- Bag air filters for air purification from dust

- Where is a bag filter usually used:

- Important Factors in Bag Filter Operation

- Device and circuit

- Applications and features of operation

- Regeneration system

- Principle of operation

- The principle of operation of the bag filter

- How does a bag filter work?

- Cleaning method using devices using photocatalysts

- How bag filters work

- Functions and purpose

- Operation in difficult conditions

- What is the latest coarse filtration trend?

- Main types of filter bags

- #1: Hardware Performance Difference

- No. 2: Classification by type of installation of sleeves

- No. 3: Varieties according to the material of manufacture

- No. 4: Classification according to the method of regeneration

- Bag filters with impulse blowing

- How bag filters work

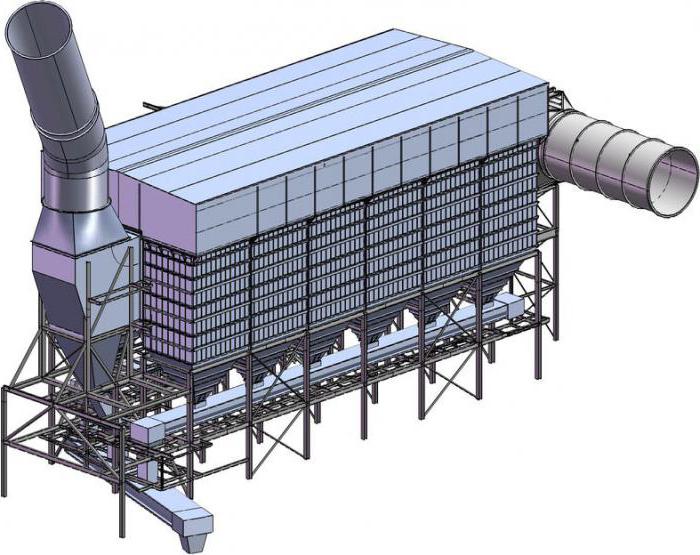

Bag air filters for air purification from dust

To clean the dust-gas-air compositions, you should use a bag filter. This is a "dry" type dust collector, which has a high degree of reliability and excellent workmanship.No equipment, be it wet cleaning or electrostatic precipitators, can compare with a bag filter, because it is equipped with filtering devices, they can be used at high temperatures, because they are made of polyamide and polytetrafluoroethylene.

The bag filter is a versatile piece of equipment because, in fact, it can be used in different technological processes. However, it will be equally effective. You do not have to constantly monitor its work, because it functions continuously.

If you need a bag filter of a certain size and with certain design features that fit exactly under your operating conditions, then you can order such a device, because such devices can be made according to individual wishes. You, most importantly, need to be sure to indicate which dust-forming composition has to be mainly cleaned. Manufacturers, starting from this, will select the right material for you to make a bag filter.

Where is a bag filter usually used:

1. In the manufacture of building materials. 2. In the field of non-ferrous and ferrous metallurgy. 3. During the foundry process. 4. In the automotive process. 5. In the energy and mining, furniture, glass and chemical industries. 6. In food production. 7. When processing metal.

Important Factors in Bag Filter Operation

In the process of choosing this filter, you need to consider several key points, which include items such as:

temperature dew point data with degree of moisture; pressure and temperature data; · quality of gases, their explosiveness and volumes of the environment which should be cleared; dust density and its type; How does this stage take place? The toxicity of dust composition substances.

In order to calculate a bag filter, it is first necessary to determine the amount of purge gas with dusty compositions that fall on the material, and then take into account the speed of the filtration process with a cloth, and it was chosen for the manufacture of a bag filter. How to operate a bag filter?

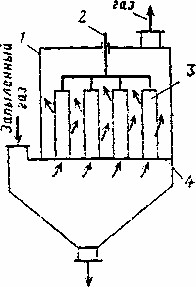

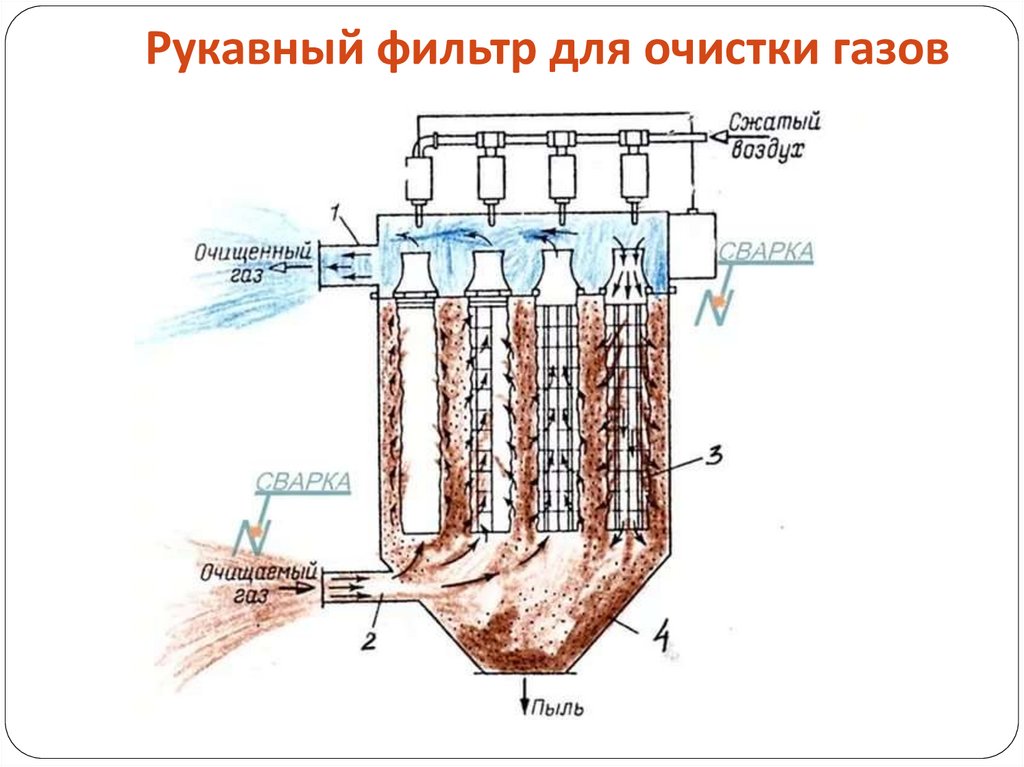

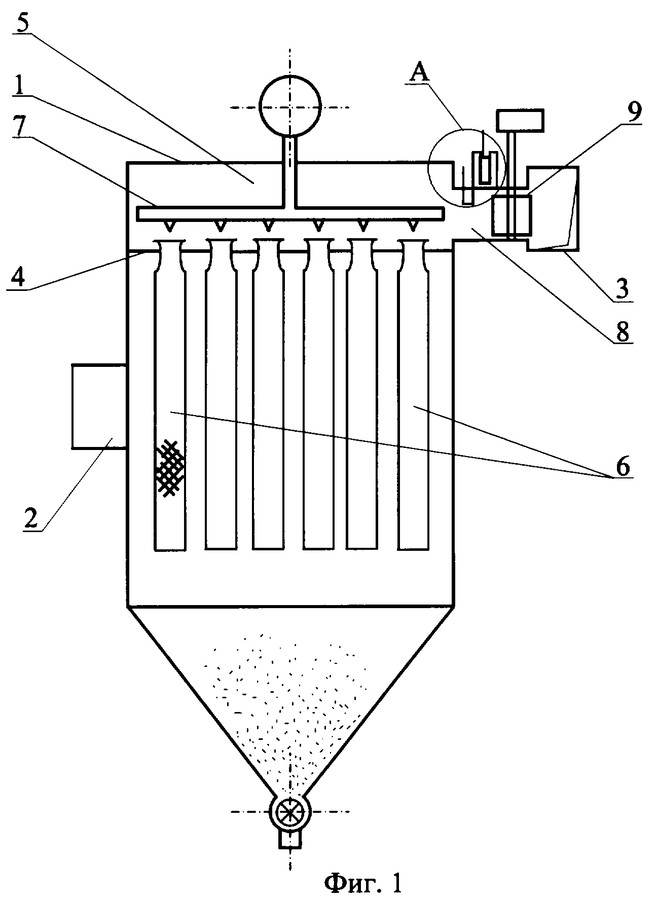

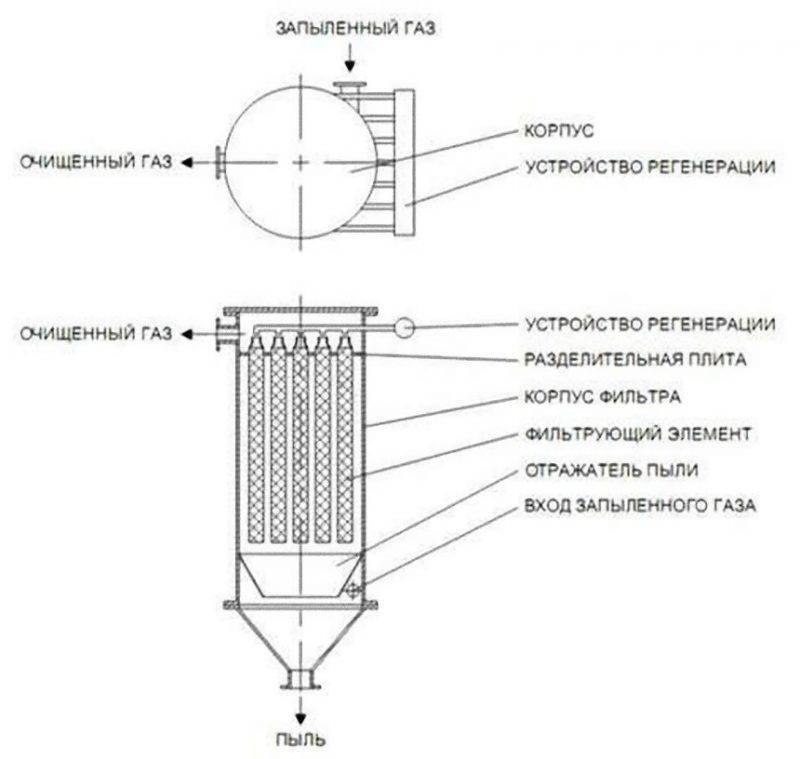

Device and circuit

The device of bag filters, their technical characteristics differ slightly from different manufacturers. The main blocks and the schematic diagram of the design consists of the following elements:

- Dirty gas chamber

- Clean gas chamber

- Bag filter housing

- Mounting plate (separation plate between clean and dirty chamber)

- Filter bags

- Regeneration system with receivers, pneumatic valves, purge pipes

- Hopper with dust discharge device and supports

- Control automation system

The filter configuration differs depending on the operating conditions and can be supplemented with service platforms, an automatic hopper unloading system, a pneumatic or vibratory hopper caving system, an emergency outside air mixing system to reduce the temperature. If the equipment is located outdoors, in order to avoid the formation of condensate on the body, the filter is equipped with heating of the pneumatic valves and the hopper, as well as thermal insulation.

For filtration of explosive dust, for example, in the production of flour, cement, coal plants, filters are made in an explosion-proof design. The explosion-proof design of the bag filter involves the use of filter bags with an antistatic coating, which prevents the formation of a static charge on the surface of the filter material. Explosive membranes are also installed on the filter housing, which release excess pressure in the event of an explosion.

The filtering material of the sleeves is selected based on the characteristics of the medium being filtered, the properties and fineness of the dust. The main materials used in bag filters are polyester (PE), meta-aramid (AR), polyimide (P84), glass fiber (FG), polytetrafluoroethylene (PTFE), polyacrylonitrile (PAN), polyphenylene sulfide (PPS) and others.

Applications and features of operation

The need for constant air purification from a large number of small particles of materials and products is experienced by a wide range of industries. Therefore, bag filter systems are common:

- in the chemical and food industries;

- at the enterprises of mining and processing production;

- in foundry production, in metallurgy, in workshops where cast iron is refined with shot blasting machines;

- at mills, elevators and other enterprises where the processing and storage of raw materials remains a source of dust;

- on production sites and in painting shops.

Depending on the requirements for air purity and the characteristics of technological processes, bag filters can be equipped with bags made of different materials - these are both natural and synthetic woven and non-woven fabrics rolled up into bags.The efficiency of air purification from certain types of contaminants can be increased by using porous materials or fabrics with releasing fibers, baize and its synthetic counterparts.

The device of the sleeve allows you to attach it in different ways: on a ring with a fabric turn, on spring elements, on clamps. As a rule, the service life of one sleeve is estimated at several years. In the absence of aggressive contaminants in the air that destroy the fabric structure, the regeneration system copes with its task and maintains the capacity of the bags throughout the entire operation cycle.

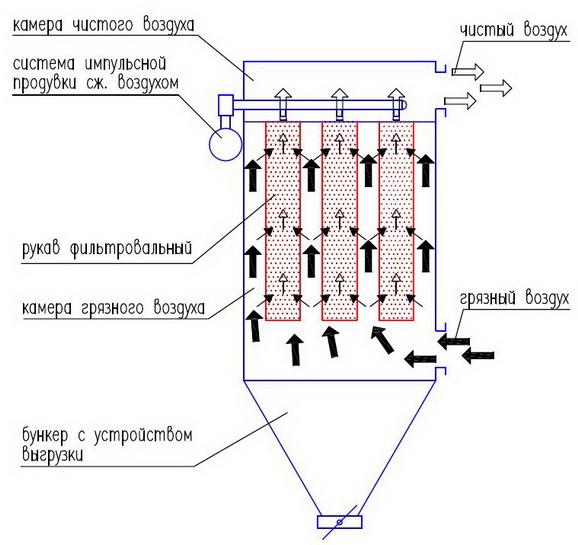

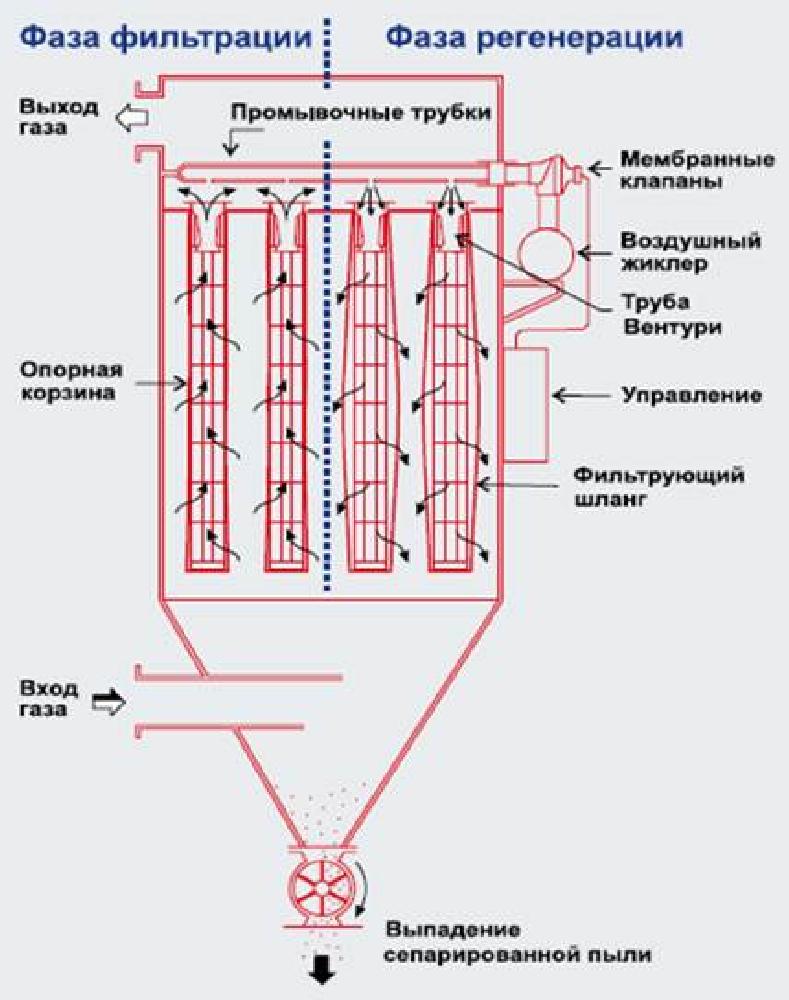

Regeneration system

As the accumulation of polluting particles increases, the throughput, productivity and efficiency of the bag filter decreases, and the resistance to air movement of the filter material increases. To prevent them, they resort to regular cleaning of the filter channels. Several schemes have been developed and successfully applied in practice:

- aerodynamic agitation or recovery by means of pulsed or return blowing of the bag filter with compressed air;

- automatic vibration shaking;

- combination of methods.

You can set the cleaning mode using a timer that gives a signal after a specified period of time. Another way is through the readings of the sensor, which fixes a significant drop in pressure and performance. For vibration use: sound waves, mechanical shaking. With the help of installed vibrators with an impact frequency of about 15 ... 25 Hz, pollution is lowered into the receiving hopper.

The back blowing scheme of the bag filter consists in intensive exposure to clean air. With pulsed blowing, small portions of compressed air are dispensed intermittently (pulses). This creates vibration in the sleeve. The pulse duration is 0.1 ... 2 seconds. The frequency depends on the nature of the change in the resistance of the bag filter. Self-cleaning takes place. Of great importance in this method is the humidity of the compressed air. Before serving, it must be dried in a special installation. With the combined method, several types of regeneration are used.

After a certain period of time and a number of regenerations, the stuck amount of dirt in the filter material stabilizes, which corresponds to the residual resistance of the material. This value depends on a number of aspiration indicators: filter cloth, parameters and properties of polluting particles, moisture content of gases, regeneration methods.

The photo shows such installations of impulse action. The preference for aerodynamic regeneration over mechanical is that during regeneration the work of the hose gas filter may not be stopped. This allows you to work around the clock, and the concentration of dust can reach up to 55 g/m3.

To unload the accumulated contaminants, several methods are used. The most productive cleaners include pneumatic transport, which is installed for several bunkers at once. Its operation does not require stopping the bag filters. He runs on his fan. Unloading takes place through a sluice reloader, the operation of which does not violate the tightness of the apparatus.Other methods require stopping the operation of the filtration system and have the inconvenience of possibly hanging the waste accumulated in the bin.

The change of the bag filter is carried out due to the loss of its filtering properties, which in many cases occurs once every 3 years. When working in a slightly aggressive environment with a low concentration of contaminants, the period of operation can reach up to 6-7 years.

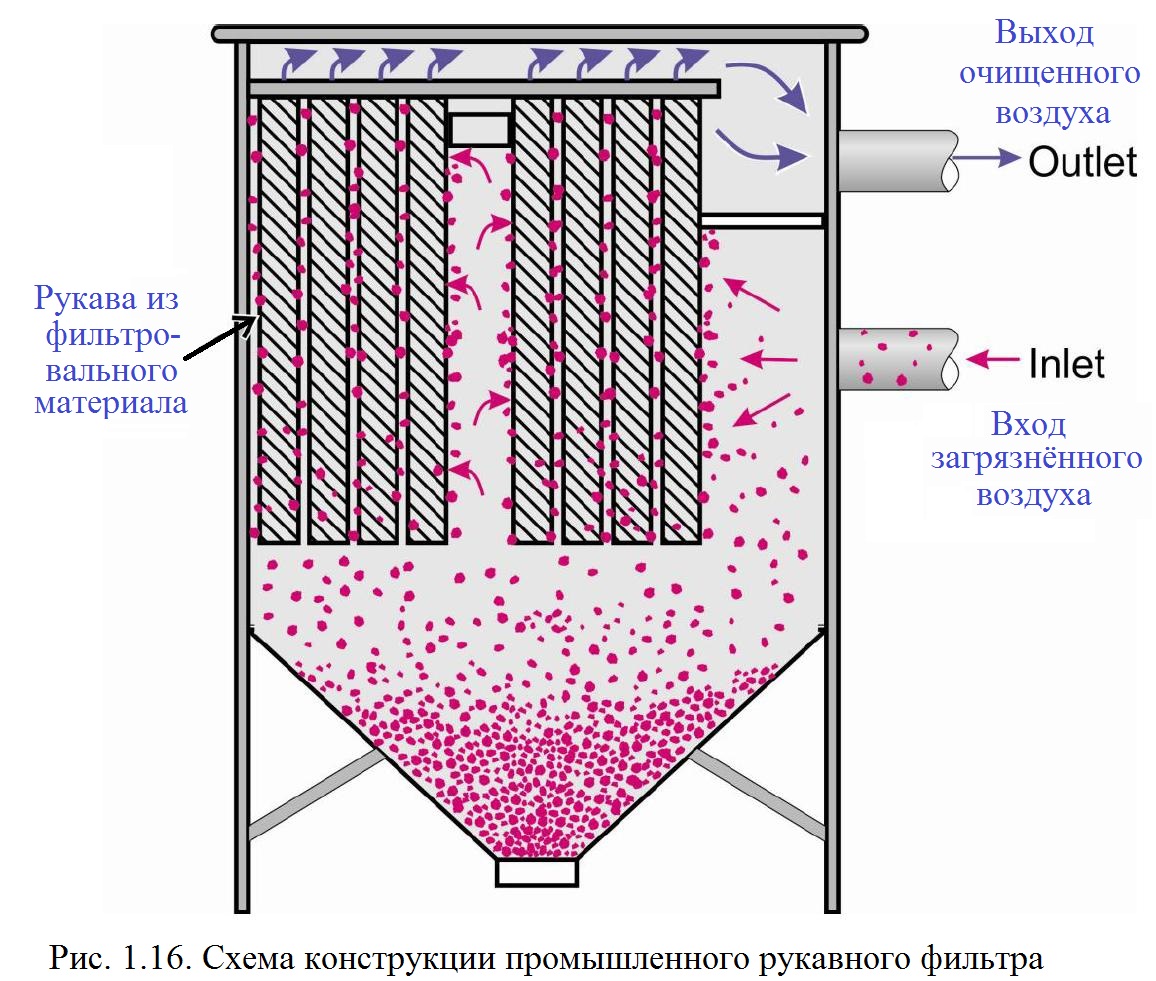

Principle of operation

The principle of operation of bag filters is based on the passage of dirty air through the pores of a non-woven filter material. Dusty air enters the dirty gas chamber through the gas duct through the inlet pipe and passes through the surface of the filter bags. Dust settles on the filter material, and the purified air enters the clean gas chamber and is then removed from the filter. As dust accumulates on the surface of the filter material, the resistance to air movement increases and the throughput of the filter bags decreases. To clean the bags from trapped dust, they are regenerated with compressed air or vibroshaking, depending on the method of bag filter regeneration. The dust discharged from the sleeves enters the storage hopper and is removed through the unloading device. Read more about pulsed blowing of bag filters.

Pulse regeneration of filters is carried out with pre-prepared compressed air of class 9 according to GOST 17433-80 with a pressure of 4 to 8 bar. Compressed air consumption is individual for each filter and is reflected in the technical specifications. Sleeves are regenerated automatically according to a timer or differential pressure signal (by differential pressure gauge), without stopping the filter operation.

The principle of operation of the bag filter

This is a relatively simple design. It can be part of any indoor ventilation that purifies dusty air and returns it to the room. Or an autonomous system for complete cleaning before being discharged to the outside.

How does a bag filter work?

The scheme and principle of operation of the bag filter are presented above. The device is designed to pass a significant amount of contaminated gases or air. Preliminarily, the air flow enters the cyclone, where the large fraction settles. Then it moves through the intake valve into the system. There, dust or soot particles are retained on the filter plane of the woven or non-woven base.

The bag filter may be a single design. But batteries are considered more efficient. The air then exits through the outlet valve, which is equipped with an automatic outlet pressure control system. The degree of purification of the bag filter depends on various factors and reaches 90-99.9%.

Thus, the use of this design allows you to perform the following tasks:

- high-quality purification of the air mixture from contaminants;

- regulation of the amount and pressure of the outgoing purified air;

- creation of uniform dust filling.

Harmful air suspensions are retained by the design of the sleeve and removed by mechanical shaking during the regeneration process.

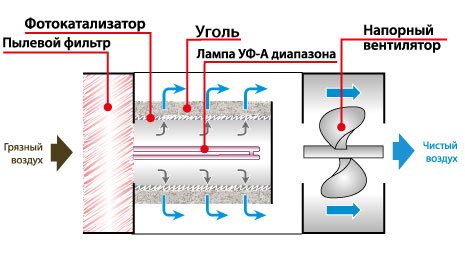

Cleaning method using devices using photocatalysts

The following devices work similarly to HEPA filters, that is, cleaning includes several stages. They completely destroy harmful impurities, and even microorganisms that are in the air masses.Such devices are equipped with a catalyst, an ultraviolet lamp, sometimes supplemented with an ion generating device, filters using activated carbon or metal plates operating on the basis of an electrostatic field. Such devices are the most effective among the devices involved in cleaning the airspace. In addition, they are environmentally friendly, safe to use, economical and unpretentious in care.

Devices equipped with a photocatalyst completely destroy any impurities in the air

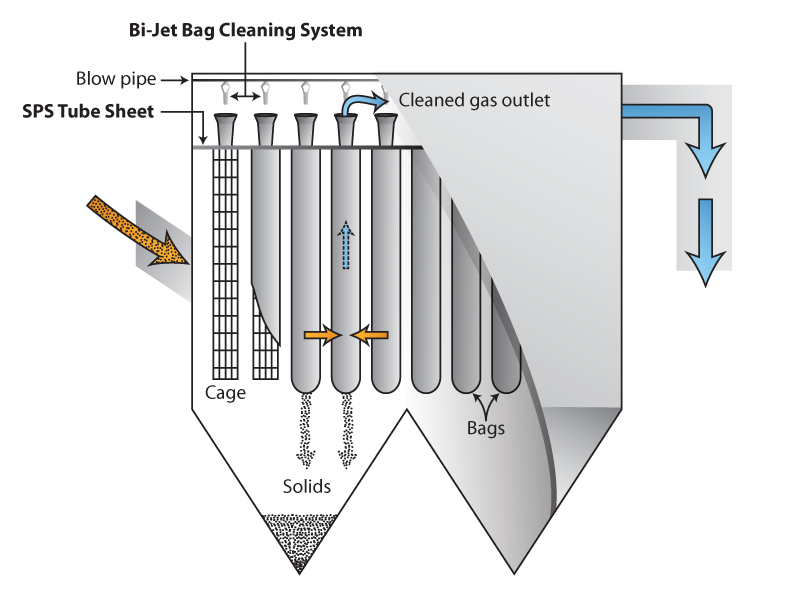

How bag filters work

Air purification occurs in several stages:

Stage #1

Due to the vacuum created by the fan, the dust-air mixture enters the filter housing, which consists of "dirty" and "clean" chambers. The purified gas passes through a "dirty" chamber, inside which there are filter elements (filter sleeves stretched over a frame mesh), on which the filtration process takes place. Passing through the filter bags made of polyester filter cloth, the dust lingers on them. The purified gas exits the filter through the outlet flange. Dust lingers on the sleeves and falls down.

Stage #2

When a layer of dust builds up on the surface of the filter sheet, the regeneration system is activated, which shakes the filter sleeves with a pulse of compressed air from the inside. The regeneration system ensures timely cleaning of the bags from dust and maintains the nominal gas permeability of the filter elements and is triggered by an increase in the hydraulic resistance between the "dirty" and "clean" cavities of the filter housing. When a certain resistance value is reached, the sleeves are shaken by a pulse of compressed air from the inside. Dust is poured into the sleeve bunker.

Stage #3

The unloading of the bunker is carried out by a sluice gate (together with the auger), which ensures the necessary tightness of the filter when unloading dust. Unloading of dust from the bunker should be carried out regularly as dust accumulates in the bunker. Accumulation of dust in the bunker for more than half of its volume is not allowed. Depending on the filter configuration: a limit switch for the filling level of bulk materials is installed on the hopper body; a sluice feeder is installed at the outlet of the bunker. All dust discharge controls are located in the dust discharge control cabinet.

Functions and purpose

During production at enterprises, the air is constantly polluted by particles of processed materials. Even if the workshop is well ventilated, it is still impossible to completely clean the room if you do not use specialized equipment, such as an industrial filter. The main tasks of such installations include ridding the environment of technical impurities and dust particles.

Some models can also carry out gas cleaning. In simple terms, they remove smoke, fumes and industrial gases from the air. They also support the function of deep preparation of ambient air. That is, they can disinfect and decontaminate the environment and even regulate microclimatic characteristics.

The regeneration system can be of two types:

- standard - gas cleaning and regeneration are carried out simultaneously;

- mode designed for difficult operating conditions. It is performed when one or another section of the operating equipment is turned off.

Operation in difficult conditions

The bag filter, whose characteristics are selected according to the conditions of use, is suitable for outdoor and indoor work. In the first option, an addition is required in the form of the following components:

- thermal insulation of the body part, which is of particular importance in the case of vapor condensation;

- heating of equipment bunkers and regeneration systems;

- a special shelter that prevents the effects of atmospheric phenomena.

Among the main types of devices, it is worth noting a two-row design, in the middle part of which there are nozzles for the inlet of contaminated and purified gas, as well as a single-row one, in which the nozzles are located on the side of the structure.

Transportation of equipment is carried out by trucks. To simplify this process, the bag filter, the drawing of which is presented above, is implemented in a partially disassembled form. Knots are made in various variations in accordance with the operating conditions. For the assembly of the structure, a welded method and bolted connections are used. Most of the devices are designed to operate with excessive vacuum or pressure.

View gallery

What is the latest coarse filtration trend?

This is the development of coarse filtration after elutriation. The reason is clear. Send more or less pure juice for fermentation. Cleaned as much as the winemaker wants.But you need to understand that you cannot filter the juice to the highest purity and think that it will be the best wine, but not even vice versa, leave as many impurities as possible and you will have the best wine. The truth is somewhere in the middle. Everything will overestimate the intention of the winemaker. He must know when, on what and how to filter. This is a difficult topic, first of all, for juices, at the leading wineries that are engaged in this, that some juices are filtered significantly to the highest purity, some are not enough, on the contrary, some even carry out blending, during which part of the sludge, after a thoughtful discussion by the technologist, returns to the filtered juice to achieve the correct level of sludge content for the future development of the wine during or after fermentation.

Frantisek Bilek

Filtration specialist and director of Bílek Filtry s.r.o.

The article was published in the magazine "Vinař Sadař" (wine grower).

Main types of filter bags

The choice of a suitable bag filter is based on the specifics of the production and the nature of the dust produced in its process. The main criteria that you should rely on when selecting this equipment are the performance of the unit and the depth of purification of the incoming air.

The remaining parameters are individual: the degree of their importance depends on the production conditions

For example, the choice of material from which the filter is made depends entirely on the characteristics of dust pollutants that arise during production.

#1: Hardware Performance Difference

Sleeve filters are divided into two main types: round and flat.The first type is designed for operation at enterprises with a large dust load and is able to pass and clean quite serious volumes of air: more than 100 thousand m 3 per hour.

Flat sleeves have a more modest performance, but they also have a more compact design. Such cleaning systems are suitable for workshops with a small dust load.

No. 2: Classification by type of installation of sleeves

By type of installation, systems with bag filters can be vertical or horizontal. The latter remain more efficient, as they allow more air or gas to pass through.

The flow path itself through the sleeve is quite long, so the pores of the filter material trap more contaminants.

Distinguish sleeves and in a form: ellipsoidal, cylindrical, rectangular.

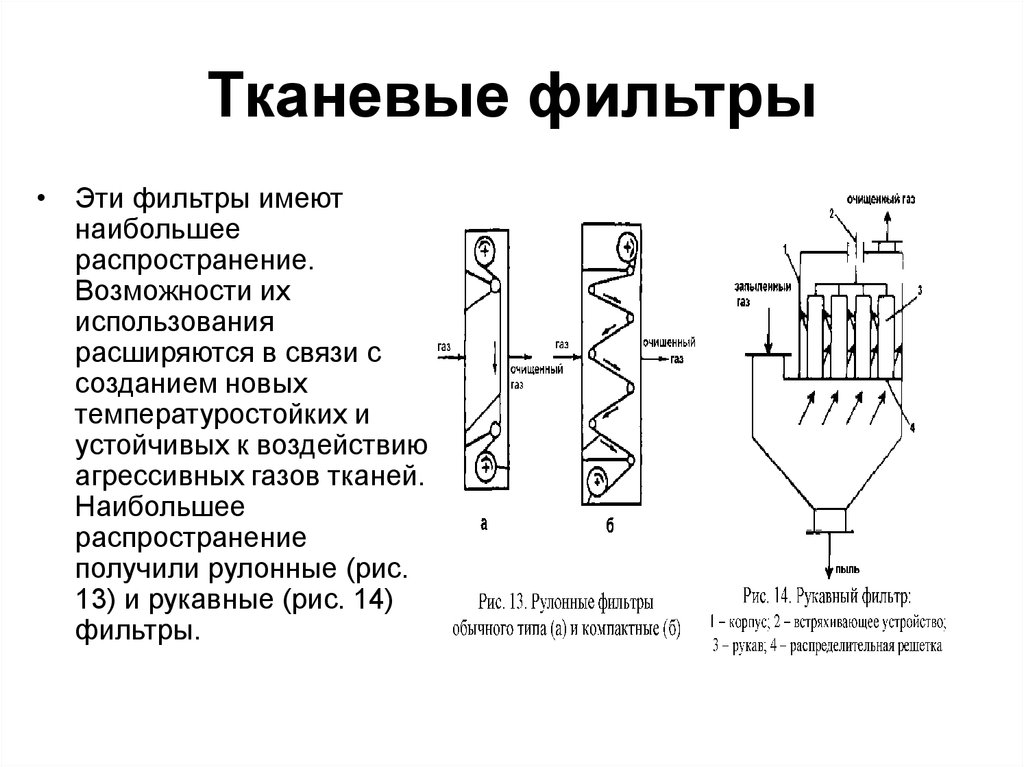

No. 3: Varieties according to the material of manufacture

The classification and principle of operation of the bag filter is also affected by the material from which the filter element is made. It is often made from fabric.

It can be either natural cotton or wool, or synthetic materials:

- polyester;

- fiberglass;

- polyamide;

- meta-aramid;

- polytetrafluoroethylene;

- polyacrylonitrile, etc.

The choice of bag material is based on the type of production, the characteristics of the mixture being filtered, the dispersion and properties of the dust, and the aggressiveness of the medium.

Recently, non-woven filters with a more uniform and finely porous structure, which, due to the fibrous surface, retain more pollutants, have become especially popular.

No. 4: Classification according to the method of regeneration

The filter recovery method can be considered another category for classifying these devices.

The regeneration of the hose assembly is an important stage in the operation of the structure, so it should be given special attention.

In fact, regeneration is a process of cleaning the sleeve from accumulated dirt.

The procedure can be carried out by several methods, the choice of which depends on the nature of the dust:

- Vibration cleaning, during which the sleeve or battery of sleeves is intensively shaken, after which the particles of contaminants fall into a special hopper for subsequent removal. Dust is removed from it using a dust transport system: a screw or pneumatic conveyor, a rotary tambour, a scraper chain, a sliding gate or a valve gate.

- Pulse purge or pneumatic cleaning. The filter is pulsed or pneumatically purged with a reverse air flow that knocks out microparticles from the pores.

- Combined cleaning. A battery or a single sleeve is subjected to combined cleaning, during which the filter is shaken and blown over with clean air flows.

Vibration cleaning can take place not only automatically: the regeneration process is sometimes carried out manually thanks to a special handle and is called mechanical cleaning of the sleeve.

But most often the regeneration process is carried out automatically due to the operation of pollution sensors, which react to the amount of collected litter and determine the pressure and throughput of the sleeve. If the structure outlet pressure drops, the sensor triggers the purge process or shaking mechanism.

With a low dust load in a non-aggressive environment in a small production area, the full functioning of a bag filter can reach up to five years, after which its scheduled replacement will be required.

Bag filters with impulse blowing

The simple design of bag filters and their efficient operation have made this type of filter mechanism the most common in the industry. Moreover, such filters have an internal classification that characterizes the type of material used and the characteristics of the gas supply.

The design of bag filters is such that it allows for gas filtration in several streams at once. The space between the sleeves allows free inflation of the sleeves under the action of the air flow and the ease of their replacement or repair.

Pulsed bag filter

The design of filter bags can be different. Usually they are made in the form of a fabric (one-piece or pieced) cylinder with or without spacer sleeves. The upper and lower edges of the sleeves, in those places where fastening with a collar, are tucked and hemmed to give them greater strength.

Filters that are used to purify gases from dust are most often made in the form of several bag filters, which are connected in parallel to batteries. In this case, the filtration occurs alternately in three blocks, which are located one after the other.

Two of these blocks perform their own filtration, and the third - sludge unloading.

Bag filter battery

During the filtration process, the gas, which is contaminated with dust, is sent to the filter bags. Dust particles from the gas remain on the sleeve, form a precipitate.

At the moment when the precipitate reaches its maximum thickness, the gas stops flowing into the apparatus. After that, air is blown into the filter sleeve in the opposite direction. And thanks to vibration, the sediment falls away from the filter sleeve.The sediment falls down and enters the cone, and from it it is unloaded into bags.

In order to completely clean the filter bags, it is switched to dust removal mode.

In order to qualitatively clean the continuous flow of gas from dust particles, a battery of three sleeves should be used, which work in turn. Two of the filters are constantly working, and the third is a backup and is shaken out during the operation of the first two.

As well as in the separation of suspensions, gas purification from suspended particles by filtration is used when separation cannot be carried out by settling in cyclones and settling chambers. The principle of operation of devices for gas purification by filtration is similar to the operation of devices for separating suspensions. In such devices, porous partitions are used that allow gas to pass through, but at the same time retain solid particles on their surface.

How bag filters work

The principle of operation of bag filters is based on the separation of dust particles when the air flow passes through the filter element.

Figure 1 shows a diagram of the bottom supply of dusty air, in Figure 2 - dusty air is supplied to the upper part of the chamber. The air supply scheme depends on the location of the filtering unit in the complex of technological equipment and the presence of additional air purification devices, such as cyclones.

Regardless of the scheme for supplying dusty air to the bag filter, the principle of operation consists of two stages:

-

air cleaning;

-

bag filter regeneration.

During the cleaning phase, the fan sucks in air, as it passes through the filter, see figures 1 and 2, the dust settles on the outside of the bag filter element.

Depending on the performance of the installation and the type of dust, compressed air is periodically released through the air valve into the sleeve, while the air flow of higher pressure shakes off the dust from the outside of the filter element.

It is important to understand that depending on the design of the pulse purge system, cleaning can be performed:

-

all filters simultaneously;

-

filter groups;

-

each filter

-

one-time or alternate shaking.

During mechanical shaking, due to periodic sharp shaking of the frame on which the filter elements are fixed, dust is discharged from the outer part of the sleeve.

A feature of the air purification technology using bag filters is the requirement for the humidity of compressed air used for pulse shaking. Before air is supplied to the valve, it must be dried in a special installation. The dryness point (dew point) depends on the type of dust.

When operating bag filters in accordance with the requirements of design documentation, the service life of the filter element is about 3 years. You can significantly increase the service life by regularly cleaning the filter periodically.