- Advantages and disadvantages of hydrogen boilers

- Pros and cons of electrode boilers for heating

- Do-it-yourself hydrogen heating boiler

- Generator manufacturing

- Boiler manufacturing

- 3 Selection criteria and operating features

- The main nuances of hydrogen boilers

- Benefits of heating with hydrogen

- Disadvantages of hydrogen boilers

- The main nuances of hydrogen boilers

- Benefits of heating with hydrogen

- Disadvantages of hydrogen boilers

- Pros and cons of hydrogen heating boilers

- How to make a hydrogen boiler with your own hands?

- Model Selection Criteria

- Experiments with eternal log

- Prospects for hydrogen as a fuel for a heating boiler

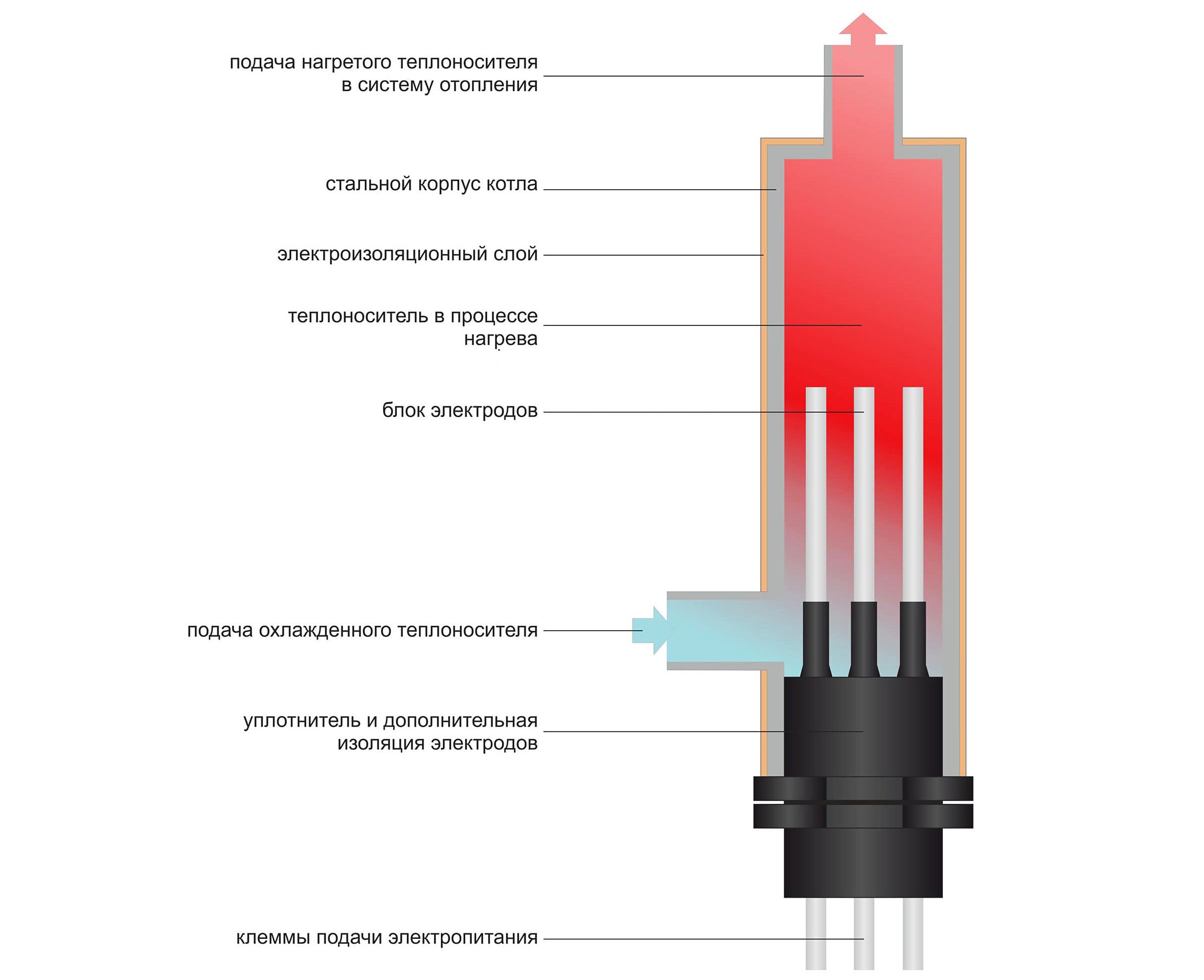

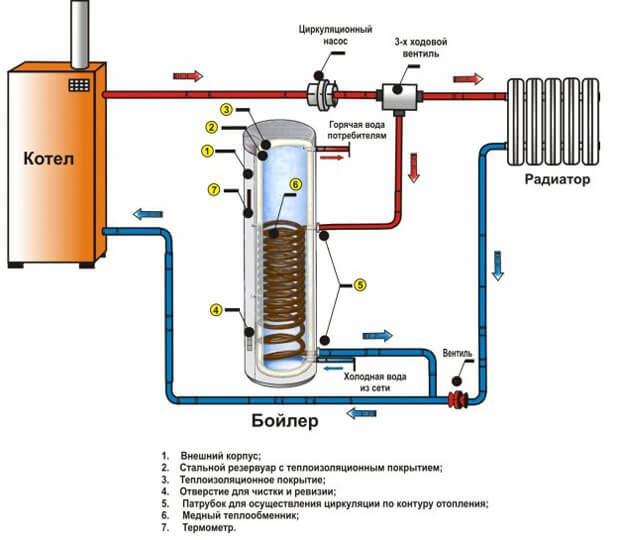

- How does a hydrogen heating boiler work

- Advantages of hydrogen boilers

- Cons of hydrogen boilers

Advantages and disadvantages of hydrogen boilers

The strengths of these devices are:

- Complete environmental friendliness. Water decomposition products do not harm the atmosphere, they are completely safe for the health of people and pets.

- High level of efficiency, which can reach 96%. This is significantly higher than the efficiency of diesel, natural gas or coal.

- Saving natural resources through the use of alternative energy sources.

- Low calorie cost. For such devices, water and a little electricity are enough.

At the same time, such devices also have weaknesses.

Among the minuses, the following nuances should be attributed:

- Maintenance requirement. For the highest degree of production of H2, it is necessary to replace the metal plates every year. In addition to changing the electrodes, the catalyst must be added regularly to produce the planned amount of energy. The frequency of this procedure depends on the power, as well as on the features of a particular model.

- High cost - factory installation will cost at least 35-40 thousand rubles.

- Danger of explosion if the rated pressure in the boiler rises.

- Shortage of hydrogen cylinders - they are quite rare to be found on sale.

- Limited choice. Since such heaters are not very common on the Russian market, it is not always possible to quickly find a suitable model, as well as to find competent specialists for the installation and repair of equipment.

- The need for communications. For the operation of the device, a permanent connection to the power supply is necessary for the implementation of the electrolysis reaction, as well as to a source of water, the consumption of which depends on the power of the device.

It should be mentioned that manufacturers pay great attention to new technologies, strive to improve hydrogen boilers, eliminating or minimizing disadvantages

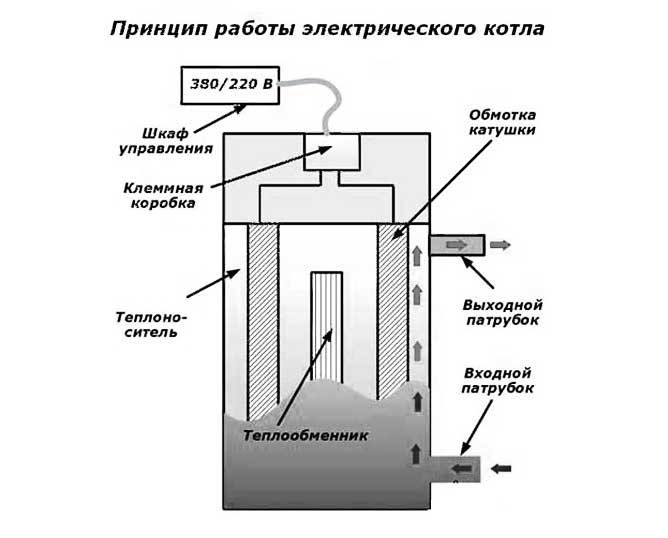

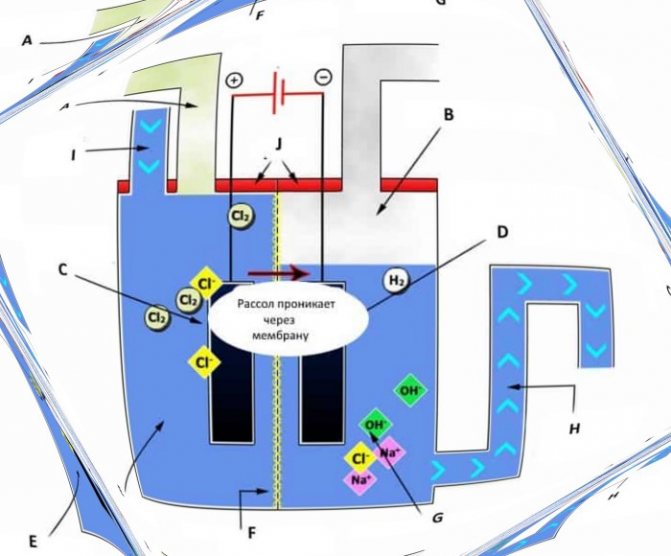

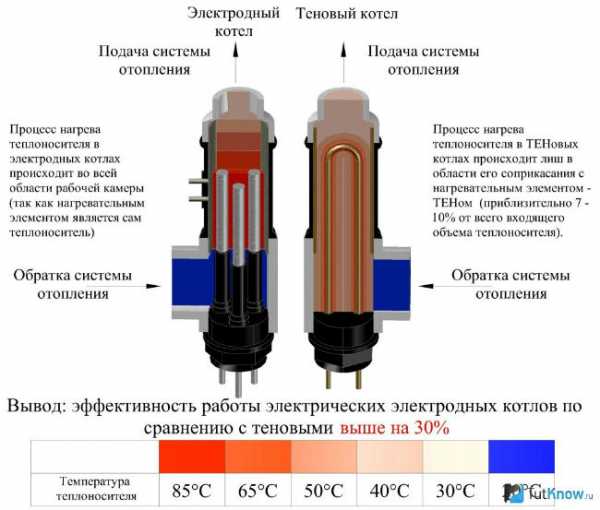

Pros and cons of electrode boilers for heating

Despite the conflicting reviews of the owners, it is impossible not to note the obvious advantages of electrode installations:

- The design of a copper provides compactness and simplicity of connection.

- Small overall dimensions allow the units to be used as additional or backup heat generators, which are switched on independently of the main one as needed.

- Boiler installation does not require a project and approval.

- If the coolant leaks, the device will not fail and can continue to work immediately after troubleshooting.

- Electrode boilers are not susceptible to voltage drops in the mains.

- No harmful emissions, and powerful electromagnetic fields.

The list of advantages is really weighty, but along with them, some objective disadvantages should be noted:

- The use of electrode devices is not advisable if there are radiators made of steel or cast iron in the heating system. Only bimetallic batteries and high-quality aluminum radiators can provide efficient operation, which significantly increases the cost of the heating circuit.

- High requirements for the quality and chemical properties of the coolant. The liquid used must provide optimal conditions for electrolysis.

- The installation of an electrode boiler is possible only in a closed circuit, which entails additional costs for a sealed expansion tank, an emergency pressure relief valve and an air vent.

- The maximum heating temperature of the coolant should not exceed 85C.

After carefully analyzing all the shortcomings of the unit, we can conclude that they are all related to the quality and chemical properties of the coolant.

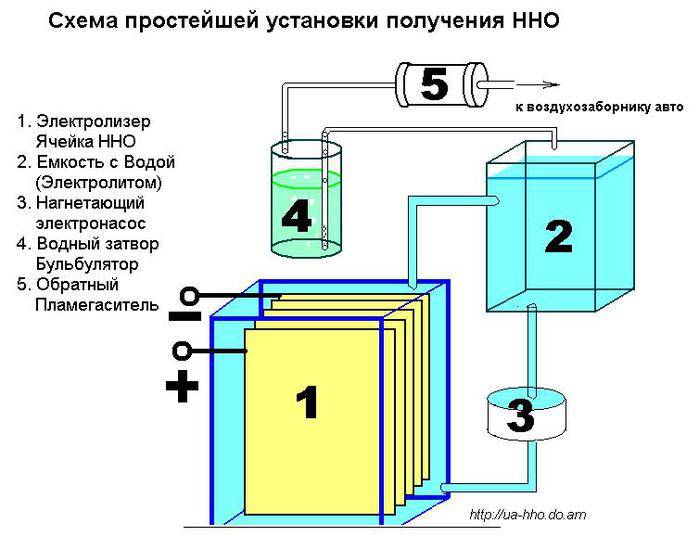

Do-it-yourself hydrogen heating boiler

To date, there is no mass production of hydrogen heating boilers and it is not easy to purchase this device.If you want to purchase such a device, then most likely you will have to place an individual order or arrange for the supply of equipment from Italy, where such a boiler was developed. However, this method is not suitable for many users due to its high cost. To resolve this issue, you can consider the method of construction do-it-yourself boiler.

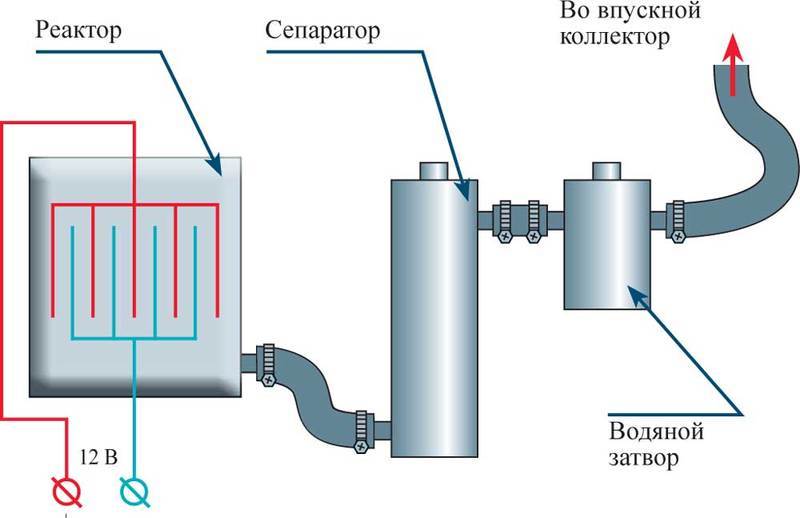

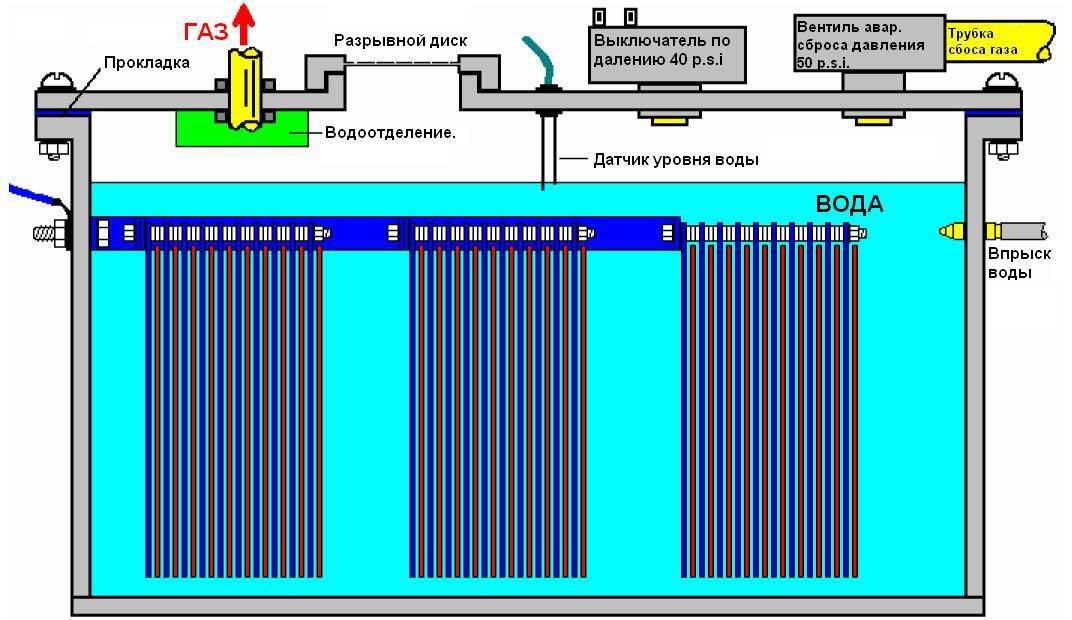

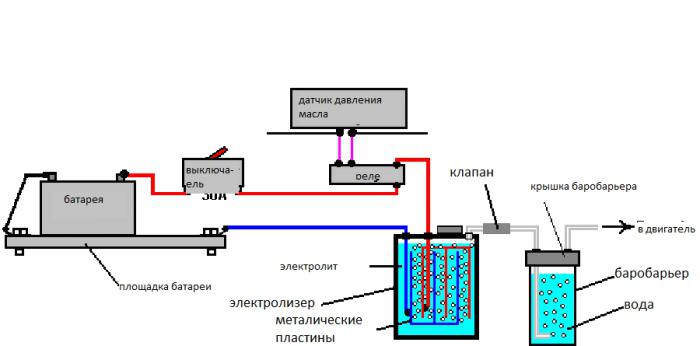

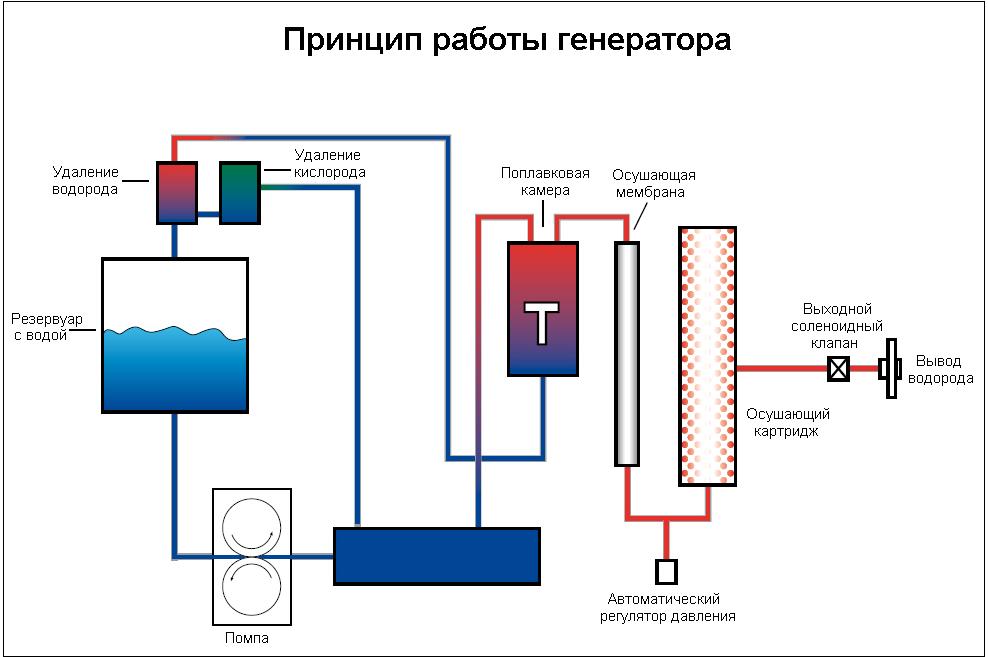

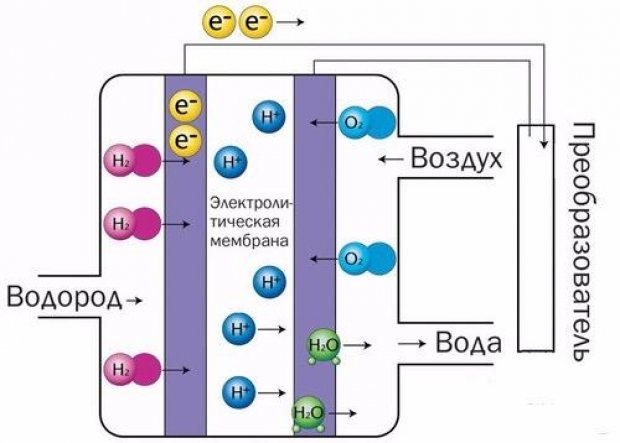

Generator manufacturing

In order to create a hydrogen boiler, you first need to build a hydrogen generator:

- At the first stage, it is necessary to cut 16 rectangles measuring 50x50 cm from a stainless steel sheet.

- One of the corners of the cut parts needs to be cut off.

- Using a drill, a hole is made in the diagonally opposite corner.

- The assembly of the structure is carried out from plates and two bolts. Tighten two washers per bolt and place them on both sides of the plate. Turn the second plate so that the cut end is at the bolt, then fix it on the second bolt so that it is above the first plate. Next, between the two plates you need to leave a strip of transparent plastic 1 mm long. The remaining rectangles are fixed in a similar way.

- In the plastic container, you need to make slots for the bolts.

- The structure assembled from the plates must be inserted into the container.

- Two holes are made in the lid: a tube for supplying hydrogen is fixed in one, and the other is created in order to fill in water with dissolved salts.

- Check device operation.

As an energy carrier, hydrogen is considered the cleanest and safest element, and heating based on it is efficient and complete.

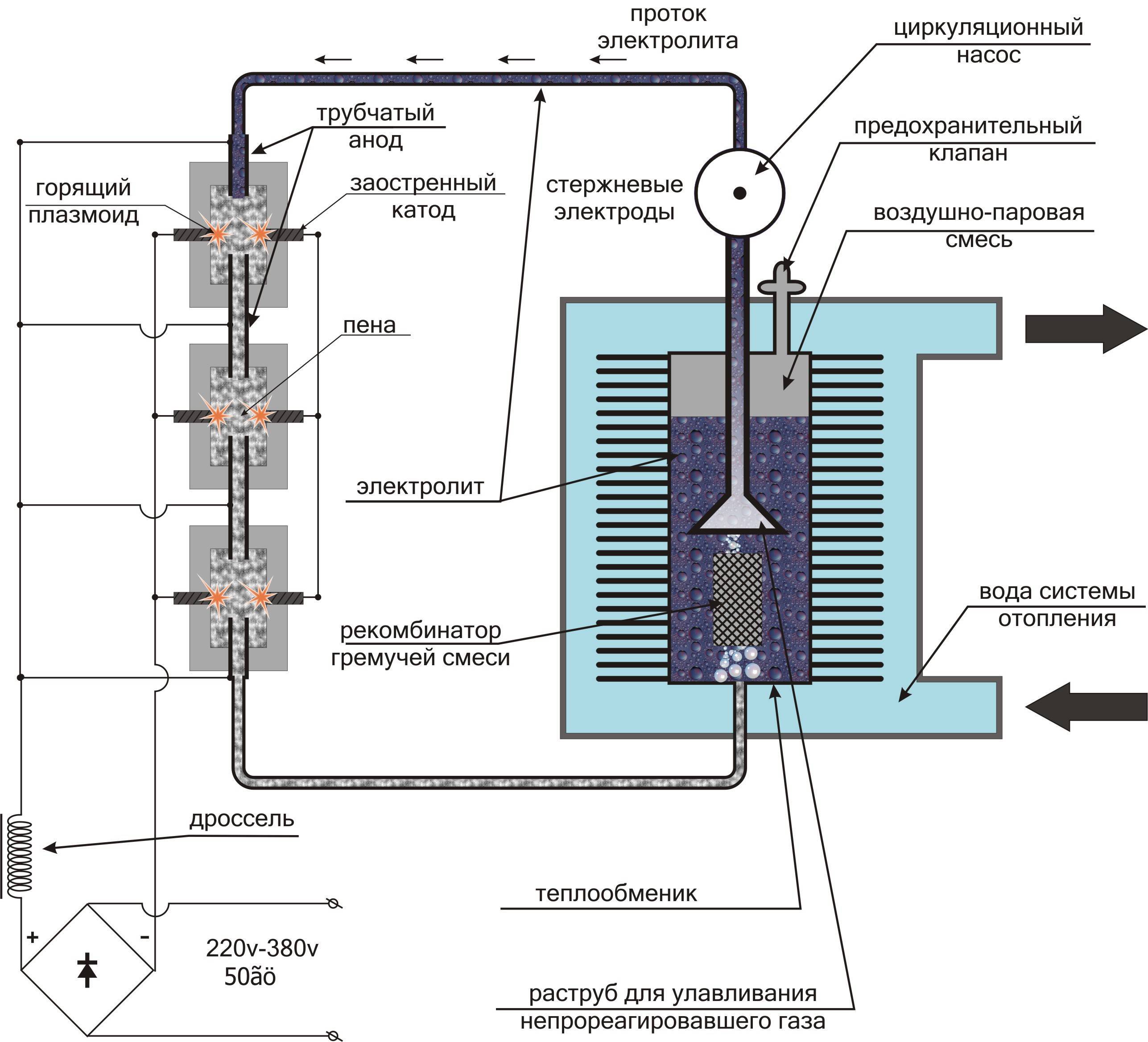

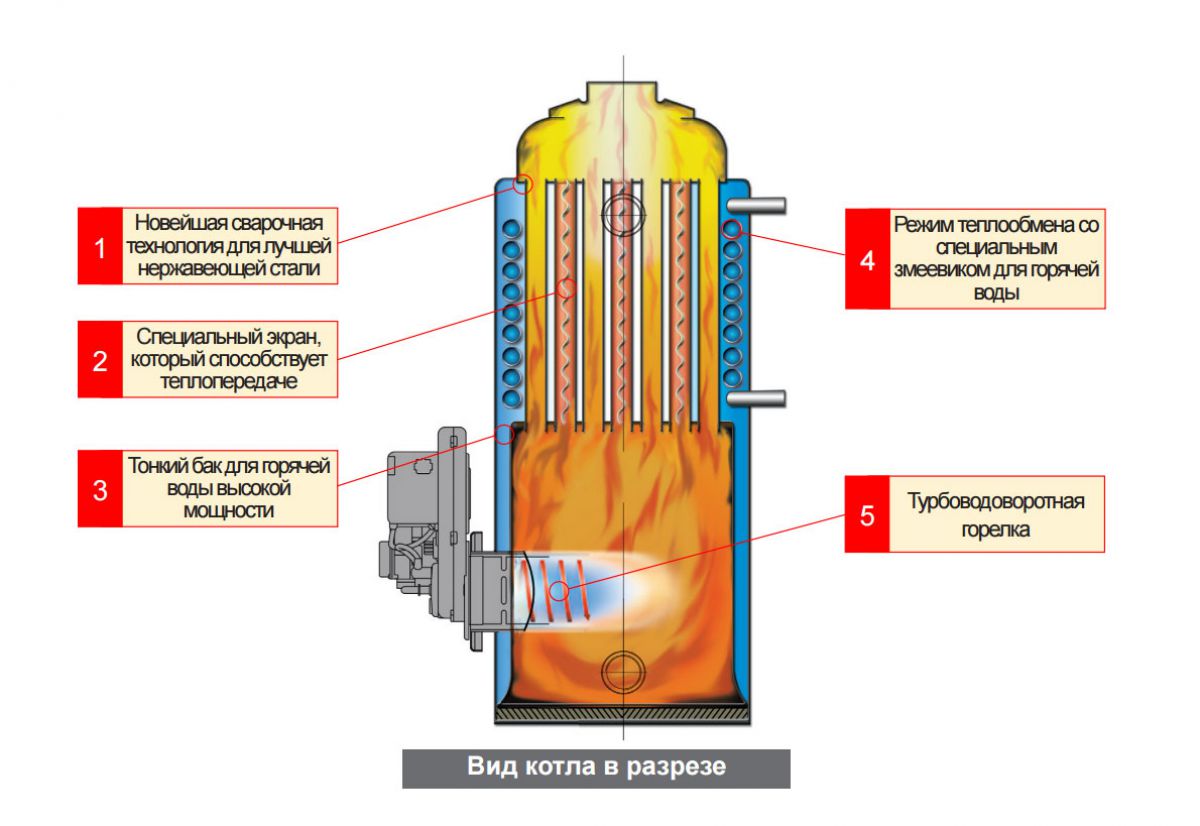

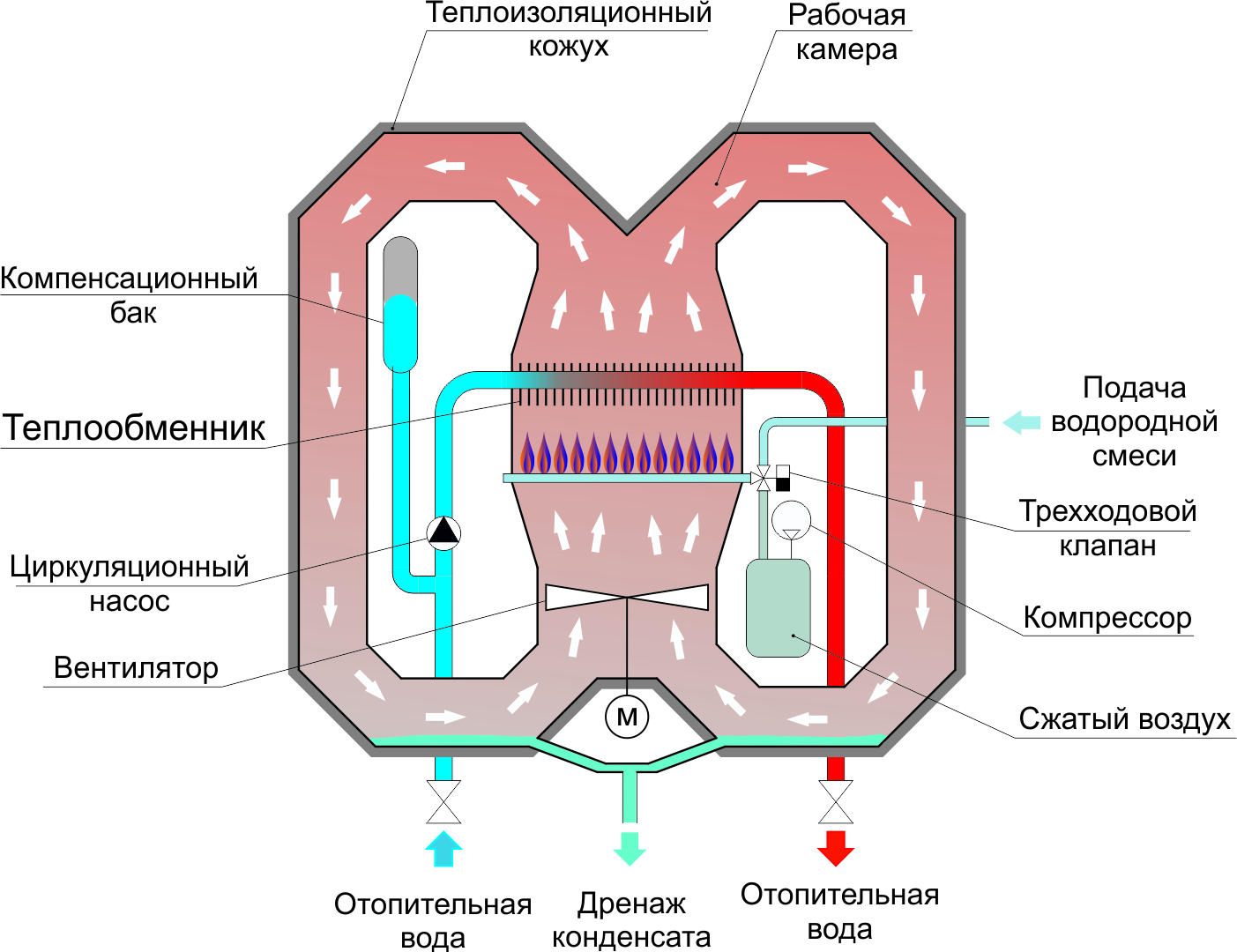

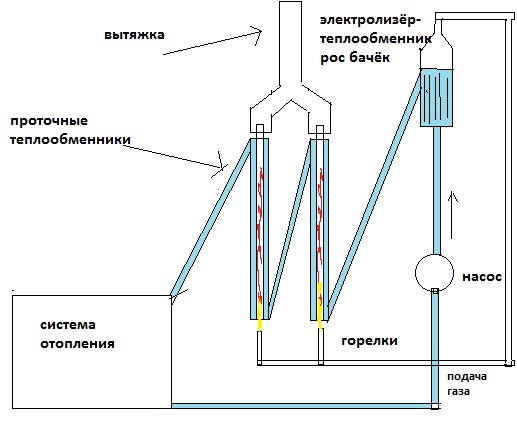

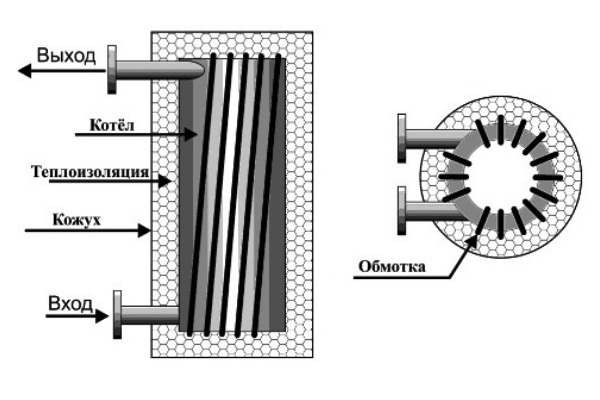

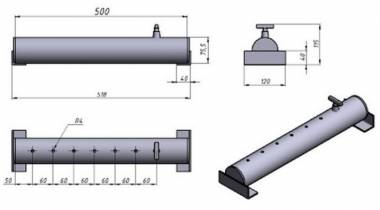

Boiler manufacturing

The creation of a hydrogen boiler is carried out as follows:

- you need to take a profile pipe 20x20 mm and cut 8 equal parts 30 cm long from it;

- then take a profile pipe 40x40 mm and cut off 3 pieces, the length of one should be 20 cm, and the other two - 8 cm;

- in a long pipe, two cuts must be made in the middle of opposite sides, 40x40 m in size. Weld 2 pieces of 8 cm to these holes;

- as a result, a crosspiece is formed, on three ends of which plugs are welded, and at the fourth end a plug with a branch pipe for connecting the hydrogen mixture supply pipe is fixed;

- at each end of the structure, one hole must be made, with a diameter of 1-1.5 cm, having previously indented 7-8 cm from the center of the cross, there should be 4 holes in total;

- pipes are welded to them and nozzles are fixed, which propane boilers often have;

- the next process will be - welding 8 pieces of a profile pipe with dimensions of 20x20 cm to the crosspiece;

DIY hydrogen boiler

then you need to cut 3 squares from sheet metal. In two of them, make 4 holes each, the diameter in one should be 2-3 cm, in the other - 1 cm; cut a pipe with a diameter of 2-3 cm into segments 50-60 cm long. Then attach them to a square with smaller holes and weld to it. make two holes in a pipe with a diameter of 20 cm: one at the bottom, the other at the top; then the pipe must be welded to a square with smaller slots; the resulting design must be turned upside down and put the second square.The tubes should enter the hole, and at the same time the square should be adjacent to the larger pipe, the square and the tubes should be welded; the process of welding the square and the structure itself is carried out by a burner: pipes for supplying the return of the coolant must be welded to two holes on the body; then the boiler is checked for leaks; and, at the last stage, it is necessary to make a protective case in which the boiler will be hidden.

Thus, by following all the above instructions, you will become the owner of a hydrogen boiler.

Currently, hydrogen fuel boilers are not widely used, despite the large number of advantages and ease of use. However, they are rapidly penetrating the heating equipment market and the prospects for their use are endless.

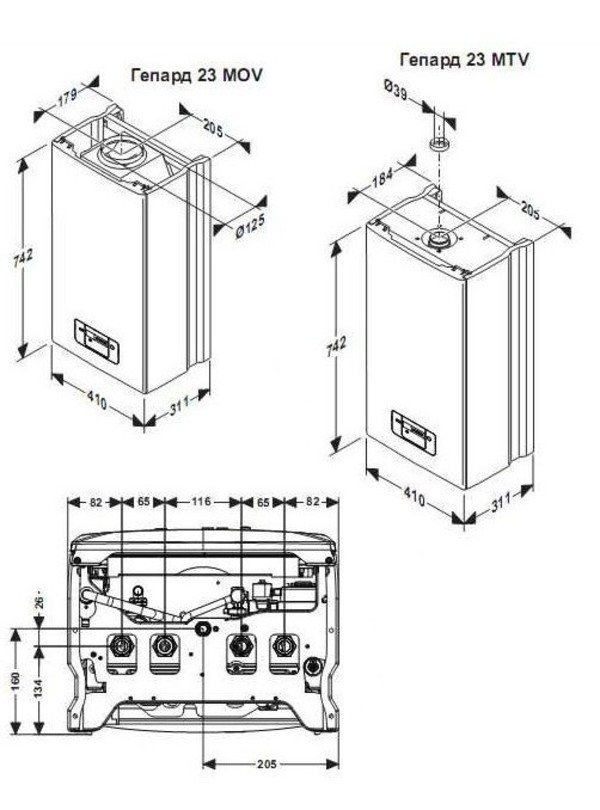

3 Selection criteria and operating features

When choosing a hydrogen boiler for your home, you should make sure that all its parts are made of quality materials.

It is also very important that the boiler protection unit is tested (certified) and complies with all safety requirements. In addition, you need to choose a model suitable for heating a particular room:

- power must correspond not only to the area of \u200b\u200bthe room, but also to the requirements of the heating system used;

- the dimensions of the chamber must correspond to the number of heat exchangers required for heating;

- the power consumption of the device must correspond to the power supply available in the building.

Having installed such a device, do not forget about safety precautions, since the fuel is explosive. The basic operating rules are aimed precisely at avoiding contact of oxygen with air (which can lead to an explosion).

Basic operating rules:

- 1. Regularly check the temperature readings on the heat exchanger sensors. The temperature should not rise above the permissible norm.

- 2. Monitor the gas pressure readings. When they increase, take measures to stabilize the regulatory pressure.

- 3. Do not use the device in modes not provided by the manufacturer.

- 4. Monitor the water supply.

- 5. Periodically replace the electrolyzer.

- 6. Take care of a stabilized power supply.

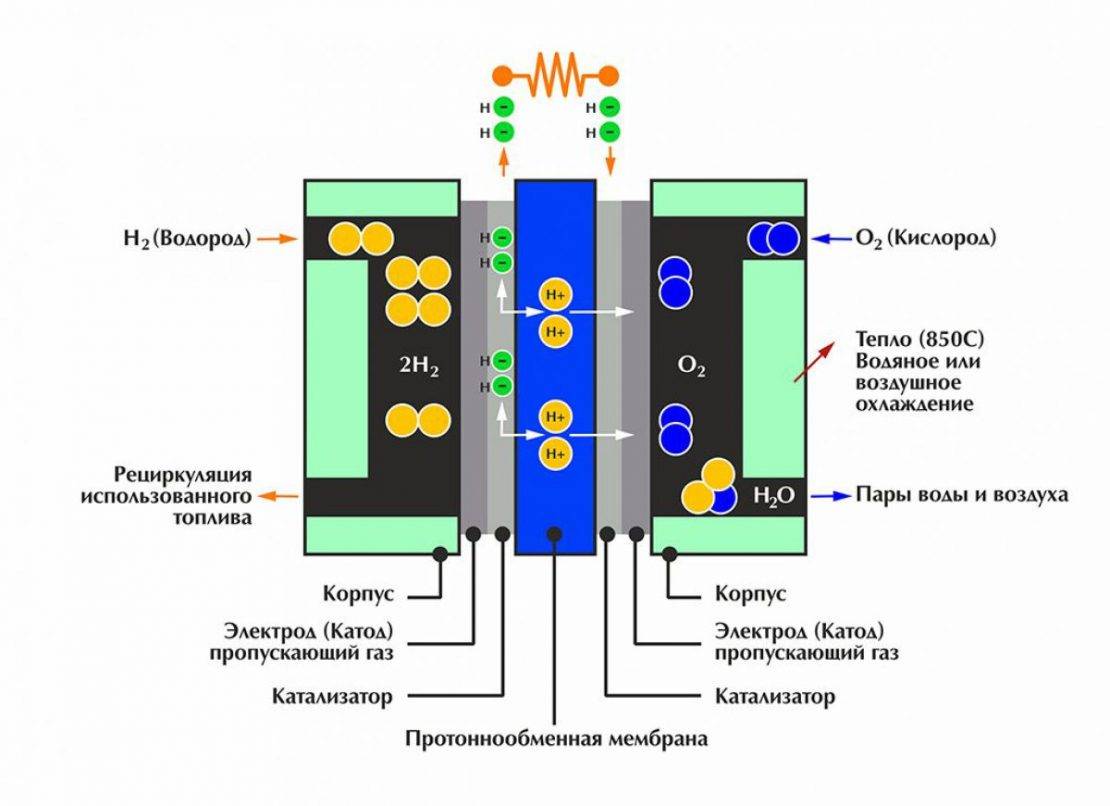

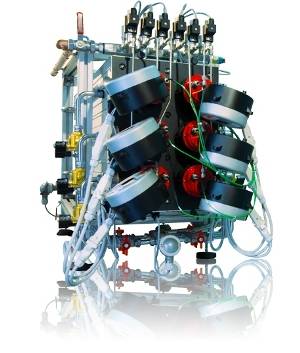

The main nuances of hydrogen boilers

The power of hydrogen-based boilers is selected depending on the area of \u200b\u200bthe structure to be heated.

With the help of technology of this kind, you can solve many problems related to heating. This is due to the simultaneous operation of several channels designed to generate hydrogen energy (there can be a maximum of 6).

The modular system inherent in hydrogen boilers ensures the independent operation of the channels, without in any way affecting the decrease in the efficiency of the installation. Each individual channel contains its own catalyst.

Benefits of heating with hydrogen

A hydrogen-powered boiler is in demand for many reasons:

- The inexhaustibility of hydrogen, as well as the ability to obtain it in any quantity.

- The production of hydrogen is considered more economically profitable than the constant extraction of minerals with combustible properties (gas, coal, oil, etc.).

- The heating system works without emissions harmful to people and the atmosphere, emitting ordinary water vapor.

- There is no need for a flame (hydrogen heating works on the basis of chemical reactions).

- The boiler has the highest efficiency.

- The device is completely silent.

- There is no need for the construction and operation of the chimney.

- The safety requirements for hydrogen heating are lower than for gas-based installations.

Disadvantages of hydrogen boilers

Despite the many advantages, it is important to know about the disadvantages of such units:

- the need for constant replenishment of the catalyst;

- explosion hazard of the element if strict requirements are not met;

- inconvenient transportation of hydrogen;

- lack of specialists in installation, as well as service maintenance of such equipment in Russia;

- insufficient number of necessary spare parts due to the undeveloped market for hydrogen heating.

The main nuances of hydrogen boilers

The power of hydrogen-based boilers is selected depending on the area of \u200b\u200bthe structure to be heated.

With the help of technology of this kind, you can solve many problems related to heating. This is due to the simultaneous operation of several channels designed to generate hydrogen energy (there can be a maximum of 6).

The modular system inherent in hydrogen boilers ensures the independent operation of the channels, without in any way affecting the decrease in the efficiency of the installation. Each individual channel contains its own catalyst.

Benefits of heating with hydrogen

A hydrogen-powered boiler is in demand for many reasons:

- The inexhaustibility of hydrogen, as well as the ability to obtain it in any quantity.

- The production of hydrogen is considered more economically profitable than the constant extraction of minerals with combustible properties (gas, coal, oil, etc.).

- The heating system works without emissions harmful to people and the atmosphere, emitting ordinary water vapor.

- There is no need for a flame (hydrogen heating works on the basis of chemical reactions).

- The boiler has the highest efficiency.

- The device is completely silent.

- There is no need for the construction and operation of the chimney.

- The safety requirements for hydrogen heating are lower than for gas-based installations.

Disadvantages of hydrogen boilers

Despite the many advantages, it is important to know about the disadvantages of such units:

- the need for constant replenishment of the catalyst;

- explosion hazard of the element if strict requirements are not met;

- inconvenient transportation of hydrogen;

- lack of specialists in installation, as well as service maintenance of such equipment in Russia;

- insufficient number of necessary spare parts due to the undeveloped market for hydrogen heating.

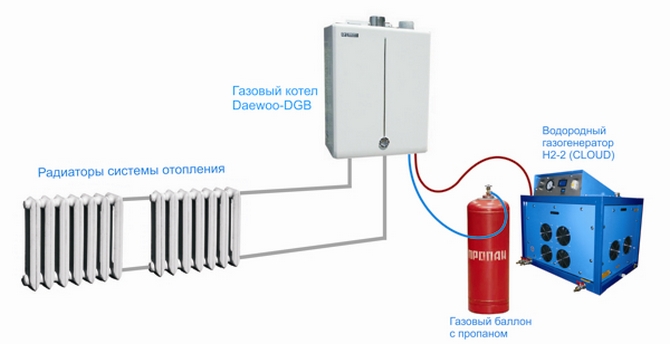

Pros and cons of hydrogen heating boilers

Since hydrogen is used as a fuel in heating devices, consider the advantages of an energy carrier:

- Hydrogen in cylinders can be purchased in any region of the country.

- Heating systems using hydrogen do not require human intervention for operation, because they represent a closed cycle.

- Affordable fuel price is the main advantage.

- The amount of thermal energy released is 121 MJ/kg, which is much higher than that of propane, which is 40 MJ/kg.

It is worth noting about the disadvantages of hydrogen fuel:

- the noise level during the operation of the old-style boiler is high;

- if the normative pressure is exceeded, an explosive situation is created;

- the unit consumes a lot of water;

- in some localities it is difficult to buy hydrogen cylinders;

- in older installations, it is necessary to make a separate chimney for the heated steam released during the catalytic reaction.

The advantages of hydrogen boilers are as follows:

- The unit does not emit harmful compounds into the atmosphere.

- Hydrogen does not burn, but gives off heat when interacting with oxygen. Water is formed as a result of a catalytic reaction.

- At a coolant temperature of only 40 degrees, heat loss is excluded.

- During the operation of the boiler, a chemical reaction takes place, which proceeds without the use of an open flame.

- Modern hydrogen boilers are distinguished by silent operation, they do not require a separate chimney, because heated steam and water are immediately supplied to the heating system. Thanks to this, the unit can be installed anywhere.

The disadvantages of hydrogen units are associated with increased quality requirements for all constituent elements and assemblies. To maintain and repair the device, you will have to involve specialists. It is quite difficult to find spare parts for heating equipment.

How to make a hydrogen boiler with your own hands?

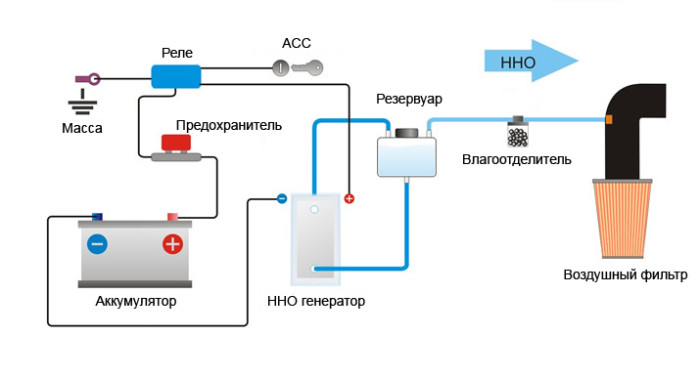

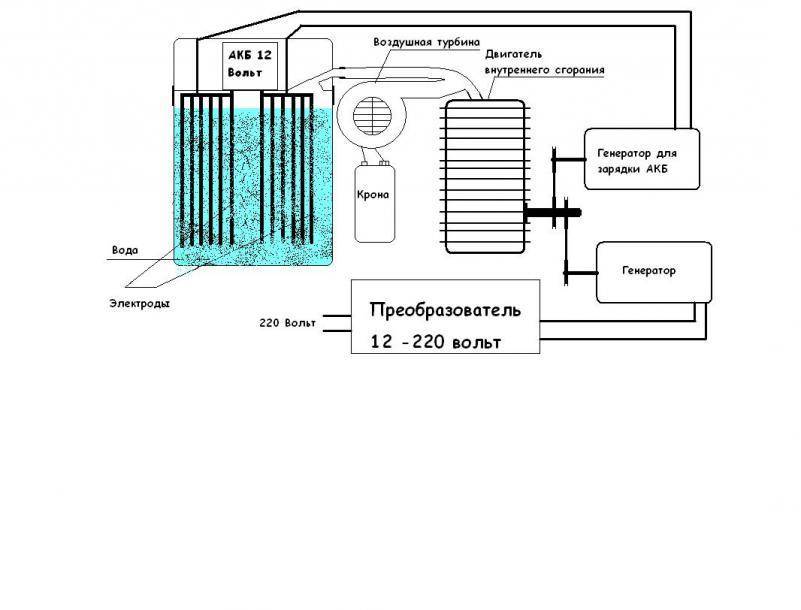

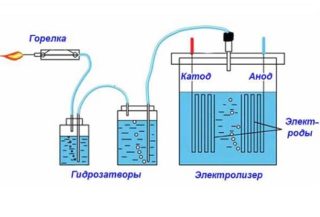

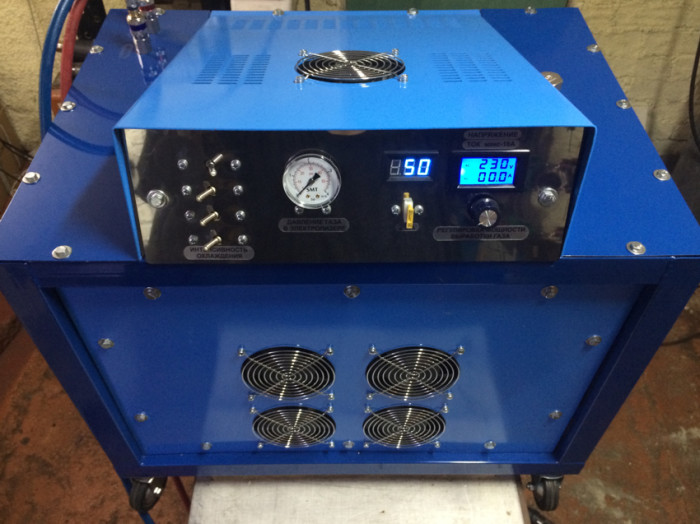

It is possible to make a heating boiler on hydrogen on the basis of an NHO generator - this is a conventional electrolyzer.

To make a burner you will need:

- stainless steel sheet 2 mm thick, 50x50 cm in size;

- a sheet of steel 2 mm thick with a size of 100x100 cm;

- sealed plastic container 1.5 l;

- transparent tube from the water level 10 m long;

- fittings for a hose with a diameter of 8 mm;

- bolts 6x50, nuts, washers;

- profile pipe 20x20 mm;

- profile pipe 40x40 mm;

- pipe with a section of 20-30 mm;

- plugs;

- Bulgarian;

- sealant;

- knife;

- welding machine;

- gas nozzles;

- drill.

To install the boiler, a 12-volt power supply is needed.

How to make a hydrogen boiler with your own hands:

- Cut out 16 rectangles of the same size from a 50x50 cm steel sheet with a grinder. The system will require a cathode and an anode, which will be plates, 8 of which will be cathodes, and 8 anodes.

- On the plates, drill a hole for the bolts, 1 hole on each plate.

- Place the plates in the container so that the alternation of plus and minus is observed. Isolate the plates with a transparent tube, which is pre-cut into washers or strips up to 2 mm thick.

- Fixing the plates on the bolts and washers in this way - put the washer on the bolt, then the anode plate, then 3 washers and the cathode plate. So, after 3 washers, string all the plates. After that, the nuts are tightened.

- Now you need to fix the structure in the container. To do this, you need to make holes in the walls of the container, where the bolts are inserted. Be sure to put washers on the bolts.

- Now you need to make 2 holes in the cover for fittings (threaded steel pipe). Nut fixation.

- Seal the joint points with sealant.

- Connect a compressor to one pipe, and a pressure gauge to the other. Pump up pressure to 2 atmospheres and check the pressure gauge for half an hour - if the pressure does not change, then the tightness is normal, if there are changes, check the joints and seal all the seams again.

- Install a check valve to the branch pipe, connect a hydrogen cylinder to it, and connect water to the second branch pipe. Connect the electrodes to the bolts for fixing the plates, through which the electric current will flow.

- In the process of passing the current, the water will begin to boil and the reaction process will begin, which is necessary for heating the system.

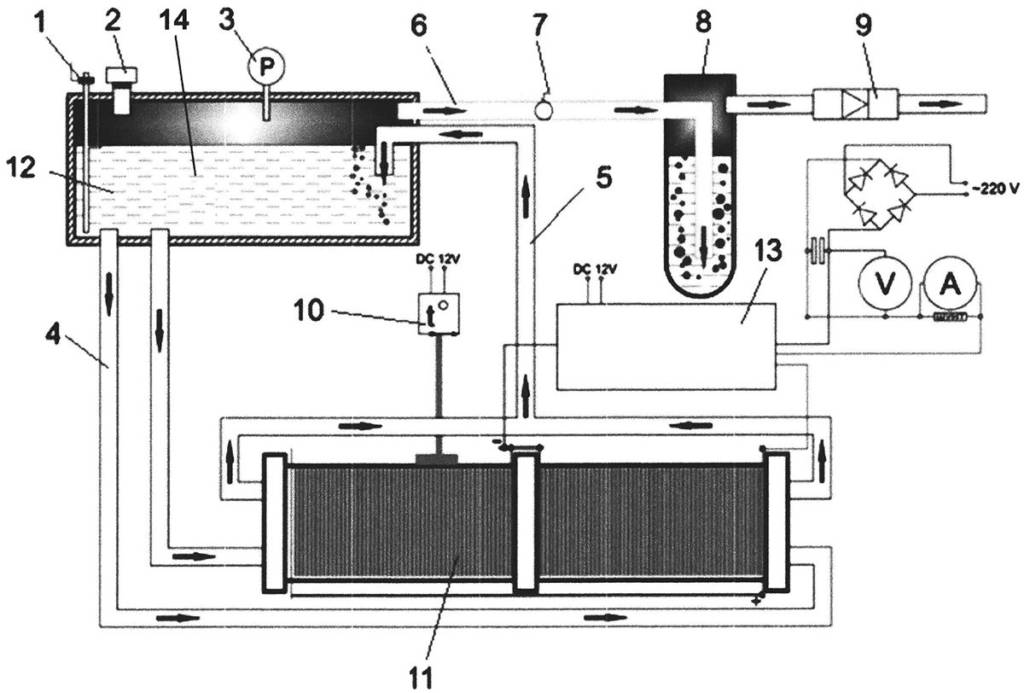

To make the boiler itself, you will need to perform the following steps:

- cut a 20x20 mm pipe into 8 pieces of 30 cm each;

- cut a 40x40 mm pipe into 3 parts - one of them is 20 cm, two are 8 cm each;

- in a pipe of 20 cm with a section of 40x40 mm, make holes in the middle of the length from two opposite sides for a pipe of 40x40 mm;

- insert tubes with a section of 40x40 mm at 8 cm into the holes at a right angle, weld;

- weld plugs to the ends of the resulting cross, and equip the fourth side with a plug with a branch pipe, which is needed to connect the hydrogen pipe;

- set aside 7-8 cm from the center of the cross and drill a hole 10-14 mm in size in each part, in total there will be 4 holes;

- weld nozzles into the holes;

- weld 2 profile pipes of section 20x20 mm to each end part in such a way that a right angle is formed with the plane of the cross;

- from the remaining sheet of steel, cut out 3 walls of the body for the boiler measuring 30x30 cm;

- drill 2 holes in 2 walls, in total you will get 4 holes with a diameter of 20-30 mm at the points where the nozzles are located, and in the third sheet make a hole with a diameter of 10 mm;

- now cut the pipe into 20-30 mm diameter pieces of 50-60 cm and weld it to a smaller steel sheet (body wall);

- take a pipe with a diameter of 10 mm 4 cm less than the welded pipes and drill a couple of holes in it at the top and bottom so that the pipe can be welded;

- attach the pipe to a steel sheet with smaller holes and weld;

- now this entire structure must be turned over and installed on a second steel sheet so that the tubes enter the pre-made holes;

- weld tubes to the sheet;

- now weld the entire structure with the burner to the last sheet of steel;

- weld pipes for transporting the coolant to the holes in the housing;

- install a temperature sensor on the inlet pipe, a combustion sensor (detector) on the burner;

- both sensors must be connected to automatic controllers and visual-sound warning systems;

- check the housing for leaks.

Now it remains to make an external protective case of the required dimensions from a steel sheet. Install the structural units inside the case, hermetically connect them and double-check the tightness. You can test the system by first dissolving salt or alkali in water to speed up the reaction and increase the hydrogen yield.

If you have any questions, watch the video.

Model Selection Criteria

A hydrogen boiler for a home must be selected taking into account the following criteria:

- heating power must comply with the requirements of the heating system and heat carrier used, and also take into account the area of \u200b\u200bheated premises;

- the dimensions of the combustion chamber must be equipped with the necessary number of heat exchangers, allowing you to organize several heating circuits;

- the electrical network in the building must withstand the power consumption of electricity by the boiler;

- all structural elements of the boiler must be made of high quality materials and have a sufficient margin of safety and wear resistance;

- the protection unit must be certified and comply with safety standards.

An example of a hydrogen heating boiler

An example of a hydrogen heating boiler

Experiments with eternal log

An eternal log is a small metal tank with small holes for the release of water vapor.This container is filled with water, the neck is tightened with a bolt, and placed on the bottom of the furnace. The container is heated to a high temperature, water vapor comes out of it, flowing directly onto burning coals.

As a result, according to the experimenters, black soot disappears in the smoke. Those. supposedly the carbon particles normally carried down the chimney now all react with oxygen.

The flame becomes intense with long tongues, etc.

But the truth is, measurements of the real heat received were not carried out, it is impossible to measure it at home, but all the signs of a large energy return are present ....

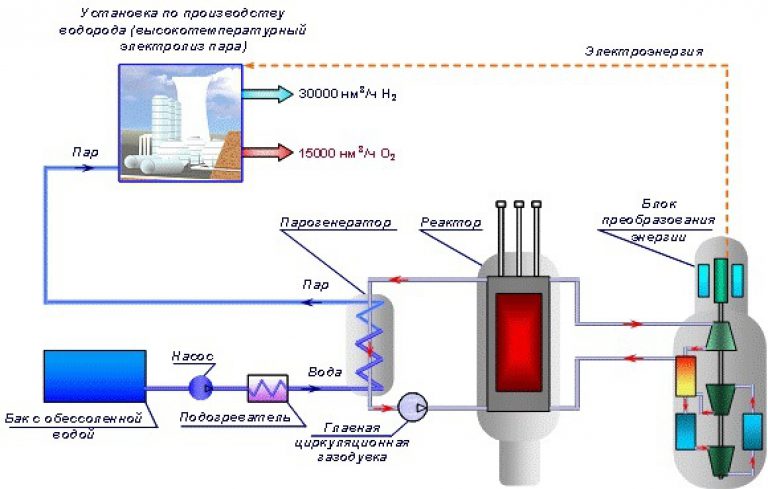

Prospects for hydrogen as a fuel for a heating boiler

- Hydrogen is the most common "fuel" in the universe and the tenth most common chemical element on Earth. Simply put - you will not have problems with fuel reserves.

- This gas cannot harm people, animals or plants - it is not toxic.

- The "exhaust" of a hydrogen boiler is absolutely harmless - the combustion product of this gas is ordinary water.

- The combustion temperature of hydrogen reaches 6000 degrees Celsius, which indicates the high heat capacity of this type of fuel.

- Hydrogen is 14 times lighter than air, that is, in the event of a leak, the “emission” of fuel will evaporate from the boiler house on its own, and in a very short time.

- The cost of one kilogram of hydrogen is 2-7 US dollars. In this case, the density of gaseous hydrogen is 0.008987 kg/m3.

- The calorific value of a cubic meter of hydrogen is 13,000 kJ. The energy intensity of natural gas is three times higher, but the cost of hydrogen as a fuel is ten times lower. As a result, alternative heating of a private house with hydrogen will cost no more than the practice of using natural gas.At the same time, the owner of a hydrogen boiler does not need to pay the appetites of the owners of gas companies and build an expensive gas pipeline, as well as go through an extremely bureaucratic procedure for coordinating all sorts of “projects” and “permits”.

In short, as a fuel, hydrogen has the brightest prospects, which have already been appreciated by the aerospace industry, which uses hydrogen to “refuel” rockets.

Modern development - hydrogen heating boiler

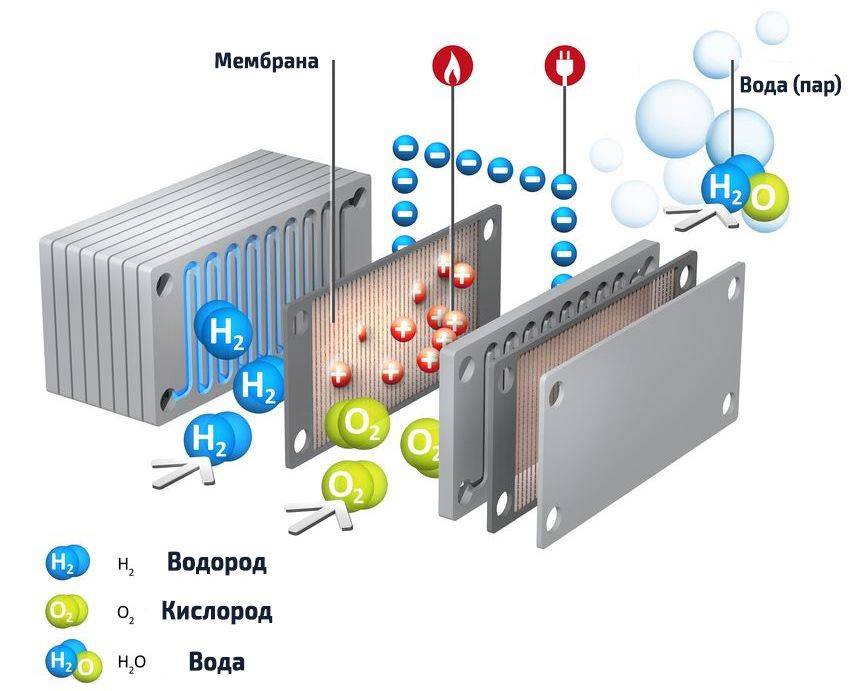

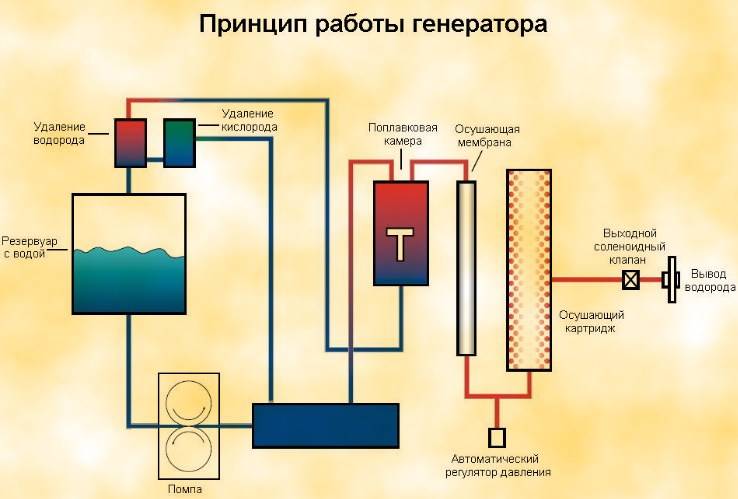

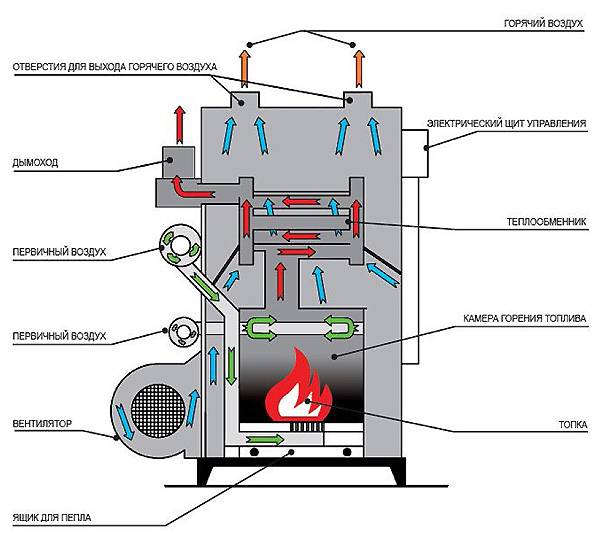

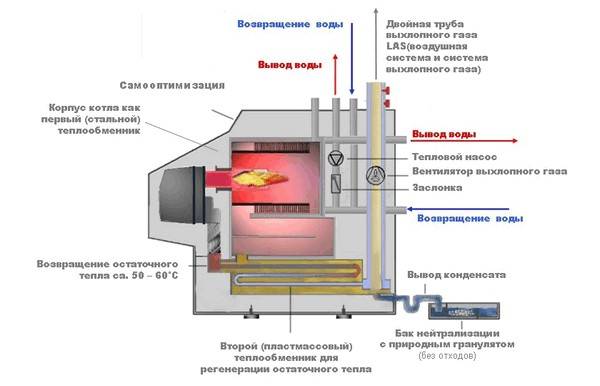

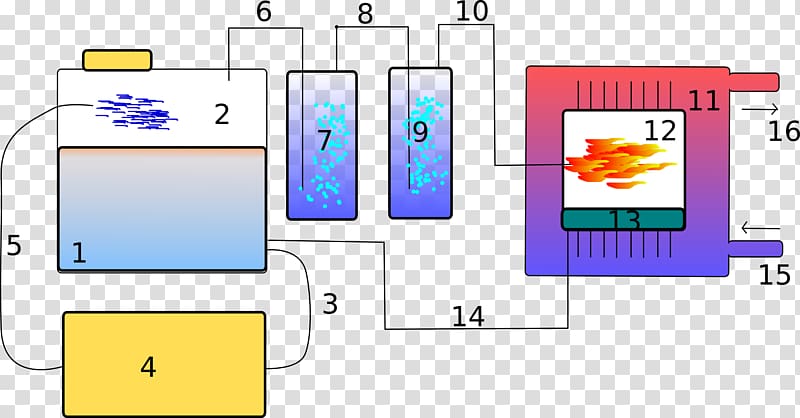

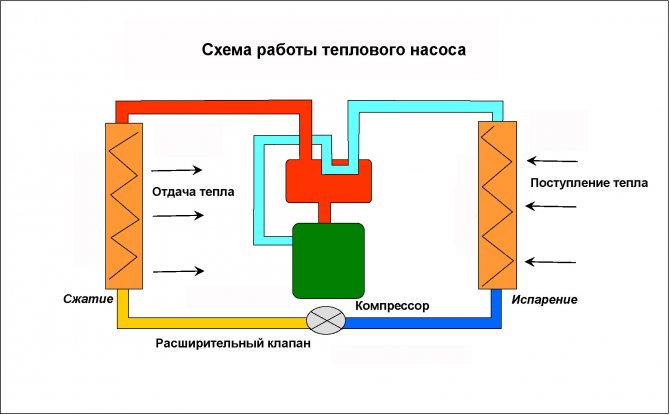

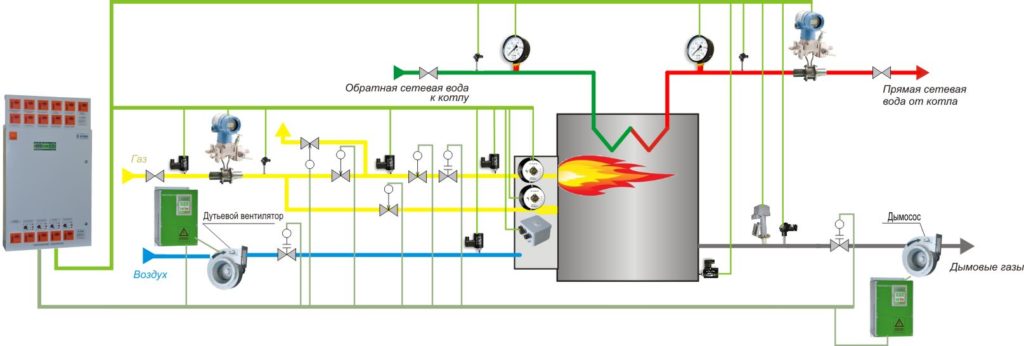

How does a hydrogen heating boiler work

In the same way as a conventional gas boiler:

- Fuel is supplied to the burner.

- The burner torch heats up the heat exchanger.

- The coolant poured into the heat exchanger is transported to the batteries.

Only instead of the main gas pipeline or tanks with liquefied fuel for the production of fuel, it is necessary to use special installations - hydrogen generators.

Moreover, the most common type of household generator is an electrolytic plant that splits water into hydrogen and oxygen. The cost of fuel produced by electric generators for heating with hydrogen reaches 6-7 dollars per kilogram. At the same time, water and 1.2 kW of electricity are needed to produce a cubic meter of combustible gas.

But in this case, you can save money on the removal of combustion products. After all, in the process of burning a mixture of oxygen and air, only water vapor is released. So such a boiler does not need a “real” chimney.

Advantages of hydrogen boilers

- Hydrogen can "fire" any boilers. That is, absolutely any - even the old "Soviet" units purchased in the 80s of the last century. To do this, you will need a new burner and granite or fireclay stone in the furnace, which increases thermal inertia and levels the effect of overheating of the boiler.

- Hydrogen boilers have increased heat output. A standard gas boiler for 10-12 kW on hydrogen will “give out” up to 30-40 kilowatts of thermal power.

- For heating with hydrogen, by and large, only a burner is needed. Therefore, even a solid fuel boiler can be converted “under hydrogen” by installing the burner in the furnace.

- The base for obtaining fuel - water - can be removed from the water tap. Although the ideal semi-finished product for the production of hydrogen is distilled water, which is mixed with sodium hydroxide.

Cons of hydrogen boilers

- A small range of hydrogen boilers and gas generators of industrial type. Most sellers offer "homemade" products with dubious certification.

- High price of industrial models.

- The explosive "character" of the fuel - in a mixture with oxygen (in a ratio of 2: 5), hydrogen turns into an explosive gas.

- High noise level of gas generating installations.

- High flame temperature - up to 3200 degrees Celsius, making it difficult to use hydrogen as a fuel for a kitchen stove (special dividers are needed). However, H2ydroGEM, a hydrogen heating boiler manufactured in Italy by giacomini, is equipped with a burner with a flame temperature of up to 300 degrees Celsius.