethane foam.

- With the help of a wire, a cover rim is made, and hooks are attached to it for installing insulation on the well shaft (the wire passes through the bottom plywood - small holes are drilled there).

decorative house

Materials:

- wooden logs;

- crushed stone and cement (used for the construction of the blind area);

- mineral wool as a heater;

- roof tiles.

Work order

- A blind area is arranged around the mine - crushed stone is compacted and cemented. Optionally, you can put a tile on top.

- On the basis obtained, a log house is mounted. At this stage, you may need the help of specialists!

- The gaps between the house and the ring protruding above the ground are closed with mineral wool.

- The roof is double pitched.

- After that, the logs of the log house must be treated with a special impregnation to provide protection from moisture.

- The log house is closed with an insulated lid.

Top ring insulation

A fur coat is a simple and effective way to protect against freezing.

Necessary materials:

- Styrofoam or Styrofoam shell (this building material has grooves for dense

- fixing the entire structure);

- wood or plywood to create a protective box.

Work execution algorithm

A small trench breaks out around the first ring (the task of the owner is to get free access to the ring located in the ground along its entire height) - the maximum depth is 1.5 meters.

A heat-insulating material is mounted around the ring.

The trench is filled with sand to ground level, and the upper part of the insulation material is protected by a wooden box. It must be painted or wrapped in foil if polystyrene foam was used as a heater, which is afraid of direct sunlight (ultraviolet is harmful). Warming is completed by installing a warm cover on the shaft.

Special insulation and polyurethane foam

These types of heaters are used as a budgetary and quick material to install.

You will need:

- roll type insulation (for example, based on foil);

- mounting gun, if you plan to apply a polyurethane mixture.

Work procedure

- Digging a trench up to 1.5 meters deep.

- The first ring is insulated using roll insulation. If processing with a polyurethane mixture is carried out, it is necessary to adhere to the temperature regime. The optimum temperature is about +20 degrees.Under such conditions, the material dries quickly (applied in a uniform layer with a thickness of at least 3 centimeters).

- The trench falls asleep. The insulation remaining on the surface is covered with paint or foil.

- Be sure to mount the cover!

It should be noted that a warm cover is needed in any case. But without insulation of the upper ring of the mine, it will not be an effective enough protection.

Foam insulation

When the trench is prepared, laying foam in 2 layers begins. First, with this material, you need to lay out the outer vertical wall of the working trench. Pieces of foam are stacked alternately. They should be placed end to end with maximum contact along the joint line. Seams are sealed with mounting foam.

The next layer of foam must be glued around the upper ring, partially capturing the next element of the well shaft. Mounting foam is blown into the cracks and joints.

Styrofoam gradually collapses under the influence of direct sunlight. To avoid this, the surface of both rings must be carefully plastered over the entire area. After complete drying, they should be covered with oil paint in 2 layers. This will protect the plaster from soaking. When the paint dries, you need to fill the trench with the removed soil and carefully tamp it. Level the surface.

Applied thermal insulation materials

When deciding how to insulate a water pipe in the ground and inside the house, it is necessary to ensure that the following requirements for thermal insulation are met:

- minimum coefficient of thermal conductivity of the material;

- stable shape retention under mechanical action;

- inability to absorb moisture or the presence of protection against it;

- easy installation work.

Specially for insulation of pipelines manufacturers of building materials produce assembly heat-insulating elements in the form of tubular shells, semi-cylinders and segments. Sheet insulation is still considered a traditional material, with which pipes are simply wrapped.

glass wool

Fiberglass thermal insulation is used for warming water pipes only in dry rooms. The durability of this material, good thermal insulation properties and low cost lose their significance due to the ability of glass wool to actively absorb moisture. Therefore, the insulation of a water supply system in a private house requires the mandatory presence of a waterproofing layer, which increases the cost of insulation and complicates installation.

Basalt insulation

They are made in the form of flat mats, semi-cylinders and segments. The ability to absorb moisture is present, but it is much lower than that of glass wool. Recommended for insulation of pipes in dry rooms. Basalt heaters are not used for insulation of underground pipeline lines.

To insulate pipelines, manufacturers manufacture products with a protective layer of foil isol or glassine already glued. The complex manufacturing technology of the material increases its cost. As a result, the insulation of small diameter pipes often becomes uneconomical.

Selection of the diameter of thermal insulation for pipes.

Styrofoam

A dense, strong and durable material with excellent thermal insulation properties is best suited for insulating a water pipe in the ground. It is produced in the form of split tubes and semi-cylinders.There may be a surface protective coating of polymeric materials or foil.

polyurethane foam

This type of insulation is used for the manufacture of pre-insulated PPU pipes in the factory. Such systems are considered the best protection against heat losses and all types of external influences. But the main disadvantage for private developers is the need to attract specialists to carry out installation work.

Foamed polyethylene and artificial rubber

Especially for the thermal insulation of pipelines, tubular casings of various diameters are made from these materials. They are put on the pipe during installation work or on already installed pipelines. To do this, a longitudinal incision is provided along the length of the casing, which allows you to open the shell and put it on the pipe, performing the installation yourself.

Tubular insulation made of polyethylene foam and artificial rubber:

- has good thermal insulation properties;

- does not pass or absorb moisture;

- easy to mount;

- durable and affordable.

However, the low mechanical strength of these materials does not allow their use in underground laying. The weight and pressure of the soil will lead to compaction of the layer and loss of thermal insulation properties. Therefore, use is only allowed with open pipe laying.

Thermal conductivity of materials.

Thermal insulation paint

This innovative material is a thick paste-like composition that is applied to the surface of the pipeline. A layer of paint 4 mm thick corresponds in its properties to 8 mm mineral wool insulation.

The coating is characterized by high strength, wear resistance and high resistance to moisture.The main disadvantage is the high cost - more than $ 150 for a bucket of 10 liters.

How to insulate a well

Water supply in a summer cottage is an integral part for a comfortable stay. And many people, in order to organize an uninterrupted supply of water, equip wells on their plots. Correctly drilling a well and laying communications is one of the main tasks, but the second equally important problem that you need to solve is to think about how to insulate the well so that it works smoothly even in winter frosts.

Why you need to insulate the well

Note! Before you insulate the well, consider the options for the available methods, which differ in the complexity of their implementation.

Ways to insulate wells

If you do not live in a country house in winter, then you will not need insulation, it will be enough to pump out water before the winter season, close the lid, fill the well with sawdust or leaves, cover it all with polyethylene and fix the structure. For those who spend the winter in country houses. There are several options for how to insulate a well.

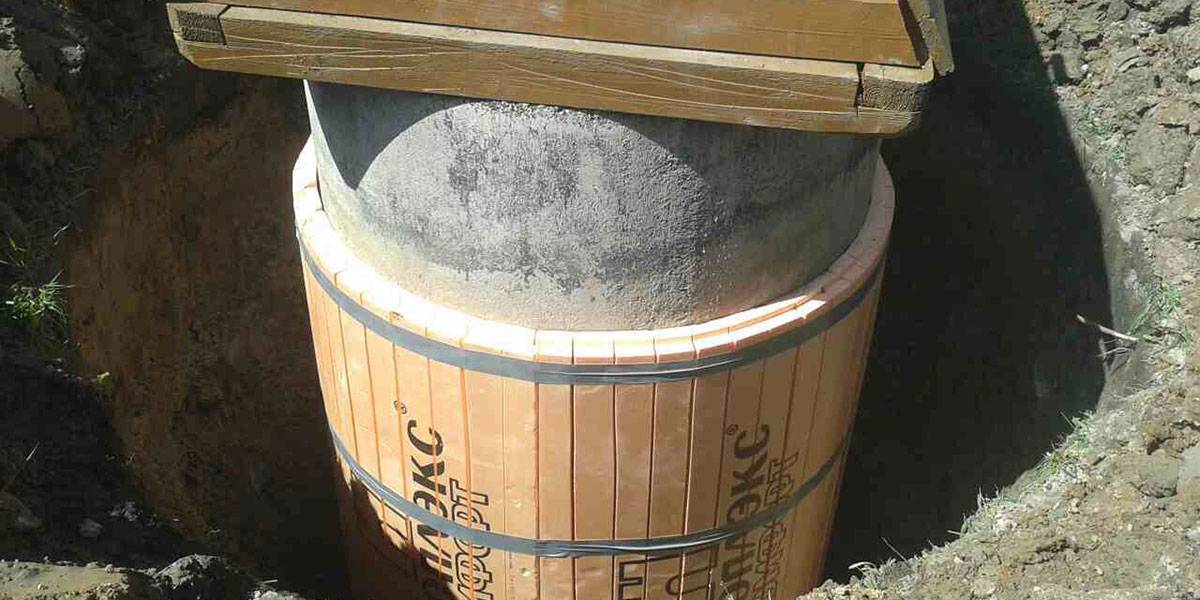

caissons

These are structures (made of concrete, iron or plastic) that are installed at the top of a well or well. They are square or round in shape and are often installed as the last link of a well, instead of a reinforced concrete ring section.

It is better to insulate the well with the installation of caissons, followed by the laying of insulation, which is used as expanded clay or fine gravel screenings.

Note! If your well is powered by an automatic pump. then in the caissons it is possible to install additional filters and other automation, which is usually located in the house

Well ring insulation

Ring insulation

You can insulate the well with expanded clay. It is necessary to dig a trench around the rings of the well to a depth of two meters and with a width of 70-80 cm, and then fill it with expanded clay or fine-grained gravel. Mineral wool can also be used, but only this will require the construction of a wooden formwork, which must be laid with roofing material. so that the heater does not rot. The insulation is also covered not with earth, but with expanded clay with concreting of the upper layer.

decorative house

You can build a small hut made of logs or bricks over the location of the well. To do this, you will need to prepare a shallow foundation and build a structure. Such a structure will well protect water from freezing and play an additional decorating role. A more spacious house, which can be used as a storage room for country equipment, will bring great benefits.

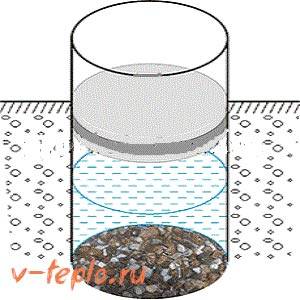

Hanging cover in the well

Hanging cover

This is a fairly simple, but no less effective way to insulate a well. An insulating cover will protect against frost, which helps to accumulate the temperature of the water in the well. It must be mounted at such a depth at which it will not reach the water, and will be slightly above the freezing level or on the same level with it.

Pipeline insulation

Making the water supply of a private house from a well and a well, the pipeline can be laid at a very shallow depth - 40-50 cm - this is quite enough. It is only necessary to lay pipes in such a shallow trench insulated. If you want to do everything thoroughly, then lay out the bottom and sides of the trench with some kind of building material - brick or building blocks. From above everything is covered with plates.

An example of laying pipes above the freezing depth in a prepared ditch. Warming of the water supply is carried out with a special heater, with a suitable inner diameter

If desired, you can fill up the soil and plant annuals - if necessary, the soil can be easily removed and free access to the pipeline is provided.

Insulation for water pipes

You can use two types of heaters:

- special energy-saving shells molded in the form of pipes, they are also called "pipe shells";

- roll material - a common insulation in the form of rolls, which is used for walls, roofs, etc.

Thermal insulation for pipes in the form of a shell is made of the following materials:

- Expanded polystyrene - multiple granules are fused together. It turns out a rather rigid and durable material with good heat-insulating characteristics.

- Extruded polystyrene foam - material cells have a closed structure (small balls). This gives the material also water-repellent properties, as well as higher thermal insulation properties. It is one of the best highly insulating materials, but its disadvantage is the high price.

-

Styrofoam - one of the options for expanded polystyrene - has good thermal insulation characteristics, but is notable for its low strength. Therefore, he needs protection - he cannot stand pressure. But it costs a little. If you lay pipes in a trench with brick or concrete walls, it can be used.

- Polyurethane foam - in terms of characteristics and price, it is between polystyrene foam and polystyrene foam. It is the one most often used for pipe insulation.

- Foamed polyethylene (of the "Energoflex" type) has good characteristics due to the high content of air in the bubbles.

- Glass wool is a roll material with good thermal insulation characteristics and a relatively low price. Its disadvantage is that special measures are needed when laying: fiberglass is very prickly, and it is unrealistic to remove microscopic particles from the skin. You also need a respirator and goggles - small particles are volatile and are harmful to health.

- Stone wool. It is made from basalt or slag. Basalt wool has the best characteristics, but is expensive. Slag is a cheaper material, but its characteristics are worse - you need to take a larger thickness, which often reduces material benefits to a minimum.

Insulation of water supply pipes in a private house is done using thermal insulation

Mineral wool - glass wool and stone wool - have one significant drawback: they are hygroscopic. By absorbing water, they lose most of their heat-insulating properties. After drying, they are restored only partially. And another very unpleasant moment, if wet mineral wool freezes, after freezing it turns into dust. To prevent this from happening, these materials require careful waterproofing. If you cannot guarantee the absence of moisture, it is better to use a different material.

How to make drip irrigation systems for greenhouses and gardens with your own hands is written here. An article about manufacturers of ready-made kits for drip irrigation is here.

Why is freezing water dangerous?

Freezing of water is dangerous at least because the sources cannot be used. But that's not all - the ice plug has a serious weight, and if it breaks, it will easily demolish the equipment installed in the mine that will be in its path.But even if you do not have cables and a pump, it is still dangerous, because, as you know, the volume of ice is greater than the volume of water. Accordingly, the cork presses on the rings. This is fraught with displacement of the rings, rupture of the seams between them, and the appearance of cracks. In turn, this leads to blockages of the soil. And this will require complex repairs. Therefore, it is better to immediately insulate the well, water pipes and sewerage for the winter than to solve the problems that have arisen later.

The argument in favor of this procedure is the fact that the rings themselves are seriously destroyed by ice, which means that they begin to age. Rings are destroyed much faster than usual. So, insulation will save you from having to dig a new well. Therefore, consider how you can prepare for the cold.

What if the well is still frozen?

If the winter is especially cold, or you haven't insulated the well, it may freeze. And if this happened, you need to follow these steps.

- First, evaluate the degree of its freezing. Sometimes it happens that only the surface layer freezes (an ice crust appears), while the water under it remains in a liquid state and still enters the house. In such cases, you can do nothing at all. If you wish, you can remove the ice crust using any suitable tool for this (for example, a crowbar). Pierce the crust with a crowbar and slightly detail it. After that, be sure to cover the structure with a lid.

- If the water is still completely frozen, then it remains only to wait for warming. As soon as this happens, dig the well and, using a heat insulator, insulate its walls (as described in one of the methods). Soon the water will slowly but surely begin to melt.

- If the water is not frozen, but for some reason it is not supplied to the house, then heat the pipeline with a building hair dryer and insulate it well. The water supply must be restored.

On a note! At low temperatures, uninsulated pipes can burst and thereby destroy the entire water supply system.

Summing up

It turned out that warming the well for the winter is often necessary. This will protect the water in the mine from freezing even at the lowest temperature.

But you need to remember about the insulation of pipes leading to the house, as this is also extremely important.

That's all. Good luck with your work and warm winters!

Method one. Cover insulation

This technology is not complicated and consists in installing an additional cover inside the structure itself at the soil level. We remind you that water from a well can be obtained in two ways - in the old fashioned way, that is, with the help of buckets, and by means of an electric pump. This article deals exclusively with the modern method.

You should start by preparing everything you need. Get ready for work:

- plywood sheet;

- glue;

- wire;

- a plastic pipe, which is necessary for ventilation;

- insulation, the thickness of which will be at least 5 centimeters (polystyrene is ideal for this);

- mounting foam.

After that, proceed directly to the construction process.

Step one. Take a plywood sheet and cut out a pair of even circles of a diameter similar to the diameter of the structure itself. In each of the circles, make two holes - one for the hose and the other for ventilation.

On a note! Ventilation in this case is mandatory, because without it, the water will soon begin to smell unpleasant, and its taste will noticeably deteriorate.

The diameter of the drilled holes is insignificant - no more than 6 centimeters, otherwise frosty air can penetrate through the cracks formed. Holes are more convenient to drill at one end. Next, along the perimeter of the second circle, make 4 more holes for the wire.

Step two. We continue to warm the well for the winter. Cut out a third circle of the same diameter, but this time from Styrofoam. Glue it on the bottom circle using quality wood glue, and fix the third circle on top. Once the glue has dried, place the ventilation pipe in the prepared hole. You can use polyurethane foam as a joint seal.

Step three. The work is almost finished, it remains only to make a special ring out of wire. To do this, take it and wrap the first ring, thereby fixing its circumference. After that, attach the wire to the ring, fixed in the four holes of the lower ring. Pass the hose through the desired hole, and then lower the finished "sandwich" to the ground line. The lid will be held with wire, the well will be properly ventilated, but the water will not freeze.

Laying pipes below freezing depth

This method is advisable to use if in winter the soil freezes no deeper than 170 cm. A trench is dug from a well or well, the bottom of which is 10-20 cm below this value. Sand (10-15 cm) is poured to the bottom, the pipes are laid in a protective casing (corrugated sleeve), then they are covered with earth.

In order not to have to insulate the water supply on the street in frosts, it is better to do this in advance

This is the easiest way to make winter plumbing in the country, but it is not the best, although it is the cheapest.Its main drawback is that if repairs are needed, you will have to dig again, and to the full depth. And since it is difficult to determine the place of a leak with this method of laying a water pipe, there will be a lot of work.

In order to have as few repairs as possible, there should be as few pipe connections as possible. Ideally, they should not be at all. If the distance from the water source to the cottage is greater, make the connections carefully, achieving perfect tightness. It is the joints that leak most often.

The choice of material for pipes in this case is not an easy task. On the one hand, a solid mass presses from above, therefore, a strong material is needed, and this is steel. But steel laid in the ground will actively corrode, especially if the groundwater is high. The problem can be solved by well primed and painted over the entire surface of the pipes. Moreover, it is desirable to use thick-walled ones - they will last longer.

The second option is polymer or metal-polymer pipes. They are not subject to corrosion, but they must be protected from pressure - they must be placed in a protective corrugated sleeve.

Even if the ditch was dug below the freezing level, it is better to insulate the pipes anyway

One more moment. The depth of soil freezing in the region is determined over the past 10 years - its average indicators are calculated. But firstly, very cold and little snow winters occur periodically, and the ground freezes deeper. Secondly, this value is the average for the region and does not take into account the conditions of the site. Perhaps it is on your piece that freezing can be greater.All this is said to the fact that when laying pipes, it is still better to insulate them, lay sheets of foam or polystyrene foam on top, as in the photo on the right, or lay them in thermal insulation, as on the left.

You may be interested in reading "How to do automatic watering".

Causes of freezing wells

In the old days, building a log house from wood, well builders at the same time provided thermal insulation of the internal space of the well. In the northern regions, the neck was additionally closed, arranging manholes and houses on the head of the structure. Wood has a fairly low thermal conductivity and reliably retains heat without the use of additional funds.

Types of insulation of concrete wells

Types of insulation of concrete wells

Now the most common option for lining a well shaft is concrete rings. Even a thick concrete wall can freeze severely when the temperature drops below -10°C. Rings, in addition to the ability to quickly give off heat to the surrounding frozen soil, do not differ in great thickness.

The walls of the well lining are about 10 cm thick and almost do not protect the mine from frost above the ground and at a depth of soil freezing (1-1.5 m or more).

Because of this, an ice plug may form in a well unprepared for winter, and if a water pipe is laid shallow (for example, in a summer cottage), pipes can also freeze.

Cover insulation

In winter, few people use the well in the country, but this does not mean that it does not need to be insulated. To prevent the destruction of the base and reinforced concrete rings in the structure, the source can be "mothballed". To do this, construct an insulating cover that protects it from the penetration of cold.

Water supply from a well: do-it-yourself plumbing and supply scheme

In this case, the insulation of the well with your own hands is as follows:

- In accordance with the diameter of the well shaft, two plywood disks with a thickness of 3 cm or more are cut out;

- One disc is coated with moisture-resistant paint to prevent it from getting wet;

- Then the painted disc is wrapped in polyethylene, after which suspension cables are attached to it;

- The prepared cover is lowered into the well shaft to a level that is slightly below the freezing level of the soil;

- A layer of heat insulator (polystyrene foam, foam rubber) is laid on top of the lid;

- The upper plywood disc is placed in the shaft at a height of half a meter from the thermal insulator;

- After that, another layer of insulation must be put on the top cover;

- From above, the well is simply covered with an ordinary lid made of metal, wood, etc.

Materials for processing

The choice of methods of protection against moisture penetration is largely determined by the specifics of the structure itself and the properties of concrete rings as its main elements. In fact, such processing can be divided into two blocks:

- surface treatment of prefabricated elements;

- protection and sealing of seams and joints with the pipeline.

In the first case, various mastics and coating materials are most often used. And to work with seams and holes, special construction adhesives or solutions are additionally used with the introduction of water-repellent additives.

Recently, the method of sprayed concrete has been increasingly used to protect structures. This approach allows you to cover the structure with a uniform layer of mineral mixture. Also, special membranes that reliably protect the structure from leakage are becoming increasingly popular.

Warming methods

The main requirement during construction work is the preservation of the ecology of the internal environment and the composition of water.

The main requirement during construction work is the preservation of the ecology of the internal environment and the composition of water.

All materials used for insulation must not impair the quality of the water. In addition, materials are divided according to functional tasks.

What is used outside is not necessarily suitable for internal processing.

Cover insulation

The lid can be made from various materials:

- tree;

- reinforced concrete;

- plastic.

Wood is a unique material, it does not require an additional insulating layer.

A wooden cover can be made double: inside the concrete ring and outside

The interior will hold back temperature changes. External will protect from dirt, snow, debris.

The second material (reinforced concrete) is distinguished by its durability, strength and reliability.

A plastic floor is installed inside a concrete log house, approximately at the level of the top layer of the earth.

Manufacturing method of the insulating closure structure:

- Two shields are cut out, the material is moisture-resistant plywood.

- One is treated with a waterproof mixture, wrapped in a film, cellophane or other material to protect against moisture penetration.

- Metal rods are fixed inside the rings, on which the first shield is laid.

- Insulation is spread, any building material except mineral wool is suitable.

- The second shield is fixed, also treated with insulation.

- All layers are fastened together, wrapped in waterproof fabric or cellophane.

The lid made in this way is complemented by a handle, it is needed for ease of lowering and raising.

It is also recommended to attach a cable that will fix the structure inside the concrete frame.

Insulation of the walls of the well

There are a lot of options for insulating material offered by trade organizations.

The choice is up to developers. To insulate the walls outside, they dig a trench. Its depth depends on the level of soil freezing.

There are few types of insulation that are popular:

- Styrofoam

The material is characterized by minimal heat transfer, maximum moisture resistance. The material protects against a strong decrease in air temperature outside.

Expanded polystyrene is fixed around the concrete with frost-resistant glue, dowel-nails are used for more rigid fastening.

The material is covered with an insulator, roofing felt or roofing paper is suitable.

Izolon

The qualities of the substance are thermal insulation, reliability. Izolon is a self-adhesive substance, it is easy to use.

Concrete well rings are wrapped around the outer surface, then covered with an insulating layer.

Polyurethane foam

A layer of substance for complete insulation requires approximately 2-3 cm.

The foam itself is fixed on concrete, fills any, even the slightest cracks, roughness and irregularities. The material retains heat, conducts excellent waterproofing.

The building composition has a drawback, it is afraid of sunlight. It is necessary to consider a coating that will protect against ultraviolet radiation.

The advantages of the material are many:

- not subject to decay;

- does not deform under mechanical influence;

- sustain application coming from the soil;

- light;

- easy to install;

- wear-resistant;

- difficult to burn.

The last stage of work after the choice of material and the insulation of the concrete structure with it, the trench is buried

For the safety of the made log house, when water is taken out by buckets or through hoses, they try to prevent water from entering the surface of the walls.Ice will damage the concrete and shorten the service life.

External insulation

From the outside, various houses are built for insulation. Their shape depends on the desire of developers.

A wooden frame above the well will serve as both a decoration for a concrete structure and a heater.

Wood retains heat and is easy to work with. Any pattern can be made from wood, it lends itself to coloring and other design details.

Such houses become a decorative decoration of the entire personal plot. Concrete rings are round in shape, wooden log cabins have corners.

Therefore, air space remains between the rings and the tree. Masters advise to fill it with expanded clay, it will complement the insulating functions of the external frame.