- The use of heat transfer fluids in boilers

- Validity of acquisition and use

- Use of double-circuit heating systems

- Classification by installation site

- Floor type boilers

- Features of wall equipment

- The nuances of parapet devices

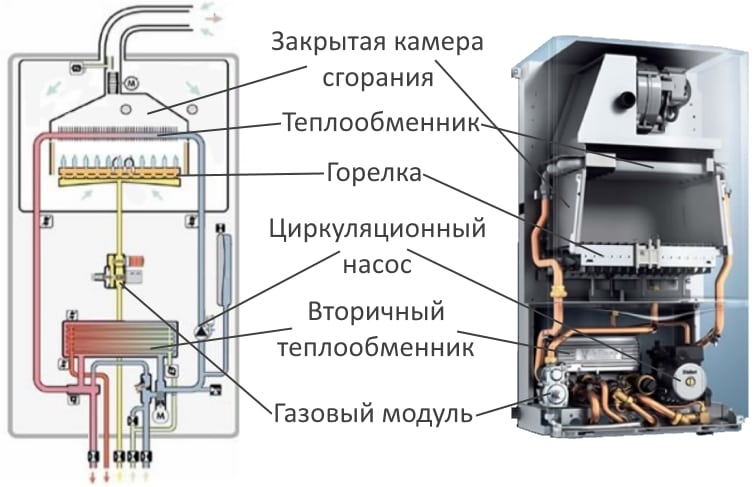

- Device

- Pros and cons

- TOP-10 rating

- Buderus Logamax U072-24K

- Federica Bugatti 24 Turbo

- Bosch Gaz 6000 W WBN 6000-24 C

- Leberg Flamme 24 ASD

- Lemax PRIME-V32

- Navien DELUXE 24K

- MORA-TOP Meteor PK24KT

- Lemax PRIME-V20

- Kentatsu Nobby Smart 24–2CS

- Oasis RT-20

- Connecting the boiler to the boiler

- Price

- The principle of operation of the boiler and its device

- The device of a gas boiler with two circuits

- 3 Unit design

- How a combi boiler works

- With bithermic heat exchanger

- With flow heater

- With instantaneous heater and standard boiler

The use of heat transfer fluids in boilers

If irregular residence or frequent and long departures are planned in the country house or in a private house, and draining and purging the liquid from the system is not considered an acceptable option, then it is necessary to prevent it from freezing.

This can be done by adding antifreezes to the coolant - substances that do not freeze to a certain negative temperature, and in the case of even lower temperatures do not harden, but turn into a gel-like substance without increasing in volume.

It is not recommended to use antifreeze in double-circuit floor-standing gas-fired boilers in most cases (these standards are less stringent for single-circuit boilers). The instructions clearly state that the heating medium in the heating system must be water.

If the user, at his own peril and risk, pours into the heating system not prepared water, but any other solution, then the problems resulting from this do not apply to warranty cases.

Some manufacturers indicate a specific brand of antifreeze that can be used to fill the heating system. As, for example, the equipment manufacturer Viessmann recommends the use of Antifrogen brand coolant.

Others indicate that, as an exception, antifreeze can be used if its manufacturer guarantees that the agent will not harm the components and materials of the boiler, in particular, the heat exchanger. In this case, it must be borne in mind that one coolant may be suitable for a certain model and another may not be suitable at all.

Therefore, if it is important that antifreeze be used as a coolant in the heating system, you need to find out in advance, before buying, whether it is possible, and if so, what brand of coolant is allowed to be used for a particular brand and model of the boiler

Validity of acquisition and use

The intended use of a double-circuit gas boiler is allowed both for individual premises and for buildings.

However, the effectiveness of such a device depends on a number of factors:

- modifications and characteristics of the unit used;

- floor space and the number of permanent users;

- indicators of thermal insulation and natural heat losses of a heated property.

Regardless of these factors, the use of double-circuit boilers is justified in rooms and buildings that are not connected to a centralized DHW circuit or experience constant difficulties with shutdowns and / or interruptions in the supply of hot water.

Use of double-circuit heating systems

This rule applies when there are no unheated rooms next to the selected room, its height is limited to 3 m, and the number of windows is small. If any of these parameters does not match, the optimal power will be considered to be about 150 W per 1 sq. m. To find out the power that the boiler should have, you need to multiply this value with the area of \u200b\u200bthe room.

Also, the owner has the opportunity to independently calculate the DHW capacity that the selected equipment should have. It must be assumed that about 400 liters of hot water flows out of a conventional water tap within an hour. Most often, the technical passport for the boiler contains information about the performance, indicated in l / min. A value of 400 liters per hour means that 6.6 liters flow out of the tap in one minute.

If there is only one hot water point in the house, a boiler with a similar capacity will be able to satisfy all your needs. When there are at least two such points, then to calculate the required performance, the value for one DHW point should be multiplied with their total number in the house.

Classification by installation site

According to the installation principle, boilers serving two communication circuits are floor, wall and parapet. Each option has its own special characteristics.

Focusing on them, the client can choose the most suitable installation method for himself, in which the equipment will be located conveniently, will not “eat up” the usable area and will not cause problems during operation.

Floor type boilers

Floor-standing units are high-power devices capable of heating and providing hot water not only to a standard apartment or residential building, but also to a large industrial premises, public building or structure.

If a double-circuit boiler is planned to be used not only for heating and supplying domestic hot water, but also for feeding warm water floors, the base unit is equipped with an additional circuit

Due to their large size and solid weight (up to 100 kg for some models), floor-standing gas boilers are not placed in the kitchen, but are placed in a separate room directly on the foundation or on the floor.

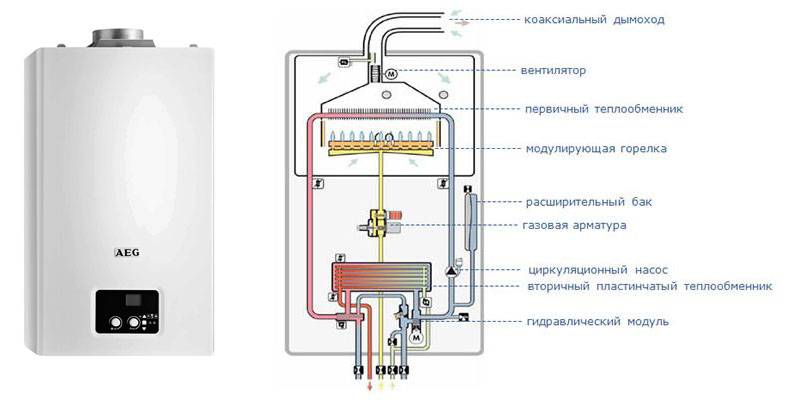

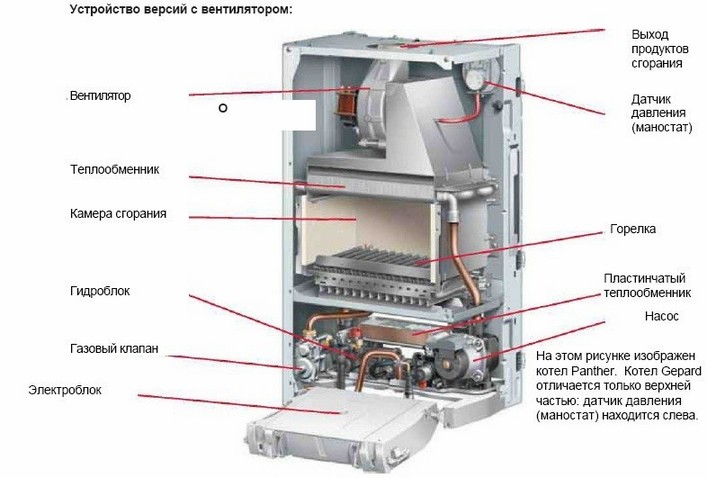

Features of wall equipment

The hinged appliance is a progressive type of household heating equipment. Due to its compact size, the installation of a geyser can be done in the kitchen or in other small spaces. It is combined with the interior solution of any type and organically fits into the overall design.

A double-circuit mounted boiler can be placed not only in the kitchen, but also in the pantry. It will take up a minimum of space and will not interfere with furniture or other household appliances.

Despite its small size, the wall-mounted boiler has the same functionality as the floor-standing device, but has less power. It consists of a burner, an expansion tank, a pump for the forced movement of the coolant, a pressure gauge and automatic sensors that make it possible to use the fuel resource with maximum efficiency.

All communication elements are "hidden" under a beautiful, modern body and do not spoil the appearance of the product.

The flow of gas to the burner is controlled by a built-in security system. In the event of an unexpected cessation of the resource supply, the unit will completely stop functioning. When the fuel begins to flow again, the automation automatically activates the equipment and the boiler continues to operate in standard mode.

The automatic control unit allows you to set the device to any operating parameters that are most suitable for the user. It is possible to set your own temperature regime for different times of the day, thus ensuring economical consumption of the fuel resource.

The nuances of parapet devices

The parapet boiler is a cross between a floor and wall unit. It has a closed combustion chamber and does not create harmful emissions. Does not require the arrangement of an additional chimney. The removal of combustion products is carried out through a coaxial chimney laid in the outer wall.

A parapet-type boiler is the best option for heating equipment for small rooms with a weak ventilation system. The device is designed in such a way that during operation it does not emit combustion products into the atmosphere of the room in which it is installed.

The device is mainly used to provide hot water and full heating for small houses and apartments in high-rise buildings, where it is not possible to mount a classic vertical chimney. The base power ranges from 7 to 15 kW, but despite such low performance, the unit successfully copes with the tasks.

The main advantage of parapet equipment is the ability to connect heating and water supply communications to the central gas system and pipelines from any side convenient for the user.

Device

The double-circuit boiler consists of the following units:

- Gas-burner. It performs the main function - it is a source of heat.

- primary heat exchanger. It is a copper or steel coil, through which the coolant moves, heated in the flame of the burner.

- secondary heat exchanger. Most often it has a lamellar design, made of stainless steel. Produces heating of domestic hot water in flow mode.

- Gas equipment. This is an important node that provides supply, regulation and other actions with gas. There is also a gas valve responsible for blocking the supply when necessary.

- Circulation pump. It is responsible for moving the coolant through the system at the same speed. There are non-volatile boilers designed for the natural circulation of fluid in the system, but most users prefer to install external circulation units to enhance operation.

- Turbo blower. It is needed to supply air to the combustion chamber. Two functions are performed at once - oxygen is provided for normal combustion of gas and excess pressure is created that displaces smoke and other gases generated during fuel combustion. The turbofan replaces the natural draft used in atmospheric boilers. It is unstable, cannot be adjusted and depends on a lot of external factors.

- Three-way valve.This is a unit of a purely mechanical design, which ensures that a cold reverse flow is mixed into the hot coolant. It is used in all kinds and types of boilers, single and double circuit, volatile and independent.

- Control fee. This is the "brain" of the gas boiler, which performs adjustment, control and other control functions. An important element of the board is the self-diagnostic system - a network of sensors located at all main nodes and performing watchdog functions. If any problems occur, the sensors send a signal to the control board, which, depending on the nature of the problem, either notifies the owner of the occurrence of problems using an alphanumeric code on the display, or immediately blocks the operation of the boiler to avoid an accident.

Pros and cons

The advantages of two-circuit systems include the following:

- fuel economy. Since the dual-circuit boiler usually competes with the “single-circuit boiler + BKS” combination, the natural gas consumption will be higher in the second case.

- Compact dimensions. Considering that the lion's share of double-circuit boilers is used in wall-mounted versions, it turns out that such systems can be located not only in the back rooms of private houses, but also in ordinary kitchens of small apartments, where they can take up no more space than a kitchen cabinet.

- Ready solution. In the case of a double-circuit boiler, there is no need to buy additional equipment and think about its compatibility. A heater, an instantaneous water heater and a circulation pump are already combined in one device. And it's all automated!

However, ideal boilers do not exist, there are also disadvantages:

- Impossibility of simultaneous operation of two circuits.When hot water is turned on, the heating system is blocked by a valve. Therefore, a large consumption of hot water can lead to a drop in the room temperature.

- Wall-mounted boilers, especially compact sizes with a small burner, cannot always heat water to the required temperature, while maintaining a strong pressure. The temperature at different points of water intake may differ - the farther the tap is from the boiler, the colder the water will be when opened at all points at the same time.

- The secondary plate circuit is quite sensitive to the quality of running water. This requires either regular cleaning with chemicals or the installation of a special softener for hard water.

The issue of cost is deliberately considered separately, since it is both a minus and a plus. The cost of any double-circuit boiler will always be higher than that of a single-circuit boiler. But when compared with a boiler to which an indirect heating boiler is connected, then a double-circuit boiler will come out cheaper.

TOP-10 rating

Consider the most popular models of double-circuit gas boilers, recognized by experts and ordinary users as the most successful in terms of design and operation:

Buderus Logamax U072-24K

Gas double-circuit boiler designed for wall mounting. Equipped with a closed-type combustion chamber and a separate heat exchanger - primary copper, secondary - stainless.

Heating area - 200-240 m2. It has several levels of protection.

Models with the index "K" perform heating of hot water in flow mode. It is possible to connect a room temperature controller.

Federica Bugatti 24 Turbo

Representative of Italian heat engineering, wall-mounted double-circuit gas boiler.Designed to work in a cottage or public space up to 240 m2.

Separate heat exchanger - copper primary and steel secondary. The manufacturer gives a 5-year warranty period, which indicates confidence in the quality and operational capabilities of the boiler.

Bosch Gaz 6000 W WBN 6000-24 C

The German company Bosch is known all over the world, so it does not need additional introductions. The Gaz 6000 W series is represented by wall-mounted models designed for operation in private homes.

The 24 kW model is the most common, it is optimal for most residential and public buildings.

There is a multi-stage protection, the copper primary heat exchanger is designed for 15 years of service.

Leberg Flamme 24 ASD

Leberg boilers are usually referred to as budget models, although there is no noticeable difference in cost with the products of other companies.

The Flamme 24 ASD model has a power of 20 kW, which is optimal for houses of 200 m2. A feature of this boiler is its high efficiency - 96.1%, which is noticeably superior to alternative options.

Works on natural gas, but can be reconfigured to liquefied gas (replacement of burner nozzles is required).

Lemax PRIME-V32

Wall-mounted double-circuit boiler, the power of which allows you to heat 300 m2 of area. It is suitable for two-story cottages, shops, public or office spaces.

Produced in Taganrog, the basic technological principles of assembly were developed by German engineers. The boiler is equipped with a copper heat exchanger providing high heat transfer.

It is calculated on operation in difficult technical conditions.

Navien DELUXE 24K

Korean boiler, the brainchild of the famous company Navien.It belongs to the budget group of equipment, although it demonstrates high performance.

It is equipped with all necessary functions, has a self-diagnosis system and frost protection. The power of the boiler is designed to work in houses up to 240 m2 with a ceiling height of up to 2.7 m.

Mounting method - wall, there is a separate heat exchanger made of stainless steel.

MORA-TOP Meteor PK24KT

Czech double-circuit gas boiler, designed for hanging installation. Designed for heating 220 m2. It has several degrees of protection, blocking in the absence of liquid movement.

It is possible in addition to connect an external water heater, which greatly expands the possibilities of supplying hot water.

Adapted to unstable power supply voltage (permissible fluctuation range is 155-250 V).

Lemax PRIME-V20

Another representative of domestic heat engineering. Wall-mounted double-circuit gas boiler, designed to service 200 m2.

The modulating burner makes it possible to distribute fuel more economically by changing the gas combustion mode depending on the intensity of the coolant circulation. It has a separate stainless steel heat exchanger, can be connected to a room thermostat.

There is a possibility of remote control.

Kentatsu Nobby Smart 24–2CS

Japanese wall mounted gas boiler providing heating of 240 m2 and hot water supply. Model 2CS is equipped with a separate heat exchanger (primary copper, secondary stainless).

The main type of fuel is natural gas, but when changing jets, it can be converted to the use of liquefied gas. Most of the performance characteristics correspond to European boilers of similar power and functionality.

It is possible to use several design options for the chimney.

Oasis RT-20

Wall-mounted double-circuit gas boiler of Russian production. Designed to work in rooms of about 200 m2. Equipped with an efficient copper heat exchanger and a stainless secondary assembly.

The combustion chamber is of a turbocharged type, there is a built-in expansion tank and a condensate trap.

With an optimal set of functions and high build quality, the model has a relatively low price, which ensures its demand and popularity.

Connecting the boiler to the boiler

In some cases, the power of a double-circuit boiler (12-14 liters per minute) may not be enough for consumer needs - at increased loads, when both kitchen taps and a shower in the bathroom are used at the same time. In addition, the temperature of hot water in the taps will differ from this indicator in the heating system.

Such situations force the use of a boiler in the water supply system. Additional equipment also eliminates the inconvenience of operating a double-circuit gas boiler associated with the duration of the water heating time. For heating the boiler, the possibilities of the DHW circuit are not used. In the scheme, the first circuit of a double-circuit gas boiler must be connected simultaneously with water heating. To do this, the boiler and boiler are connected through a distribution manifold. The latter performs an intermediary function and disperses the hot heat carrier between the heating system and the boiler. Heating of such a structure is carried out by a double-circuit boiler.

To avoid overspending on water heating, a separate pump is connected to the boiler circuit.A thermostat is installed on it in such a way that it reacts to starting and turning off the pump.

In such a scheme, during the cooling of the boiler, the thermostat signals the pump to turn on, and the water begins to heat up. When the desired temperature is reached, the thermostat sends a signal to the pump to turn off.

There is also another inexpensive but good solution. To do this, a conventional electric storage water heater is included in the hot water supply system. A device with a capacity of 30 liters will be enough.

The water heater is connected to the water supply system, between the double-circuit gas boiler and the draw-off point, which acquires the following advantages thanks to it:

- The consumer always has a supply of hot water in the amount of 30 liters;

- When you open a hot water tap, there is no need to wait for it to heat up - it is immediately supplied from the water heater tank to the required degree of warmth;

- In the event of a shutdown of the gas boiler in the summer or during its maintenance, the water heater is a backup source of hot water supply;

- Savings on utility costs: water is not drained into the sewer while it is being heated; gas is also consumed less, since the number of boiler starts is reduced; in small volumes, the consumption of electricity is reduced;

- The resource of the gas boiler increases, as it turns on and works less often. Accordingly, all nodes will last much longer.

Read also:

Price

The market for double-circuit gas boilers is very extensive, however, there are also key players here, whose products are well known and trusted.

Among the Italian manufacturers, the Ferroli trademark is widespread.The average model Fortuna Pro costs in Russia from 23 to 30 thousand rubles, depending on the capacity and distributor in the region.

German boilers Vaillant enjoy well-deserved popularity among consumers

German boilers Vaillant enjoy well-deserved popularity among consumers

German quality is promised by such factories as Vaillant and Viessman. The Vaillant TurboFit model for 24 kW will cost 40-45 thousand rubles, Viessman Vitopend is slightly cheaper - about 35 thousand rubles with the same power.

No less popular are the products of the Slovak company Protherm. The price of a 24-kilowatt Jaguar fluctuates around 30 thousand rubles.

A huge variety in the market of boiler equipment makes you carefully approach the choice. After drawing up the project and determining the power parameters, proceed to the choice of model

Pay attention not to loud statements, but to the actual characteristics - the material of the heat exchanger, the power of the circulation pump, the presence of forced draft from the combustion chamber. The electronic stuffing can only be checked by operation, so demand transparency of warranty obligations

Approach the choice carefully, and let your home be warm.

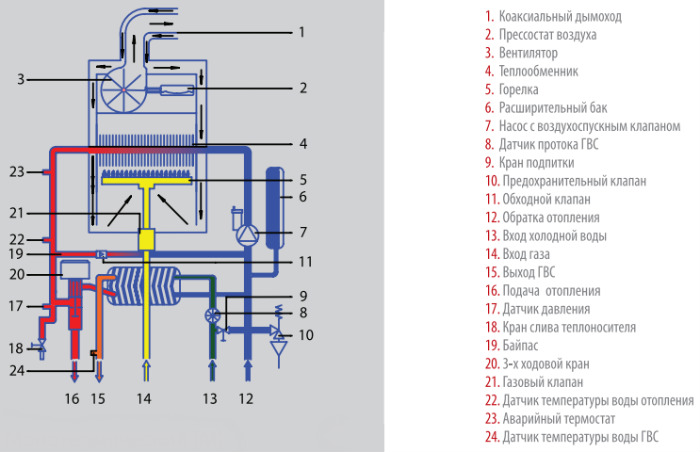

The principle of operation of the boiler and its device

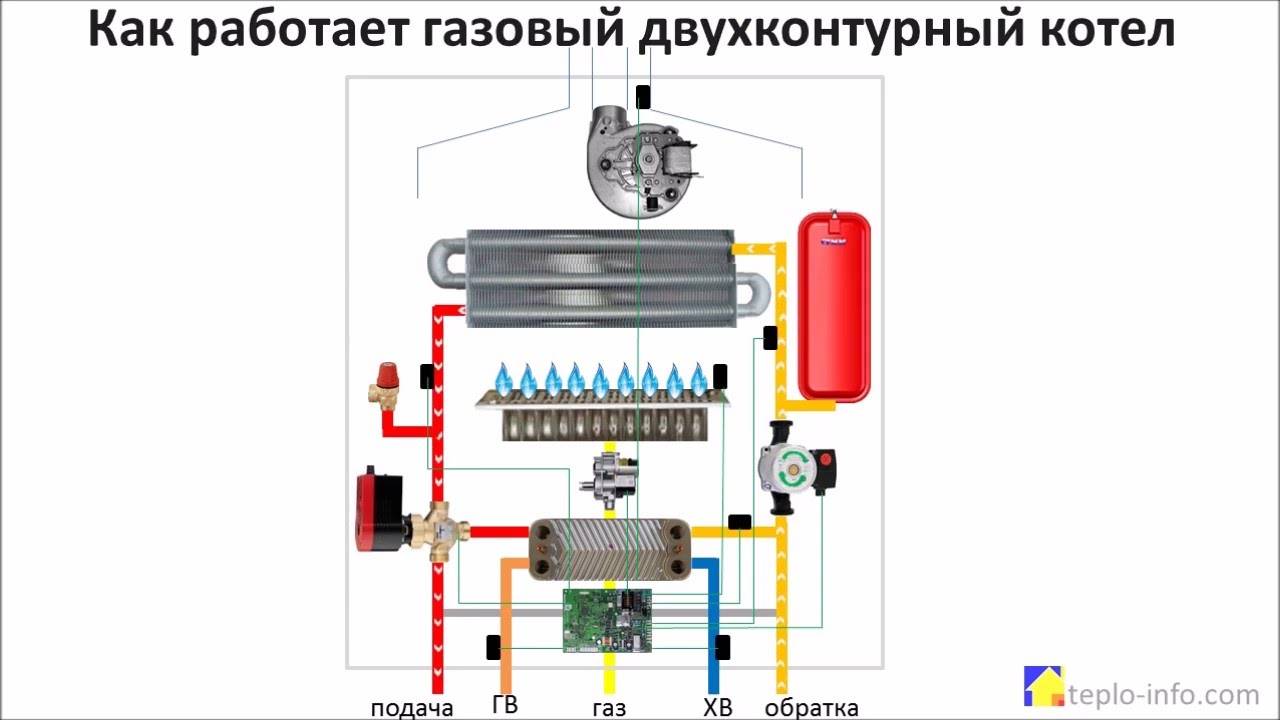

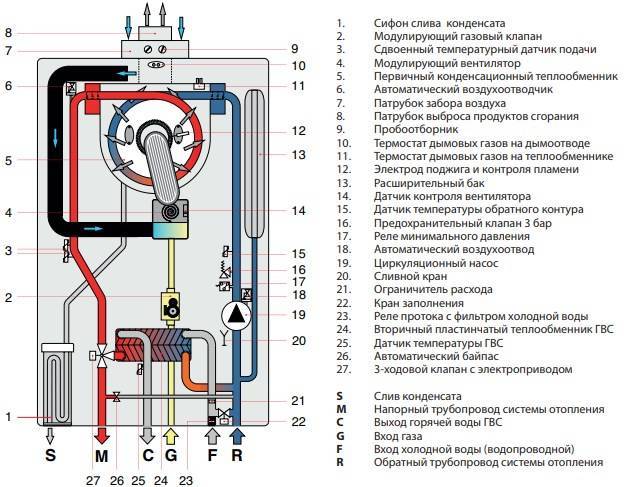

Image 1. Hydraulic diagram of a double-circuit boiler in heating mode.

Gas appliances with two heating circuits have the following principle of operation. The heat of the burnt natural gas is transferred to the heat exchanger, which is located above the gas burner. This heat exchanger is included in the heating system main, that is, the heated water in it will circulate through the heating system. Water circulation is carried out by means of a pump built into the boiler. For the preparation of hot water, the double-circuit device is equipped with a secondary heat exchanger.

The presented diagram in PICTURE 1 shows the ongoing work processes and equipment arrangement:

- Gas-burner.

- Circulation pump.

- Three-way valve.

- DHW circuit, plate heat exchanger.

- Heating circuit heat exchanger.

- D - input (return) of the heating system for heating;

- A - supply of ready-made coolant for heating appliances;

- C - cold water inlet from the main;

- B - output of ready hot water for sanitary needs and domestic use.

The principle of preparing water for domestic hot water is as follows: the heated water in the first heat exchanger (5), which is located above the gas burner (1) and is designed to heat the heating circuit, enters the second plate heat exchanger (4), where it transfers its heat to the domestic hot water circuit.

As a rule, double-circuit boilers have a built-in expansion tank to compensate for changes in the volume of the coolant.

The scheme of a double-circuit boiler allows you to produce hot water and heat it for heating only in certain modes.

The design of a double-circuit gas boiler.

Using the boiler for both domestic hot water and heating at a certain point in time is not possible. For example, during operation of the device, the heating system is heated at a given temperature, the process of maintaining the temperature is controlled by the automatic boiler, and the circulation of the coolant through the heating network is carried out by a pump.

At a certain moment, the hot water tap for domestic needs is opened, and as soon as the water begins to move along the DHW circuit, a special flow sensor installed in the boiler is activated. With the help of a three-way valve (3), the water flow circuits in the boiler are reconfigured.Namely, the water heated in the heat exchanger (5) ceases to flow into the heating system and is supplied to the plate heat exchanger (4), where it transfers its heat to the DHW system, that is, the cold water that has arrived from the pipeline (C) is also heated through the pipeline (B) served to consumers of an apartment or house.

At this moment, the circulation goes in a small circle and the heating system does not heat up for the duration of the DHW use. As soon as the tap on the DHW intake is closed, the flow sensor is triggered and the three-way valve opens the heating circuit again, further heating of the heating system occurs.

Most often, the scheme of the device of a double-circuit gas boiler implies the presence of a plate heat exchanger. As already mentioned, its purpose is to transfer heat from the heating circuit to the water supply circuit. The principle of such a heat exchanger is that sets of plates with hot and cold water are assembled into a package where heat transfer occurs.

The connection is made in a hermetic way: this prevents the mixing of liquids from different circuits. Due to the constant change in temperature, processes of thermal expansion of the metal from which the heat exchanger is made occur, which contributes to the mechanical removal of the resulting scale. Plate heat exchangers are made of copper or brass.

Connection diagram for a double-circuit boiler.

There is a double-circuit boiler scheme, which includes a combined heat exchanger.

It is located above the gas burner and consists of double tubes. That is, the heating circuit pipe contains a hot water pipe inside its space.

This scheme allows you to do without a plate heat exchanger and slightly increase the efficiency in the process of preparing hot water.

The disadvantage of boilers with a combined heat exchanger is that scale is deposited between the thin walls of the tubes, as a result of which the operating conditions of the boiler deteriorate.

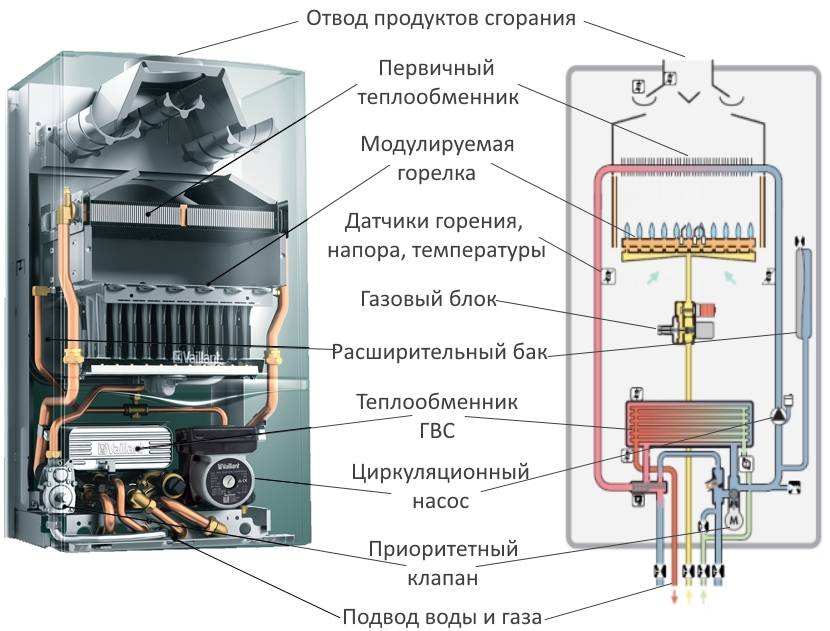

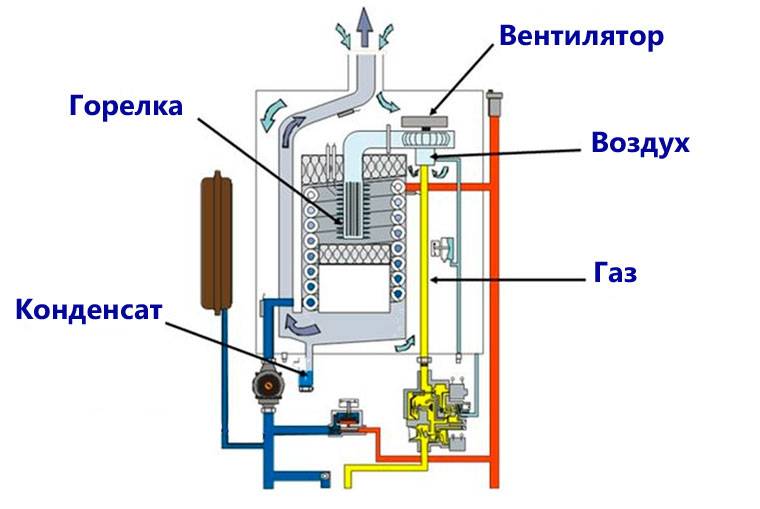

The device of a gas boiler with two circuits

In order to understand how a double-circuit gas boiler works, you need to familiarize yourself with its design. The device consists of a large number of different elements that are responsible for heating the coolant in the heating circuit and switch to the hot water circuit. Thanks to the coordinated work of all nodes, you will receive a high-quality device that will function without failures and malfunctions.

Consider the main elements included in the design of a double-circuit gas boiler:

- The burner, which is located in an open or closed combustion chamber, is the heart of each unit, is responsible for heating the coolant and generating the thermal energy necessary for the operation of the hot water circuit. In order to be able to maintain a given temperature regime, it includes an electronic flame modulation system.

- Circulation pump. Thanks to this, the element ensures the forced movement of the coolant through the heating system and during the operation of the DHW circuit. The operation of the pump is not accompanied by any extraneous sounds, so do not worry that the device will make noise.

- The combustion chamber, it is in it that the burner is placed. It happens open and closed.A fan is located above the closed combustion chamber, which provides air injection and removal of combustion products.

- Three-way valve - puts the system into hot water generation mode.

- The main heat exchanger - in double-circuit heating units, it is located above the burner, in the combustion chamber. This is where the heating medium takes place.

- Secondary heat exchanger - here the preparation of hot water is carried out.

- Automation. Based on the indicators of thermostats and sensors, it displays how much the system lacks thermal energy. After that, it activates the gas valve. Water, which acts as a heat carrier, is heated in the heat exchanger to the desired temperature and enters the heating circuit through the circulation pump. Also, automation is responsible for monitoring all indicators of the operation of equipment, checks the temperature of the coolant and hot water, turns on / off various nodes.

- At the very bottom of the case there are branch pipes necessary for connecting the heating system, pipes with cold / hot water and gas.

Based on the foregoing, it is clear that the device of a double-circuit gas boiler is not easy, but if you consider and understand what the purpose of certain nodes is, all difficulties will disappear. A distinctive feature of such units is the presence of a built-in piping - an expansion tank, a circulation pump and a safety group.

The device of a double-circuit, condensing gas boiler

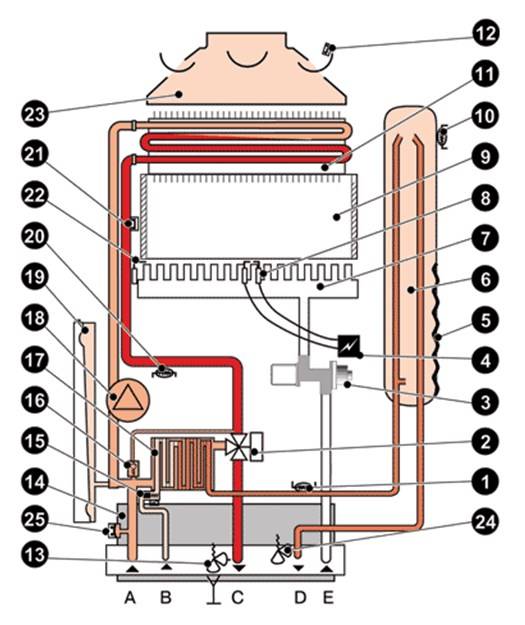

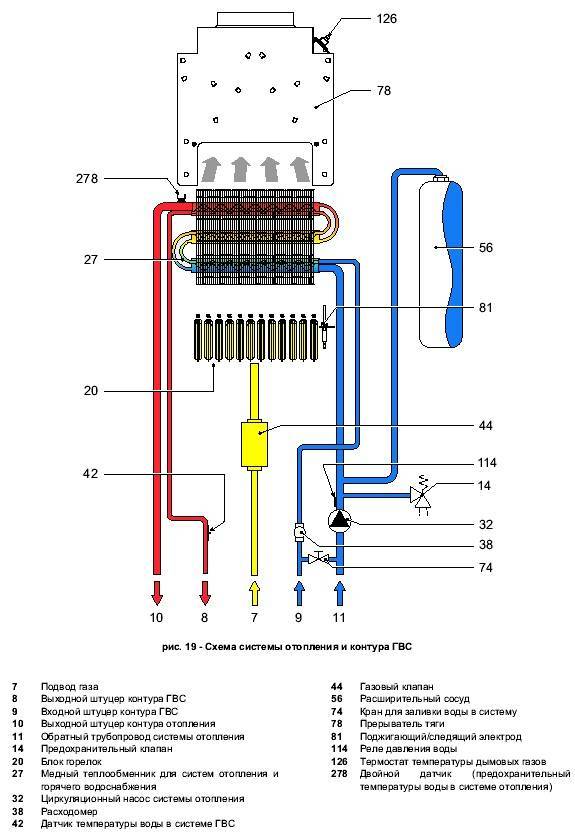

3 Unit design

To understand how a gas boiler works, you need to read the instructions, look at the drawing, which shows the frontal projection of the section of the apparatus, which gives a visual representation of the design of the equipment.

The unit consists of the following units:

- burner;

- heat exchanger;

- expansion tank;

- automation system.

The coolant is located above the burner. Antifreeze or water can be used as it. If the boiler is single-circuit, then the coolant is carried through the batteries and heats the room. Cold water enters the boiler again, heats up, and the cycle repeats.

How a combi boiler works

The same way of heating water does it differently. As boilers of different capacities heat a certain volume of water at different times, so different types of boilers heat running water, heat the room and emit carbon monoxide in different ways.

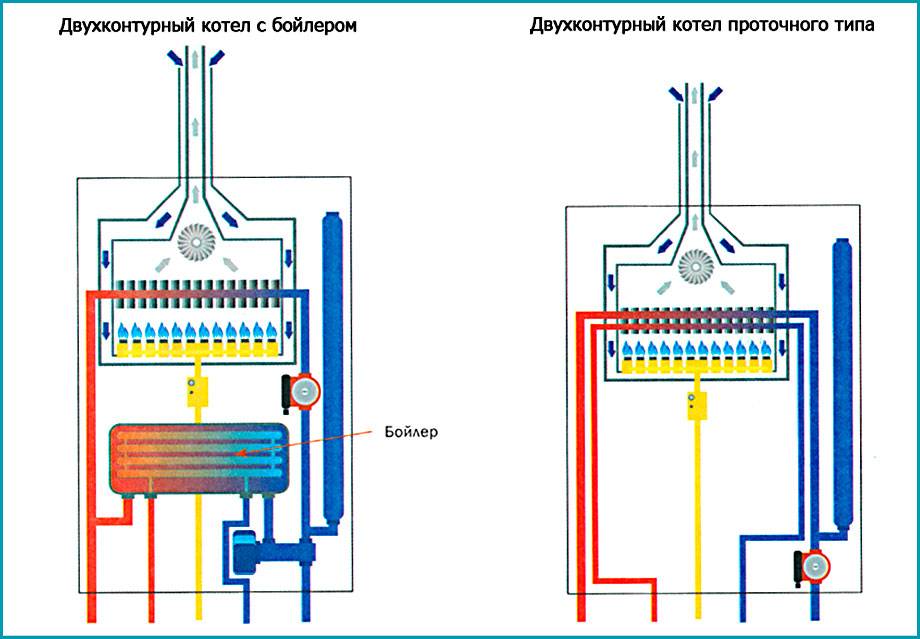

With bithermic heat exchanger

A bithermic heat exchanger is similar in structure to a coaxial chimney. This design does not require a three-way valve. A clear advantage of such a scheme is not only its economy, but also its small size.

Important! There is a huge downside to the incoming water, as a two-way valve is more likely to be clogged when in contact with water containing a lot of salt. T

That is, if the water is very heavily chlorinated, the chance of it blocking and exiting the system is much higher than with a three-way. Although, roughly speaking, this is just a delay in time, since it is necessary to periodically thoroughly clean the pipes, preferably once every six months.

With flow heater

Flow heater - permanent heating of water during use.To get warm water from the faucet, you need to wait a few seconds for the cold water to drain. Such a scheme does not save time, but the gas savings are enormous.

Note! Water in such a water supply system is heated only when it is needed for this.

With instantaneous heater and standard boiler

A flow heater and a boiler are a unique tandem. One is designed to save energy and heat water at the right time, the other heats water constantly. Such a system is suitable only when hot water is required constantly. It has few advantages, but those cover significant financial costs.

The principle of connecting a double-circuit boiler

The diagram above conventionally shows the boiler itself (pos. 1) and the power supply line connected to it (pos. 2) - a gas main or a power cable, if we are talking about an electrical unit.

One circuit closed in the boiler works exclusively for the heating system - a heated coolant supply pipe (pos. 3) comes out of the unit, which is sent to heat exchange devices - radiators, convectors, underfloor heating, heated towel rails, etc. Having shared its energy potential, the coolant returns to the boiler through the return pipe (pos. 4).

The second circuit is the provision of hot water for domestic needs. This kennel is constantly fed, that is, the boiler is connected by a pipe (pos. 5) to a cold water supply. At the outlet, there is a pipe (pos. 6), through which heated water is transferred to water consumption points.

The contours can be in a very close layout relationship, but nowhere do their "contents" intersect.That is, the coolant in the heating system and the water in the plumbing system do not mix, and can even represent completely different substances from the point of view of chemistry.

The scheme of the boiler in heating mode only

The yellow arrow shows the gas flow to the gas burner (item 1), above which is the primary heat exchanger (item 3). The circulation pump (pos. 5) ensures the movement of the coolant through the pipes from the return of the heating circuit through the heat exchanger to the supply pipe and back to the circuit (blue arrows with a transition to red). The coolant does not move through the secondary (pos. 4) heat exchanger. The so-called "priority valve" - an electromechanical valve device or a three-way valve with a servo drive (pos. 7), closes the "small circle", opening the "large", that is, through the heating circuit with all its radiators, underfloor heating, convectors, etc. P..

In the diagram, in addition to the nodes mentioned, other important parts of the boiler design are marked with numbers: this is a safety group (pos. 9), which usually includes a pressure gauge, a safety valve and an automatic air vent, and an expansion tank (pos. 8). By the way, although these elements are mandatory for any closed heating system, they may not be structurally included in the boiler device. That is, often they are simply purchased separately and "cut" into the overall system.

Changes that occur when starting hot water

If the hot water tap was opened, then water began to move through the pipe (blue arrows), to which the turbine of the flow sensor (pos. 6) immediately reacts. The signal from this sensor is processed by the control unit, from where a command is transmitted to the three-way valve (pos. 7) to change the position of the valves.Now the “small” circle is open and the large circle is “closed”, that is, the coolant rushes through the secondary heat exchanger (pos. 4). There, heat is taken from the coolant and transferred to hot water, leaving for an open point of consumption. The circulation of the coolant in the heating system is suspended for this time.