- Membrane replacement

- The principle of operation of the accumulator

- Features of the pumping station

- How to find and fix a breakdown

- How to replace the membrane in a hydraulic accumulator?

- What should be the pressure in the accumulator

- Pre-check and pressure correction

- What air pressure should be

- How to make sure that it is the hydraulic tank that is to blame?

- Airing the pump

- Characteristics of the accumulator

- Problems with the accumulator

- No water enters the hydraulic tank

- What are hydraulic tanks

- Problems with the accumulator

- Anti-smoking on balconies

- Characteristics of the accumulator

- Expansion tank

- Maintenance Rules

- How to adjust air pressure

- Terms of service of the accumulator

Membrane replacement

With minimal skills in working with plumbing equipment, replacing the membrane on the hydraulic tank is not difficult. By following the correct procedure, replacing a node takes a minimum amount of time:

- Disconnecting the tank from the water supply.

- Remove excess air pressure with a nipple.

- Drain the water from the container.

- Remove the pressure gauge, while freeing up space for the diaphragm to exit.

- Remove non-working part.

- Install a new membrane, fix the pressure gauge.

- Pump up pressure 0.2 less than the lower pressure of the pump switch.

- Install back.

After that, it is necessary to check the operability of the water supply. To do this, it is necessary to fill the system with water and control the operation of the tank.

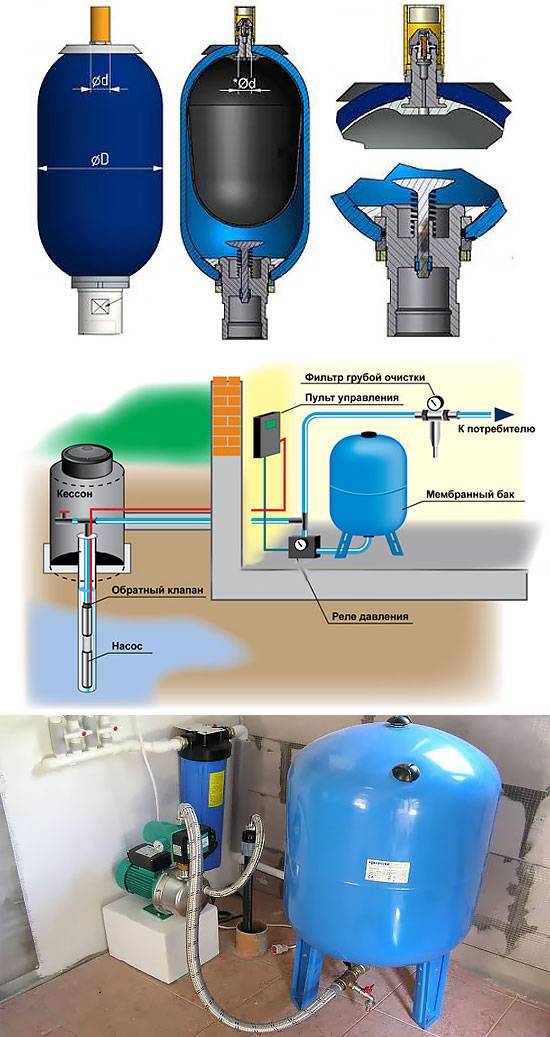

The principle of operation of the accumulator

Hydraulic accumulator (Greek hydor - ‘water,’, Latin accumulator - ‘collector’), hydraulic tank for water supply - an auxiliary unit in the water supply system that protects the system from water hammer.

Hydraulic accumulator functions:

- balances the loads and force of the pump, softening pressure surges at the stages of turning on and off the equipment;

- absorbs hydraulic shocks. Therefore, the accumulator device for water supply systems provides for a thread of at least one inch;

- reduces the number of pump starts;

- compensates for leaks;

- creates a supply of water in emergency or emergency situations.

Features of the pumping station

The design of the pumping station consists of several important key points that will not be able to work if one of them fails:

- a pump is a device responsible for raising liquid from the bowels of the earth to the surface;

- a hydraulic accumulator is a reservoir in which water accumulates as a reserve and after the station is turned off, it is thanks to it that the pressure level is maintained in the pipeline;

- control unit that automatically turns the pump on and off.

Thus, it can be seen that the pumping station is operating intermittently. That is, if necessary, the pump pumps water, and as soon as the required pressure in the pipeline is reached, it automatically turns off. This greatly extends the life of the equipment.And in the event of a system failure, when the pumping station does not turn off and continues to supply water, it must be stopped immediately. Most often, the cause of such problems lies in a small box called a pressure switch.

How to find and fix a breakdown

Hydraulic tank device

To find the problem yourself, you need to know the device of the hydraulic accumulator. Parts of his design:

- metal case;

- rubber membrane;

- flange with outlet for water supply;

- nipple for pumping air;

- installation platform.

Frequent switching on of the pump causes several factors:

- Low air pressure in the tank. It is eliminated by pumping the compressor through the nipple.

- Loss of tightness. Holes appear in the metal case due to rust or mechanical damage. The container is covered with a liquid soapy solution to find a leak. The tightness is restored by specialists.

- A small threshold difference is set on the pressure control switch. The problem is corrected by adjusting the small spring of the device.

- Membrane rupture. The rubber pear inside the tank may burst due to excessive stretching, friction against the walls of the tank, due to natural wear. The breakdown is corrected by replacing or repairing the membrane. Vulcanization of a rubber product restores its integrity. When replacing, choose an original part of the same size.

Low water pressure:

- Insufficient pump power. Check the calculations for the correspondence between the volume of the accumulator and the characteristics of the unit.

- Bypass check valve. Replace the part after shutting off the water.

Membrane for accumulator

Membrane for accumulator

Constant drop in water pressure:

The rarefaction of the air environment - should be pumped up with a compressor or pump up to 1.5-2 atmospheres.

Nipple breakage. The device through which air is pumped may break. The tank is leaking. You can replace the nipple in the accumulator with your own hands or take the device to a service center

The part is fixed with a nut, it is carefully unscrewed, then removed. When installing a new nipple, a rubber gasket and sealant are used.

Fluid leaks on body:

- The flange is fluid-permeable. If the part is new, it is enough to tighten the screws with a wrench. The old rusty flange needs to be replaced. Parts are sold in a specialized store. They are available entirely in metal or with plastic inserts.

- Leak from the nipple. The cause of the problem is a rupture of the membrane. To replace, remove the flange, then remove the rubber container. It is recommended to wash the tank from the inside. The new membrane is installed after complete drying. It is secured with a flange.

How to replace the membrane in a hydraulic accumulator?

The membrane for the hydraulic tank is made of high-strength EPDM rubber, its service life is about 10 years. During normal operation, nothing happens to her. It bursts or tears against the wall of the case, if the air pressure in the tank was not controlled, if the air escaped.

Replacing the membrane in the accumulator is easy.

- Turn off the pump, release the pressure in the system.

- Unscrew the bolts, remove the flange, get the torn membrane.

- Put a new one without using sealant or gaskets. The use of glue in the places of fasteners creates a decrease in friction between metal and rubber. The result is a displacement of the edge of the membrane, a decrease in the density of the connection. Loose fasteners will soon lead to water leakage.

- Put the flange, tighten the bolts.

- Pump air into the accumulator up to 1.4-1.5 atm.

- Fill the pump with water, plug it into the socket.

- Pressurize the system.

The procedure for installing a new membrane in collapsible accumulators for water supply is the same: the design of the device does not depend on its size.

Hydraulic tanks come with a non-removable membrane - the manufacturer guarantees that it will not break under any pressure surges. If something happens, you need to change the entire unit.

The principle of operation of the accumulator increases the life of the pump of the water supply system.

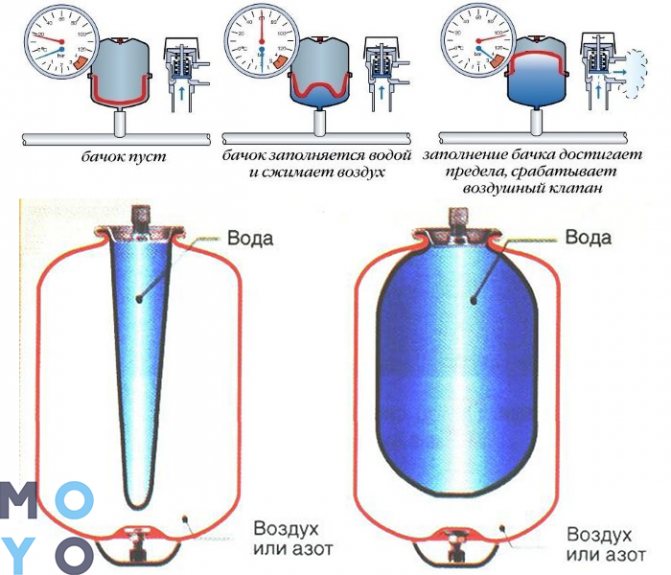

What should be the pressure in the accumulator

Compressed air is in one part of the accumulator, water is pumped into the second. The air in the tank is under pressure - factory settings - 1.5 atm. This pressure does not depend on volume - and on a tank with a capacity of 24 liters and 150 liters it is the same. More or less may be the maximum allowable maximum pressure, but it does not depend on the volume, but on the membrane and is indicated in the technical specifications.

Pre-check and pressure correction

Before connecting the accumulator to the system, it is advisable to check the pressure in it. The settings of the pressure switch depend on this indicator, and during transportation and storage the pressure could drop, so control is very desirable. You can control the pressure in the gyro tank using a pressure gauge connected to a special inlet in the upper part of the tank (capacity of 100 liters or more) or installed in its lower part as one of the piping parts. Temporarily, for control, you can connect a car pressure gauge. The error is usually small and it is convenient for them to work.If this is not the case, you can use the regular one for water pipes, but they usually do not differ in accuracy.

If necessary, the pressure in the accumulator can be increased or decreased. To do this, there is a nipple at the top of the tank. A car or bicycle pump is connected through the nipple and, if necessary, the pressure is increased. If it needs to be bled off, the nipple valve is bent with some thin object, releasing air.

What air pressure should be

So the pressure in the accumulator should be the same? For the normal operation of household appliances, a pressure of 1.4-2.8 atm is required. To prevent the tank membrane from tearing, the pressure in the system should be slightly higher than the tank pressure - by 0.1-0.2 atm. If the pressure in the tank is 1.5 atm, then the pressure in the system should not be lower than 1.6 atm. This value is set on the water pressure switch, which is paired with a hydraulic accumulator. These are the optimal settings for a small one-story house.

If the house is two-story, you will have to increase the pressure. There is a formula for calculating the pressure in a hydraulic tank:

Vatm.=(Hmax+6)/10

Where Hmax is the height of the highest draw point. Most often it is a shower. You measure (calculate) at what height relative to the accumulator its watering can is, substitute it into the formula, you get the pressure that should be in the tank.

If the house has a jacuzzi, everything is more complicated. You will have to select empirically - by changing the relay settings and observing the operation of water points and household appliances. But at the same time, the working pressure should not exceed the maximum allowable for other household appliances and plumbing fixtures (indicated in the technical specifications).

How to make sure that it is the hydraulic tank that is to blame?

The simplicity of the design gives the right to hope for a long and trouble-free operation of this tank. This is absolutely correct, because there are not so many problems that occur in the operation of the device. Therefore, first you need to consider options when other equipment can “jump”, the work of which is directly related to the “collector” of water.

The hydraulic accumulator is far from always the culprit of the weak water pressure, the unsatisfactory operation of the system. Often the problem lies in an incorrectly selected, or improperly functioning, pump. In the first case, the power of the device is simply not enough, in the second case, some kind of malfunction interferes with the operation of the pump. Do-it-yourself pump repair is a risky operation, especially for those for whom such work is “terra incognita”. Therefore, it is better for them to turn to specialists.

A fairly common phenomenon is frequent switching on or constant (almost continuous) operation of the pump. If the hardware is behaving strangely, you should first make sure that it is (or not) its fault. The procedure is as follows:

- Outlet pressure check. The norm is 0.15-0.2 MPa (1.5-2 atm.) If the value is different, then the provocateur of the problem has been detected.

- Checking the source. If the pressure is in order, then the next possible culprit is a well or a well. In this case, the pump is tested as follows: it is lowered into a container with liquid - into a barrel, a capacious canister, etc. When the pressure is normal, the problematic "source - source" of water.

- Pressure switch adjustment. This is another possible way. The relay cover is removed, then the springs are compressed or weakened with an adjusting screw: the smaller of them is responsible for the lower pressure limit.A large and thicker detail - for the top. After adjustment, the pump must stop working.

- The last operation is to inspect the water supply, because another possible reason for the continuous operation of the pump is the presence of a leak in the system. To confirm or refute the guess, the valve is closed after the tie-in point of the hydraulic tank. If the fault lies with the leak, then after a while the pump should stop.

Airing the pump

The water station stops gaining pressure and performing its functions if air enters the working chamber or the pump line. This phenomenon is not uncommon, especially if a surface pump is used: when the water in the well drops below the permissible level or the suction hose is deformed, air inevitably enters the pumping system.

To squeeze out the air, you need to connect a special tee to the pump and put water under pressure. And subsequent actions will depend on the cause of airing.

If the problem is in the well, you just need to lower the hose slightly below the original level or equip the pump with a float switch. If airing was due to hose deformation, you need to find all the cracks and close them with plumbing tape. In case of large holes, it is recommended to completely replace the hose.

Characteristics of the accumulator

To begin with, we list the main points due to which hydraulic accumulators are so significant - what the devices in question are needed for. First of all, they are necessary for the effective implementation of the following tasks:

- accumulation of a reserve supply of life-giving moisture, which can be used in case of an unforeseen situation;

- reliable protection of the pipeline from water hammer resulting from the inclusion of the pump;

- stabilization of excess pressure in the system;

- extension of the uninterrupted operation of the pump (the pump mechanism is activated only when necessary);

- "leveling" the pressure of water with its intensive consumption;

- maintaining a constant pressure in the pipes when the pump is turned off.

As for the design of the device for water supply, it provides for the presence of the following elements:

- platform;

- case made of durable stainless steel;

- membrane;

- flange with valve for water injection;

- nipple for air supply.

As you can see, the accumulator is not only extremely important, but also not the simplest device from a technical point of view. It works a lot and intensively, and therefore one should not be surprised at the malfunctions that appear in it over time. At the same time, its quick failure is not the norm, since high-quality hydraulic accumulators, which are produced in accordance with current standards, have a solid operational resource.

Problems with the accumulator

You can check the pressure in the accumulator with a car pressure gauge

You can check the pressure in the accumulator with a car pressure gauge

The most common malfunction is a decrease in pressure inside the water supply network. There is only one reason - the pressure between the rubber membrane and the steel walls of the accumulator has dropped. In the factory, nitrogen is pumped into the tank at a pressure of 1.5 atm. It creates pressure inside the water supply network by pressing on the membrane into which water is pumped from a well or well by a pump.

Nitrogen pressure decreases for various reasons, but more often due to the weak holding capacity of the nipple. Solving this problem is easy on your own.To do this, use a car pressure gauge, which check the pressure by installing it on the nipple. The latter is located on the opposite side of the hydraulic tank inlet.

- Remove the protective cover of the nipple, made of plastic.

- Install a manometer, check the pressure inside the tank.

- If the parameter is underestimated, air is pumped through the same nipple with a conventional automobile pump to the desired value.

- Close the nipple with a cap.

Even if after that the pressure in the used accumulator quickly drops, the cause must be sought elsewhere. Most often these are smudges at the joints of the plumbing system. Therefore, it is necessary first of all to investigate the entire plumbing system. Usually they check the joints between pipes, joints with fittings, with shutoff valves, with filters for various purposes, with consumers and other products installed in the plumbing system of a private house. If leaks are found, they must be fixed.

There are two more reasons why the accumulator does not hold the required pressure. This also applies to reducing the nitrogen pressure inside the tank.

- Over time, areas of leaks appear at the junction of the flange-nipple connection. They are leaking gas. To solve this problem, it is necessary to unscrew the nipple, remove the old flange and install a new one in its place. Spare parts and parts from hydraulic tanks are sold in all hardware stores.

- The same applies to the junction of the flange and the rubber pear-shaped membrane. Sometimes this problem is solved by simply tightening the mounting bolts (there are six of them in the tank design).

If the pressure is set incorrectly, the diaphragm wears out quickly

If the pressure is set incorrectly, the diaphragm wears out quickly

Sometimes in a hydraulic accumulator, the membrane simply breaks due to wear. To replace the rubber bulb, you need to disassemble the device:

- the pump is turned off;

- one of the consumers opens, water is drained from the water supply network;

- flexible hoses connecting the accumulator with the water supply are unscrewed;

- six bolts connecting the flange to the membrane are unscrewed with a wrench;

- the flange is removed, the pear is pulled out;

- the container is washed and dried;

- a new membrane is installed;

- a flange is mounted, which is pressed with fixing bolts;

- from the side of the nipple, air is pumped into the tank using a car pump to a pressure of 1.5 atm.;

- the hydraulic accumulator is connected with flexible hoses to the water supply;

- the pressure switch is configured to turn on and off the pumping unit, taking into account the passport pressure of the hydraulic tank.

This repair process can take several hours. The service center will do it in half an hour. But since the procedures are simple, they can be done by hand.

No water enters the hydraulic tank

This reason for the inoperative state of the hydraulic tank is common. It's all about the degree of contamination of water that is pumped from a well or well. Filters are installed in front of the pump and the entrance to the house, which periodically become clogged. This causes the accumulator doesn't take on water.

With the first filter, the pump has the least problems. It rarely clogs because it has a mesh structure with large cells. Its task is to prevent stones and debris from entering the pumping unit.

Filters installed inside the house in the water treatment system are often clogged. The dirtier the water, the faster the blockage occurs. Usually they change cartridges for new ones.In the passports of these products, the standards for the life of the devices are established. They should be taken as the basis of prevention.

Another reason why accumulators do not fill with water is a sharp decrease in mains voltage. The pump is not working properly. Its characteristics such as pressure and productivity are falling. Head loss is the drop in pressure of the water flow itself. It cannot withstand the nitrogen pressure inside the accumulator. The gas pumped into the tank simply does not allow the liquid to penetrate into the rubber bulb.

The problem is solved by purchasing a step-up transformer, which is installed between the connection point and the pumping station.

The third reason is the airing of the water main. This phenomenon is not uncommon in autonomous networks, especially if a surface pump is installed in them. In some area, an air lock is formed, which stands still and prevents the water from moving further.

To do this, a tee is usually mounted on the suction circuit with the installation of a drain cock or valve. When such a situation arises, you just need to open the faucet and drain the water along with the air.

The causes of airing can be different situations:

- deformation of the suction hose, the appearance of through cracks or holes on it, in this case it is better to replace the hose with a new one;

- a decrease in the water level in a well or well, due to which air is drawn into the suction pipe, the problem is easily solved - you need to lower the hose lower.

What are hydraulic tanks

Types of membrane tanks and their features are classified according to their purpose and installation methods.

By appointment - industrial, household, for hot or cold water.

Hydraulic tanks for different water temperatures are distinguished by color. For the hot water supply system (heating), they produce red ones with a membrane that can withstand high temperatures. The types of blue membrane tanks and their features are determined by the fact that they are made to supply cold water; they contain rubber without impurities harmful to health, the membrane can be changed independently.

According to the installation method, vertical and horizontal hydraulic accumulators for water supply are produced.

Their device differs by the method of reducing the critical pressure. The vertical ones have a nipple-air vent mounted on top to relieve "excess" pressure. In horizontal hydraulic tanks, air is removed through a block connected to the pipeline with a ball valve, an outlet air nipple into the sewer drain.

Problems with the accumulator

You can check the pressure in the accumulator with a car pressure gauge

The most common malfunction is a decrease in pressure inside the water supply network. There is only one reason - the pressure between the rubber membrane and the steel walls of the accumulator has dropped. In the factory, nitrogen is pumped into the tank at a pressure of 1.5 atm. It creates pressure inside the water supply network by pressing on the membrane into which water is pumped from a well or well by a pump.

Nitrogen pressure decreases for various reasons, but more often due to the weak holding capacity of the nipple. Solving this problem is easy on your own. To do this, use a car pressure gauge, which check the pressure by installing it on the nipple. The latter is located on the opposite side of the hydraulic tank inlet.

- Remove the protective cover of the nipple, made of plastic.

- Install a manometer, check the pressure inside the tank.

- If the parameter is underestimated, air is pumped through the same nipple with a conventional automobile pump to the desired value.

- Close the nipple with a cap.

Even if after that the pressure in the used accumulator quickly drops, the cause must be sought elsewhere. Most often these are smudges at the joints of the plumbing system. Therefore, it is necessary first of all to investigate the entire plumbing system. Usually they check the joints between pipes, joints with fittings, with shutoff valves, with filters for various purposes, with consumers and other products installed in the plumbing system of a private house. If leaks are found, they must be fixed.

There are two more reasons why the accumulator does not hold the required pressure. This also applies to reducing the nitrogen pressure inside the tank.

- Over time, areas of leaks appear at the junction of the flange-nipple connection. They are leaking gas. To solve this problem, it is necessary to unscrew the nipple, remove the old flange and install a new one in its place. Spare parts and parts from hydraulic tanks are sold in all hardware stores.

- The same applies to the junction of the flange and the rubber pear-shaped membrane. Sometimes this problem is solved by simply tightening the mounting bolts (there are six of them in the tank design).

If the pressure is set incorrectly, the diaphragm wears out quickly

Sometimes in a hydraulic accumulator, the membrane simply breaks due to wear. To replace the rubber bulb, you need to disassemble the device:

- the pump is turned off;

- one of the consumers opens, water is drained from the water supply network;

- flexible hoses connecting the accumulator with the water supply are unscrewed;

- six bolts connecting the flange to the membrane are unscrewed with a wrench;

- the flange is removed, the pear is pulled out;

- the container is washed and dried;

- a new membrane is installed;

- a flange is mounted, which is pressed with fixing bolts;

- from the side of the nipple, air is pumped into the tank using a car pump to a pressure of 1.5 atm.;

- the hydraulic accumulator is connected with flexible hoses to the water supply;

- the pressure switch is configured to turn on and off the pumping unit, taking into account the passport pressure of the hydraulic tank.

This repair process can take several hours. The service center will do it in half an hour. But since the procedures are simple, they can be done by hand.

Anti-smoking on balconies

Friends, hello everyone. I hope to listen to the forum members on this issue. Actually, the essence is that there is an apartment building, many balconies, as soon as one of the neighbors comes out to smoke, everything immediately sucks into our rooms (summer, the windows are open). I would like to…

This is interesting: What to do to avoid an increase in pressure in the cold water circuit - we analyze carefully

Characteristics of the accumulator

To begin with, we list the main points due to which hydraulic accumulators are so significant - what the devices in question are needed for. First of all, they are necessary for the effective implementation of the following tasks:

- accumulation of a reserve supply of life-giving moisture, which can be used in case of an unforeseen situation;

- reliable protection of the pipeline from water hammer resulting from the inclusion of the pump;

- stabilization of excess pressure in the system;

- extension of the uninterrupted operation of the pump (the pump mechanism is activated only when necessary);

- "leveling" the pressure of water with its intensive consumption;

- maintaining a constant pressure in the pipes when the pump is turned off.

As for the design of the device for water supply, it provides for the presence of the following elements:

Hydraulic accumulator device diagram

- platform;

- case made of durable stainless steel;

- membrane;

- flange with valve for water injection;

- nipple for air supply.

As you can see, the accumulator is not only extremely important, but also not the simplest device from a technical point of view. It works a lot and intensively, and therefore one should not be surprised at the malfunctions that appear in it over time. At the same time, its quick failure is not the norm, since high-quality hydraulic accumulators, which are produced in accordance with current standards, have a solid operational resource.

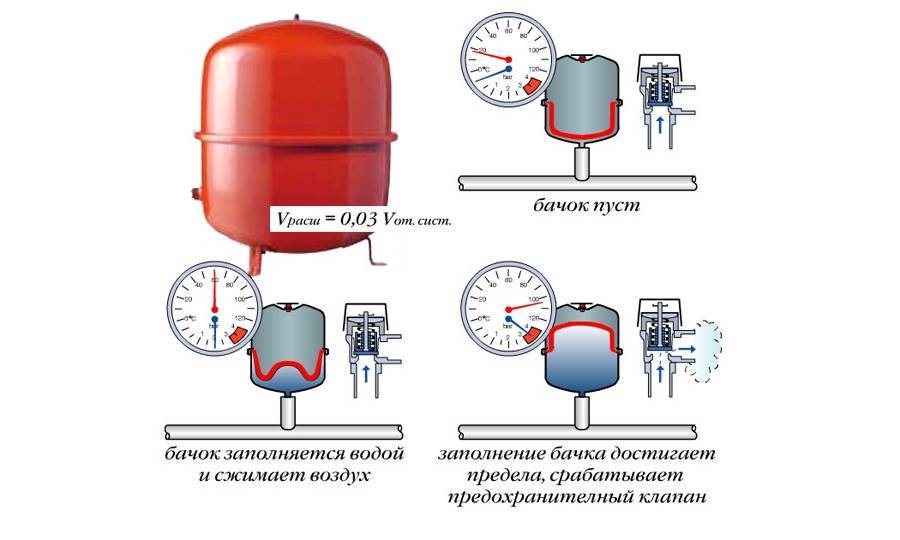

Expansion tank

Heating water is designed to transfer heat from the boiler to the radiators. It is known that when heated by 10 ° C, the volume of water increases by about 0.3%, from which it follows that heating to the prescribed 70 ° C will give an increase in volume by about 3% of the original. It is known from the school physics course that liquids are practically incompressible, therefore even such a seemingly insignificant increase in volume can lead to a rupture of the pipeline or leaks at the joints. In order to prevent this from happening, an expansion tank is installed in the heating system.

Initially, such containers were open, which led to certain problems:

- the liquid in them constantly evaporates, you have to monitor the water level and replenish it regularly; - an open expansion tank must be installed in the upper part of the system and insulated to prevent freezing of the coolant and, as a result, an increase in the cost of the structure; - constant access of oxygen contributes to corrosion; - pressure regulation with an open circuit is difficult.

Modern materials and, in particular, the durable and elastic material of the membrane, make it possible to equip a closed system, without access of oxygen to the coolant. This also allows for a constant water level and the ability to adjust the pressure. Another advantage of the closed tank is the ease of installation and maintenance. It can be installed anywhere in the heating system and, if necessary, can be easily dismantled and connected elsewhere.

Maintenance Rules

Optimum in the accumulator ensures a constant water pressure and prevents wear of system parts

Optimum in the accumulator ensures a constant water pressure and prevents wear of system parts

Like all plumbing fixtures, the accumulator has a certain operational resource. To increase it, it is necessary to carry out periodic maintenance. If the switching on and off of the pumping unit has become more frequent, this indicates that the pressure inside the tank has decreased - an air leak has occurred.

How to adjust air pressure

You can cope with the reason for the frequent activation of the accumulator with your own hands. To do this, you need a pressure gauge that measures the pressure in automobile wheels. The sequence of operations performed:

- the pump is disconnected from the mains supply;

- any faucet or faucet in the water supply network is opened to relieve water pressure;

- the protective cover of the nipple is removed, which is located on the opposite side of the inlet pipe;

- a manometer is connected to the nipple;

- the air pressure reading is taken, it must correspond to the parameter indicated in the product passport or on a metal plate located on the accumulator body.

If the pressure is much lower than the passport pressure or it does not exist at all, air is pumped into the tank using a conventional automobile pump or compressor.

It is very important to properly adjust the air pressure. If this parameter is higher than the passport one, a situation may arise when the air will squeeze the membrane to the maximum, causing it to shrink

It will be impossible to pump water into it. Therefore, after injection, it is necessary to check the pressure with a manometer. If the indicator turned out to be higher than required, it is necessary to bleed the air.

In the factory, the accumulator is usually filled with nitrogen. This does not mean that gas cannot be replaced by air. You just need to release it first.

It is necessary to check the hydraulic accumulator for operability once every six months. If the pressure drops, which means that there is a malfunction in the junction between the body and the nipple. Solving this problem is also easy. It is necessary to tighten the nipple or bolts on the flange. The leak test is usually carried out with a soapy solution.

Terms of service of the accumulator

Hydraulic accumulator device

There are recommendations from manufacturers that must be used during the operation of accumulators. If you strictly adhere to them, you can almost double the operational life of the device.

- Once a month, check for compliance with the set value for switching on and off the pumping unit.

- Once every six months, inspect the accumulator for external condition: the presence or absence of dents, corrosion, smudges, and other things.

- Once every six months, check the air pressure with a manometer.

- If the country house will not be used in cold weather, care must be taken to drain the water from the accumulator for the winter.