- Varieties

- mud aggregates

- explosion-proof

- High pressure

- 2 Types and their differences, scope

- 1 Applications

- 1.1 General characteristics and features

- Tips & Tricks

- Pumps from different manufacturers: their advantages and disadvantages

- Subtleties of installation and repair

- Main types

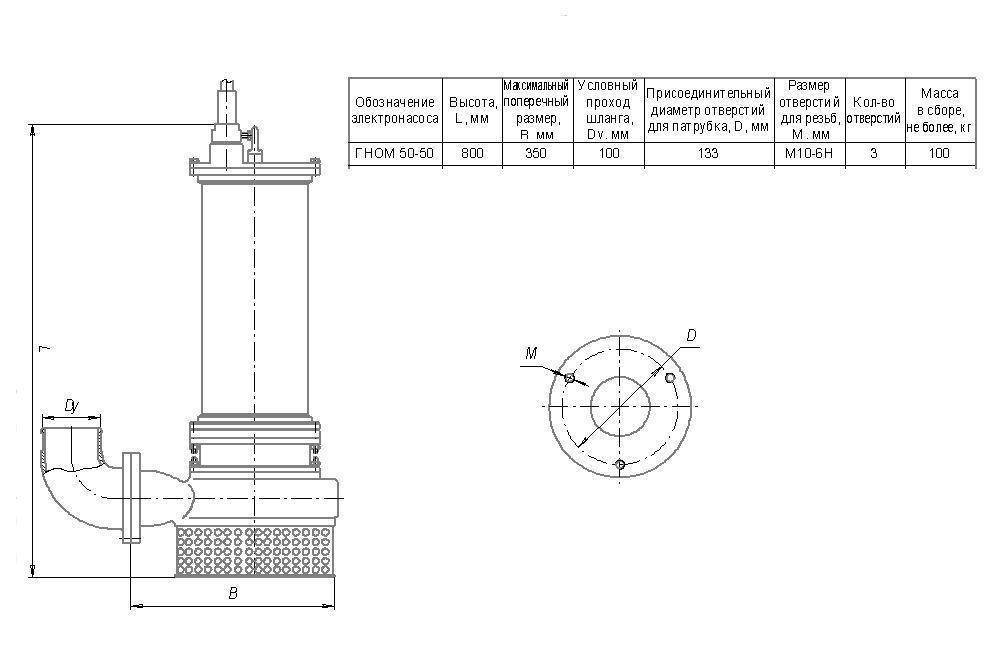

- Specifications and markings

- Repair of pump parts “Gnome”

- Bearing replacement sequence

- Impeller replacement

- Repair of impeller shaft and casing

- Adjustment of the gap between the impeller and the diaphragm

- Repair of the electric motor of the pump "Gnome"

Varieties

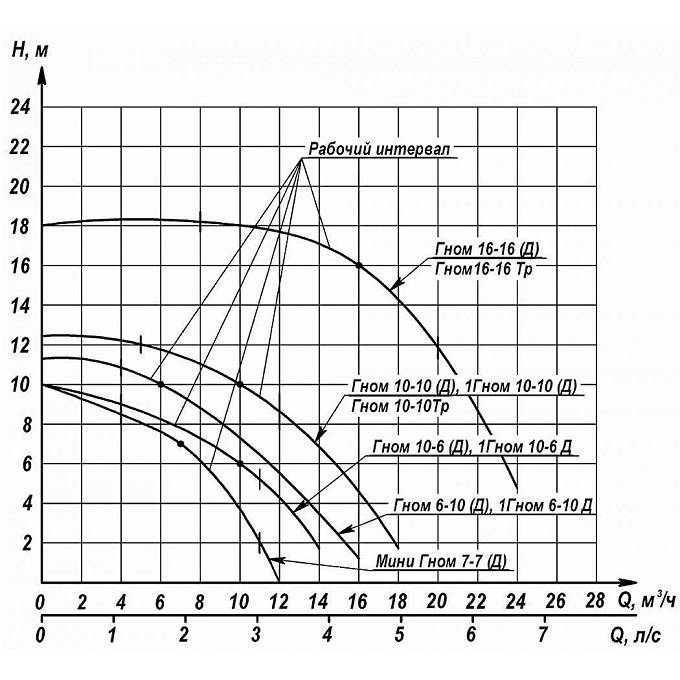

The range of Gnome pumps from various manufacturers includes about a dozen models. At the same time, the marking of the unit has the following form: “Gnome 35-35”. The first number indicates the performance, measured in cubic meters per hour, the second number is the fluid pressure.

Conventionally, all submersible pumps of the Gnome series can be divided into three types:

- Traditional mud pumps.

- Explosion-proof.

- High pressure.

mud aggregates

This is the most popular and numerous series of such pumping devices. This series includes about a hundred modifications of Gnome drainage pumping devices. All of them differ in technical characteristics and features of operation. We list the most popular of them:

- Gnome pumping equipment with the designation 6-10 is a unit with a capacity of 6 m³ / h and a liquid head limit of 10 m. Its power is 0.6 kW.

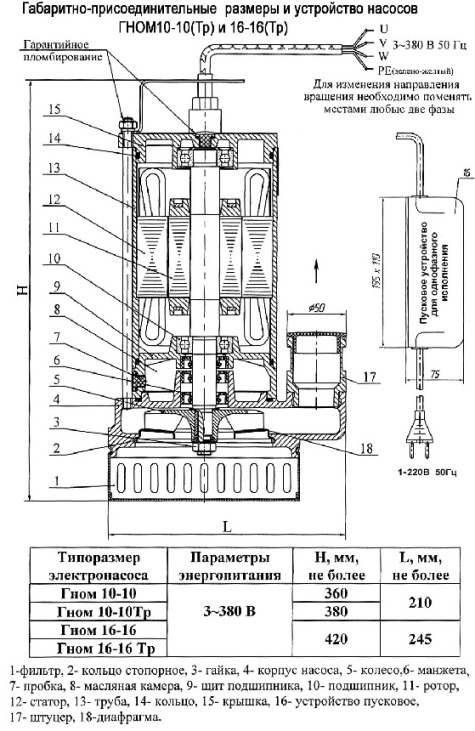

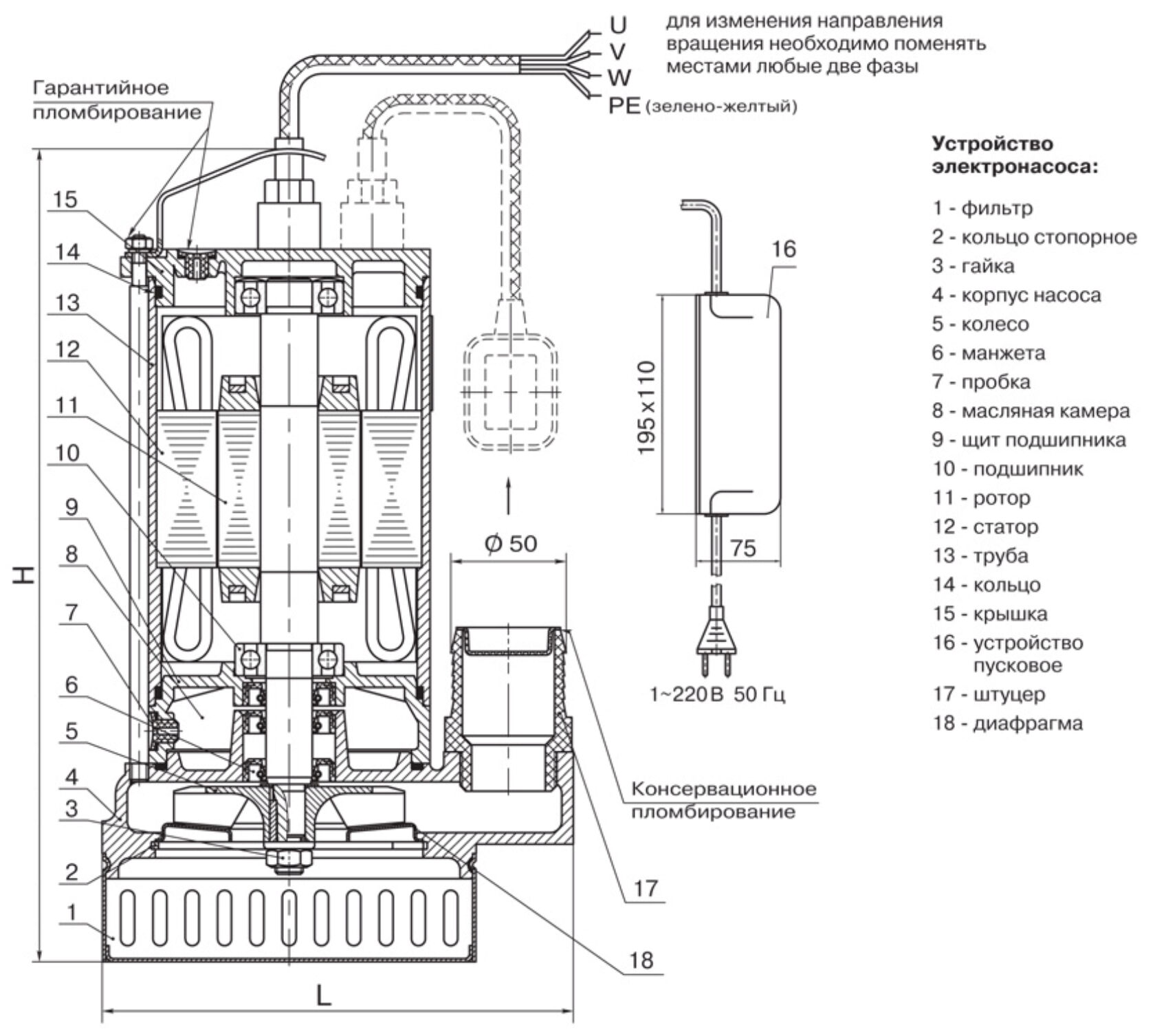

- Dwarf marked 10-10. The performance of this drainage pumping equipment is 10 m³ / h, the allowable head is 10 m. There are models with a power of 0.75 and 1.1 kW on sale. Two versions of this unit are also produced for networks of 220 V and 380 V. This model has a modification for pumping hot liquids marked Tr.

- The Gnome modification electric pump with the designation 16-16 is a model with a head of 16 m and a capacity of 16 m³ / h. There are three variations of this unit with a capacity of 1.1; 1.5 and 2.2 kW.

- Gnome submersible pumping equipment marked 25-20 creates a water pressure of 20 m and has a capacity of 25 m³ / h. The unit is available in three different capacities 2.2; 3 and 4 kW. In this series, you can purchase a model that pumps hot liquids.

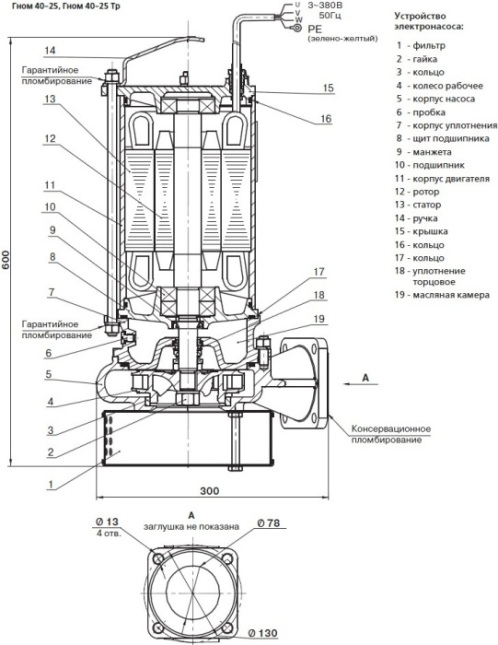

Also, the category of mud pumps should include models with markings from 40-25 to 600-10. Some of these modifications are equipped with control stations. Usually the prices for such devices are 1.5 times higher than for traditional mud models.

explosion-proof

This is not such an extensive series. It has only 10 modifications of Gnome pumps. For domestic needs, this unit is unlikely to be useful, but for industrial and manufacturing enterprises it is simply irreplaceable. To distinguish explosion-proof models from ordinary ones, you should look at the markings. It must contain the letters EX.

The model range of this series includes some of the above models only in a protected hermetic case and with increased power. Three of them are designed to work in a hot environment.

The cost of such models in comparison with traditional mud units increases several times. Therefore, the choice of this pump should be made only if it is appropriate to use it.

High pressure

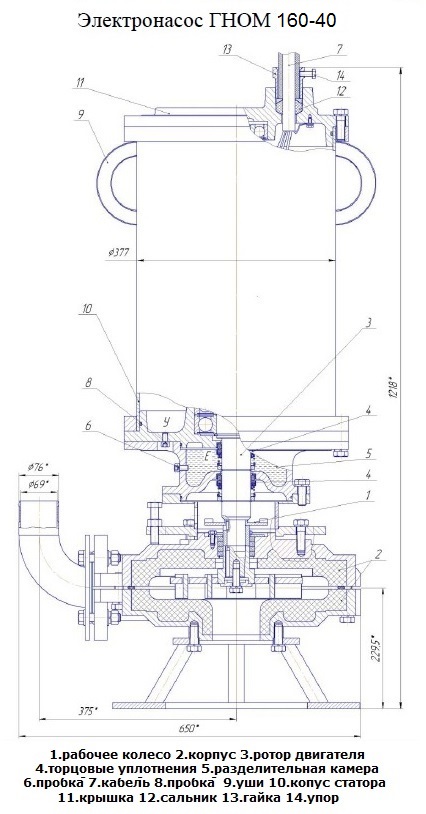

The category of high-pressure pumping devices includes only seven Gnome modifications. For domestic needs, such pumps are not suitable, because they have very powerful characteristics. As for the parameters of these units, they are as follows:

- The high-pressure unit Gnome 50-80 has a capacity of 50 m³ / h, a maximum head of 80 m. The power of such pumping equipment is 30 kW.

- The Gnome 60-100 pump has a capacity of 60 m³ / h and a maximum head of 100 m. Its power is 45 kW.

- The Gnome 80-70 unit is a high-pressure pump with a power of 35 kW, a capacity of 80 m³ / h and an allowable head of 70 m.

- Pumps with a power of 45 kW are devices marked 160-40, 140-50, 100-80. Their performance and pressure can be judged by the digital designation.

- The unit with a capacity of 40 kW is a high-pressure pump Gnome 110-60.

2 Types and their differences, scope

All Gnome submersible pumps available today and all their varieties have approximately the same design. In order to know what you can count on, and whether the Gnome submersible drainage pump will cope with the planned volume of work, it is necessary to consider all its performances presented to date and their classifying features.

First of all, it should be noted that the presence of two numbers near the name of the pump, for example, a submersible pump gnome 16 16, means: the performance of the system (in cubic meters / hour), and the second number indicates its maximum pressure (the ability to raise water to a certain height.).

Types of pumps brand Gnome

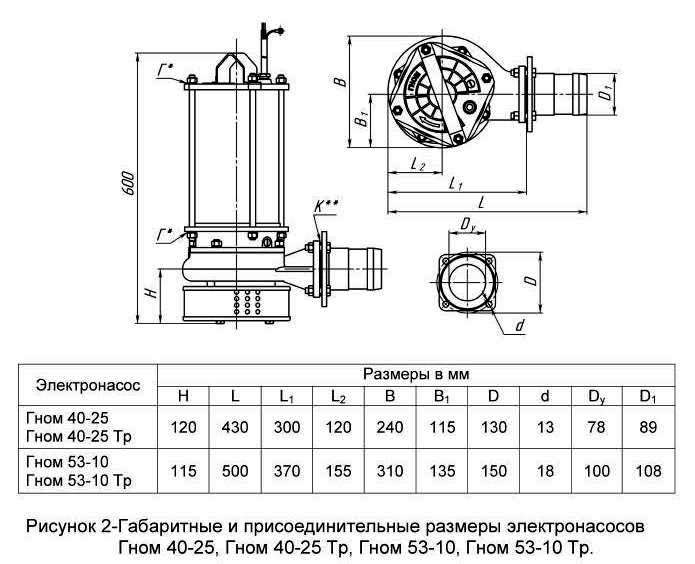

That is, for the above pump, the maximum water supply is 16 cubic meters per hour, and the maximum pressure is also 16 meters. Depending on the tasks that will be performed, you can choose among the following types of Gnome submersible pumps: 6 10; 10 10; 16 16; 25 20; 40 25; 53 10.

The first three of the presented types are more widespread, as they optimally fit into the standard operating conditions of a small enterprise, while, like the last three Gnome submersible pumps, they have an increased power electric motor, which will allow them to be used with large and constant volumes of pumped liquid.

So for what specific purposes can a drainage gnome pump be used?

- Pumping out excess fluid from construction trenches and excavated pits.

- Organization of irrigation works, practically on any area of the earth.

- Drainage during land reclamation work.

- Pumping out sewage that fell into the wells of underground utilities.

- Getting rid of water from the basements of buildings.

The advantage of such a pump is the ability to work in a wide temperature range from 0 to 95 degrees Celsius. Also, the Gnome drainage pump will help you out if you need to pump liquids containing particles of fuel and lubricants, as it has explosion protection for such situations.

In order to choose the right drainage pump gnome, it is necessary to take into account all the nuances.The pump manufacturer Gnome makes us a fairly good range of proposals for choosing a unit that is suitable for our production / facility.

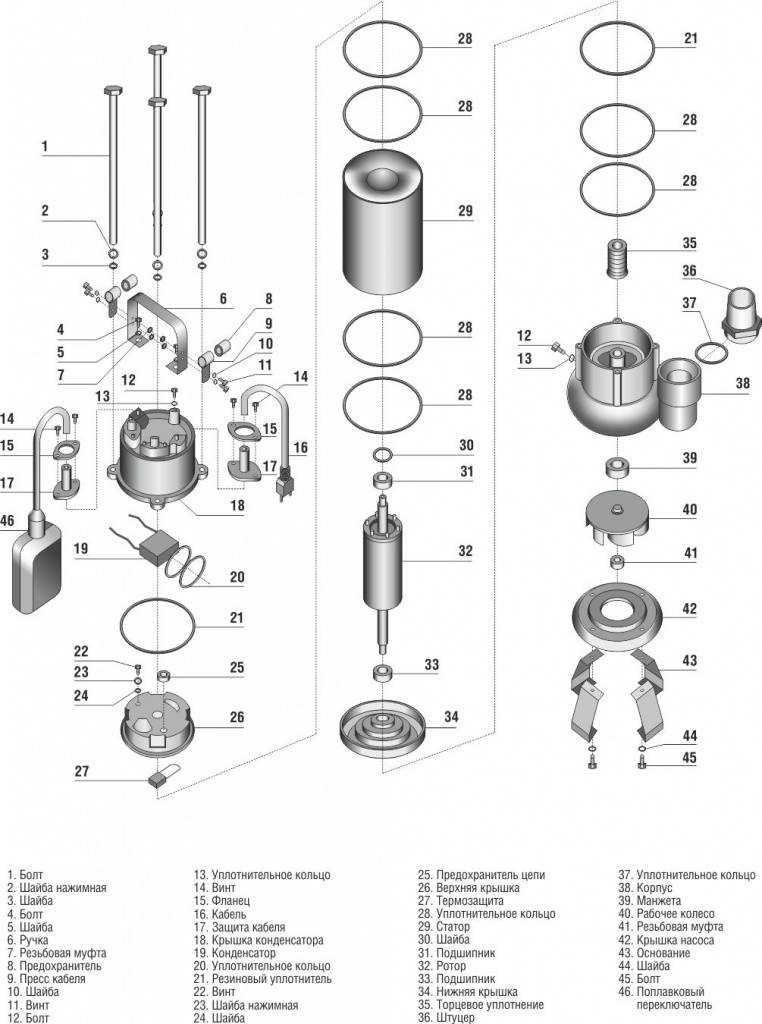

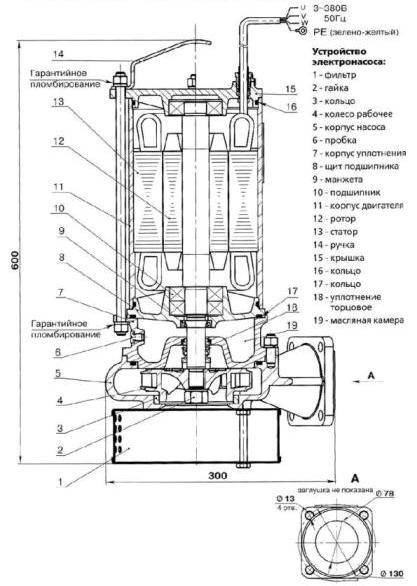

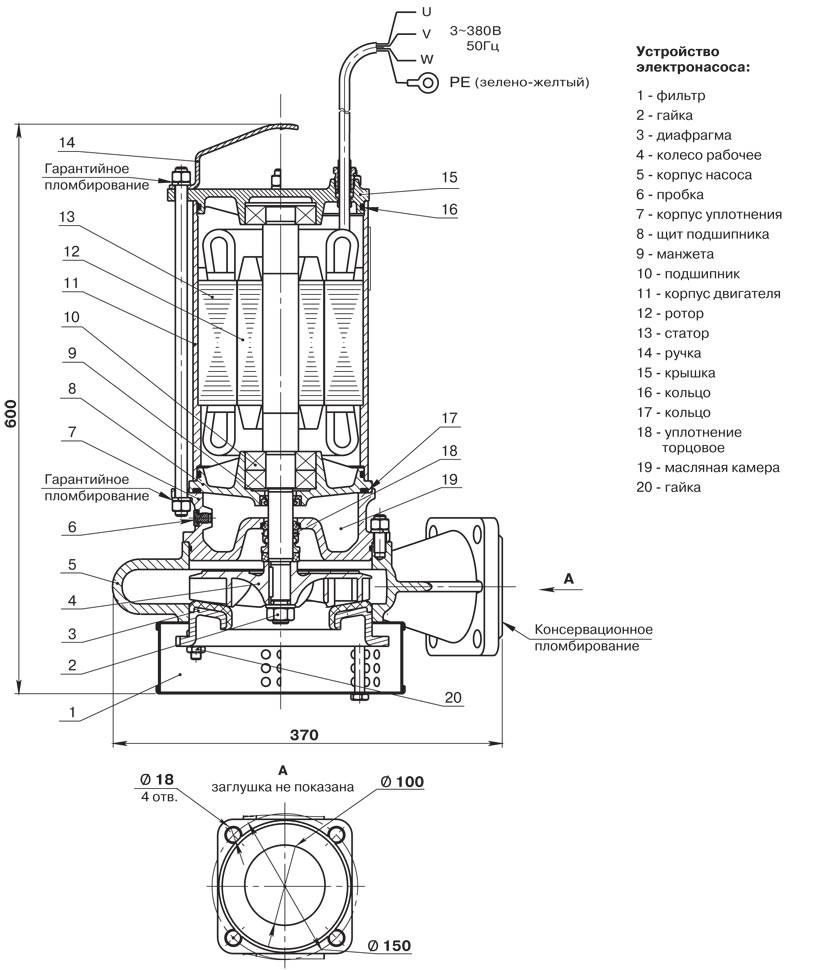

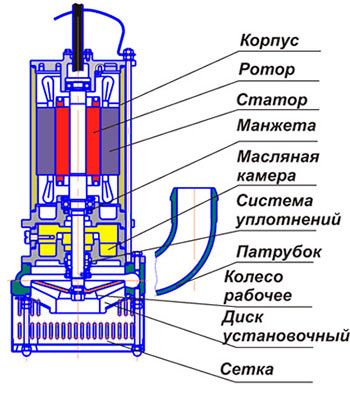

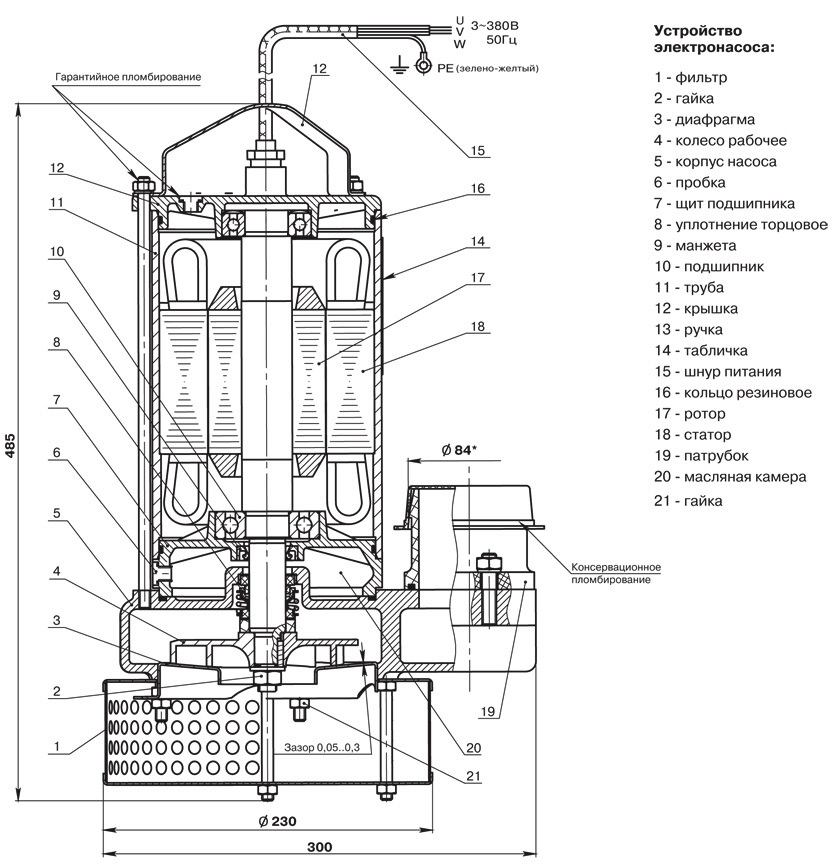

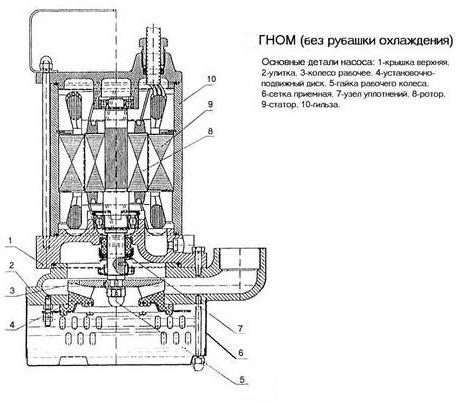

Gnome pump device

In order for your choice to be balanced and correct, carefully and slowly think through all the technical nuances of operation, and, if possible, consult with a specialist.

To begin with, decide for yourself what power and performance the pump should be. Next, be sure to consider whether you need a pump with high temperature resistance to meet your needs. Since in cases where “hot” water enters a conventional pump, breakdowns cannot be avoided.

Most reviews about the Gnome pump are positive. People like the “armor-piercing” of its case and the reliability of the mechanism itself. At the same time, you can observe negative comments about the failure of the device.

This happens (for the most part) from violation of the conditions recommended for the operation of a particular type of pump. Therefore, regularly check the technical condition and operating environment of the submersible pump.

Main manufacturers

The Russian pump manufacturer gnome has the widest distribution in the CIS market, including: Valdai Pump Plant, Moscow Pump Plant, Livgidromash, Euromash, Agrovodkom and others. The choice of manufacturer is up to you.

Our advice would be to analyze the entire market before buying: prices, offers, cash models. And you also need to take into account the fact that at the beginning of the season the price of the pump rises slightly. So make your choice wisely.

1 Applications

Gnome drainage pumps are ideal for pumping dirty water with a small, which is very important, content of foreign matter. Moreover, this type of pump can also be used for pumping clean water.

Like any other submersible pump, Gnome pumps are used in a wide range of industries. Most often, a fecal submersible pump is used to clean or pump water from the following sources:

- Industrial water;

- Domestic water from wastewater (with the exception of fecal);

- Ground water, usually from construction trenches or, more rarely, from pits;

- Waters of heavily polluted or marshy reservoirs.

At the same time, the Gnome brand submersible pump is used in the following areas:

- Communal economy. In cases of a pre-accident or emergency flood, pumps of this type are used as a fecal cleaner, for pumping contaminated water from various basements;

- Metropolitan, for pumping fluid in pits or trenches;

- The submersible drainage type pump has proven itself in industrial and civil construction. With it, you can pump out flood waters from pits. In addition, the pump does an excellent job with groundwater;

- In agriculture for land reclamation;

- ONE HUNDRED. The fecal drainage pump Gnome is used at service stations to drain wastewater from various equipment when washing cars;

- The submersible drainage apparatus is used, ultimately, in industrial enterprises. It is necessary in production processes and for the organization of drainage-type treatment facilities.

Drainage pumps Gnome with cable

1.1 General characteristics and features

The technical characteristics of Gnome pumps allow them to work in a liquid medium at temperature ranges between 0 and +95 degrees Celsius. The permissible pH range is 5 - 10 pH. During the operation of pumps of this type, the content of impurities is not more than ten percent, and the size of impurities, as well as particles with inclusions, should not exceed 5 millimeters.

Considering that the Gnom submersible drainage pump is distinguished by a reliable design and excellent strength of the housing mechanism, while having excellent technical characteristics, this type of pump can be used in difficult and aggressive conditions. In addition, pumps of this type also have the following advantages:

- Easy to remove and clean filter;

- Easy repair. However, given the rugged design of the device, it is rarely necessary to repair it. Moreover, repair is usually required when the pump parts are completely worn out, where repair, as such, is no longer possible and a complete replacement of the part is needed;

- The submersible drainage pump has a long period of maintenance-free operation;

- High-quality materials from which the device is made, and high wear resistance of the device allow it to work in more than aggressive environmental conditions without "whims" for repairs;

- Huge work efficiency;

- Ease of installation and subsequent operation along with maintenance;

- The design of Gnome-type pumping systems allows the simultaneous use of several devices at once. This allows you to perform work more efficiently and, if necessary, carry out repairs right during the operation of the pump.

Tips & Tricks

Multifunctional pumps "Gnome" occupy high positions in the popularity rating among other brands. The deciphering of the name of these units speaks for itself and sounds like this - Dirty Water Pump Single Stage Monoblock. Well-established production ensures the creation of high-quality devices that are actively used in a variety of industries.

In the process of acquiring a Gnome pump, it is necessary to take into account many important factors that are directly related to the further use of the product. First of all, it is worth deciding on the future purpose of the unit, after which you can start choosing a model with suitable power and performance.

With regular use of the Gnome device, it is recommended to carry out a technical inspection in a timely manner, fixing entries in a special passport. Manufacturers recommend monthly maintenance of the units in order to increase their service life and timely troubleshooting.

Maintenance involves the following actions:

- oil control;

- checking the integrity of the power cord, as well as eliminating deformations on the hose;

- inspection and elimination of the resulting damage;

- measurement of the insulation safety level.

It is recommended to fill the oil every 250 operating hours or when foreign liquids and elements get into it. To do this, the Gnome unit is installed on a flat surface, the plug in the bearing shield is removed, after which the oil is topped up or replaced. A complete replacement requires a volume of 300 ml. Suitable as a special oil designed exclusively for pumps, as well as the usual technical version with medium or low viscosity.

After using the unit for the purpose of pumping liquid with mud impurities, it is worth starting the device for pumping clean water in order to clean the internal structural elements. When the mechanism has not been used for a long time, before turning it on, you need to check the degree of rotation of the impeller. Compliance with these rules and recommendations will help to preserve the original qualities of products for a long time, as well as extend their service life.

Numerous reviews indicate that the Gnome pumps have practically no analogues. Due to their impeccable quality, functionality and reasonable cost, these products are widely demanded in the world market. They are actively used not only at home, but also at large industrial facilities. A well-established production process, as well as the use of the most modern technologies and materials, make the devices of this brand truly in demand, because each model harmoniously combines only the best characteristics.

In the next video, watch the review of the Gnome 25-20 pump.

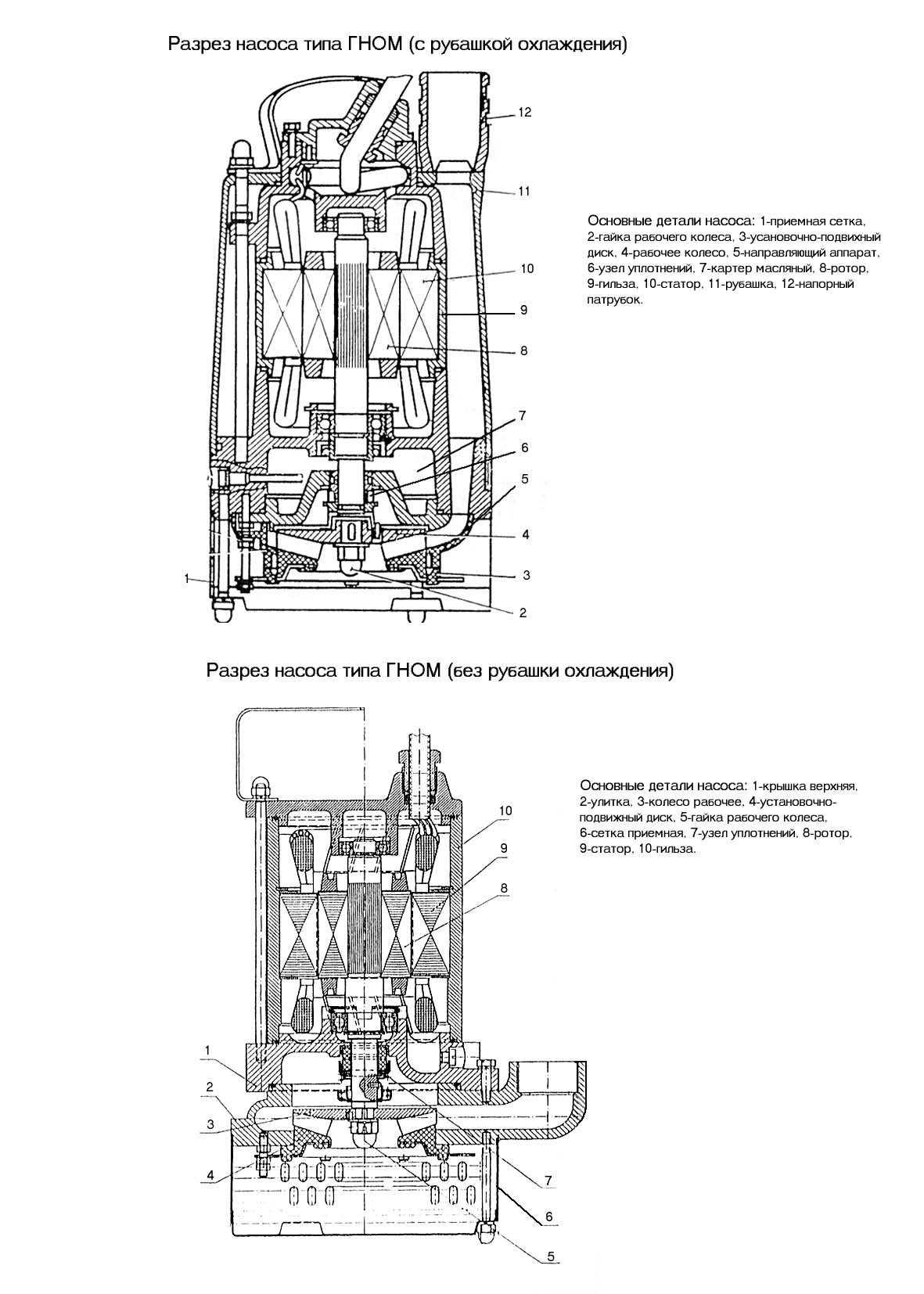

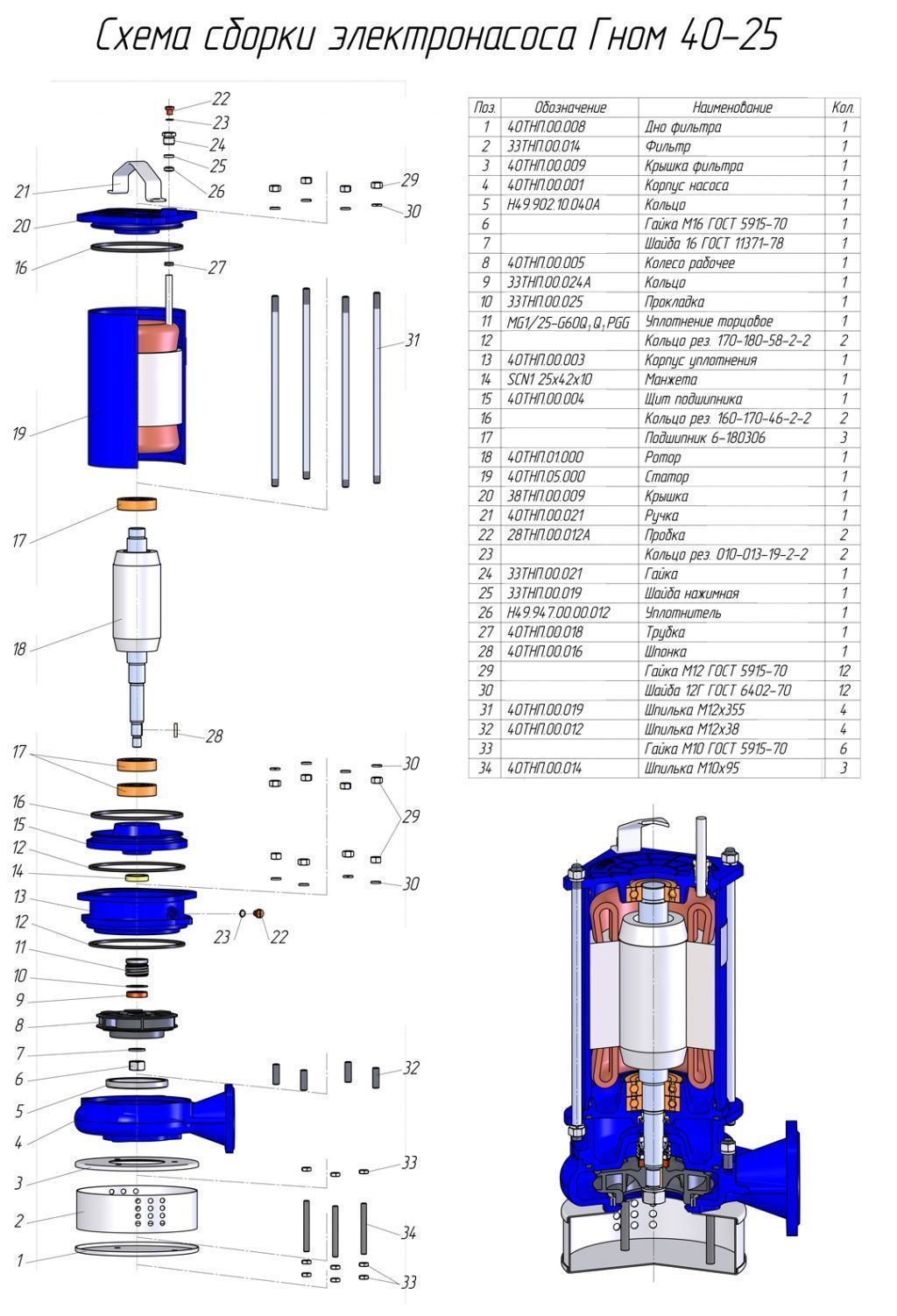

Pumps from different manufacturers: their advantages and disadvantages

Most often on the market you can find the products of the Odintsovo Pumping Plant and MNZ No. 1. The undeniable advantages of the first group include:

- Possibility to choose devices of two main modifications: without or with a cooling jacket.

- The high quality of assembly guaranteeing reliability and excluding defects.

- Thoughtful design.

The main disadvantages, according to customer reviews, can be considered the high cost of installations, too expensive repairs and expensive spare parts for them.In addition, due to the unofficial policy of the manufacturer, free warranty repairs are practically impossible. It is worth noting that there are very few models of this manufacturer intended for domestic needs.

Everyone who used the devices of the Odintsovo plant emphasizes that these are excellent high-quality devices that should be purchased by those who want to get high reliability, however, for decent money.

Anyone who decides to purchase such a pump should pay attention to models with a cooling jacket. It allows the device to work in a semi-submerged state and significantly extends its service life.

Pumps from Odintsovo can be produced with or without a cooling jacket

The products of the plant MNZ No. 1 are distinguished by:

- The lowest cost in comparison with other manufacturers.

- Low cost of repairs and spare parts.

- Possibility of pumping heavily polluted waters, such as drains from car washes, liquids containing cement, etc.

- Light weight of the device.

However, buyers note that a number of significant shortcomings appear during operation:

- Poor build quality.

- High sensitivity to deviations of the voltage standard in the network, up to the failure of the electric motor and starting capacitor.

- Fragility of plastic parts: bottom filter housing and carrying handle.

- Unsuccessful design of the oil chamber, due to which, if the assembly is of poor quality, oil may leak from the chamber into the outlet pipe of the unit.

- Assembly on tie rods sometimes causes the endshield or top cover to tilt, which can cause the motor rotor to seize.

The pump can only work in a fully submerged state, otherwise severe overheating and motor failure are possible.

The most inexpensive of the gnome pumps are devices manufactured by MNZ No. 1

According to reviews, the gnome water pump, produced at MNZ No. 1, does an excellent job with its functions during fairly rare emergency work. In addition, it is purchased for operation in difficult conditions, when, in order to complete the task, the safety of a relatively inexpensive mechanism can be neglected. These units are maintainable, and the cheapness of their spare parts, excluding the engine, allows them to compete with more reliable, but much more expensive devices from other factories.

Less often on the shelves there are pumps manufactured by Livgidromash and Polesyeelectromash. These are reliable and high-quality models. However, their cost is also quite high, in addition, if repairs are necessary, difficulties may arise due to the small number of service centers in Russia. Devices are most often sent directly to the factory.

Livnensky gnomes - high-quality and reliable installations

A variety of models of gnome pumps makes it easy to choose the best one. The devices have established themselves as an almost indispensable option that allows you to quickly and efficiently solve the problem of pumping out a sufficiently large volume of liquid with a variety of contaminants.

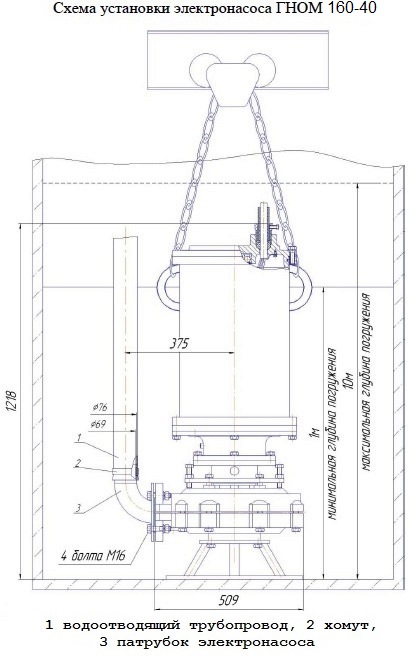

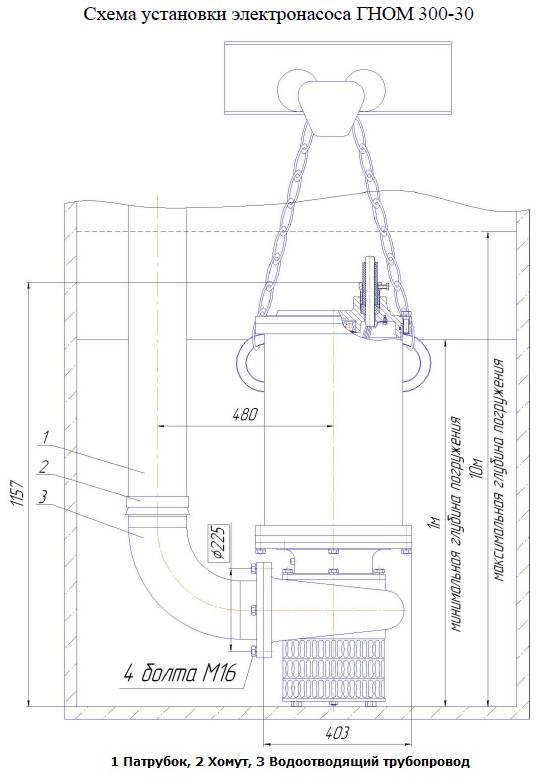

Subtleties of installation and repair

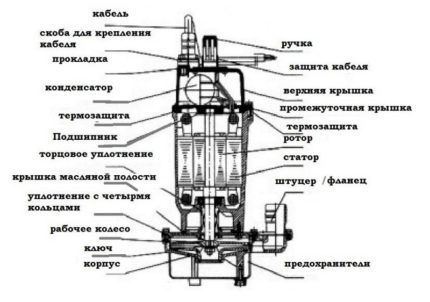

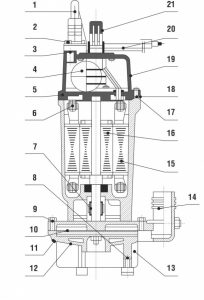

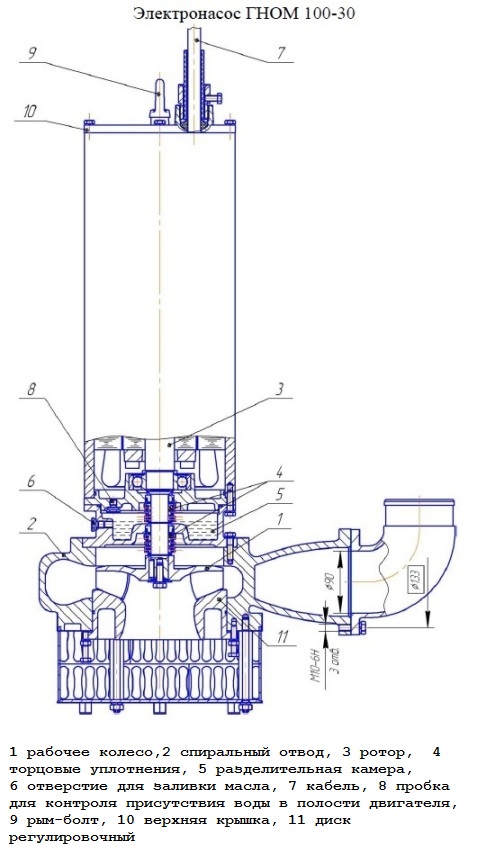

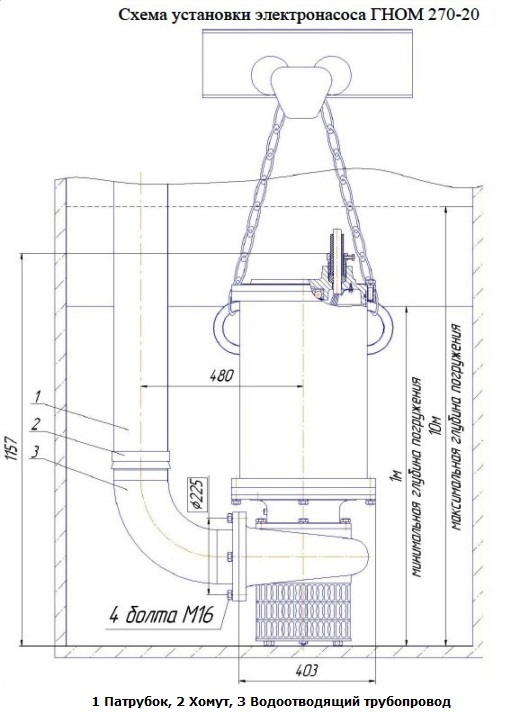

Pumps "Gnome" are presented on the world market in the form of monoblocks, consisting of two parts: an electric motor and a pump part.The drive of the unit is carried out by a starting device, which is located on the cord. For maximum convenience, Gnome products are equipped with special capacitors and circuit breakers, which serve as protection against engine overheating. Immediately before turning on the device, it is completely or partially immersed in water. Without water, it is allowed to operate the unit for no more than 15 minutes.

When preparing the Gnome pump for operation, it is necessary to inspect the device for body damage that can occur not only on the body, but also on the power cable. Be sure to check the presence of oil in the corresponding chamber. After that, you need to remove the plug from the nozzle, connect the device to a flexible hose, which is fixed on both sides with special clamps. The size of the hose is selected individually for each pump model, taking into account the parameters of its discharge pipe.

In the process of immersing the pump "Gnome" with a cable into the pit, it must have an exclusively vertical position with a permissible deviation of not more than 10 degrees. It is necessary to ensure a full drain from the hose, preventing the appearance of bends and fractures on it. When installing the unit on a sandy or muddy bottom, it is worthwhile to first lay a substrate in the form of a rubberized mat at the installation site. Such a measure will create a stable and anti-slip base on the installation of the device. After adjusting the pump and observing all the operating rules, you can start.

It should be noted that all types of Gnome pumps are easily repaired due to the simplicity of their design.

The main causes of problems, as well as their solutions are:

- No power supply.Most often, the cause of such a problem is associated with a cable break or a breakdown of the engine itself. To eliminate it, it is necessary to check the voltage level, as well as inspect the cable for damage and neutralize them. If the engine itself breaks down, additional help from qualified craftsmen will be required.

- Inability to pump water. This reason occurs when there is no water in the source or the hose is connected incorrectly.

- Increased vibration and noise. Occurs due to bearing failure. You can replace it yourself or contact a service center.

- Loss of pressure. Occurs when a leak occurs on the line or due to a decrease in voltage in the network. In some cases, the pump may be clogged with debris. Then the device is subject to disassembly with subsequent cleaning and washing of the pumping chamber.

Main types

According to the scope and technical characteristics, "Gnomes" are divided into three main groups:

Household, designed for dirty water, with average power and performance. Experts often call such pumps ordinary. The main purpose of the equipment is domestic drainage work. Models differ mainly in performance - from 10 to 25 cubic meters per hour, and power (energy consumption) - from 600 W to 4 kW.

Explosion-proof, industrial design - a fairly small line, the models of which are made in a special protective case. These professional models are marked with the EX mark and are most often used in industrial production. Their price is appropriate - from 45,000 rubles.

High-pressure - another type of industrial pumps with impressive performance productivity - up to 50 cubic meters per hour, and power - up to 45 kW. The price of one such pump varies within 250,000 rubles.

Specifications and markings

Pumps of the "Gnome" line belong to the class of single-stage vertical submersible pumps of a monoblock design. They are designed for pumping out drainage and ground water containing no more than 10% of solid mechanical particles by weight, the density of which does not exceed 2.5 thousand kg/m3. It is allowed to pump fractions no more than 5 mm. The temperature of the pumped liquid is up to +35ºС, and for models marked "Tr" - up to +60ºС.

The housing of the submersible electric pump is made of plastic, cast iron or steel. Impellers and motor casing are made of cast iron. The equipment is produced with different types of motor, depending on which it is determined whether it can be powered from a household power supply with a voltage of 220 V or from a three-phase industrial one with a voltage of 380 V and a frequency of 50 Hz.

Manufacturers of Gnome centrifugal pumps offer a wide range of products with different technical characteristics, so you can choose a model with the necessary parameters

The electric pump package includes: a 10 m power cord for a three-phase power supply or a power cord and a starting device for a single-phase power supply. Most manufacturers, for a fee and at the request of the buyer, include in the kit an automatic machine for protecting a motor operating from a 380 V network.

Specifications such as power, power supply parameters, performance (pumping speed), maximum head, as well as the dimensions and weight of the equipment depend on the specific model. You can compare the technical characteristics of the Gnome pump models using the table:

The technical characteristics of the pumps are indicated in the nominal mode and may differ by no more than ten percent for pressure indicators and no more than three percent for efficiency

All pumps produced under the Gnome brand are marked. Knowing what is hidden behind the numbers and designations, you can easily understand what characteristics and features the pump has. The word "Gnome" itself is an abbreviation and stands for: G - dirty water, H-pump, O - single-stage, M - monoblock.

The main advantage of the Gnome series of pumps is the simplicity of design. You can disassemble for cleaning and assemble the unit without problems with your own hands

The first digit in the marking indicates the capacity in m3 / h, the second - the head in meters. For example, "Gnome 10-10 Tr" is a pump with a capacity of 10 m3 / h and a head of 10 m. The designation "Tr" indicates that this equipment can pump water with a temperature of up to +60 C. The letter "D" means, that the equipment is equipped with a float switch (level sensor).

Pumps marked with the abbreviation "Ex" belong to the explosion-proof group. Such units are capable of pumping water with impurities of oil products, which contain no more than 3% sulfur. In emergency cases, the pump can be used to work in an environment containing up to 100% crude oil products.

Image gallery

Photo from

Gnome submersible pumps are designed for pumping liquid media containing mineral inclusions up to 1250 kg/m3

Modifications of this brand are used both for pumping water from open reservoirs, and for draining basements and pits

Water is sucked in by a centrifugal device located in the lower part of the body, then the liquid is pushed out to the branch pipe with a pipe connected to it

Gnome models can pump liquids with mineral particles ranging in size from 5 to 25 mm. In order to prevent larger particles from entering the system, the suction part is protected by a filter

Gnome brand pump models

Scope of pumps Gnome

The principle of operation of centrifugal units

Submersible pump filter Gnome

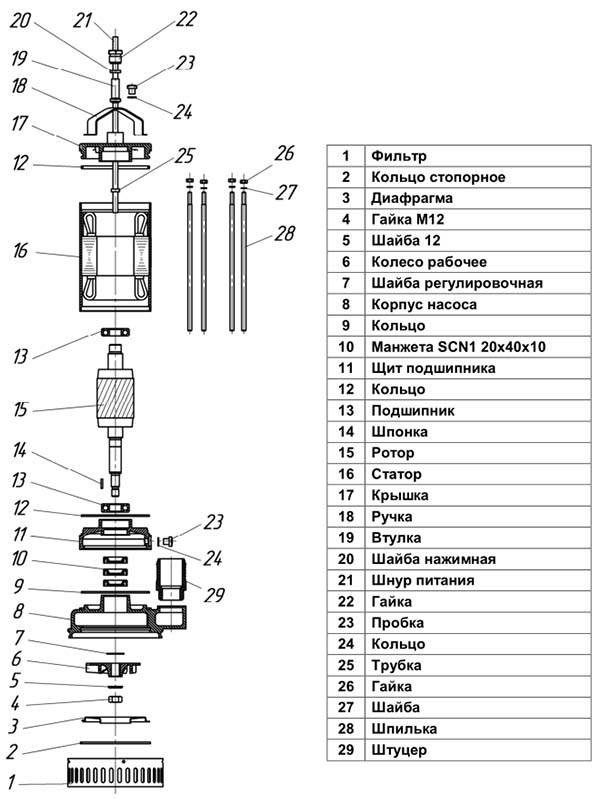

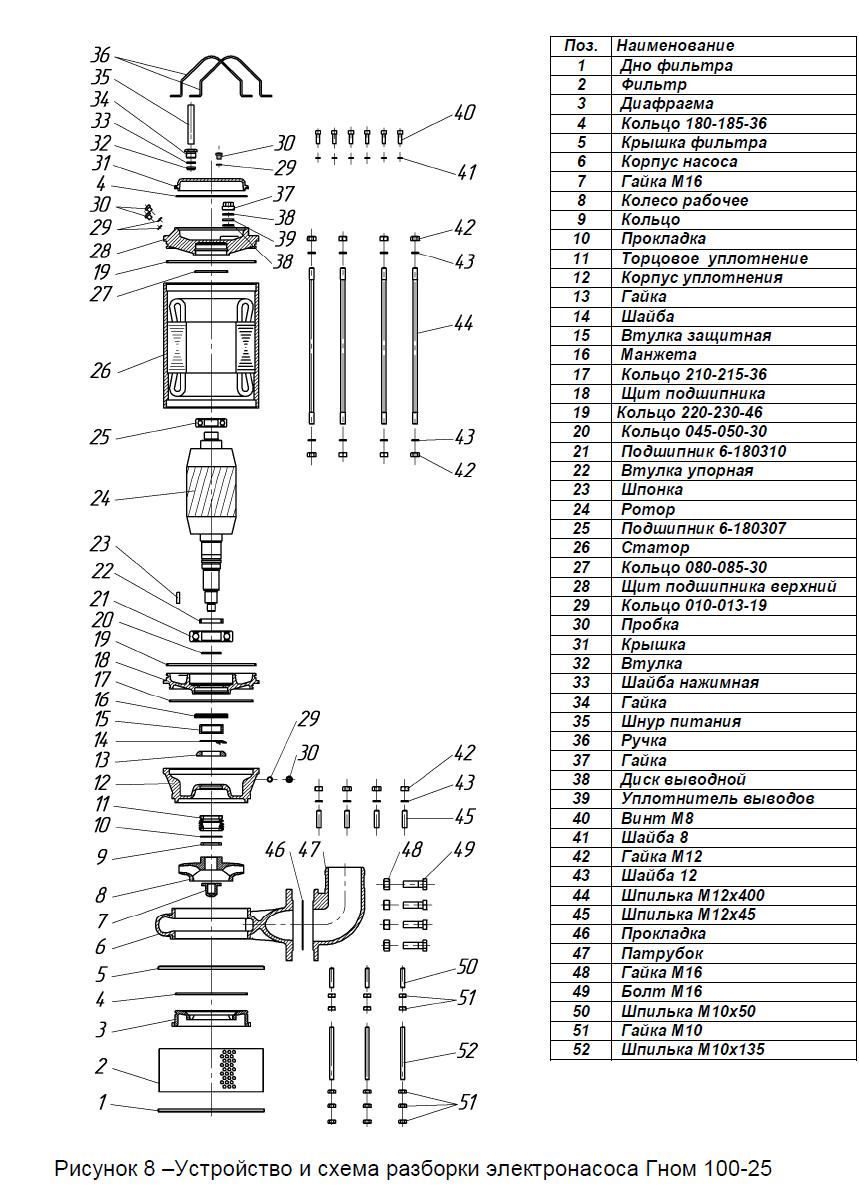

Repair of pump parts “Gnome”

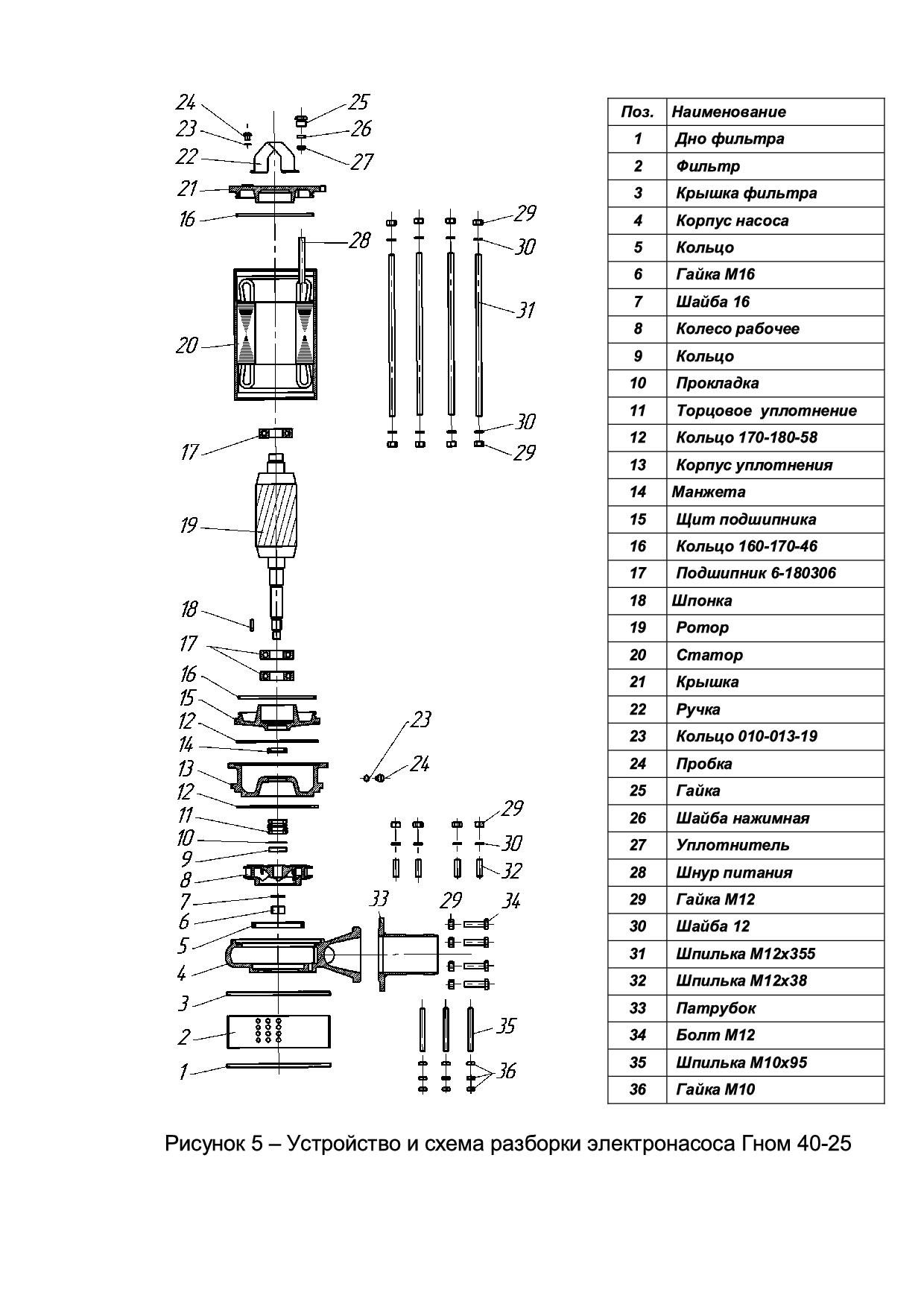

Having considered the causes of malfunctions of pumps of the Gnom brand, you can see that almost all problems are solved by replacing the following parts: bearings, impeller, impeller shaft. Also, some malfunctions are eliminated after adjusting the gap between the impeller and the diaphragm.

Bearing replacement sequence

If the bearings are worn, the pump may pump water, but make unusual sounds due to friction and swaying of worn bearings. Bearings must be changed if there are gaps of more than 0.1-0.3 mm. This usually happens after 3-6 years of operation of the Gnome electric pump.

The process of replacing bearings is very simple: the pump is disassembled, the bearings are removed and replaced with new ones taken from a special repair kit. Do not use self-made similarity of bearings or from analogues from repair kits of other modifications, because.this can again disable the equipment in the very near future.

Impeller replacement

To replace the impeller, it is necessary to disassemble the Gnome electric pump and remove the impeller. Then install a new impeller and assemble the pump in reverse order. When installing a cover with a setting-moving disk, it is necessary to screw the fasteners onto the studs and tighten them simultaneously until the minimum clearance between the impeller blades and the cover with the disk is reached.

After assembly, it is required to check for tightness and, if it is broken, then refuse to use a permanently damaged electric pump.

In some cases, if you have experience and appropriate equipment, you can not replace the impeller with a new one, but try to fix the existing annular workings with the help of surfacing, followed by its processing on a lathe.

Impeller defects in stainless steel or cast iron can be corrected by electrode welding followed by turning of the welding spot on a lathe

Repair of impeller shaft and casing

If the working shaft is damaged (bent, cracked), it is best to replace it completely. The body of the "Gnomes" is theoretically repairable, but in practice it is almost impossible to carry it out correctly.

In nine out of ten cases, the tightness of the case will be broken, and this defect can only be corrected at the factory or at a service center.

Given that such breakdowns are found in pumps that have worked for a long time, and therefore not subject to warranty service, it is necessary to think about the feasibility of repair.In most cases, it is faster, cheaper and easier to purchase a new submersible pump.

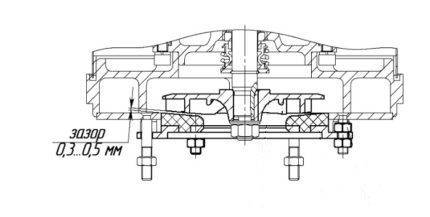

Adjustment of the gap between the impeller and the diaphragm

The main reason for the decrease in pressure and performance of the Gnome electric pump is the increase in the gap between the impeller and the diaphragm during operation. To reduce the gap, you need to adjust it.

To do this, remove the bottom of the filter and unscrew the top nut. Then tighten the parts of the diaphragm with nuts located on different sides until it comes into contact with the impeller.

Then loosen the lower nuts half a turn. With this adjustment, the gap will be 0.3-0.5 mm. The adjusted location of the diaphragm relative to the impeller is fixed with the upper nuts. After completing the adjustment, it is necessary to check the ease of rotation of the impeller, it should rotate without any effort.

Gap adjustment between diaphragm and impeller necessary after repair work related to the dismantling of the Gnome pump

Gap adjustment between diaphragm and impeller necessary after repair work related to the dismantling of the Gnome pump

Repair of the electric motor of the pump "Gnome"

Gnome brand pumps are equipped with a reliable asynchronous electric motor. It is very difficult to repair an electric motor on your own. The maximum that can be done without special stands is to determine the resistance of the motor windings using a household multimeter.

If the resistance indicator tends to infinity, then this indicates that the winding is damaged and needs to be replaced. To replace the winding, a complex disassembly of the electric motor and the presence of a rewinding machine will be required.

But the main difficulty lies in the assembly process - the unit must be assembled in such a way as to provide an impeccable barrier against water penetration into the electric motor. That is why it is better to entrust the repair of the Gnome pump engine to professionals.

The most difficult repair of Gnome pump modifications is the restoration of engine performance. It is not worth taking on this business without skills and auxiliary equipment.