- How to diagnose problems?

- Drain mechanism

- Toilet cistern device: where does the water come from?

- Works with a tank built into the wall

- Leave a request Departure within the Moscow Ring Road for free

- Types of toilet flush cisterns

- Tank repair

- What to do if the toilet cistern with a button is leaking?

- No water is drawn into the tank

- Decreased flow strength

- Elimination of external leaks

- Condensation forms on the tank

- How to clean a rusty toilet bowl?

- Types of fittings for flush cisterns

- Separate and combined options

- Materials for the manufacture of devices

- Place of water supply

- Classification

- By material

- By location

- By type of construction

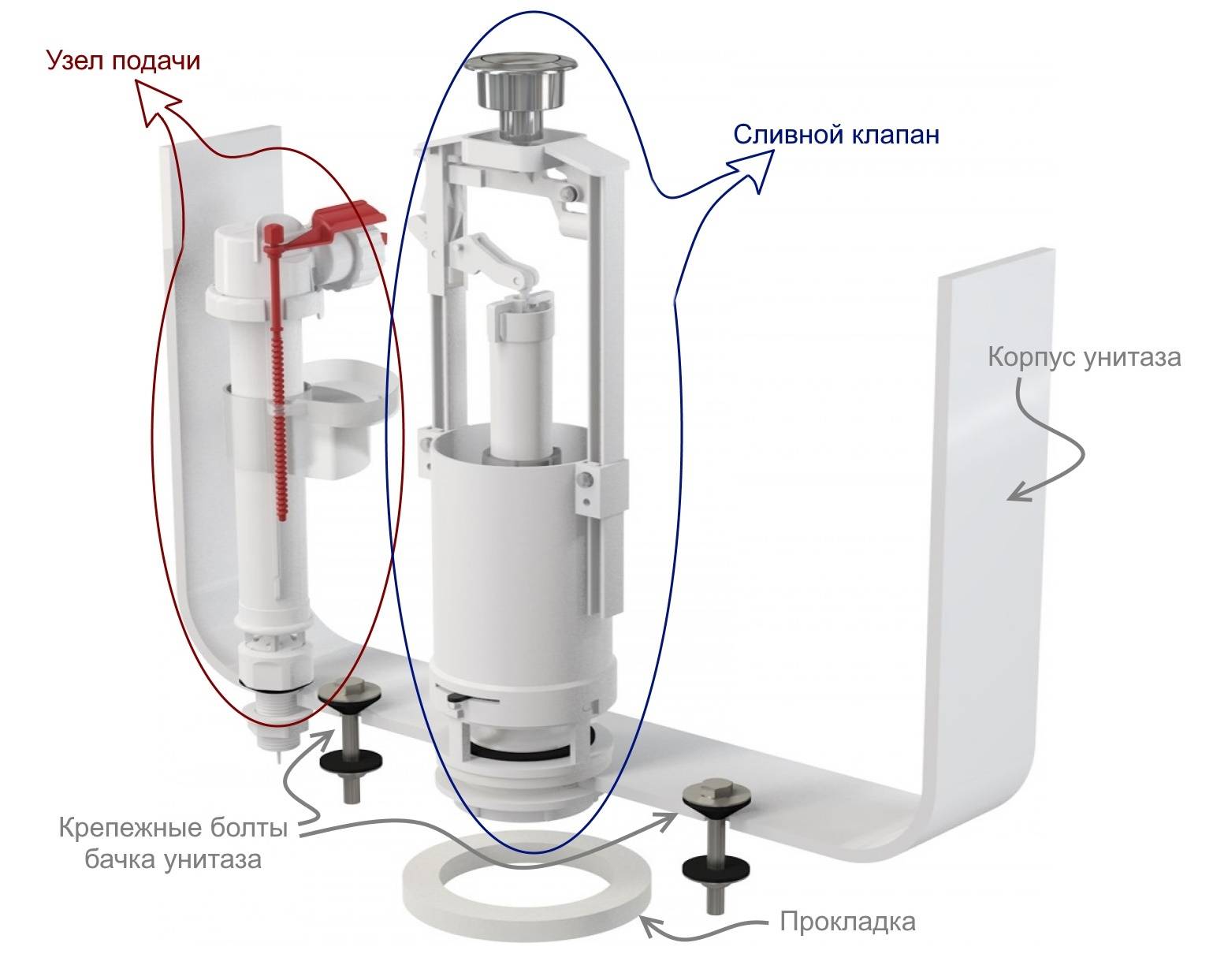

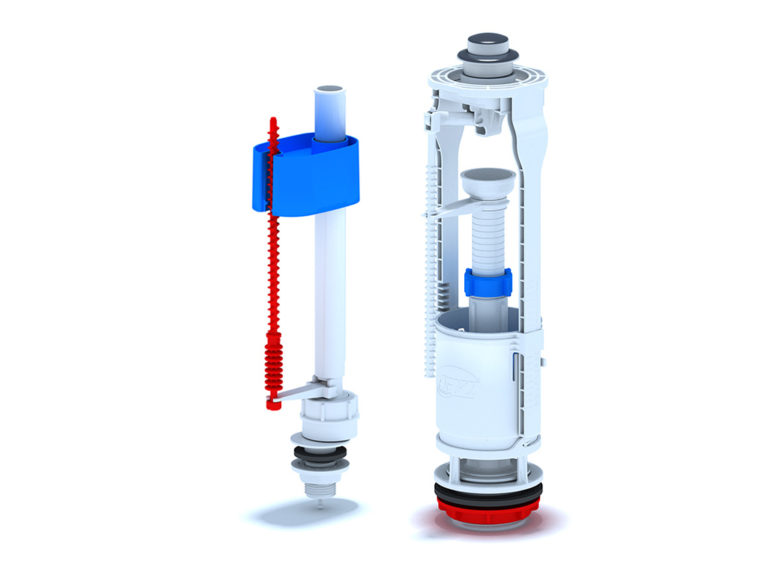

- Components of the drain fittings

- Filling mechanism

- Drain and overflow mechanism

- Damage not related to rebar

- Preventive measures

- Briefly about the main

- Possibilities for adjustment and repair

- How to adjust the water level in the tank

- Toilet cistern leaks

- The tank does not draw water

- What is the result

How to diagnose problems?

If the cistern is faulty, it quickly becomes apparent: water either leaks into the toilet bowl or starts dripping onto the floor. Sometimes it happens that the container is not filled.

No matter how ultra-modern and complex the design of the tank may be, breakdowns appear the same in all models.

External leaks are not always immediately visible. It happens that water drips out for weeks, but its amount is so small that the damp areas are not striking. Then the leak can be determined by the appearance of red spots and rust streaks.

If they are, it is worth disassembling the tank and establishing the cause of the breakdown.

If there is no coarse filter, dirt and rust particles constantly enter the tank. They accumulate in the container and can damage the internal mechanisms of the structure, cause damage

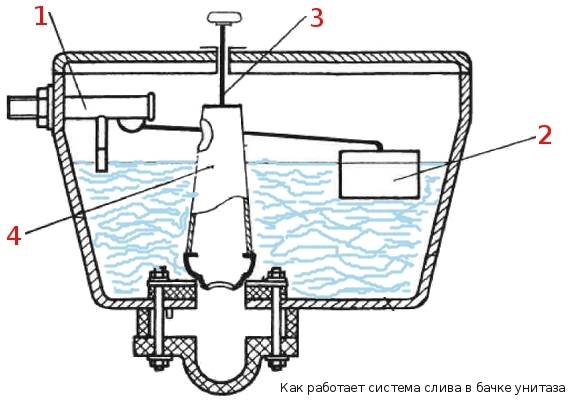

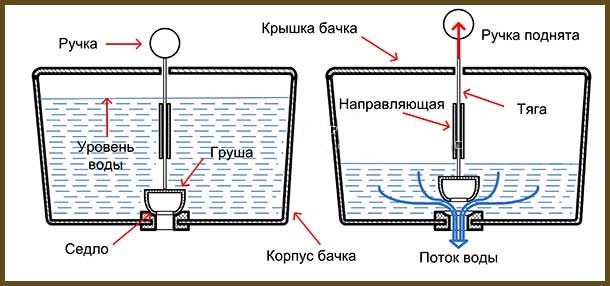

Normally, the tank is filled to a predetermined level, and the rubber bulb is pressed against the drain hole, securely closes it and is held in this position due to water pressure. When you press the descent mechanism, this pear rises and opens the drain hole.

The rubber bulb must be constantly filled with air. To prevent water from getting into it, a special guide tube is provided in the design. It ensures the correct position of the pear in the "saddle".

If the integrity of the pear or tube itself is violated, the mechanism fails.

This is how the rubber pear of the tank should look like, if it is in working order. It should remain elastic and fit well to the saddle.

The first thing to do after disassembling the tank is to inspect the pear. If it has lost its elasticity, cracked, then it is in it that the cause of the leak lies. Worn rubber cannot cover the drain hole well, water leaks into cracks and gaps.

Rubber products of this type cannot be repaired, so the pear should simply be replaced.

If everything is in order with it, you need to make sure that particles of dirt and rust do not get under the rubber, which can also interfere with the normal operation of the pear.

There are cases when you can solve the problem of leakage by simply cleaning the tank. If it turns out that dirt has accumulated under the rubber bulb, it can be removed with a regular sponge. Often this is enough to restore normal operation. It also makes sense for prevention to wipe the container walls with a rag and remove plaque.

If the pear is in order, then you should continue to inspect the toilet tank in search of the cause of the leak.

The tank is not filled if:

- inlet hose defective;

- the inlet valve of the float mechanism is worn out.

Water can leak out if:

- the gasket between the tank and the toilet is worn out;

- a leak appeared at the place where the connecting screws were installed.

Internal leaks appear when:

- overflow tube not adjusted;

- valve is defective;

- float has failed.

All these components should be carefully checked, repair, adjust or replace damaged parts. How to disassemble the tank and find these elements is shown in the video:

Drain mechanism

The flush mechanism allows you to release water into the toilet bowl to flush sewage into the sewer. It is activated by pressing a lever or button.

Toilet bowl with top cistern and lever

Drainage devices differ in design, but in most cases they are interchangeable if they are designed for installation in tanks of standard dimensions, with holes of standard sizes. The general principle of the mechanism is as follows:

- the drain hole is blocked by a valve retaining water;

- when you press the button or lever, the valve rises, and water rushes into the bowl with a powerful stream;

- valve falls into place.

The design includes an overflow pipe with an open top. Water that has risen above a predetermined level flows through it into the toilet bowl - this eliminates the overflow of the tank, prevents water from leaking through the edges of the tank to the floor.

Toilet cistern device: where does the water come from?

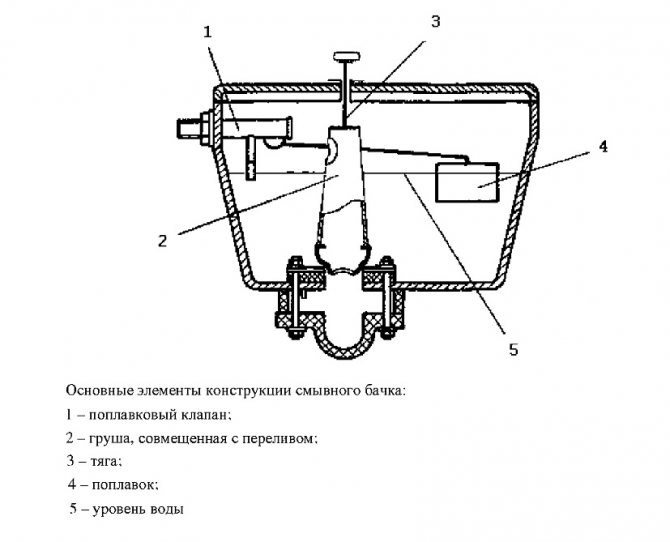

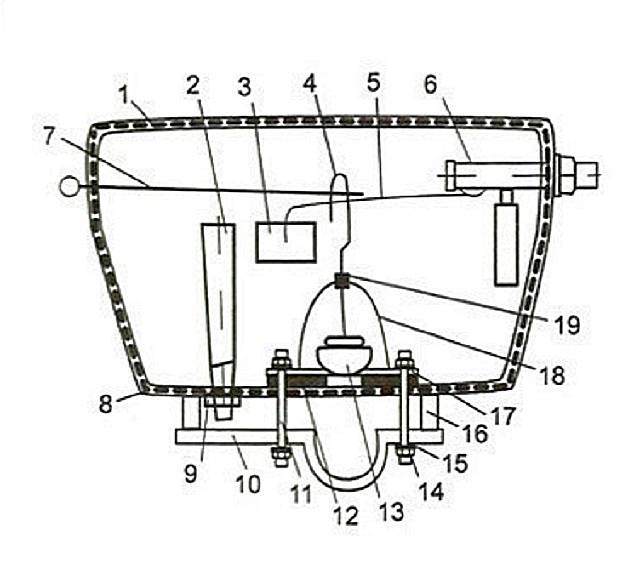

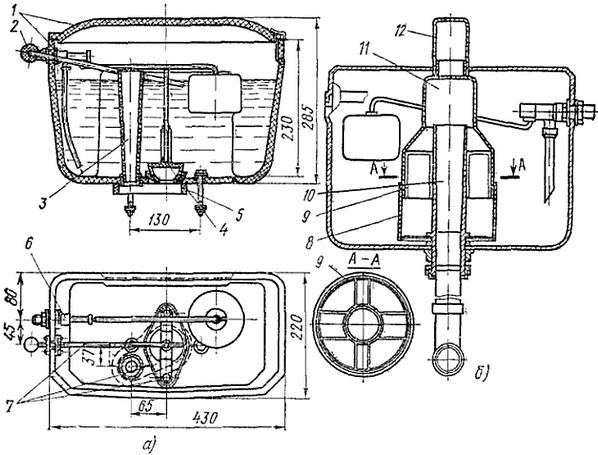

A tank is a container made of plastic, ceramic or metal, which can be made in various shapes, can be equipped with different triggers, but it has one purpose - to draw and drain water. This action is possible due to the internal structure of the tank. In fact, the toilet cistern device is a mechanism that consists of only two main elements: a drain mechanism and a water supply mechanism.

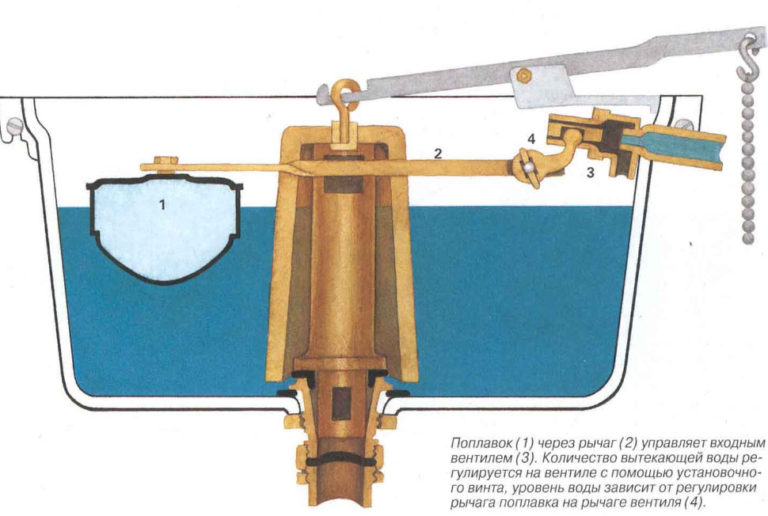

With a more detailed examination inside the tank, you can also find a float, float valve, pear, overflow, levers. These elements can be made of different materials, for example, the float can be brass or plastic, and the pear is plastic or rubber, they can also have differences in shapes and methods of connecting to each other, but the principle of their operation does not change.

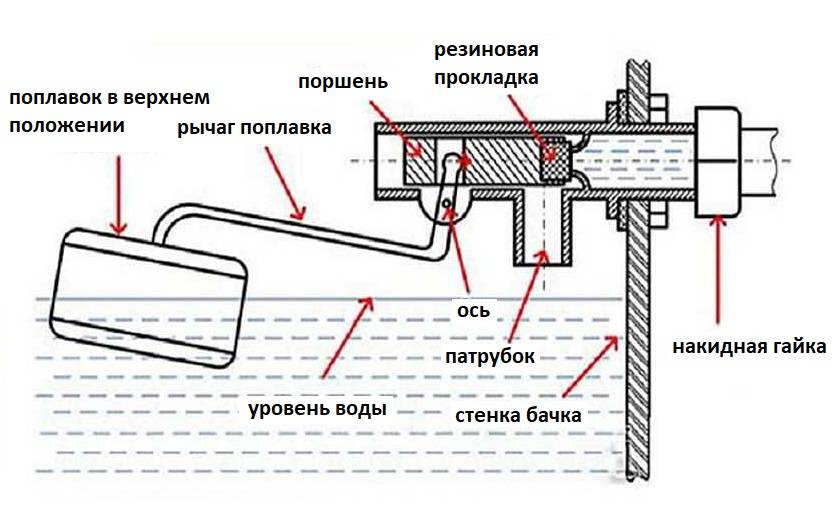

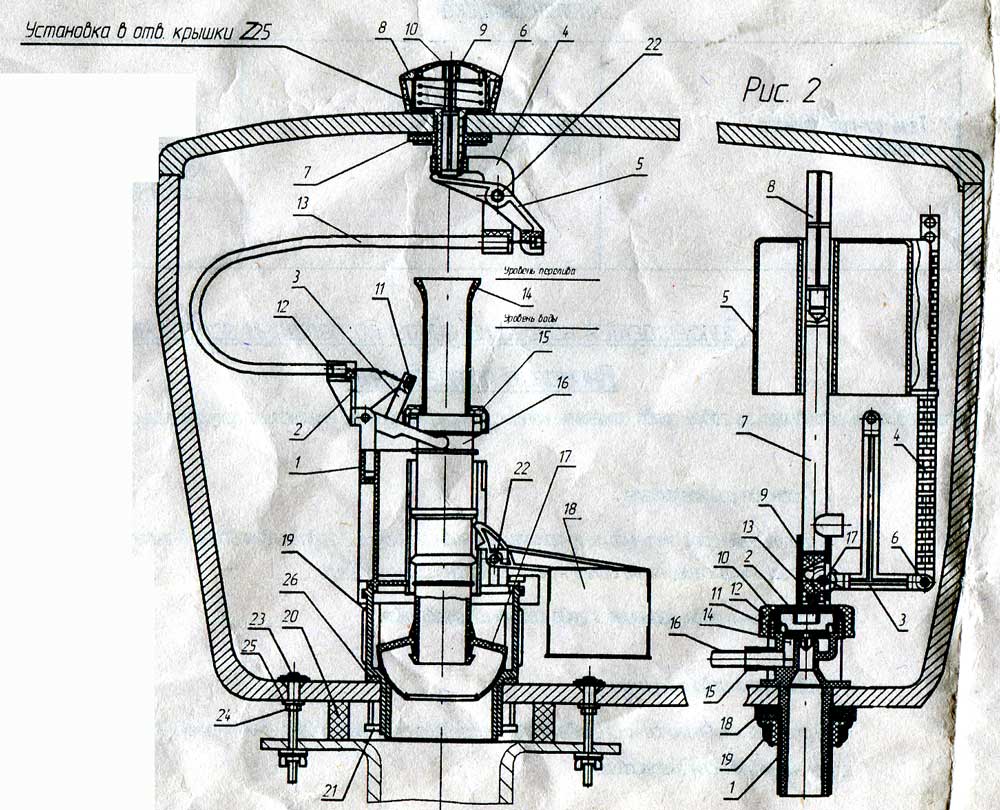

The water supply mechanism operates with the help of fittings, which is responsible for the intake of water into the tank. The water supply system can be made in two ways:

- the fitting is at the top of the drain tank, water enters through the side channel. The float in this version is located at the tip of the lever, and when it reaches a certain level, the other end of this lever presses on the rod, and it blocks the water supply with the help of a membrane. A rather noisy method, but very common among domestic plumbing manufacturers;

- fittings are located at the bottom of the drain tank - bottom feed.The float in this system moves along a vertical rod. Energy is transferred to the locking membrane as a result of the movement of the float with the help of a special thrust, which is a regulator for limiting the liquid level in the tank. A quieter version of water intake compared to the previous one.

In principle, the water supply mechanism is a fairly simple design based on the laws of physics. But even the most elementary systems sometimes fail and require intervention. Breakdowns that may occur in the float mechanism:

- slow water supply. This problem is caused by clogging of the overlapping membrane. The solution is quite simple - you need to clean the water supply hole from debris. The main thing is to carefully disassemble the membrane mechanism, and then assemble it sequentially, without leaving unnecessary details. No special tools are needed, and everyone has pliers and wire cutters;

- excessive amount of water in the tank. In this case, you need to adjust the water level in the tank. The way to solve this problem depends on the type of float. If it is a side feed, then the level is adjusted by unscrewing the lever nut, after which the side of the lever with the float drops lower. If this is a bottom feed, then the float level is set by rotating the plastic screw rod. You need to rotate so that the float drops, then the water level in the tank will be lower;

- the float arms are broken. This malfunction cannot be repaired, it is necessary to change the entire float mechanism of the drain tank.

Works with a tank built into the wall

It is quite difficult to change and repair fittings if the drain container is removed into the wall and masked with finishing materials.To do this, you first have to dismantle the wall panel with flush keys, after which the frame on the hole in the wall is unscrewed with a screwdriver. The partition is removed, after which access to the hidden water fittings is opened.

The water is shut off, after which the valves and other structural elements are dismantled. The breakdown is eliminated, after that the defective plastic parts are replaced with new ones, and the mechanism is assembled in the reverse order. Without experience, it is quite difficult to correctly assemble the components, so it is better to entrust the hidden mechanisms to a specialist. Such fittings are easy to damage, and to completely replace the container, you will have to dismantle the decorative trim.

Leave a request Departure within the Moscow Ring Road for free

Responsible attitude to the condition of plumbing can prevent most breakdowns. It is better not to save on the installation of water filters, as they significantly extend the life of plumbing. It is necessary to change the fittings only for high-quality parts of proven brands, this will avoid repeated malfunctions and expensive repairs. However, if you have certain skills and tools, you can even solve the problem on your own.

For other materials:

Shower rollers - how to choose and install

Types of toilet flush cisterns

The first flush tank was designed back in 1596 for Elizabeth I. But this design gained popularity only 200 years later, when sewage and water supply began to appear in the UK.At first it was a flush tank for a valve-type toilet bowl, then half a century later a tank with a handle was invented, thanks to which it was easier to remove unpleasant odors in the restroom.

Today, the classification of drain tanks is much more diverse. In order not to get lost in a wide range, it does not hurt to get a little familiar with this plumbing object and its varieties.

According to the type of material from which they are made, tanks are:

- metal (usually cast iron) - durable, but outwardly not very aesthetic;

- plastic (plastic) - the lightest of all types, easy to install, but also easily damaged;

- ceramic - reliable, easy to install, have a wide selection of shapes and colors.

By type of launcher:

- Lateral - a rope (chain) attached to the tank, which is located at a certain height from the toilet. The principle of operation of the drain mechanism is as follows: the rope pulls the lever, and a plug with a gasket rises on its opposite shoulder, and water enters the drain pipe.

- Top - a button or head, which is located on top of the cover, usually in the center. In this case, water enters the drain pipe after pressing the button or lifting the rod (rod) up. At the moment of pressing, the rubber bulb rises from its saddle and passes water.

Trigger type:

- Manual mechanism - the reservoir valve opens at the request of the user, who can therefore regulate the amount of liquid used;

- Mechanical - everything is regulated without user intervention.

You can also distinguish the types of drain tanks according to the method of their installation:

- Option 1: the tank is located almost under the very flow, connecting to the toilet with a long armature.This option provides maximum water pressure during the descent, but does not look very attractive in a modern design.

- Option 2: the tank is fixed on the toilet. Compact version, convenient for various repairs.

- Option 3: the drain tank is built into the wall. This option allows you to save space in the restroom and looks very neat and aesthetically pleasing. A significant drawback is the complexity of installation and repair work.

Photo of a hanging toilet cistern,

Photo of a toilet bowl with a flush tank

Photo of a toilet cistern device,

Photo of the toilet flush mechanism,

Photo how to assemble a toilet flush tank, sdelaysam.by

Tank repair

Any, even the most reliable mechanism, can fail sooner or later, this undeniable axiom applies to the drain system. Consider several characteristic shelves of the tank fittings and how to eliminate them without the help of a plumber.

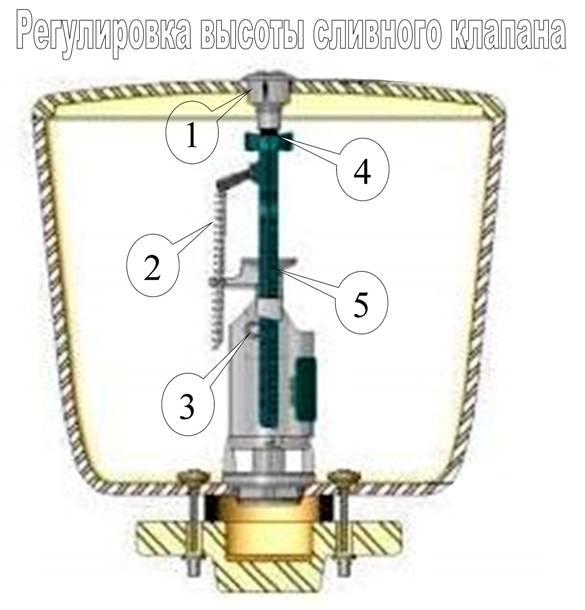

What to do if the toilet cistern with a button is leaking?

There are several reasons that can lead to water leaking into the toilet bowl, we list them:

- The float on the shutoff valves has gone astray, as a result, after filling a certain level, water flows through the overflow pipe. This is easy to find by removing the tank cap and inspecting the insides. To eliminate the leak, it is enough to adjust the height of the float. Alternatively, there may be a loss of tightness by the float, in which case it must be removed and replaced, or repaired (sealed).

- The regulator responsible for the height of the button has shifted, as a result, a gap has formed between the drain valve and the hole in the toilet bowl. To fix the problem, just adjust the height of the button.

- The valve on the stop valve broke.It is checked by pressing the lever coming from the float, if the water does not stop flowing, this indicates a valve malfunction. In this case, the shut-off valves should be changed (not forgetting to first shut off the water supply).

- At the base of the overflow tube, the nut has loosened, as a result, water drips into the toilet bowl, the connection should be tightened.

No water is drawn into the tank

This malfunction clearly indicates problems with the shutoff valves, as a rule, this is a clogged valve or a float stuck on the pulley. In the first case, it is necessary to clean the valve (the procedure did not give results; the fittings will need to be replaced, but before that it is recommended to check the presence of water supply), in the second, adjust the float.

Decreased flow strength

If even with a completely filled tank, due to a weak flow, the cleaning of the toilet bowl is unsatisfactory, this indicates that the drain hole has become clogged. The reason may also be a jumped off rubber hose (installed to reduce noise). In this case, you will need to dismantle the tank (by disconnecting it from the water and removing the mounting bolts) and clean it.

Elimination of external leaks

If water begins to appear under the toilet, this indicates an external leak. It is available in the following locations:

- Between cistern and toilet. The reason can be caused by both improper installation of the tank, and aging of the gasket. In any case, the tank must be dismantled, then the joints must be cleaned and dried, and only after that a gasket of the same type should be installed. Silicone adhesive can be used to guarantee tightness (applied to the joints and gasket).

- At the point of water supply.Turn off the water, then remove the hose, wind the thread around the thread and twist the connection.

- The places where the mounting bolts are installed let water through, the reason is improper installation or the rubber seals have dried up. To eliminate the leak, it is necessary to unscrew and remove the fasteners (the tank can not be dismantled) and change the gaskets (we recommend installing conical gaskets).

Condensation forms on the tank

There are two reasons for such a visual manifestation of the laws of physics:

- High room humidity. Eliminated by installing forced ventilation.

- A malfunction associated with the constant flow of cold water into the tank (water is leaking into the toilet bowl). It is enough to eliminate the malfunction, and the condensate will stop collecting.

How to clean a rusty toilet bowl?

The accumulation of dirt and rust is one of the reasons for the failure of the drain mechanism, so regular maintenance is necessary. To do this, it is necessary to completely drain the water and treat the inner surface with special products, such as Domestos or Sanfor, and then rinse the tank several times with water.

There is another way to clean rust: Sanoxgel is poured into the water of the toilet tank, after which about half a liter of vinegar essence is added. Leave this mixture for a couple of hours, after which it is necessary to draw and drain water several times.

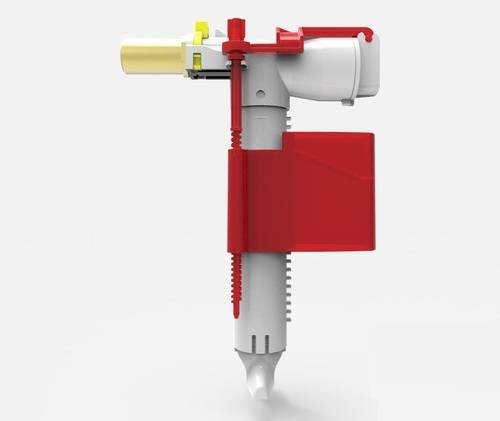

Types of fittings for flush cisterns

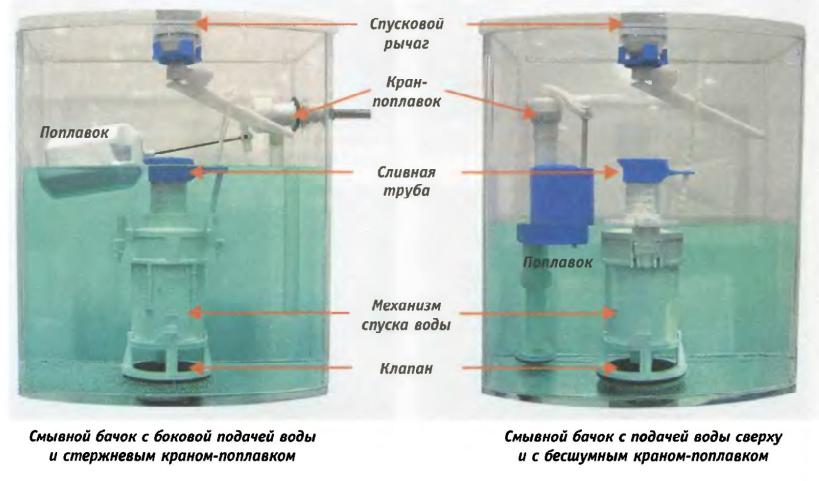

The principle of operation of a conventional tank is not complicated: it has a hole through which water enters and a place where water is discharged into the toilet. The first is closed by a special valve, the second - by a damper.When you press the lever or button, the damper rises, and the water, in whole or in part, enters the toilet, and then into the sewer.

After that, the damper returns to its place and closes the drain point. Immediately after this, the drain valve mechanism is activated, which opens the hole for water to enter. The tank is filled to a certain level, after which the inlet is blocked. The supply and shutoff of water are regulated by a special valve.

A cistern fitting is a simple mechanical device that draws water into a sanitary container and drains it when a lever or button is pressed.

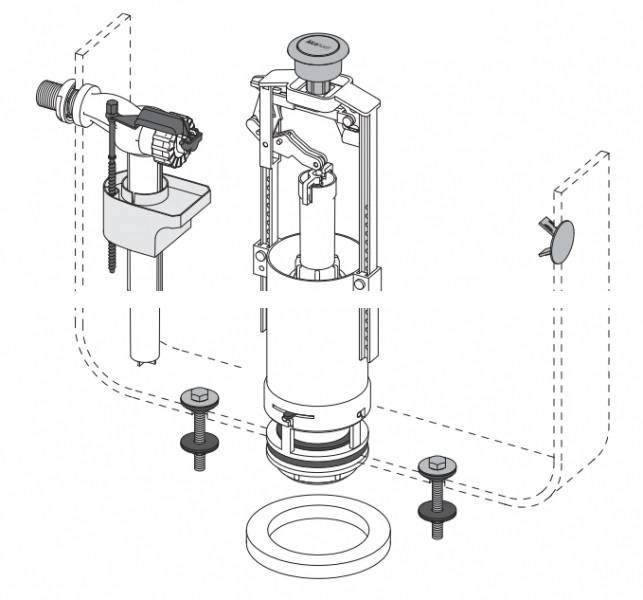

There are separate and combined designs of fittings that collect the volume of water necessary for flushing and drain it after activating the flushing device.

Separate and combined options

The separate version has been used for many decades. It is considered cheaper and easier to repair and set up. With this design, the filling valve and the damper are installed separately, they are not connected to each other.

The shut-off valve for the tank is designed in such a way that it is easy to install, dismantle or change its height.

To control the inflow and outflow of water, a float sensor is used, in the role of which even a piece of ordinary foam is sometimes used. In addition to a mechanical damper, an air valve can be used for the drain hole.

A rope or chain can be used as a lever to raise the damper or open the valve. This is a typical option for models made in retro style, when the tank is placed quite high.

In compact toilet models, control is most often carried out using a button that needs to be pressed. For those with special needs, a foot pedal may be installed, but this is a rare option.

In recent years, models with a double button have been very popular, which allow you to empty the tank not only completely, but also halfway to save some of the water.

The separate version of the fittings is convenient in that you can repair and adjust individual parts of the system separately.

Combined type fittings are used in high-end plumbing, here the drain and inlet of water are connected into a common system. This option is considered more reliable, convenient and expensive. If this mechanism breaks, the system will need to be completely dismantled for repair. The setup can also be a little tricky.

The fittings for the toilet cistern with side and bottom water supply are different in design, but the principles of setting up and repairing them are very similar

Materials for the manufacture of devices

Most often, toilet fittings are made of polymeric materials. Usually, the more expensive such a system is, the more reliable it is, but this method does not give clear guarantees. There are fakes of well-known brands, and quite reliable and inexpensive domestic products. An ordinary buyer can only try to find a good seller and hope for good luck.

Fittings made of bronze and brass alloys are considered much more reliable, and it is much more difficult to fake such devices. But the cost of these mechanisms will be much higher than that of plastic products.

Metal filling is usually used in high-end plumbing.With proper configuration and installation, such a mechanism functions smoothly for many years.

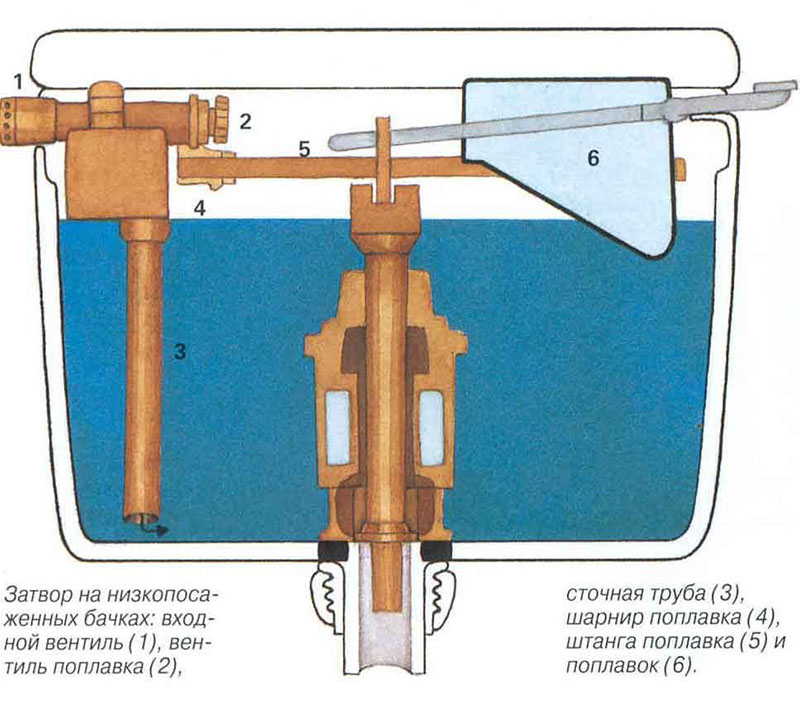

In bottom-fed toilets, the inlet and shut-off valve are very close. When adjusting the valve, make sure that the moving parts do not touch.

Place of water supply

An important point is the place where water enters the toilet. It can be carried out from the side or from below. When water is poured from the side hole, it produces a certain amount of noise, which is not always pleasant for others.

If the water comes from below, it happens almost silently. The lower water supply to the tank is more typical for new models released abroad.

But traditional cisterns of domestic production usually have a lateral water supply. The advantage of this option is the relatively low cost. The installation is also different. The elements of the lower water supply can be installed in the tank even before its installation. But the side feed is mounted only after the tank is installed on the toilet bowl.

To replace the fittings, they are selected taking into account the option of supplying water to the sanitary tank, it can be side or bottom

Classification

Inlet mechanisms can be divided into groups according to three criteria:

- material composition,

- location,

- construction type.

By material

- Brass or bronze. Products made from these alloys are practical, durable, reliable and completely resistant to corrosion. But such metal valves have a rather high cost.

- Plastic. Plastic products are very popular, because along with a long service life, they are quite inexpensive.

By location

- With bottom line. Valves with this connection are located at the bottom of the tank.With this method, the water intake is completely silent. Also, the lower location allows you to hide the inlet hose and free up the space of the toilet room from unnecessary fittings.

- With lateral connection. Valves with this connection are located, respectively, on the right or left side of the tank. This design is the simplest, which has a positive effect on its service life.

It is necessary to choose inlet units depending on the design of the toilet bowl. Also, when choosing, you must adhere to the following rules:

- The complete set of goods should include the valve itself, the float, o-rings and the fixing nut.

- O-rings must be elastic, of correct shape and without defects.

- The plastic element should not have visible scratches and notches.

- The movement of the float should be smooth, without sudden jumps.

By type of construction

Once the valves were spherical, the device had the form of a ball, which was used in all tanks. The modern device is called an inlet, as it has no resemblance to the design of ball mechanisms, but is used together with a float. There are several types of float devices for the toilet cistern:

- Croydon valves consist of a shell, a float with a lever and a piston with a seat. In this mechanism, the movement of the lever is perpendicular to the operation of the piston. Such a system is used in old tanks and has a fairly low price.

- Piston are equipped with a forked stud with a lever axle. Here, the water is adjusted by horizontally raising the lever that drives the piston, at the end of which there is a special seal that comes into contact with the seat and blocks the flow of fluid.This is a fairly common model and is included in the middle price category.

- Diaphragm valves have a rubber or silicone membrane instead of a gasket, which is displaced by the movement of the piston. This is the latest device that is used only in the latest models of toilet bowls. The advantages of this valve include a quick intake of water, instantaneous shutoff of the liquid intake and, depending on the quality of the fittings, silent filling of the tank. Among the shortcomings, one should take into account the presence of a constant pressure of water in the system (0.05-0.1 MPa) and the purity of the liquid, since if the membrane is damaged, it is impossible to replace it on its own. In this case, you will have to purchase the entire intake mechanism.

Components of the drain fittings

Knowing how the toilet flush tank works, it will be very easy to repair it or replace failed parts. It goes without saying that the design of various models may vary, but the fundamental elements and the principle of their operation are the same for all types of valves.

Filling mechanism

As mentioned above, the task of the filling mechanism is to ensure that water enters the tank and closes it, at the time when it is needed. This mechanism consists of the following elements:

| Stop valve | It is located in a housing located at the "entrance" to the tank. The task of the toilet cistern valve is to shut off the water. |

| Float with lever | The task of the part is contained in the regulation of the valve position. When the float drops, the valve opens. At a time when the float is at the top, the valve completely shuts off the water. |

It must be stated that modern valves look a little different, in particular, the float moves only in a vertical plane, and the valve itself is located below, and not on the side. But, the principle of operation of the mechanism remained the same.

Such a device of the toilet tank made it possible to ensure not a gradual shutdown of water, but a complete one at the very end of the set. That is why the capacity is recruited much faster.

Drain and overflow mechanism

The most simple and the first drain mechanism was a pear system. She worked extremely simply - a rubber pear was placed in it, hermetically blocking the drain hole. It was worth lifting the lever or pulling the handle on the chain, as the water rushed into the toilet with noise.

Currently, the device of the toilet cistern has changed. This reinforcing unit consists of two main elements:

| overflow | Prevents overfilling of the container. If the water level reaches the maximum allowable level, water begins to drain into the toilet. |

| Plum | Starts to function when pressing the button located on a cover of a tank. In modern toilet models, there are two buttons - for partial and complete draining, which allows you to save water. |

Despite the more complex design, the principle of operation of the drain remains the same - the drain hole hermetically closes the drain valve, which rises when the button is pressed.

be directed to emphasize that, according to the type of placement, there are two types of tanks:

Suspended - in this case, the container with the toilet is connected using a pipe through which water flows.

- Mounted on the toilet shelf - in this case, the drain hole of the container is directly aligned with the hole in the toilet bowl. For tightness of connection of pipes the rubber sealant is used.

- Mounted in the wall - unlike the two options described above, such a container is installed in the wall. According to the principle of connection with the toilet, the design resembles hanging containers.

Now knowing how the toilet tank works, you can independently determine the cause of the device malfunction and fix it yourself.

Damage not related to rebar

It is important to know how to repair the cistern or the toilet itself if there are cracks in the body. Leaked water can cause a flood, so if you find a problem, you should act immediately.

Glue for ceramics will help to close the crack, but in the near future the plumbing will have to be replaced.

A leak can also occur if:

- The nuts on the bolts with which the tank is attached to the toilet pan have loosened. Fasteners must be carefully tightened with a wrench. If it is necessary to replace the seals, the tank will have to be dismantled and reinstalled.

- The connecting cuff between the tank and the toilet shelf is deformed or damaged. It must be replaced, but as a temporary measure, the resulting gaps can be sealed with silicone sealant.

How to quickly close a crack in the tank

Preventive measures

To avoid problems associated with leaks, with excessive consumption of water constantly flowing into the toilet bowl from the reservoir, it is important to know the design of the flush tank, to be able to adjust and repair the mechanisms. Recommended systematically:

Recommended systematically:

- check the condition of the flexible piping, connection node;

- inspect the fittings inside the tank, clean it from lime deposits and other contaminants;

- check the tightness of the connecting collar and bolt fasteners with a paper towel;

- inspect the tank and toilet for cracks.

Preventive measures allow you to extend the life of the mechanisms.

Briefly about the main

The cause of the breakage of the flush tank is usually worn or damaged fittings, improper adjustment, deformation and contamination of the seals or the drain valve. Knowing how to fix a drain tank, you can fix or adjust the water supply mechanism, return the functionality of the drain device, completely replace the fittings, or replace damaged elements, including seals.

Possibilities for adjustment and repair

During the operation of the toilet, various minor problems arise from time to time. You should not immediately run to the store and buy a new filling in the tank, since some problems can be solved in no more than half an hour. At the same time, it is not necessary to invite a specialist and pay him money, but it is enough to try to do it yourself.

How to adjust the water level in the tank

In devices with a bottom water supply, it is always better to adjust the water level after installing the toilet, since they are all adjusted at the factory to the maximum level, which can be redundant and uneconomical. To adjust the level in the drain tank, it is enough:

- Drain the water tank and turn off the water supply.

- Unscrew the button.

- Remove cover.

-

Adjust the height of the float using a special screw located at the top of the float mechanism.

- Close the tank with a lid and install the button.

There are cases when, after installing the toilet, water constantly flows from the tank. This indicates that the water level in the tank is high enough and the water flows through the overflow system. In this case, it is necessary to reduce the water level by lowering the float according to the technology described above.

If the float mechanism consists of a curved lever, then the water level is adjusted by bending this lever, which is even easier

It is important to understand that the lower the float in the tank, the less water it will take.

Toilet cistern leaks

Water leaks in the toilet are possible even if the water level is normal, but then you will have to look for other reasons. Water may leak if:

- The sealing gum of the drain valve has silted up, so it will have to be cleaned. For this you will have to:

-

- Turn off the water supply and empty the tank.

- Remove the water release mechanism.

- Remove the bleed valve and carefully inspect the gasket. If necessary, it is cleaned or polished with a fine emery cloth.

- Install the mechanism back into the drain tank, turn on the water and test the device. If this does not help, then you will have to replace the gasket.

The escapement mechanism was demolished during operation. This is easy to check, just press the mechanism with your hand. If the water stops flowing, then that's the way it is. In this case, you can make the glass heavier by adding some weight to the bottom of the glass.

Adding weight

In any case, you will have to disassemble the mechanism, and then assemble it and check it. If these little tricks do not help, then it is better to buy a new drain mechanism and replace the old one with it. In fact, this is the best option.

The tank does not draw water

There is also such a problem that water is not drawn into the tank at all or is drawn, but rather slowly. If the water pressure normal, then the reason is obvious - the filter, tube or valve is clogged. The way out of this situation is quite simple and comes down to cleaning the filter, tube or inlet valve. To do this, you will have to completely remove the water supply mechanism, and then assemble everything as it was.

How to do it right, you can see in the video.

What is the result

As you can see, in the design of a modern car, increased requirements are put forward for the engine cooling system and its correct operation. For this reason, a special tank is additionally used in the design for effective functioning.

You also need to know if the specified expansion tank of the engine cooling system is involved in the circuit, that it is highly desirable to fill the system with only antifreeze or antifreeze, and not water

As for breakdowns, if pressure builds up in the cooling system or air pockets form, special attention must be paid to the cover of the expansion tank . ), the engine may overheat, etc. Violation of the valves in the cover often leads to the fact that the pipes are damaged, the thermostat fails faster, the cooling system pump (pump) suffers, the engine may overheat, etc.

Violation of the valves in the cover often leads to the fact that the pipes are damaged, the thermostat fails faster, the cooling system pump (pump) suffers, the engine may overheat, etc.