- Peculiarities

- Wall insulation with “warm” plaster compositions: stages of thermal insulation work

- Wooden base insulation

- A few words about materials

- Highlights of insulation technology

- Wood floor insulation

- Tools and materials

- Floor preparation

- concrete floors

- Blitz Tips

- A few words about materials

- Features and characteristics of ecowool

- Work performance technology

- Finally

Peculiarities

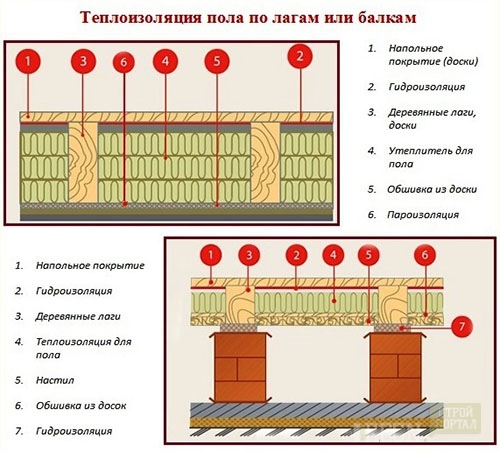

Even the correct laying of floorboards without cracks and gaps fades over time due to the peculiarities of the wood structure. Boards can dry out and heat loss is inevitable. Up to 30% of heat escapes through a floor that has not been reconstructed, so it is necessary to insulate a wooden floor, but it is worth remembering the features of this work.

The wooden floor does not consist of only boards, it has a more complex structure. The basis of the floor is logs, which are wooden blocks. Either a draft floor is attached to them, consisting of raw boards, plywood, chipboard, and which is the basis for finishing coatings (laminate, parquet), or a finishing floor, the basis of which is boards processed by a cutter.

In order for the floor to be comfortable, various types of insulation are used, but for normal operation, one insulation is not enough - it is necessary to use layers of waterproofing.

Wall insulation with “warm” plaster compositions: stages of thermal insulation work

The advantages of "warm" plaster mixtures is the ability to obtain a uniform coating without cold bridges.

To insulate the walls of the bathroom, you can apply “warm” plaster on them. A feature of "warm" plasters is their high vapor permeability and low thermal conductivity. Vapor permeability of plasters is achieved due to their cement base, and low thermal conductivity is ensured by the introduction of various additives into the composition. Depending on the filler, vermiculite, sawdust and polystyrene foam compositions are distinguished.

The advantages of "warm" plaster mixtures are the ability to obtain a uniform coating without cold bridges, before applying the mixtures it is not necessary to pre-level the surface, and their high adhesion allows plasters to be applied to any surface. The disadvantage of these heat-insulating materials is a thick plaster layer, which significantly reduces the usable area of the room, as well as the need for additional finishing.

Before applying plaster compositions, it is necessary to prime the surface to be insulated.

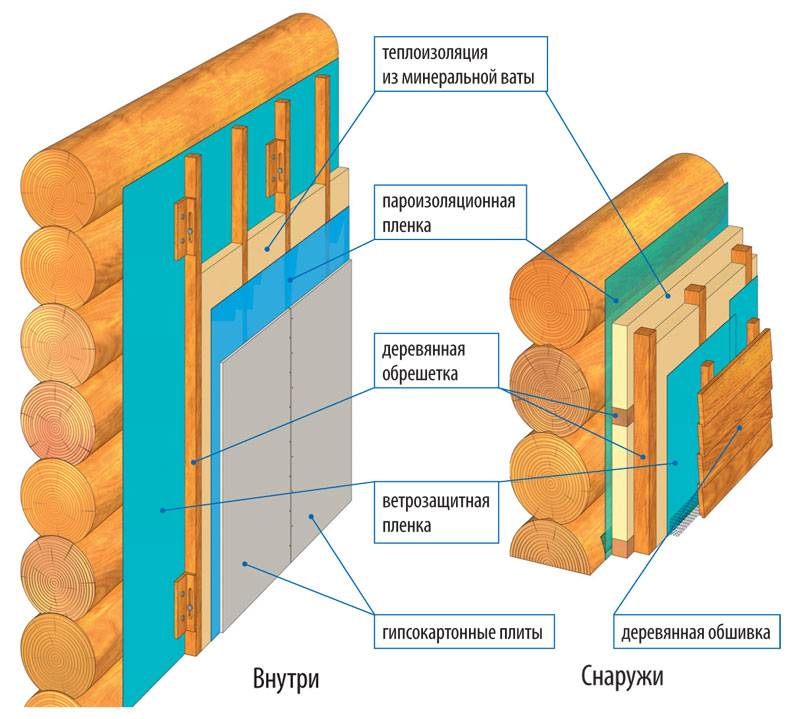

Wooden base insulation

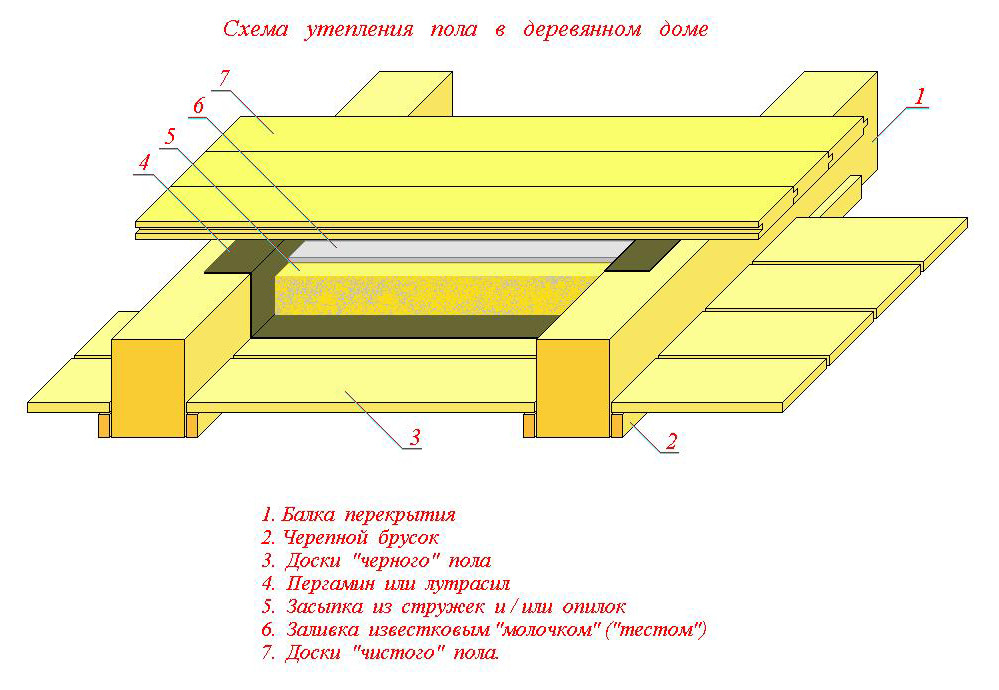

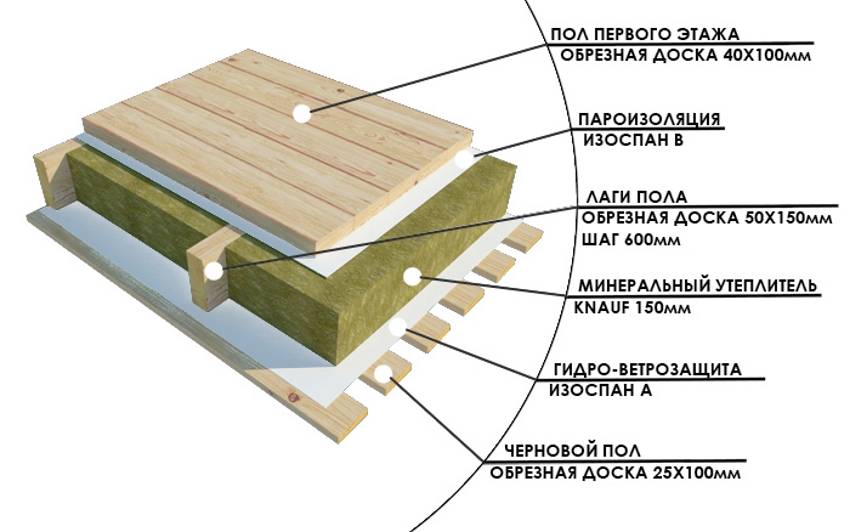

The traditional way to insulate a wooden floor is to lay the selected type of heat insulator in the space between the joists.

Scheme of warming a wooden floor along the logs

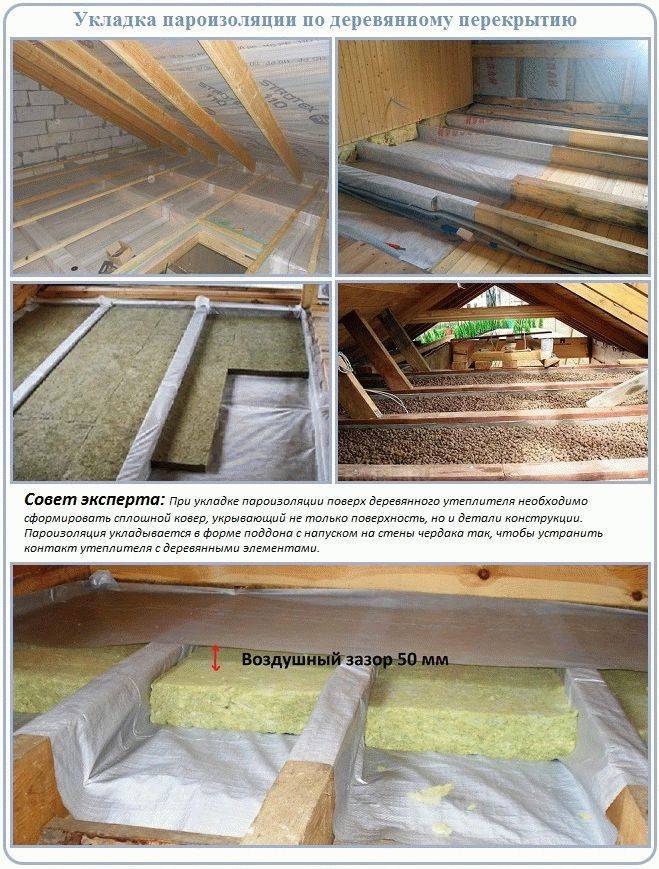

To do this, perform the following steps. The first step is to remove the old floor covering, open the floor.A vapor barrier layer is laid, for example, a polyethylene or polypropylene film. The material is unfolded and the strips are laid over the wooden frame of the floor, overlapping them by 15-20 cm. The joints are securely insulated with special adhesive tape. When laying, a vapor barrier film is placed on the walls to a height of 3-5 cm.

Laying a vapor barrier film is necessary so that moisture does not penetrate into the insulation layer

A heater is laid between the lags. When using expanded clay, it is evenly poured between the lags, leveling to one level with the rule. Sheet or roll insulation is laid close to the logs, without gaps.

Formation of an insulating layer of mineral wool

On top of the insulation (if mineral wool or glass wool was used), another layer of vapor barrier is created.

The second layer of vapor barrier protects the insulation from steam penetrating into the ceiling from the room

Wooden boards, thick plywood, OSB or GVL sheets are laid over the insulated floor.

Flooring boards over the log

If necessary, install the finish coating: laminate, parquet, linoleum, carpet, etc.

A few words about materials

There are a wide variety of thermal insulation materials on the market today. We will consider the most popular and frequently used.

Insulation must have a certain set of qualities

Therefore, you should pay attention to: weight, environmental friendliness, thermal conductivity, compressive strength, moisture resistance, service life. In addition, the insulation should have medium, and preferably high adhesion with a wooden surface. Thermal conductivity indicators of popular heaters according to SNIP

The lower the value of the indicator, the warmer and drier it will be in the room.

Thermal conductivity indicators of popular heaters according to SNIP. The lower the value of the indicator, the warmer and drier it will be in the room.

Also, one of the criteria for choosing a heater is its thickness. This indicator is critical for residents of multi-storey buildings.

In addition, the choice of material is influenced by the type of foundation and ceiling, the presence of a basement, as well as the features of operation - a permanent living space or a summer cottage.

Cotton wool (mineral, stone, glass wool). This material requires high-quality waterproofing, as any cotton wool gets wet quickly.

Mineral wool is one of the most affordable materials for insulating wooden floors, it is unpretentious, easy to work with and holds heat well.

Most often, mineral wool is used to insulate a wooden floor in conjunction with good waterproofing. Mineral wool is produced in the form of rolls and pressed plates. It is quite easy to work with it, as it is light and easily cut.

For insulation of the first floor, it is worth using mineral wool with a thickness of 20-30 mm, and for the second floors and above - 10-15 mm.

The classic of insulation is the laying of mineral wool between the joists or directly on the subfloor.

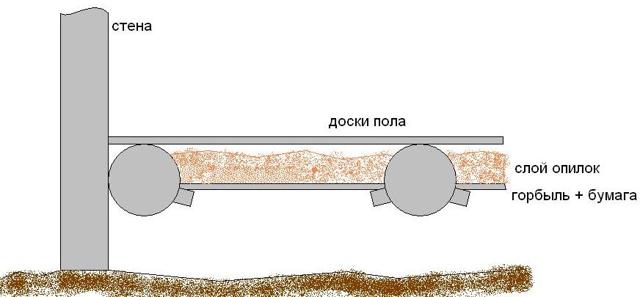

Sawdust is another popular insulation material. They are of several types: wood, sawdust granules, sawdust, wood concrete. They require very high quality waterproofing. You need to use prepared sawdust, which lay in a dry place for at least 5-6 months. It is better not to use this material for warming residential premises, since it quickly gets wet and begins to sag.

Sawdust, in order to reduce heat loss, should be laid in a thick layer, at least 30 cm.This is the best option for warming cottages or outbuildings.

An equally popular material is expanded clay, which is made from clay. It is a cheap and environmentally friendly heater. It is most often used for dry screed or simply fall asleep on the subfloor or between the lags.

Granular expanded clay should be laid in a thick layer. It should be about 5 times larger than wool-based insulation

Styrofoam or extruded polystyrene foam can be used in rooms with a high level of humidity. These materials are quite dense in structure and sheets of various thicknesses can be purchased.

Polyurethane foam can also be used as a thermal insulation material. For its laying, special equipment for spraying is used. You can use it on any foundation, and the foam itself can last up to 10 years.

Penofol is a fairly popular material for Russian-made thermal insulation. Insulation sheets with dense reflective foil. Several types are produced. The classic version is made in the form of foil-coated polyethylene foam sheets. There is also a self-adhesive Penofol C, and on one side of which moisture-resistant glue and an anti-adhesive film are applied, and on the other there is aluminum foil.

Fiberboard, which has excellent sound insulation, is also considered popular. It is made from sawdust filled with liquid cement mortar. Produced in the form of plates.

Izolon insulation is available in the form of rolls, has a low thermal conductivity. It happens in the standard silver color, but in other bright colors.It has excellent sound insulation, despite the fact that the sheets are quite thin.

Most often, heaters are used in the form of rolls, so they are easy to stack.

Izolon in rolls should be overlapped, and not in a joint. You can fasten the seams with bituminous mastic or polymer glue

Highlights of insulation technology

The order of the thermal insulation of a wooden floor practically does not change for different materials. However, before starting work, it is necessary to determine the conditions under which the floor will be used in the future. Under them it is necessary to understand the expected load on the surface, the main purpose of the room, temperature and humidity indicators.

The method of warming a wooden floor depends on the functional purpose of the room.

Warming work is carried out in the following order:

- first, wooden logs are mounted;

- from below, boards or shields made of wood are attached to them;

- a selected heat insulator is arranged between the lags. The material is recommended to be laid as tightly as possible. To close the gaps, it is customary to use a sealant. You can also use foam;

- a vapor barrier is laid on the laid insulation. Usually polyethylene film is used. The material must be fixed on the logs, and any kind of gaps, various joints, etc. glue with metallized adhesive tape;

- at the end, it is necessary to lay the boardwalk and finish the finish.

In preparation for work, it is necessary to determine the optimal thickness of the heat insulator. Usually it ranges from 5-15 cm and depends mainly on the climate in the region where the building is located and the type of insulation chosen. This parameter is determined on an individual basis and is one of the most important.

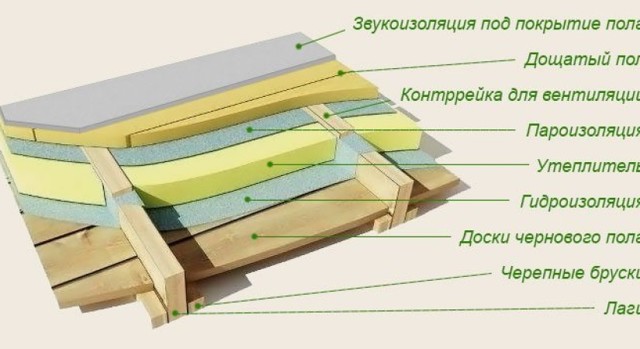

Wood floor insulation

If the floors in the country house are very strong and even, and there is no desire to open them, you can perform insulation directly on the boards. The disadvantage of this method is that the height of the ceilings will decrease by about 8-10 cm.

Tools and materials

For work you will need:

- grinding nozzle;

- jigsaw;

- building level;

- primer;

- putty on wood;

- bars 50x50 mm;

- sheet material, for example, chipboard;

- vapor barrier film;

- insulation;

- self-tapping screws;

- screwdriver;

- construction tape.

The bars will perform the functions of a lag, so they must be even, without defects, and well dried. Since the workflow will take very little time, the bars should be pretreated with antiseptic impregnation and dried.

Floor preparation

Step 1 Carefully remove the baseboards and clean the floor from dust. Check the levelness of the surface with a level gauge.

Step 2. If there are protrusions on the floor, the surface is treated with a grinding nozzle. The gaps between the boards and the recesses are puttied.

Puttying a wooden floor

Step 3. The working surface is covered with two layers of primer mixture, the floor is allowed to dry.

Step 4. The beam is laid out on the floor in parallel rows with a step of 30 cm. From the extreme beams to the walls, the distance is 2-3 cm. Using a level and wooden wedges, the bars are set exactly horizontally and screwed to the base with self-tapping screws.

Laying and fastening lag

Step 5. The space between the bars is filled with insulation. Mineral wool and polystyrene are best suited for this. The formed seams need to be blown out with foam.

Laying insulation in the space between the lags

Step 6The insulation is covered from above with a vapor barrier membrane, carefully spreading the material and fixing the seams between the strips with adhesive tape.

Mineral wool is covered with a membrane

Step 7. The sheet material is cut into squares for convenience and proceed to the flooring. Starting from the second row, the sheets are laid with a joint offset of 20-25 cm. The seams should be minimal, so fit the squares as tightly as possible.

Laying sheet material on logs

Step 8 If you plan to lay boards on top of chipboard, additional processing of the subfloor is not needed. For thinner finishes, it is necessary to putty the joints and sand the entire floor with a sanding attachment. After that, remove the dust, apply a primer and wait until the floor dries.

The described options are the most practical for giving; subject to the technology, it will not be necessary to change the heat-insulating layer for at least 10 years.

Insulated floor in the country will last at least 10 years

comparison table floor heaters

concrete floors

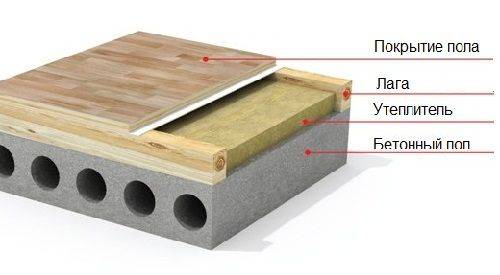

In modern construction, wooden floors are used very rarely; they have long been replaced by concrete floors. The main advantage of a concrete floor is low cost, ease of installation, high strength and durability, as well as environmental friendliness and fire resistance.

But there is one big “BUT”, the concrete floor has a high thermal conductivity, which is why even on the hottest days it blows cold. Therefore, it is necessary to cover the concrete floor with a special insulation. You can use the same materials as for the wooden floor on the logs.

A well-dried concrete floor must also be covered with a waterproofing film before laying the thermal insulation layer. The technology for laying thermal insulation with lags is the same as for a wooden floor. It should be noted that when warming along the logs, the floor height will increase by 10-15 cm.

Another good way to insulate concrete floors is to use chipboard. This material is in no way inferior to mineral heaters and is quite often used for insulation in private houses and suburban buildings. Organic insulation materials include wood shavings, moss and sawdust. You can also add straw, small dry grass, reeds, hay, sedge or peat chips.

To protect the chipboard from moisture, the concrete is covered with a polyethylene film with high waterproofing. Then chipboards are laid. In this case, the slabs do not need to be laid close to the walls, keeping a distance of about 1.5 cm. This is necessary so that the slabs do not warp during strong temperature and humidity changes.

The plates are firmly fixed with dowels. After fixing the plates, all joints must be reinforced with a construction mesh and covered with putty, which is mixed 1: 1 with oil paint. Then a plinth is mounted around the perimeter. Linoleum or carpet is laid on the finished structure.

You can insulate the floor in the house with your own hands using "warm" linoleum. This material consists of two layers - a warm substrate and polyvinyl chloride, resistant to chemical and mechanical damage. The substrate of such linoleum is made on the basis of natural felt or synthetic non-woven material. Its thickness is about 3-4 mm.

When laying insulated linoleum, it is cut in such a way that there is a small distance between it and the wall, otherwise after a few days it will warp due to an increase in size as it is trampled down.

The concrete floor can also be insulated with a technical cork, which is practical and durable. It is made from the bark of a cork oak, which is glued together with the resin contained in the cork mass. Such material is 100% environmentally friendly, does not pass water, has high heat resistance and does not burn. But there is also a significant drawback - the high cost.

Isolon is also considered one of the best and most effective heat insulators. It is very easy to insulate the floor with it - you need to roll it out on a well-dried concrete floor, and then proceed with laying the floor covering.

Warming the floor in the country is a necessary measure by which you will make your home even more comfortable. It's so nice to sit down on the warm floor with the whole family, when the weather is "non-flying" outside the window, and play, for example, monopoly or twister.

Blitz Tips

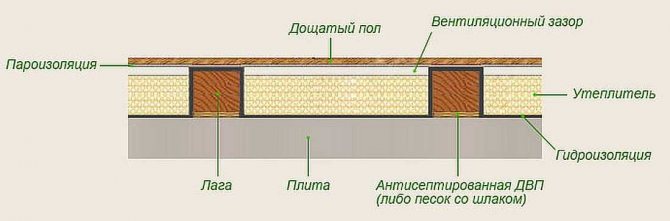

- If the building does not have a basement, basement or concrete pavement, then the perimeter of the building should be backfilled with gravel and sand, with a layer up to 12 centimeters thick. A subfloor is laid on this "pillow". Then the waterproofing is installed. Along the perimeter, logs are attached to the draft floor, insulation and vapor barrier are laid. A gap of about 4 centimeters is left, a finishing floor is laid.

- If the house has a basement or basement. An insulator is selected for the basement ceiling. It is best to use mineral wool with plates up to 120 mm thick. Before work, the surface is cleaned of all irregularities and the plates are glued to the ceiling.Cement-based adhesive is diluted with water. Dilute as much glue as they can work out. Cement hardens very quickly, so you need to work quickly and accurately. There should be no empty spaces on the ceiling. The first row is laid out and pressed against the surface. The next row is glued end-to-end to the edge, and we also press it. When the plates are straightened, the surface of the ceiling is equal to the mineral plaster and painted.

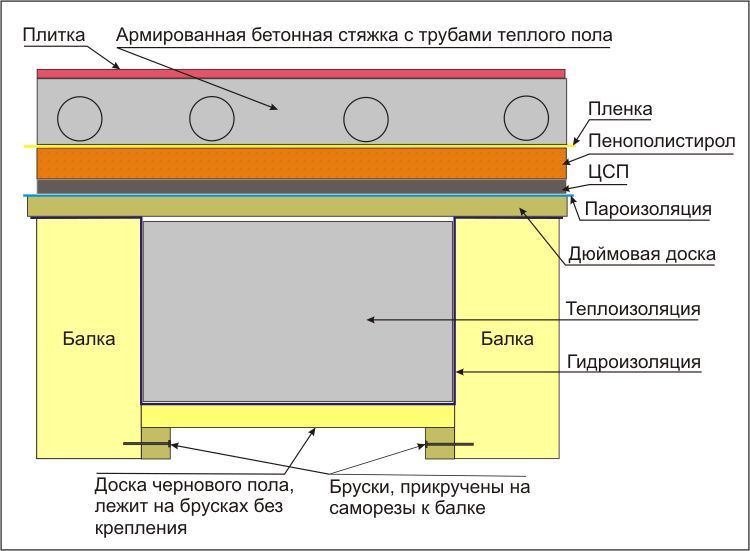

- If lags are not applied. It is possible to carry out thermal insulation on a concrete floor or on a rough wooden floor, using polystyrene foam, ecowool. When laying insulation on concrete, it is necessary to make a double waterproofing. Then expanded polystyrene is laid, a screed is made and the final floor is laid.

A few words about materials

There are a wide variety of thermal insulation materials on the market today. We will consider the most popular and frequently used.

Insulation must have a certain set of qualities

Therefore, you should pay attention to: weight, environmental friendliness, thermal conductivity, compressive strength, moisture resistance, service life. In addition, the insulation must have medium, and preferably high adhesion with a wooden surface.

Thermal conductivity indicators of popular heaters according to SNIP. The lower the value of the indicator, the warmer and drier it will be in the room.

Also, one of the criteria for choosing a heater is its thickness. This indicator is critical for residents of multi-storey buildings.

In addition, the choice of material is influenced by the type of foundation and ceiling, the presence of a basement, as well as the features of operation - a permanent living space or a summer cottage.

Cotton wool (mineral, stone, glass wool).This material requires high-quality waterproofing, as any cotton wool gets wet quickly.

Mineral wool is one of the most affordable materials for insulating wooden floors, it is unpretentious, easy to work with and holds heat well.

Mineral wool is one of the most affordable materials for insulating wooden floors, it is unpretentious, easy to work with and holds heat well.

Most often, mineral wool is used to insulate a wooden floor in conjunction with good waterproofing. Mineral wool is produced in the form of rolls and pressed plates. It is quite easy to work with it, as it is light and easily cut.

For insulation of the first floor, it is worth using mineral wool with a thickness of 20-30 mm, and for the second floors and above - 10-15 mm.

The classic of insulation is the laying of mineral wool between the joists or directly on the subfloor.

Sawdust is another popular insulation material. They are of several types: wood, sawdust granules, sawdust, wood concrete. They require very high quality waterproofing. You need to use prepared sawdust, which lay in a dry place for at least 5-6 months. It is better not to use this material for warming residential premises, since it quickly gets wet and begins to sag.

Sawdust, in order to reduce heat loss, should be laid in a thick layer, at least 30 cm. This is the best option for warming summer cottages or outbuildings.

An equally popular material is expanded clay, which is made from clay. It is a cheap and environmentally friendly heater. It is most often used for dry screed or simply fall asleep on the subfloor or between the lags.

Granular expanded clay should be laid in a thick layer. It should be about 5 times larger than wool-based insulation

Granular expanded clay should be laid in a thick layer. It should be about 5 times larger than wool-based insulation

Styrofoam or extruded polystyrene foam can be used in rooms with a high level of humidity. These materials are quite dense in structure and sheets of various thicknesses can be purchased.

Polyurethane foam can also be used as a thermal insulation material. For its laying, special equipment for spraying is used. You can use it on any foundation, and the foam itself can last up to 10 years.

Penofol is a fairly popular material for Russian-made thermal insulation. Insulation sheets with dense reflective foil. Several types are produced. The classic version is made in the form of foil-coated polyethylene foam sheets. There is also a self-adhesive Penofol C, and on one side of which moisture-resistant glue and an anti-adhesive film are applied, and on the other there is aluminum foil.

Fiberboard, which has excellent sound insulation, is also considered popular. It is made from sawdust filled with liquid cement mortar. Produced in the form of plates.

Izolon insulation is available in the form of rolls, has a low thermal conductivity. It happens in the standard silver color, but in other bright colors. It has excellent sound insulation, despite the fact that the sheets are quite thin.

Most often, heaters are used in the form of rolls, so they are easy to stack.

Izolon in rolls should be overlapped, and not in a joint. You can fasten the seams with bituminous mastic or polymer glue

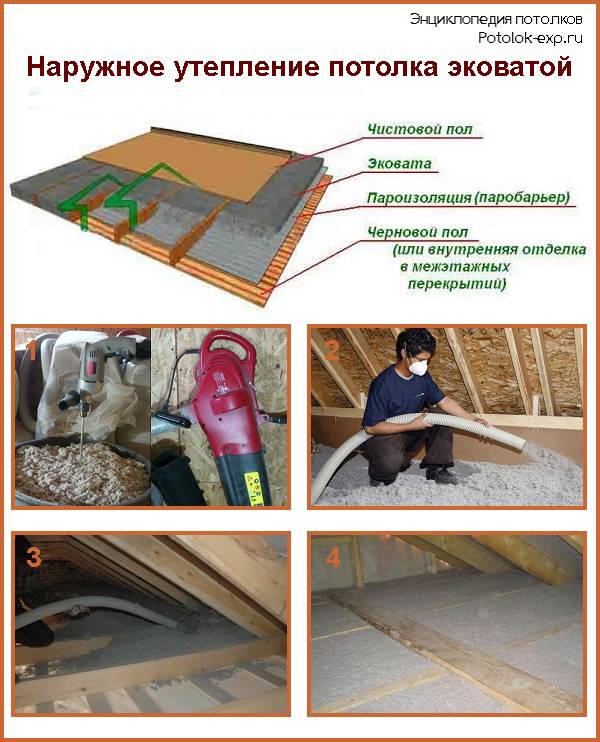

Features and characteristics of ecowool

The material is made from waste paper industry, waste paper. Being a loose powder, ecowool contains 80% cellulose, 12% antiseptic (boric acid), 8% antiprene compounds - they are needed to reduce combustible properties.The use of ecowool is indicated for buildings of any type: residential, industrial, public. The material is considered environmentally friendly, harmless to human health.

Product Features:

- Noise absorption. A layer of ecowool 15 mm thick eliminates noise up to 9 dB, so the material is used in the buildings of airports and stadiums.

- Small expense. For arranging insulation for 1 m3, 28-65 kg is enough to achieve high-quality insulation of the ceiling, wall panels, and floor. Such a large “run-up” of numbers is explained by the choice of application technique.

- Harmlessness. To pick up the "cleanest" material, give preference to borax as an antiseptic and antiprene - ammonium sulfate smells sharp.

- Versatility. Ecowool is used in buildings made of any material, qualitatively seals gaps of various sizes and fills inter-plate seams, joints.

- When using a seamless styling option, the owner saves quite well on energy. There will be no cold bridges, which means that the house will not freeze even in the most severe cold.

- The low cost of the material will not increase the cost estimate for repairs, and paper raw materials are extremely rarely allergic - ecowool can be used in homes with high requirements for product cleanliness.

It is permissible to lay insulation at sub-zero temperatures, but laying out is associated with a large amount of paper dust, so personal protective equipment is needed and you will have to work indoors. Experts recommend avoiding the use of insulation when finishing chimneys and fireplaces.

Work performance technology

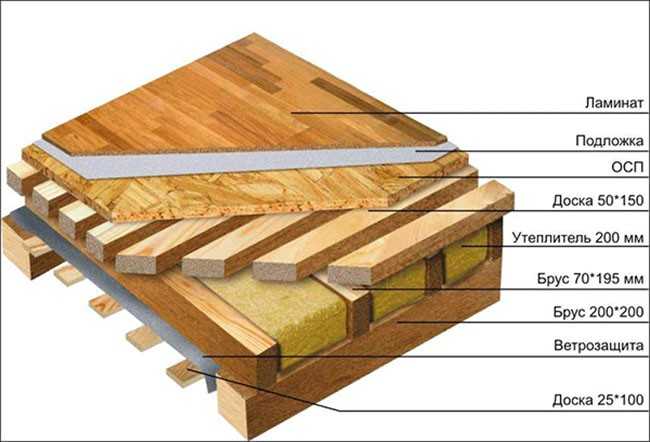

The double floor is a structure implemented on two levels:

- Draft - these are boards fixed on beams, on top of which an insulating flooring is supposed.

- Finishing - a tier that serves to paving the last layer of insulation.

The general laying technology is a collection of heat-insulating "pie":

- dismantling of the old floor;

- along the bottom, over the entire area, auxiliary boards are attached;

- logs of the required size are treated with antiseptic agents to prevent decay;

- prepared logs are laid on top of the support layer with a distance of 0.6 or 0.7 m, maximum - 1 m.

- between them, the selected insulation is placed on the draft layer. If a solid version is used as it, for example, polystyrene foam, the joints must be treated with silicone, foam or other mixtures to eliminate gaps;

- a vapor barrier is placed on top of the insulating material, which is mounted to the logs with thin bars 20x30. To improve the energy-saving effect, the joints are glued with a special adhesive tape containing metal.

- Next, the main floor layer is laid.

Also, there are methods in which an impromptu net is used, which is a strong weave of fishing line. It is attached to beams with nails and is used as a "black" floor, however, over time, such a design can stretch and sag, thereby making the idea unreliable.

Underfloor heating technology

In private houses, insulating the floor of the first floor, the raw materials are also laid along the logs fixed on small brick hills, while laying waterproofing and plank sheathing between them.

Finally

Cold floors are a common problem in houses built with wood. This nuance makes staying in it uncomfortable and increases bills for space heating.Correctly produced thermal insulation can save you from these difficulties.

It doesn't matter what material you choose. The main thing is to strictly observe the isolation procedure and use the general rules of technology.

In addition, do not forget about the features of a particular type of thermal insulator. Most often, the costs incurred are replenished by saving on energy resources already during one cold season.