- One or two circuits for wall and floor boilers?

- Heating equipment device

- Structural features of the unit

- Variants of schemes with a boiler

- Modes

- Boiler power

- The principle of operation of gas boilers

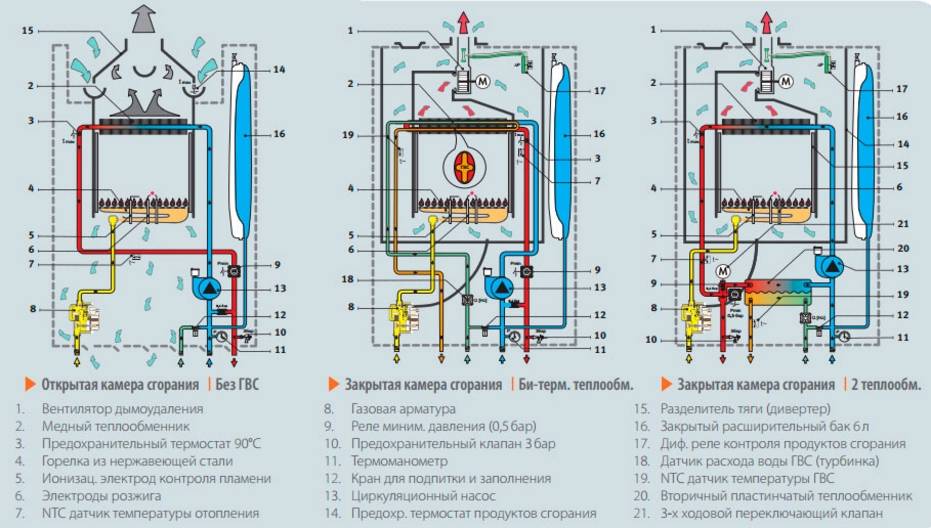

- Boilers with open and closed combustion chamber

- How a combi boiler works

- With bithermic heat exchanger

- With flow heater

- With instantaneous heater and standard boiler

- 3 Equipment classification

- Types of gas burners

- Condensing and convection type

- Final step: connection revision

- Classification by installation site

- Floor type boilers

- Features of wall equipment

- The nuances of parapet devices

- The specifics of the operation of boilers with two circuits

One or two circuits for wall and floor boilers?

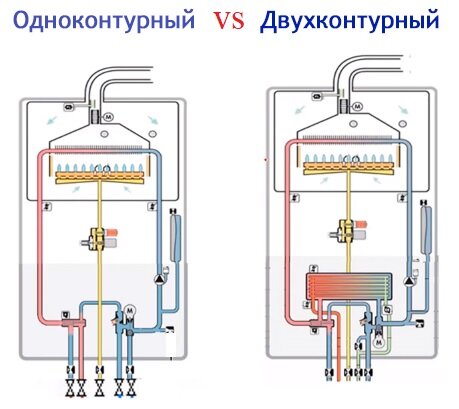

The main difference between a single-circuit boiler and a double-circuit boiler is the ability to heat running tap water.

One-circuit consists of three parts:

- Burners.

- Heat exchanger.

- Control and management systems.

Double-circuit is much more complicated than single-circuit. It has nodes responsible for heating hot water. These are an additional heat exchanger, a three-way valve, a circulation pump, a sensor system and electronic automation.

The double-circuit boiler operates in two modes:

- Heating medium heating mode.The burner burns gas that heats the coolant. The inclusion and intensity of the flame is regulated by the simplest mechanical or electrical automation, the coolant is pumped by a pump.

- DHW mode. The user opens the shower faucet, for example. Water begins to circulate through the boiler, the pressure sensor turns on. Automation includes a three-way valve. The hot coolant begins to circulate through the secondary heat exchanger, which heats the shower water. As soon as the user has closed the tap, the circulation of the coolant through the secondary heat exchanger stops.

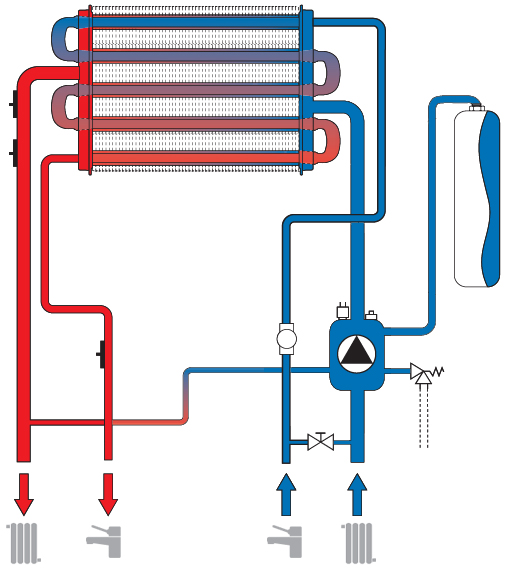

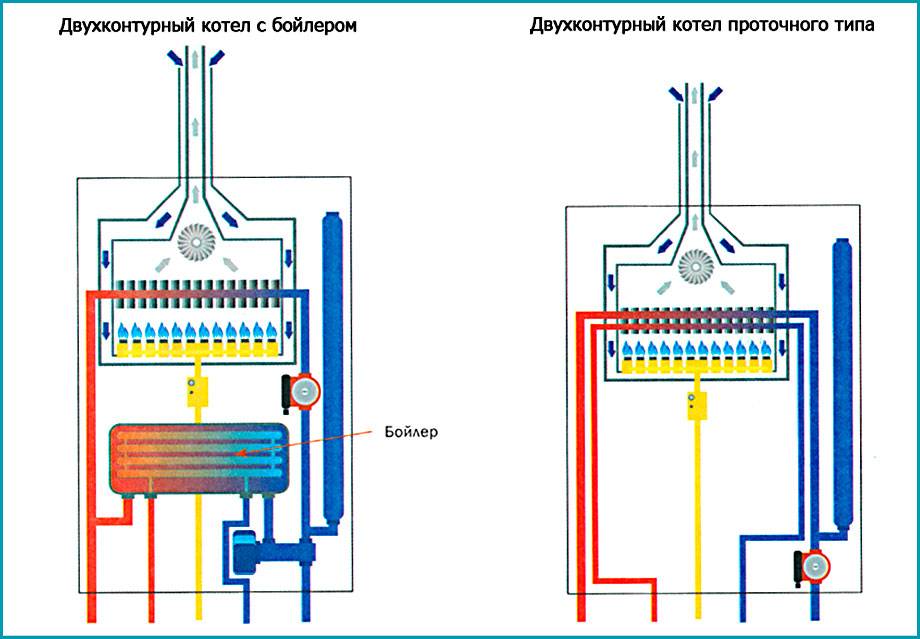

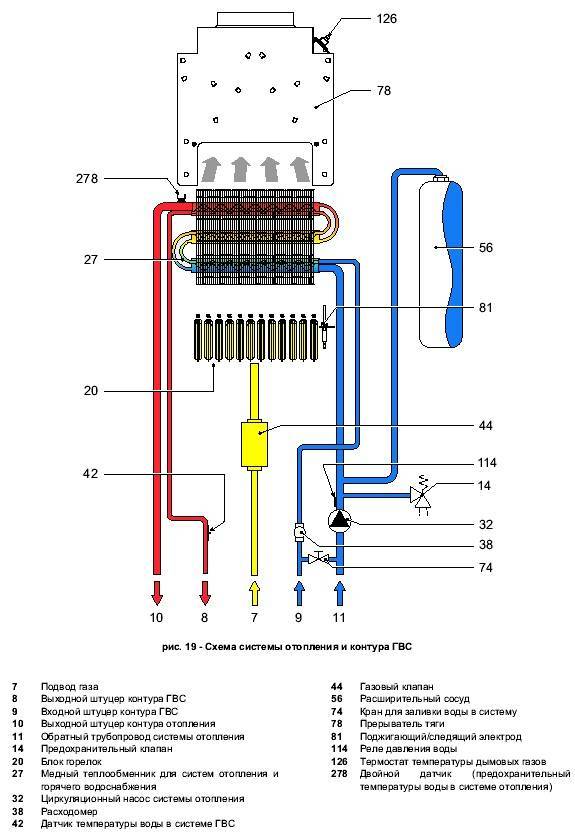

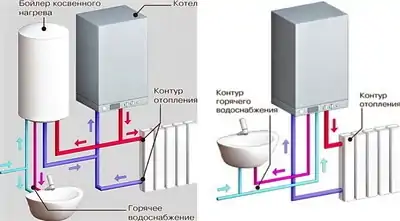

Photo 1. Scheme showing the operation of a double-circuit boiler. Blue represents the movement of cold water, red - hot.

If the house already has a heating system with a single-circuit boiler, hot water is provided by an additional indirect heating boiler. This scheme has both advantages and disadvantages. Using a double-circuit is cheaper, modern boilers are technologically advanced and allow you to heat as much water as you need with the accuracy of maintaining the set temperature.

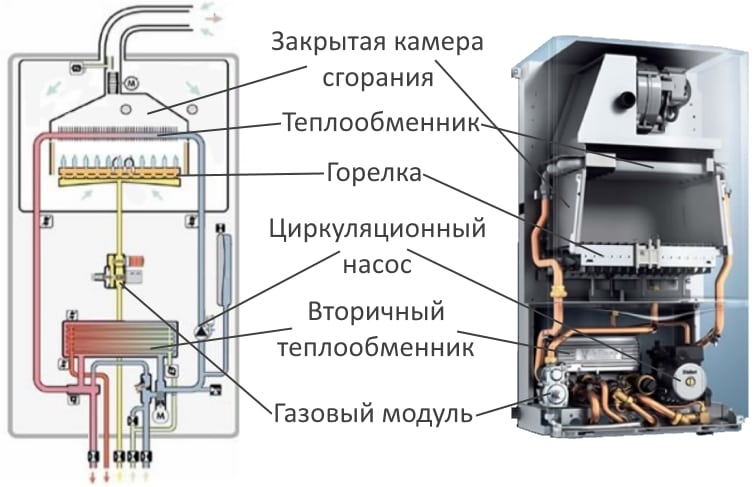

Heating equipment device

Various elements of the gas boiler are made from materials that correspond to the tasks.

When choosing, you should pay attention to several useful little things that affect the cost and durability of the device.

- The body and parts of a three-way valve or sensors with a moving part are made of brass, bronze or plastic. The use of corrosive metals is undesirable.

- The boiler piping is often made of the same material as the heat exchanger.

- The body and frame are made of sheet steel.

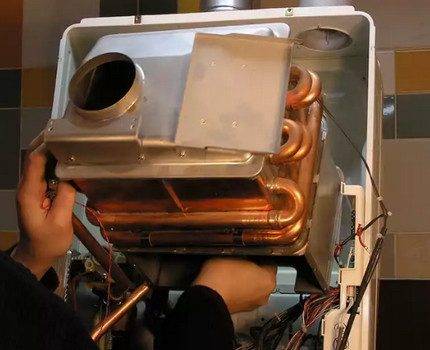

- Heat exchangers of single-circuit boilers are made of steel or cast iron, less often of aluminum or copper.For double-circuit copper or stainless steel is used. It is best to choose boilers with copper heat exchangers, since copper is less susceptible to corrosion and has excellent heat transfer characteristics.

Important! When choosing and installing the boiler, it is advisable to ensure that no electrochemical pair is formed. If there are copper and aluminum elements in the system, the latter will inevitably corrode

Therefore, do not install aluminum batteries and a copper heat exchanger.

Structural features of the unit

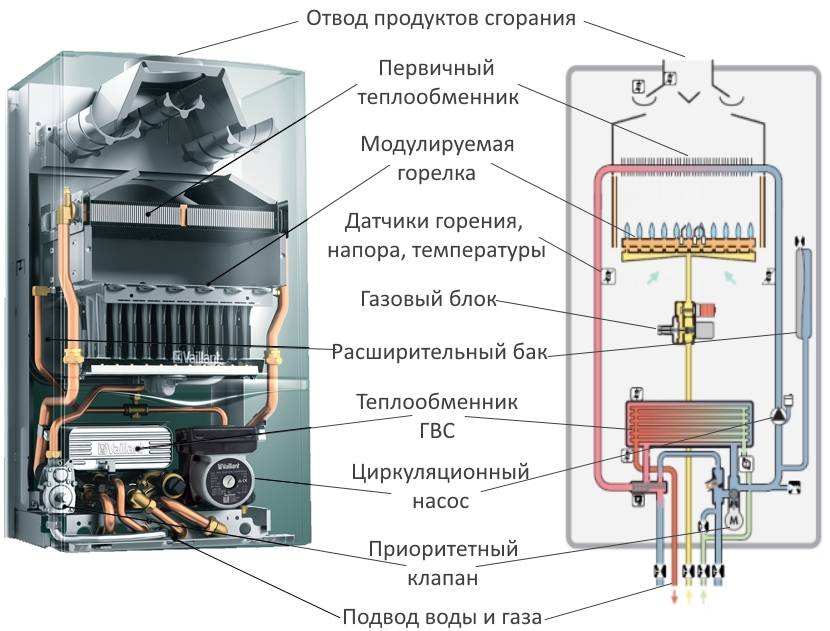

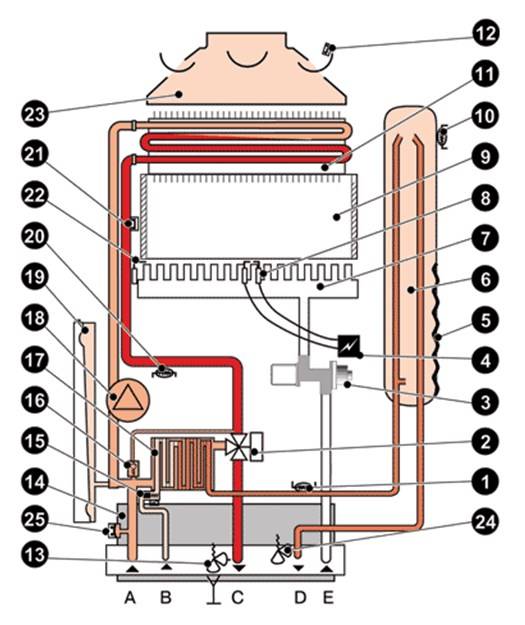

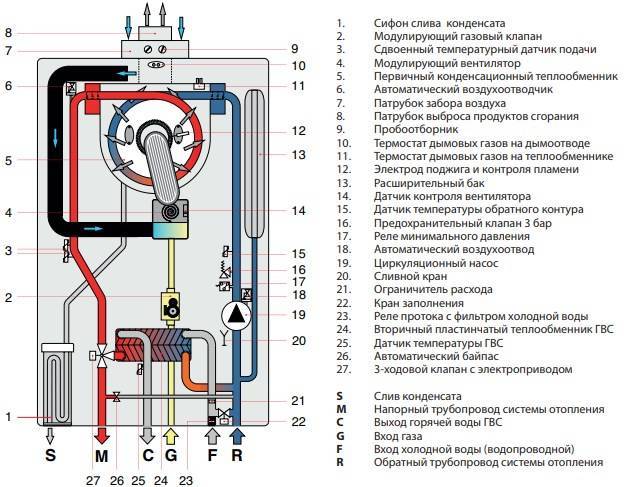

The household gas appliance consists of a housing, two communication circuits, a built-in burner, a heat exchanger, an expansion tank, a combustion products outlet unit, a gas valve and a control unit.

The main circuit is connected to a common heating system in a closed circuit. With the active operation of the unit in heating mode, the coolant circulates through the pipes of the primary circuit, and does not enter the hot water supply (DHW) communications system, since a special valve blocks the path there.

When installing equipment with two contour elements, it must be remembered that the length of the communication pipe connecting the boiler to the farthest point of water intake should not exceed 7 meters. Otherwise, mineral elements deposited in the form of scale in the area of the heat exchanger will begin to impede the movement of the working fluid and the productivity of the water heater will significantly decrease.

When the user turns on a hot tap in the kitchen or bathroom, the valve is activated, closes the inlet to the heating pipes and directs the heat carrier into the DHW circuit to warm up the water in the heat exchanger.

From there, the liquid enters the tap and is used for its intended purpose.When the need for hot water disappears and the tap closes, the reverse switch occurs and the valve again redirects the coolant to the heating circuit.

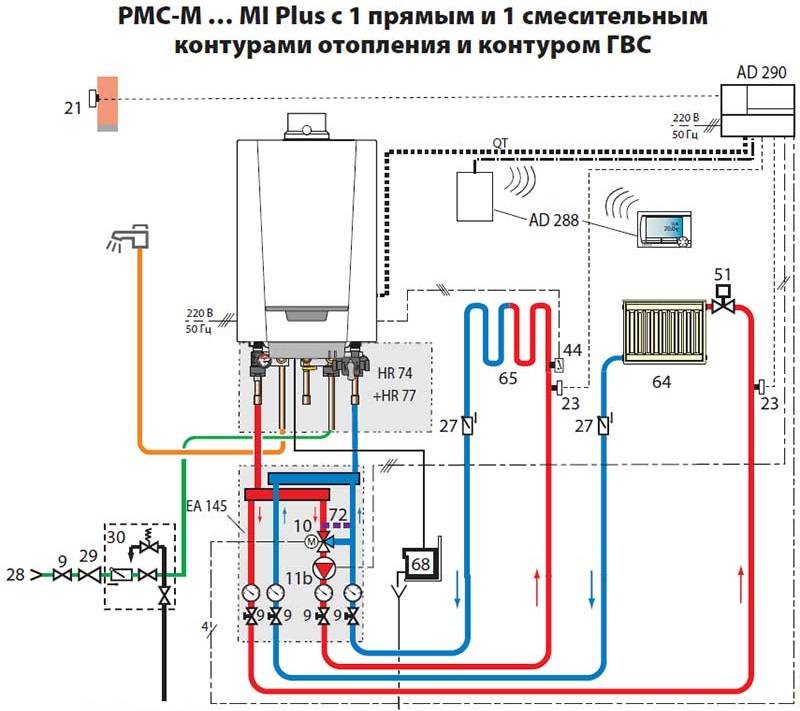

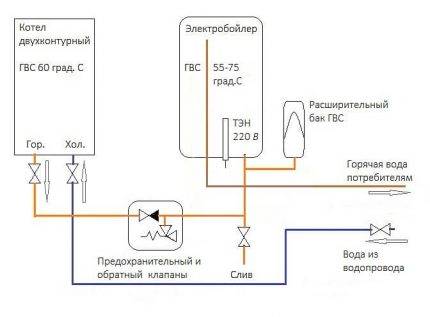

Variants of schemes with a boiler

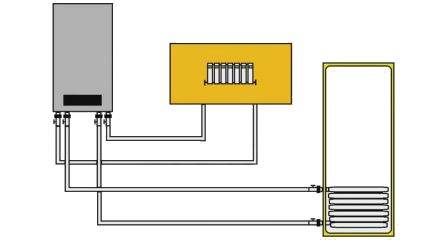

When the standard device power of 9-13 liters is not enough to meet the needs of residents (example: there is a bath in the bathroom), the system is supplemented with a boiler. If an indirect heating boiler is selected, then it is impossible to simulate the flow by an additional circulation pump, which is turned on and stopped by a thermostat signal.

An incorrect scheme entails a problem in the form of prolonged heating of the boiler. At this time (up to 2 hours), the heating of the house does not occur, the premises cool down. Plus, the boiler resource is reduced due to the “clocking” effect and hot water entering the second circuit, and not cold. Bacteria multiply in the boiler itself.

The correct scheme is to connect an indirect boiler to the heating circuit. The thermostat is connected to the boiler automation. DHW outlet pipes are simply muffled

The correct scheme is to connect an indirect boiler to the heating circuit. The thermostat is connected to the boiler automation. DHW outlet pipes are simply muffled

In such a scheme, heating between the circuits is provided by a three-way valve. The boiler is loaded in 20-25 minutes. Plugs do not affect the resource of the heat generator.

More practical options - installation layer heating boiler (there are models for dual circuits) or an electric drive. The first one does not have a heat exchanger, which reduces the cost of the system. The second significantly improves the comfort of using hot water.

In the circuit with an electric boiler, check and safety valves are mounted on the supply pipe. From the latter, water sometimes flows out, which must be disposed of. The safety valve requires a manual check 2 times a month

In the circuit with an electric boiler, check and safety valves are mounted on the supply pipe. From the latter, water sometimes flows out, which must be disposed of. The safety valve requires a manual check 2 times a month

In the case of an electric boiler, it is recommended to additionally install an expansion tank. And if the pressure in the system is more than 6-8 bar, you will need a pressure reducing valve to reduce it.

Modes

Work takes place in two modes:

- heating;

- supply of hot water.

In both modes, the system will not work. A three-way valve is mounted in a double-circuit boiler. The part allows you to direct the coolant to receive hot water.

The heating action is similar to a flow heater. After switching on, the burner continues to work for a long time, increasing the temperature to the required level. When reached, the feed stops. If you put a temperature controller, automation takes information from it. The functions of the burner in the heater with two circuits are affected by the automation according to the weather in the summer, winter season. Controls the outdoor temperature. From the burner, the heat carrier is heated, moving in the system not arbitrarily, but under pressure.

A three-way valve is installed so that the water flow can overcome the main heat exchanger without obstacles. The removal of combustion products is carried out spontaneously, sometimes a fan on top of the equipment helps. DHW remains unused.

Boiler power

One of the key points in choosing a heating boiler is determining the required power. If we approach this with full responsibility, it is necessary to consider the heat loss of each room, if we are talking about an apartment or a building as a whole, if the boiler is selected for heating a private house. The calculations take into account the materials of the walls, their thickness, the area of windows and doors, the degree of their insulation, the presence / absence of an unheated room at the bottom / top, the type of roof and roofing material

Geographic location and a whole bunch of other factors are taken into account

Such a calculation can be ordered from a specialized organization (at least in GorGaz or a design bureau), if desired, you can master it yourself, or you can take the path of least resistance - calculate based on average norms.

Where does the heat leave the house?

Based on the results of all calculations, the norm was derived: 1 kW of heating power is required for heating 10 square meters of area. This standard is suitable for rooms with ceilings of 2.5 m, with walls with an average degree of thermal insulation. If your room falls into this category, divide the total area that needs to be heated by 10. You get the required boiler output. Then you can make adjustments - increase or decrease the resulting figure, depending on the actual conditions. It is necessary to increase the power of the heating boiler in the following cases:

- The walls are made of a material with high thermal conductivity and are not insulated. Brick, concrete fall into this category for sure, the rest - according to the circumstances. If you are choosing a boiler for an apartment, you need to add power if the apartment is corner. For "internal" heat loss through them is not so terrible.

- Windows have a large area and do not provide tightness (old wooden frames).

- If the ceilings in the room are higher than 2.7 m.

- If in a private house the attic is not heated and poorly insulated.

- If the apartment is on the first or last floor.

The design power is reduced if the walls, roof, floor are well insulated, energy-saving double-glazed windows are installed on the windows.The resulting figure will be the required power of the boiler. When looking for a suitable model, make sure that the maximum power of the unit is not less than your figure.

The principle of operation of gas boilers

All existing models can be divided into two main groups:

Convection boilers have a simpler design and low cost. You can find these models everywhere. Heating of the coolant occurs solely due to the effect of an open flame of the burner. In this case, most of the thermal energy is transferred to the heat exchanger, but some (sometimes quite significant) part of it is lost along with the discharged products of gas combustion. The main drawback is that the latent energy of water vapor, which is part of the removed smoke, is not used.

Convection boiler Gaz 6000 W

The advantages of such models include a fairly simple design, the possibility of diverting products combustion due to natural draft (if there are chimneys that meet the requirements).

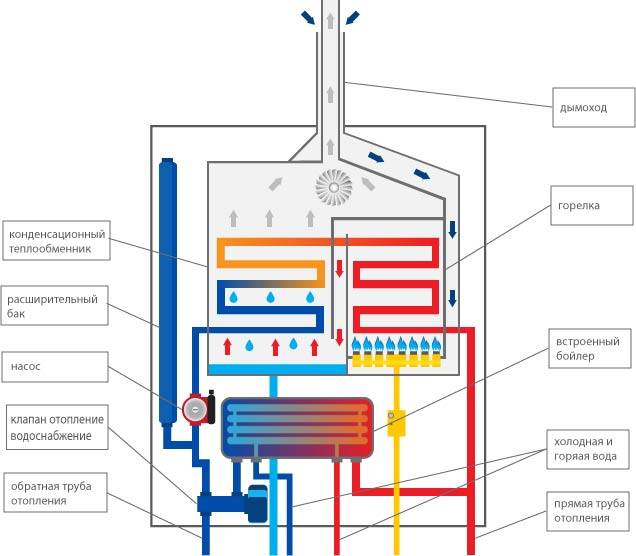

The second group is convection gas boilers. Their peculiarity lies in the following - convection equipment cannot use the energy of water vapor removed with smoke. It is this drawback that the condensing circuit of a gas boiler allows to eliminate.

Gas boiler Bosch Gaz 3000 W ZW 24-2KE

The essence of the operation of such devices is that combustion products that have a sufficiently high temperature pass through a special heat exchanger, into which water enters from the return of the heating system. Provided that the temperature of such a coolant is below the dew point for water (about 40 degrees), steam begins to condense on the outer walls of the heat exchanger.In this case, a sufficiently large amount of thermal energy (condensation energy) is released, which provides preheating of the coolant.

But there are some negative points that characterize the condensation technique:

To operate in condensing mode, it is necessary to provide a return temperature of no more than 30-35 degrees. Therefore, such units are mainly used for low-temperature (not more than 50 degrees) heating systems. Also, boilers of this type can be used in systems with high heat transfer, for example, in systems with a warm water floor. Boilers in which a condensing heat exchanger is used to provide hot water have proven themselves quite well.

Maintenance and adjustment of the optimal operating mode of the boiler can only be performed by a competent specialist. In the regions, there are not too many craftsmen who can understand condensing boilers. Therefore, maintenance of the device can be quite expensive.

In addition, the very cost of equipment of this class is high, it will not be possible to attribute such equipment to the budget option even with a strong desire.

But is it really worth giving up the opportunity to save more than 30% of the energy carrier because of such shortcomings. It is this savings and the short payback period of condensing boilers that make their purchase expedient from an economic point of view.

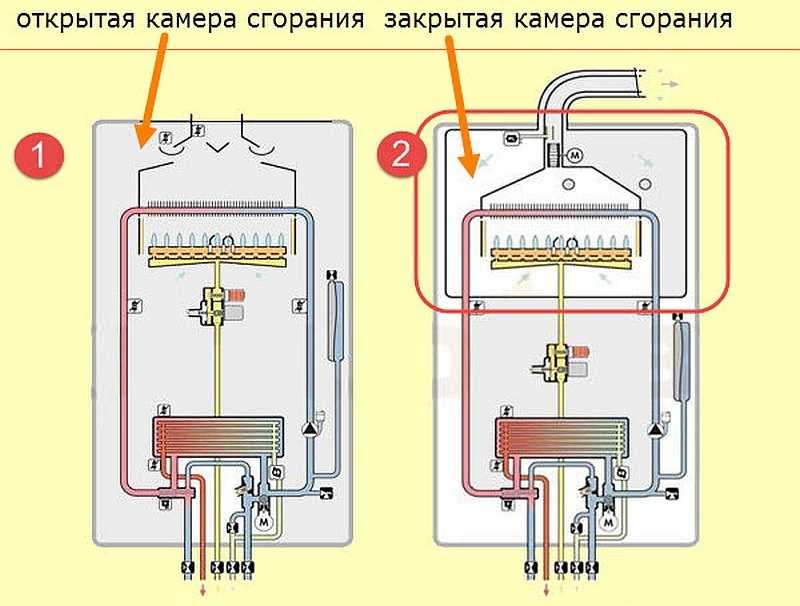

Boilers with open and closed combustion chamber

Such boilers differ significantly in their technical capabilities, while the conditions for their use also differ.

Atmospheric boilers are equipped with an open combustion chamber. The air necessary for gas combustion enters the chamber directly from the room.Therefore, when choosing such boilers, it is necessary to strictly control compliance with the regulatory requirements for air exchange in the room. An effective ventilation system must operate in the room, in addition, the removal of combustion products in the natural draft mode is possible only with the installation of high chimneys (smoke removal above the level of the roof of the building).

Wall-mounted gas boiler Logamax U054-24K atmospheric double-circuit

The advantages of such boilers include a fairly reasonable cost, simplicity of design. But it should be borne in mind that the efficiency of such units is most often not too high (compared to more advanced models).

The turbocharged wall-mounted double-circuit boiler is equipped with a closed-type combustion chamber. Such units are connected mainly to coaxial chimneys, which provide not only the removal of combustion products, but also the supply of fresh air to the combustion chamber from the street. To do this, a low-power electric fan is built into the design of the boiler.

Gas boiler FERROLI DOMIproject F24 wall-mounted double-circuit turbocharged

The main advantage of a turbocharged boiler is increased productivity, while the efficiency of the device reaches 90-95%. This makes it possible to reduce fuel consumption. But it is worth considering that the cost of such boilers is quite high.

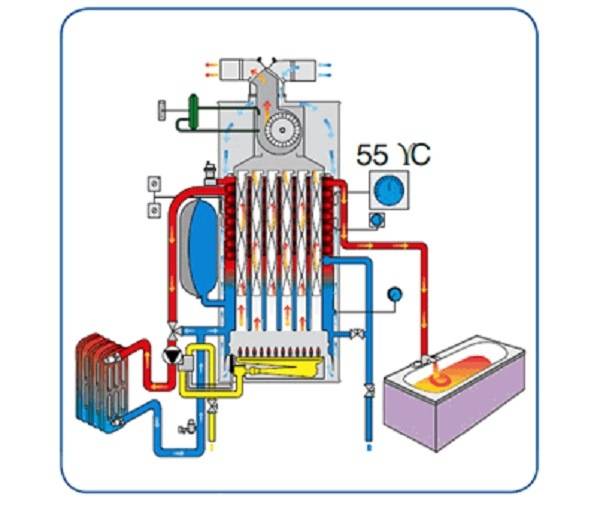

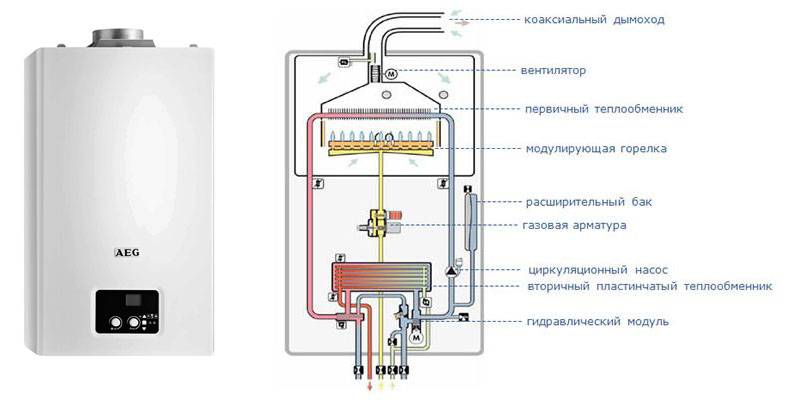

How a combi boiler works

The same way of heating water does it differently. As boilers of different capacities heat a certain volume of water at different times, so different types of boilers heat running water, heat the room and emit carbon monoxide in different ways.

With bithermic heat exchanger

A bithermic heat exchanger is similar in structure to a coaxial chimney.This design does not require a three-way valve. A clear advantage of such a scheme is not only its economy, but also its small size.

Important! There is a huge downside to the incoming water, as a two-way valve is more likely to be clogged when in contact with water containing a lot of salt. T

That is, if the water is very heavily chlorinated, the chance of it blocking and exiting the system is much higher than with a three-way. Although, roughly speaking, this is just a delay in time, since it is necessary to periodically thoroughly clean the pipes, preferably once every six months.

With flow heater

Flow heater - permanent heating of water during use. To get warm water from the faucet, you need to wait a few seconds for the cold water to drain. Such a scheme does not save time, but the gas savings are enormous.

Note! Water in such a water supply system is heated only when it is needed for this.

With instantaneous heater and standard boiler

A flow heater and a boiler are a unique tandem. One is designed to save energy and heat water at the right time, the other heats water constantly. Such a system is suitable only when hot water is required constantly. It has few advantages, but those cover significant financial costs.

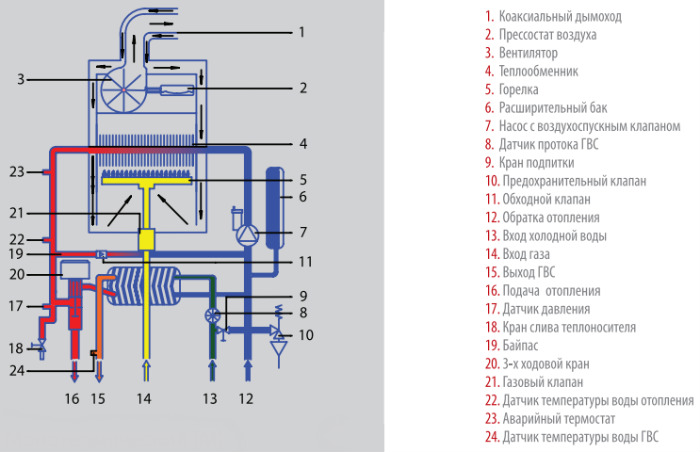

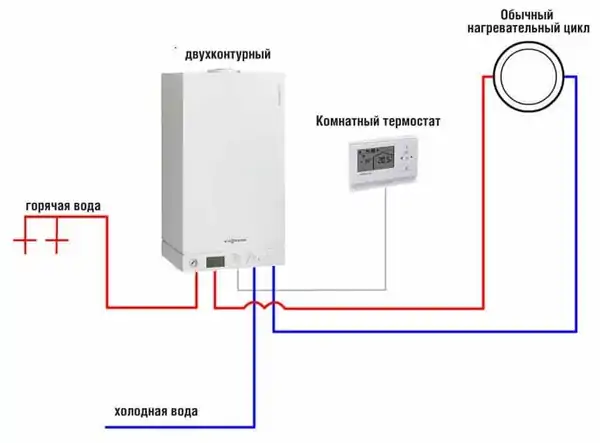

The principle of connecting a double-circuit boiler

The diagram above conventionally shows the boiler itself (pos. 1) and the power supply line connected to it (pos. 2) - a gas main or a power cable, if we are talking about an electrical unit.

One circuit closed in the boiler works exclusively for the heating system - a heated coolant supply pipe (pos. 3) comes out of the unit, which is sent to heat exchange devices - radiators, convectors, underfloor heating, heated towel rails, etc. Having shared its energy potential, the coolant returns to the boiler through the return pipe (pos. 4).

The second circuit is the provision of hot water for domestic needs. This kennel is constantly fed, that is, the boiler is connected by a pipe (pos. 5) to a cold water supply. At the outlet, there is a pipe (pos. 6), through which heated water is transferred to water consumption points.

The contours can be in a very close layout relationship, but nowhere do their "contents" intersect. That is, the coolant in the heating system and the water in the plumbing system do not mix, and can even represent completely different substances from the point of view of chemistry.

The scheme of the boiler in heating mode only

The yellow arrow shows the gas flow to the gas burner (item 1), above which is the primary heat exchanger (item 3). The circulation pump (pos. 5) ensures the movement of the coolant through the pipes from the return of the heating circuit through the heat exchanger to the supply pipe and back to the circuit (blue arrows with a transition to red). The coolant does not move through the secondary (pos. 4) heat exchanger. The so-called "priority valve" - an electromechanical valve device or a three-way valve with a servo drive (pos. 7), closes the "small circle", opening the "large", that is, through the heating circuit with all its radiators, underfloor heating, convectors, etc. P..

In the diagram, in addition to the nodes mentioned, other important parts of the boiler design are marked with numbers: this is a safety group (pos. 9), which usually includes a pressure gauge, a safety valve and an automatic air vent, and an expansion tank (pos. 8). By the way, although these elements are mandatory for any closed heating system, they may not be structurally included in the boiler device. That is, often they are simply purchased separately and "cut" into the overall system.

Changes that occur when starting hot water

If the hot water tap was opened, then water began to move through the pipe (blue arrows), to which the turbine of the flow sensor (pos. 6) immediately reacts. The signal from this sensor is processed by the control unit, from where a command is transmitted to the three-way valve (pos. 7) to change the position of the valves. Now the “small” circle is open and the large circle is “closed”, that is, the coolant rushes through the secondary heat exchanger (pos. 4). There, heat is taken from the coolant and transferred to hot water, leaving for an open point of consumption. The circulation of the coolant in the heating system is suspended for this time.

3 Equipment classification

To date, there are several modifications of gas double-circuit boilers, which may differ in their design, power, purpose and performance. When choosing heaters, it is necessary to take into account the principle of operation of a double-circuit boiler, the type of installation, the location of the combustion chamber, the design of the device, and the specific model of equipment. It is customary to distinguish several main types of thermal gas equipment:

- With one heat exchanger, which is used simultaneously for heating water and heat carrier in the heating system.

- With two heat exchangers, significantly accelerating the heating of water.

- With boiler and flow heat exchanger.

Depending on its modification and the mode of operation of the boiler, it can be floor and wall. For private houses where it is required to heat a room with an area of 200 meters or more, it is necessary to choose installations that develop 15–20 kW. Such equipment is carried out exclusively in the outdoor version. Wall-mounted installations will be an excellent choice for a summer residence or a small private house where 2-3 people live.

Thrifty homeowners can pay attention to volatile appliances that have an open combustion chamber. Such boilers have an affordable cost, they do not differ in performance, therefore it is recommended to install them only in summer cottages and in private houses with an area of \u200b\u200bno more than 100 square meters.

Wall-mounted heaters with a closed combustion chamber have appeared on the market relatively recently. They are equipped with sophisticated electronics, which improves the performance of the equipment and is responsible for the safety of equipment operation.

Types of gas burners

Double-circuit wall-mounted boilers are produced with an open type of gas burner and with a closed one. An open gas burner in the boiler requires the supply of the necessary amount of air for combustion of gas from the room where the gas boiler is installed. For example, the usual scheme of a typical geyser for heating water.

The device with a closed burner has an isolated space for combustion of gas from the room. Air intake for the combustion process is carried out outside the building. Most often, such devices are connected using a coaxial chimney that goes to the outer wall of the building.It consists of two pipes located one in one. Combustion air is taken in through the outer pipe, and combustion products are removed through the inner pipe.

It is possible to connect with the emission of combustion products into the provided chimney of the building and air intake with a lateral pipeline supply. Boilers with a closed burner are called turbocharged, as they have a built-in turbine-type electric air blower. The advantage of such gas appliances is the safety of operation. Their work does not require constant monitoring of the air supply, ventilation of the room, the ingress of combustion products into an apartment or house is excluded. Due to the excess traction, more efficient combustion and faster heating of the water occur.

The device of a wall-mounted gas boiler.

Double-circuit gas appliances can be connected in boiler mode. This mode of operation involves heating the water and its subsequent accumulation in the boiler, and from it the water is already supplied to the water intake points.

Condensing gas heaters are distinguished by the fact that their design allows the water vapor contained in the products of gas combustion to condense. During the condensation process, additional heat is released, which is used either for the heating circuit or for the DHW circuit. The scheme may include the formation of condensate on a specially shaped primary heat exchanger or on an additional device that is located above the primary heat exchanger.

All double-circuit gas boilers must include an automation unit and control sensors for proper and safe operation.Automation monitors the set parameters of water heating in the circuits, can be used in conjunction with remote sensors for indoor air temperature. Traction sensors, control of emergency shutdown of gas supply allow you to operate the boiler in the safest way.

For long-term use of a gas appliance, a competent installation should be made, including power calculation, installation in accordance with safety standards, and high-quality commissioning operations.

Work on the installation of gas equipment should be carried out only by special gas services that have a certificate for its implementation.

Condensing and convection type

The convection boiler has a heat exchanger of a simple geometric shape, the heating of the coolant is carried out in one stage: the burner heats up the container with water.

The convection boiler has a heat exchanger of a simple geometric shape, the heating of the coolant is carried out in one stage: the burner heats up the container with water.

In addition, there are condensing boilers: inside the tank there is a closed steel spiral with small holes through which steam enters. The steam is discharged to a collector connected to the return line and condenses with heat release.

The condensate flows down to the sump and is removed from the system from there. The efficiency of such a model is higher than the convection one due to the secondary heat transfer. In a high-quality convection boiler, the efficiency reaches 95%, in a condensing boiler 98.

Another feature of this type of boilers is the presence of a mechanism for enriching the gas with oxygen, due to which the fuel burns out with greater efficiency.

The second function of this burner is to minimize the impact on the heat exchanger of the aggressive components of the steam used for condensation.

The operating limitation of condensing boilers is low flow and return temperatures. Such models are successfully used in the installation of underfloor heating operating in low-temperature mode (up to 50 degrees). For radiators that are designed for more intense heating, this boiler is not the most suitable option.

Video about double-circuit gas boilers.

Final step: connection revision

After all the stages of connecting a gas boiler have been completed, you should not rush to start it. It is necessary to check the correctness of all stages of installation work. The operation of the gas unit can only be started after there is one hundred percent confidence that everything has been done flawlessly.

Be sure to check the connection of the water circuit and identify possible leaks. There is nothing complicated about this, since water leakage appears immediately. But the shortcomings associated with the gas pipeline, you just won’t see it. Proceed as follows: the gas pipe is abundantly moistened with soapy water and the appearance of air bubbles is monitored. If everything is in order, there will be no bubbles.

The first test run of the gas unit is recommended to be carried out under the supervision of specialists from the gas supply organization. To do it yourself, you need to have special permission. However, only professionals can accurately determine whether the gas boiler is connected correctly or not. Experts will advise you on how to connect heating to a gas boiler and help you avoid possible mistakes.You should not neglect their advice, as we are talking about the health and life of people.

Classification by installation site

According to the installation principle, boilers serving two communication circuits are floor, wall and parapet. Each option has its own special characteristics.

Focusing on them, the client can choose the most suitable installation method for himself, in which the equipment will be located conveniently, will not “eat up” the usable area and will not cause problems during operation.

Floor type boilers

Floor-standing units are high-power devices capable of heating and providing hot water not only to a standard apartment or residential building, but also to a large industrial premises, public building or structure.

If a double-circuit boiler is planned to be used not only for heating and supplying domestic hot water, but also for feeding warm water floors, the base unit is equipped with an additional circuit

Due to their large size and solid weight (up to 100 kg for some models), floor-standing gas boilers are not placed in the kitchen, but are placed in a separate room directly on the foundation or on the floor.

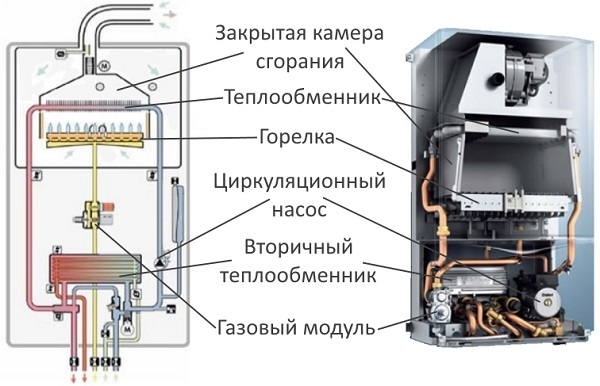

Features of wall equipment

The hinged appliance is a progressive type of household heating equipment. Due to its compact size, the installation of a geyser can be done in the kitchen or in other small spaces. It is combined with the interior solution of any type and organically fits into the overall design.

A double-circuit mounted boiler can be placed not only in the kitchen, but also in the pantry. It will take up a minimum of space and will not interfere with furniture or other household appliances.

Despite its small size, the wall-mounted boiler has the same functionality as the floor-standing device, but has less power. It consists of a burner, an expansion tank, a pump for the forced movement of the coolant, a pressure gauge and automatic sensors that make it possible to use the fuel resource with maximum efficiency.

All communication elements are "hidden" under a beautiful, modern body and do not spoil the appearance of the product.

The flow of gas to the burner is controlled by a built-in security system. In the event of an unexpected cessation of the resource supply, the unit will completely stop functioning. When the fuel begins to flow again, the automation automatically activates the equipment and the boiler continues to operate in standard mode.

The automatic control unit allows you to set the device to any operating parameters that are most suitable for the user. It is possible to set your own temperature regime for different times of the day, thus ensuring economical consumption of the fuel resource.

The nuances of parapet devices

The parapet boiler is a cross between a floor and wall unit. It has a closed combustion chamber and does not create harmful emissions. Does not require the arrangement of an additional chimney. The removal of combustion products is carried out through a coaxial chimney laid in the outer wall.

A parapet-type boiler is the best option for heating equipment for small rooms with a weak ventilation system. The device is designed in such a way that during operation it does not emit combustion products into the atmosphere of the room in which it is installed.

The device is mainly used to provide hot water and full heating for small houses and apartments in high-rise buildings, where it is not possible to mount a classic vertical chimney. The base power ranges from 7 to 15 kW, but despite such low performance, the unit successfully copes with the tasks.

The main advantage of parapet equipment is the ability to connect heating and water supply communications to the central gas system and pipelines from any side convenient for the user.

The specifics of the operation of boilers with two circuits

Those who think that both circuits in such a system heat up at the same time at once are mistaken, in fact, everything works in a completely different way. In normal operation, such equipment operates on an ongoing basis only to heat the coolant circulating in the system. How often it will turn on and how intense the flame seems to be during the operation depends on the temperature sensor that controls these processes. Together with the burner, the pump starts, but only if the circulation of the coolant in a natural way does not have any effect on the operation of the heating system. After the temperature of the latter reaches the desired level, a signal is sent from the sensor that the burner activity should be reduced. After that, the boiler operates only in passive mode until the temperature indicator reaches the programmed level. Next, the sensor sends a signal to the automation, which, in turn, starts the valve responsible for supplying fuel.

It is enough to first familiarize yourself with certain intricacies of the functioning of gas boilers equipped with two circuits in order to understand what benefits can be obtained from their operation. Moreover, the purchase of such heating systems allows you not to purchase additional equipment that may be required in any other case in order to provide the house with hot water. Even if one circuit fails, the second can be operated further, replacing one circuit will still cost much less than repairing the entire heating installation.

A double-circuit boiler may well be operated in the summer, when there is no need for heating and it is only necessary to provide heating of water intended for domestic needs. In this way, you can really save money, since buying two units at the same time, each of which operates autonomously, will cost much more.

Read also: