- General classification of gas burners by type of fuel

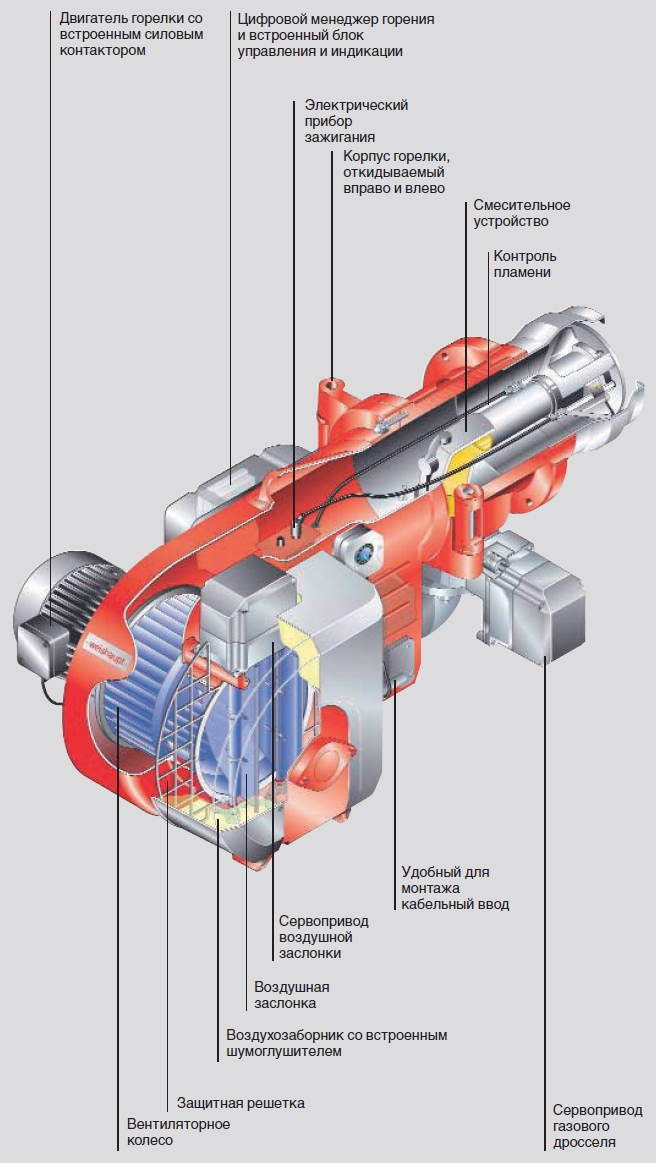

- Turbocharged types of gas burners and their design differences

- Boiler gas burner device

- Setting the gas burner flame

- Features of setting the boiler burner

- When is flame adjustment necessary?

- use and useful video on the topic

- Flame Adjustment of the gas burner

- Features of the boiler setting burner

- When to Adjust Gas

- When is a burner flame adjustment required?

- Choice of burners for different types and models of boilers

- HEALTH REQUIREMENTS BEFORE STARTING WORK

- Adjusting the power of a gas boiler

- Heater Maintenance

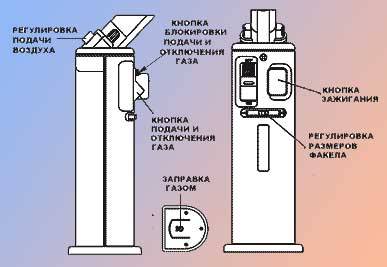

- Homemade units

- Types of burners

General classification of gas burners by type of fuel

Country houses can not always be provided with natural gas supplied from a common highway. Therefore, the variability of the burners in terms of the use of different types of fuel is provided. If the fuel comes from a gas main, propane-butane gas burners are most likely used for heating boilers.

Main gas-methane is the most affordable natural fuel for boilers. However, now there is no big benefit in the price of liquefied blue fuel (propane-butane mixture).General heating provided by the main pipeline is also expensive.

Gas boilers operating on different types of fuel mixtures have approximately the same design. There is a slight difference in cost, but it is also insignificant (equipment for liquefied fuel will cost more). The burners themselves are slightly different, having different nozzles for liquid fuel and blue gas.

If natural gas is not supplied to the house, propane-butane gas burners are used.

Propane burners require adjustment to this type of fuel with the installation of a jet. When burning, the flames give off a yellowish color, soot accumulates more in the chimney. The jet is responsible for normalizing the pressure.

Modern burners operate in a wide temperature range - from -50 to +50 °C. Part of the equipment can be adapted for other types of energy carriers:

- waste oil;

- diesel fuel;

- fuel oil;

- kerosene;

- propanobutane base;

- arctic diesel fuel.

Modern fixtures often come with both types of nozzles or universal equipment for fuel varieties, which makes them easy to reconfigure.

Homemade gas burners are most often used in solid fuel boilers.

It is safer to purchase simple gas equipment adapted for gas in cylinders. Homemade equipment, although more affordable, but unsafe! Usually carry out "alterations" on the basis of old units.

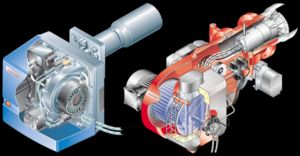

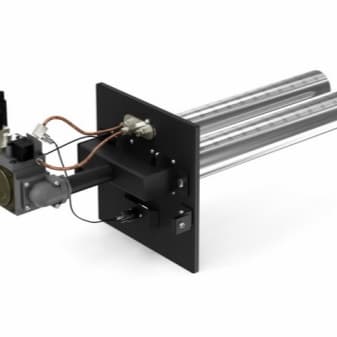

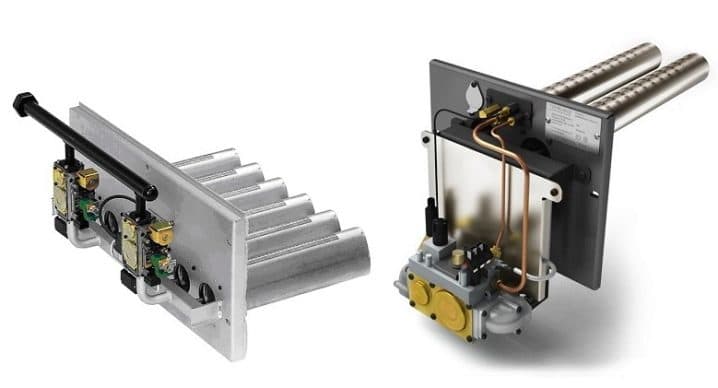

Turbocharged types of gas burners and their design differences

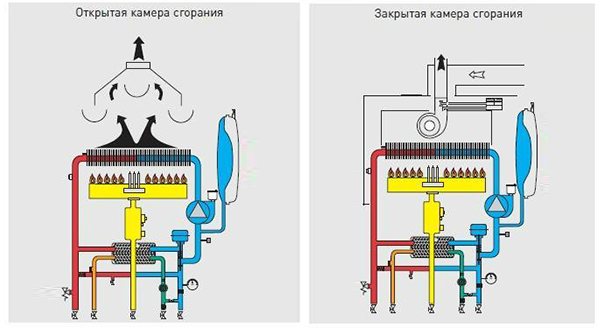

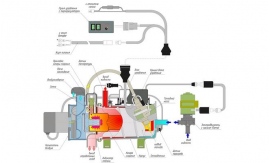

Among modern gas equipment, many experts prefer closed-type burners for turbocharged boilers.They are self-sufficient in terms of design, suggest the presence of a compact chimney, which can even be diverted into general ventilation with autonomous heating.

The heating unit with a special closed-type combustion chamber receives oxygen from the outside - through a special supply pipe (coaxial chimney). In approximately the same way, combustion products are removed to the outside. Heating equipment is controlled by a sufficiently powerful fan on automatic control.

Fan gas burners have a drawback - this is the price due to the complex design of the product

Such a device is much more expensive than atmospheric heating equipment. However, for an additional fee, the buyer receives a number of benefits, including autonomous operation in a residential area. This device, thanks to automatic control, has a high level of security.

Turbocharged equipment has the highest efficiency and flexible temperature scheme

Fuel burns almost completely, which is important for environmental performance. There are also disadvantages, including structural complexity, causing difficulties during installation and repair.

Gas burners for combined equipment are most often used in solid fuel boilers. This is a rather complex unit, so all nodes must meet certain requirements for efficiency and safety. The automatic device is able to switch from one type of fuel to another for uninterrupted heat supply. According to this principle, pellet and pyrolysis boilers are arranged, equipped with gas for burners, which drives the ignition process.

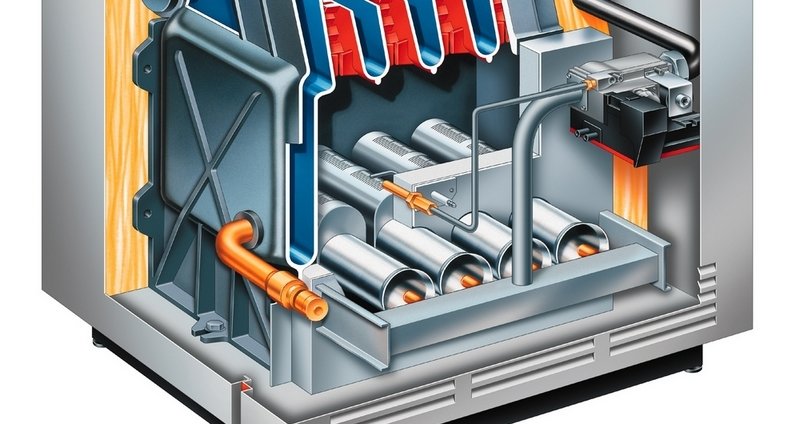

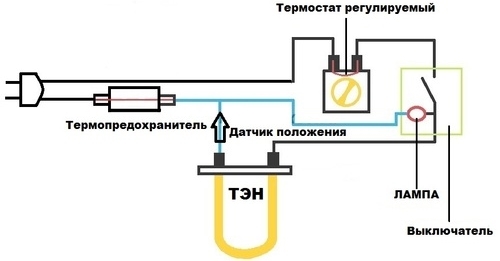

Boiler gas burner device

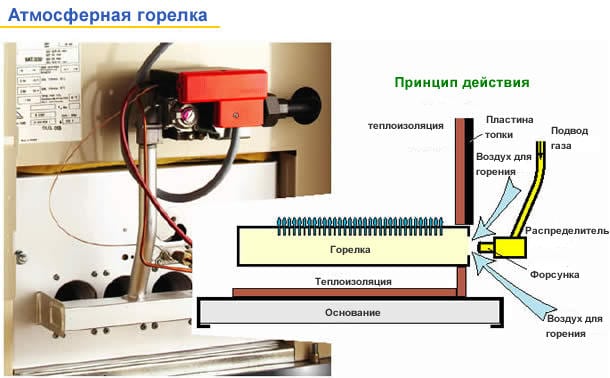

Atmospheric and fan burners differ in their structure. This is due to the different way of supplying oxygen to the chamber during fuel combustion.

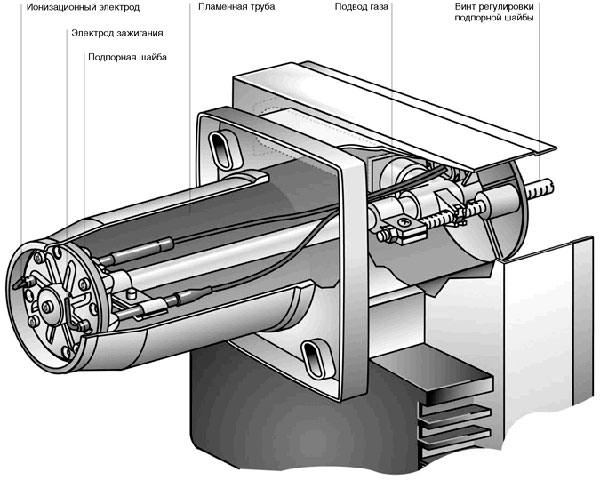

Atmospheric burner device.

Air enters the combustion chamber directly from the room. Nozzles are located inside the burner channel. Gas is fed into the nozzles, mixing with air, which also has access here. At a short distance from the nozzles, there are outlet slots through which the finished fuel mixture is supplied. A low pressure area is created between the nozzles and the outlets, which helps to continuously pump air for mixing.

The ignition burner is constantly working in the combustion chamber to ignite the main device.

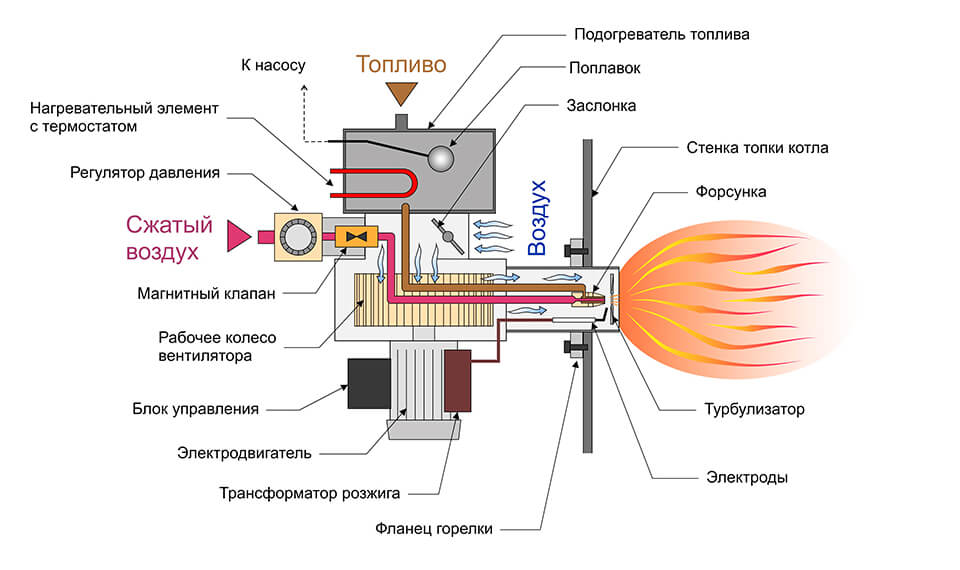

Fan burner device.

The device block consists of:

- engine;

- fan

- automatic control unit;

- reducer;

- air pressure switch;

- fuel mass mixer.

Air is forced from the outside by a fan, fed into the combustion chamber to form a fuel substance. The ratio of air and gas can be adjusted with a damper and a fan.

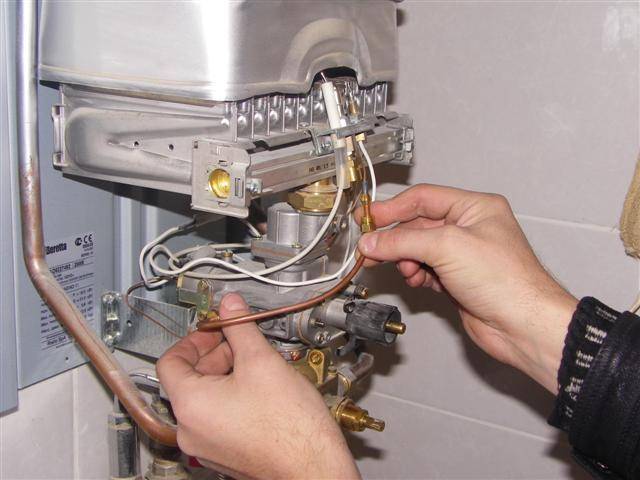

Setting the gas burner flame

In order to qualitatively adjust the burner of a gas boiler, first of all, you must be guided by the instruction manual for the gas appliance. Next, we’ll talk about how to properly start and set up a gas burner, and in what cases flame adjustment is necessary. But first things first.

Features of setting the boiler burner

It is recommended to adjust the burner flame using a gas analyzer. It shows information about the amount of air that is mixed with the gas, namely the level of oxygen involved in the process and the amount of CO.

As a rule, CO should be no more than 50 ppm, oxygen concentration should be about 3 to 5%. If it is less, then it is most likely that the gas will not have time to burn out, as a result of which a lot of soot will accumulate, the level of CO2 will be higher than the norm, and the efficiency of the equipment will decrease.

If the air is above the norm, then the temperature of the household burner of the gas boiler will be too high, and this can lead to tragic consequences, up to the explosion of the equipment.

The flame in the gas burner should be blue. If you find that the color has an orange tint, then try reducing the amount of gas. Reduce until the color turns blue (cyan). This color is a sign of optimal operation of the gas appliance. The main thing is not to reduce the fuel supply until the moment when the flame becomes almost colorless. In this case, it will go out very quickly.

Setting the initial gas supply is only necessary during ignition and does not affect the performance of the device. But if necessary, it is possible to adjust it. First, reduce the starting fuel supply. Decrease until the burner stops turning on. After that, you can turn the knob until the ignition resumes. For more details on setting the flame of a household gas burner, you can watch the video at the end of this article.

We also recommend that you familiarize yourself with the intricacies of adjusting the gas boiler.

When is flame adjustment necessary?

An atmospheric type gas burner, which operates without a built-in fan, very often fails, a turbocharged one breaks much less often.During prolonged use of the device, its components may break down or stop working at full capacity.

For example, a gas-fired boiler may experience reduced efficiency or a reduced flame.

And this can happen for the following reasons:

- Large burner power installed for equipment that is designed for less powerful burners. In this case, there is not enough space for proper combustion of the fuel, the fuel burns unevenly, which leads to the fact that soot quickly accumulates on the parts of the equipment.

- A lot of soot in the chimney can adversely affect the draft of a gas boiler. Because of this, the subsequent withdrawal of combustion products is very weak, little air enters, and the flame becomes yellow.

- The presence of burner defects is one of the reasons for the decrease in the efficiency of the boiler, but in this case, adjusting the flame will not help but correct the problem.

- Pressure drops during the gas supply can also contribute to the formation of soot and soot, and this will significantly reduce the productivity of the equipment.

All these causes can affect the temperature of the flame in the gas burner, in which case repair is required.

use and useful video on the topic

We advise you to watch a thematic video on setting the flame in

gas given. In the burner video, talks about the main

gas burner problems when flame adjustment is required.

next Watch the video clip, which details the main

the reasons why your gas burner does not work are told

properly, or ceased to ignite at all. The most

a common cause is the accumulation of a large amount

soot, which is formed from incomplete combustion gas:

Try to use your own if,

equipment to start the burner of a gas boiler with which something happens

interruptions, then you need to urgently diagnose and find out

reason for interruptions, otherwise the device may harm your

property life or.

It is also worth remembering about storage and gas transportation.

burners. To do this, it is necessary to study the rules of operation, which

written in the documentation. documents These should be included

when buying equipment. In any case, when troubleshooting something

which, urgently contact the gas service reliable or

professionals to help you resolve the situation.

Would you like to supplement the above information with useful information

on the topic of the article? wish Or share with other users

own customization experience of household gas burner? Write comments

your own, share your experience, participate in the discussion - feedback

The contact form is below.

Flame Adjustment of the gas burner

In order to qualitatively set up the burner of a gas boiler, first

turn to be guided by the instruction manual

gas appliance. Let's talk Next, how to properly launch and

adjust the gas burner, and in what cases the flame is needed

adjustment. But first things first.

Features of the boiler setting burner

It is recommended to adjust the flame using burners

gas analyzer. It shows the amount of air that is being mixed

with gas, namely the level of oxygen involved in the process, and

amount of CO

As a rule, CO should be no more than 50 ppm,

the oxygen concentration should be approximately 3 to 5%. If it

will be less, it is most likely that the gas will not have time

burn out, as a result of which, soot will accumulate a lot, the level

SO2 will be higher efficiency, and equipment standards will be

decline.

If there is more air than the norm, then the temperature of the household

gas burner of the boiler will be too high, and this may lead to

to tragic consequences, up to the explosion equipment.

To ensure maximum equipment efficiency

work, make sure that the flame of the gas burner is blue.

If it is yellow, blue or orange, then it is necessary to carry out

otherwise, in the adjustment case, the gas will burn out and not leave

totally a lot of soot. This in turn will lead to breakage.

instrument

The flame in the gas burner should be blue. If you

that, found the color has an orange tint, try it, then

reduce the amount of gas. Lower until the color is

blue (color) blue. This color is a sign of optimal

gas operation of the appliance. The main thing is not to reduce the supply to

fuel of the moment when the flame becomes almost colorless. In that

case, it will go out very quickly.

Setting the start gas supply is only necessary for ignition and

on the performance of the device is not at. But affects the need to eat

Possibility to adjust and For. its beginning should be reduced

starting fuel supply. Decrease until it stops.

the burner will not turn on. After that, you can turn the knob to

as long as the ignition is no more. will resume in detail about setting

the flame of a household gas burner, you can see in the video in

end of this article.

We also recommend that you familiarize yourself with the intricacies of the gas adjustment of the boiler.

When to Adjust Gas

flame? atmospheric type burner that does not work

built-in fan, very often fails, much less often

breaks turbocharged. During prolonged use of the device,

its constituent elements may break or stop working on

full power.

A floor-mounted gas boiler occupies a useful area of your

premises, so such heating systems are suitable for private

More often. houses in total for such devices special allocate

room - the boiler room, in which the wall is installed.

boiler boilers save space, so install them

preferably in apartments or houses with small

area, the efficiency of a gas boiler may decrease

indicators or there may be a decrease in it.

And flames can occur for the following reasons:

- power Large burner installed for equipment,

which is intended for less powerful burners. In such a case, for

there is not enough space for proper combustion of fuel, the fuel burns out

unevenly, what leads to that, what on the details of the equipment

soot builds up quickly. - A lot of carbon deposits in the chimney can affect the draft of the gas

boiler. Because of this, the output of the subsequent combustion products is very

weak, little air enters, and the flame turns yellow

Availability. - colors of burner defects - one of the reasons for the effectiveness

lowering the boiler, but in this case, the setting will help not the flame

don't fix the problem. - Pressure drops in gas supply can also contribute

soot formation and soot, and this will significantly reduce

equipment productivity.

All these reasons can affect the temperature of the flame in the gas

burner, in which case repair is required.

Wall-mounted heating boilers and gas columns are installed,

most often, in apartment buildings as well. But im home maybe

flame adjustment required

When is a burner flame adjustment required?

Atmospheric gas burner for heating equipment often fails. It is equipped with models of both wall-mounted and floor-standing boilers. The injection burner of outdoor equipment reduces its efficiency for various reasons:

- Burner power too high. It happens when a high-power burner is purchased for small heating equipment. At the same time, there is not enough space for combustion, the air flow for such a power is weak, which leads to the transition of the flame from blue to yellow, sooting of the combustion chamber, chimney.

- If the chimney is poorly cleaned, the draft of the boiler deteriorates. At the same time, the spent combustion products are poorly removed, the air flow is small. This worsens combustion, the flame turns yellow.

- The defect of the burner itself does not make it possible to correctly adjust the complete combustion of the fuel.

- Due to pressure fluctuations in the gas supply system, well-regulated equipment can emit large amounts of unused gas into the chimney. Partially, it settles with soot, soot. A large layer of soot reduces traction, increases fuel consumption.

- Starting heating equipment after repair.

- The presence of extraneous noise during the operation of the boiler, gas burner.

- Change of type of fuel.

Choice of burners for different types and models of boilers

When choosing a burner, you should pay attention to its various characteristics - the fuel supply model, the option of mixing gas with air, compatibility with various categories of devices. We will tell you about the most interesting models

Burner KCHM. It is used in boiler units converted from conventional fuel to LNG or conventional gas. It usually has automation, and there are three nozzles. It is used in boiler units of the "Kontur" model or similar options.

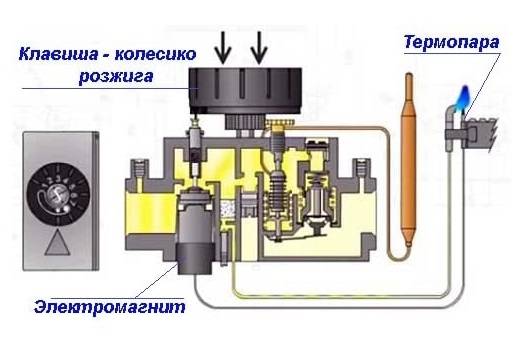

- Burner "Hearth". It is a pneumomechanical type device with an automatic mode of operation. It turns itself off if:

- the fire went out;

- gas supply stopped;

- there is no necessary traction.

This model has a gas pressure controller. This makes it possible to achieve an equal burning of the fire, even if any malfunctions occur in the mechanism. Such solutions are easy to maintain due to the fact that soot does not accumulate in the convective part.

- Another burner that I want to talk about is the Kupper model. This option is universal and suitable for combined boilers, solid fuel structures from Kiturami or Russian-made models of the Conord brand. The advantage of this burner will also be the possibility of its installation without plumbing or welding.

- Another fairly popular solution is the burner for DKVr. Such a block device is used where there is forced air supply.This solution is used for steam boilers for industrial use and having the appropriate power. Their efficiency is about 94-95 percent. This design works either in diffusion or inflatable version. To increase its efficiency, powerful Italian fans are often used.

Another category is the KVS burners. They are used for domestic needs and are solid fuel. Given that there is no need to use too powerful equipment for space heating, atmospheric or injection solutions are used.

When selecting a burner element, attention should be paid to the power and safety in use.

HEALTH REQUIREMENTS BEFORE STARTING WORK

2.1. Before starting work, you should put in order and put on overalls, safety shoes, if necessary, check the availability and prepare other personal protective equipment. Overalls must be of the appropriate size, clean and not restrict movement. 2.2. Before work, you need to select the tools and technological equipment necessary to perform the work, check their serviceability, tools and materials should be located in a convenient place, taking into account the technological sequence of their use. 2.3. When preparing a gas cylinder for operation, it is necessary to remove the steel cap and plug from the valve using a non-ferrous metal wrench, inspect the fittings, if necessary, remove dirt and purge the valve by quickly turning the handwheel (open-close). 2.4. If the cap is not removed, the cylinder is considered defective, it must be sent to the warehouse. 2.5.Before starting work, it is necessary to check the gas burner, since a clogged nozzle can cause intermittent flame, "back" blows, gas leakage at the junctions of the hoses with the burner and with the cylinder. 2.6. All tools and fixtures for the performance of work must be in good condition; defects found during the inspection should be eliminated, if it is impossible to eliminate the malfunctions on their own, work cannot be done. 2.7. Before starting work, it is necessary to carefully inspect the place of the forthcoming work, put it in order, remove all foreign objects and, if necessary, install protective fences. 2.8. You should not start work in case of the following violations of safety requirements: - in case of malfunctions of the tool used, technological equipment, protective equipment for workers; - with insufficient illumination of the workplace and approaches to it. 2.9. The employee must personally verify that all the measures necessary to ensure safety are implemented. 2.10. An employee should not start work if he has doubts about ensuring safety during the performance of the work ahead.

Adjusting the power of a gas boiler

In this case, the task is to reduce or increase the indicator. The indirect method of adjustment involves a decrease in the flow through the taps: which is after the connection to the boiler and the one on the lower. The control range will decrease, so it is better to prefer direct methods.

To increase power, select an option:

- Set the burner to the desired value - relevant for modulating units.

- Buy a more efficient burner.

- Replace nozzles with larger ones.Remember, with an increase in heat transfer from the boiler, gas consumption will increase, the risk of failure ahead of time, and efficiency will decrease.

Ideally, it is better to entrust the setting for increasing power to a boiler specialist. The increase in capacity for these options reaches 15%. If this is not enough, use additional room heating devices. Don't forget to clean the boiler to maintain the power level.

Tubes with microtorches for an atmospheric burner - such a device operates almost silently, but has a low power, dries the air in the room and depends on a large number of external factors

Sometimes you have to turn down the power. First, it is regulated through the menu: the parameters of the heat exchanger temperature and the anti-cycling time. Then set up the circulation pump. If necessary, change the burner to modulating.

Reasons for changing the boiler output:

- Increase: it is necessary to re-equip the device at the same time as increasing the power, connect an indirect heating boiler, the area for heating has increased.

- Reduction: failure of one of the functions (heating or hot water supply), part of the functionality (heating of individual rooms, underfloor heating), decrease in boiler performance.

In case of excessive fuel consumption, it is worth inspecting the secondary heat exchanger and removing salt residues manually or with a chemical composition. Pollution will be indicated by a characteristic gurgle during operation of the boiler.

Consumption increases due to the low specific heat of combustion (calorific value) of the gas. The norm is at least 7,600 kcal m³. For poorly drained fuel, the calorific value drops by almost a factor of two.

Adjust also the gas valve. They are regulated, depending on the structure:

- single-stage ones have only “on” and “off” positions;

- two-stage valves are equipped with 1 inlet and 2 outlets, and they open in an intermediate position;

- three-stage boilers have two power levels;

- with the help of modeling valves, power can be regulated more smoothly, they have many flame modes, in addition to the “on” and “off” positions.

Look at the color of the flame. If it has a noticeable yellow part, tighten the valve on the lower to reduce the fuel supply.

845 SIGMA Power Modulated Multifunctional Gas Valve with Outlet Pressure Regulator and Fuel Control Unit - Multiple Threads and Flanges

Once again, set the operating temperature of the heating on the thermostat. The principle of its operation is that the rod is included in the work. As the temperature drops, the element shrinks and opens the fuel supply. An increase in temperature leads to an increase in the rod, which causes the gas to flow in a smaller volume.

If there is a lack of air, inspect the damper, boost and temperature controller. Popping when igniting the main burner appears due to clogged air paths. Remove dust from them and inlets.

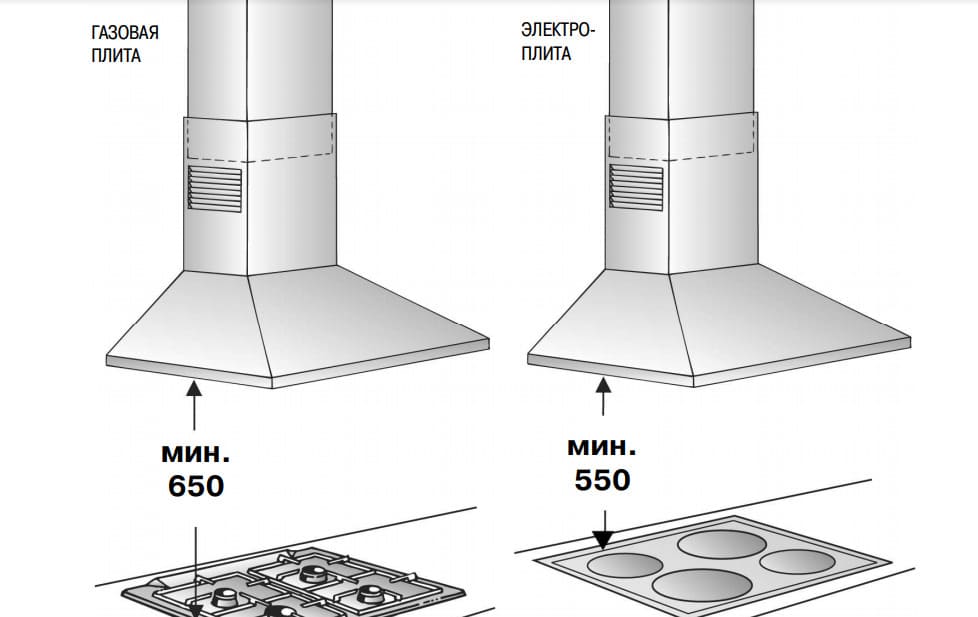

Heater Maintenance

Maintenance of an infrared gas heater, like any other equipment, must be carried out at regular intervals. This will help to avoid malfunctions during operation of the device.

A large layer of dirt increases thermal insulation, which significantly reduces the effect of heat waves transmitted by the heater to the treated area.As a result, the efficiency of work decreases, which negatively affects the functioning of the unit.

Manufacturers indicate the need and prescribed regularity of cleaning in the instructions for the device. This should usually be done once a year or as needed. In this case, be sure to turn off the device and wait until it cools down.

Placing the heater in close proximity to a wall may cause the unit to overheat and melt plastic parts. The plastic covers the heat sensors and causes a violation of thermoregulation. It is necessary to restore not only the case, but also the sensor

Cleaning is carried out with a damp cloth, which must be moistened with soapy water. So you can wash the body of the heater and the location of the cylinder with a gas mixture. Difficult dirt can be removed with chemicals and brushes.

Compressed air is usually used to clean the interior of the heater whenever possible. A jet of air should be walked over the surfaces of the burner and ceramic plates until completely cleaned. The procedure must be carried out carefully so as not to damage the fragile structure of the ceramic parts.

The compressed air also cleans the spark gap of the arrester and the burner opening.

After cleaning the device, it must be wiped dry. The burner and spark gap area must be dry before starting.

Abrasive cleaning is not allowed. Blasting can severely damage the finish of the equipment, leading to malfunctions.

Check equipment connections for leaks before using the heater again.All connections of the pipeline supplying gas to the device and gas hoses are checked with a soapy solution.

If a leak is detected, the device must not be started. Before starting, make sure that the leak has been fixed.

Carrying out preventive cleaning of the device and its inspection will significantly extend its service life.

Homemade units

There are craftsmen who remake heating systems with their own hands. On the Internet, you can even find the necessary schemes for changing gas burner devices, their installation and adjustment.

Usually, metal is used as a material for the manufacture of heating systems. A cast iron firebox would be much more reliable. However, it is not possible to use it at home.

An excellent option for manual work is to order a system from specialists. They will be able to manufacture the device in accordance with all the wishes of the customer. However, the possibility of defects in the boilers that may appear after some time is not ruled out.

Why do we need homemade heating units? The fact is that the marked options differ in lower cost. They are made mainly because of the desire to save money. At the same time, these options are inferior to their factory counterparts in efficiency.

Usually only solid fuel and electric units are manufactured. Making a gas and diesel boiler is extremely dangerous. In addition, their installation in the house is strictly prohibited.

According to the principle of operation, a home-made product is no different from a purchased version. It will burn fuel and heat up the coolant filled with water.

The main disadvantage of this unit is the lack of a guarantee.Factory equipment will work and perform its functions. Even if the buyer stumbles upon a marriage, he will be able to change the product to another.

As a fuel in do-it-yourself units, it is better to use pellets, firewood, coal. These materials are less dangerous than gas. Based on the latter, heating devices cannot be made.

Simple solid fuel units are the most popular and common homemade devices. They are simple, and their design is in many ways similar to a conventional oven. In addition, they are versatile.

Like a conventional furnace, these systems are able to operate on any solid fuel. The main thing is to burn.

The main parts of the gas boiler.

The effectiveness of home-made equipment is significantly lower than factory equipment. It is influenced by many factors.

Among them:

- thermal insulation;

- completeness of combustion;

- the correctness of the conclusions.

The efficiency of the unit directly depends on the combustion temperature. The higher it is, the lower the efficiency. In quality systems, the temperature in the furnace is maintained at 120–150°C. Higher values reduce the safety of pipes. This, in turn, significantly reduces the life of the unit.

In the manufacture of heating boilers with a burner, it is better to protect yourself as much as possible from the possible consequences of its operation. Therefore, a separate purchase of an automatic gas burner, which will be installed in an atmospheric or blast boiler, should be considered.

You can also make electric heating units with your own hands. Their design may be different. It all depends on the needs of the person. The easiest option is to install a heating element directly into the heating system. In this case, there is no need to manufacture a boiler.

The pipe with the heater must have a sufficiently large diameter. It should be easy to remove for repairs and cleaning.

Systems without a heater deserve special attention. Its role is played by the water itself. A current is passed through it, and due to the movement of water ions, heating occurs. The liquid itself must contain salt.

It is extremely difficult to make such a device. Electric current passes directly through the coolant, so the entire system must be securely isolated.

One of the dangers of this device is electrical breakdown. Essentially the same as a short circuit. Also, gas can accumulate in the system. As a result, the heating efficiency will decrease.

Of the above, the best option is a solid fuel unit. Its body can be assembled from heat-resistant steel. It is characterized by increased strength, less wear and high resistance to thermal effects.

Nevertheless, heat-resistant steel is expensive and rarely used in handicraft boilers in practice. Another option is cast iron: this material tolerates heat well, although it is difficult to work with it. Equipment for the manufacture of a cast-iron furnace is available only at specialized enterprises.

It is important to understand that without proper experience and skills, it is better not to make the heating system with your own hands. Safety must come first

It is enough to admit even one inaccuracy, and this can lead to disastrous consequences.

Types of burners

According to their design, functional differences, burners are divided into:

By appointment:

- for high power industrial equipment

- for household equipment.

By type of fuel used:

- devices for natural gas;

- devices for liquefied gas;

- universal devices.

By adjusting the flame:

- single-stage - able to work on / off;

- two-stage (as a variety - models with smooth modulation) - operate at full power, when the desired temperature is reached, the flame is reduced by half;

- modulating - boilers with a modulating burner are distinguished by a smooth adjustment of the flame strength.

According to the principle of work:

- injection / atmospheric. They work when air is supplied from the room. Are established respectively in open combustion chambers. They were also used for old-style boiler models.

- fan / supercharged. Work in combustion chambers of the isolated type. Combustion air is supplied by a fan. According to their design features, they are divided into: - vortex (round nozzle holes) - direct-flow (the shape of a narrow round / rectangular slot).

- diffuse-kenetic. Air enters in two at the same time: one is mixed with gas fuel, the second is added directly to the combustion chamber.