- Types of pumping stations and distance to the water table

- Pump stations with built-in ejector

- Pumping stations with remote ejector

- Automatic systems and elements that ensure control and reliable operation of the pumping station system

- Water supply station with ejector

- Design features of a modern pumping station for domestic needs

- What is a good pumping station without a hydraulic accumulator

- How to choose a place for equipment?

- The device and principle of operation of the pumping station

- Device and principle of operation

- List of basic set of NSP equipment

- Automatic fire extinguishing

- Water foam fire extinguishing: sprinkler and deluge

- Operation and features of the control unit

- Specifications

- Choosing a location for a water supply station

Types of pumping stations and distance to the water table

There are pumping stations with a built-in and remote ejector. The built-in ejector is a structural element of the pump, the remote one is a separate external unit, immersed in the well. The choice in favor of one or another option depends primarily on the distance between the pumping station and the water surface.

From a technical point of view, the ejector is a fairly simple device. Its main structural element - the nozzle - is a branch pipe with a tapered end. Passing through the constriction water gains a noticeable acceleration. In accordance with Bernoulli's law, an area with low pressure is created around a stream moving at an increased speed, i.e., a rarefaction effect occurs.

Under the action of this vacuum, a new portion of water from the well is sucked into the pipe. As a result, the pump spends less energy to transport liquid to the surface. The efficiency of pumping equipment is increasing, as is the depth from which water can be pumped.

Pump stations with built-in ejector

Built-in ejectors are usually placed inside the pump casing or located in close proximity to it. This reduces the overall dimensions of the installation and somewhat simplifies the installation of the pumping station.

Such models demonstrate maximum efficiency when the suction height, i.e., the vertical distance from the pump inlet to the level of the water surface in the source, does not exceed 7-8 m.

Of course, distance must also be taken into account. horizontally from well to location of the pumping station. The longer the horizontal section, the smaller the depth from which the pump is able to lift water. For example, if the pump is installed directly above the water source, it will be able to lift water from a depth of 8 m. If the same pump is removed from the water intake point by 24 m, then the depth of water rise will decrease to 2.5 m.

In addition to low efficiency at large depths of the water table, such pumps have another obvious drawback - an increased noise level. The noise from the vibration of a running pump is added to the sound of water passing through the ejector nozzle.That is why it is better to install a pump with a built-in ejector in a separate utility room, outside a residential building.

Pumping station with built-in ejector.

Pumping stations with remote ejector

The remote ejector, which is a separate small unit, unlike the built-in one, can be located at a considerable distance from the pump - it is connected to the part of the pipeline immersed in the well.

Remote ejector.

To operate a pumping station with an external ejector, a two-pipe system is required. One of the pipes is used to lift water from the well to the surface, while the second part of the raised water returns down to the ejector.

The need to lay two pipes imposes some restrictions on the minimum allowable well diameter, it is better to foresee this at the design stage of the device.

Such a constructive solution, on the one hand, allows to significantly increase the distance from the pump to the water surface (from 7-8 m, as in pumps with built-in ejectors, to 20-40 m), but on the other hand, it leads to a decrease in the efficiency of the system to 30- 35%. However, given the opportunity to significantly increase the depth of the fence water, you can easily put up with the latter.

If the distance to the water surface in your area is not too deep, then there is no need to install a pumping station directly near the source. This means that you have the opportunity to move the pump away from the well without a noticeable decrease in efficiency.

As a rule, such pumping stations are located directly in a residential building, for example, in the basement. This improves equipment life and simplifies system setup and maintenance procedures.

Another undoubted advantage of remote ejectors is a significant reduction in the noise level produced by a working pumping station. The noise of water passing through an ejector installed deep underground will no longer disturb the residents of the house.

Pumping station with a remote ejector.

Automatic systems and elements that ensure control and reliable operation of the pumping station system

It is necessary to say in more detail about modern systems as part of pumping stations that will ensure uninterrupted water supply to your home, as well as guarantee long-term operation of the pump.

So, when implementing a pumping station of any type, it is necessary to implement the following automation systems: from dry running pump (“Protection against “dry running” for a well pump using a pressure switch and level sensors.

Electrical circuit for protecting the pump from "dry running");

- The use of a pressure switch or electrocontact pressure gauge (signaling) to maintain pressure in the water supply system (“Water pressure switch (installation, characteristics, design, configuration)” and the article “Electrocontact pressure gauge (signaling) (principle of operation, application, design, marking and types) for water supply systems”.

In addition, if you are assembling a pumping station, which is said from A to Z, then information on choosing a receiver “Hydraulic receiver (hydraulic accumulator)” will also be useful here for water pumping station at home (selection, design)”, as well as information on pipe installation “Installation of metal-plastic (metal-polymer) pipes with threaded fittings”, “Do-it-yourself soldering of plastic (polypropylene) pipes”.

Now, having already a certain amount of information, and, accordingly, knowledge, we hope that the selection of components, as well as the assembly and connection of your pumping station will take place more deliberately, faster, and also with minimal deviations and errors.

The problem of water supply is at the forefront of creating a comfortable living environment in the country. This most often helps to solve the problem of connecting the pumping station to the water. Communications to provide a home is not just a banal plumbing facility with liquid Gander, after all, a complete home water supply system.

The need for an independent water supply, the basic needs of rural dwellers, leads to the constant use of water for cooking, sanitary and domestic use, as well as refrigerants in the heating system.

Household pumps are not always faced with such a variety of work functions.

In addition, installing a pumping station in a private home allows evacuation and supply of water to increase system pressure if the existing pump is not strong enough to deliver liquids to the right place on the surface, in the garden, in the garden or at home. It offers various models on the market, but only a few components for a sufficient distribution of the base model, which is reflected in each pump installation system:

- storage tank;

- pump;

- control relay;

- non-return valve that does not allow leakage;

- filter.

A filter is needed, otherwise the grain of the grains will lead to rapid abrasive wear of machine parts.

Equipment location

The installation and operation of the pumping station ensures long-term reliable operation of the equipment, subject to the following conditions:

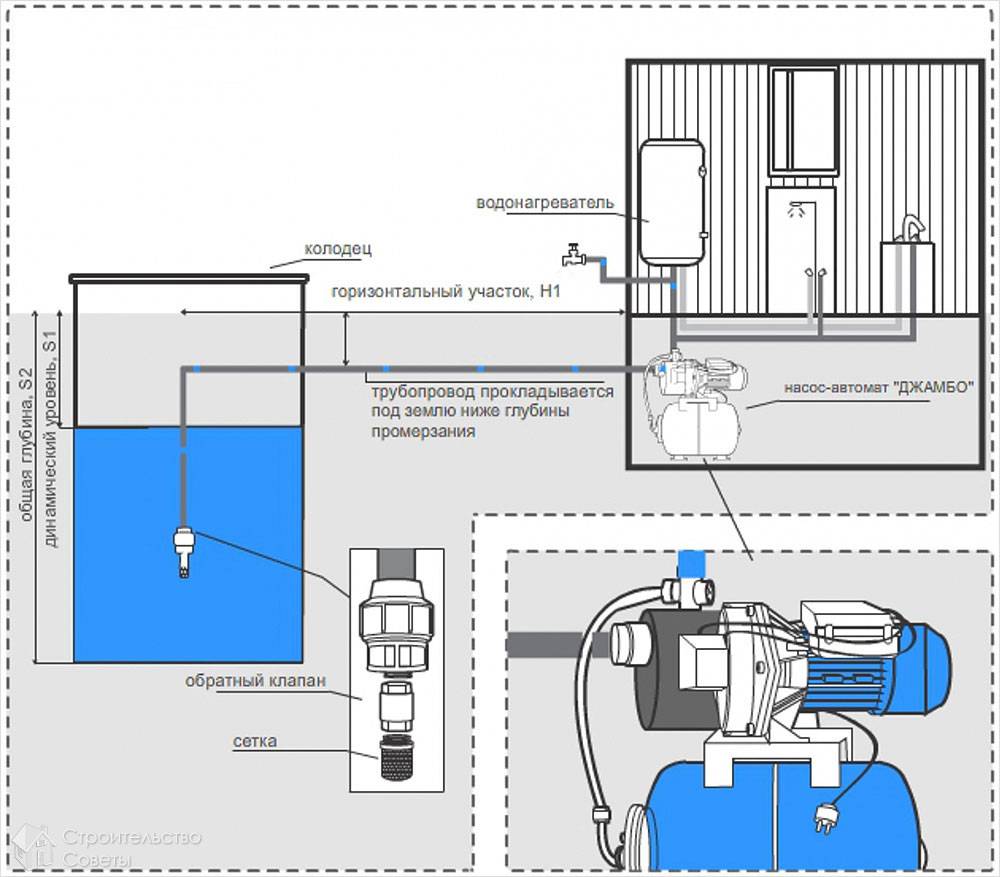

- when installing the station in a bunker, it is placed below the level of soil freezing in winter, which is at least two meters;

- The place where the station is installed (basement or casson) must be heated in winter;

- When assembling the connection plan by hand, it is necessary to prepare a stand, which is then installed on the station in order to prevent groundwater floods.

It is important!

Do not touch the equipment with walls so that the mechanical vibration of the operating mechanism does not affect the room.

Water supply station with ejector

Device. Operating principle

An ejector is essentially a device that transfers energy from one medium that is more mobile to another that is less mobile. In the narrowing sections of the unit, a special zone of lower pressure is formed, which thus provokes the suction of an additional medium. Thus, there is a possibility of movement and removal from the suction points, due to the interaction of the original environment.

Units equipped with an internal format ejector are intended directly for specialized pumping of liquids from a relatively shallow type of wells, the depth of which does not exceed eight meters, as well as various specialized storage tanks or reservoirs.

The immediate distinguishing feature of this interaction is precisely the capture of liquids, which is located at a lower level from the nozzle. Based on this, a preliminary filling of the unit with water will be required.The working wheel will pump the liquid, which will redirect it to the ejector, as a result of which an ejecting jet will be formed.

It will move along a specialized tube and accelerate. Naturally, the pressure will decrease. Due to this effect, it will also decrease inside the suction chamber.

One of the varieties of such surface units is a pumping station with an ejector. They differ in that the external element is immersed in a water supply source.

As a rule, the scope of such devices is similar to their counterparts. A definite difference lies in the different depths of use and application.

Design features of a modern pumping station for domestic needs

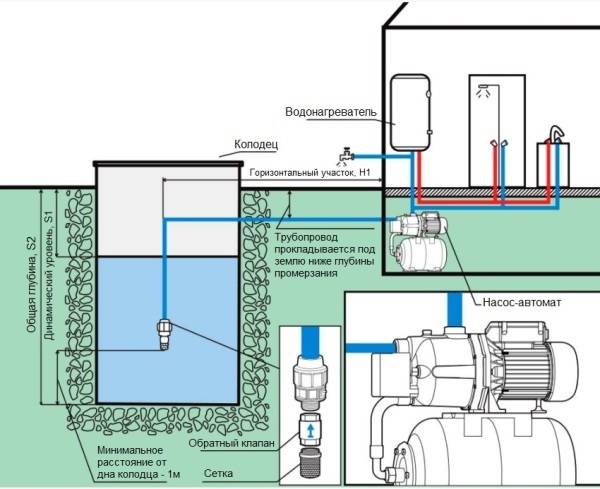

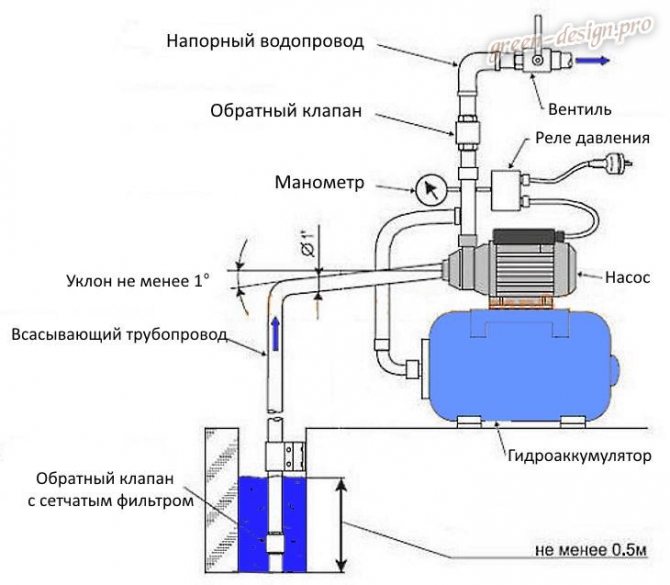

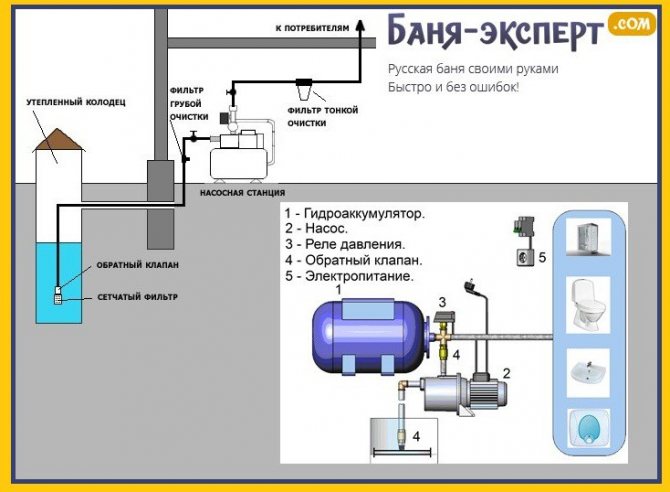

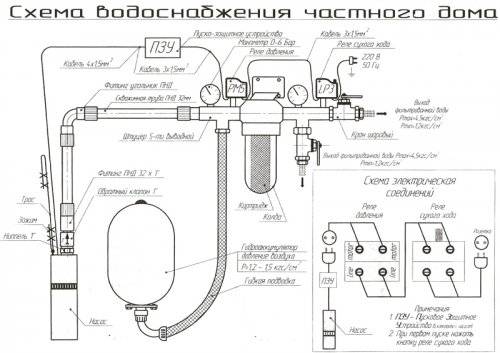

Building water supply system with diagram pumping station, included in it as an integral part, includes several main elements.

- A well or well in which the primary accumulation and settling of liquid occurs. For year-round use, it should be insulated.

- Suction piping equipped with check valve. Usually, a coarse filter from mechanical impurities is installed on it in a well or directly in front of the pumping station.

- The pumping station itself, which provides the facility with water at the required flow rate and pressure.

- Pressure pipeline with a fine filter leading to all water-folding devices.

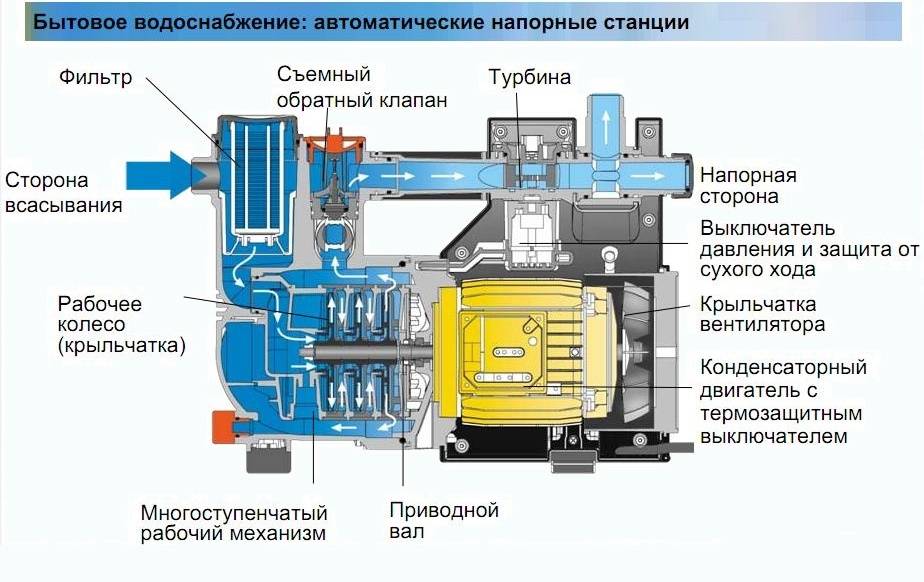

The device of a pumping station for home plumbing is extremely simple and functional. It includes the following mechanisms.

- Water centrifugal pump driven by an electric motor. When it is turned on, a vacuum is created in the intake pipe and excess pressure in the pressure pipe.As a result, liquid is sucked from the well and injected into the water supply manifold of the house.

- A manometer that allows you to monitor the operation of the pump on site.

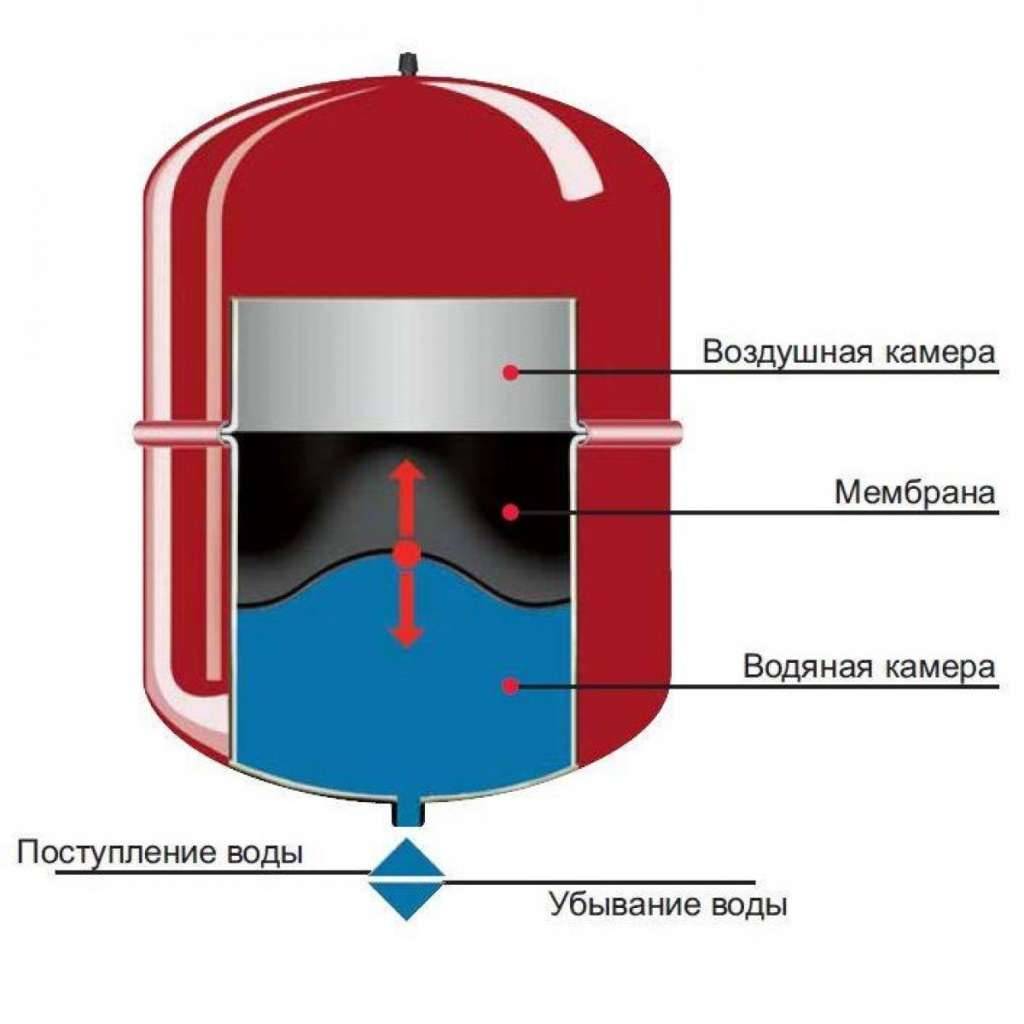

- Membrane hydraulic accumulator, responsible for the constant presence in the system of the necessary supply of water with a working pressure.

- Pressure switch that gives control signals to start and turn off the electric motor.

- Flexible hose connecting the pump to the accumulator.

- Stop valves for the possibility of shutting down pipelines for the period of inspection, maintenance and repair of equipment.

Important! The device of the centrifugal type pump does not allow it to be turned on for a long time without filling with liquid. This can lead to overheating of individual parts and failure of the entire unit.

To exclude the creation of such situations, a dry-running sensor is provided that turns off the engine in the absence of water.

Dry running sensor DPR-6

This is interesting: Installation and connection of a pumping station to a well - an algorithm of work

What is a good pumping station without a hydraulic accumulator

A pumping station without a hydraulic accumulator is located in many suburban areas. Its main difference from pumps with a hydraulic accumulator is, as you might have noticed, the absence of a hydraulic accumulator.

If the pump does not have one, then most likely it works with a storage tank. This is the second type of pumping station. This is an old design, but it is still used in summer cottages. The amount of water in the tank can be estimated by the float that is placed in the tank. When the volume of water has decreased to the limit values, then at this moment the sensor is triggered. At that moment, he sends a signal to start pumping water.

Among the disadvantages of the system are:

- Low water pressure;

- Large tank sizes;

- Difficulty of installation;

- The storage tank must be installed above the level of the pump;

- If the sensor breaks down, which signals an overflow, water can flood the house.

The main advantage of such a pump is its low cost. A hydraulic accumulator is not cheap, so without it you can save money.

A pumping station without a hydraulic accumulator with a storage tank is the last century. Summer residents do not recommend buying it if it is possible to buy a pump with a hydraulic accumulator. Despite the low cost of such pumps, you run the risk of flooding your home with water. Therefore, it is better not to purchase such pumps.

How to choose a place for equipment?

To operate pumping equipment, try to comply with some conditions:

- minimum removal of the station from the water source;

- the required temperature regime;

- the possibility of reducing the noise level;

- convenient location of equipment for maintenance.

Taking into account the above factors, the most suitable places for installing the station are the caisson, the basement of the house and the boiler room, although each place has its pros and cons.

It is customary to call a caisson a structure equipped in the ground. It is arranged directly above the exit of the wellbore, while pulling out a deep pit, which should be below the level of soil freezing. If the pump is not installed deep enough, it will not be able to work year-round, as it will fail at the first frost.

For the manufacture of the caisson, concrete rings, brickwork, monolithic concrete blocks, metal cubes are used.The entrance to the caisson is located at the top of the structure and is a hatch with a tight-fitting lid.

The caisson requires waterproofing and additional insulation of the upper part - the roof. In addition, the volume of the room should be sufficient so that repairs can be made if necessary.

The advantage of installing a pumping station directly in a borehole caisson arranged above the wellhead is that the operating unit will be located away from residential premises and will not cause discomfort with loud noise.

A good option for installing the station is the basement. It is located further from the well than the caisson, but in the basement it is easy to equip a place for installation. Given the risk of flooding, the unit is installed on a small stable elevation.

A good option for placing a pumping station in the basement: living quarters are located at some distance, the exit to the outside is located approximately at the same level as the main line leading from the well

In the basements of country houses, utility rooms are often arranged (laundries, pantries, cellars for storing canned food), so heating is provided in advance. If, nevertheless, the basement is not heated, you need to take care of additional thermal insulation, and even more practical - install an additional radiator.

We do not recommend arranging a boiler room near living rooms, since the noise level of operating equipment is quite high. If you still decide to install a pumping station in a corridor or pantry, try to isolate the room as much as possible.

There is another solution, but it will be of interest only to those who visit the cottage exclusively in the summer.

You can purchase a compact portable unit and install it in a small temporary hut - a wooden structure that resembles a box. The main thing is that the building is protected from precipitation. For the winter, the pumping station, together with the temporary water supply, is dismantled and placed in a warm room.

The device and principle of operation of the pumping station

Does a pumping station differ in any way from a conventional electric pump and, if so, what are its advantages?

Firstly, the pumping station is able to provide good pressure, which is necessary for the full supply of water to the house and site.

Secondly, this system is fully automated and can work without constant monitoring by the owner - once installed, and you can not remember about it until the time for routine inspection and verification comes.

A conscious choice of a pumping station will be impossible if due attention is not paid to its design and basic components.

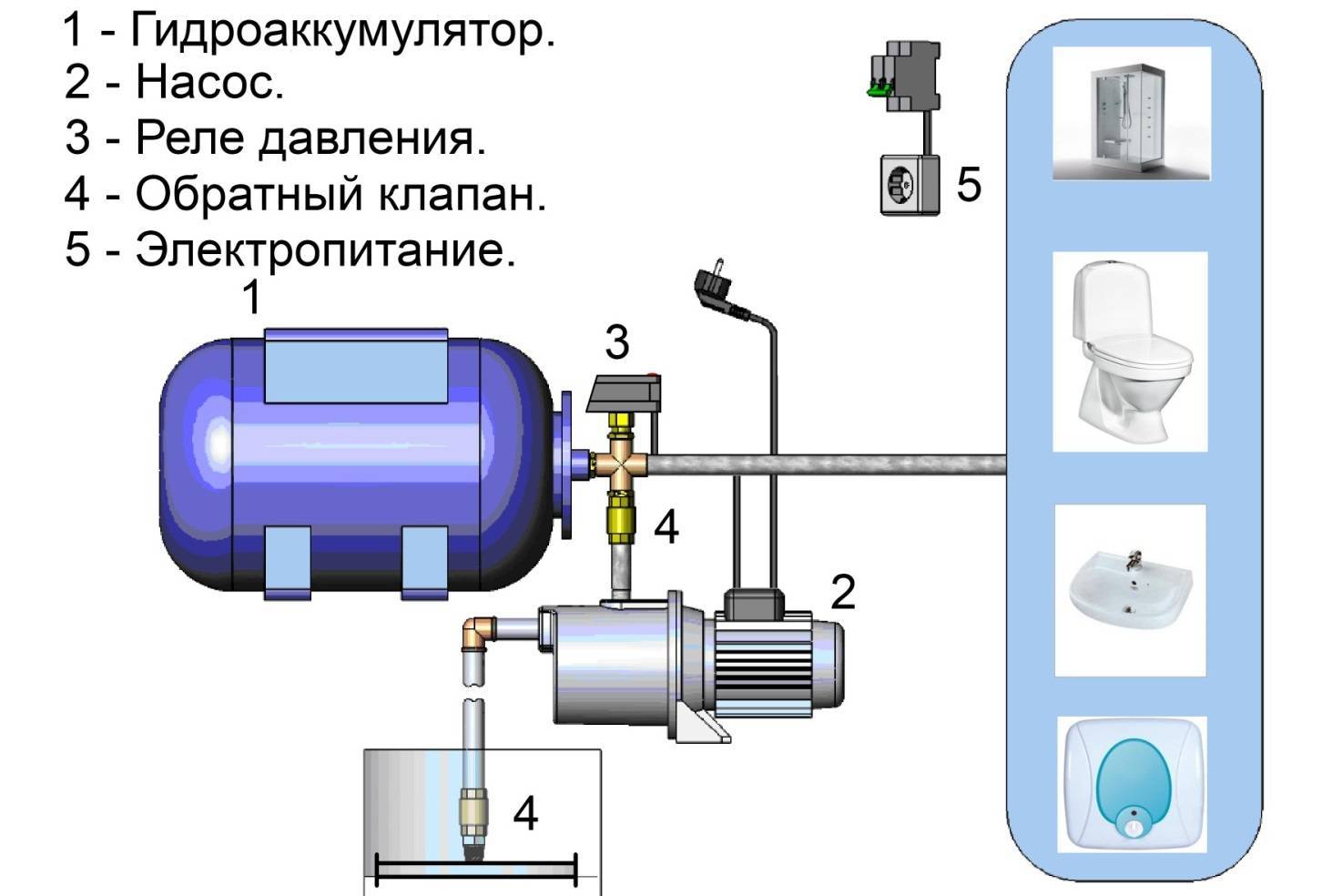

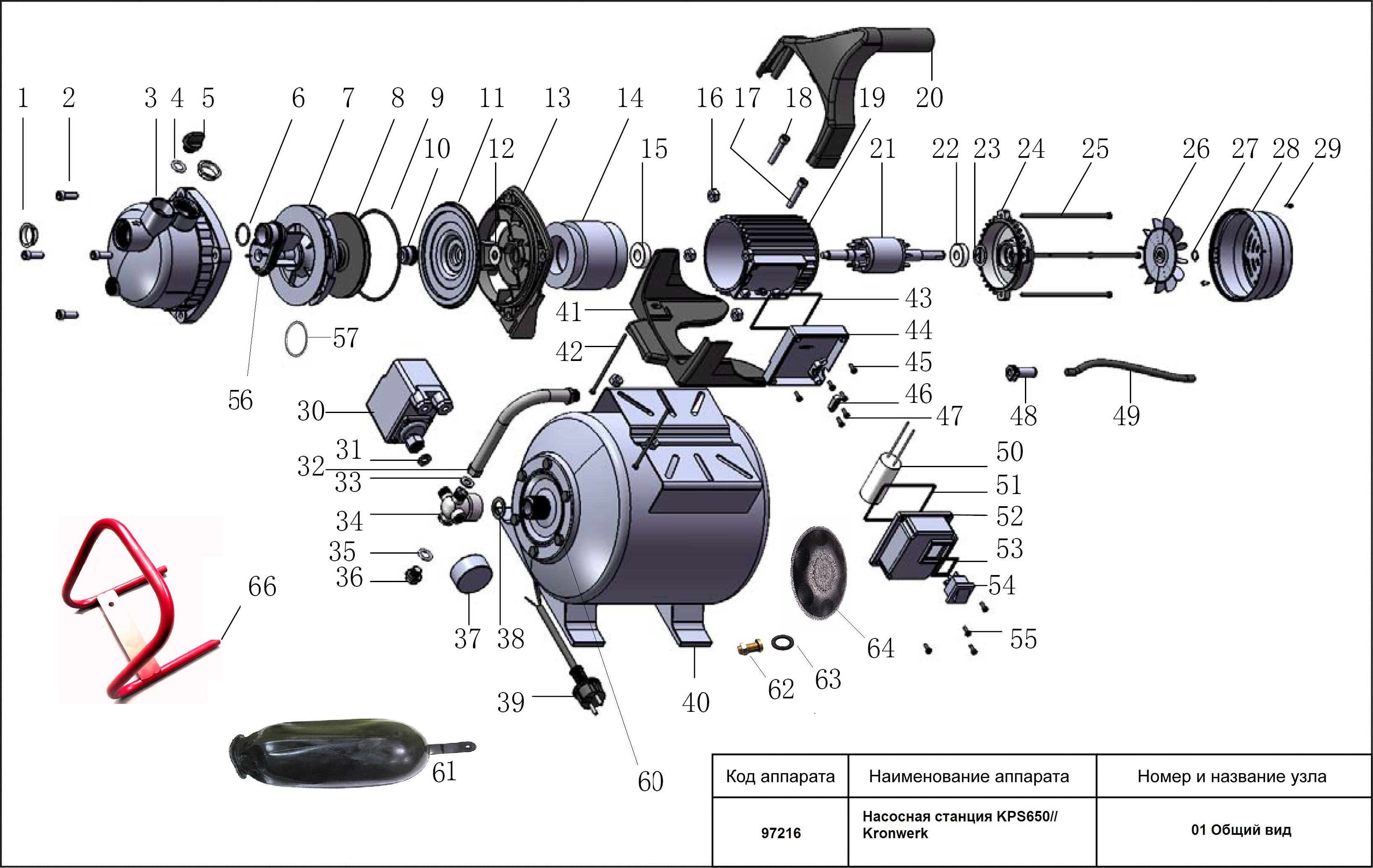

The main structural elements of the pumping station are a surface pump and a hydraulic accumulator (pressure hydraulic tank) connected to each other, as well as automatic pressure switchthat controls the operation of the pump. This is not enough for the autonomous functioning of the system.

But we will talk about the purpose and arrangement of additional components a little later, now we will focus on the main structural elements.

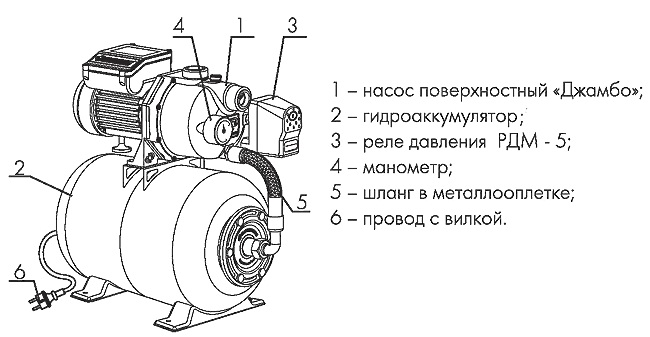

Pumping station device

1. Electric block.2. Outlet fitting.3. Inlet fitting.

4. Electric motor.5. Manometer.6. Pressure switch.

7. Hose connecting pump and receiver.8. Hydraulic accumulator.9. Legs for fastening.

The "heart" of the pumping station is the pump.The design type of the pump used can be almost any - vortex, rotary, screw, axial, etc. - but for domestic water supply, as a rule, centrifugal-type pumps are used, which are distinguished by their simplicity of design and high efficiency.

The second important structural element of the pumping station - the accumulator - is, in fact, a storage tank (which actually follows from its name). However, the purpose of the accumulator is not only the accumulation of pumped water.

Without this element, the pump would turn on / off too often - every time the user turns the tap on his mixer. The absence of a hydraulic accumulator would also have a negative impact on the pressure of water in the system - the water would either flow from the tap in a thin stream, or would whip with too rapid a stream.

How can a pump, a hydraulic accumulator and a pressure switch put together be able to automatically provide us with water?

We will understand the principle of operation of the pumping station.

The pump, when turned on, begins to pump water, filling the storage tank with it. The pressure in the system then gradually increases. The pump will work until the pressure reaches the upper threshold. When the set maximum pressure is reached, the relay will operate and the pump will turn off.

What happens when the user turns on the tap in the kitchen or takes a shower? Water consumption will lead to a gradual emptying of the accumulator, and hence to a decrease in pressure in the system. When the pressure drops below the set minimum, the relay will automatically turn on the pump, and it will start pumping water again, compensating for its flow and increasing the pressure to the upper threshold value.

The upper and lower thresholds at which the pressure switch operates are set at the factory. The user, however, has the ability to make minor adjustments to the operation of the relay. The need for this may arise, for example, if it is required to increase the water pressure in the system.

Due to the fact that the pump, which is part of the pumping station, does not operate continuously, but only turns on from time to time, equipment wear is minimized.

A short video showing the principle of operation of the pumping station:

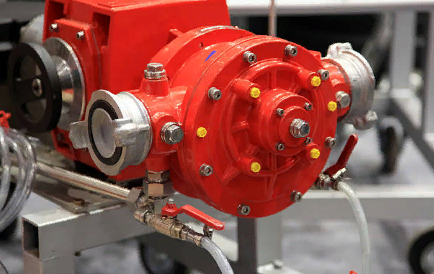

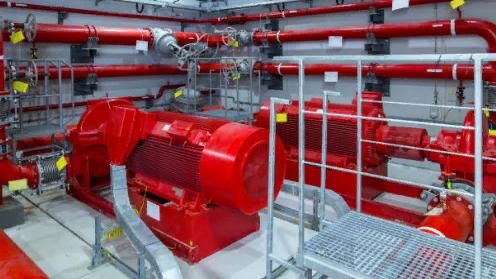

Device and principle of operation

Fire extinguishing pumping stations are used to work with foam, water fire extinguishing installations and on fire water supply. The main function of the equipment is the delivery of fire extinguishing agent to the source of fire.

The average installation includes two pumps, locking mechanisms, check valves, distribution devices, flanges, manifolds, a storage tank, water tanks, a control panel.

The principle of operation of the devices is as follows. The fire extinguishing station is in standby mode. When the working pressure drops below the minimum, a sensor is activated that transmits a signal to the automation unit. The valve of the foaming agent opens, the pumps turn on and move the substance to the proportioner. The solution is mixed in it, after which it is fed into the solution pipeline system and the tank. When the tank is full, the electric valves close.

List of basic set of NSP equipment

Fire station equipment

Fire station equipment

The basic set of nsp includes the following components:

- Main pump.

- Backup pump (there may be several at large facilities).

- suction manifold.

- Discharge manifold.

- Locking mechanism.

- Automatic control panel.

- Control and measuring devices.

Also, at the design stage, additional elements and devices can be added to the system.

Automatic fire extinguishing

Automatic fire extinguishing installations include all PNS as part of the AUPT and some varieties from the ERW systems. The latter can have a manual start from a button, manual call points.

Water foam fire extinguishing: sprinkler and deluge

Foam water fire extinguishing systems are the most common types. Their advantages include low cost, the ability to create an unlimited supply of water, high efficiency.

There are two main types of fire fighting:

- sprinkler systems. They work exactly on the source of ignition. This reduces the risk of material damage from water on furniture, interiors and other items. They are considered systems with high-precision flame extinguishing.

- Deluge. They create water curtains along the path of flame propagation. They can protect even hard-to-reach places, for example, openings of building barriers, where it is impossible to make fire doors. Allows you to extinguish fires at large production facilities.

Operation and features of the control unit

For the full operation of the station, its management is necessary. The device of the station for home water supply is as follows:

- continuous automatic control of pressure in the system is performed around the clock;

- when it drops below a predetermined limit, the pump immediately turns on and the system is filled with water, pressure increases;

- when the pressure reaches above the set barrier, a relay is activated that turns off the pump;

- the pressure is at the same level until the water intake tap opens and it starts to fall.

To do this, you need a pressure gauge that measures pressure. And a pressure switch where the lower and upper limits are set.

Specifications

Regardless of the depth of the well (8.10, 15 or 20 meters), all pumping stations are divided into domestic and industrial. For a private house, household units are used. However, they may have different performance characteristics.

In order for your unit to meet the needs of the family in water, as well as the parameters of the hydraulic structure, it is necessary to pay attention to the following technical characteristics when choosing:

equipment power, measured in W;

device performance in cubic meters per hour (this characteristic is selected after determining the needs of residents for water);

liquid suction height or the maximum mark to which the pump can raise water (these characteristics depend on the depth of the water intake, for example, for wells with a depth of 15-20 meters, you need an aggregate with an indicator of at least 20-25 m, and for wells with a depth of 8 meters, a device with a value 10 m);

the volume of the accumulator in liters (there are units with a volume of 15, 20, 25, 50 and even 60 liters);

pressure (in this characteristic, it is necessary to take into account not only the depth of the water mirror, but also the length of the horizontal pipeline);

additional protective functions will not interfere (protection against "dry running" and overheating);

it is also important to consider the type of pump being used. For example, a submersible pump is mounted in a well, so it does not make noise during operation, but it is more difficult to repair and maintain it.

A surface-type unit is easier to maintain and repair, but makes more noise during operation.

To make it easier for you to choose a unit suitable for a country house, we give approximate technical characteristics of such a device:

the power of the device should be in the range of 0.7-1.6 kW;

depending on the size of the family, a station with a capacity of 3-7 cubic meters per hour will suffice;

lifting height depends on the depth of the well or well;

volume of hydraulic tank for one person equal to 25 liters, with an increase in family members, the volume of the storage tank should increase proportionally;

the choice of the device for the maximum pressure should be done taking into account the depth of the hydraulic structure, the length of the horizontal pipeline leading from the unit to the house, as well as the height of the house (if there are water consumption points on the upper floors: bathrooms or bathrooms);

well, if the device will have protection against "dry" operation

This is especially important for hydraulic structures characterized by unstable water levels. Then the pump will not be able to pump out all the water and run idle;

in addition, a surface-type pumping station will need protection against motor overheating

The thing is that in submersible units, the motor is constantly in the water, so it is effectively cooled. But the motor of a surface station can easily overheat and fail. To prevent this from happening, you need protection against overheating, which will work in time and turn off the pump.

Choosing a location for a water supply station

When choosing a location for a pumping station, it is necessary to focus on the characteristics of the hydraulic pump.Every ten meters of a horizontal pipe between the water source and the pump reduces its suction capacity by 1 m. If they are supposed to be separated by more than ten meters, then the model of the pump unit must be selected with an increased suction depth.

The automatic station of the autonomous water supply system can be located:

- on the street in a caisson near the well;

- in an insulated pavilion built specifically for pumping equipment;

- in the basement of the house.

The stationary outdoor option provides for the arrangement of a caisson and the laying of a pressure pipe from it to the cottage below the freezing level of the soil. When installing a year-round pipeline, laying it below the seasonal freezing depth is mandatory. When arranging temporary summer highways for the period of residence in the country, the pipeline is not buried below 40 - 60 cm or is laid on the surface.

If you install the station in the basement or basement, then you do not have to be afraid of the pump freezing in winter. It is only necessary to lay the suction pipe below the freezing line of the soil so that it does not freeze in extreme cold. Often a well is drilled right in the house, then the length of the pipeline is significantly reduced. But not in every cottage such drilling is possible.

Installation of water supply pumping stations in a separate building is possible only if the equipment is operated during a period of positive temperatures. However, for areas with very low winter temperatures, this option, designed to function all year round, needs to be insulated or a heating system installed. It is better to immediately mount the pumping station right in the heated house.