- Faults

- How to determine the rupture of the membrane?

- How to choose a hydraulic accumulator

- Calculation of the optimal volume of the hydraulic tank

- The principle of operation of the accumulator

- Types of hydraulic tanks

- The principle of operation of the accumulator

- Types of hydroaccumulator tanks

- How to properly adjust the pressure in the accumulator

- Benefits of installing a hydraulic tank

- Hydraulic accumulator device

- Hydraulic tank connection diagrams

- Checking and correcting pressure

- Types of hydraulic tanks for water supply systems

- What is a hydraulic accumulator

- Calculation of pressure in the accumulator

- Optimal Performance

- Why do you need a hydraulic accumulator?

- Operating recommendations

- Why do you need to know how to select a hydraulic tank?

- Optimal parameters

- Role in the heating system

- Device and principle of operation

Faults

Most often, hydraulic accumulators fail for the following reasons:

- too frequent start / shutdown of the pump;

- valve leakage;

- too low water pressure at inlet/outlet.

Before identifying the cause that served as a weakening of the pressure, it is necessary to determine what exact pressure should be in the hydraulic tank of the station.

In this case, the problems may be as follows:

- incorrect pressure;

- damage or deformation of the membrane part or housing;

- relay failure.

Difficulties can be dealt with in the following ways:

- pressurization in case of its decline;

- restoration of the damaged membrane;

- restoration of a damaged hull;

- differential adjustment based on the pump mode.

How to determine the rupture of the membrane?

Another common problem is the rupture of the internal membrane of the accumulator. The membrane is made of very durable rubber, and is able to withstand several years of service, periodically filling with water and shrinking, squeezing water into the pipeline network. However, any part has a tensile strength and a certain service life. Over time, the membrane can lose its elasticity and strength, eventually bursting. Direct evidence of a rupture of the membrane are the following signs:

- The pressure in the system is not uniform. The faucet spits out water in batches.

- The pressure gauge needle of the accumulator moves abruptly, from maximum to minimum.

To make sure that the membrane is broken, bleed the air from the spool from the back of the tank. If water escapes along with the air filling the membrane space, then the rubber partition is definitely broken and needs to be replaced. It is quite possible to change the membrane with your own hands. To do this, purchase a new membrane in a plumbing store. When buying, make sure that the rubber component is from your hydraulic tank model.

Then we disassemble the accumulator by unscrewing the connecting bolts. The torn part is removed and a new membrane is put in its place. Then the tank is assembled, and all connecting bolts are evenly and firmly tightened.

How to choose a hydraulic accumulator

First of all, you need to decide for which system you plan to use the accumulator.

- For a device that will monitor the supply of cold water, it is necessary to proceed from the number of people living in the house and, according to the consumption rates of cold and drinking water per person, purchase a suitable accumulator.

- The unit supplying hot water is also purchased after calculating the consumption of hot water per person per day.

- The accumulator, which ensures the uninterrupted operation of the heating system, is selected based on the area of \u200b\u200bheated premises. Depending on this, the capacity of the hydraulic tank is selected.

It is also necessary to take into account that the operation of the entire unit is based on the use of a membrane tank, which is located inside the hydraulic tank.

The choice of accumulator

The service life of the entire system depends on its survivability. For cold water, it is better to purchase a tank with an isobutyl rubber membrane, the water from which is safe for use in cooking.

Further, when making a choice, you need to pay attention to the flange that secures the water supply system. Its quality affects the life of the accumulator

accumulator flange

The better the flange, the longer the accumulator will work. It is made of galvanized steel, stainless steel or composite plastic.

Calculation of the optimal volume of the hydraulic tank

GOST on the volume of the hydraulic tank does not exist. Everyone chooses a container for using water individually. It is necessary to proceed from two parameters.

Tank dimensions

- The size of the utility room where at least one hydraulic tank will be installed. For example, a tank size of 100 liters is a barrel standing upright, about 850 mm high, and 450 mm in diameter.

- Next, you need to calculate the amount of water consumed by each family member (approximately).Also, take into account the water consumption for washing, washing dishes and other household needs. In any case, even if an error was made in the calculations, you can always replace the tank with an increase in its capacity.

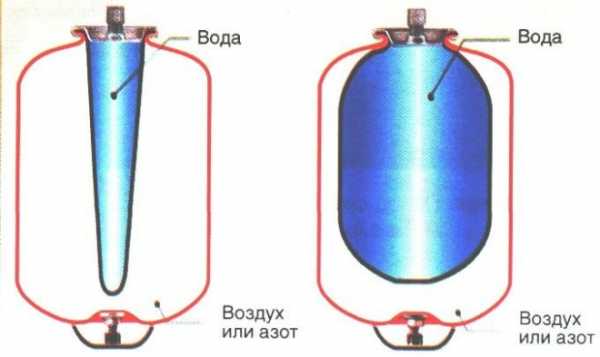

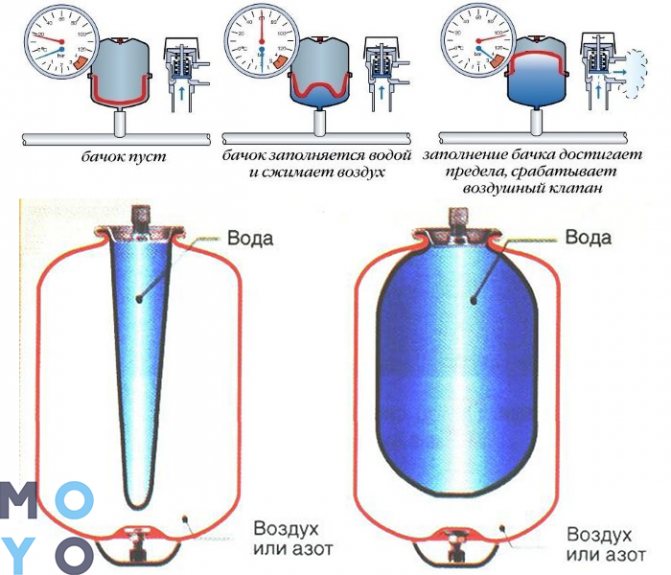

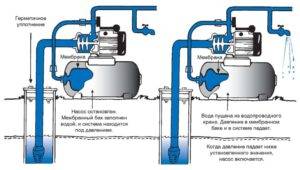

The principle of operation of the accumulator

The principle of operation of the hydraulic accumulator.

When there is air inside the structure, the nominal pressure is 1.5 atm. When the pumping equipment is turned on, water is pumped into the tank. The more liquid enters, the more the free space of the hydraulic tank is compressed.

When the pressure reaches a predetermined level (for 1-storey cottages - 2.8-3 atm.), The pump is turned off, which stabilizes the workflow. If at this time the tap is opened, water will flow from the tank until the pressure level in the water supply system drops to 1.6-1.8 atm. After that, the electric pump is turned on and the whole cycle is restarted.

Automation is responsible for turning on the surface and deep pumps, depending on the indicated indicators. This is a pressure gauge and pressure switch, thanks to which the operation of the equipment is optimized.

Types of hydraulic tanks

There are vertical and horizontal devices, they are installed in different ways. Typically, tanks with a capacity of up to 50 liters are placed horizontally, and larger ones are placed vertically so that they do not take up much space. This does not affect efficiency. You can choose a model that will be more convenient to use and suitable for the place where it will be placed.

The total volume of a hydraulic tank and the amount of water that it can hold are different indicators. Capacity is selected depending on the characteristics of the plumbing system

In vertical and horizontal models, a nipple - an air valve is provided to remove air from the part into which air or gas is pumped. It is very easy to use it.

It is located at all types of hydraulic tanks from the side opposite to the installation of the flange, designed to connect the equipment to the water supply.

Membrane tanks with a red body are designed for hot water systems or for heating. They must be used strictly for their intended purpose.

The color of the tank is usually blue or blue, in contrast to the red expansion tanks for heating. They are not interchangeable; different materials are used to make the membrane. In "cold" hydraulic tanks, food grade rubber is used.

In addition, blue-coloured accumulators can tolerate higher pressures than heating and domestic hot water devices. You can not use such containers for other purposes, they will quickly fail.

In vertically oriented HAs, water is supplied from below, and excess air is removed, if necessary, from above, bleeding it through a nipple. In horizontal versions, both water supply and air bleed are made from the side.

The threaded connection for connecting to the water supply is always the same size, this is 1 1/2 inches. The thread for connecting the membrane can be internal or external. Their sizes are also unified, the internal thread is standardly 1/2 inch, the external thread is 3/4 inch. This is an important point, because for a reliable connection, it is necessary that the dimensions of the pipe and the water pipe match.

Imported GA models look very presentable, but they are not always suitable for local use. Before buying such a device, you should study the reviews

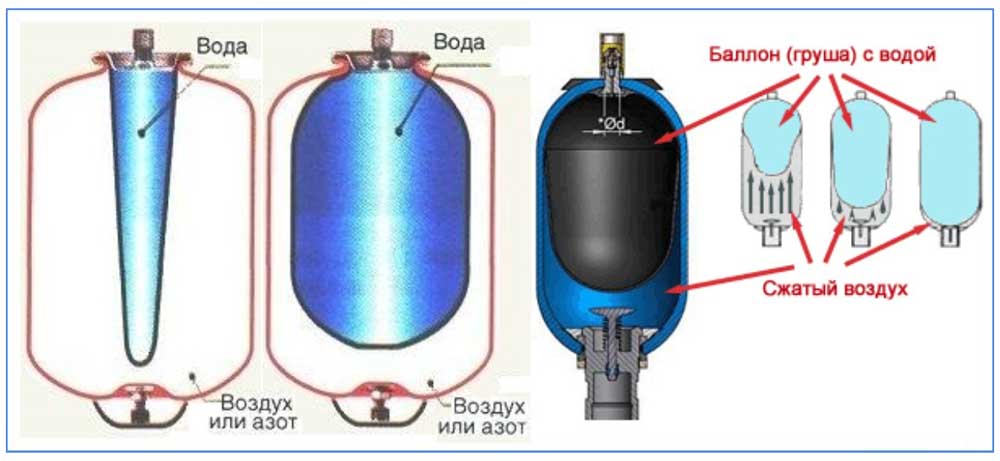

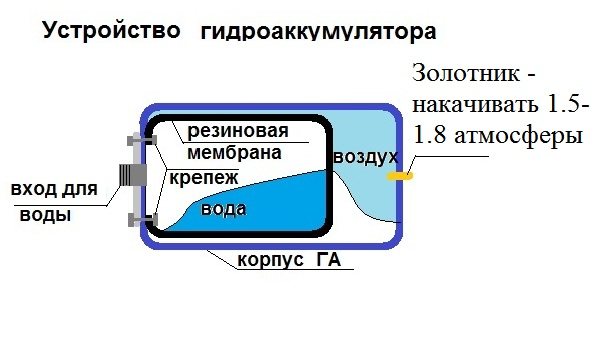

The principle of operation of the accumulator

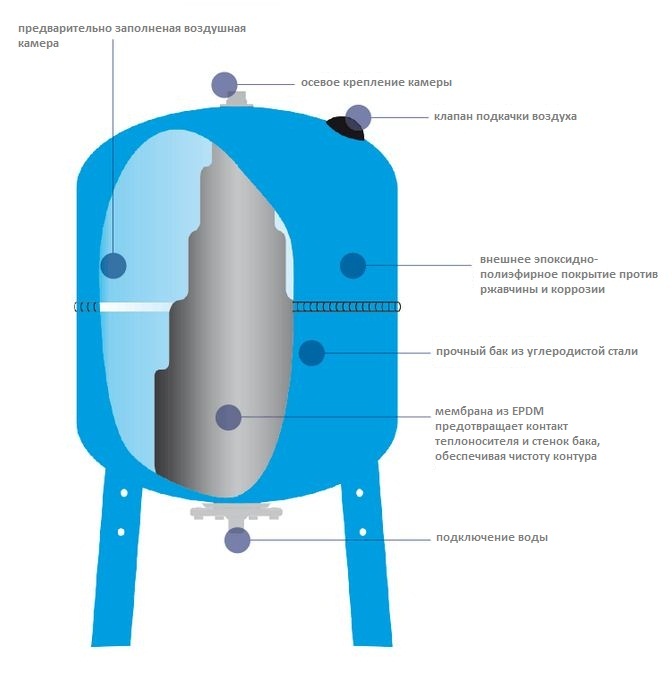

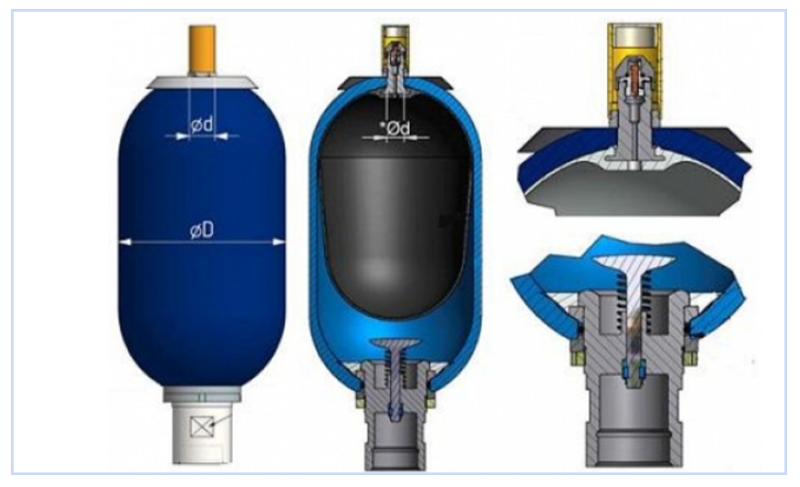

The hydraulic accumulator consists of a housing with a rubber membrane, a flange, a nipple for pumping air into the cavity, an air bleed valve, a fitting for attaching the membrane, etc.

What is the principle of operation of a hydraulic accumulator?

When water enters under pressure from a well or well, the membrane connected to the water supply system increases in volume. Accordingly, the volume of air between the metal walls of the hydraulic tank and the membrane begins to decrease, thereby creating even more pressure. As soon as the set pressure level is reached, the pressure switch opens the contacts for supplying electricity to the pump and it turns off. What happens? The air located between the membrane and the body of the accumulator presses under pressure on the “pear” with water inside. When you open the tap to supply water, the pressurized air pressing on the membrane will push water out of the hydraulic tank to your tap. At the same time, in the membrane, as the water flows, the pressure pumped up by the pump will fall. And as soon as it drops to the set level, the contacts on the pressure switch will close again and the pump will start working again. Thus, both water and air are always in working condition in the accumulator, separated from each other by a rubber membrane. It should be noted that the pressure of the air in the cavity of the accumulator may decrease during operation. It is recommended to check the air pressure in the hydraulic tank once a year when there is no water in it. If it is less than normal, you can pump it through the nipple using a simple car pump. It should also be borne in mind that water never completely fills the entire volume of the accumulator.The actual volume of water in it depends on a number of parameters: on the shape of the accumulator, the initial air pressure in it, the geometric shape and elasticity of the diaphragm, the set upper and lower limits of the pressure switch, etc.

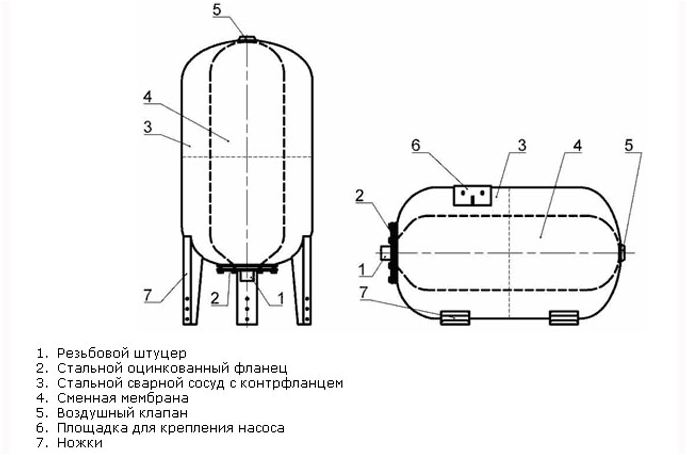

Hydraulic accumulators, depending on the method of their installation, are horizontal and vertical

Which accumulator is better to choose? If the dimensions of the room allow, then you should pay attention to how the air accumulating inside the rubber membrane is removed. The thing is that in the water in the water supply system there is always dissolved air.

And over time, this air is released from the water and accumulates, forming air pockets in various places in the system. To remove air pockets in the design of hydraulic accumulators of large volumes (100 liters or more), a fitting is additionally provided, on which a valve is installed, through which the air accumulating in the system is periodically bled. For vertical accumulators with a capacity of 100 liters or more, all air accumulates in their upper part and is removed using this air vent valve. In horizontal hydraulic accumulators, air can be removed using an additional section of the pipeline, which consists of a ball valve, an air outlet nipple and a drain to the sewer. Hydraulic accumulators with a small volume do not have such a fitting. Their choice is justified only by the convenience of the layout in a small room. The removal of the air accumulating in them is possible only with periodic complete emptying.

Types of hydroaccumulator tanks

Hydraulic accumulators differ in the type of installation: they are horizontal and vertical. Vertical accumulators are good because it is easier to find a suitable place for their installation.

Both vertical and horizontal varieties are equipped with a nipple. Together with water, a certain amount of air also enters the device. It gradually accumulates inside and “eats” part of the volume of the hydraulic tank. In order for the device to work properly, it is necessary to bleed this air from time to time through this same nipple.

According to the type of installation, vertical and horizontal hydraulic accumulators are distinguished. They have some differences in the maintenance process, but the choice is largely influenced by the size of the installation site.

In hydraulic accumulators that are installed vertically, a nipple is provided that is designed specifically for this purpose. Just press it and wait for the air to leave the device. With horizontal tanks, things are a little more complicated. In addition to the nipple for bleeding air from the tank, a stopcock is installed, as well as a drain to the sewer.

All this applies to models capable of accumulating a liquid volume of more than 50 liters. If the capacity of the model is less, then there are no special devices for removing air from the membrane cavity, regardless of the type of installation.

But the air from them still needs to be removed. To do this, water is periodically drained from the accumulator, and then the tank is refilled with water.

Before starting the procedure, turn off the power supply to the pressure switch and the pump, or the entire pumping station if the hydraulic tank is part of such a device. After that, you just need to open the nearest mixer.

The water is drained until the container is empty.Next, the valve is closed, the pressure switch and the pump are energized, the water will fill the tank of the accumulator in automatic mode.

Hydraulic accumulators with a blue body are used for cold water, and red ones for heating systems. You should not use these devices in other conditions, since they differ not only in color, but also in the material of the membrane, and the ability to tolerate a certain level of pressure.

Usually, tanks intended for autonomous engineering systems differ in color: blue and red. This is an extremely simple classification: if the hydraulic tank is blue, then it is intended for cold water supply systems, and if it is red, it is for installation in the heating circuit.

If the manufacturer has not designated its products with one of these colors, then the purpose of the device should be clarified in the technical data sheet of the product. In addition to color, these two types of accumulator differ mainly in the characteristics of the material used in the manufacture of the membrane.

In both cases, it is a high quality rubber designed for food contact. But in blue containers there are membranes designed for contact with cold water, and in red ones - with hot water.

Very often, a hydraulic accumulator is supplied as part of a pumping station, which is already equipped with a pressure switch, pressure gauge, surface pump and other elements.

Blue devices are capable of withstanding higher pressures than red containers. It is not recommended to use accumulators designed for domestic hot water systems for cold water and vice versa. Incorrect operating conditions will lead to rapid wear of the membrane, the hydraulic tank will have to be repaired or even completely replaced.

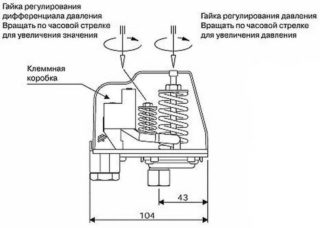

How to properly adjust the pressure in the accumulator

Correct operation of the pumping station requires the correct setting of three main parameters:

- The pressure at which the pump turns on.

- The shutdown level of a functioning unit.

- Air pressure in the membrane tank.

The first two parameters are controlled by the pressure switch. The device is installed on the inlet fitting of the accumulator. Its adjustment takes place empirically, to reduce the error of the action, it is performed several times. The relay design includes two vertical springs. They are planted on a metal axis and secured with nuts. The parts differ in size: a large spring controls the activation of the pump, a small one is required to set the difference between upper and lower pressure. The springs are connected to a membrane that closes and opens electrical contacts.

Adjustment is made by turning the nut with a wrench. Clockwise rotation compresses the spring and increases the threshold for turning on the pump. Turning counterclockwise weakens the part and reduces the actuation parameter. The adjustment procedure takes place according to a certain scheme:

- The air pressure in the tank is checked, if necessary, it is pumped up by the compressor.

- The large spring nut turns in the right direction.

- The water tap opens. The pressure drops, at a certain moment the pump turns on. The pressure value is marked on the manometer. If necessary, the procedure is repeated

- The difference in performance and the shutdown limit is regulated by a small spring. It is sensitive to the setting, so the rotation is carried out by half or a quarter of a turn.

- The indicator is determined with the taps closed and the pump turned on.The pressure gauge will show the value at which the contacts will open and the unit will turn off. If it is from 3 atmospheres and above, the spring should be loosened.

- Drain the water and restart the unit. The procedure is repeated until the required parameters are obtained.

The factory settings of the relay are taken as a basis. They are indicated in the device passport. The average pump start indicator is 1.4-1.8 bar, shutdowns are 2.5-3 bar.

>

Benefits of installing a hydraulic tank

There are a number of reasons why a hydraulic accumulator is needed in a water supply system:

The main task is that thanks to the hydraulic accumulator, the pump starts and stops less often. The engine does not overheat and does not fail longer.

In addition to creating a supply of water, the drive softens hydraulic shocks in the water supply system. The air contained inside the cylinder reduces pressure drops in the pipeline due to its compressibility

As a result, all elements of the system wear out less.

During a power outage, a reserve supply of water remains in the hydraulic tank, which is important in case of frequent power outages.

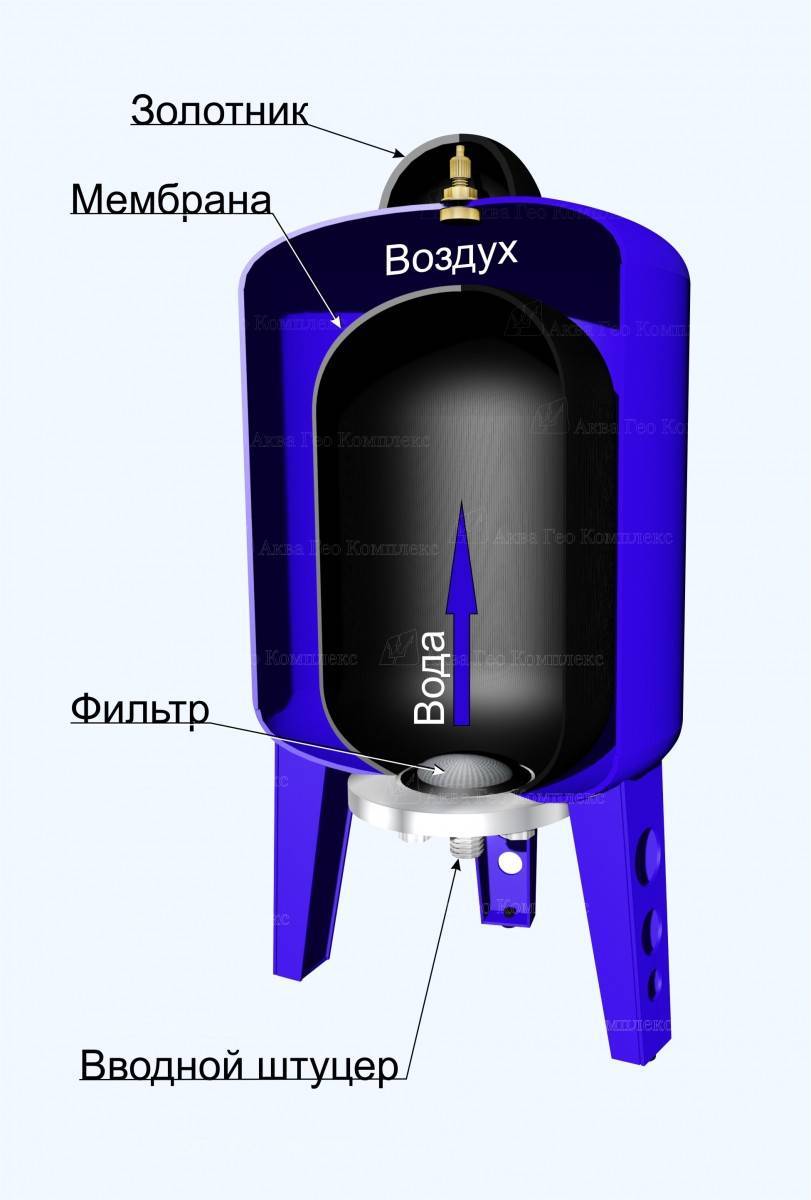

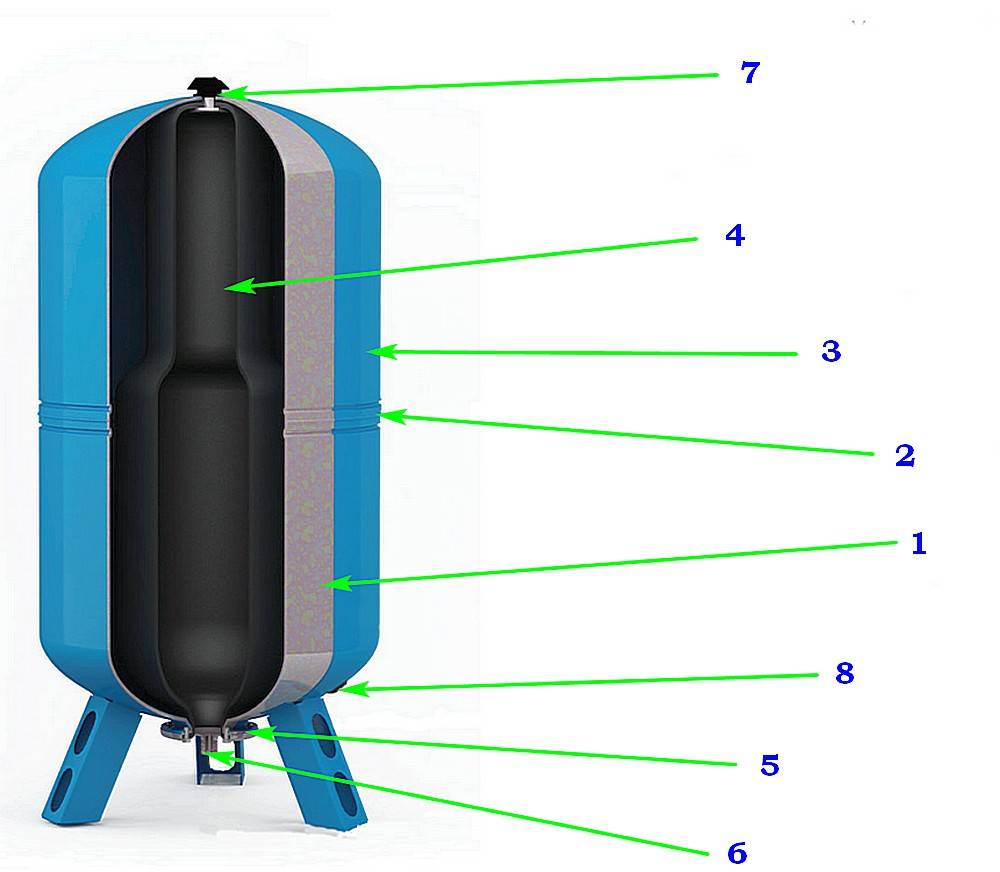

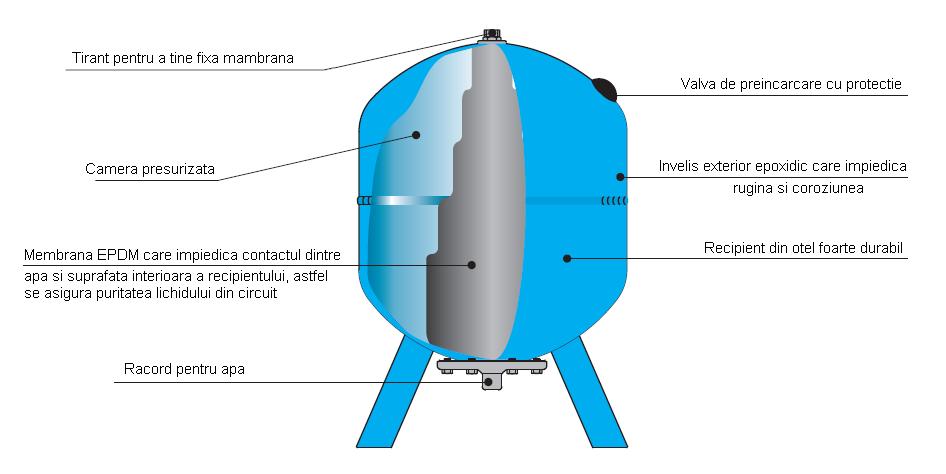

Hydraulic accumulator device

The device of the accumulator is not complicated, it consists of a metal tank with a built-in pear-shaped membrane or a flat rubber diaphragm. The diaphragm is mounted across the body between its halves, a pear-shaped cylinder is installed at the inlet near the neck - this type is used to supply water for individual water supply. A nipple is installed in the rear part of the metal container, with the help of which air is pumped into the hydraulic tank body, adjusting its internal pressure to the system.

Hydraulic tanks are produced for heating systems, hot water (red) and cold water supply (blue). Depending on the volume of the hydraulic tank and the method of installation, there are models with a horizontal arrangement and volumetric vertical units that are mounted on legs.

Horizontal models of small capacity are more often used in pumping stations with a built-in surface-type centrifugal electric pump and elements of an automatic control system. Hydraulic tanks with a vertical arrangement are used separately, they are more convenient to mount when working with submersible electric pumps. Vertical tanks are structurally different from horizontal models: the membrane shell is attached to the upper and lower parts of the body, in addition to the nipple for pumping air, they have an additional fitting for bleeding it out of the rubber shell.

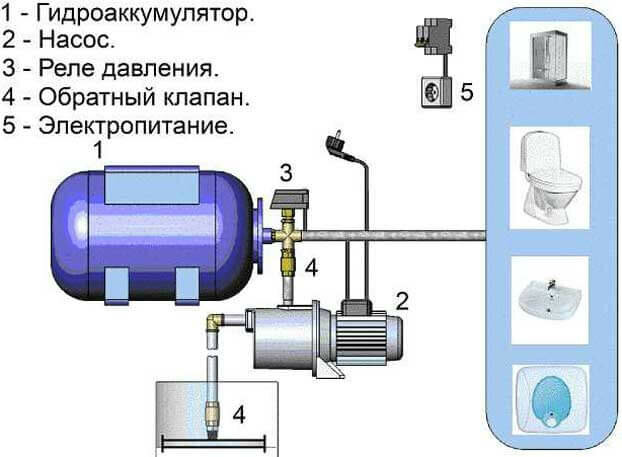

Hydraulic tank connection diagrams

Depending on the type of water supply network, the hydraulic tank can be connected according to one of the following schemes:

- With a booster pumping station (PS): such PSs consist of a main pump, which, as a rule, operates constantly, and several additional ones. They are used in systems with high water consumption. Here the accumulator is needed mainly to smooth out hydraulic shocks when starting additional pumps.

- With one pump: it is this scheme that is used when organizing autonomous water supply in a private house. It has been described in sufficient detail above.

- With a water heater: heating water in a storage water heater (boiler), as you know, is accompanied by an increase in its volume.In this scheme, the hydraulic tank plays the same role as the expansion tank in heating systems: it absorbs excess volume, saving the system from rupture.

Checking and correcting pressure

So, just before connecting, it is recommended to check the pressure level in the accumulator itself. Due to this information, you will be able to correctly configure the pressure switch.

Moreover, it is extremely important to carry out future control of the pressure level. For this purpose, a manometer is intended. Some home craftsmen temporarily use a car pressure gauge

Its error is minimal, so it is quite a normal option.

Some home craftsmen temporarily use a car pressure gauge. Its error is minimal, so it is quite a normal option.

If necessary, the pressure level can be reduced or added. For this purpose, there is a nipple on the top of the accumulator. A car or bicycle pump is connected to it. Due to this, the pressure rises. If the air pressure, on the contrary, needs to be lowered, then there is a special valve in the nipple. You should take a sharp and thin object and press on it.

Types of hydraulic tanks for water supply systems

Hydraulic accumulators available on the market, the principle of operation of which is the same, are divided into several types according to a number of features and functional features. First of all, according to the installation methods, they distinguish:

- Horizontal - used for large volumes of water. It is somewhat more difficult to operate due to the low location of the neck (you have to completely drain the water to change or inspect the working membrane or spool).

- Vertical - used for small and medium volumes.Easier to operate, since there is no need to completely drain the water and dismantle part of the piping, as is the case with horizontal tanks.

According to the temperature of the working fluid, hydraulic tanks are:

- For hot water - a heat-resistant material is used as a material for the membrane. Most often it is butyl rubber. It is stable at water temperatures from +100-110 degrees. Such tanks are visually distinguished by red color.

- For cold water - their membrane is made of ordinary rubber and cannot work stably at temperatures above +60 degrees. These tanks are painted blue.

Rubber for both types of accumulators is biologically inert and does not release any substances into the water that spoil its taste or harm human health.

According to the internal volume of hydraulic tanks there are:

- Small capacity - up to 50 liters. Their use is limited to extremely small rooms with a minimum number of consumers (in fact, this is one person). In the version with a membrane or hot water cylinder, such devices are often used in closed-type heating systems.

- Medium - from 51 to 200 liters. They are used exclusively for hot and cold water supply. They can give water for some time when the water supply is turned off. Versatile and reasonably priced. Ideal for houses and apartments with 4-5 residents.

- Large volume from 201 to 2000 liters. They are able not only to stabilize the pressure, but also to provide consumers with a supply of water for a long time in the event that its supply from the water supply is turned off. Such hydraulic tanks have large dimensions and weight. Their cost is also great.They are used in large buildings such as hotels, educational institutions, sanatoriums and hospitals.

What is a hydraulic accumulator

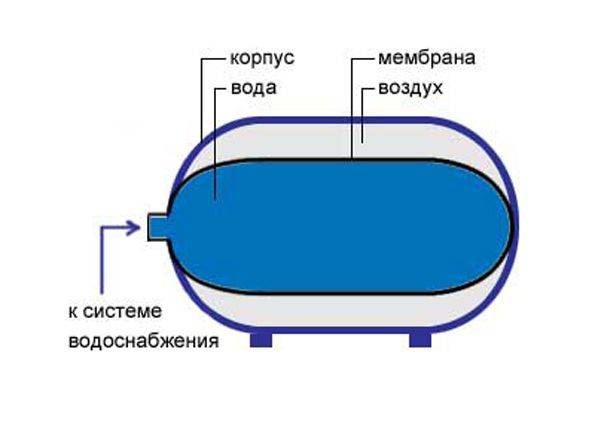

It is worth noting that the capacity of the hydraulic tank is sealed and divided into two chambers using a special membrane, the first is reserved for water, the second is for air.

In the accumulator, contact between the aqueous medium and the metal case is excluded, because it is placed in a special water chamber. Water chambers are made of durable rubber material - butyl, which is resistant to bacterial attack and meets the requirements put forward to water in the field of hygiene and sanitary standards.

Hydraulic accumulator device

Hydraulic accumulator device

As for the air chamber, it has a pneumatic valve that regulates pressure. The connecting branch pipe, with a carving, allows to fill the hydroaccumulator with water.

The connecting pipeline is selected in such a way that it matches the pressure pipe in diameter, as this directly affects the occurrence of hydraulic losses in the water supply system.

Calculation of pressure in the accumulator

In order for the equipment to work efficiently and meet the needs of the residents of the house, the pressure in the hydraulic tank must be excessive.

For stable operation, a difference of 0.5-0.6 bar is required between the pressures at the lower and upper points.

The factory settings provide for the required pressure of 1.5-2 bar, which is optimal for the operation of the accumulator. To control it, a tonometer is built into the device.

A tonometer is required to control the pressure in the hydraulic tank

If the pressure parameter deviates downward, it can be corrected by pumping air with a car pump, for which a nipple is provided in the device body.

Optimal Performance

In addition to the capacity, just as important is a suitable pressure indicator in an unfilled reservoir. This value is usually marked on the body of each individual model. It will not be difficult to calculate which parameter will be ideal in a particular case. It is detected based on hydrostatic pressure, because it depends on the height to which it is necessary to raise the liquid. For example, if the height of the pipes in the dwelling reaches 10 m, then the pressure parameter will be 1 bar

In addition, it is very important to consider that the working pressure of the hydraulic tank should not be more than the starting pressure of the pump.

For example, to ensure a stable supply of liquid in a house with two floors, you will need a high-quality hydraulic tank with an operating power level of 1.5 bar and a top power of up to 4.5 bar. In most cases, manufacturers form an air pressure in the accumulator of 1.5 bar. However, in certain cases, the values may be different. That is why, before starting to use the unit, you need to check these values using a pressure gauge. This part connects to the hydraulic accumulator nipple.

Why do you need a hydraulic accumulator?

A hydraulic accumulator (in other words, a membrane tank, a hydraulic tank) is used to maintain a stable pressure in the water supply system, protects the water pump from premature wear due to frequent switching on, and protects the water supply system from possible water hammer. In the event of a power outage, thanks to the hydraulic accumulator, you will always have a small supply of water.

Here are the main functions that a hydraulic accumulator performs in a water supply system:

- Protecting the pump from premature wear. Due to the water reserve in the membrane tank, when the water tap is opened, the pump will turn on only if the water supply in the tank runs out. Any pump has a certain rate of inclusions per hour, therefore, thanks to the accumulator, the pump will have a supply of unused inclusions, which will increase its service life.

- Maintenance of constant pressure in the plumbing system, protection against drops in water pressure. Due to pressure drops, when several taps are turned on at the same time, sharp fluctuations in water temperature occur, for example in the shower and in the kitchen. The hydraulic accumulator successfully copes with such unpleasant situations.

- Protection against water hammer, which can occur when the pump is turned on, and can spoil the pipeline in order.

- Maintaining a supply of water in the system, which allows you to use water even during a power outage, which happens quite often in our time. This feature is especially valuable in country houses.

Operating recommendations

After the accumulator is installed, it must be properly maintained. Approximately once a month, the pressure switch settings should be checked and adjusted if necessary.In addition, it is necessary to check the condition of the housing, the integrity of the membrane and the tightness of the connections.

The most common failure in hydraulic tanks is a rupture of the membrane. Constant cycles of tension - compression over time lead to damage to this element. Sharp drops in pressure gauge readings usually indicate that the membrane has torn, and water enters the “air” compartment of the accumulator.

To make sure there is a breakdown, you just need to bleed all the air from the device. If water flows out of the nipple after it, then the membrane definitely needs to be replaced.

Luckily, these repairs are relatively easy to make. For this you need:

- Disconnect the hydraulic tank from the water supply and power supply.

- Unscrew the bolts that hold the neck of the device.

- Remove damaged membrane.

- Install a new membrane.

- Assemble the device in reverse order.

- Install and connect the hydraulic tank.

At the end of the repair, the pressure settings in the tank and the pressure switch should be checked and adjusted. The connecting bolts must be tightened evenly to prevent warping of the new diaphragm and to prevent its edge from slipping into the tank housing.

Replacing the accumulator diaphragm is relatively easy, but care must be taken to ensure that the new diaphragm is the same as the old one.

To do this, the bolts are installed in the sockets, and then literally a couple of turns of the first bolt are alternately made, move on to the next one, etc. Then the membrane will be pressed against the body equally around the entire circumference. A common mistake newcomers make to repairing a hydraulic accumulator is the incorrect use of sealants.

The installation site of the membrane does not need to be treated with a sealant, on the contrary, the presence of such substances can damage it. The new membrane must be exactly the same as the old one in both volume and configuration. It is better to first disassemble the accumulator, and then, armed with a damaged membrane as a sample, go to the store for a new element.

Why do you need to know how to select a hydraulic tank?

The hydraulic accumulator for water supply systems performs two important functions:

- maintaining constant pressure in the water supply;

- protection of the pump against too frequent switching on and off.

Its device scheme is quite simple - there is a metal tank, which is divided into two parts by a rubber membrane. There is water in the membrane itself, and the necessary pressure is created by air, which is pumped into the second part of the tank.

Thus, when using water at points of consumption, the submersible pump does not have to turn on every time the tap is opened. Indeed, in the pear there is a certain supply of water under pressure sufficient for the normal operation of the water supply system. And the pump will turn on only when this volume drops to the set minimum.

In this case, it should be borne in mind that the maximum allowable number of pump starts is 20-30 times per hour. And the optimal one is 15-20 times. Therefore, you need to know in advance how to choose a hydraulic accumulator for water supply in order to avoid mistakes.

Optimal parameters

The main factors on which the operation of the water supply network and the service life of hydraulic equipment depend are as follows:

The main factors on which the operation of the water supply network and the service life of hydraulic equipment depend are as follows:

- Competent calculation of the maximum and minimum pressure values at which the pump should turn on (turn off).

- Correct pressure setting in the receiver.

Pressure air pre-injection is 1.5 - 2 bar (depending on the volume of the tank). The determination of the air pressure value for working in tandem with a specific pumping station is based on the factory parameters of the pressure switch. The average value of the pressure at which the pump turns on is from 1.4 to 1.8 bar. The shutdown threshold is usually in the range of 2.5 - 3 bar. The optimal value of air pressure should be 10-12% less than the pressure on the pump.

If these requirements are met, after turning off the hydraulic pump, a certain amount of water is guaranteed to be stored in the accumulation tank, sufficient to create a stable pressure until the next pump start.

Role in the heating system

The main tasks of the accumulator:

- accumulation of “surpluses” of the coolant during its expansion;

- air removal;

- replenishment of the volume in case of possible leaks or a drop in the water level (antifreeze).

There are two types of tanks - open and closed. The second option is used in most modern heating systems. This is a fully sealed hydraulic accumulator with a membrane or pear (it is used in large tanks).

Hydraulic accumulators are installed only for heating with a circulation pump, since this system is characterized by a high working pressure.

Device and principle of operation

The device has the form of a box of various shapes with controls under the lid. It is attached to one of the outlets of the fitting (tee) of the container. The mechanism is equipped with small springs that are adjusted by turning the nuts.

Working principle in order:

- The springs are connected to a membrane that reacts to pressure surges. Increasing the rate compresses the spiral, decreasing leads to stretching.

- The contact group responds to the indicated actions by closing or opening the contacts, thereby transmitting a signal to the pump. The connection diagram necessarily takes into account the connection of its electrical cable to the device.

- The storage tank fills up - the pressure increases. The spring transmits the pressure force, the device operates according to the set values and turns off the pump, sending it a command to do so.

- The liquid is consumed - the onslaught weakens. This is fixed, the engine turns on.

The assembly consists of the following parts: a body (plastic or metal), a membrane with a cover, a brass piston, threaded studs, metal plates, cable glands, terminal blocks, a hinged platform, sensitive springs, a contact assembly.