- In what cases is a collector heating system acceptable?

- What is a collector?

- Recommendations for choosing a heating collector

- Installation of a heating collector

- Installation and connection rules

- Storm sewers

- Functions and features of storm collectors

- Some of the use of systems in practice

- Purpose and types

- materials

- Equipment

- What is it needed for?

- Zoning

- Collector: device and principle of operation

- Mounting Features

- Preparing for installation

- Installation of a radiant heating system

- Principle of operation

- Advantages and disadvantages of the collector system

- How to install?

- Solar collector saving opportunity

- General requirements for the installation of beam wiring

- Conclusions and useful video on the topic

In what cases is a collector heating system acceptable?

There is no standard solution when drawing up a scheme of a collector system; there are also no generally accepted planning standards. The selection of equipment should be carried out by specialists, taking into account the specific tasks that need to be solved.

The opinion of experts should not be ignored: such a system is not can be recommended for heating in multi-storey buildings.

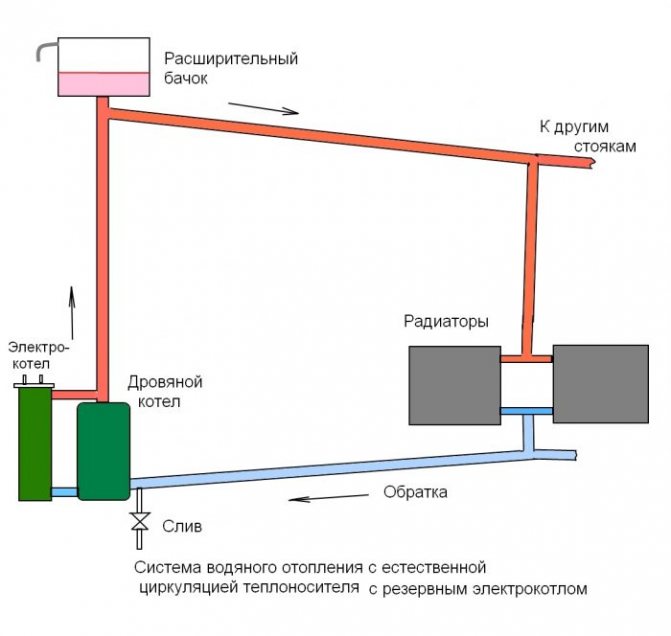

Heating system options in multi-storey buildings

The problem is that the heating in the apartment is provided by the supply of coolant by at least two risers. A prerequisite for the system under consideration is the connection of all radiators to one riser.

Leaving one source of heat, it will be necessary to block the rest, i.e. boil them. The entire load will be concentrated on the abandoned riser, while within a particular apartment, a closed hydraulic circuit will form.

All radiators located on the upper floors will be cut off from the centralized heating system and the coolant will not flow into them. Naturally, the residents of the upper floors will express dissatisfaction and will demand the restoration of the old communications by force.

What is a collector?

When installing plumbing from scratch or changing an old one, it is necessary to consider the location of all consumers: a toilet bowl, a washbasin, a washing machine.

In an ordinary apartment of plumbing fixtures, the number varies from four to a dozen. Experienced plumbers recommend that their customers install a water manifold.

The water collector is a kind of distributor, which is an important plumbing element cold and hot water systems, heating. It is installed on the central riser and hidden in a plumbing cabinet. Access to the distribution comb must not be blocked by furniture or sewn tightly into the wall. However, professional repairmen will give the engineering unit an aesthetic appearance.

Recommendations for choosing a heating collector

To choose a device, you need to pay attention to certain parameters:

- The indicator of the maximum allowable pressure.This determines the type of material from which the control valve is made.

- Node throughput and availability of auxiliary devices.

- The number of outlet pipes. They should be no less than the cooling circuits.

- Possibility of adding additional elements.

Operational characteristics are indicated in the device passport. For heating to work independently on each floor, a heating comb is needed, which means that the elements are connected one at a time per floor, and the type is selected according to the number of outlets (there must be as many or more than autonomous circuits).

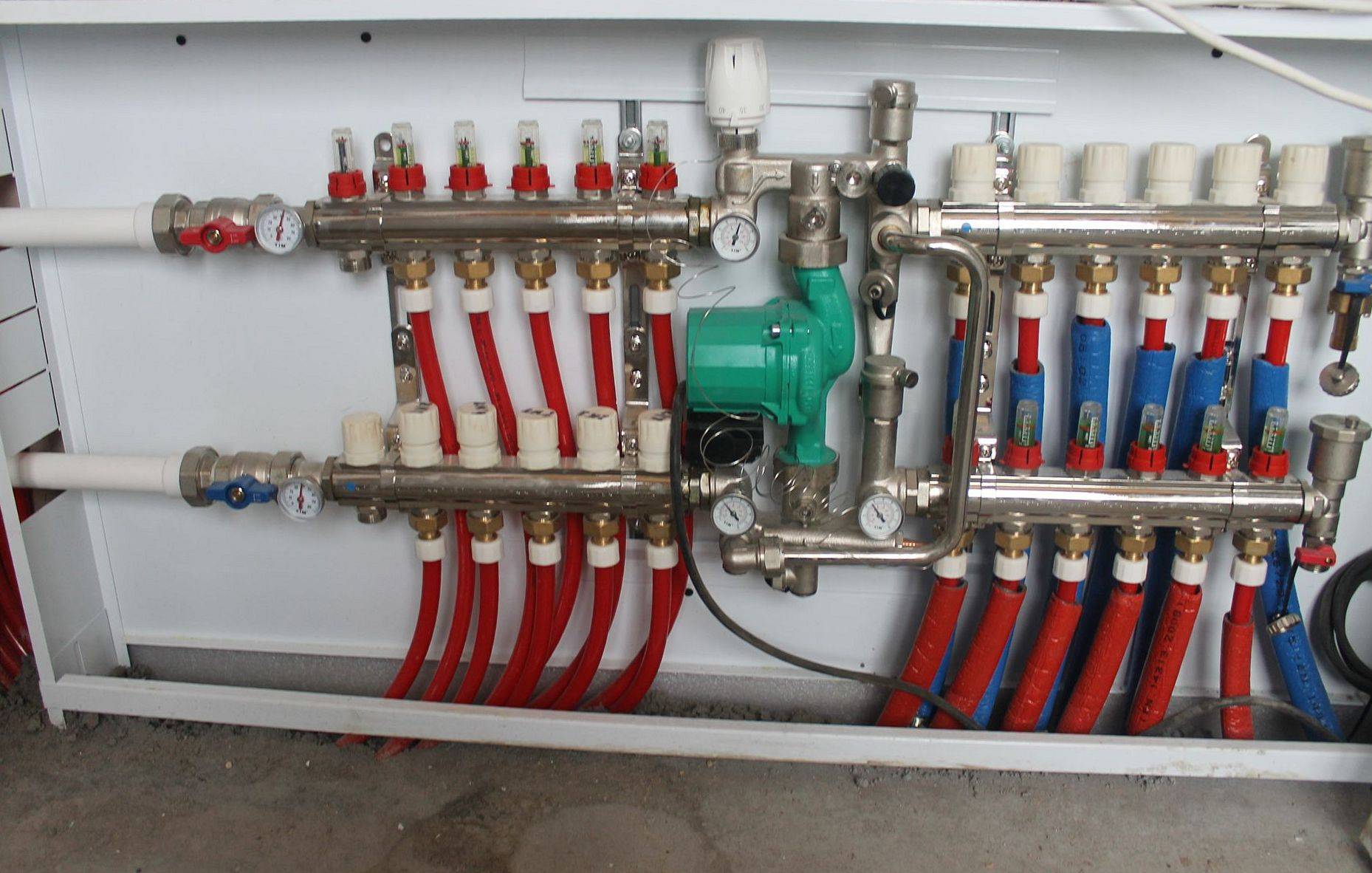

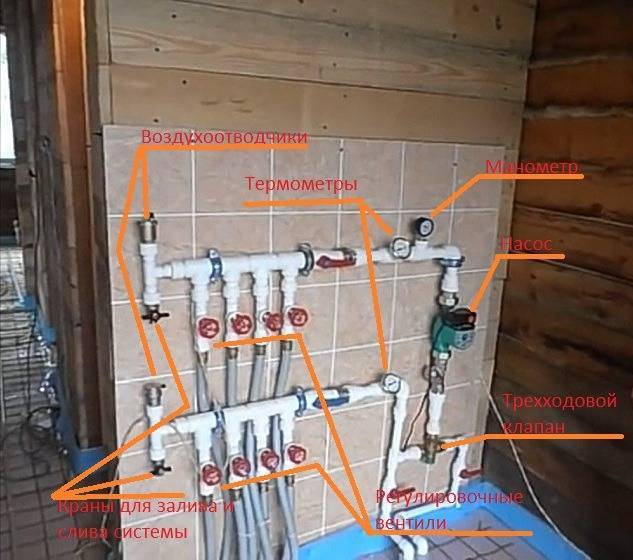

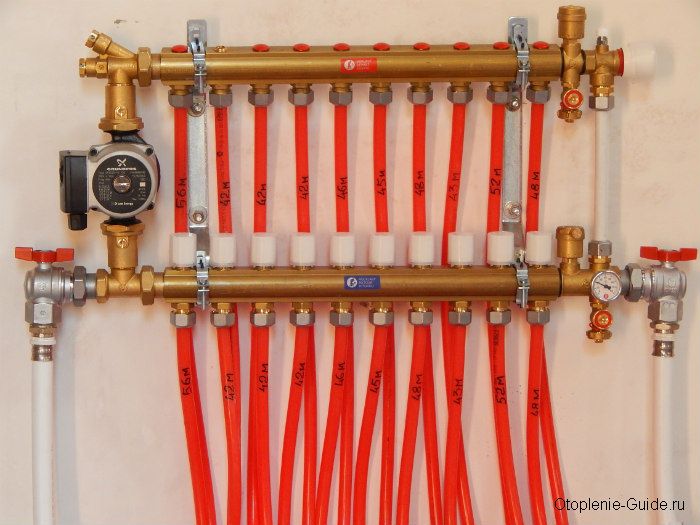

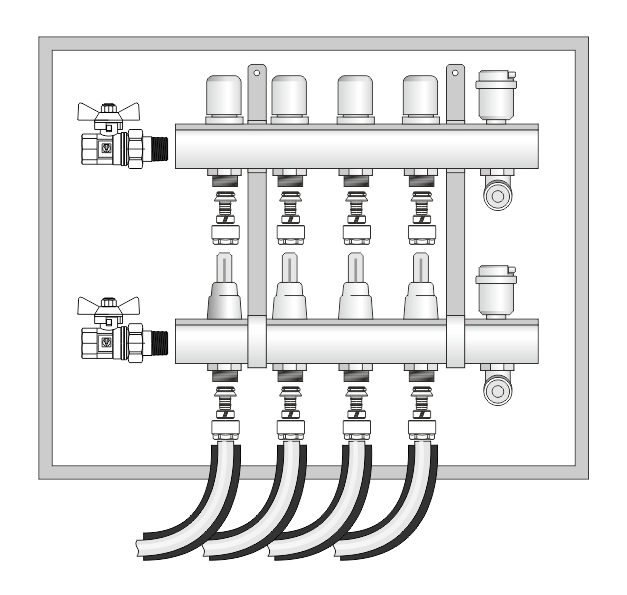

Installation of a heating collector

It is better to provide for the installation of a heating collector at the stage of forming an autonomous circuit. The installation is carried out in rooms without excessive humidity, it is possible to mount the collectors on the walls in special cabinets or without them, hanging the devices so that the distance from the floor is negligible.

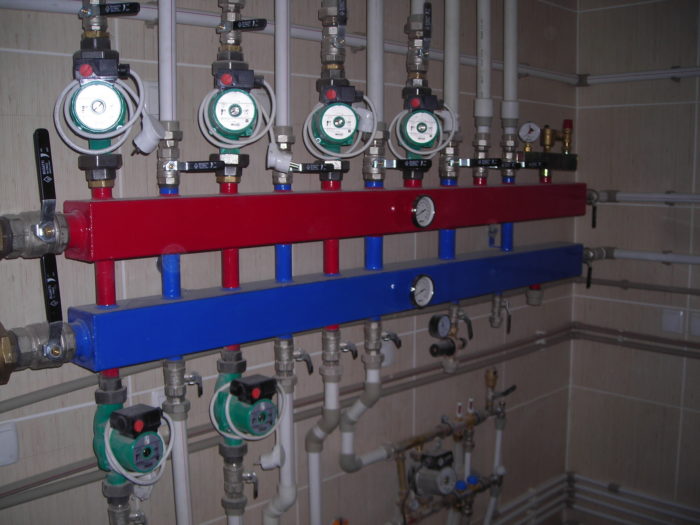

There is no standard installation scheme, but there are a number of rules and features that should be considered:

- You need to install an expansion tank. The capacity of the structural element must be at least 10% of the total volume of the coolant in the system.

- Circulation pumps are installed for each circuit.

- The expansion tank is installed in front of the circulation pump on the coolant return flow pipeline. If a hydraulic arrow is used, then the tank is installed in front of the main pump - this will help ensure the desired intensity of coolant circulation in the small circuit.

- The location of the circulation pump does not really matter, but experts advise installing the device on the return line in a strictly horizontal position of the shaft, otherwise the air will cause the unit to remain without cooling and lubrication.

The high cost of equipment forces users to abandon the use of a collector circuit in the trunk. But there are options for self-manufacturing equipment.

Consider how to make a collector for heating with your own hands, and also prepare the necessary materials:

- polypropylene pipes with an index of 20 for an autonomous system and with an index of 25 for a central one - it is better to take reinforced pipes;

- plugs on one side in each group;

- tees, couplings;

- Ball Valves.

The assembly of the structure is simple - first connect the tees, then install a plug on one side, and a corner on the other (required for lower coolant supply). Now weld the segments onto the bends, on which the valves and other devices are installed. Soldering of polypropylene pipes is carried out with a professional device or a home soldering iron, before soldering, the ends are degreased, chamfered, after joining, the products must be allowed to cool.

The longest in the system is the accelerating collector, through which water rises when heated and then enters separate circuits. After the equipment is manufactured, the connection is carried out in the usual manner - with installation circulation pump for each circuit and installation of an expansion tank.

With the ability to handle tools, the master can make a heating collector with his own hands, and will help in this video:

In this case, the device will cost much cheaper than factory analogues and is suitable for circuits of various types.

Installation and connection rules

It is best to choose and install a collector at the design and installation stage of the heating system.

Install such intermediate structures in rooms protected from excessive moisture. Most often, for these purposes, a place is allocated in the corridor, pantry or dressing room.

On sale there are overhead and built-in models of metal cabinets. Each model is equipped with a door and stamping on the sides.

For lack of the ability to install a metal cabinet, it is easier to fix the device directly on the wall. A niche for arranging the collector block is placed at a low height relative to the floor.

There is essentially no generally accepted installation instruction for collector distribution circuits. But there are a number of key points regarding which experts have come to a common denominator:

- The presence of an expansion tank. The volume of the structural element must be at least 10% of the total amount of water in the system.

- The presence of a circulation pump for each laid circuit. Regarding this element, not all experts are unanimous in their opinion. But still, if you plan to use several independent circuits, it is worth installing a separate unit for each of them.

An expansion tank is placed in front of the circulation pump on the return line. Thanks to this, it becomes less vulnerable to the turbulence of water flows that often occur in this place.

If a hydraulic arrow is used, the tank is mounted in front of the main pump, the main task of which is to ensure circulation in a small circuit.

The location of the circulation pump is not important. But, as practice shows, the resource of the device is somewhat higher precisely on the "return".

The process of assembling and connecting the collector system is clearly presented in the video block.

Storm sewers

The main purpose of storm sewer collectors is to collect all atmospheric water discharged from a certain area in one place. They are sealed tanks to which pipelines are connected from all points of the catchment area.

The sewer collector, as a rule, has a sufficiently large capacity and is installed in a previously prepared well or in the ground.

This tank is mounted below the freezing point, or insulated with modern materials (for example, glass wool, stone wool).

Questionnaires for calculating and ordering storm sewer elements:

Modern rainwater collectors used in autonomous sewerage systems of private houses and cottages, industrial enterprises and social and cultural facilities are made of materials that are durable and resistant to corrosion, aggressive environments and temperature fluctuations. The well-known Russian company Flotenk develops and manufactures them from fiberglass, mounts them directly at customer sites.

The company "Flotenk" for the production of storm collectors uses a composite material such as fiberglass. It is thanks to its excellent characteristics that these containers perform the tasks assigned to them in the best possible way.

First of all, it should be said that fiberglass collectors for collecting rainwater in terms of their strength characteristics, resistance to static and dynamic mechanical loads significantly exceed those produced by other companies made of plastics (usually polypropylene), and are almost as good as metal ones.

These collectors have a very small mass, which facilitates their transportation, handling, and installation.

One of the features and at the same time advantages of fiberglass storm sewers is that they have an almost perfectly smooth inner surface, deposits form on it very slowly, and therefore it is rarely necessary to clean the walls of the tanks.

It makes sense to buy or order fiberglass rainwater collectors from the Flotenk company also because they are offered at a very competitive price. This company itself develops and manufactures them, so the cost of the tanks is quite reasonable, significantly lower than that of numerous intermediaries.

Functions and features of storm collectors

The sewage collector is, in fact, the accumulator of all surface runoff, which is settled in it, while being cleaned of mechanical impurities. If there are a lot of them in the discharged waters, then these devices can be additionally equipped with either filters or gratings.

When designing rain collectors to collect stormwater from a particular area, designers must take into account the following two factors: the expected maximum amount of accumulated runoff, as well as the method of its disposal.Depending on these conditions, it is determined what kind of capacity the tank should have in a particular case. From rain sewer collectors, settled water can be removed to filtration fields or (if the level of their pollution complies with current standards) directly to the environment (ravines, reservoirs)

Often they try to use it more rationally: they pump it out using submersible pumps, and then use it for irrigation or for other household purposes.

From the rain sewer collectors, settled water can be removed to filtration fields or (if the level of their pollution complies with current standards) directly to the environment (ravines, reservoirs). Often, they try to use it more rationally: they pump it out using submersible pumps, and then use it for irrigation or for other household purposes.

Some of the use of systems in practice

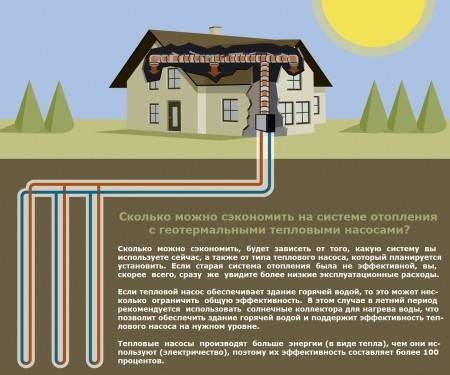

I decided to add this section because real usage data appeared. My good friend installed it 3 years ago (Ukraine, Kyiv region).

A solar system is used for heating a house of 100 sq m and hot water for 6 people. Gas costs were for heating and hot water 33 400 UAH in year. The decision was made to purchase a solar collector.

The set includes 6 flat collectors and a storage tank of 1000 liters. Result:

- — 100% within 6 "warm" months according to the load on the hot water supply (temperature 55 degrees),

- — 50% within 6 "cold" months according to the load on the hot water supply,

- — 25% within 6 "cold" months according to the load on heating in the supporting mode.

The total savings for the year amounted to 11 300 UAH (in terms of rubles, the amount must be multiplied by 2.2).

The whole system was 94000 UAH. With such a gas price, it will pay off in 8.4 years. Manufacturers give a guarantee of 15 years, so a minimum of 7 years will be a net profit.

Purpose and types

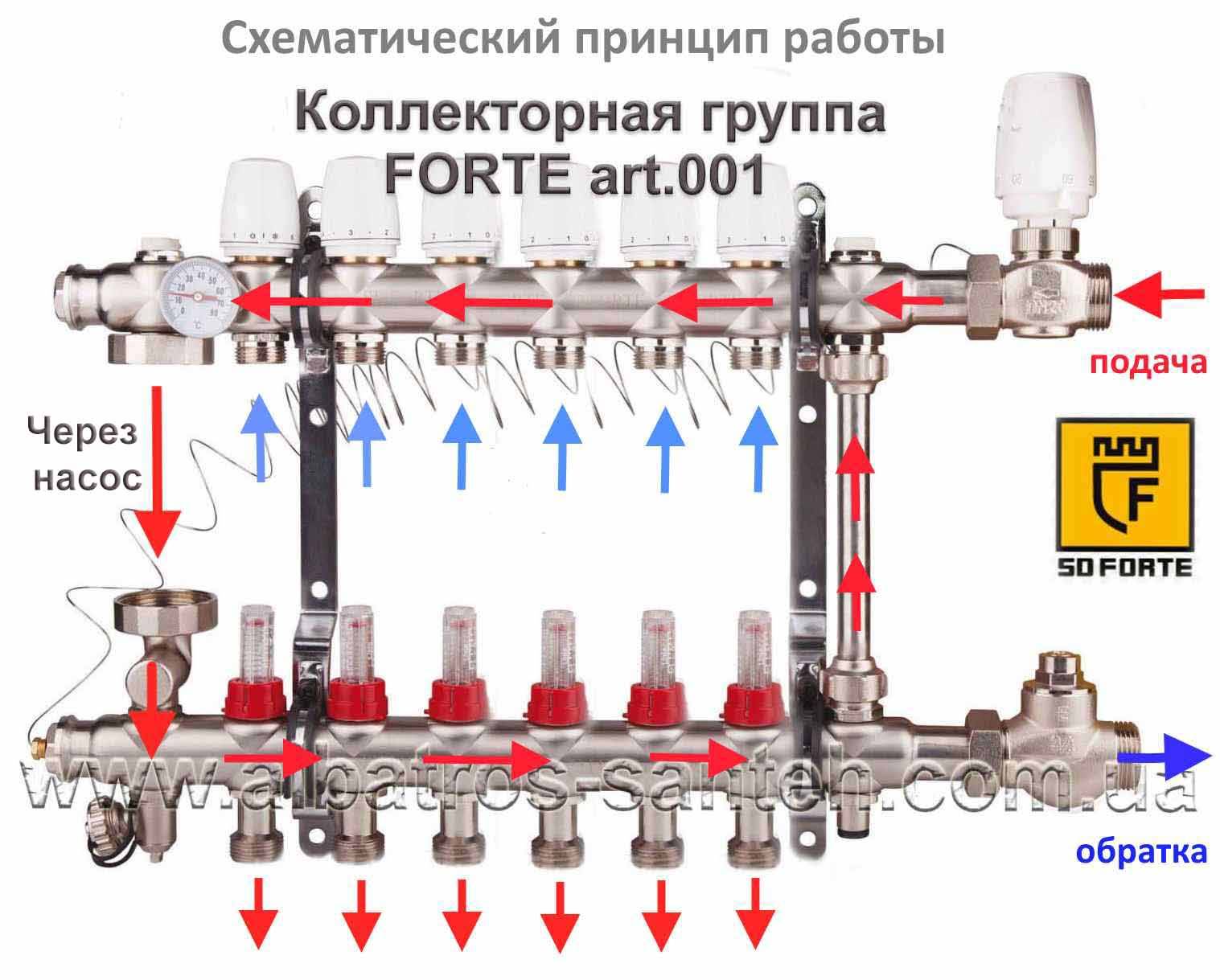

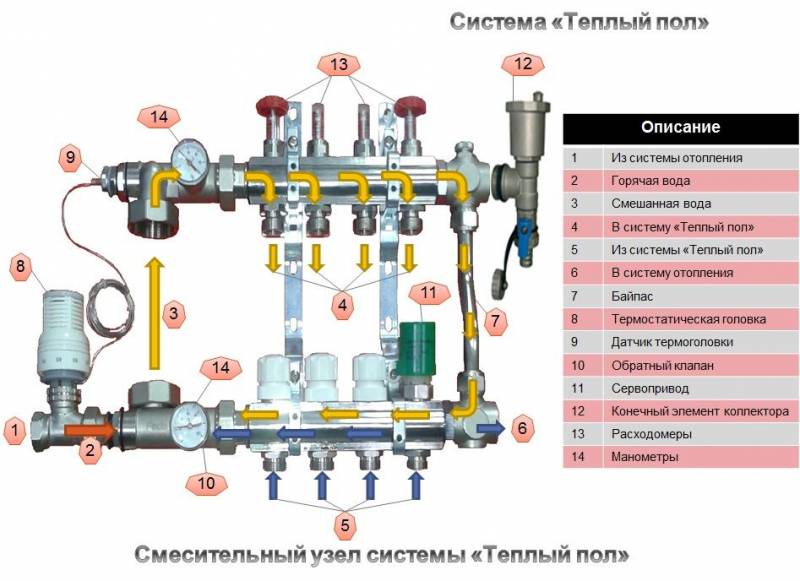

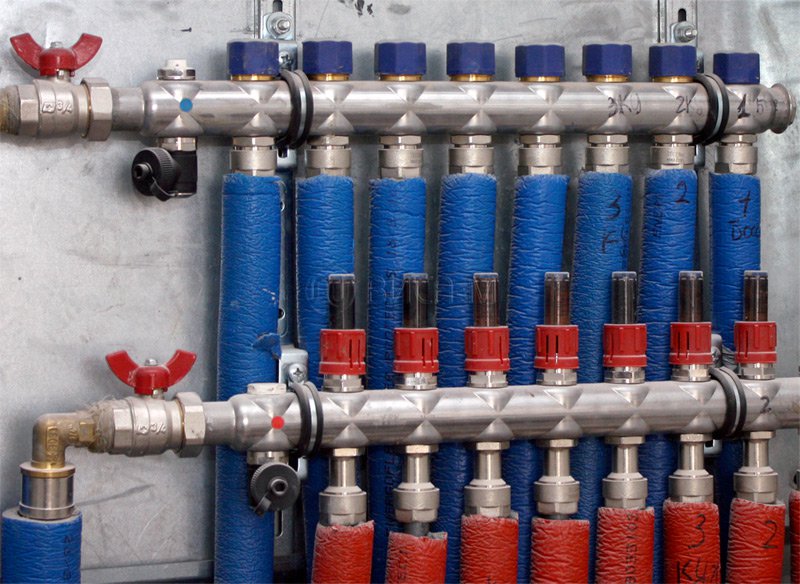

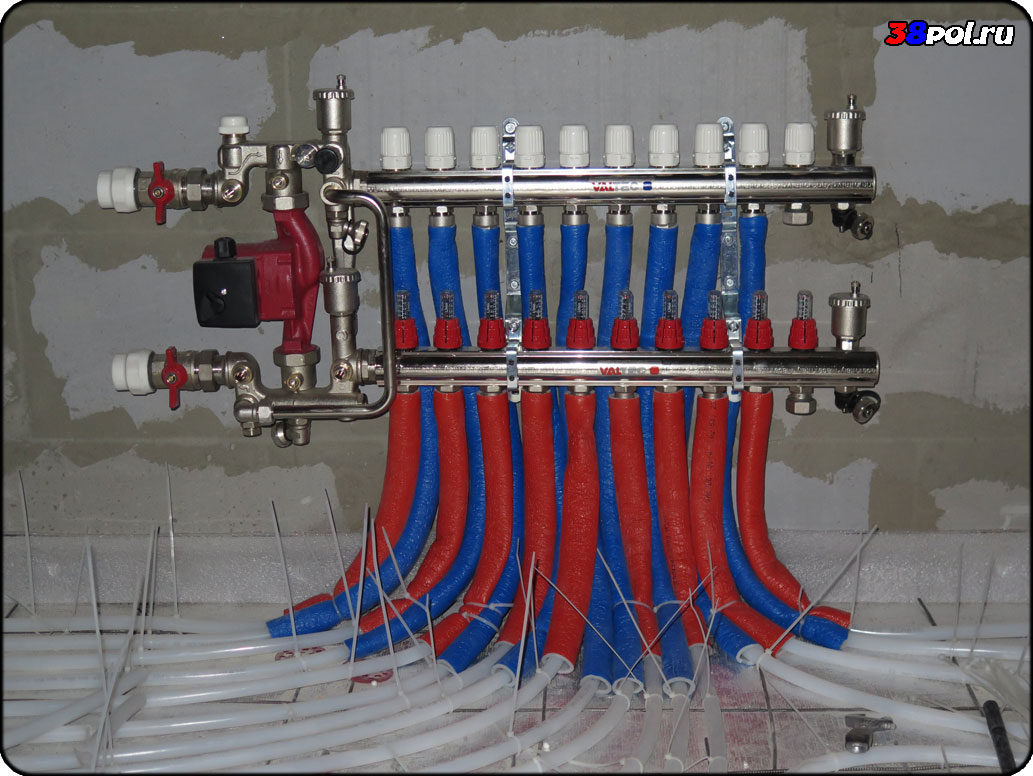

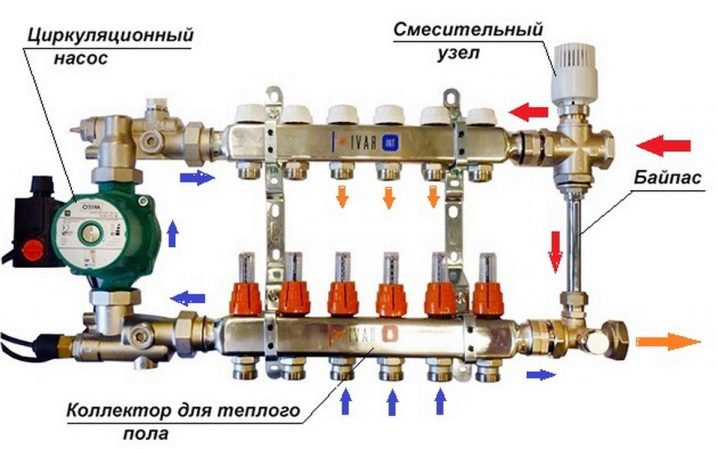

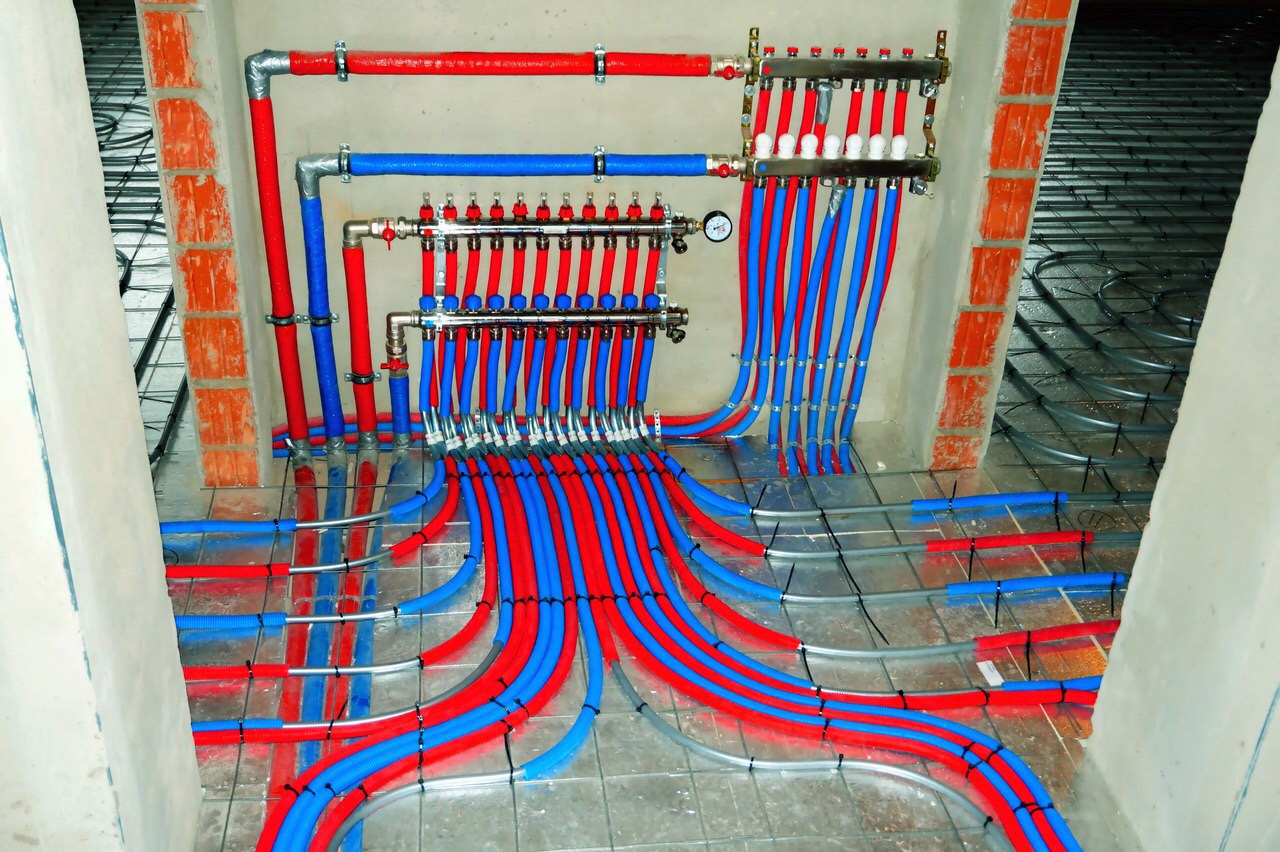

A warm water floor is distinguished by a large number of pipe contours and a low temperature of the coolant circulating in them. Basically, heating of the coolant to 35-40°C is required. The only boilers that can operate in this mode are condensing gas boilers. But they are rarely installed. All other types of boilers produce more hot water at the outlet. However, it cannot be launched into the circuit with such a temperature - the floor is too hot and it is uncomfortable. To lower the temperature, you need mixing nodes. In them, in certain proportions, hot water is mixed from the supply and cooled from the return pipeline. After that, through a collector for a warm floor, it is fed to the circuit.

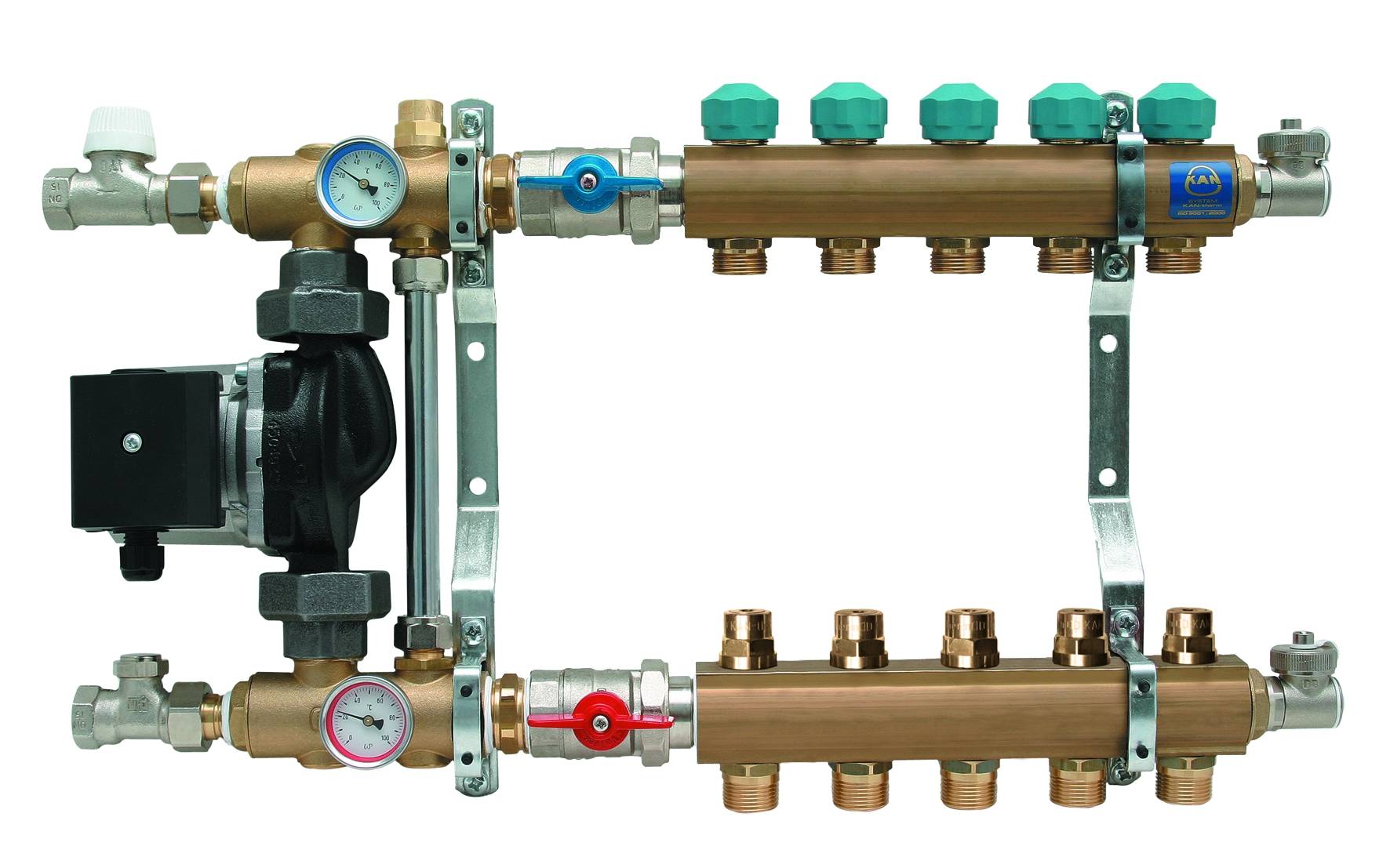

Collector for underfloor heating with mixing unit and circulation pump

In order for all circuits to receive water of the same temperature, it is supplied to the underfloor heating comb - a device with one input and a certain number of outputs. Such a comb collects cooled water from the circuits, from where it enters the boiler inlet (and partially goes to the mixing unit). This device - supply and return combs - is also called a collector for underfloor heating. It can come with a mixing unit, or maybe only combs without any additional “load”.

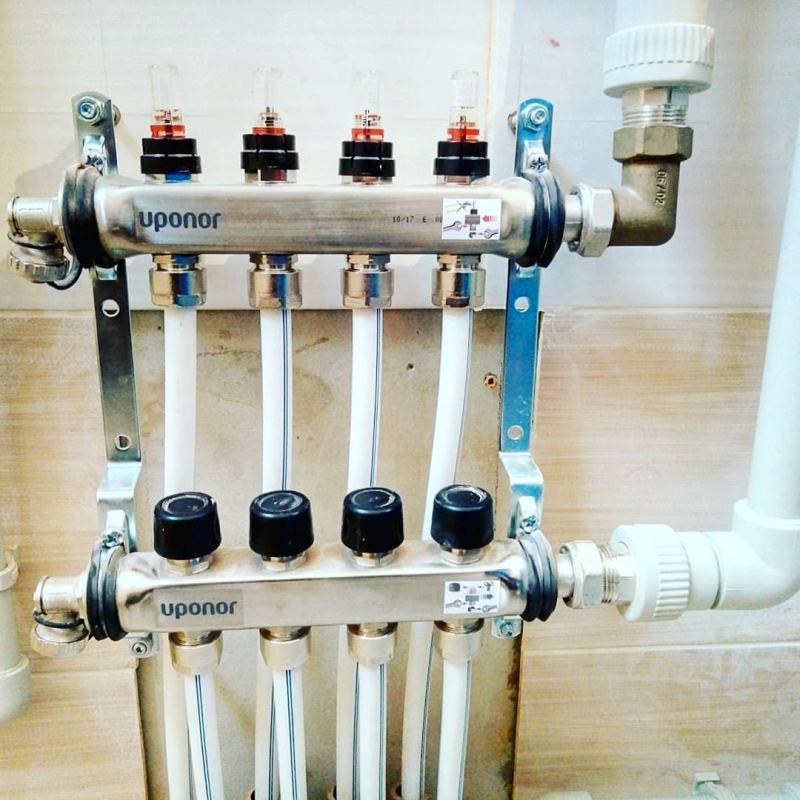

materials

The collector for a warm floor is made of three materials:

- Of stainless steel. The most durable and expensive.

- Brass. Average price category. When using a high-quality alloy, they last a very long time.

-

polypropylene. The cheapest.To work with low temperatures (as in this case), polypropylene is a good budget solution.

When installed, the inputs of the underfloor heating circuits are connected to the supply manifold of the collector, and the outputs of the loops are connected to the return pipeline comb. They are connected in pairs - to make it easier to regulate.

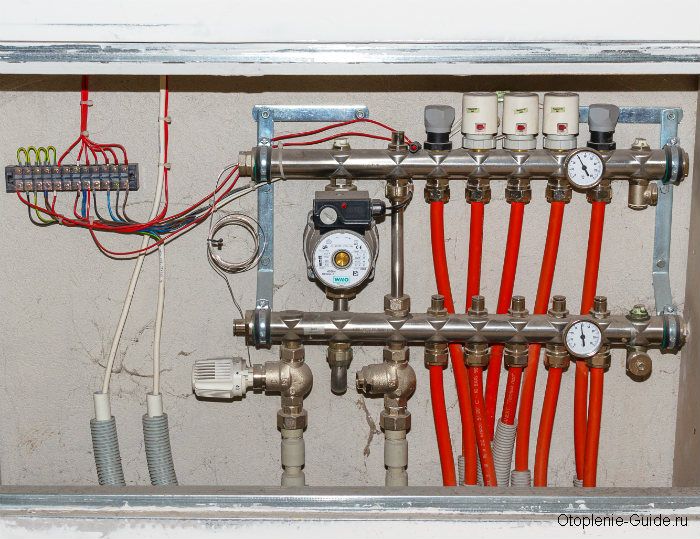

Equipment

When installing a water-heated floor, it is recommended to make all circuits of the same length. This is necessary so that the heat transfer of each loop is the same. It's just a pity that this ideal option is rare. Much more often there are differences in length, and significant ones.

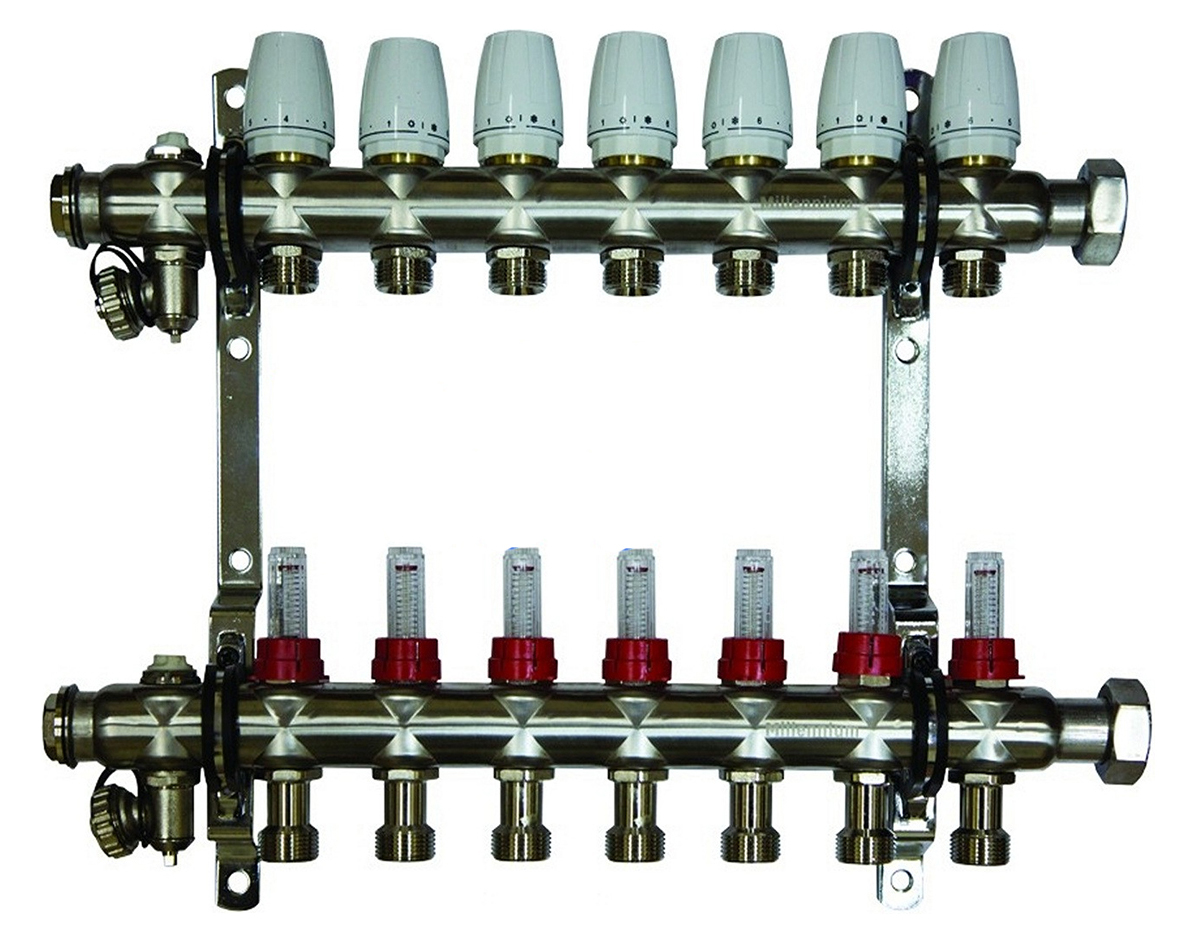

To equalize the heat transfer of all circuits, flow meters are installed on the supply comb, and control valves are installed on the return comb. Flowmeters are devices with a transparent plastic cover with graduations. There is a float in the plastic case, which marks the speed at which the coolant moves in this loop.

It is clear that the less coolant passes, the cooler it will be in the room. To adjust the temperature regime, the flow rate on each circuit is changed. With this configuration of the collector for underfloor heating, this is done manually using control valves installed on the return comb.

The flow rate is changed by turning the knob of the corresponding regulator (they are white in the photo above). To make it easier to navigate, when installing the collector assembly, it is advisable to sign all the circuits.

Flow meters (right) and servos/servomotors (left)

This option is not bad, but you have to adjust the flow rate, and therefore the temperature, manually. This is not always convenient. Servo drives are installed at the inputs to automate the adjustment. They work in tandem with room thermostats.Depending on the situation, the servo is given a command to close or open the stream. In this way, maintaining the set temperature is automated.

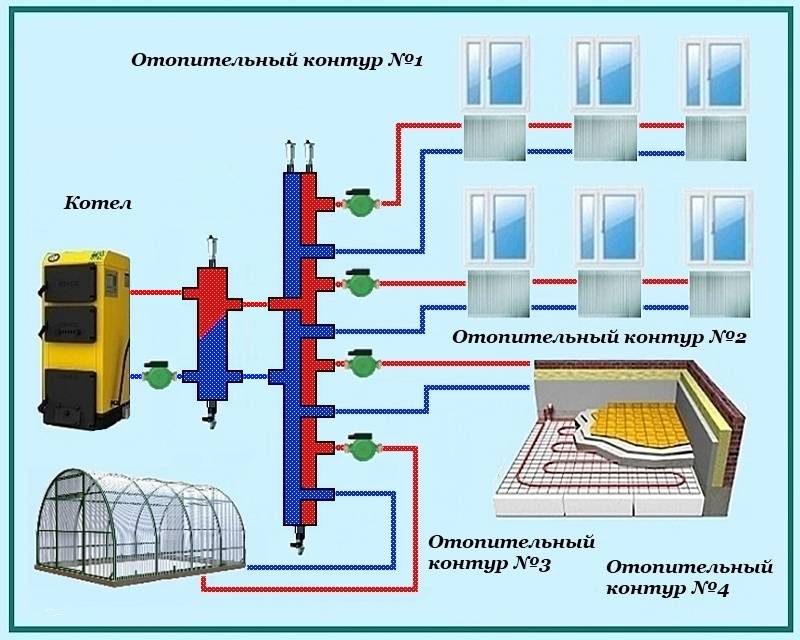

What is it needed for?

When installing water pressure systems, there is a rule: the total diameter of all branches should not exceed the diameter of the supply pipe. With regard to heating equipment, this rule looks like this: if the diameter of the boiler outlet fitting is 1 inch, then two circuits with a pipe diameter of ½ inch are allowed in the system. For a small house heated only with radiators, such a system will work effectively.

In fact, there are more heating circuits in a private house or cottage: underfloor heating, heating of several floors, utility rooms, and a garage. When they are connected through a tapping system, the pressure in each circuit will be insufficient to effectively heat the radiators, and the temperature in the house will not be comfortable.

Therefore, branched heating systems are performed by collectors, this technique allows you to adjust each circuit separately and set the desired temperature in each room. So, for a garage, plus 10-15ºС is enough, and for a nursery, a temperature of about plus 23-25ºС is required. In addition, warm floors should not heat up more than 35-37 degrees, otherwise it will be unpleasant to walk on them, and the floor covering may be deformed. With the help of a collector and a shut-off temperature, this problem can also be solved.

Video: using a collector system for heating a house.

Zoning

Designers are not advised to succumb to fashion trends and copy design ideas without taking into account dimensions, location and other nuances. Before planning and arranging furniture, every detail is thought through.

There are a few simple rules that the master advises to follow:

- Let the room have natural light. To do this, demolish extra walls (except load-bearing).

- If the rooms in the apartment are small (12 sq m or 16 sq m), the layout of the kitchen combined with the dining room will be the right decision.

- If the ventilation system is planned incorrectly, the smell of food will spread in the apartment.

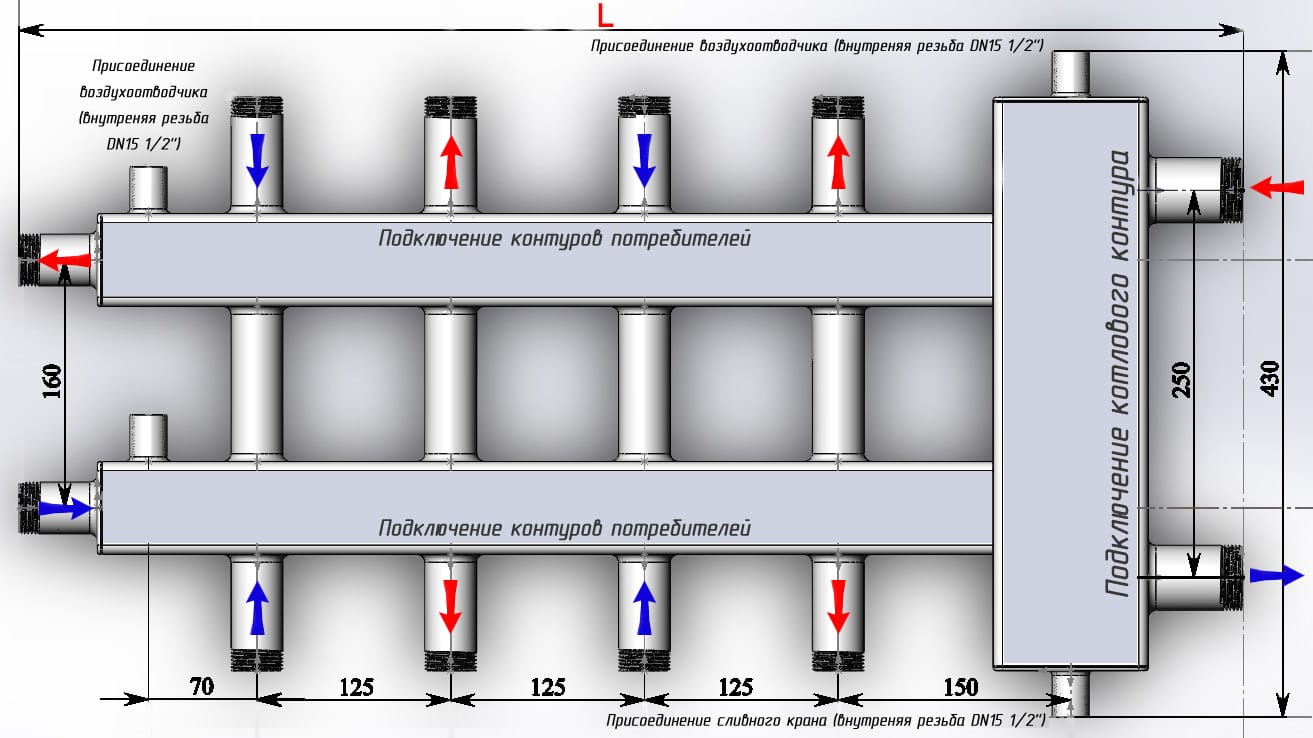

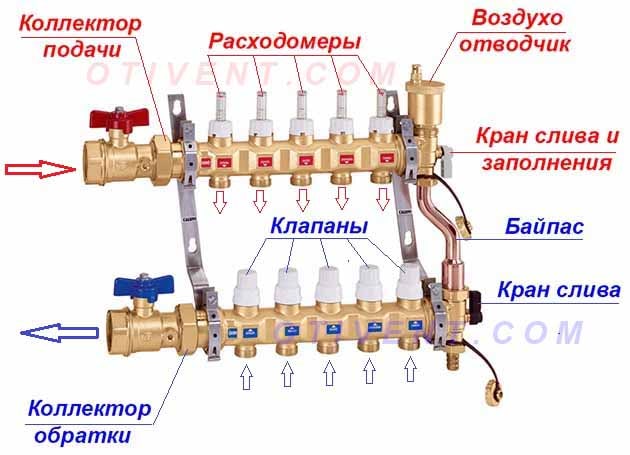

Collector: device and principle of operation

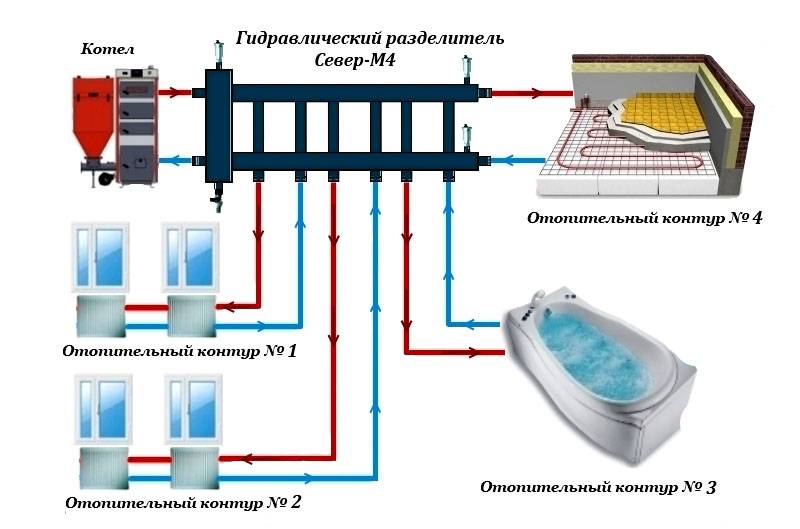

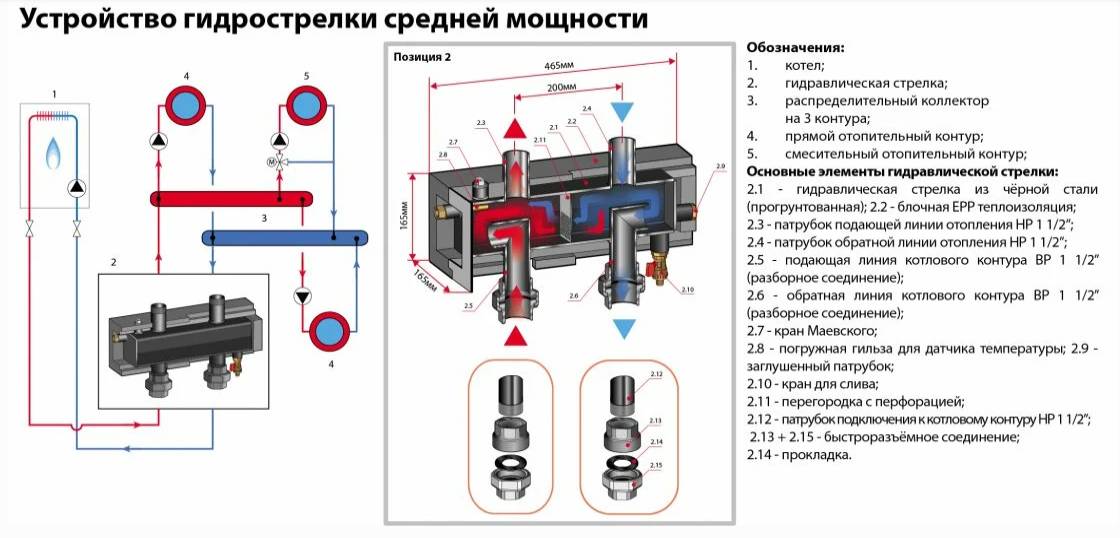

The node is an element in the form of a comb, from which conclusions for connecting heating devices extend. The number of withdrawals may vary. If necessary, the element can be extended with additional taps. Drainage and air outlet valves, as well as heat meters can be installed on the collector. The outputs can be equipped with regulating or shut-off valves, which makes it possible to regulate or turn off the coolant flow. The device is installed in the heating system in the form of a collector block, which includes a return and supply comb, equipped with outlet valves and corresponding taps.

The collector heating system functions quite simply. The coolant, heated by the boiler to the desired temperature, enters the supply comb. Here it is distributed between heating devices. A pipeline is laid to each of them, through which the coolant is directed.In the radiator, having given up part of its heat, the liquid is partially cooled, and through another pipe it enters the return comb and from there to the boiler. This distribution contributes to the uniform heating of the radiators, since each of them has a separate supply pipe.

The coolant heated in the boiler goes to the supply manifold, where it is distributed through pipes suitable for each radiator. The cooled liquid through the return manifold is sent back to the boiler

Note! Distribution heating system comb, installed on each floor of a heated building, allows you to get floor-by-floor separate heating circuits with autonomous control. If necessary, you can turn off the heating of the entire floor or only a few devices, which greatly facilitates the maintenance and repair of the system

This will not affect the functioning of the entire structure at all. The use of a collector increases the efficiency of the equipment, since devices that regulate the temperature and pressure of the coolant, as well as flow meters can be installed on its outputs.

Mounting Features

Laying pipes of a hidden type implies the mandatory organization of thermal insulation. Heating elements can be heated up to +90 ° C, which can have a bad effect on both the screed and the wooden elements. You just need a thermal insulating material that restrains the rate of heat transfer so that the heat has time to be distributed by the system. The market offers special polyethylene casings for concealed laying of pipelines.

To mount metal-plastic, certain skills will be required.

The quality of the prepared pipe (its end with a calibrator) is very important for a tight connection with a fitting. Usually reliable compression fittings are used, the connections of the branches with fittings on heating batteries and collectors are not collapsible

What are the fittings for metal-plastic pipes, you can read here.

Preparing for installation

Before you start all installation work, you should correctly select all the required elements and consider the location of the devices, including the following:

- Decide on the place of installation of heating batteries.

- Choose the type of radiators in connection with the pressure indicators and the type of heat carrier. Calculate the required number of sections or the area of panel heaters so that there is enough heat to heat all rooms.

- Draw a diagram of heating radiators and laying pipes. Do not forget about other heating elements (boiler, pump and collectors).

- Write down all the necessary elements on paper, and stock up. In order to be sure of the calculations, you can consult with a specialist.

You can read more about the distribution comb here.

Installation of a radiant heating system

Initially, radiators are installed in each room. Their location on the same level is checked with a level. The power of the devices is calculated based on heat loss. Plugs, thermostatic head connection points, taps are placed on the heating batteries (transitional fittings for metal-plastic are connected to them).

Collector box installed. As a rule, simple and cheap distributors are selected, equipped with ball valves with outlets to 16 mm and ¾ connection. American women are mounted on the collector.

You can connect the collector device to the boiler (to the tees of the line from the boiler) hidden under the floor or along the walls. Then the collector is connected with a supply and return of 16 mm to all heating devices.

Principle of operation

The main working element in the heating manifold circuit is the distribution unit, it is also called the comb.

This is a type of plumbing element of the system, used to distribute water heated from the boiler through independent pipelines. Also in the collector heating circuit are: a circulation pump, an expansion tank and automatic security systems.

The main node of the collector heating system in an apartment and a private house consists of several elements:

- Input - this element is connected to the boiler using a supply pipe, receives and distributes the coolant throughout all rooms.

- Output - this element is connected to the return pipes, receives the cooled coolant and is responsible for redirecting it to the boiler.

In this video you will learn how to assemble a heating manifold:

The main difference between the collector system and the classic connection is that each heating radiator has an independent wiring. This solution makes it possible to adjust the temperature of each heating device in a particular room, and, if necessary, completely turn it off.

Advantages and disadvantages of the collector system

Due to the emergence of a variety of plastic and polyethylene pipes, the collector heating system replaced the tee system, due to the following advantages:

- When installing and operating a collector heating system, you can do without highly qualified specialists.

- The coefficient of performance (COP) increases due to the fact that the coolant delivers heat to the radiators faster and with less loss. This is achieved due to the operation of the circulation pump and the poor thermal conductivity of plastic pipes. These pipes, with the least loss, carry heat to radiators, which, thanks to their special design, effectively heat the room.

- Increasing the efficiency of the heating system makes it possible to reduce pipe diameters and boiler power, and also saves fuel.

- Since plastic pipes from heaters to collectors do not have connectors (joints), they can be walled up in the floors and walls of the house. This gives an aesthetic look to the room.

- It makes it possible to heat the house without traditional radiators, using underfloor heating.

- High maintainability. Since it is possible to disconnect any section of the pipeline from the water supply, while not violating the performance of the entire heating system.

- Simplicity of design, as there is no need to apply complex mathematical calculations.

- The ability to adjust the temperature regime on each heater. What creates a certain comfort

The disadvantages of the collector heating system are:

- Airing the system. Air remains in the system after filling it with coolant, which enters the heating devices horizontally and quickly under the influence of the pump. Air from microscopic bubbles combines and accumulates at the highest points of the radiators.

- High cost, due to the presence of a pump, manifolds, valves and a large number of pipes for moving the coolant.

- Cannot work without circulation pump.

- A special room for the manifold cabinet is required.

- The complexity of installation and material consumption.

From the foregoing, it can be seen that the collector heating system is considered reliable and comfortable for a low-rise cottage. But the cost of this system is much higher than the tee.

How to install?

Before you install a water distribution unit for cold and hot water supply, give an accurate answer to the following questions and consider the following points:

- How many water consumers are at the facility? The number of collector outlets must match or be slightly more than consumers. Excess outlets are closed with plugs.

- What type of pipes will be used for the installation of the water supply? It is necessary to purchase devices designed specifically for pipes made of the selected material.

- Estimate in advance the position of all engineering elements in the space of the sanitary cabinet (you can make markings on the wall). Please note that a meter and a water filter are installed in front of the distribution comb. The convenient location of all devices facilitates maintenance and repair work.

- Get a reliable fixing - a poorly fixed distribution unit can lead to depressurization of connections and damage to the pipeline.

- Before installation, make sure that you have all the necessary consumables at hand: sealing material, gaskets, adapters.

Installation of the water distribution unit takes place in the following sequence:

- Install inlet shut-off valves on the water supply riser.

- Install the meter, filter and check valve.

- Connect the collector and fix it securely on the wall

- Install plumbing for each consumer.Fix the pipes with fasteners.

Such an algorithm of work will avoid errors. Regardless of whether you need a collector for water supply or heating, its installation is the same. Such wiring requires more time, skill and money, but pays off quickly and provides comfort in future use. Collectors are appropriate not only in cottages and large houses, but also in apartments.

Solar collector saving opportunity

It is possible to connect several heat carrier heating sources to the heating circuit. Often solid fuel boilers operate in parallel with electric ones. this allows you to maintain the mode of operation of the heating system at night or in the absence of the owners for several days.

But such a regime cannot be called economical - electricity is one of the most expensive resources. Modern developments make it possible to use solar energy for heating the coolant by installing a solar collector.

A solar collector is an installation that can be used all year round even at cloudy temperatures. On sunny days, it is most efficient and heats up to the temperature of the boiler supply circuit - up to 70-90 degrees.

Homemade solar collector

The solar collector is a fairly simple device, it is not difficult to make it yourself. In terms of efficiency, a home-made solar water heater may be inferior to industrial models, but given their price - from 10 to 150 thousand rubles, a do-it-yourself solar collector will very quickly justify itself.

For its manufacture you need:

- a coil made of a metal tube, usually copper, you can take a suitable one from an old refrigerator;

- cuttings of a copper pipe with a thread of 16 mm on one side;

- plugs and valves;

- pipes for connection to the collector node;

- storage tank with a volume of 50 to 80 liters;

- wooden planks for the manufacture of the frame;

- expanded polystyrene sheet 30-40 mm thick;

- glass, you can take window glass;

- aluminum thick foil.

The coil is freed from freon residues by washing it with a stream of running water. From a wooden slat or bar, a frame is made with a size slightly larger than the coil. Holes are drilled in the lower part of the frame for the output of the coil tubes.

On the reverse side, a sheet of expanded polystyrene is attached to it with glue or self-tapping screws - this will be the bottom of the collector. This material has excellent thermal insulation characteristics, which will help reduce heat loss.

The top of the solar collector is covered with glass, fixing it on glazing beads or rails. Pipes are attached to the ends of the coil for connection to the heating manifold assembly. This can be done using adapters or flexible piping.

The collector is placed on the southern slope of the roof. Pipes lead to a storage tank equipped with an air valve, and from there to a heating distribution manifold.

Video: how to make a solar heater yourself

A collector heating system is the most efficient way to connect various heaters to one or more heating sources. With it, you can ensure a stable temperature and comfort in the house, as well as uninterrupted and coordinated operation of all elements of the system.

General requirements for the installation of beam wiring

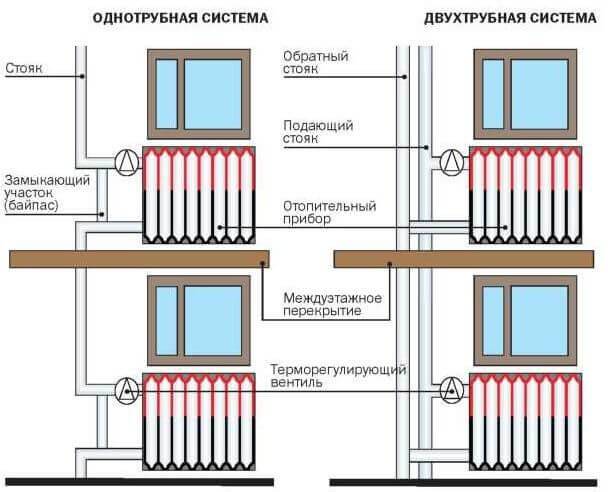

With collector-beam wiring, the method of laying pipes in the floor in a screed is common, the thickness of which is 50-80 mm. Plywood is laid on top, closed finishing flooring (parquet, linoleum). Such a thickness of the screed is quite sufficient for the free "embedding" of the intra-apartment (intra-house) radiant wiring of the heating system. It is possible to lay pipes outside along the walls under decorative plinths, which inevitably increases the length of the pipelines. Known options for laying pipes for beam wiring in the space of a false (suspended) ceiling, in strobes.

Connecting radiators with a collector-beam scheme.

Metal-plastic or cross-linked polyethylene pipes (PEX-pipes) are used, laid in a corrugated pipe or in thermal insulation. PEX pipes have an undoubted advantage here. According to SNiP, only inextricable joints can be “embedded” in concrete. PEX-pipes are connected by means of tension fittings related to inextricable connections. Metal-plastic pipes use compression fittings with union nuts. To “monolichize” them means to violate the SNiP. Each detachable pipe connection must be accessible for maintenance (tightening).

Even without fittings, not every metal-plastic pipe is unambiguously suitable for laying in a floor screed. Manufacturers' products suffer from a serious defect: layers of aluminum and polyethylene delaminate under the influence of repeatedly changing coolant temperature. After all, metal and plastic have different coefficients of volumetric expansion. Therefore, the adhesive connecting them should be:

- internally strong (cohesive);

- adhesive to aluminum and polyethylene;

- flexible;

- elastic;

- heat resistant.

Not all adhesive compositions of even well-known European manufacturers of metal-plastic pipes satisfy these requirements, which delaminate over time, the inner layer of polyethylene in such a pipe “collapses”, reducing its cross section. The normal operation of the system is disrupted, and it is almost impossible to find the place of the malfunction - they usually “sin” for malfunctions of thermostats, pumps and other products with moving parts.

In the light of the foregoing, we recommend that readers pay attention to metal-plastic pipes from VALTEC, which uses an American adhesive from the DSM concern, which ensures the strength of the metal / plastic connection, adhesion and the complete absence of delaminations.

Conclusions and useful video on the topic

How to properly install:

By installing a collector heating system in your home, you will be able to individually adjust the operating modes of the devices.

And the additional costs of increasing the length of the pipes are compensated by reducing their diameter and simplifying the installation of the system.

Do you have a collector heating system at home? Or are you just planning to equip it, but for now you are studying the information? Maybe you have a question about drawing up a wiring diagram for a collector system? Ask your questions, share your personal experience in arranging heating in the house, leaving comments under this article.