- Overview of manufacturers of boilers with a generator

- What is automation for a gas boiler. General view

- By material and type of heat exchanger

- Minimum pressure switch (gas) ↑

- The principle of operation of a double-circuit gas boiler

- Hot water operation

- The principle of operation of the gas valve Eurosit 630

- Overview of the best models and manufacturers

- The principle of operation of the boiler room

- Primary heat exchanger

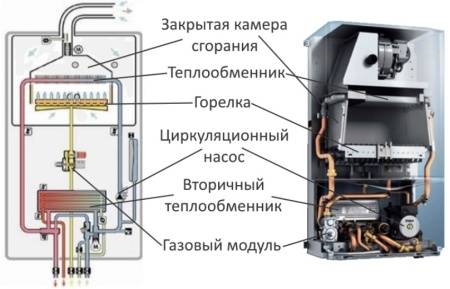

- Varieties and device of a gas boiler

- The design of a two-circuit device

- Advantages of gas boilers

- Boiler operation options

- How to choose the right model

- Characteristics of a double-circuit gas boiler

- Boiler room requirements and safety precautions

- Classification and varieties

- Scheme of a steam boiler

Overview of manufacturers of boilers with a generator

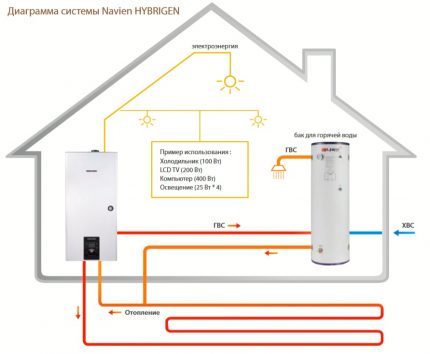

Let's consider specific examples of domestic boiler systems that exist today, in which the principle of using exhaust gases (combustion products) for generating electricity has been successfully implemented. The South Korean company NAVIEN has successfully implemented the above technology in a HYBRIGEN SE boiler.

The boiler uses a Stirling engine, which, according to the passport data, generates electricity with a power of 1000W (or 1kW) and a voltage of 12V during operation.The developers claim that the generated electricity can be used to power household appliances.

This power should be enough to power a household refrigerator (about 0.1 kW), a personal computer (about 0.4 kW), an LCD TV (about 0.2 kW) and up to 12 LED bulbs with a power of 25 W each.

navien hybrigen se boiler with built-in generator and Stirling engine. During the operation of the boiler, in addition to the main functions, electricity is generated on the order of 1000 W of power.

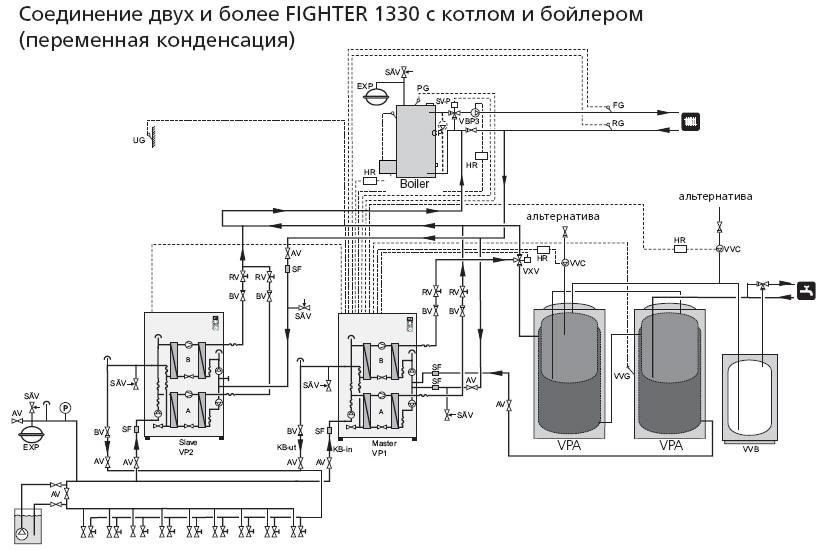

Of the European manufacturers, Viessmann is engaged in developments in this direction. Viessmann has the opportunity to offer two models of boilers of the Vitotwin 300W and Vitotwin 350F series to the customer's choice.

The Vitotwin 300W was the first development in this direction. It has a fairly compact design and looks very similar to a conventional wall-mounted gas boiler. True, it was during the operation of the first model that the "weak" points in the operation of the engine of the Stirling system were identified.

The biggest problem turned out to be heat dissipation, the basis of the operation of the device is heating and cooling. Those. developers faced the same problem that Stirling faced in the 40s of the last century - efficient cooling, which can only be achieved with a significant size of the cooler.

That is why the Vitotwin 350F boiler model appeared, which included not only a gas boiler with an electricity generator, but also a built-in 175l boiler.

The storage tank for hot water is made in the floor version due to the large weight of both the equipment itself and the liquid prepared for sanitary purposes

The storage tank for hot water is made in the floor version due to the large weight of both the equipment itself and the liquid prepared for sanitary purposes

In this case, the issue with the problem of cooling the Stirling piston using water in the boiler was effectively resolved. However, the decision led to the fact that the overall dimensions and weight of the installation increased. Such a system can no longer be mounted on the wall like a conventional gas boiler and can only be floor-standing.

Viessmann boilers provide for the possibility of feeding the boiler operation systems from an external source, i.e. from the central power supply networks. Viessmann positioned the equipment as a device that provides for its own needs (operation of boiler units) without the possibility of extracting excess electricity for domestic consumption.

The Vitotwin F350 system is a boiler with a 175l water heating boiler. The system allows you to heat the room, provides hot water and generates electricity

In order to compare the efficiency of using generators built into the heating system. It is worth considering the boiler, which was developed by the TERMOFOR companies (Republic of Belarus) and the Krioterm company (Russia, St. Petersburg).

It is worth considering them not because they can somehow compete with the above systems, but to compare the principles of operation and the efficiency of generating electrical energy. These boilers use only firewood, pressed sawdust or wood-based briquettes as fuel, so they cannot be put on a par with models from NAVIEN and Viessmann.

The boiler, named "Indigirka Heating Stove", is oriented to long-term heating with wood, etc., but is equipped with two thermal electricity generators of the TEG 30-12 type. They are located on the side wall of the unit. The power of the generators is small, i.e.in total they are only able to generate 50-60W at 12V.

The fundamental device of the Indigirka stove allows not only to heat the room, but also to cook food on the burner. Complementing the system - two heat generators for 12V with a power of 50-60W.

The fundamental device of the Indigirka stove allows not only to heat the room, but also to cook food on the burner. Complementing the system - two heat generators for 12V with a power of 50-60W.

In this boiler, the Zebek method, based on the formation of an EMF in a closed electrical circuit, has found application. It consists of two dissimilar types of material and maintains contact points at different temperatures. Those. developers also use the heat generated by the boiler to generate electrical energy.

What is automation for a gas boiler. General view

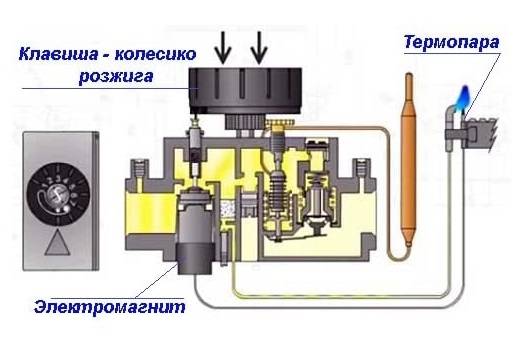

Automation used for gas boilers are special devices that provide control over the operation of heating equipment after it is started. The main purpose of automatic control devices is to ensure the safety of operation of heating units and maintain the optimum temperature in the room.

By functionality, automation is divided into two main types:

- volatile devices;

- non-volatile control devices.

The first type - volatile automation used in autonomous heating systems, has a simpler design and works according to the residual principle. The signal from the temperature sensor about temperature changes is sent to the solenoid valve, which closes or opens, shutting off the gas supply to the gas boiler. Almost all heating boilers are equipped with this type of control equipment.

The second type of automation - non-volatile devices operate on the basis of the physical properties of the substance inside the closed circuit of the device.When heated, the substance expands, creating increased pressure inside the device. Under the action of high pressure, it is actuated, blocking the gas supply to the combustion chamber. The boiler is switched on in the reverse order. When the temperature decreases, the volume of the substance decreases, as a result of which the pressure in the device decreases. The valve returns to its normal position, allowing gas to enter the burner. Such automation devices are equipped with non-volatile gas boilers. Models of automation system blocks may differ only in the standard set of functions.

By material and type of heat exchanger

Heat exchangers can be:

- cast iron;

- copper;

- aluminum-silicon;

- carbon or stainless steel.

The design of the heat exchanger can also vary.

The most popular are separate heat exchangers. Separately passes heating water, separately water for household needs of residents. They are slightly more expensive, but more reliable.

The bithermic heat exchanger looks like a pipe in a pipe. In the inner pipe, the DHW water that needs to be warmed up, and the heating coolant circulates in the outer pipe.

The third type is a heat exchanger in which a coil is built in. The water tank is heated by the coolant flowing in the coil. The indirect heating system is good for everyone, but in the summer you either have to heat the boiler or live without hot water.

The bithermic option is not recommended for use where hard water is present. And be prepared that each time, scalding water will drain from the tap first, and only then the temperature you need.

Minimum pressure switch (gas) ↑

Honeywell Brand Gas Valve for Small Boiler Equipment

Gas burners are designed to be used at nominal gas pressure - they are designed for this. It is with such indicators that the declared useful power of the boiler will be ensured. With a decrease in gas pressure, a drop in power is also observed. Boilers equipped with atmospheric gas burners are sensitive to a decrease in gas pressure - pipes can burn out. The falling pressure of the gas leads to the “settlement” of the flame so that the metal part of the burner is in the zone of the torch itself. And this can lead to breakdowns.

In order to protect the boiler and burner, a minimum gas pressure switch is used. The relay switches off the boiler when the pressure drops below the set value. The limit value can be changed during commissioning of the boiler. The gas pressure switch is structurally a kind of membrane that acts on a group of contacts. When the pressure decreases, the membrane moves under the influence of the spring and the electrical contacts switch. Switching contacts breaks the electrical circuit, which just controls the operation of the boiler. The power supply to the gas valve stops - and the boiler stops working. When the gas pressure is restored, the membrane will return to its original position, the contacts will switch again - and the boiler is ready to start again. Only here other processes are further determined by the logic of the actual control automation, and they may differ. Minimum pressure switches are mounted on the gas inlet to the boiler directly in front of the multiblock. Or in front of the front gas valve.

Dungs gas valve for floor standing boilers

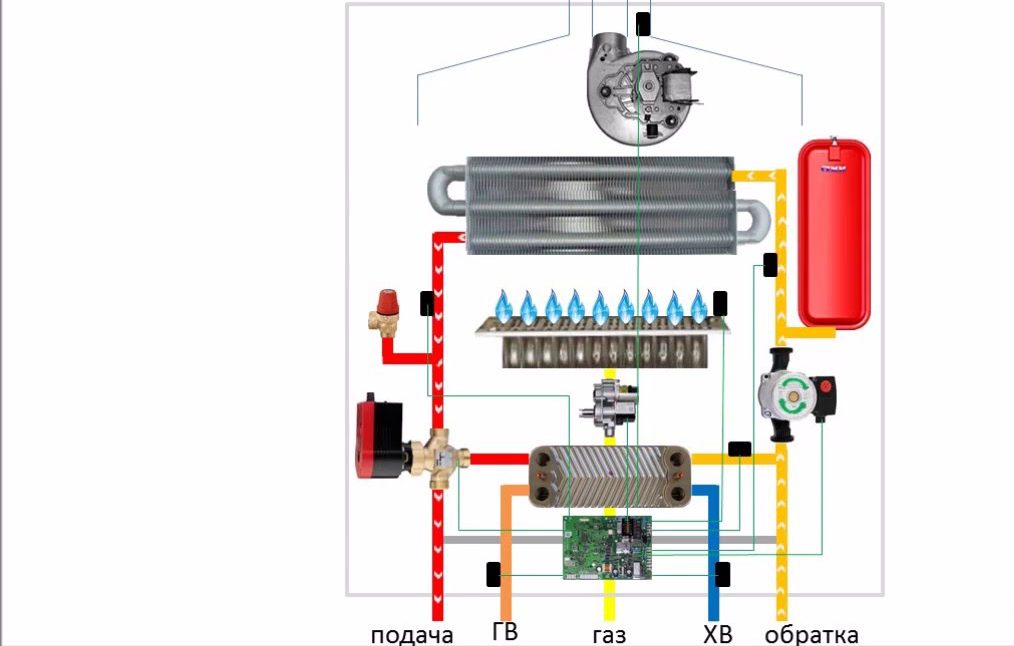

The principle of operation of a double-circuit gas boiler

Now we will begin to analyze the principle of operation of a gas double-circuit boiler. We found out the purpose of individual nodes and modules, now this knowledge will help us understand how all this equipment works. We will consider the principle of operation in two modes:

- In heating mode;

- In hot water generation mode.

In heating mode, the boiler provides your home with heat.

Immediately, we note the fact that operation in two modes is immediately impossible - for this, double-circuit boilers have a three-way valve that directs part of the coolant to the DHW circuit. Let's look at the principle of operation during heating, and then find out how the technique works in hot water mode.

In heating mode, a double-circuit boiler works in the same way as the most common instantaneous heater. When first turned on, the burner works for a rather long time, raising the temperature in the heating circuit to the set point. As soon as the required temperature is reached, the gas supply will turn off. If an air temperature sensor is installed in the house, then the automation will take into account its readings.

The operation of a gas burner in double-circuit boilers can also be affected by weather-dependent automation that controls the temperature of the outside air.

The heat from the operating burner heats the coolant, which is forced through the heating system. The three-way valve is in such a position to ensure the normal passage of water through the main heat exchanger. Combustion products are removed in two ways - independently or with the help of a special fan located in the upper part of the double-circuit boiler. The DHW system is in the off state.

Hot water operation

As for the hot water circuit, it starts at the moment when we turn the handle of the water tap. The appeared current of water leads to the operation of a three-way valve, which turns off the heating system. At the same time, the gas burner is ignited (if it was turned off at that time). After a few seconds, hot water starts flowing from the faucet.

When switching to hot water mode, the heating circuit is completely switched off.

Let's look at the principle of operation of the DHW circuit. As we have already said, turning it on leads to the shutdown of the heating operation - only one thing can work here, either the hot water supply or the heating system. It's all controlled by a three-way valve.

It directs part of the hot coolant to the secondary heat exchanger - note that there is no flame on the secondary. Under the action of the coolant, the heat exchanger begins to heat the water flowing through it

The scheme is somewhat complicated, since a small circle of coolant circulation is involved here. This principle of operation cannot be called the most optimal, but double-circuit gas boilers with separate heat exchangers can boast of normal maintainability. What are the features of boilers with combined heat exchangers?

- A simpler design;

- High probability of scale formation;

- Higher efficiency for DHW.

As we can see, the disadvantages are closely intertwined with the advantages, but separate heat exchangers are valued more. The design is somewhat more complicated, but there is no scale here.

Please note that at the time of DHW operation, the flow of coolant through the heating circuit stops.That is, its long-term operation can disrupt the heat balance in the premises.

As soon as we close the tap, the three-way valve is activated, and the double-circuit boiler goes into standby mode (or the heating of the slightly cooled coolant immediately turns on). In this mode, the equipment will be until we open the tap again. The performance of some models reaches up to 15-17 l / min, which depends on the power of the boilers used.

Having dealt with the principle of operation of a gas double-circuit boiler, you will be able to understand the purpose of individual components and even be able to independently understand the issues of repair. At first glance, the device seems very complicated, and the dense internal layout commands respect - after all, the developers managed to create an almost perfect heating equipment. Double-circuit boilers from companies such as Vaillant. are actively used for heating buildings for various purposes and for generating hot water, replacing two devices at once. And their compactness allows you to save space and get rid of the need to purchase a floor boiler.

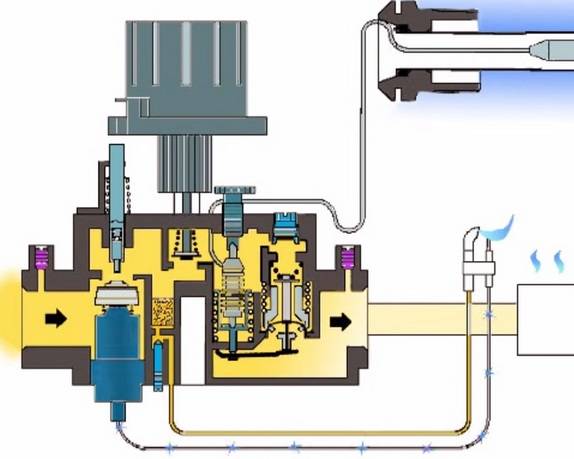

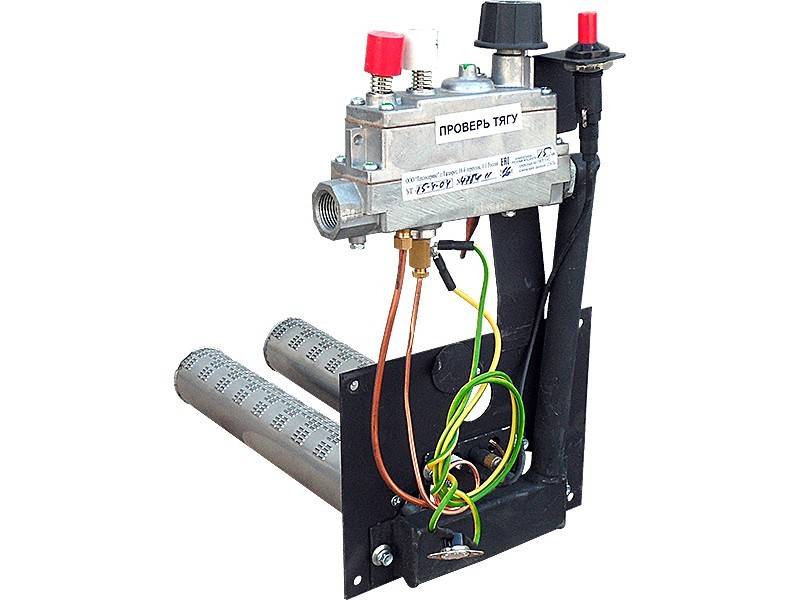

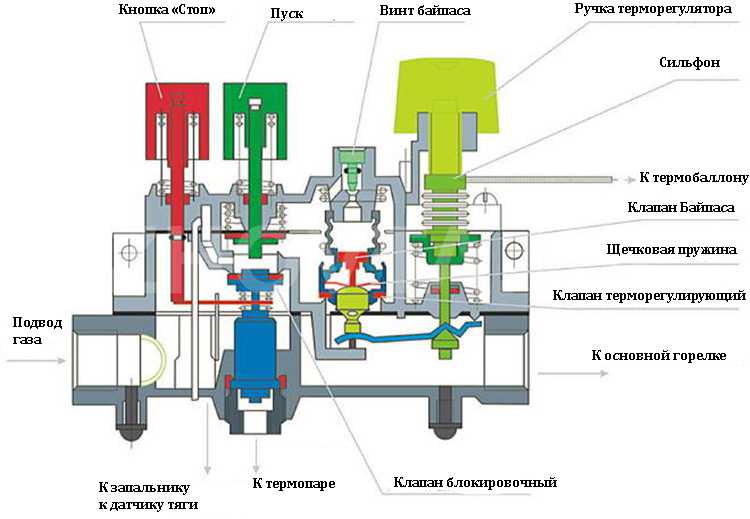

The principle of operation of the gas valve Eurosit 630

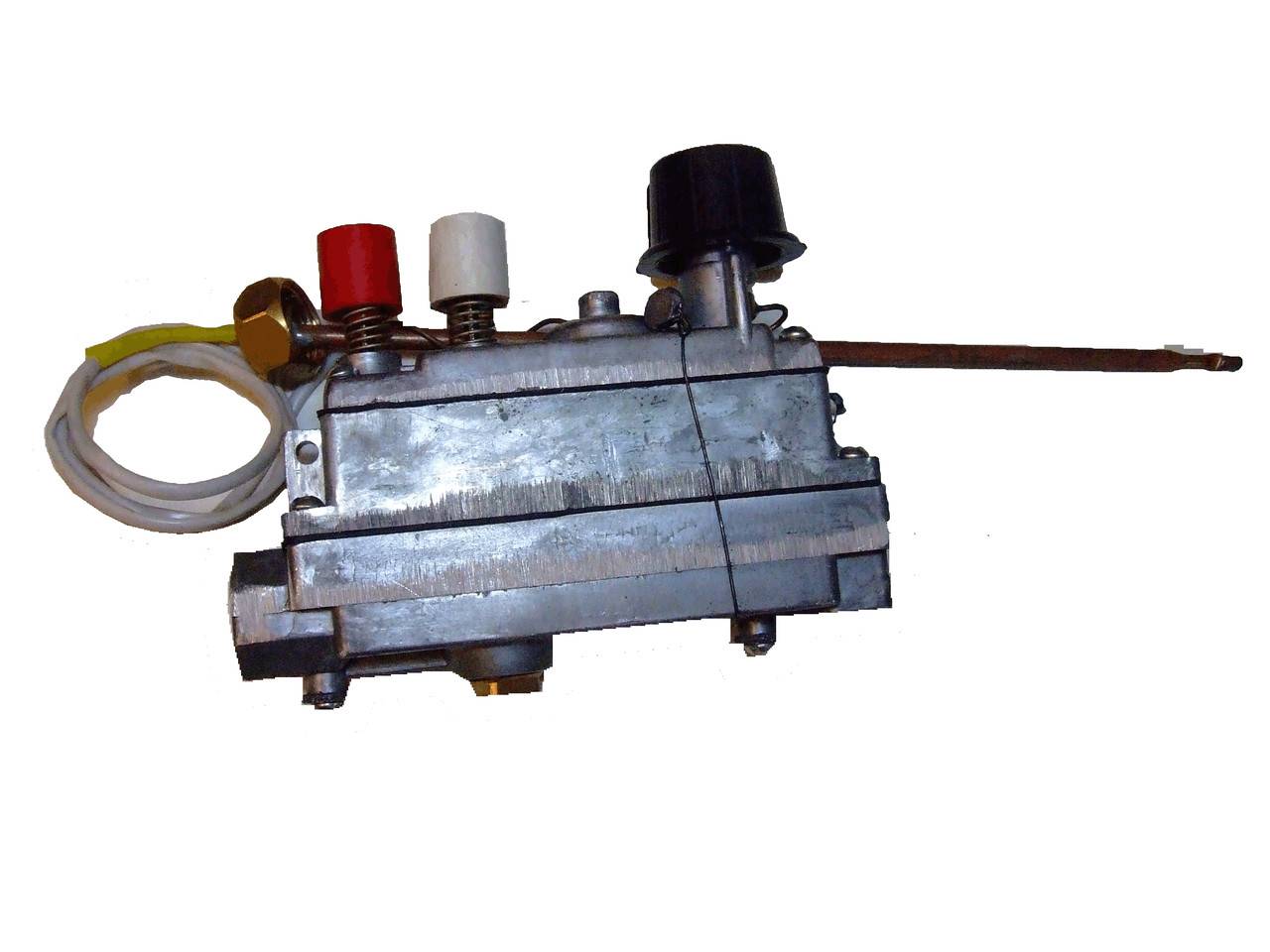

Eurosit 630 is a device that regulates the supply of fuel, having a modulating thermostat and the function of fully turning on the main burner. The valve for the Eurosit 630 gas boiler is a non-volatile device that allows the boiler to operate on liquefied gas or from a gas tank. The device can be of various modifications, it is used on almost any equipment that consumes gas.

Any automatic gas burner device equipped with a EUROSIT valve is put into operation manually. Consider the principle of operation of the device.Prior to operation, the fuel system is closed by a solenoid valve. We press the regulator washer, the valve opens, and the fuel chambers are filled with gas, the gas rises through the small fuel line to the igniter.

Further, without releasing the puck, turn on the piezo button and set fire to the igniter. The igniter heats up the temperature sensitive element in 10-30 seconds, which gives a voltage that can keep the solenoid valve open. The washer can then be released, rotated to the desired value and open the path to the burner for the fuel. The burner in the device independently ignites from the igniter.

Gas burners with automation for heating boilers then independently maintain the set temperature, and human intervention is not needed. The safety of operation of such a burner is ensured by combining the design of gas combustion with a fan.

The principle of operation of the Eurosit 630 device is presented in this video:

Overview of the best models and manufacturers

The most famous brand among Western manufacturers is the Italian automation company EUROSIT, which is popular throughout the post-Soviet space.

In second place are American manufacturers of automation Honeywell, whose equipment has a more loyal pricing policy. At the same time, American technology is practically not inferior to Italy in the range of services provided.

Using the example of a model with the designation Honeywell VR 400, you can consider a list of useful features:

- device for smooth ignition;

- modulation mode of hot water boilers;

- built-in mesh filter;

- a mode designed to maintain the burners at a low flame;

- inputs for installing a relay that controls the minimum as well as intermediate pressure.

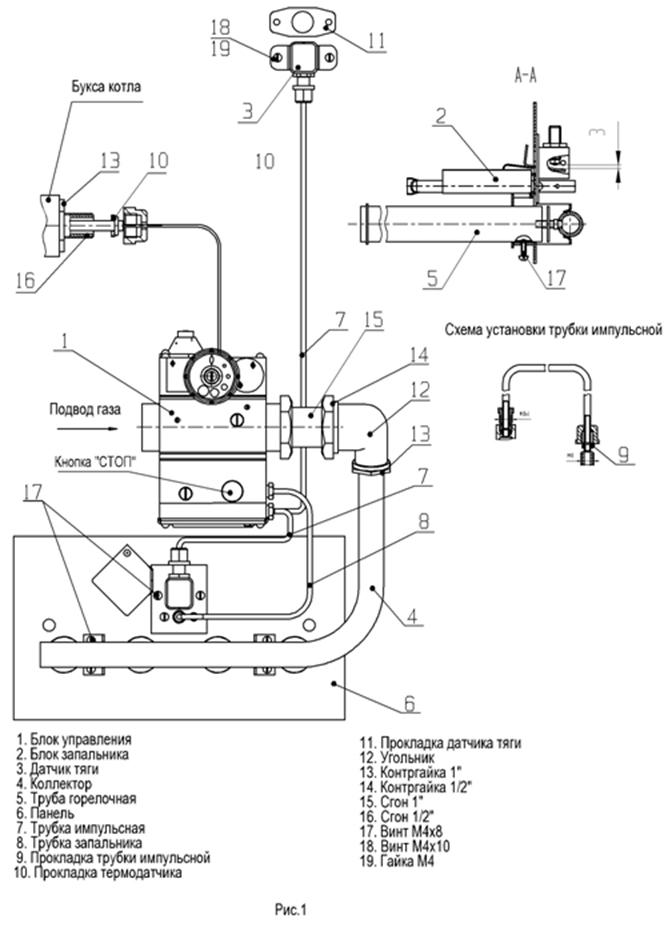

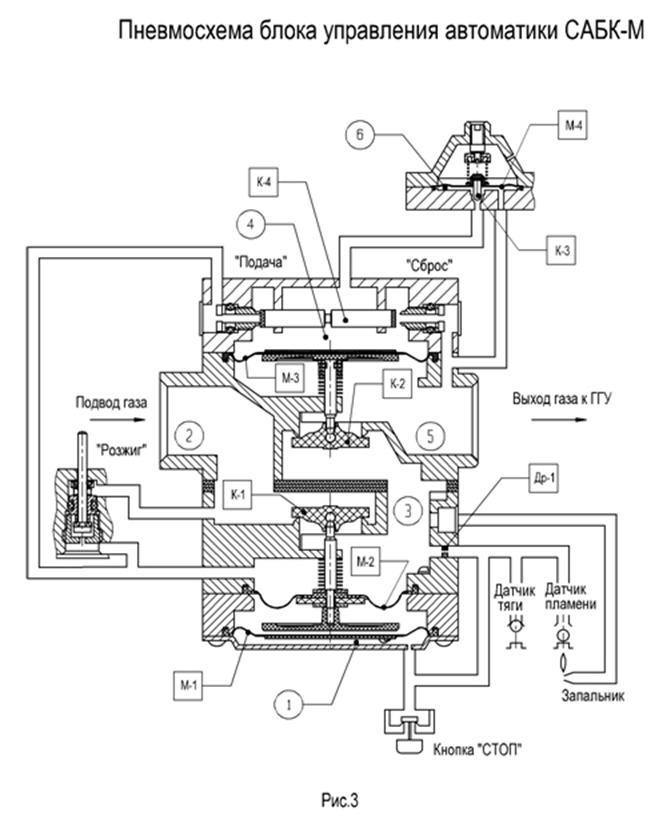

Among domestic manufacturers, the Orion company is considered the most famous, as well as the Service Gas company, which produces SABC security automation in the city of Ulyanovsk.

SABC security automation is known for its wide range of systems offered, which can have both the most necessary elements and a wider comfort list.

All SABC gas automation, depending on the cost, is divided into several consumer groups. When selecting equipment, be sure to clarify all questions with the seller.

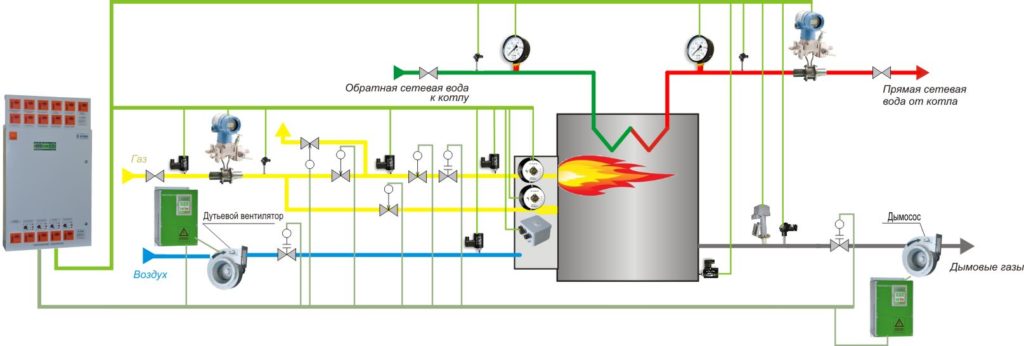

The principle of operation of the boiler room

A boiler room is a separate room that is allocated for the installation of heating equipment.

Depending on the location of the premises, the following types of boiler rooms are distinguished:

- When constructing a separate building for the installation of gas equipment, they talk about a separate boiler room. The heating lines that go from this building to the house are well insulated so that there is no heat loss. The advantage of such options is reliable protection against noise emitted by operating equipment, as well as safety for people in case of poor carbon monoxide removal.

- The attached variety is adjacent to a residential building. This option is more advantageous in that you do not need to pull communications from a separate building to the house and insulate them well. Moreover, the entrance to this room can be organized directly from home, so that in winter you do not have to walk down the street to adjust the operation of the boiler and check the system.

- The built-in type of such premises is located inside the house. In this case, it is much easier to lay the heating circuit and other necessary communications.

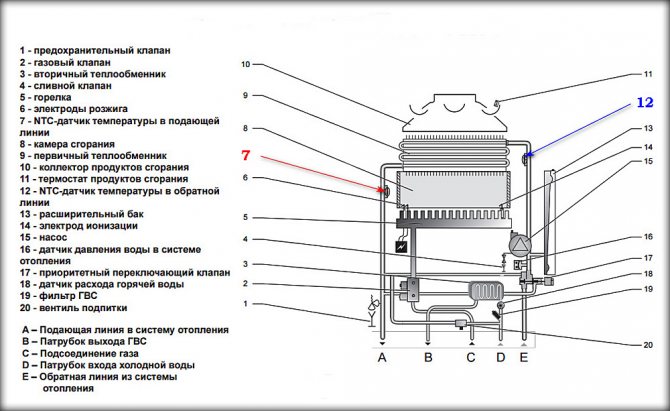

Primary heat exchanger

gas boiler heat exchanger

It is a defining element in the operation of the boiler, it serves to transfer heat from the fire to the heating fluid further into the heating system. The device of such a heat exchanger, as a rule, is the same for all types of boilers of all manufacturers. Outwardly, this is a copper pipe, inside which heating fluid flows. Such heat exchangers are called "copper". Since the heat exchanger is located above the burner flame, the heat from the fire heats up the copper pipe, which transfers the heat to the heating fluid. It is noteworthy that it was copper that was chosen as the metal that successfully copes with the task of retaining heat and, if necessary, its rather rapid loss, because. has a high heat transfer coefficient. Also, copper does not rust quickly, due to which the term of its functionality is quite high. In addition to the copper pipe, the heat exchanger is equipped with special plates that help to smoothly distribute all the heat from the fire, thereby contributing to uniform heating of the heat exchanger.

Varieties and device of a gas boiler

The classification of boilers operating with gas is as follows:

- samples of floor and wall type. If we talk about convenience, then wall-mounted equipment, which is more typical for private buildings, will be more acceptable. The main advantage of the outdoor unit is its much greater power, as a result of which it can be used to heat a room with a very significant area. Such models are very often used in production;

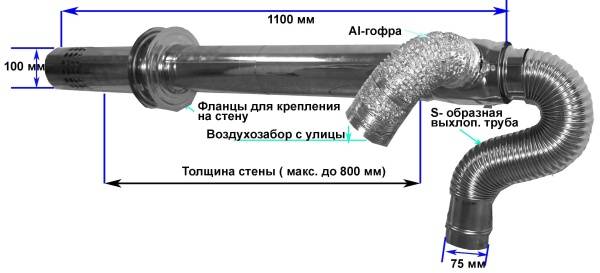

- atmospheric and turbocharged gas boilers. To understand how gas heating with an atmospheric boiler works, you can recall the principle of operation of a standard stove, where air from the room enters a specially designed chimney due to natural draft. Turbocharged devices are equipped with a fan, which is included in the design, and the fuel combustion chamber is completely closed, so all the necessary amount of air comes from the street (for more details: “How does a turbocharged gas boiler work - the principle of operation, advantages and disadvantages”);

- mechanisms with one and two circuits. The device of a gas boiler with one circuit is designed so that this equipment is used exclusively for heating rooms, while appliances with two circuits can also play an important role in the water supply system, providing the room with hot water;

- boilers equipped with a conventional burner or a modulating burner (in more detail: “What are gas burners for heating boilers - types, differences, rules of use”). In the second case, the power of the operating equipment is automatically regulated, which can significantly reduce fuel costs;

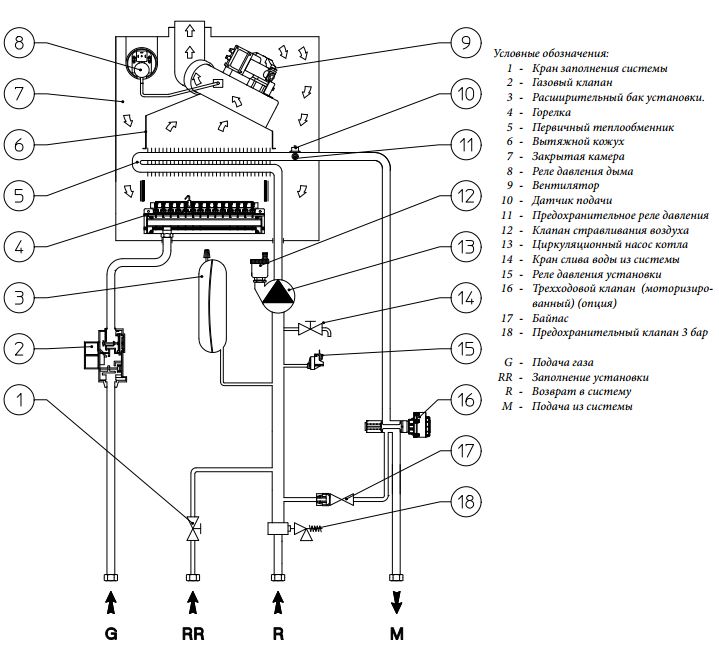

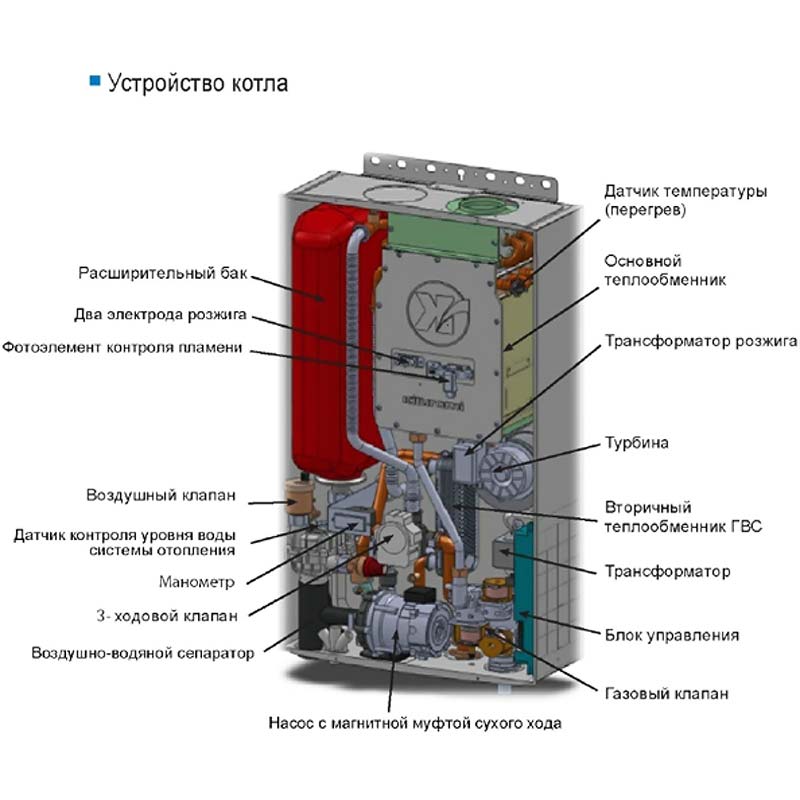

The design of a two-circuit device

The device of a double-circuit gas boiler (Fig. 4) consists of three main nodes that are in all types of the device:

Also, an invariable part of the gas heating unit is a housing with a layer of thermal insulation.

Rice. 4 Design of a double-circuit gas boiler

Rice. 4 Design of a double-circuit gas boiler

The gas burner is a design with perforations along the entire body, and there are nozzles inside. Nozzles deliver and distribute gas for a uniform flame. The burner can be of several types:

- Single-stage - this burner is designed so that it cannot be regulated, it works in one mode;

- Two-stage - this device has 2 power adjustment positions;

- Modulated - the power of such a burner can be adjusted, due to this, the boilers consume fuel more economically.

Heat exchanger. In double-circuit gas appliances there are 2 heat exchangers:

- Primary - the coolant for the heating circuit is heated in it. Made from steel or cast iron;

- The secondary is a heat exchanger in which water is heated for the hot water circuit. It is usually affected by a temperature slightly less than the primary, so it can be made from materials such as copper, stainless steel, etc.

Rice. 5 Primary heat exchanger for double-circuit gas appliance

Rice. 5 Primary heat exchanger for double-circuit gas appliance

Automation is a node that controls the operation of a gas device. It includes an electronic circuit and a sensor system. Sensors give indications of the operation of a double-circuit boiler to an electronic circuit that sets the operating mode or turns off the device.

Circulation pump - this device is needed for a forced circulation heating system. This is a component part for a volatile system. Such a pump provides the desired pressure indicator.

The system for removing combustion products can be with:

- natural traction. In this case, the combustion products are discharged into the chimney, which must rise above the roof by at least 1 meter;

- forced traction. Boilers with such a system have a fan in their design to discharge combustion products into a coaxial chimney (pipe in pipe). Such boilers are called turbocharged.

Expansion tank.When the coolant is heated to a high temperature, it expands, and its excess temporarily enters the expansion tank. The volume of the tank can be different, it depends on the volume of the coolant in the system and the power of the boiler.

The combustion chamber looks like a container made of metal with thermal insulation. It is above it that the primary heat exchanger is located, and at its bottom there is a burner. The combustion chamber of a gas device can be:

A double-circuit gas appliance with an open chamber is a device that can be non-volatile, since it takes combustion air directly from the room in which it is installed. It is recommended to install such units in separate rooms - boiler rooms. They must be arranged according to all the rules, namely, have good ventilation and a window. If a double-circuit boiler with an open combustion chamber does not have enough air, it will emit carbon dioxide.

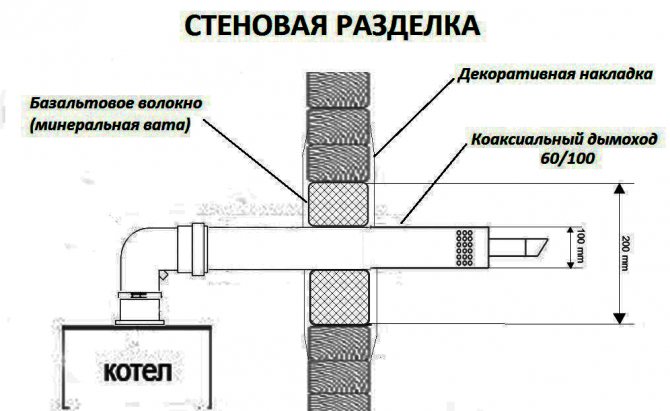

A double-circuit gas appliance with a closed chamber is a device that takes combustion air from the street through a coaxial chimney. The principle of the coaxial gas exhaust system lies in its special design - "pipe in pipe" (Fig. 6). That is, a pipe with a smaller diameter is in a pipe with a larger diameter. Combustion products exit through a small pipe, and air is taken into the gas boiler through a large one. The advantage of a coaxial chimney is that it can be installed both horizontally and vertically.

Rice. 6 Pipe for coaxial chimney (pipe in pipe)

Rice. 6 Pipe for coaxial chimney (pipe in pipe)

Advantages of gas boilers

Gas heating systems have the following advantages:

- Automation ensures the stability of work and ease of operation of the heating unit.

- Gas boilers quickly pay off due to efficient operation and low fuel costs.

- Capable of heating large areas.

- The principle of operation is designed for a really long service life.

- Demonstrate high levels of efficiency.

- Do not force the user to monitor the level of the flame. The gas is supplied continuously, and in the event of the burner attenuation, the automation for gas heating boilers informs the system about this and resumes combustion.

- The boiler gives off more energy than it consumes itself.

Boiler operation options

Despite the variety of automatic modes, as a rule, only one of the possible modes is used: in which the boiler heats up to the value set on the control panel and continues to maintain it. This mode is acceptable, but not optimal. According to the coolant temperature, the boiler operates in modulation mode, which is good. At the same time, the boiler devices do not have data on the situation at the facility that serves the heater. Room temperature data missing. There is only one parameter: the temperature of the coolant. When the set value is reached, the boiler output is reduced. Then the heating pad turns off, the device is idle for a while. As soon as the carrier temperature drops by the set number of degrees, a restart is performed.

How to choose the right model

The main criterion is the specification of the model. There are devices that are suitable only for certain models of boilers from one manufacturer, they are produced as additional equipment for the boiler, information about their purpose is usually contained in the name itself.Of course, if there is such an opportunity, it is better to choose a GSM module from the same manufacturer as the boiler (it will be tailored to a specific line of models and their specifics).

But there are also universal models that are suitable for absolutely any boilers that have the appropriate terminals, it is these universal GSM modules that are discussed in the article.

Today, the choice of universal GSM modules is small (about 20-25 models), so it is difficult to single out a sufficient number of criteria. We recommend studying the most famous and successful models (see below) and choosing from them, studying the functionality and convenience of each, comparing prices

But we also recommend paying attention to such criteria as:

- The presence of an application and a web-interface, which greatly simplifies management, allows you to see and analyze the statistics of work. If the manufacturer has not provided interface examples, you should look for screenshots in the image search of any of the search engines. An example of a web interface for ZONT modules, the interface is available in your account on the manufacturer's website.

- Standard equipment. Some modules come with external temperature sensors that can be placed in rooms remote from the boiler room and guided by their measurements, which is an obvious advantage. The equipment with the presence of a remote antenna is considered good, which makes it possible to seriously improve the quality of communication, and in some cases, when the antenna is moved higher, it is completely possible to catch the signal that is absent on the ground floor or in the basement of a distant house.

- The capacity of the built-in battery should be at least 100-150 mAh, with such parameters it will last for 2-4 hours of module operation.

Characteristics of a double-circuit gas boiler

When choosing a double-circuit boiler, you should pay attention not only to the materials, but also to the declared characteristics:

- Power. The larger the area of \u200b\u200bthe heated house and the greater its heat loss, the more powerful the boiler will be required. For a house of 100 square meters in temperate latitudes, you will need a boiler with a capacity of 12 kW.

- Efficiency. Improved heat exchangers and burners of double-circuit boilers, the presence of "smart" automation and control programs make it possible to bring the efficiency closer to the fantastic 98%.

- View of the combustion chamber. Allocate boilers with open and closed combustion chambers.

With a closed combustion chamber, air is supplied and combustion products are ejected by a special coaxial chimney. The open combustion chamber uses the air in the room, and the exhaust goes to a stationary natural draft chimney. Boilers with an open combustion chamber require a chimney, a separate boiler room. With a closed combustion chamber, they can be installed near any external wall, but they are more expensive.

- The presence of an additional condensing system. The temperature of the outgoing gases of a conventional boiler is about 150 degrees, and a condensing boiler is only 40. The temperature difference is used to heat the house.

Boiler room requirements and safety precautions

It's worth saying that boiler room for an apartment building and private construction differs in many parameters.

Since we are talking about an autonomous system, consider the requirements that apply to a private version of these premises:

- The minimum area of the boiler room should not be less than 4 square meters.

- The height of the room cannot be lower than 250 cm.

- Be sure to have a separate exit to the street. In this case, the minimum width of the doorway is 800 mm.

- It is necessary to make a window in the gas boiler room. Its dimensions depend on the volume of the room. So, for every 10 m³ of volume, a glazing area of 0.3 squares is needed. The window must have an opening window.

- In addition to water supply, sewerage and power supply networks, a ground loop is equipped, to which the boiler must be connected.

- The room is equipped with a natural or forced ventilation system and a chimney. It is not necessary to make a chimney if a unit with a closed combustion chamber and a coaxial smoke exhaust system is installed.

- Be sure to provide lighting at night.

- A solid base is made under the floor boiler, finished with non-combustible materials.

Classification and varieties

All gas boilers for heating a private house consist of the same basic elements. Also, they may contain additional details, thanks to which they acquire specific features.

All existing boilers are divided into many varieties. According to the number of circuits, they are single-circuit and double-circuit. If the device has only one circuit, then it is intended only for heating the room. Units with two circuits are able to additionally provide residents with hot water.

Useful: how to choose a double-circuit wall-mounted gas boiler.

Gas boilers can be installed in different places. Some models are designed to be installed directly on the floor of the room, while others are fixed on the wall. Wall-mounted boilers are small in size, they are most often preferred by owners of cottages and residential country houses. However, their disadvantage is low power.

Floor-standing boilers can heat large rooms due to their high power, so they are most often placed in industrial premises.

According to the efficiency of fuel combustion, boilers are convection and condensing. The latter appeared relatively recently. The main difference between these two types of boilers is the metal water economizer, which contributes to the condensation of water vapor. They are equipped with condensing boilers, but traditional convection devices are deprived of such an element.

This is interesting: what does a condensing boiler mean.

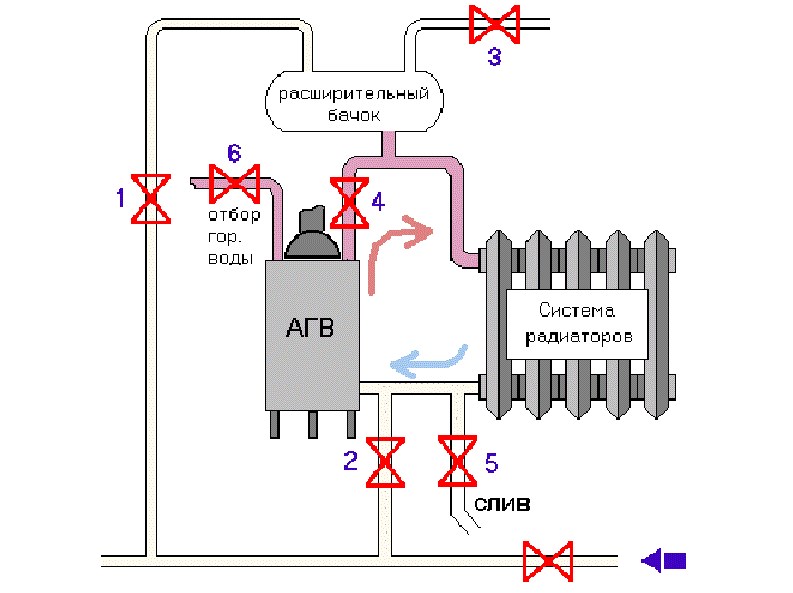

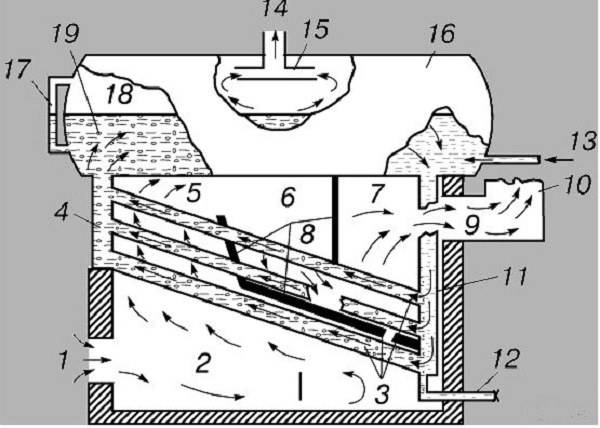

Scheme of a steam boiler

Scheme of movement of the coolant

Scheme of movement of the coolant

PCs are installed in the boiler room, which can be located in separate, adjoining and built-in non-residential buildings.

Designations according to the scheme:

- Fuel supply system of a gas steam boiler, No1.

- Burning device - furnace, No2.

- Circulation pipes, No3.

- Steam-water mixture zone, evaporation mirror, No4.

- Direction of feed water movement, No. 5, 6 and 7.

- Partitions, No8.

- Gas flue, No9.

- Chimney, No10.

- Circulating water outlet, from the steam boiler tank, No11.

- Purge water drain, No12.

- Make-up of the boiler with water, No13.

- Steam manifold, No14.

- Steam separation in the drum, NoNo15,16.

- Water-indicating glasses, No17.

- Saturated steam zone, No18.

- Steam-water mixture zone, No19.