- Varieties of drainage wells

- Device and installation features

- Types and features of wells

- Classification of wells for sewerage

- Accessories for a concrete well

- Dimensions of concrete rings

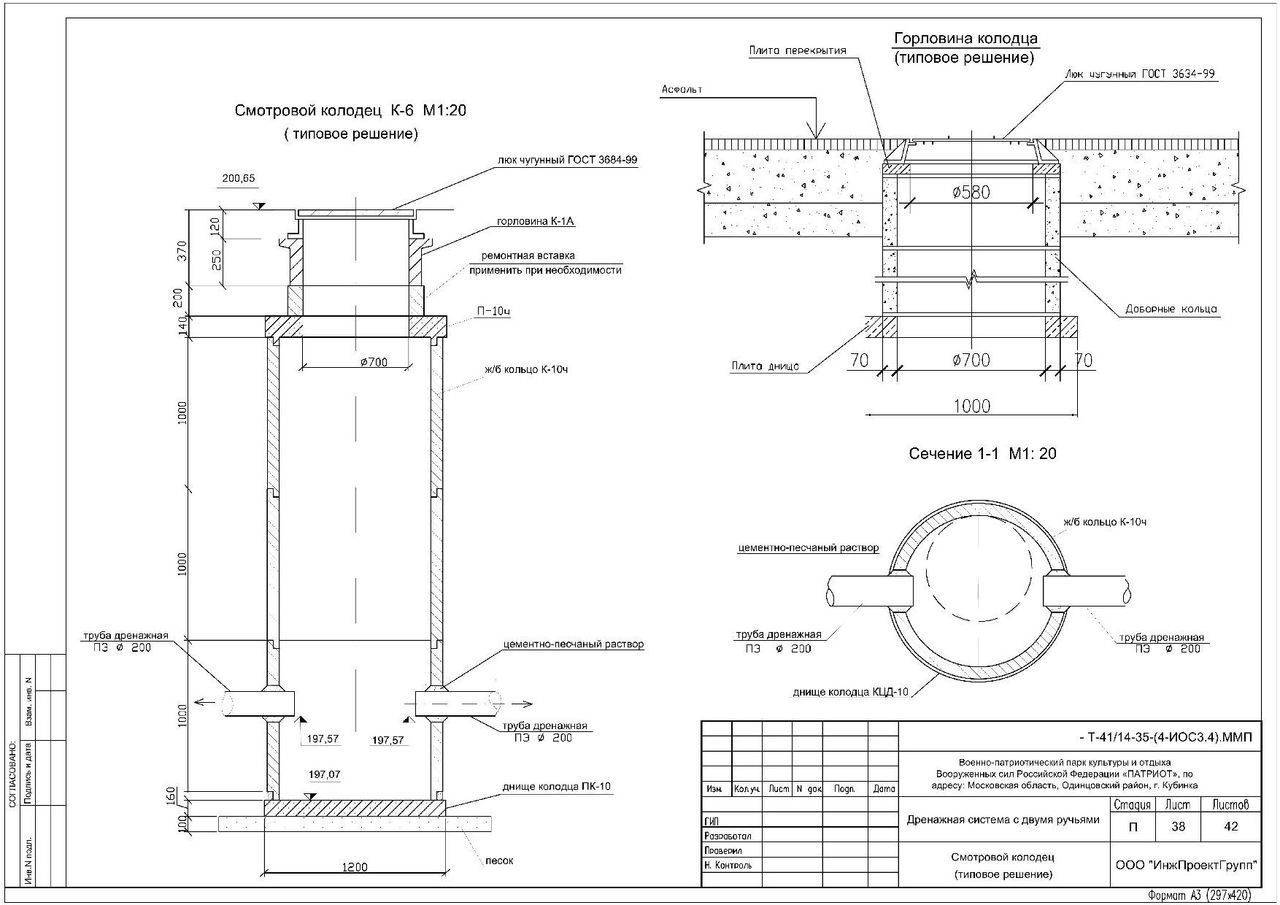

- Manhole device

- stone wells

- Self-installation of drainage wells

- Installation of a storage well made of plastic

- Installation of a well from concrete rings

- Installation of an inspection hatch and pipe laying

Varieties of drainage wells

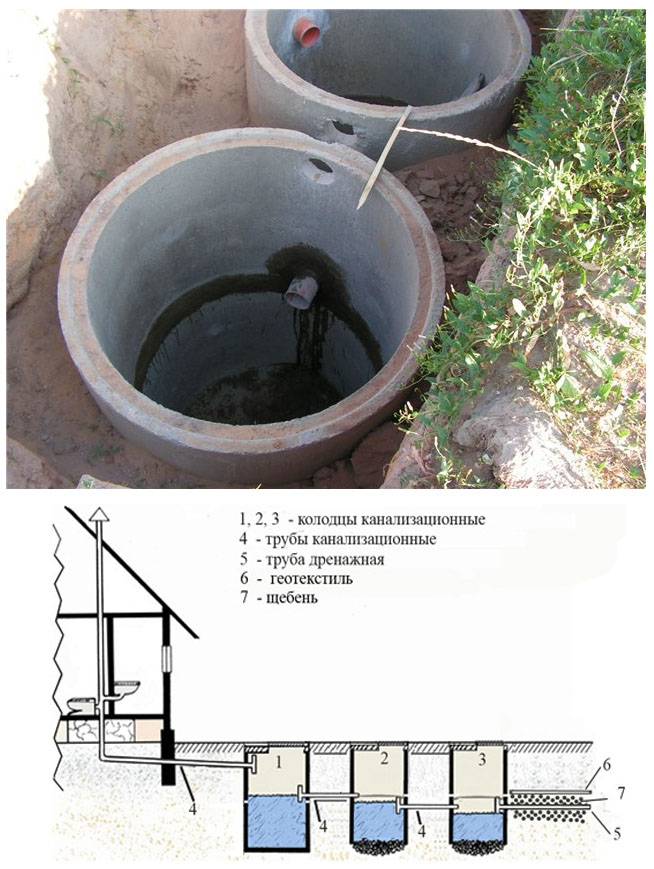

By appointment, the mine for drainage can be:

- Lookout.

- Collector.

- Absorption.

The manhole for drainage has several other working names. It can be called revision or inspection. Designed to monitor the technical condition of the drainage system, its timely cleaning, maintenance and repair.

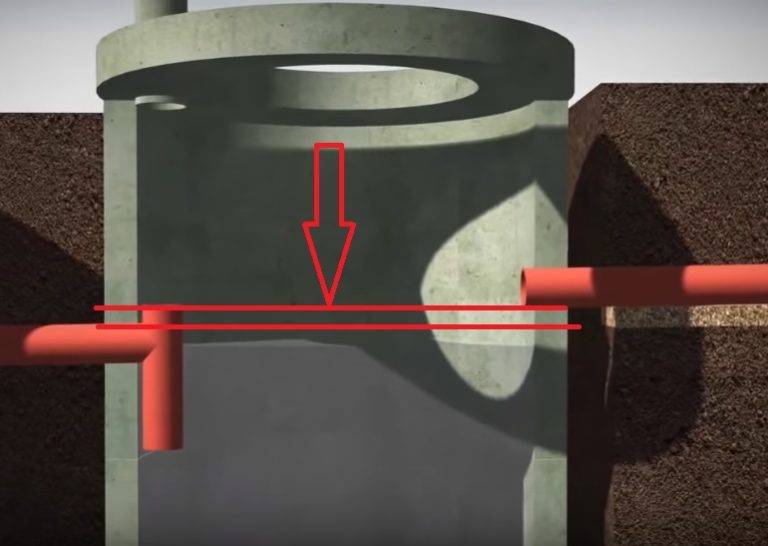

Lookout is installed local drainage well turning pipes or changing their direction. On straight pipes, shafts are installed every 30 meters with a pipeline diameter of 15 cm or every 50 meters with a pipeline diameter of 20 cm. Additionally, a manhole for drainage can be installed at the intersection points of drains.

If it is planned that there will be a descent for maintenance, then the plastic manhole shaft must have a diameter of at least 1.0 meters.If the shaft is cleaned by water pressure from an external hose, then the diameter of 35-45 cm will be optimal for the shaft.

Storm assembly plastic wells are typical for private country houses. If the site has a slope, then the installation of the shaft is carried out at the lowest point of the site.

If the ground is level, then installation of drainage pipes perform under a slight sewer slope, and storm wells are installed slightly below the level of the pipes. This will ensure an arbitrary outflow of water from the pipes into the shaft.

Fluid may accumulate or drain naturally into a central drainage channel, the nearest body of water. If there is no outlet, then the pumping of water is carried out by a pump, which often comes with the tank.

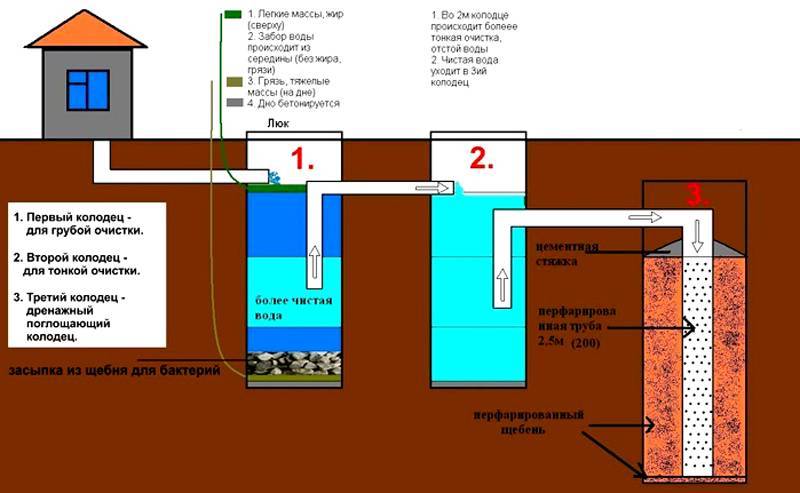

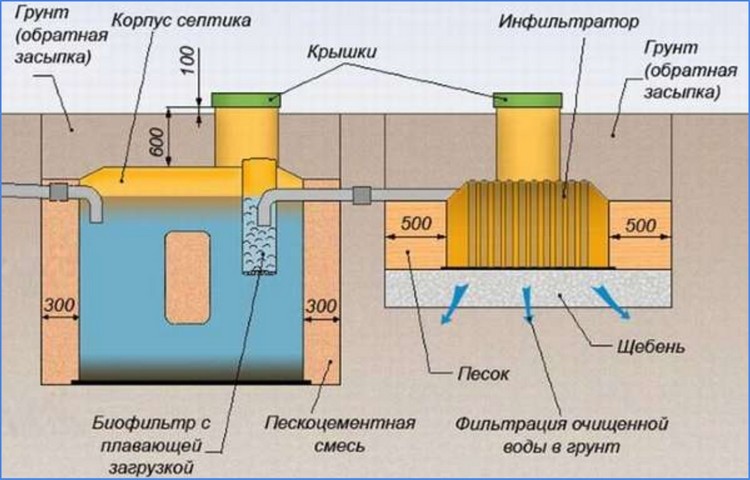

The collector drive can serve as an element of the sewer system. The drainage well for sewerage is equipped with a solids cleaning system. After passing through the septic tank several levels of cleaning, fluid accumulates in the mine, which is subsequently pumped out. The dimensions of the drive are not regulated, it all depends on the wishes of the owner.

The absorbing or filtering accumulator is designed to drain a certain small area of area, to which it is impossible or not necessary to bring a common drainage structure. For drainage, the soil is selected, on which the volume of liquid passing through the well is not more than 1 cubic meter. m.

A characteristic difference between the well is the absence of a bottom, the shape and method of installation. It has the shape of a truncated cone, which is installed with a smaller diameter up. If desired, you can install a shaft of a different shape.

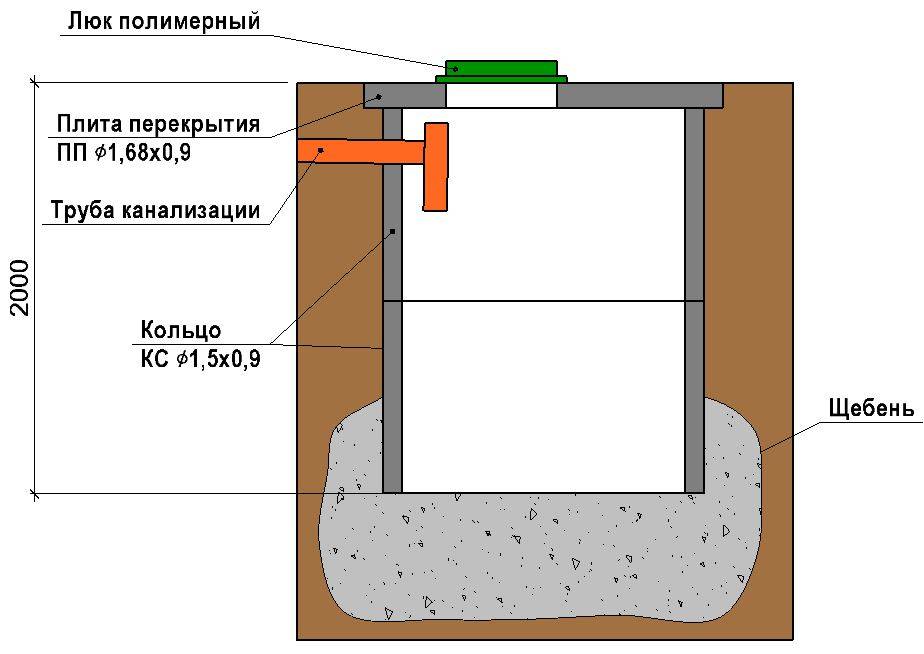

For installation, a pit is equipped, with a depth of about 2.0 meters. At the bottom of the pit lay a pillow of crushed stone, 2-3 cm thick.But the pillow is installed with a cone wrapped in geotextile. Inside the shaft, a lining is made of small stone, crushed stone or slag, which is covered with geotextiles. When filling the mine, the liquid is pumped out, and the geotextile is replaced.

By type, wells are divided into:

- Turning.

- Tee.

- Cross.

- Checkpoint.

- Dead end.

- No holes.

The rotary drainage well plastic is established in places of turn of pipes. Often these are the outer and inner corners of buildings. These places are most vulnerable to clogging. Branch pipes at the rotary well are located at an angle of 90 °.

A well-cross and a well-tee can be in place of rotary shafts, to which additional drainage lines are connected. The cross and tee can be used as viewing points in separate areas where several drainage lines are connected to one point.

Branch pipes at such mines are located at an angle of 90 ° in relation to each other. The dead-end type of the mine is applicable to the collector well, it has one inlet pipe. A storage tank without holes is used as an absorption shaft.

Device and installation features

You can install a plastic drainage well on the site without specialists. For installation, you will need 1-2 assistants, mainly to release the container to the bottom. But before that, it is necessary to make preparatory work.

With a monolithic product, everything is simpler, it is almost ready for installation. Collapsible finished products must be assembled according to the instructions. And if you decide to make a tank from a large diameter pipe, then first you need to cut it to the required length.

In finished products, there are often holes for pipes, and in home-made ones, they are pre-cut in accordance with the diameter of the drains.Rubber seals and plastic couplings are inserted into the holes. All seals are lubricated with sealant to prevent leakage.

After that, they begin to dig and prepare the pit, taking into account several parameters:

- The depth should be such that the entry points of the pipes pass below the freezing point of the soil, and the bottom of the tank is at least half a meter above the groundwater level.

- You also need to take into account that at the bottom of the pit a pillow of crushed stone 15-20 cm high will be covered.

- The width of the pit is 40-60 cm more than the diameter of the container.

- The hatch after will have to rise 10-15 cm above the ground.

If the area is characterized by a seasonal rise in groundwater, then an additional cement base must be poured onto the bottom.

After the cement has hardened, you can install:

- The tank is released to the bottom.

- Use a level to check if the container is level.

- Connect the pipes for the drainage well to the nozzles. Be sure to treat all joints with sealant.

- The tank is backfilled with sand and gravel. Do this in layers, each layer is carefully rammed.

- Install a plastic cover (hatch).

This completes the installation. If necessary, a drainage pump is released into the collector.

Installation video of the Wavin Tegra 1000 well:

Types and features of wells

There are two types of water wells:

- tubular;

- mine.

The first type is commonly called a column. Usually they were installed on the streets of villages. A hand pump is used to extract water from the depth in such wells. These wells are installed in places of shallow occurrence of aquifers. Its installation is very fast.But for the construction of a tubular well, drilling equipment will be needed, because they do not dig a hole, but drill it.

A shaft well is the most affordable option for self-assembly. It is dug with a shovel, and the walls are strengthened. It's traditional well for country houses and dachas. Depending on the material of manufacture, several types of mine water wells are distinguished:

- plastic;

- reinforced concrete;

- brick or stone;

- wood.

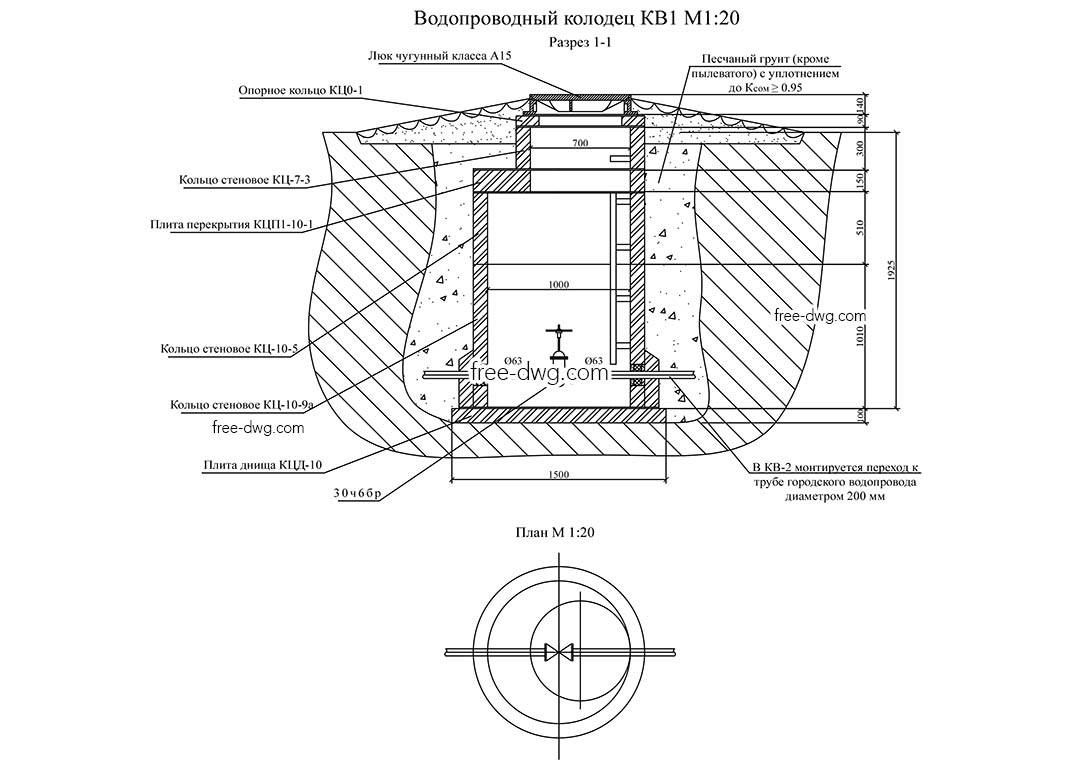

Reinforced concrete wells are the most popular. They are durable (can last up to 50 years). Their depth reaches 15-20 m. However, the installation of such a water intake device will require a lot of labor. First of all, a lot of effort will be spent on digging a deep hole. At the same time, its diameter must be larger than the size of the rings in order to perform a sand and gravel backfill from the outside. And to lower the concrete rings, you will have to order a construction crane. At the bottom of such a well, a filter is arranged from a sand and gravel cushion 300-400 mm high.

Recently, more and more often the owners of private houses choose plastic water wells. Their main advantage is that it is a one-piece construction due to the high tightness of all joints and seams. The dimensions of such structures can be any, depending on the requirements. They are no less durable than reinforced concrete devices, and can also last up to 50 years. Their additional advantage is the speed of installation without the use of construction equipment.

Wooden and brick water intake structures are a thing of the past. Now they are practically not made due to the laboriousness and duration of the construction process.In addition, these structures do not meet the requirements of SNiP, because silt and dirt quickly settle on the brick and wooden walls of such water wells, which reduces the quality of drinking water.

Sewerage depth and SNiP requirements

Classification of wells for sewerage

Structures related according to technical terminology to sewer wells are divided into several varieties.

The division is made depending on what classifying features we will use. For example, wells can be divided according to the material of manufacture, according to their purpose, or according to the method of their construction.

There are the following classifying features and their corresponding types of modern sewer wells. The first is carried out according to the environment, the transportation of which is carried out by the sewer system.

drainage networks, on which sewer wells are installed, are designed to move effluents of various composition and degree of aggressiveness, these are:

- Household. These include waters that have changed their composition as a result of mixing with waste and garbage. Depending on the contaminants included in the composition, they are divided into household and fecal.

- Industrial. These include waters that have changed their mechanical and chemical composition as a result of pollution by industrial waste.

- Atmospheric. These include waters formed as a result of the active melting of winter precipitation, flood and rain water.

In addition to the listed types of wastewater, the sewerage system receives flows collected by the drainage system, the task of which is to drain the territory or drain groundwater from underground building structures.

Wells of sewer systems are divided according to the material of manufacture into:

- Brick. Once upon a time, brick was a commonly used material for the manufacture of wells, but over time, brick structures are becoming less and less.

- Concrete. Concrete structures are today the traditional material for a sewer well.

- Plastic. Obviously, polymer-based compounds are the material of the future, it is he who will someday replace both brick and concrete.

Plastic or composite prefabricated well structures attract with lightness, easy to install. Pleased with resistance to chemical influences during prolonged contact with aggressive environments. They are well tolerated by sharp and smooth temperature fluctuations, they do not pass or absorb water at all.

Sewer systems are divided into floating and export. The former move effluents to treatment plants, facilities or discharge fields. The latter only collect wastewater for subsequent pumping and removal. The wells included in both types of systems perform both the same and different functions.

According to their functional responsibilities, they are divided into:

- Cumulative. Used to accumulate wastewater for subsequent extraction and removal. Naturally, they are built in the export sewer networks.

- Collector. Designed to collect wastewater from several sewer branches and direct it to a storage tank, treatment plant or unloading fields. They are arranged both in floating and export branched networks.

- Filtering. Are applied to utilization of liquid fraction of drains in the natural way.They play the role of compact treatment facilities that transport the environment freed from pollution into the ground or into water bodies. Accompany exclusively alloyed varieties of sewage.

- Lookouts. They are built on collector sections longer than 50 m, as well as at all turning points and nodal connection of highways. Necessary for monitoring the operation of the sewer system, for periodic cleaning and repair activities. They are satisfied in both types of sewers.

- Variable. They are arranged in areas with sharp elevation changes. The reasons for the construction include the provision of a buried outlet into the reservoir and the need to slow down the drains on the sections of the pipeline with a large slope. They can be present both in the export and in the floating sewer.

The classification of manholes is much more complex. We will talk about this a little lower, and now we will consider different types of wells in more detail.

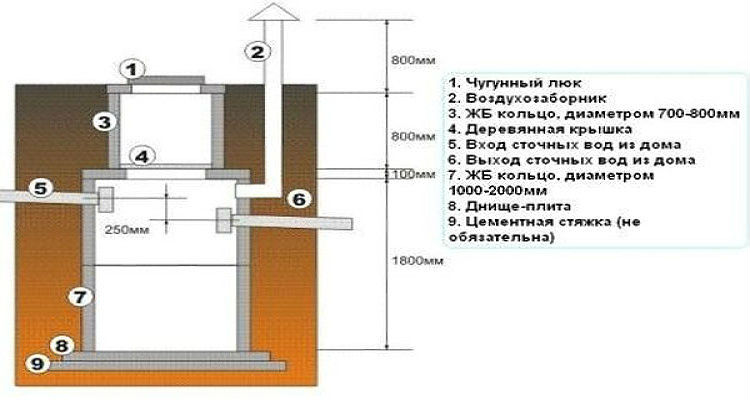

Accessories for a concrete well

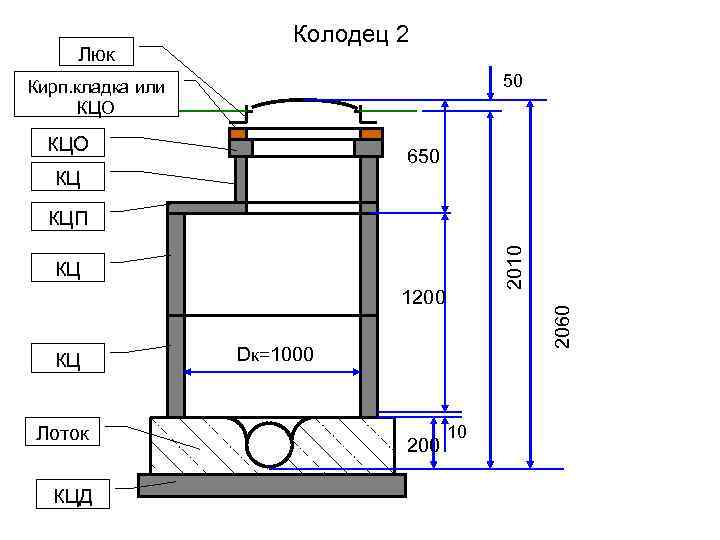

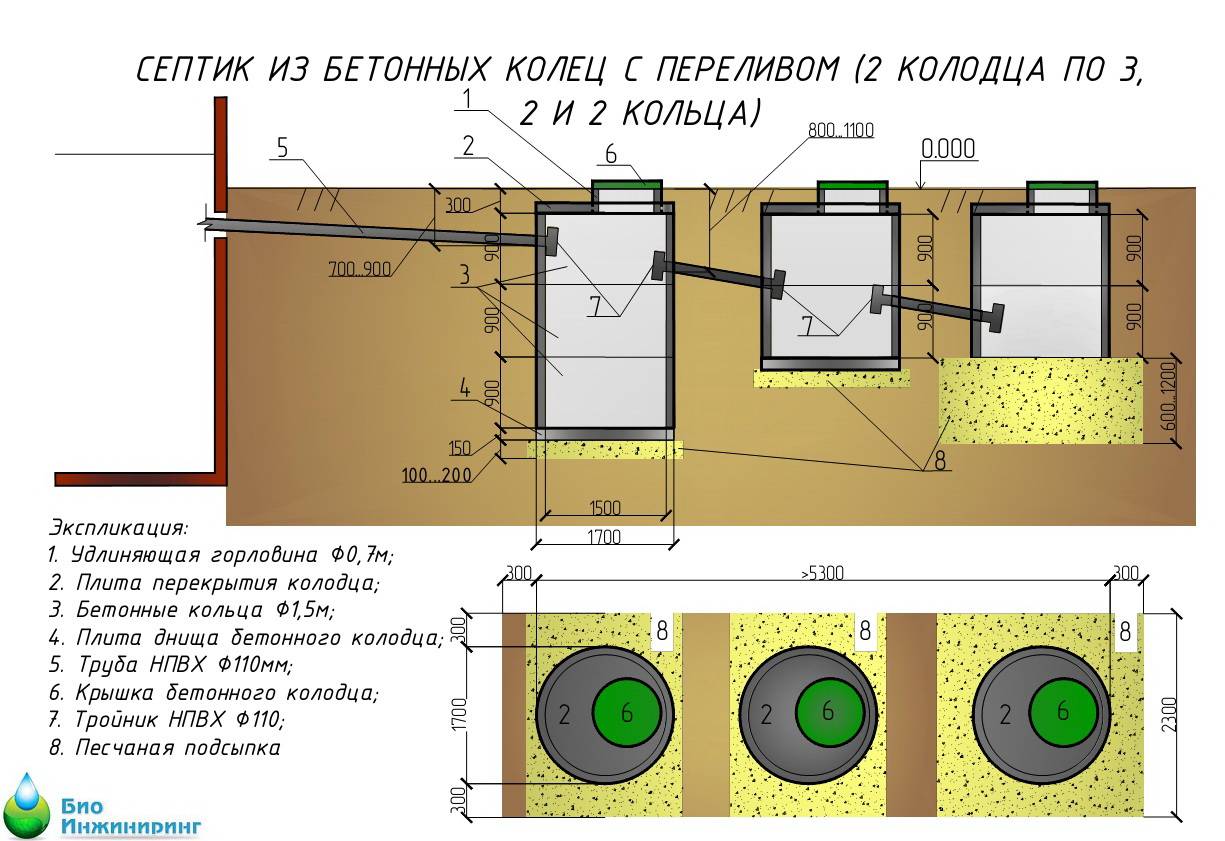

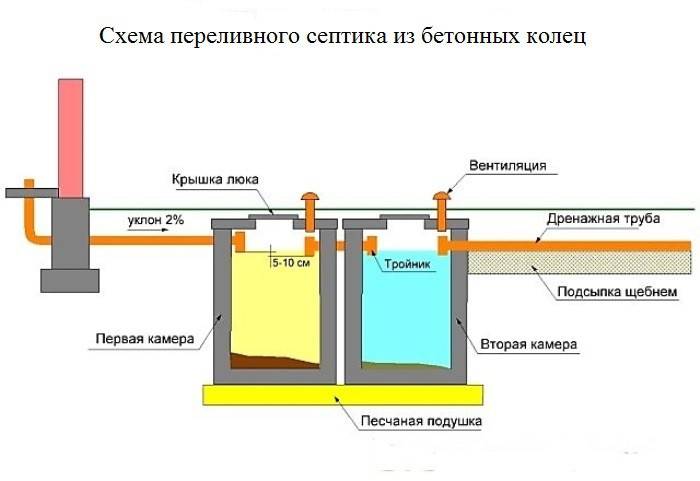

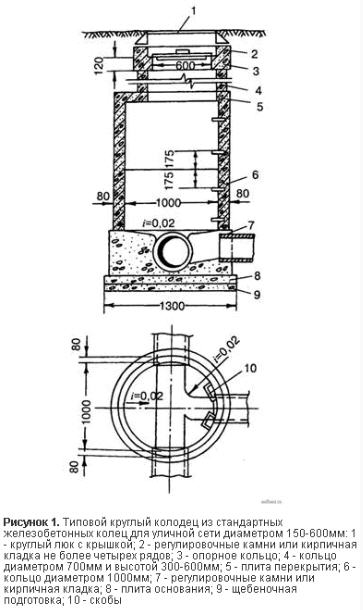

Today, manufacturers produce concrete rings of different sizes, so choosing the right one for you is not difficult. The wells themselves are built from the same set of components, which include:

- bottom - reinforced concrete slab;

- rings;

- neck;

- hatch cover;

- plate for the partition inside the ring - serves to create multi-stage cleaning.

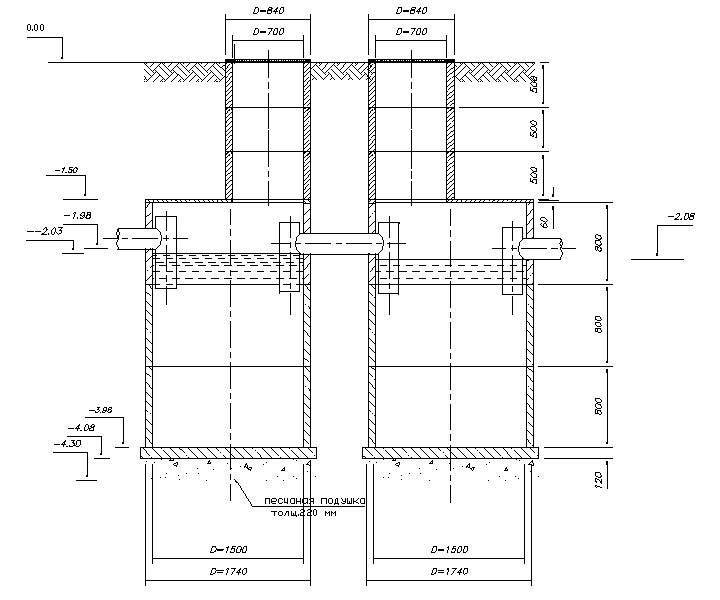

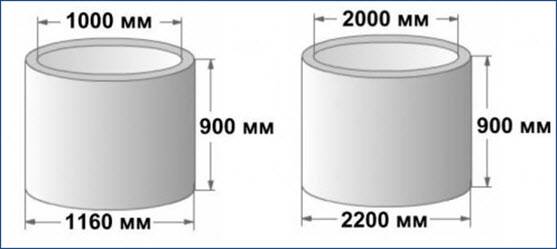

Dimensions of concrete rings

The size of the purchased rings depends on the type of well for which they will be used. Below, the table shows the main sizes used for the construction of sewer wells:

| Marking | Size (mm) | Weight, kg) | ||

| Inner diameter | Wall thickness | Height | ||

| KS-7-1 | 700 | 80 | 100 | 46 |

| KS-7-1.5 | 700 | 80 | 150 | 68 |

| KS-7-3 | 700 | 80 | 350 | 140 |

| KS-7-5 | 700 | 80 | 500 | 230 |

| KS-7-6 | 700 | 100 | 600 | 250 |

| KS-7-9 | 700 | 80 | 900 | 410 |

| KS-7-10 | 700 | 80 | 1000 | 457 |

| KS-10-5 | 1000 | 80 | 500 | 320 |

| KS-10-6 | 1000 | 80 | 600 | 340 |

| KS-10-9 | 1000 | 80 | 900 | 640 |

| KS-12-10 | 1200 | 80 | 1000 | 1050 |

| KS-15-6 | 1500 | 90 | 600 | 900 |

| KS-15-9 | 1500 | 90 | 900 | 1350 |

| KS-20-6 | 2000 | 100 | 600 | 1550 |

| KS-20-9 | 2000 | 100 | 900 | 2300 |

When buying, pay attention to the marking, it contains all the necessary data, for example, KS-20-9:

- KS - wall ring;

- 20 - diameter;

- 9 - height.

The diameter and height in the marking are indicated in decimeters.

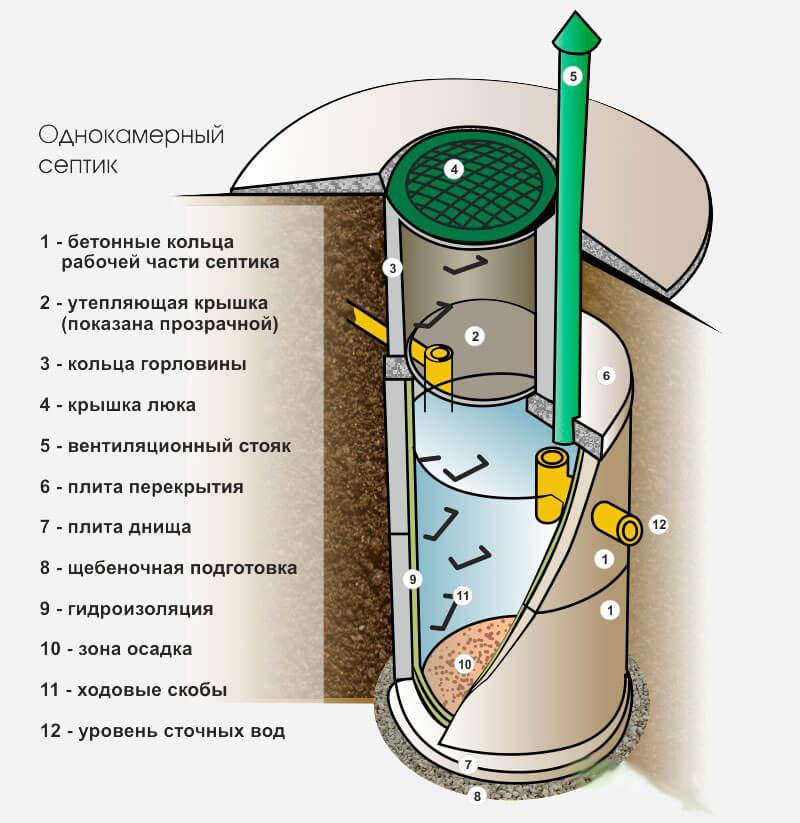

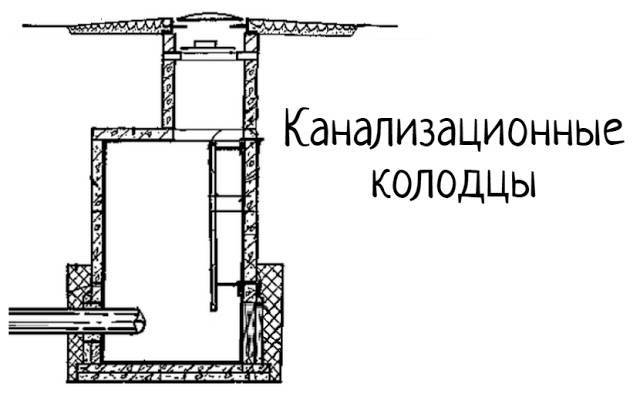

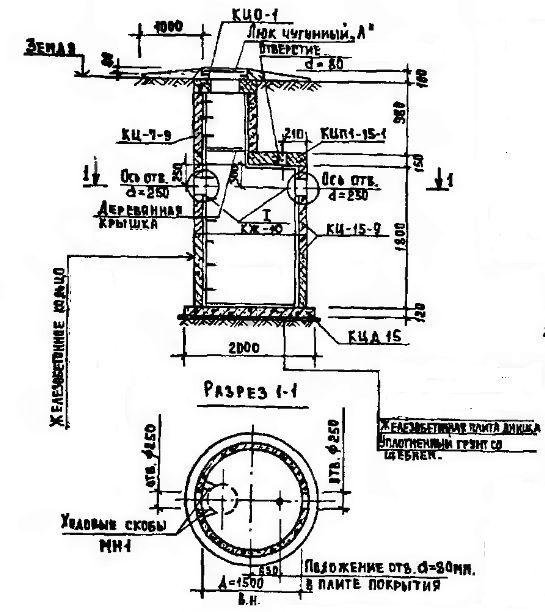

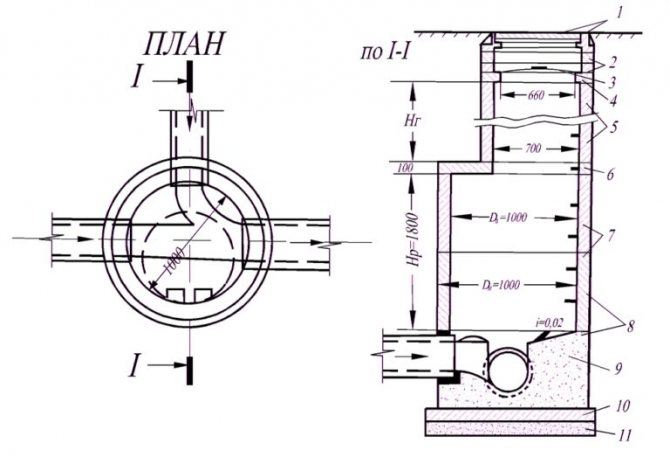

Manhole device

All structures, regardless of their type and purpose, have a similar structure. The main details are:

- tray;

- bottom;

- Luke;

- neck;

- mine or chamber.

Most often, wells are a round shaft made of various materials. Cameras are mounted if:

- inlet and outlet pipelines differ in diameter;

- the slope of the pipeline changes;

- the flow of water changes direction;

- several pipes are connected into one.

Straight sections are also equipped with chambers, not shafts. Tray - serves to connect pipes, usually made of concrete, the height is equal to the diameter of the pipe. The bottom is poured with concrete, and the neck, as well as the shaft, can be varied. The material for the shaft are concrete rings or polymeric materials with high ring strength, such as Korsis pipes.

Video: Plastic sewer wells

stone wells

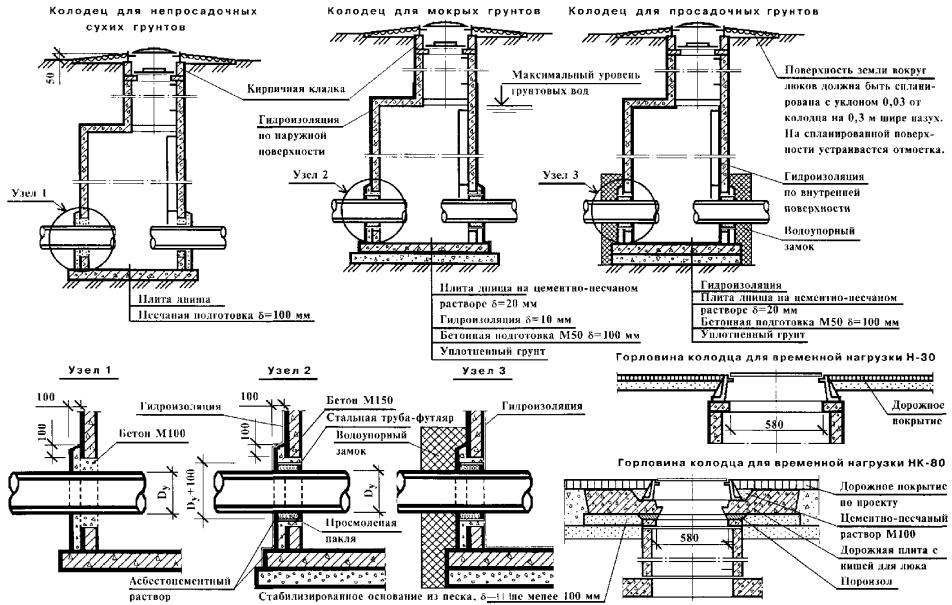

Insulation of pipes in a well with bitumen After that, the following work is performed for a concrete or reinforced concrete well:

- Foundation preparation. Laying a slab or placing a concrete pad 100 mm thick from concrete M-50

- Arrangement of a tray of the desired shape made of M-100 concrete with steel mesh reinforcement

- Concrete and bitumen sealing of pipe ends

- Bitumen insulation of the inner surface of concrete rings

- Rings of sewer wells are installed (carried out after the curing of the concrete of the tray, 2-3 days after laying) and the floor slab on the M-50 mortar

- Grouting with cement mortar the joints between the prefabricated parts of the well

- Waterproofing joints with bitumen

- Finishing the tray with cement plaster, followed by ironing

- Arrangement at the entry points of pipes of a clay lock with a width of 300 mm and a height of 600 mm more than the outer diameter of the pipes

- Well testing (carried out during the day by filling with water to the upper edge, with the installation of temporary plugs on the pipes). Considered successful if no visible leaks are found

- External backfilling of the walls of the well, followed by tamping

- The device of a concrete blind area 1.5 m wide around the neck of the well

- Insulation of all remaining joints with hot bitumen

Similarly, brick sewer wells are installed, but here, instead of installing prefabricated elements, masonry is made.

Waterproofing is done in exactly the same way.

Thus, the installation of wells made of stone materials is carried out for all types of sewerage: domestic, storm or drainage.

However, in the case of a storm well, lattice hatches can be installed on the well, which simultaneously perform the function of a catchment area.

For drainage - the well itself can be an element of drainage, through special holes in the walls, but this design requires a special calculation.

At the same time, there are slight differences in the components that the series defines: sewer wells KFK and KDK - for domestic wastewater, KLV and KLK - for stormwater, KDV and KDN - for drainage.

The table of sewer wells by standard sizes is as follows:

Table of sewer wells

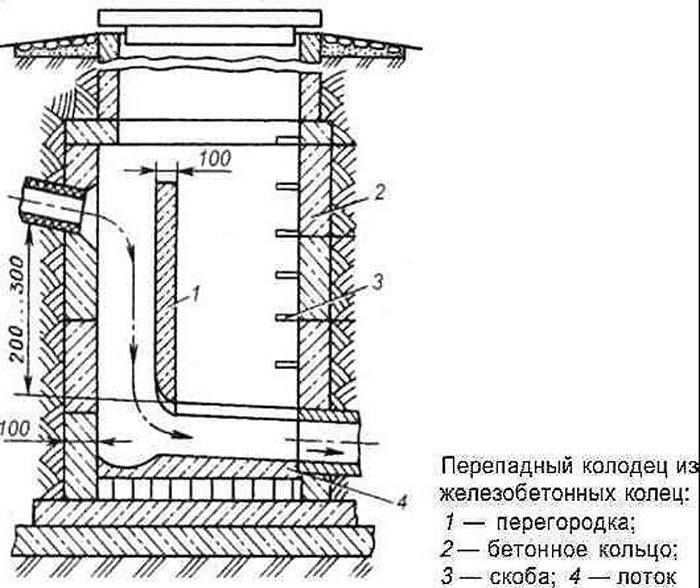

The process for differential wells looks a little more complicated due to their more complex configuration.

drop well

Here, depending on the specific design, in addition to the tray device, in some cases it is necessary:

- Riser installation

- Water breaking equipment

- Installation of a water barrier wall

- Create a practice profile

- Pit device

The very installation of the body of the mine, base and ceiling is carried out according to the same rules.

The only exception concerns a drop well with a riser - at its base it is supposed to lay a metal plate that prevents the destruction of the concrete part of the structure.

It looks like this:

- Riser

- water cushion

- Metal plate at the base of the pillow

- Riser intake funnel

Design of a well with a riser The intake funnel is designed to compensate for the rarefaction that can be created in the riser due to the rapid movement of wastewater.

It is necessary to create differential sewer wells with your own hands using a practical profile only in exceptional cases - a similar design is provided for pipelines with a diameter of 600 mm and a drop height of up to 3 m.

Similar pipe diameters are not used in individual drainage systems. But other types of wells can be used in local sewage with success.

In accordance with the requirements of SNiP, sewer overflow wells are installed:

- If necessary, reduce the depth of the pipeline

- At intersections with other underground utilities

- For flow control

- In the last flooded well before the discharge of waste into the reservoir

Typical cases when the installation of a drop well in a suburban area is advisable:

- High-speed flow scheme If there is a big difference between the estimated depth of the intra-yard sewerage and the level of effluent discharge into the septic tank or central collector (laying the pipeline at a shallower depth will seriously reduce the amount of excavation)

- If there is a need to bypass other engineering networks underground

- If there is doubt about the consistency of the flow rate in the system with the volume of effluents. With a small volume, too high a speed can prevent self-cleaning (washing out of sediment) of the pipe walls. Equally, if the speed is too low - the sediment may form too intensively, then it makes sense to arrange a fast current for acceleration.

The meaning of such a drop is that due to the creation of a large slope in a short section of the system, the drains begin to move much faster, not having time to cling to the inner walls of the pipe.

Self-installation of drainage wells

Consider, how to make drainage do-it-yourself well. Depending on the type of well, the methods of its manufacture also differ.

Installation of a storage well made of plastic

Material for making such a well can serve as a corrugated plastic pipe of various sizes.

Important: It is necessary to install wells of this type below all drainage pipelines, ensuring unhindered flow of water to them. 1. A pit is being dug for a future tank

Digging a pit for a future reservoir

1. A pit is dug for the future tank.

2. The required length of the corrugated pipe is measured, after which it is cut.

3. A sand cushion is poured into the pit or a solid concrete base is created.

4. A prepared container is installed in the prepared pit, having pipe fittings. Holes for inlet pipes can be made after the container has been installed in a permanent place. Many ready-made wells already have special taps, so connecting them to the drainage system is not difficult.

5. Using bituminous mastic, a plastic bottom is glued to the pipe.

6. Drainage pipes are introduced into the well and the cracks are sealed.

7. The gaps between the walls of the well and the pit are covered with rubble, sand or a mixture of sand and cement.

Tip: It is advisable to immediately place a drainage pump inside the well. through which water will be pumped out. You can also use a submersible pump, which will be lowered into the well manually, as needed, or a surface-type pump.

8. From above, the storage tank is covered with a lid to prevent its contamination, and on this the installation of the drainage well can be considered completed.

The do-it-yourself inspection-type drainage well is made in a similar way, except for installing a pump. Also, there is no need to place it at the lowest point of the site.

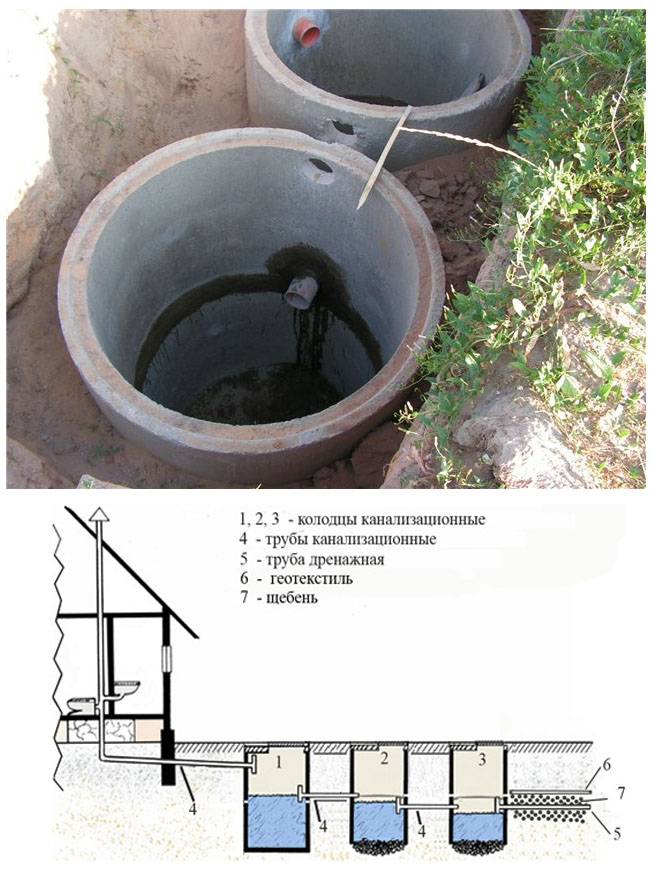

Installation of a well from concrete rings

For the manufacture of concrete wells, it is better to use reinforced rings with a lock. If they are not available, then ordinary concrete products will do. The thicker they are, the longer they will last.

The work is carried out using special loading equipment in the following sequence:

1. A pit of the required size is being prepared.

2. At the bottom of the pit is poured sand or gravel. If a filter container is made, then the thickness of the pillow must be at least half a meter.

3.The first ring with the bottom is placed on the pillow. If rings without a bottom are used, then a concrete screed is made from the bottom of the first ring.

4. The next rings are stacked on top of the previous ones. When installing concrete rings, the joints between them are sealed with concrete mortar or bituminous mastic.

5. When the last ring is installed, holes are made in it (if not already) for the entry of drainage pipes.

6. Pipes are led into the holes of the ring, after which all joints are carefully sealed.

7. A cover is installed on top of the well. You can use plastic or metal covers, as concrete products are too heavy.

8. The voids between the walls of the pit and concrete rings are filled with sand, gravel or crushed stone.

Arranging a drainage well is not a very difficult task. You can cope with such work yourself, especially when installing plastic products.

Installation of an inspection hatch and pipe laying

In order to properly build a sewer shaft, it is necessary to take into account the features of the assembly of parts at all stages of its construction. Not the last place in the installation process is the installation of an inspection hatch. Its device is quite simple, but it requires a clear implementation of the necessary work:

- The last ring of the well is covered with a flat slab with a hole for an inspection hatch;

- A metal rim is mounted along the edge of the hole. It will protect the stove from mechanical damage while opening the lid;

- Then carefully mount a metal hatch, preferably cast iron.

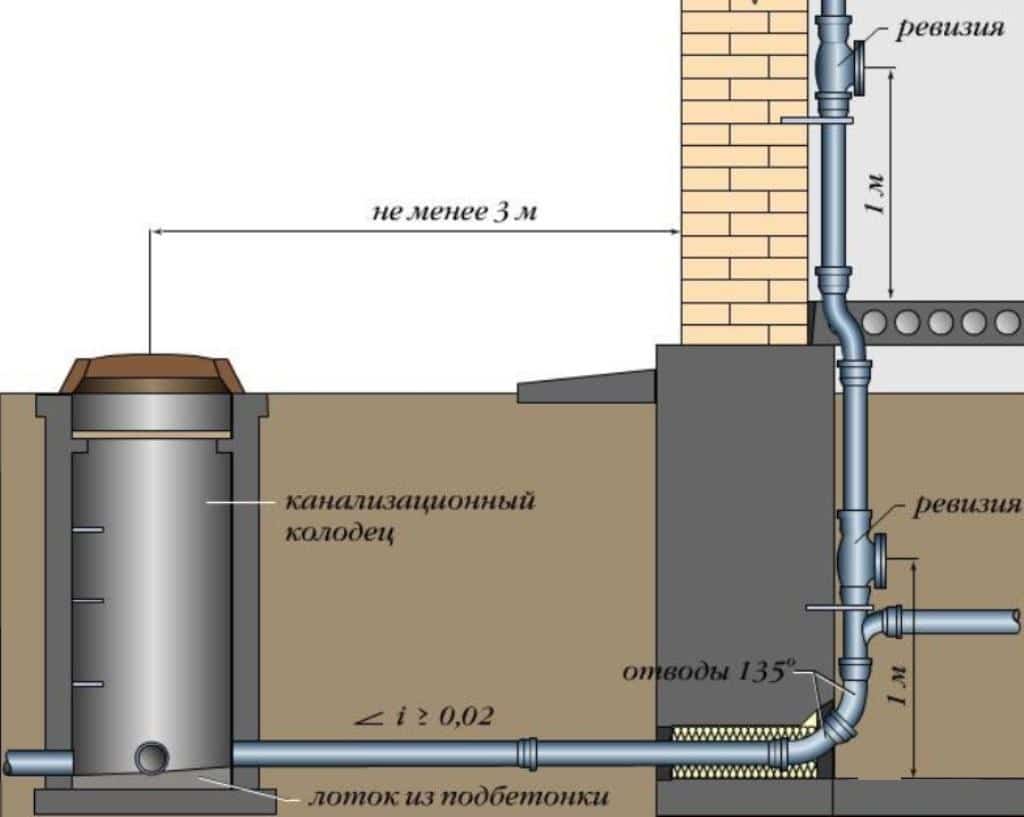

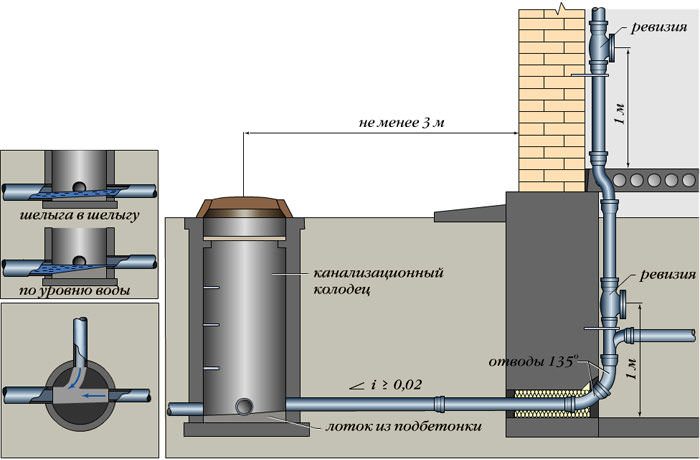

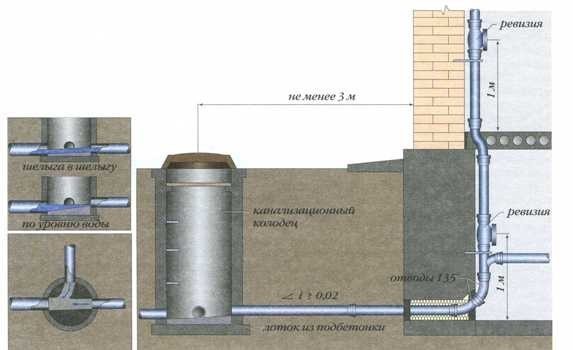

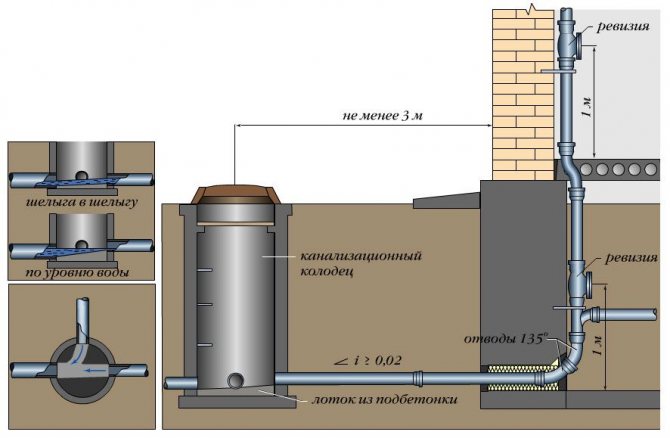

When the well device is completed, it is worth immediately proceeding with the laying of sewers. According to the SNiP standards, in the process of their installation, the following parameters must be taken into account:

- The depth of laying the sewers should be at least 70 cm;

- In order for sewage to pass along the main by gravity, the slope of the pipes must be at least 2 cm per 1 linear meter. sewer line meter;

- The entry of the pipeline into the sewer shaft must be located above the level of the sewage pipe.