- Leak test and completion

- Screwing on the new shut-off valve

- How to fill a gas bottle?

- How to change the valve on a propane tank?

- Varieties of gas valves

- Components of a gas cylinder

- Why is it not worth refueling at conventional gas filling stations?

- Independent work

- Leak test and completion

- Gas valve troubleshooting guide

- How does a cylinder reducer work:

- 1 Direct reducer

- Membrane

- 2 Reverse gear

- Hands off!

- What will happen

- Types of plates for gas cylinders

- Desktop and floor

- Number and type of burners

- Availability of additional options

- Design features

Leak test and completion

When checking the tightness of the valve connection, it will be necessary to pump gas under pressure into the gas cylinder.

This can be done in two ways:

- Inject gas using compressor equipment or a car pump.

- Connect two cylinders with a hose, the first of which is empty (tested), and the second is filled with gas.

First, under the control of a pressure gauge, fill the test cylinder with gas with a pressure of 1.5-2 atmospheres. After that, soap suds are applied to the connection and the tap opens slightly.

If soap bubbles do not inflate anywhere, then the connection is tight.But if at least slight swelling of the foam appears, then you will have to twist the valve again.

When the valve is immersed in water, it is advisable to close the side fitting with a plug so that water and suspended particles contained in it do not enter the locking mechanism.

If the balloon is small, then you can immerse its valve in a small bowl of water and look for bubbles.

After replacing the shut-off valves in the passport of gas cylinders, a corresponding mark must be put down.

It should be remembered that the methods described above for replacing a used valve are applicable only to metal tanks. If you have a composite cylinder for storing gas, this cannot be done because of the possibility of damaging the flask and breaking its tightness.

Screwing on the new shut-off valve

Before tightening the valve, all connected parts must be degreased to prevent clogging of the locking mechanism. To do this, you can use a cloth with ordinary detergent or moistened with white spirit. After that, rinse the surfaces with plain water and allow them to dry.

A new valve is never bolted to the cylinder with bare threads. It is imperative to use a sealant: a special thread lubricant or a fluoroplastic fum tape. They are applied to the lower fitting and only after that the valve is tightened.

No additional gaskets are intended to be used between the valve and the cylinder body, a seal and adequate clamping force will suffice

The thickness of the gas fum tape is more than the plumbing one and is 0.1 - 0.25 mm, and its reel should be yellow. The tape is wound with tension in 3-4 layers.It is better to twist it once more at break than to make the seal loose.

Clamp the valve preferably with a torque wrench. Steel valves are screwed with a maximum force of 480 Nm, and brass - 250 Nm. After clamping the valve, you can proceed to the next steps to test the tightness of the resulting connection.

How to fill a gas bottle?

Refuel such devices on the territory of special points, which can be located autonomously and enter the gas station. In the conditions of the latter, it is possible to refuel with gas motor fuel.

The most important nuance in this process is the fact that you need to refuel not by volume, but by weight. As a safety precaution, gas containers should be filled to a maximum of 85 percent of the total volume, in order to avoid excessive pressure.

In order to follow safety precautions and its standards, such a device with any volume is marked with a number with a maximum allowable weight, corresponding to the same allowable 85 percent. The tanks are placed on the scales, including fuel injection. The process stops after reaching the required mass.

But even when refueling relative to the mass, overflows are not excluded, which is especially important for small-volume containers - by 5 or 12. They should be refueled by 2 and 6 kilograms, respectively. The high speed of refueling sometimes does not allow you to see the achievement of the limit rate. If this happened to you, be sure to ask for the excess gas to be drained. In the future, it is better to choose another place for refueling.

In general, the basic criterion for choosing a tanker is the availability of license documents for the use of fire and explosive objects.If the documents are present, then we can conclude that you are served by qualified specialists who annually undergo special certification.

In other cases, you take responsibility for the operation of the refilled container. And you risk not only your money, but also the safety of your home and life. In addition, an unlicensed gas station is a violation of the law and may entail not only administrative, but also criminal liability regarding the article on illegal entrepreneurial activity.

The information provided in the review does not claim to be accurate encyclopedic data and is largely dictated by our experience. But we are sure that it can help you save a lot of time and money.

How to change the valve on a propane tank?

Liquefied propane is used both in everyday life and in production. Bottled gas is indispensable for autonomous gasification, so containers are often installed in summer cottages and other remote places. If the valve breaks off the cylinder or other malfunctions of the control device occur, it is recommended to contact specialists. It is not always possible to replace it yourself.

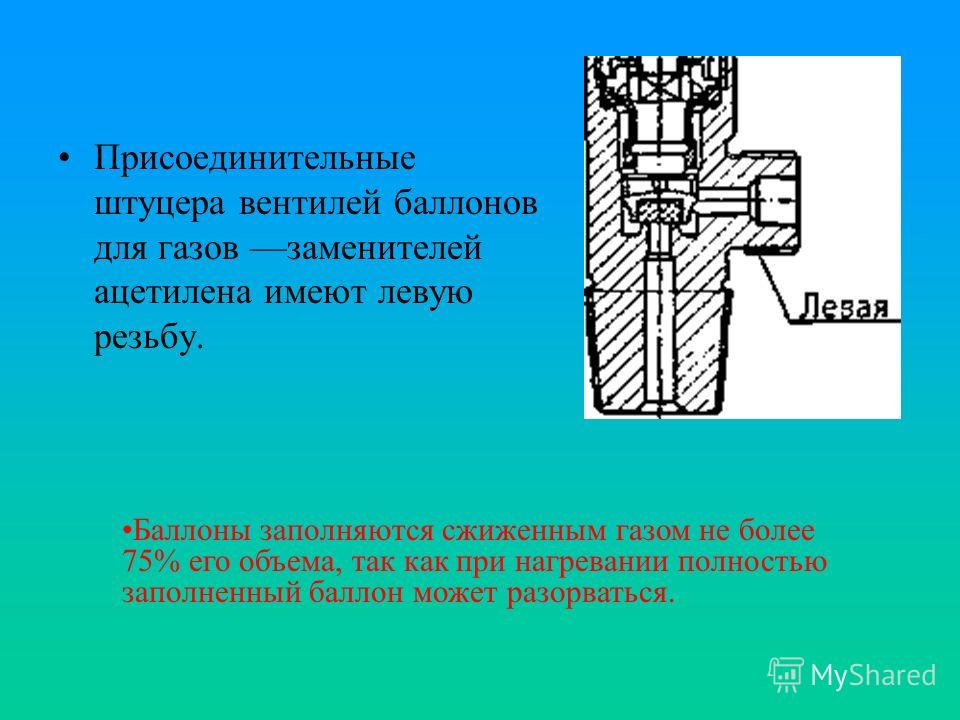

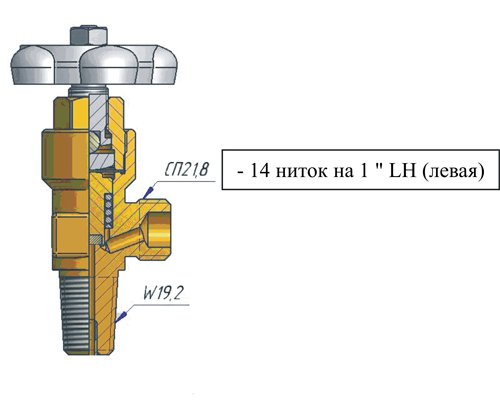

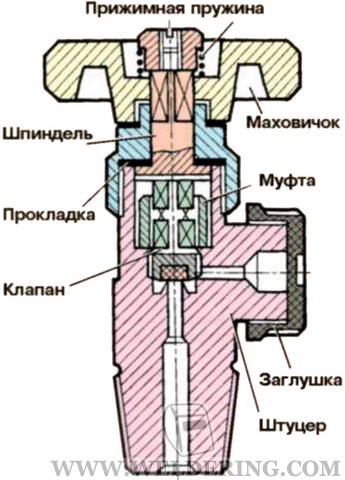

Varieties of gas valves

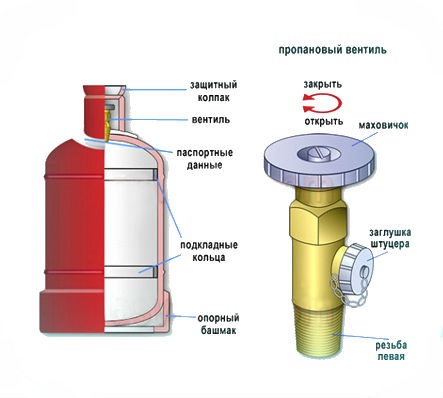

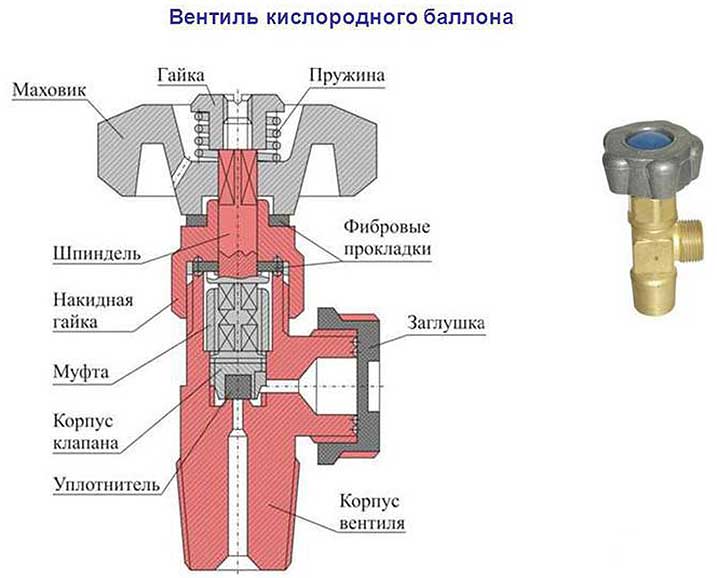

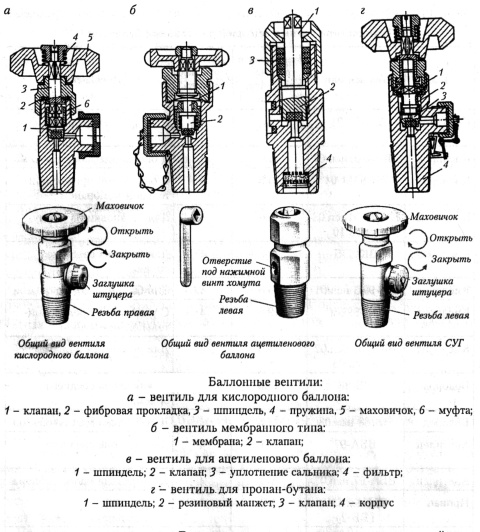

Before considering the shut-off valves in detail, it is necessary to clarify that they are just a part of a container for transporting and storing various gases under pressure. Cylinders are made of carbon or alloy steel according to GOST 949-72. Between themselves, they differ in color and volume, but the device is the same. So, a gas cylinder consists of a valve, a seal, a thread and a seamless tank with the passport data assigned by the manufacturer to be stamped on it.

Valves are divided into several varieties, depending on what the cylinders are filled with: liquefied gas, oxygen or propane-butane. At the same time, there are practically no distinctive features of the structures, only the marking of valves according to GOSTs differs:

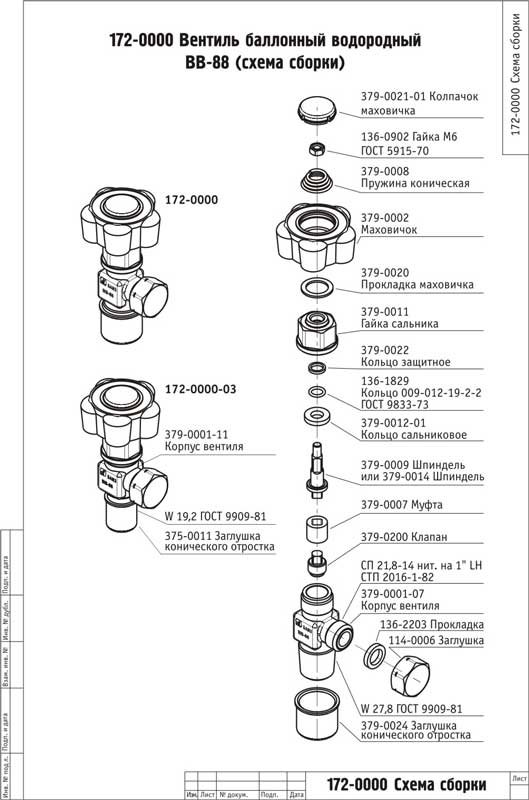

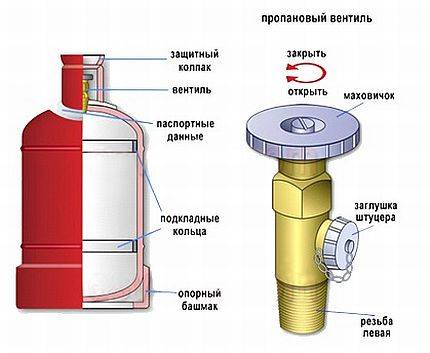

Components of a gas cylinder

Requirements for production processes and technical characteristics of gas cylinders are regulated by rather old GOSTs 949-73 and 15860-84.

The maximum working pressure in the devices ranges from 1.6 MPa to 19.6 MPa, and the wall thickness can vary from 1.5 to 8.9 mm.

A standard gas cylinder assembly consists of the following items:

- The body of the balloon.

- Valve with stop valves.

- Closing valve cap.

- Backing rings for fixing and transportation.

- Base shoe.

An important element of the cylinder is also the technical information stamped on it.

The bottom of the cylinders has the shape of a hemisphere for uniform distribution of internal pressure. For better stability of the body, a shoe is welded on the outside, on the lower edges of which there are often holes for attaching the cylinder to horizontal surfaces.

The types of gas cylinders and the features of their marking will be introduced in the article, which we recommend viewing and reading.

Why is it not worth refueling at conventional gas filling stations?

The question of whether it is possible to fill household gas cylinders at gas filling stations should be considered in more detail. According to the law, liquefied gas can only be sold at special equipped points. But many car filling stations bypassing the law are trying to make money on this.

When purchasing gas at such a gas station, consumers should be aware not only of legal liability, but also of the danger that an incorrectly filled cylinder is fraught with.

Filling household cylinders is possible only at points where there is special equipment and a license. Compliance with the rules indicated in the poster is a prerequisite that guarantees safety

And the risks are great if:

- the container is not checked for leakage;

- control of the survey, and therefore, serviceability, is not carried out;

- but most importantly, there is no way to check the filling capacity at car filling stations, which is provided for by the approved standards (85% of the volume).

The free zone creates a "vapor cap" that prevents the expansion of the gas. For example, when heated under the sun. How much liquid substance is needed is easy to calculate by dividing the nominal volume by 1.43. For example, for a cylinder designed for 22 liters, it is enough to add 15.38 liters of liquefied gas.

If there is no cutter, the work is carried out literally “by eye”, therefore, there is a high possibility of overflowing the tank, which means an increase in the possibility of a catastrophic risk.

Therefore, before filling an empty gas cylinder at a gas filling station, make sure that the point has special equipment for this, including weighing scales. But it is better to fill the containers at special gas filling stations in order to guarantee weight control.

Before refueling, the cylinder is weighed so as not to exceed the permissible mass parameters after refueling

Independent work

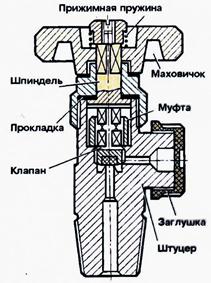

What to do if the gas cylinder leaks gas? The following manipulations will be required (only suitable for VK-94 models).

A 2.7 cm wrench is taken. The nut is tightened (indicated in the image).The motion vector is clockwise (CS).

When the flywheel opens and the propane tank valve poisons, unscrew the flywheel in reverse vector to the very limit.

If these options do not work, then you need to:

- Unscrew the nut located under the flywheel. Movement - against emergency situations. Then it is removed from the tank.

- Using a wrench, unscrew the nut at the top of the flywheel by 1 cm.

- The stem is taken out of it. There is a gasket there.

It should have two holes:

- internal - maximum 8.5 mm.

- external - identical to the parameter of the nut from the inside (diameter).

After installing a new product, the stem must be placed very tightly. He needs to be beaten. You can do this with a hammer or the flat side of the key. After that, the flywheel returns to its position and is screwed with a nut. It should not be screwed to the limit. The spring does not need to be clamped here. It must be tight. Otherwise, the flywheel will not rotate.

Such measures often become a solution to the dilemma - what to do if the gas cylinder poisons? It is important at the end of the operation to put the assembly back on the cylinder and screw it on with a nut. Vector - ES

You need a 2.7 cm key. Force: 5-7 kg. Screw not to the limit.

If you have a VKB crane, you cannot disassemble it yourself. If there is still gas in the container and even a small percentage of residual pressure, opening the nut is life threatening! After all, only she restrains the pressure in this unit. It can only be repaired in a devastated state.

There is a small hole in the back of this valve. If the diaphragms break through, gas comes out of it.

The VKB modification is usually mounted on a helium tank. For other gases, VK-94 is placed.

Leak test and completion

When checking the tightness of the valve connection, it will be necessary to pump gas under pressure into the gas cylinder. This can be done in two ways:

- Inject gas using compressor equipment or a car pump.

- Connect two cylinders with a hose, the first of which is empty (tested), and the second is filled with gas.

First, under the control of a manometer, fill the test cylinder with gas with a pressure of 1.5-2 atmospheres. After that, soap suds are applied to the connection and the tap opens slightly. If soap bubbles do not inflate anywhere, then the connection is tight. But if at least slight swelling of the foam appears, then you will have to twist the valve again.

When the valve is immersed in water, it is advisable to close the side fitting with a plug so that water and suspended particles contained in it do not enter the locking mechanism.

If the balloon is small, then you can immerse its valve in a small bowl of water and look for bubbles.

After replacing the shut-off valves in the passport of gas cylinders, a corresponding mark must be put down.

Gas valve troubleshooting guide

A modern gas cylinder complies with GOST 949-72 and is a durable all-welded element made of carbon or alloy steel. According to the standard, the thickness of the cylinder walls cannot be less than 2 millimeters. In order for the gas inside to press equally on the upper and lower parts, they are made concave and convex.

The cylinders themselves, depending on the substance in them and its quantity, can have different sizes, shapes and colors. But one thing remains unchanged - any gas cylinder must have passport data assigned at the factory.In the upper part there is a neck, equipped with a thread, into which the valve is inserted.

- Valve malfunction - the flywheel does not turn or there are other problems;

- Corrosion, dents or other damage on the cylinder body and valve part;

- Examination date is overdue;

- Feel the gas in the air;

- Crooked or damaged cylinder shoe;

- There is no plug on the fitting.

The balloon itself is one-piece, and something can hardly break there. Therefore, the main number of faults concerns gas valves.

Procedure:

- Repair is carried out in a well-ventilated area;

- We open the shut-off assembly to allow the remaining gas to come out;

- To unscrew the valve manually or with a gas wrench, it is necessary to warm up this element. In this case, there is no danger, since only gas vapors are in the cylinder, and not their mixture with air, which is explosive in the first place. The only thing to watch out for is moderate heating of the structure, since overheating can increase the pressure in the cylinder. The meaning of warming up is that the metal expands and it becomes possible to unscrew the valve even manually, or with a slight lever effort in the form of the same gas key;

- After removing the element, the conical fitting is sealed - a sealant is applied to it, or a fluoroplastic tape;

- A new valve is mounted, after which the fact and time of repair are recorded in the cylinder passport. Installation is carried out with a special torque wrench, which makes it possible to correctly dose the forces and not to break the thread. The maximum pressure allowed in this case is 480 Nm for steel valves, and 250 for brass valves;

- Having removed the valve from the cylinder, it is necessary to drain the condensate from it, if we are talking about propane-butane, which is widely used by us. This procedure is practically not performed by anyone, despite the fact that it is highly desirable. However, it is necessary to drain away from residential buildings, since this condensate has an extremely unpleasant odor.

Requirements for production processes and technical characteristics of gas cylinders are regulated by rather old GOSTs 949-73 and 15860-84.

The maximum working pressure in the devices ranges from 1.6 MPa to 19.6 MPa, and the wall thickness can vary from 1.5 to 8.9 mm.

The protective cap on gas cylinders can be screwed onto a special neck thread, completely closing the valve, or be welded to the body and only protect the valve from accidental external shocks

A standard gas cylinder assembly consists of the following items:

- The body of the balloon.

- Valve with stop valves.

- Closing valve cap.

- Backing rings for fixing and transportation.

- Base shoe.

The information stamped on the cylinder is used by service centers when refueling and re-examining the equipment, so it should not be heavily painted over with paint

The bottom of the cylinders has the shape of a hemisphere for uniform distribution of internal pressure. For better stability of the body, a shoe is welded on the outside, on the lower edges of which there are often holes for attaching the cylinder to horizontal surfaces.

The types of gas cylinders and the features of their marking will be introduced in the article, which we recommend viewing and reading.

- it is forbidden to use faulty gas cylinders;

- it is forbidden to store cylinders in places of permanent residence of people;

- the valve must not be opened very quickly: the head electrified by the gas jet can cause an explosion;

- periodically check the serviceability and tightness of the valve;

- it is forbidden to use or stay at the same workplace two propane-butane cylinders at the same time.

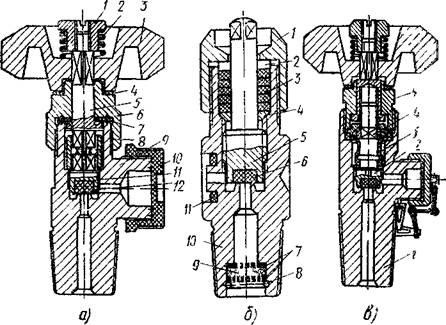

How does a cylinder reducer work:

1 Direct reducer

The usual simple gas pressure reducing apparatus consists of two chambers with an area of high and low pressure separated by a rubber membrane. In addition, the “reducer” is equipped with an inlet and outlet fitting. Modern devices are designed so that the bellows liner is screwed directly into the gearbox. Increasingly, you can find a gas reducer with a third fitting designed for mounting the monomer.

After gas is supplied through the hose and then through the fitting, it enters the chamber. The generated gas pressure tends to open the valve. On the reverse side, a locking spring presses on the valve, returning it back to a special seat, commonly called a “saddle”. Returning to its place, the valve prevents the uncontrolled flow of high-pressure gas from the cylinder.

Membrane

The second operating force inside the reducer is a rubber membrane that separates the device into a high and low pressure area. The membrane acts as an “assistant” to high pressure and, in turn, tends to lift the valve from the seat, opening the passage. Thus, the membrane is between two opposing forces.One surface is pressed by a pressure spring (do not confuse with a valve return spring), which wants to open the valve, on the other hand, the gas that has already passed into the low pressure zone presses on it.

The pressure spring has a manual adjustment of the pressing force on the valve. We advise you to buy a gas reducer with a seat for a pressure gauge, so it will be easier for you to adjust the spring pressure to the desired output pressure.

As the gas exits the reducer to the source of consumption, the pressure in the chamber of the working space decreases, allowing the pressure spring to straighten. She then begins to push the valve out of the seat, again allowing the device to be filled with gas. Accordingly, the pressure creeps up, pressing on the membrane, reducing the size of the pressure spring. The valve moves back into the seat narrowing the gap, reducing the gas filling of the reducer. The process is then repeated until the pressure equalizes to the set value.

It should be recognized that direct-type gas cylinder reducers, due to their complex design, are not in high demand, reverse-type reducers are much more widespread, by the way, they are considered devices with a high degree of safety.

2 Reverse gear

The operation of the device consists in the opposite action described above. Liquefied blue fuel is fed into a chamber where high pressure is created. Bottled gas builds up and prevents the valve from opening. To ensure the flow of gas into the household appliance, it is required to turn the regulator in the direction of the right-hand thread.

On the reverse side of the regulator knob is a long screw, which, by twisting, presses on the pressure spring.By contracting, it begins to bend the elastic membrane to the upper position. Thus, the transfer disk, through the rod, exerts pressure on the return spring. The valve begins to move, begins to open slightly, increasing the gap. Blue fuel rushes into the slot and fills the working chamber at low pressure.

In the working chamber, in the gas hose and in the cylinder, the pressure begins to increase. Under the action of pressure, the membrane is straightened, and a constantly compressing spring assists it in this. As a result of mechanical interactions, the transfer disc is lowered, weakening the return spring, which tends to return the valve to its seat. By closing the gap, naturally, the flow of gas from the cylinder into the working chamber is limited. Further, with a decrease in pressure in the bellows liner, the reverse process starts.

In a word, as a result of checks and balances, the swing can be balanced and the gas reducer automatically maintains a balanced pressure, without sudden jumps and drops.

Hands off!

Let's talk about prohibitions first. Yes, yes, dear reader, I have no doubt that you are full of enthusiasm and eager to carry out the transfer of the gas pipe in the kitchen yourself. However, take the restrictions I have listed as seriously as possible:

You can not move the gas riser in the kitchen. All you can do is change where the branch is attached to it or the length of this branch;

Polyethylene and plastic pipes in general cannot be used indoors. SNiP 2.04.08-87 in clause 4.85 expressly states that polyethylene is prohibited for laying in residential buildings, and in clause 6.2 it states what materials should be used;

It is impossible to block the general plug, ball valves and gate valves on the inlets and risers of gas supply. If at the time when you turn off the gas, someone cooks food, the fire will go out, and after starting it will continue to flow into the kitchen. The result of such a development of events is usually described in TV reports by bystanders: there is no one among the residents to tell about it;

Finally, the main thing: PB (safety rules) 12-368-00 prohibit any gas hazardous work carried out by persons who have not been instructed and examined in safe working methods.

Simply put: only a representative of Gorgaz or a licensed gas equipment maintenance company should connect any gas appliances.

What will happen

If you are fabulously lucky and you, without the necessary knowledge and practical experience, do not allow a gas leak, your amateur performance will be revealed at the very first scheduled inspection of gas equipment by representatives of the gas service.

The consequences are unpredictable: they can either turn a blind eye to the work you have done or draw up a protocol on an administrative offense that endangered the life and health of people.

Worst scenario... Comrades, I won't spoil your mood. What is a gas explosion in a residential building - everyone represents.

It should be noted: in the gas pipeline there is relatively low pressure (in contrast, for example, from the water supply system). Based on this, it is not necessary to block the entire gas network. However, security measures still need to be taken. First of all, when carrying out work, the window must be wide open. The doors to the kitchen should be tightly closed, and the cracks plugged with rags or towels.

We begin the work with the dismantling of the old gas valve. We remove it with a gas wrench. As soon as the faucet was removed, we plug the pipe with a thumb pad. At this time, the assistant winds the FUM tape on the new faucet or applies sealant to the threaded connection.

Next, you need to make sure the connection is tight. To do this, use the old proven method with a soap solution. A soapy solution should be applied to the connection and if bubbles appear, the connection will leak. It is necessary to correct the defect immediately: remove the tap and repeat the sealing of the connection.

Read more: Self-clamping terminal blocks varieties and features of use selection rules

At the end of the work, thoroughly ventilate the kitchen area and connect the gas stove to the system. Even in the absence of professional skills, the operation to replace the gas valve takes no more than 15 minutes. Plus, doing the work yourself is a significant cost savings. However, if there is no self-confidence, it is better to entrust this work to specialists from the service department of the gas supplier.

Types of plates for gas cylinders

It should be said right away that there are gas stoves that can work with both main natural gas and bottled liquefied gas. Reconfiguration requires nozzle replacement and adjustment. So, in principle, any of them is suitable for giving.

Tabletop gas stoves are mobile...why not...

Another thing is that in the "field" conditions they use it much less and less often than in everyday life. For this reason, the simplest and smallest models are chosen. After all, now water for tea is heated, most often, with an electric kettle, cooked food is heated in a microwave oven.On a gas stove in the country, they only cook, and the simplest dishes. Some other housewives make twists. That's all. That's why they usually buy one or two burner stoves. However, there is a fairly wide selection for any requirements and needs.

Desktop and floor

According to the installation method, gas stoves for summer cottages are divided into desktop and floor. Technical characteristics do not differ only in dimensions. Desktop ones are usually made the simplest, without any additional options. This is exactly the country / camping option with a minimum weight and dimensions.

For rare visits, "and so it goes", but you can't put a balloon next to it

What is the best gas stove for giving under a cylinder? Desktop or floor? It's all about free space. If there is somewhere to install a floor version, take it. Although they cost more, they can serve as a cabinet themselves. And they (cabinets), usually, are not enough in the country. Just remember that you still need to find a place to store the balloon. It can be located nearby (the minimum distance between the stove and the cylinder is 0.5 meters and at a distance of at least 1 meter from the heating devices), or it can stand outside in a special cabinet that is locked with a key.

If, on the contrary, there is space on the table, but not on the floor, a desktop version of the gas stove will do. The best part is that they cost one and a half to two thousand rubles.

Number and type of burners

A gas stove for giving under a cylinder can have from one to four burners. A single burner is suitable if there are one or two people in the country and you do not spin. For cooking breakfast / dinner for a family of three or four people and a small amount of conservation, two burners are enough.Well, if you need it and dinner for a full-fledged family, take it with three or four burners.

Options for desktop gas stoves for giving under the cylinder

Recently, in addition to burners of a standard, medium size, they began to make even larger and smaller ones. This is convenient, as the dishes come in different diameters. Such "excesses" are available only on four-burner options.

In addition, there are models in which, in addition to gas burners, there are also electric ones. If there is light on the site, and you need a stove to give a cylinder for three or four burners, this is also convenient. The gas in the cylinder tends to end at the most inopportune moment. If there is no spare, at least make a fire. And if you have an electric burner, you can finish the process and hold on until the balloon is filled.

Availability of additional options

The arsenal of additional functions only for gas burners is small. This is an electric or piezo ignition and gas control. Both functions are useful, but only you can judge how necessary. It should be said right away that they are very rare in desktop versions.

Gas cooker with electric oven underneath

Design features

Tabletops are available in just a few types. The simplest is one, more often two burners, and that's it. But there are also models with a built-in electric oven. A good option if you use an oven. This is where the "diversity" ends.

Outdoor gas stoves for summer cottages have a little more design options:

- With built-in gas or electric oven at the bottom.

- With shelves at the bottom.

-

With a small cabinet and doors.

The cabinet under the gas stove can be used to install a small gas cylinder in it.This is contrary to the requirements of gas workers (the distance between the stove and the cylinder must be at least 0.5 meters), but it is still used.

Where can you put the balloon? In the basement or basement floor, in a residential area.