- Vortex impeller pumps

- Device diagram and principle of operation

- Benefits of home use

- Main Differences Between Peripheral and Centrifugal Pumps

- Types of self-priming pumps by the presence of an ejector

- Ejector

- Application area

- What are the benefits of a centrifugal pump?

- General description and varieties

- Principle of operation + video review of models

- Types of self-priming pumps

- The device and principle of operation of a centrifugal pump

- Working principle of self-priming peripheral pump

- Self-priming units

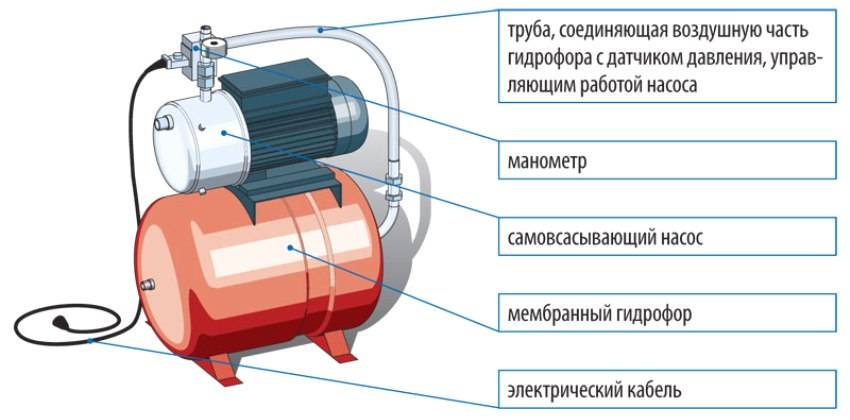

- Characteristics of pumping stations

- Structure and principle of operation

- Centrifugal

- Vortex

- Correct installation of the suction line

Vortex impeller pumps

For pumping clean water and carbonated (foaming) liquids in everyday life and in production, vortex pumps are used.

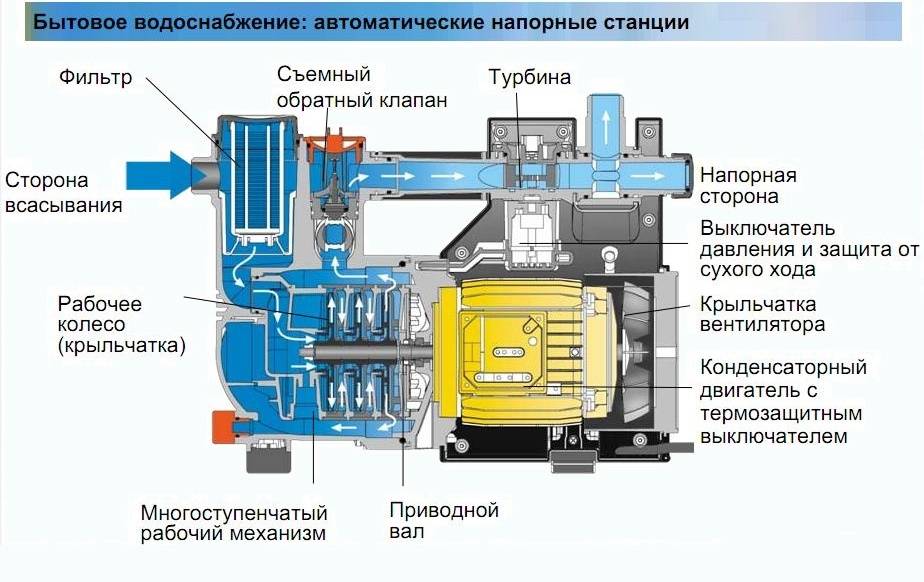

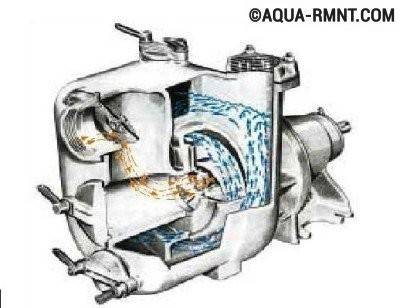

Device diagram and principle of operation

The vortex pump consists of an electric motor with a fan, a shaft, an impeller (impeller), housing parts and fasteners. The scheme of the device for each model is different. According to the principle of operation, the device belongs to dynamic - it uses centrifugal force, but the water in the working chamber moves towards the center in a spiral, a water vortex is formed.

Benefits of home use

The main advantage of vortex pumps is their simplicity of design, they are easy to install and repair on their own.When pumping water, they create a powerful pressure

Another important advantage of these units is that they can operate even in the presence of air in the pipeline, as they are suitable not only for liquids, but also for gaseous media.

Only powerful submersible units are suitable for pumping water from wells with a depth of more than 8 m. Their disadvantages are high price, complexity of maintenance and repair, high power consumption. It is cheaper and easier to install a surface pump with an ejector (ejector, ejector).

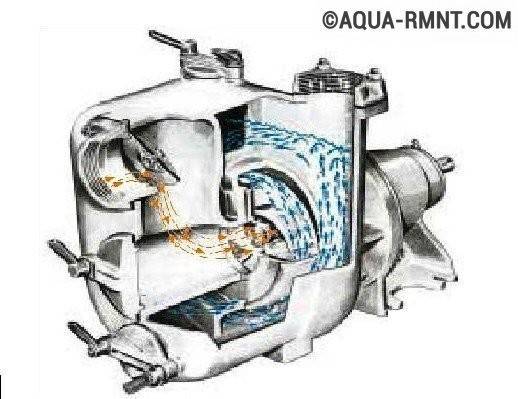

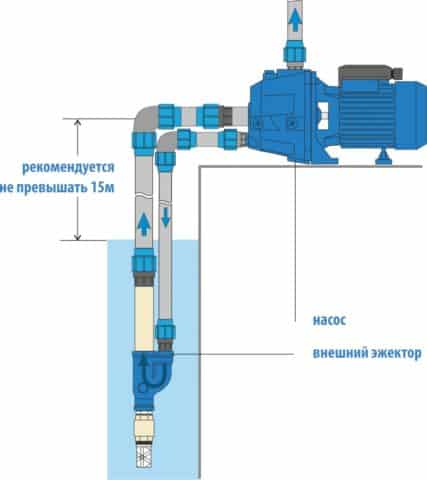

An ejector is a device that transfers the kinetic energy of a liquid jet moving at a high speed to the pumped medium. There are two types of these devices:

- Submersible (remote, external). It is installed at the bottom of a well or well in the suction line above the check valve. Suction depth - up to 30 m.

- Built-in (internal). The device is inside the pump. The suction depth increases slightly - up to 9 m.

For use in the garden, you can make an ejector with your own hands.

Main Differences Between Peripheral and Centrifugal Pumps

Centrifugal models are much superior to vortex ones in size and weight, however, they work somewhat quieter. In addition, the simplicity of their design without fear can allow pumping liquids with foreign inclusions - such as fecal and drainage aggregates. Vortex pumps are quite sensitive, so they are specially equipped with filters;

Centrifugal units are considered more reliable - their service life can be up to 20 years. In repair, they are also quite simple, if desired, the problem can be fixed independently.Vortex units are considered thinner equipment that conducts scrupulous cleaning and high-speed pumping of liquid - it is unlikely that they will be able to repair them themselves;

Types of self-priming pumps by the presence of an ejector

The best mobile application for experienced BPlayers has appeared and you can absolutely free download 1xBet on your Android phone with all the latest updates and discover sports betting in a new way.

All models of self-priming units are divided into two types:

- Devices with built-in ejector;

- Pump with remote ejector.

In the first case, the mechanism pumps water by discharging the liquid itself. At the same time, the pump unit makes too much noise during operation, which requires a special room for equipment installation. The main advantage of such a unit is the ability to supply water from a depth of up to 10 meters.

Pumps with an external ejector are quieter, but at the same time, the level of immersion of the intake hose is several times lower. The principle of operation of such a mechanism is based on a hydraulic working unit that sucks in water and delivers it upward under high pressure.

Ejector

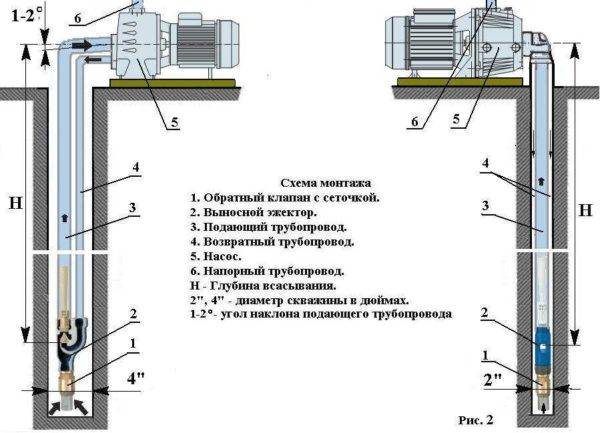

The greatest depth from which surface vortex and centrifugal pumps can lift water is 8-9 meters, often it is located deeper. To "get" it from there, an ejector is installed on the pumps. This is a tube of a special shape, which, when water moves through it, creates a vacuum at the inlet. So such devices also belong to the category of self-priming. The ejector self-priming pump can lift water from a depth of 20-35 m, and this is already more than enough for most sources.

External ejector connection diagram for wells of different diameters - two-inch on the right, four-inch on the left

The disadvantage is that in order to ensure operation, part of the understood water must be returned back, therefore, productivity is significantly reduced - such a pump can provide not very large water consumption, but no less electricity is spent on ensuring performance. When the injector is installed in a well or a well of sufficient width, two pipelines are lowered into the source - one supply of a larger diameter, the second, a return one, of a smaller one. An ejector is connected to their outlets, and a filter and a check valve are installed at the end. In this case, the disadvantage is also obvious - double the consumption of pipes, which means a more expensive installation.

In small diameter wells, one pipeline is used - the supply pipeline, and the well casing is used instead of the return one. Thus, a rarefaction zone is also formed.

Application area

Taking into account modern technological progress, vacuum installations have been significantly improved, they have found wide application in various fields of industry and in household appliances. Due to a special screw, the small dimensions of the device allow you to quickly create a high degree of rarefaction of the medium.

Vacuum water pumps are considered economical, have various applications:

- in the manufacture of metal products with a dense structure without pores;

- in the production of textiles, for quick drying without exceeding the temperature regime;

- when packaging dairy products, packaging meat and fish;

- in equipment with special requirements for a dry environment;

- for the full operation of vacuum suction cups;

- in scientific laboratories of various directions;

- in the pharmaceutical field, medicine.

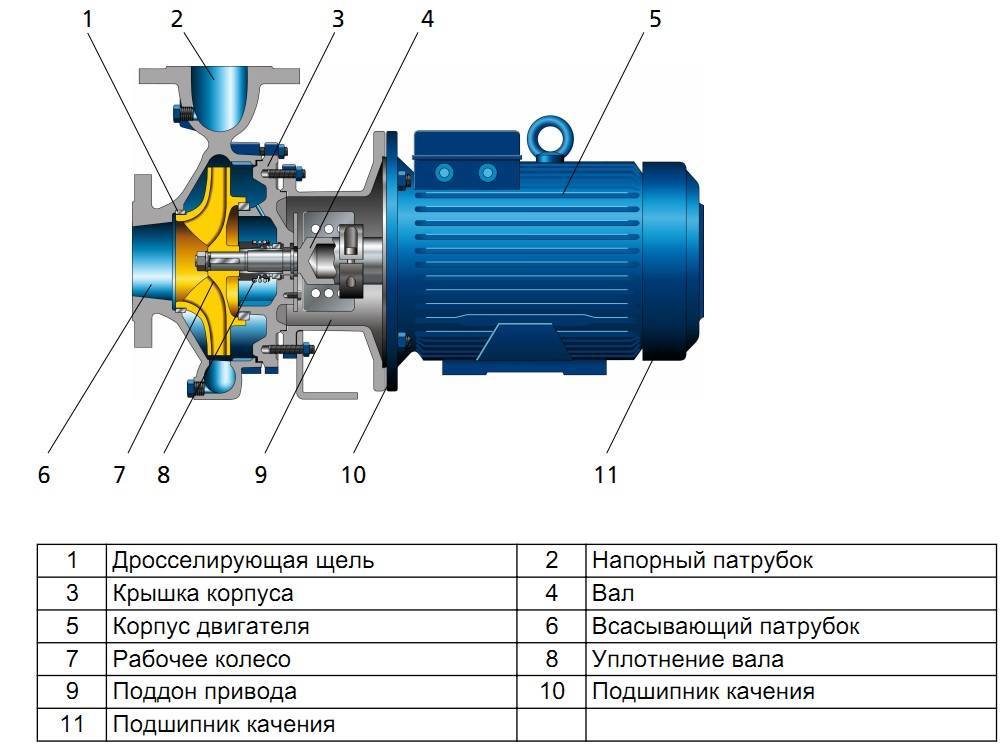

What are the benefits of a centrifugal pump?

Centrifugal pumps are used in industrial conditions, as well as for household needs at home and in the country. The basis of the operation of such devices is the formation of centrifugal force, which moves water and creates pressure. Rotating working mechanisms capture water, pressing it against the walls, and then throw it into the outlet hole.

Design features and purpose determine the presence of many varieties of this type, so in stores you can find single- and multi-stage pumps, submersible, surface, cantilever, horizontal, vertical.

All mechanisms of products are made from high-quality raw materials, there is practically no wear of parts. It is expected that the operation of the equipment will be continuous, so factors such as uncomplicated and quick service after purchase are taken into account in the production.

water pump for summer cottages (centrifugal) - pictured

The peculiarity of the centrifugal pump is that it can work even at high temperatures, in an aggressive environment. Each specific model range of pumps has its own characteristics, characteristics and specifics, some samples can operate at a temperature of +350 °C.

The main advantage of centrifugal pumps is durability, long service life, reasonable price, high efficiency, and it is also possible to install automation. In addition to a large number of advantages, models of this type have disadvantages - the need to fill the case with water (a small centrifugal force inside does not allow water to be sucked into the pipe), air entering the inlet can stop the pump, voltage drops in the mains affect the operation of the device not in the best side.

The cantilever centrifugal pump is quite widespread and is used to perform work related to impurities and small solid particles. Single-stage horizontal cantilever pumps are used for water supply at home, cottages. Multi-stage models are able to create powerful pressure thanks to several identical, series-connected single-stage devices.

Water pumps for homes, cottages, irrigation and irrigation systems, as a rule, are purchased centrifugal so that they can be installed in a heating system powered by a well. Submersible and semi-submersible pumps have their pros and cons, the first type is easy to install, the second is serviced. To install a submersible pump, certain conditions must be created. The work is quite laborious, however, many summer residents and owners of private houses prefer to buy submersible pumps. The disadvantage of submersible products is their high responsiveness to various contaminants and sand.

submersible water pump in operation - pictured

Quattro Elementi Drenaggio 400 is a good submersible drainage pump, centrifugal, suitable for summer cottages. It pumps out water, the maximum diameter of solid particles is 5 mm, so that it will pump over turbid, not too dirty liquid without problems. According to reviews, pumping too far - the power is not enough, and the turbine inlet slots, which constantly need to be cleaned, can become clogged. Maximum pumping per hour 7000 liters.

In comparison, below are the models of centrifugal pumps that are in the greatest consumer demand:

➤ surface - Caliber NBC-600 PK, Caliber NBC-380, Patriot R1200 INOX, Patriot R900, Parma NBC-037 A, Sturm WP9751A for clean water, STAVR NP-800, ZUBR ZNS-800 self-priming, etc.;

➤ submersible - Caliber YGWC-1.2 / 50-370 borehole, Aquarius BTsPE 0.5 for wells or a well, Italian-made Nocchi Dominator, Whirlwind CH-60, Gileks Aquarius Prof 55/35, Grundfos SBA 3-35A;

➤ drainage - Quattro Elementi Drenaggio 400, General pump S-500S. AL-KO SUB 6500 Classic, Hummer Nap 550B, Elitech NPD 600H, Redverg RDS 750 PD etc.

General description and varieties

Self-priming pump is a system for movement of liquids. It is commonly used to move water from wells or open sources for consumption. In addition, there is also a non-self-priming one, but such a device is not as effective and is rarely used.

The self-priming pump is small in size, so it can be placed even in a small room

Such a pump is usually of a surface type, that is, pumping water from a depth of up to 10 meters, it lifts it into the main device. Lifting occurs due to special wheels equipped with blades, and at the same time creating an area of \u200b\u200blow pressure. Thus, the so-called absorption of water occurs. In addition, any suction system or pump of this type is equipped with an engine and a working chamber. The injection mechanism is located in the working chamber. The pump and the motor, or rather, their shafts, are connected using a pump. How reliable the connection is determines the type of seal selected.

They, in turn, are of two types:

- Omental. Pretty budget option, but do not rely on its reliability. Tightness and resistance to water flow at a very low level.

- End.Very reliable option, has excellent hermetic properties, does not let water through. But its price is quite high compared to the previous version.

Household pumps without pre-filling liquid can be divided into three types:

- Centrifugal;

- Vortex;

- Ejector.

They will be discussed below.

Principle of operation + video review of models

The basis of the functionality is the forced mechanical removal of the environment from a limited space. This happens in several ways:

jet type pump

The unit functions by supplying a jet of water or steam molecules from the side pipe, which carries out the substance at high speed and creates a vacuum. The advantage of this scheme is the absence of moving elements, which significantly increases the life of the structure. The downside is the mixing of components and low efficiency.

Mechanical type pump

The principle of operation of the vacuum pump includes a rotating design or reciprocating action, which creates the effect of expanding the space inside by filling it from the inlet pipe for subsequent expulsion through the outlet pipe. There are a sufficient number of constructive solutions of this principle. Such designs are characterized by high efficiency.

Types of self-priming pumps

Manufacturers produce self-priming pumps with a built-in or remote ejector. In this type of pumping equipment, the suction and rise of the liquid occurs due to its discharge. During operation, ejector installations make too much noise, so a special room is selected for their placement on the site, located at a sufficient distance from the residential building.The main advantage of self-priming pumps with an ejector is their ability to lift water from a great depth, on average about 10 meters. In this case, a supply pipe is lowered into the water intake source, and the pump itself is installed at a certain distance from it. This arrangement allows you to freely control the operation of the equipment, which affects the duration of its use.

The second type of equipment includes self-priming pumps that provide water lifting without ejectors. In models of this type of pumps, liquid suction is provided by a hydraulic device that has a special multi-stage design. Hydraulic pumps operate silently, unlike ejector models, but they are inferior to them in terms of the depth of liquid intake.

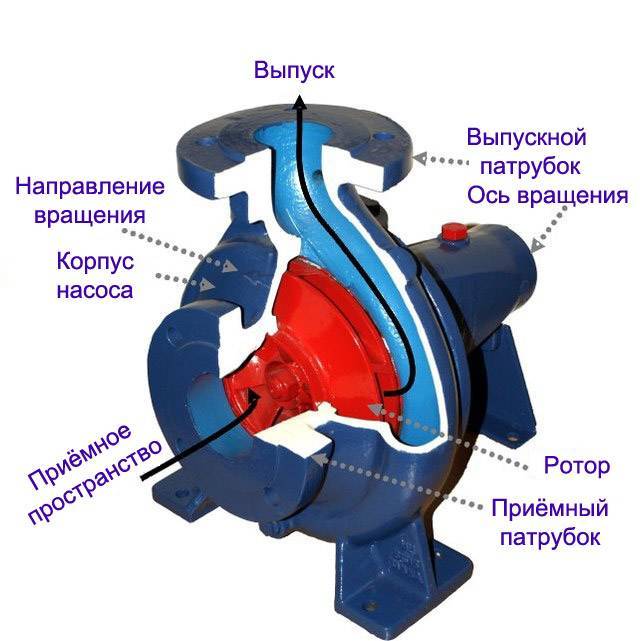

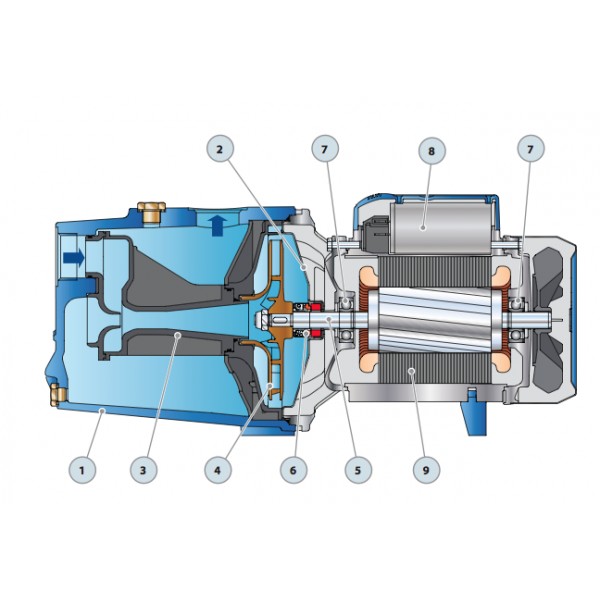

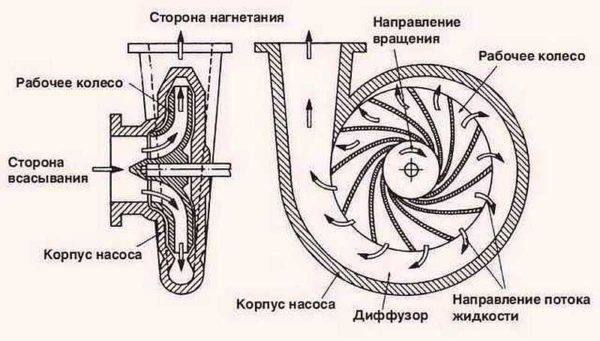

The device and principle of operation of a centrifugal pump

The figure shows the device of a self-priming centrifugal pump. In the body, which has a spiral shape, there is a rigidly fixed wheel, which consists of a pair of disks with blades inserted between them. The blades are bent in the opposite direction from the direction of rotation of the impeller. With the help of nozzles of a certain diameter, the pump is connected to the pressure and suction pipelines.

So schematically, you can imagine the device of a self-priming centrifugal pump for pumping water used in private homes and cottages

The principle of operation of centrifugal self-priming pumps is as follows:

- After the casing and the suction pipe are filled with water, the impeller starts to rotate.

- The centrifugal force that occurs when the wheel rotates displaces water from its center and throws it to the peripheral areas.

- Due to the increased pressure created in this case, the liquid is displaced from the periphery into the pressure pipeline.

- At this time, in the center of the impeller, on the contrary, the pressure decreases, which causes the flow of liquid through the suction pipe into the pump casing.

- According to this algorithm, water is continuously supplied by a self-priming centrifugal pump.

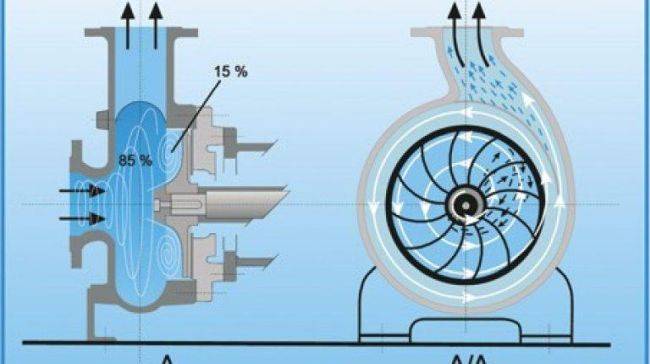

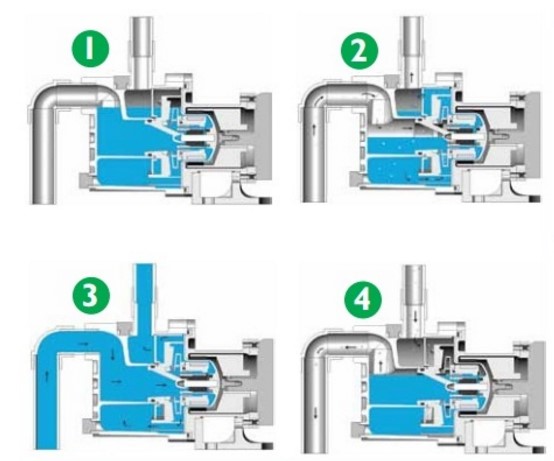

Working principle of self-priming peripheral pump

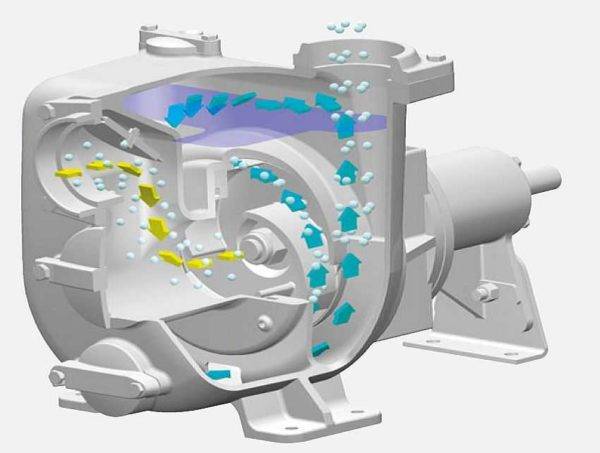

The air, shown in yellow in the figure, is sucked into the pump housing due to the vacuum created by the rotation of the impeller (impeller). Next, the air that has entered the pump is mixed with the working fluid contained in the unit housing. In the figure, this liquid is shown in blue.

This figure shows the device and principle of operation of a vortex self-priming pump for lifting liquid to a height of no more than eight meters.

After the mixture of air and liquid enters the working chamber, these components are separated from each other, based on the difference in their densities. In this case, the separated air is removed through the supply line, and the liquid is recirculated in the working chamber. When all air is removed from the suction line, the pump fills with water and starts working in centrifugal installation mode.

Possible versions of vortex self-priming water pumps manufactured by manufacturers for domestic use by owners of private houses and country cottages

A non-return valve is installed on the suction flange, which is designed to prevent backflow of air into the pipeline, as well as to ensure a constant presence in the chamber working fluid pump. Thanks to this device and the principle of operation, vortex self-priming pumps are capable, with a filled chamber, of lifting liquid from a depth not exceeding eight meters, without installing a bottom valve.

Self-priming units

Many, for sure, remember that in order to start the water pump, it is necessary to first fill the system with water, otherwise the device cannot draw in the liquid itself and its current will not start. Also, due to dry running, overload and overheating occur, which can lead to premature equipment failure.

The main difference between a self-priming pump is that it is able to independently remove air from the pipes, so it does not require constant monitoring, although water will also have to be added for the first start.

These devices are used for different purposes:

- Increasing pressure in the water supply system;

- Raising water from a well or well.

Self Priming Centrifugal Pump

All self-priming pumps are divided into the following types according to the principle:

- centrifugal;

- Vortex;

- Axial;

- Inkjet;

- Membrane;

- piston;

- Rotary.

There is also a division according to the installation method:

- Submersible - work directly in the water, sink to the bottom of the well, where they push the water up. The advantage of such equipment is greater productivity - they are able to raise water to a greater height. The disadvantage is the complexity of maintenance.

- Surface - placed in a dry place in a well or in a specially equipped room. They cannot raise water to a height of more than 7-8 meters.

Centrifugal self-priming food pumps with ejector

By power, working life and performance, pumps are divided into domestic and industrial.

Self-priming pumps are not only used for plumbing. They are used in storm systems, for watering land, sewers, drainage systems, and so on.

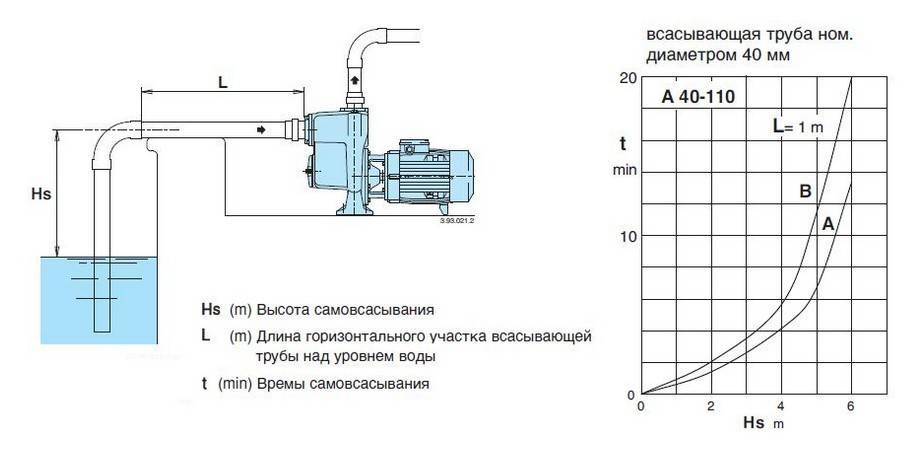

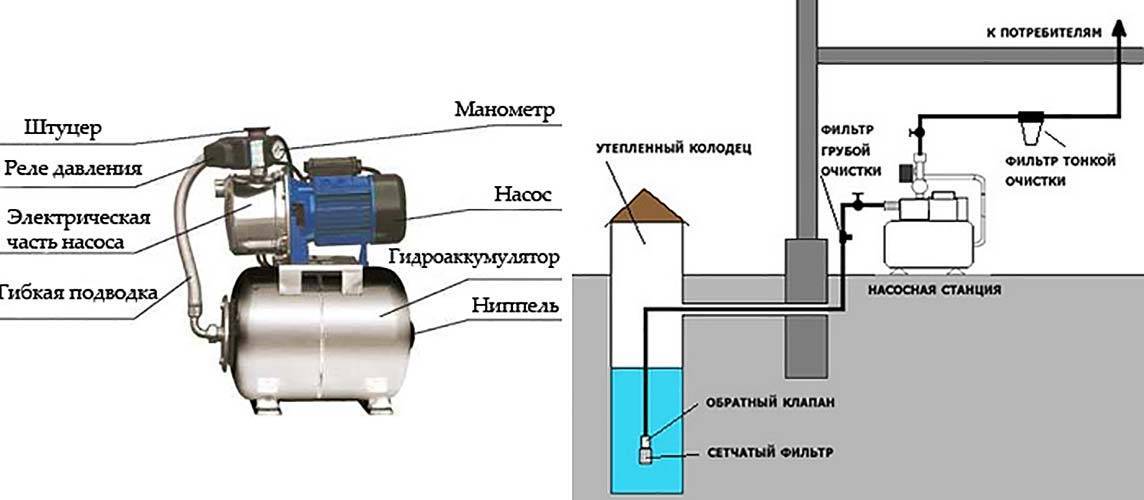

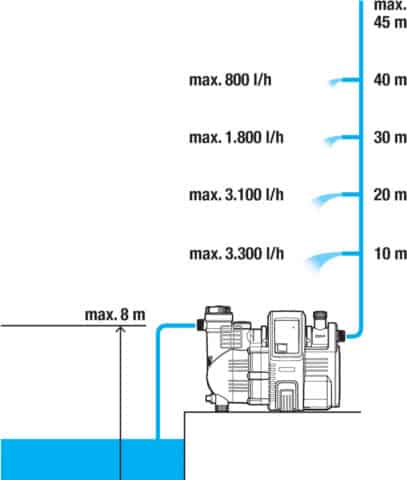

Characteristics of pumping stations

Now let's take a closer look at the main operating parameters of pumping equipment.

First of all, it is worth correlating the depth of water rise with the capabilities of the selected unit. In this case, the horizontal length of the pipeline to the pump must also be taken into account.

As mentioned earlier, for surface pumps, this parameter rarely exceeds 7 meters. Theoretically, it is possible to reach 10, but then such power and its losses will be required that such water will literally become “golden”.

Maximum liquid lifting height for the pump

If the depth of the well is much greater, then you will have to use a submersible or ejector pump. The first one goes down, and the second one is also mounted on the surface, but unlike the simple version, it is equipped with an additional device - an ejector.

The principle of operation of the external ejector

Such a unit is capable of lifting water from a depth of up to 25 meters. The effect is achieved due to the fact that part of the raised water returns back down and is injected under pressure through an additional nozzle into the main stream. Bernoulli's law comes into force, and water from the bowels rushes up due to the speed of the current.

The disadvantage of such units is increased noise and reduced efficiency, since part of the raised liquid is transferred back.

It is also worth paying attention to other parameters:

Maximum temperature of the working environment;

Maximum outlet pressure;

The volume of pumped liquid in liters per hour;

Permissible degree of water pollution - important when choosing a garden pump;

Structure and principle of operation

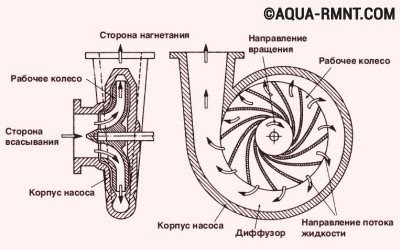

According to the mode of action, a self-priming pump can be vortex and centrifugal. In both, the key link is the impeller, only it has a different structure and is installed in a housing of a different handicap. This changes the principle of operation.

Centrifugal

Centrifugal self-priming pumps have an interesting structure of the working chamber - in the form of a snail. Impellers are fixed in the center of the body. There can be one wheel, then the pump is called single-stage, there can be several - a multi-stage design. Single-stage always operate at the same power, multi-stage can change performance depending on the conditions, respectively, they are more economical (less power consumption).

Self-priming centrifugal pump device

The main working element in this design is a wheel with blades. The blades are bent in the opposite direction with respect to the movement of the wheel. When moving, they seem to push the water, squeezing it to the walls of the case. This phenomenon is called centrifugal force, and the area between the blades and the wall is called the "diffuser". So, the impeller moves, creating an area of increased pressure on the periphery and pushing water towards the outlet pipe.

Scheme of the movement of water in a centrifugal pump

At the same time, a zone of reduced pressure is formed in the center of the impeller. Water is sucked into it from the supply pipeline (suction line). In the figure above, incoming water is indicated by yellow arrows. Then it is pushed by the impeller to the walls and rises up due to centrifugal force. This process is constant and endless, repeating as long as the shaft is spinning.

Their disadvantage is connected with the principle of operation of centrifugal pumps: the impeller cannot create centrifugal force from the air, therefore, the housing is filled with water before operation. Since pumps often operate in intermittent mode, so that water does not flow out of the housing when stopped, a check valve is installed on the suction pipe. These are the features of the operation of centrifugal self-priming pumps. If the check valve (it must be mandatory) is at the bottom of the supply pipeline, the entire pipeline has to be filled, and this will require more than one liter.

| Name | Power | pressure | Maximum suction depth | Performance | Housing material | Connecting dimensions | Price |

|---|---|---|---|---|---|---|---|

| Caliber NBTs-380 | 380 W | 25 m | 9 m | 28 l/min | cast iron | 1 inch | 32$ |

| Metabo P 3300 G | 900 W | 45 m | 8 m | 55 l/min | cast iron (stainless steel drive shaft) | 1 inch | 87$ |

| ZUBR ZNS-600 | 600 W | 35 m | 8 m | 50 l/min | plastic | 1 inch | 71$ |

| Elitech HC 400V | 400W | 35 m | 8 m | 40 l/min | cast iron | 25 mm | 42$ |

| PATRIOT QB70 | 750 W | 65 m | 8 m | 60 l/min | plastic | 1 inch | 58$ |

| Gilex Jumbo 70/50 H 3700 | 1100 W | 50 m | 9 m (integrated ejector) | 70 l/min | cast iron | 1 inch | 122$ |

| BELAMOSS XI 13 | 1200 W | 50 m | 8 m | 65 l/min | stainless steel | 1 inch | 125$ |

| BELAMOS XA 06 | 600 W | 33 m | 8 m | 47 l/min | cast iron | 1 inch | 75$ |

Vortex

The vortex self-priming pump differs in the structure of the casing and the impeller. The impeller is a disk with short radial baffles located at the edges. It's called an impeller.

The structure of the vortex pump

The housing is made in such a way that it quite tightly covers the "flat" part of the impeller, and a significant lateral clearance remains in the baffle area. When the impeller rotates, the water is carried away by the bridges. Due to the action of centrifugal force, it is pressed against the walls, but after some distance it again falls into the zone of action of the partitions, receiving an additional portion of energy. Thus, in the gaps, it also twists into vortices. It turns out a double vortex flow, which gave the name to the equipment.

Due to the peculiarities of work, vortex pumps can create pressure 3-7 times more than centrifugal ones (with the same wheel sizes and rotation speed). They are ideal when low flow and high pressure are required. Another plus is that they can pump a mixture of water and air, sometimes they even create a vacuum if they are filled with only air. This makes it easier to start it up - no need to fill the chamber with water or a small amount is enough. The disadvantage of vortex pumps is low efficiency. It cannot be higher than 45-50%.

| Name | Power | Head (lifting height) | Performance | Suction depth | Housing material | Price |

|---|---|---|---|---|---|---|

| LEO XKSm 60-1 | 370 W | 40 m | 40 l/min | 9 m | cast iron | 24$ |

| LEO XKSm 80-1 | 750 W | 70 m | 60 l/min | 9 m | cast iron | 89$ |

| AKO QB 60 | 370 W | 30 m | 28 l/min | 8 m | cast iron | 47$ |

| AKO QB 70 | 550 W | 45 m | 40 l/min | 8 m | cast iron | 68 $ |

| Pedrollo RKm 60 | 370 W | 40 m | 40 l/min | 8 m | cast iron | 77$ |

| Pedrollo RK 65 | 500 W | 55 m | 50 l/min | 8 m | cast iron | 124$ |

Correct installation of the suction line

When installing a water supply system, it is important not only to install a self-priming pump or pumping station, but also to install a suction line.

The pressure value (7-8 m) is calculated taking into account the height of the water rise and the parameters of the hydraulic resistance that occurs during the movement of the liquid

When creating a sealed water supply, it is necessary to control the ratio of the diameter of the pipeline to the diameter of the branch pipe, and also to shorten (if possible) the length of the entire line.

The longer the suction line, the higher the resistance, respectively, the lower the pressure. The presence of leaks can lead to equipment failure - this condition is relevant for centrifugal models that are not designed for pumping air-liquid media.

Pay attention to the location of the pipes. The suction line should not have kinks, kinks, or a complex prefabricated structure that rises above the level of the pump, otherwise air pockets may form that disrupt the suction process and are difficult to remove from the system

Try to position the suction line in such a way that it is the simplest configuration with straight pipes and one angle, that is, it would resemble the letter "L"

As additional equipment installed directly on the line, a check valve (or a simple non-return analogue) and a filter are used. Thanks to the valve, water is kept in the pipeline and does not flow back, thereby protecting the owner of the pump from refilling.

The filter protects the equipment from ingress of bottom sediment with large inclusions, pieces of aquatic plants, clay impurities.

Can a self-priming model be replaced with a conventional pump? If there is no other way out, then they do it - for the period of repair or purchase of new equipment.

However, do not forget about some of the nuances:

- you will have to completely fill the pump chamber and the line with water before turning it on;

- air must be avoided, otherwise the equipment will fail;

- filling should be done after each "accident" caused by depressurization of the water supply.

Practice shows that users of self-priming pumps are in no hurry to switch to conventional ones, especially since the choice of equipment is often dictated by optimal suction conditions.