- When insulation can become meaningless

- What is better to use?

- Varieties of material used for wall insulation

- How to properly insulate your home from the outside

- Traditional installation of a heat insulator

- Wall insulation inside the house

- How to insulate a wooden house with mineral wool or foam?

- Use of fibreboard (Fibreboard)

- Materials for insulation of the facade of the house from the outside: foam, polystyrene

- The main advantages of using penoplex

- Types of mineral wool

- stone mineral wool

- glass wool

- Basalt wool

- Why insulate a brick house

- The main technologies for insulating the facades of private houses

When insulation can become meaningless

Even before buying thermal insulation materials, you will need:

- Check ventilation.

- Carry out a thorough treatment of masonry with antiseptics, wherever the "pie" will be applied.

- Order a complete thermal imaging inspection of the house.

The estimate for these events significantly hits the pocket, but if the ventilation system is not done properly, after warming the house will be stuffy. The windows will begin to "sweat", the mold fungus will multiply.

With a “thin” roof, there is no point in spending money on insulation. A thermal imaging survey will show all the places through which heat loss occurs. And, in the end, it will turn out that it is cheaper to patch holes in the roof than to start the total insulation of the facade.

What is better to use?

Choosing the right material for an experienced craftsman is quite simple, but it will not be easy for beginners to decide. You can focus on ready-made recommendations, for example, depending on the materials with which the house will be lined.

Table. The choice of insulation depending on the material from which the wall cladding will be made.

wall/facade type

Recommendations

Brick facing

In the presence of such a facing material, it is important to ensure the presence of a small layer of air, otherwise the wall materials will get wet. Here it is recommended to make a wall structure consisting of three layers.

ventilated

Finishing is done on the crate

It is easiest to insulate with mineral wool - ideal for hinged facades.

wooden house

Such buildings are insulated only with mineral wool, the technology of the so-called hinged facade mounting method is used.

Wet

Usually insulation is made with mineral wool, but sometimes polystyrene foam is used, but it is important to leave a gap for air.

Insulation of the facade of a wooden house

The regulatory document will answer the question about the number of layers of thermal insulation. You can insulate a house from the street in two or three layers. In the latter version, paneling or plastering does not go for a separate layer, so in a three-layer wall a third layer of structural material must be laid.

Varieties of material used for wall insulation

There are two main types of materials used in the production of cotton wool - glass and mineral. Glass wool is made by pulping pulp with the addition of other ingredients. Mineral wool is obtained by melting rocks, it is also called stone or basalt.Glass wool is non-flammable, vapor-permeable and flexible, suitable for all unloaded and non-slip structures such as sloped walls, various cavities and gaps, even ceilings.

In the production of cotton wool, materials such as glass and mineral are involved.

In the production of cotton wool, materials such as glass and mineral are involved.

Stone wool for facade insulation is a little more difficult to use due to the fact that it is heavier than glass wool and less elastic, but the material provides ideal thermal insulation for the outer cladding of the building. Any facade wool must always be glued to a dry and hard substrate.

When insulating the facade with mineral wool, the following types of material are used:

- Transverse fiber orientation. Suitable for façade systems where heavier tiles will be used. The material has high tensile strength.

- Longitudinal orientation of fibers. Designed for application to external walls and contact insulation systems.

Due to its good characteristics and low flammability, cotton wool can be used in conjunction with any materials. It is popular to insulate the facade of the house from the outside with mineral wool for siding, in this case it will be possible to get both a heat-efficient and beautiful house.

Any kind of facade wool must always be glued to a solid and dry substrate.

Any kind of facade wool must always be glued to a solid and dry substrate.

How to properly insulate your home from the outside

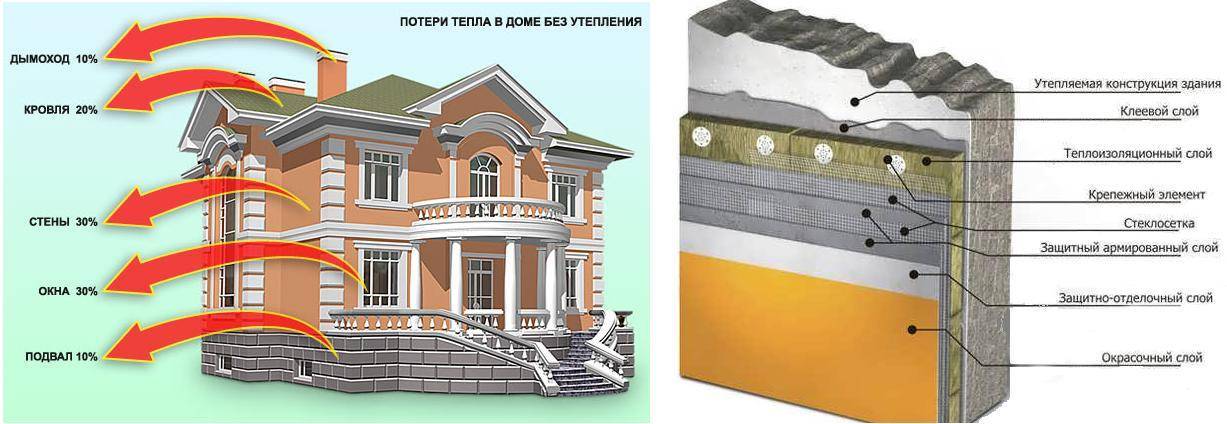

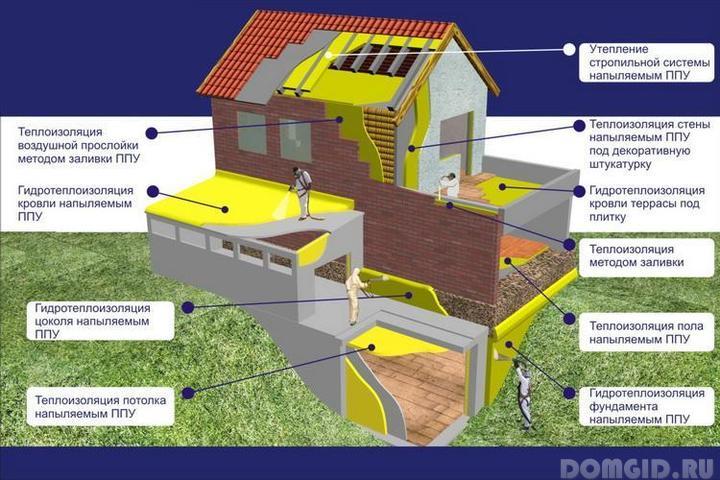

If you do not insulate the facade of the house, the building will be constantly exposed to temperature changes, which will not have a positive effect on its frame.

The presence of facade insulation also prevents other problems, such as:

- destruction of interpanel joints;

- cracks in the main building material caused by frost / warming, especially if the frame is made of foam blocks;

- change in the bearing properties of walls due to wear.

In addition, by insulating the house from the outside, it will be possible to improve its thermal insulation properties, which will help reduce heating costs and increase the comfort of life for home owners. Before insulating the facade of the house, it is necessary to choose the right heat insulator, the use of which will be economically and practically justified.

Insulation of facades of houses can be ventilated and non-ventilated.

Insulation of facades of houses can be ventilated and non-ventilated.

Based on the regulatory documents, according to which the facades of private houses are insulated, two- and three-layer heat-insulating structures are distinguished. At the same time, often the top layer of plaster is not considered an independent unit, although it still differs in some thermal insulation qualities. If we talk about three-layer walls, then here the third layer is the structural material.

On a note! In addition to dividing by the number of layers, facade insulation is also classified depending on the ventilated and non-ventilated layer.

According to regulatory documents indicating how to insulate the house from the outside, it is recommended to use these types of materials depending on the type of box:

According to regulatory documents, the insulation of house facades is divided into two- and three-layer heat-insulating structures.

According to regulatory documents, the insulation of house facades is divided into two- and three-layer heat-insulating structures.

- Houses made of brick or reinforced concrete with flexible connections, as well as buildings made of expanded clay, can be lined with any type of insulation.

- Buildings made of wood are protected by a building envelope with two- and three-layer walls separated by a ventilated air gap.

- Thin sheet studded walls require three-layer walls with a layer of thermal insulation in the middle, which is surrounded by a ventilated or non-ventilated interlayer.

- Bearing walls made of cellular concrete also require the presence of ventilated and non-ventilated interlayers. Top is decorated with brick cladding.

Traditional installation of a heat insulator

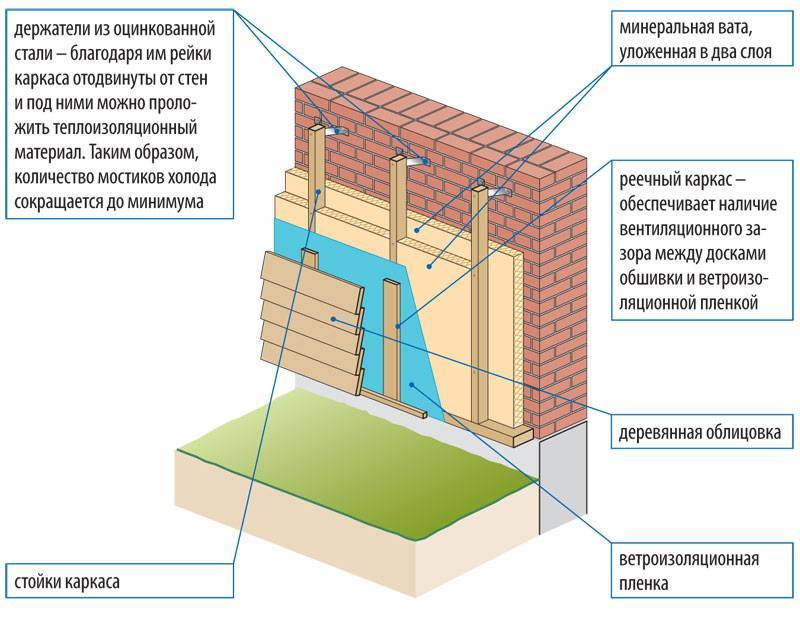

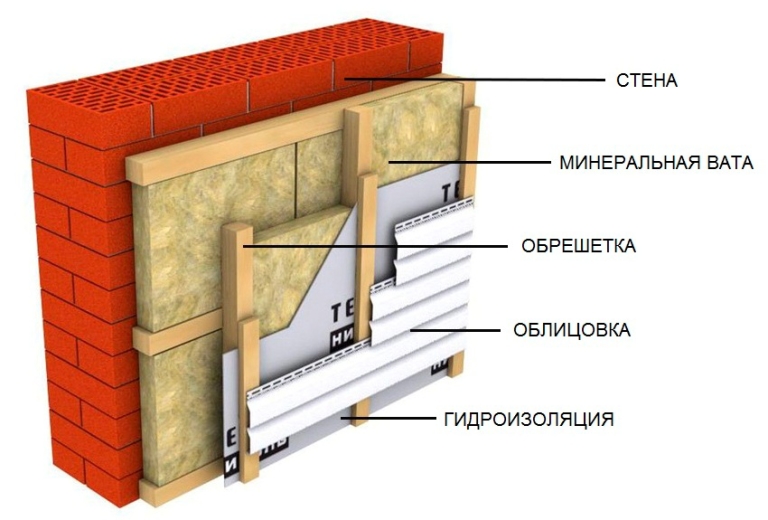

A proven method of insulation consists in laying slab mineral wool insulation between the bars of a wooden crate. The process takes place in the following sequence.

Table. Step-by-step instructions for laying slab mineral wool insulation between the bars of a wooden crate

Illustration

Description

Stage 1: wood processing

First you need to prepare the surface of the walls. To do this, wood is treated with antiseptics and antiperms for several times.

Each subsequent layer is applied after the previous one has dried. When processing a log house, it is important to carefully walk through the corner and end sections of the logs - these are the most vulnerable places.

Stage 2: fixing the support beam of the crate

The frame is mounted using a beam with a section of 30 x 30 mm

When buying a beam, you should pay attention to its appearance - there should be no signs of infection with microorganisms and fungal infections on the surface of the wood. First, the horizontal lower support beam and the upper one are fixed, then the horizontal elements are fixed. The step between them should be equal to the height of the insulation

In order for the slab insulation to hold tightly in the recess, the distance between the bars can be made smaller by a few millimeters

For fixing the elements of the crate, galvanized self-tapping screws are used that are not subject to corrosion.

Stage 3: fixing 2 layers of battens

Now install the vertical elements.The beam is also fixed around windows and doors.

Stage 4: installation of insulation

Mineral wool slabs are removed from the packaging. If a full-sized element does not fit somewhere, then with the help of a sharp construction knife, the excess is cut off. Small fragments are useful for warming the areas around the openings. The slab insulation is placed between the elements of the first layer of the crate and fixed with dish-shaped dowels. Then lay the second layer of heat insulator. At the same time, it is important to observe the spacing of the seams so that the joints of the second layer do not coincide with the joints of the first layer of insulation.

Stage 5: installation of wind protection

A windscreen is fixed on top of the insulation. The canvas is laid with an overlap of at least 10 cm. Usually, the membrane has a corresponding marking on the surface. The canvas is fixed to the bars with a construction stapler. All joints must be sealed with waterproofing tape. The membrane is also fixed around the openings.

Stage 6: installation of the crate for decorative sheathing

A crate is fixed on top, on which the finishing front cladding of the facade will be held.

Stage 7: siding

The front skin is fixed to the rails. At the final stage, they fix the drainage system, window shutters, slopes, cashing, and fix the decor.

Wall insulation inside the house

External insulation of the facade of the house is considered more effective. When the external finishing work has already been completed, and the next stage is the interior decoration, it is logical to carry out thermal insulation from the inside of the room. The main task is to insulate the walls.

Internal thermal insulation of walls is the most problematic method of insulation. Some experts advise resorting to it only as a last resort. The main problem is the transition of the wall into the cold zone.If there are no insulation materials on the walls, warm room air warms the walls from the inside. If an additional layer with insulation is added to the wall, then the air will not penetrate the wall, it will remain cold, and this is fraught with the appearance of cracks. This reason makes you seriously think about whether it is necessary to conduct insulation inside, and not outside. In addition to cracks, there is a risk of condensate accumulation if the work is not done correctly.

Despite the significant shortcomings of warming the house from the inside, the inhabitants of Russia resort to it more and more often. Homeowners take risks to ensure the maximum comfort of living in their home. Therefore, before starting work, you need to carefully study the technology of thermal insulation and follow it in the process.

Wall insulation from the inside of a sip-panel house is more related to the need for soundproofing. You can choose a material with good soundproofing characteristics, but this does not mean that ordinary mineral wool heaters will not work. It is quite possible to use the same insulation as for the facade.

The insulation of a wooden house made of timber or rounded logs directly depends on the quality of the caulking. During the construction of the house, needle-punched felt is laid between the logs, and after the structure shrinks, the cracks are caulked (sealed). Styrofoam, mineral wool are perfect for warming wooden cottages. They are also used for outdoor work. Wood fiber boards can act as insulation. To work with them, you need to know some subtleties.

How to insulate a wooden house with mineral wool or foam?

These materials are suitable as a heater for wooden and brick houses. There are two ways to lay it on the walls.The first method is similar to the installation of external insulation: surface cleaning, installation of plates, mechanical fixation, reinforcement, decoration. It is this method that can lead to cracking of the walls. In addition, the internal area of \u200b\u200bthe room is reduced due to the additional layer on the walls.

How to insulate a house with foam plastic in another way? The second method is called wireframe. First you need to mount a frame made of wood or metal, lay a heater in it. The design is somewhat similar to the one described above, the difference is that the insulation is not tightly attached to the walls.

Note! An excellent option would be to install removable panels with insulation. Then the formation of condensate is easier to observe.

Use of fibreboard (Fibreboard)

When using wood fiber boards for internal insulation, experts advise not to neglect facade insulation work. Fiberboard is a widely used means for warming a house from the outside. The plates absorb sound well, retain heat, and also show good resistance to parasites and temperature extremes. The material is easy to process and install. It is easy to cut with any tool, and fasten to the wall with long nails.

Note! Plates can be glued to the plaster with PVA glue or special mastic.

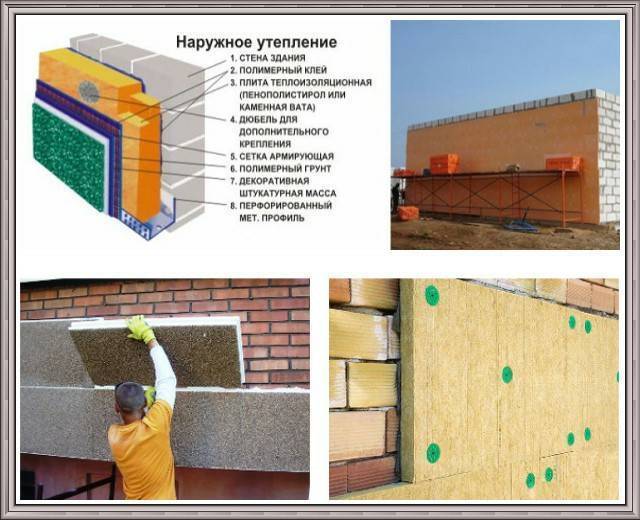

Materials for insulation of the facade of the house from the outside: foam, polystyrene

Thermal insulation of the facade with expanded polystyrene is considered effective due to the closed cellular structure of the material. 98% of the heat insulator is air or inert gases, which fill tightly closed cells, which ensures the sheets are light in weight.Polyfoam is not subject to moisture absorption, which means that it can be effectively used both for the facade and for warming the foundation, basement and constantly wet basement. The material is optimally suited for warming the facade of the house from the outside under the plaster. Benefits of using expanded polystyrene:

The disadvantage of polystyrene is its low vapor permeability and susceptibility to destruction when exposed to direct sunlight.

- Due to its low weight, the insulating material will not exert a large load. This means that it can be used to repair the facade of an old house without doing any work to strengthen the foundation.

- The sheets are easy to mount, which allows you to insulate the facade of the house from the outside with polystyrene foam with your own hands, even for a beginner in the construction business. When working with the material, it is not required to use personal protective equipment - gloves and a respirator, because the process is not accompanied by the release of toxic substances or small particles.

- The synthetic components that make up the insulation sheets are not susceptible to the reproduction of microorganisms, so the material is not afraid of either fungus or mold.

- The shelf life of the material reaches 50 years, especially if you follow the installation technique. The insulation shows good resistance compared to saline and chloride solutions, and also does not change the structure under the influence of alkali.

The disadvantages of insulating the facade of the house with polystyrene are the low vapor permeability of the sheets and the susceptibility to destruction when exposed to direct sunlight.In addition, it is worth noting the low soundproofing performance, as well as the fact that when heated above 30 degrees, the material begins to release formaldehyde, styrene and other toxic substances, the amount of which increases during combustion.

Styrofoam does not absorb moisture, so it can be used both for facade insulation and for foundations or plinths.

The main advantages of using penoplex

Extruded polystyrene foam, or penoplex, is produced in a similar way. Unlike foam, there is a lower gas content here, as a result of which the sheets are thinner, denser, slightly heavier, but at the same time more durable. Before insulating the facade with foam, you need to distinguish between its varieties:

- Plates marked with the marking 31 are used for facade insulation and for roof insulation.

- Penoplex-35 is most often used in construction. In addition to the facade, it is laid as a layer of insulation under the floor covering.

- Sheets 45 are suitable for roof insulation, even if it is under load. Due to the high cost, they are rarely used in construction.

Unlike foam plastic, foam plastic has a lower gas content, so the sheets of this material are thinner, denser and stronger.

When insulating the facade of the house with your own hands from the outside with foam, the following types of material are used:

- "Foundation". Great for those parts of the house that are underground - this is the basement or basement.

- "Roof". High density allows the material to be used for insulation of any roofs.

- "Wall". The material is specially designed for external structures and is resistant to atmospheric influences.

- "Comfort".Suitable for use in all conditions, even with high humidity.

It is important to pay attention to the fact that both polystyrene foam and polystyrene are susceptible to rodents that love to gnaw through the granules. Therefore, pest control should be carried out regularly.

Expanded polystyrene, like polystyrene, is susceptible to rodents, it is necessary to regularly treat pests

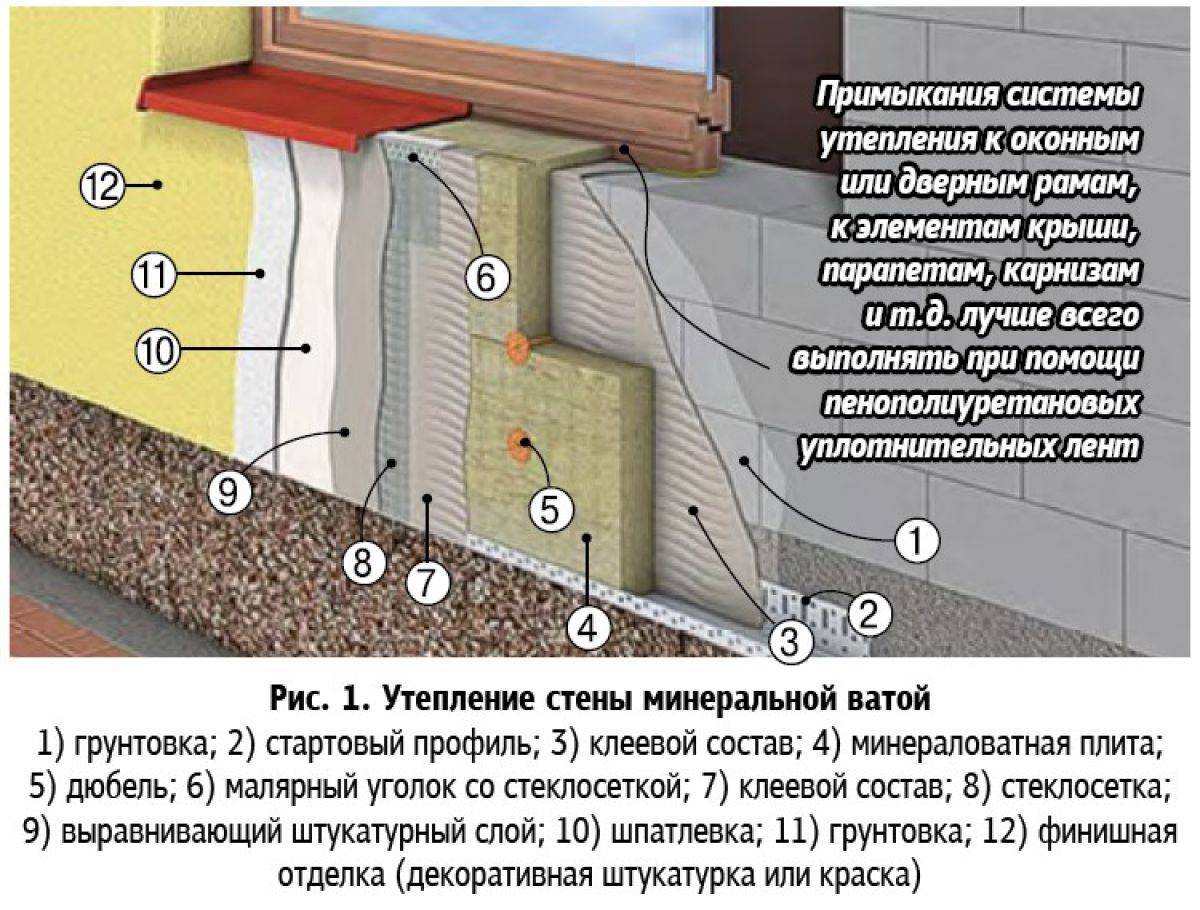

Types of mineral wool

Mineral wool is a group of materials with a fibrous structure, which includes:

- stone wool: obtained from the melt of minerals of rocks; it is she who is often called mineral wool; one of its varieties includes more moisture-resistant basalt wool

- glass wool: thin fibers obtained from molten glass or sand in a process of heating under the influence of ultrahigh temperatures

- slag wool: the cheapest material, which is based on blast-furnace slag; due to increased hygroscopicity, it is not used for insulation of buildings

The benefits of mineral wool include:

- high thermal insulation properties

- low flammability

- rot resistance

- acceptable cost

Types of mineral wool

Most types of mineral wool absorb moisture and have low mechanical strength, so it must be covered with a layer of vapor barrier, and then sheathed with airtight sheathing.

It is undesirable to use rolled mineral wool for finishing facades - it has less thermal protection plus shrinks, eventually forming "cold bridges". For finishing the building, it is better to use material in the form of dense slabs.

stone mineral wool

Excellent technical characteristics plus an acceptable price ensured sufficient demand for this material.This type of mineral wool has a low thermal conductivity, almost does not absorb moisture, while due to the cellular structure it is able to “breathe”, that is, let air through and remove condensate.

stone mineral wool

Depending on the type of raw material and the method of production, it can have a different degree of rigidity. Stone wool is produced in the form of sheets, semi-rigid mats or slabs of increased strength. Due to its high fire resistance and high degree of thermal insulation, it is widely used in construction - it is used as a heater and sound insulator of facades, roofs of buildings, which has an increased risk of fire.

It is allowed to use stone wool for insulation of underground utilities, chimneys, cladding of rooms with installed stoves or boilers.

In order to avoid the appearance of "cold bridges" when using any types of plate heaters, all seams must be additionally glued.

glass wool

Due to its low density and increased hygroscopicity, it is not recommended to use it for finishing facades. Plus, glass wool under the influence of elevated temperatures is able to melt, completely losing its thermal insulation properties.

glass wool

This inexpensive rolled material is most often used for thermal insulation of pipelines and technical rooms.

When working with it, special care is required - thin fibers, breaking off, fall on the skin, causing irritation. When inhaled into the lungs, small particles of glass wool can provoke inflammation.

Basalt wool

This material is more expensive than ordinary stone wool, but it is more durable and voluminous. Another advantage is the lower degree of moisture absorption and shrinkage.Formaldehyde, which is part of the basalt sheets, is able to scare away rodents, which often settle in the insulation.

They easily tolerate significant temperature changes without loss of quality, do not rot, do not ignite. High and their heat-insulating properties.

Basalt wool

Basalt wool has a significant drawback - high brittleness

Therefore, you need to work with it carefully, be sure to wear protective clothing, goggles and a respirator. Dust generated during sawing causes skin irritation

She is able to settle in the lungs.

Just as in the case of stone wool, it is better to use not rolled, but more durable slab material for facade cladding. Basalt wool is also applied by spraying with the help of special equipment - in this case, a special type of material is used in the form of granules.

How to make a greenhouse with your own hands: for seedlings, cucumbers, tomatoes, peppers and other plants. From polycarbonate, window frames, plastic pipes (75 Photos & Videos) + Reviews

Why insulate a brick house

A brick-built house has its own characteristics associated with the type of material used. The degree of thermal conductivity of the outer walls depends on the type of brick used - hollow or solid.

The type of masonry produced also affects the thermal conductivity of brick walls. Masonry is solid or well, with an air gap. These two points determine the layer of heat-insulating material used.

Insulation of a brick house from the outside is easier to carry out even at the stage of building walls. At this point, it is easier and more accessible to carry out the necessary work.

The main reason for the insulation of brick walls is their increased thermal conductivity. To provide the necessary heat inside the room, their thickness should be about 2 meters. And this is an unbearable load on the foundation.

Another reason for insulating the walls of a brick house is the ever-increasing tariffs for utilities. It becomes important to keep the generated heat inside the house so that it is not used to heat cold walls, floors or ceilings.

The reason to insulate the house is from the outside

External insulation of the walls of the house prevents the appearance of mold on them. It appears from the difference in temperature inside and outside the room. Indoor moisture collects on the inside surface of the outer wall, causing mold to form.

The main technologies for insulating the facades of private houses

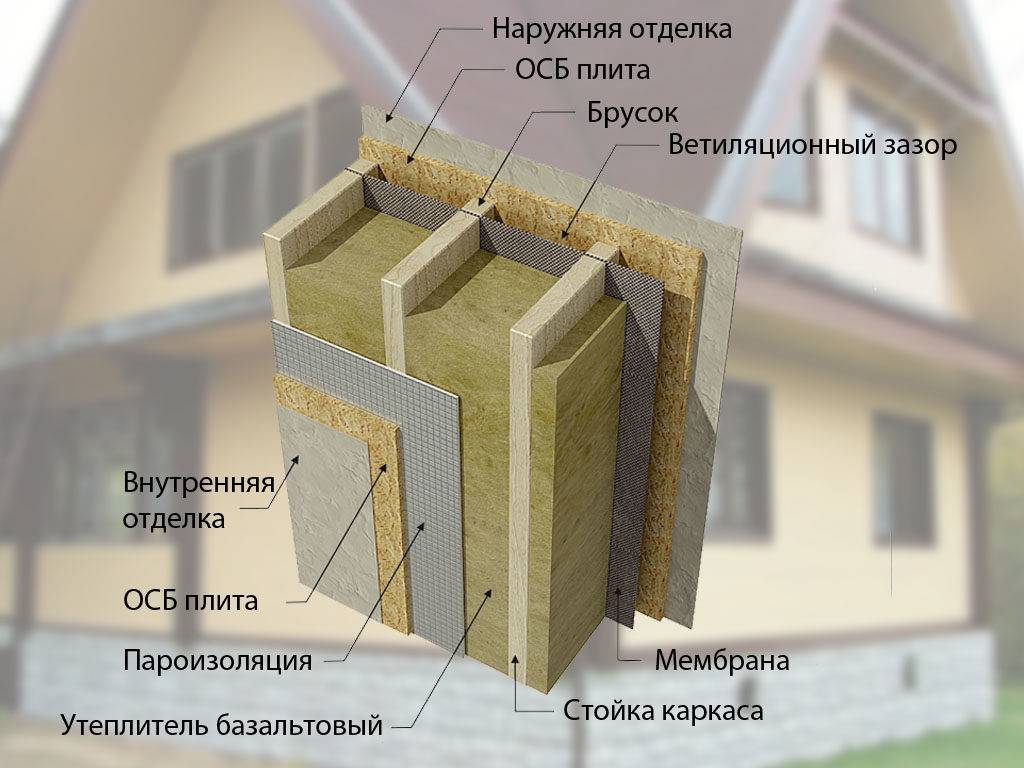

In general, there are two ways to insulate external walls:

- Dry. This includes options such as prefabricated and hinged facades. The technology involves the use of a prefabricated structure, which is made from prefabricated elements interconnected by a dry method.

- Wet. This laying technology includes the use of water-soluble building materials, which include glue, plaster and other solutions.

There are also several facade insulation systems:

- Ventilated. In this case, an additional layer is required, placing it between the outer facing material and the insulation layer. To do this, a metal or wooden crate is mounted. The insulation of the facade with siding is carried out only after the installation of the crate.

- Non-ventilated. Here the insulating layer is represented by a complete system, which does not provide for the presence of an air gap.

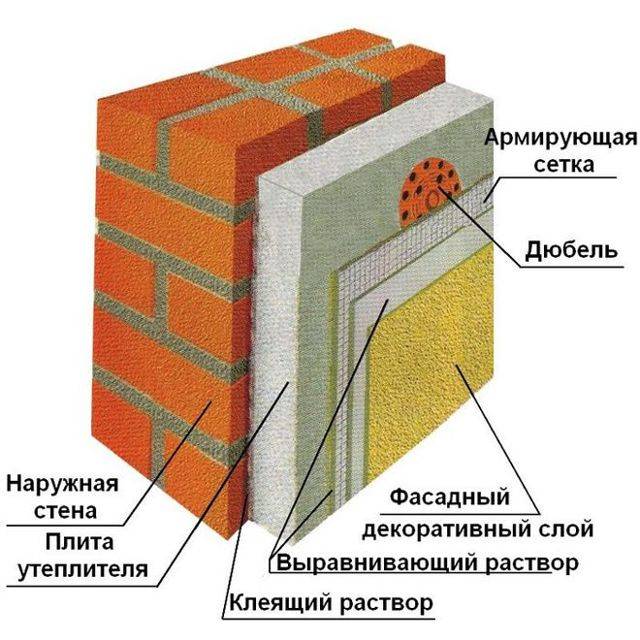

When creating a wet facade, heat-insulating, adhesive, protective and decorative layers are successively applied, which form a single wall array in thickness. Key recommendations:

The creation of a wet facade includes the application of a heat-insulating, adhesive, protective and decorative layer.

The creation of a wet facade includes the application of a heat-insulating, adhesive, protective and decorative layer.

- You should choose the right density materials: for mineral wool - 150-180 kg / m2, for polystyrene - 35. The moisture absorption coefficient should not exceed 1.5%.

- An adhesive mixture is used, intended only for outdoor use, in addition, the sheets are fastened with dowels-umbrellas.

- It is mandatory to have a reinforcing layer, for which a fiberglass mesh treated with an anti-alkali solution, laid with overlapping sheets, is used.

- With a large area of \u200b\u200bthe facade, for every 24 squares, the presence of an expansion joint should be considered.

Facing the facade with a wet method using foam boards will cost 1000 rubles per square.

The most popular facade insulation system is considered to be a hinged ventilation facade, the essence of which is the presence of a through air gap between the facade and the insulation. The ventilated layer prevents the penetration of moisture, and the air currents in the hinged frame cool the wall well during the hot season, even with direct sunlight.

For a hinged facade, it is permissible to use the same types of insulation as when making a wet facade, however, you can purchase less durable materials. This is because in this case they will not be affected by a heavy facing layer, because it is mounted on a frame mounted on the main part of the outer wall.

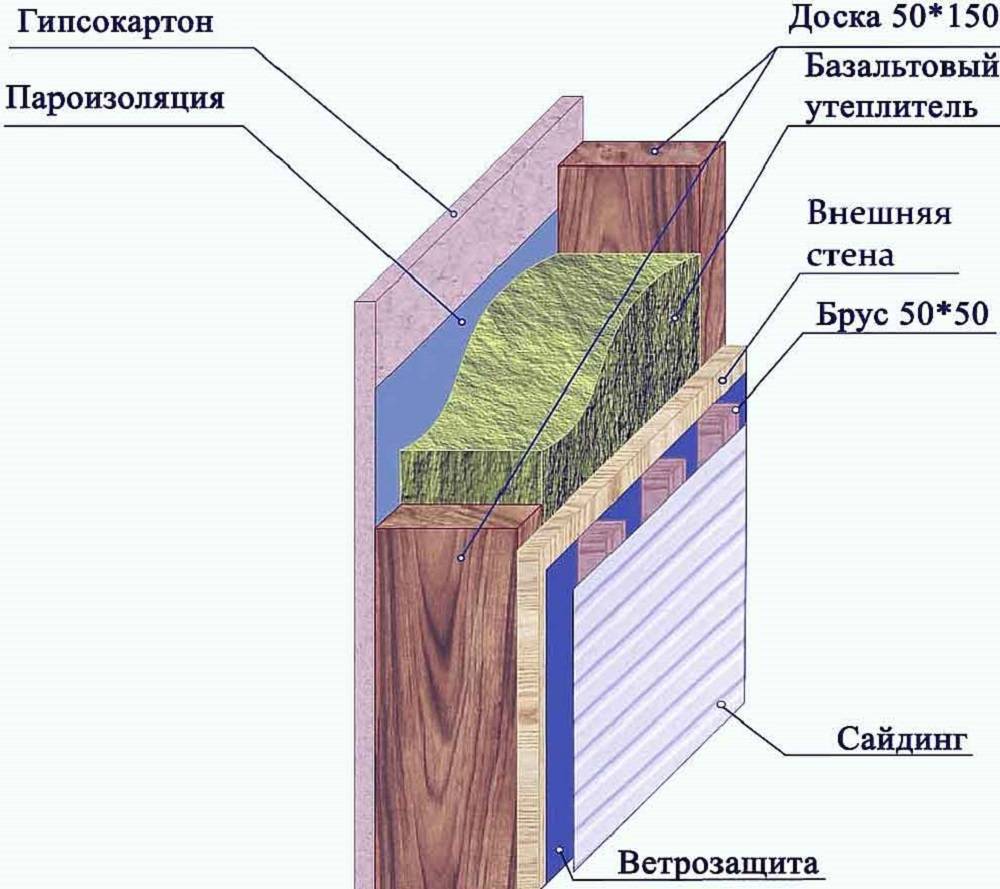

Warming the facade with a dry method for siding is one of the most popular methods. Note! If a blown insulation such as mineral wool is used, it should be covered with a diffusion membrane that protects the insulation from wind and moisture, but allows water vapor to pass through.

Warming the facade with a dry method for siding is one of the most popular methods. Note! If a blown insulation such as mineral wool is used, it should be covered with a diffusion membrane that protects the insulation from wind and moisture, but allows water vapor to pass through.

Thermal insulation of the facade under the siding by the dry method is considered one of the most popular options. The frame for cladding can be made of metal or wooden crates. If a tree is used for this, it should be pre-treated with anti-mite and fire-fighting mixtures. The pitch of the crate should be chosen 2-3 cm less than the width of the insulation sheet itself. The size of the air gap between the facing material and the insulation should vary from 60 to 150 mm.

Prices for the implementation of the ventilation facade will depend mainly on the type of frame for cladding. If a metal prefabricated structure is used, the cost will be about 2000 rubles per sq. m, in the case of using a wooden crate - 1000 rubles.

Insulation of the facade of the house from the outside is a profitable investment that will help not only significantly reduce heating costs in the cold season, but also save on air conditioning in the hot season. Properly performed insulation will create an ideal microclimate in the house and provide reliable protection for the supporting structure. The main thing is to choose the right material and adhere to the laying technology.

Window decoration outside: photo examples and step-by-step instructions (read more)