- Coaxial chimney as a ventilation element

- Chimney Requirements

- Bet on a chimney in the form of a steel pipe

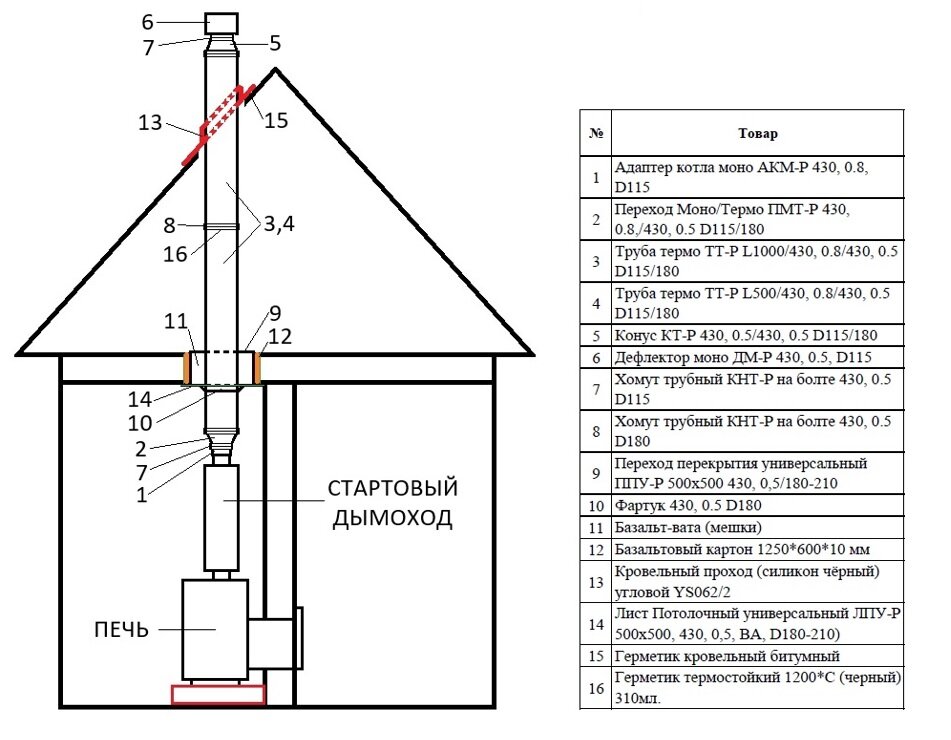

- Chimney installation

- Chimney assembly instructions

- How is the chimney

- The main mistakes during installation

- Installation rules

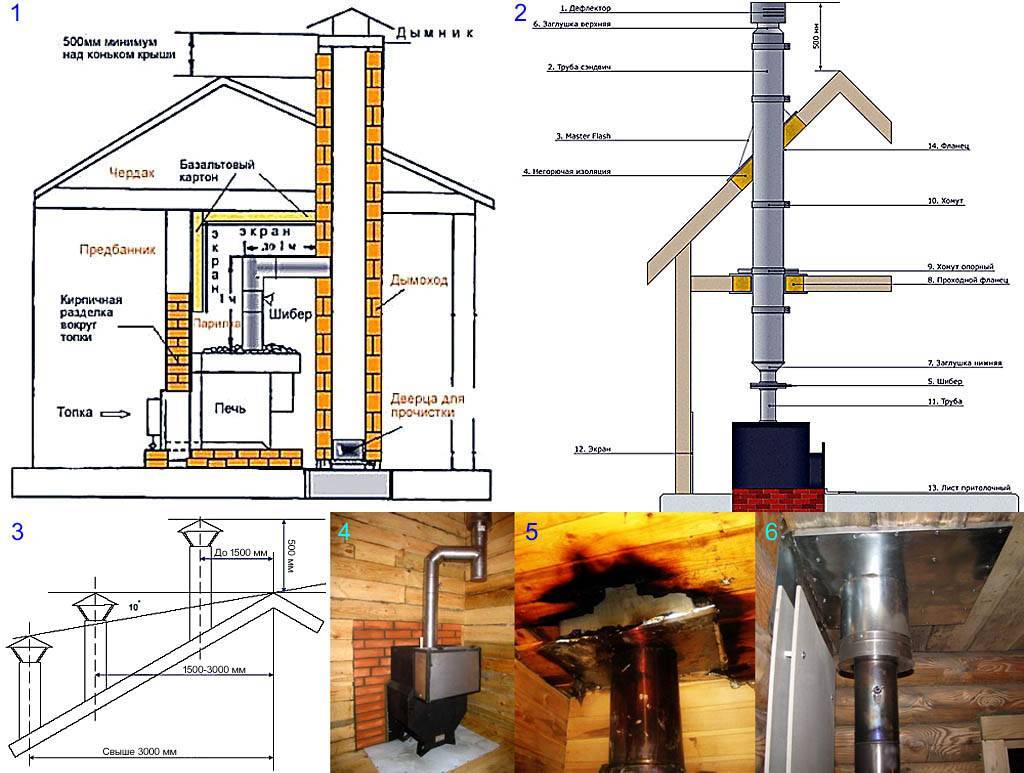

- Brick chimney technology.

- Do-it-yourself tool for laying a brick chimney chimney:

- Steps for making a brick chimney:

- main parameters

- Steel chimney manufacturing and installation technology

- Tools and materials

- Calculations

- Assembly and installation rules

- Wall preparation

- Kinds

- cutting

- Interference and obstacles

- Chimney located on one side of the furnace

- Manufacturing

- Gas chimneys

- What materials are suitable for gas chimneys?

- Does the type of boiler affect the choice of chimney?

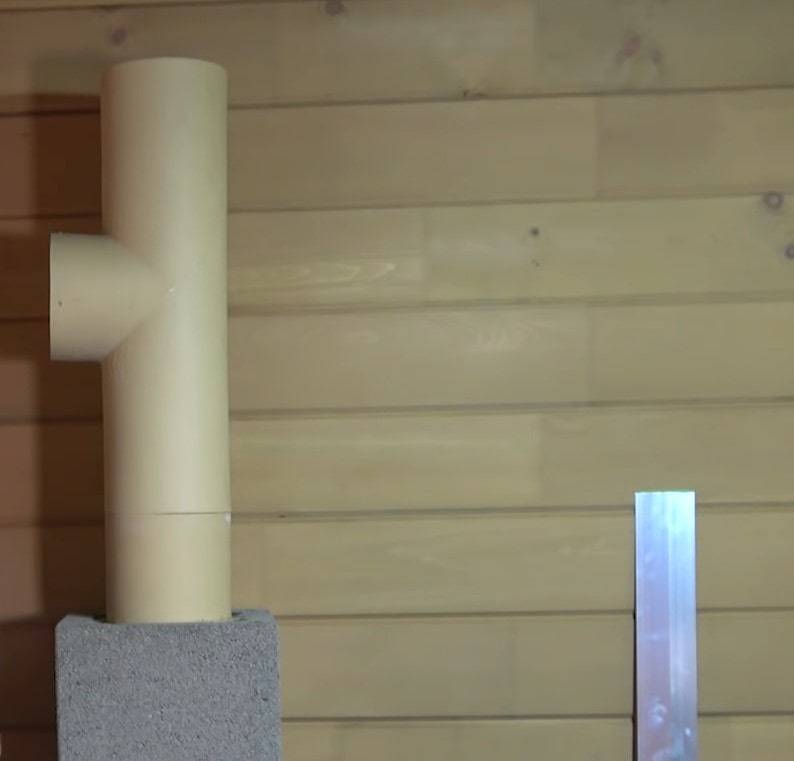

- How to install a coaxial chimney?

- Is it possible to change the chimney?

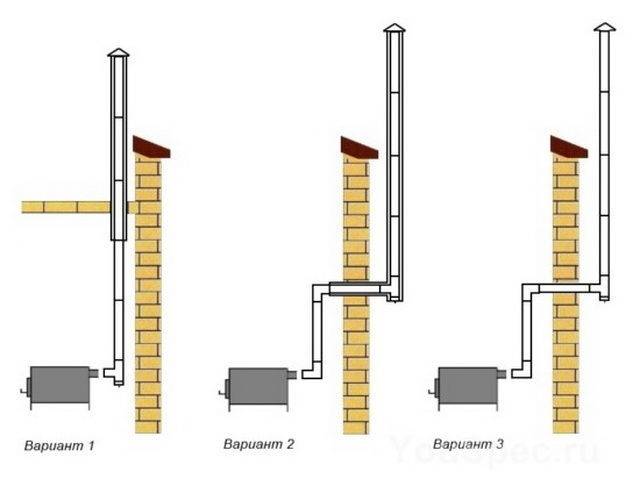

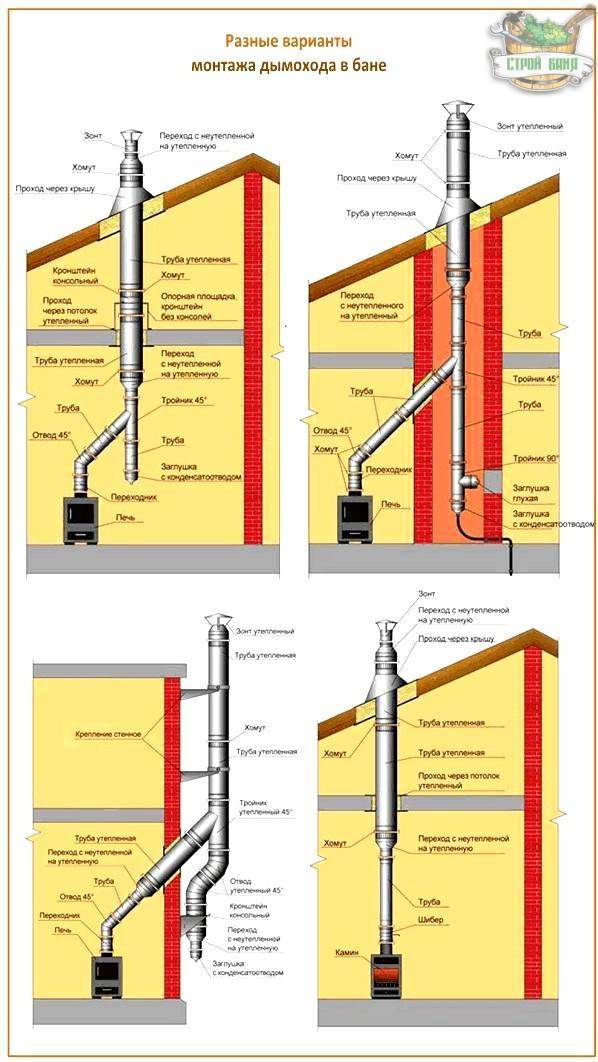

- Chimney outlet methods

Coaxial chimney as a ventilation element

Due to their design, coaxial chimneys are quite reasonably popular. They are assembled according to the “pipe in pipe” scheme, which allows you to perform two functions necessary for gas equipment at once: the output of combustion products to the outside and the air supply to ensure the combustion process.

Coaxial chimneys are divided into two types: horizontally and vertically located.The first are installed in the wall, the second are led out through the ceiling to the attic, then to the roof. A vertical flue gas system is longer, more expensive, more difficult to install and requires the installation of a condensate trap.

The only disadvantage of the equipment is the risk of freezing of condensate on the outer part brought out. The problem is solved by insulating the pipe with mineral wool or other heat-insulating material, although in cold weather this will not save

To combat frost, the end of the pipe is equipped with a lattice head.

A few rules for correct coaxial chimney installations:

- The pipe outlet is recommended to be equipped at a height of 2 m above the ground.

- The distance from the pipe to the window located on top is at least 1 m.

- A condensate collector is not necessary if the pipe is installed at an inclination of 3-12° towards the street.

- It is prohibited to bring the line to the adjacent room.

If there is a gas pipe near the chimney outlet, the distance between them must be 0.2 m or more.

The standard equipment of horizontal equipment consists of a pipe, an elbow for connecting to the boiler, adapters, decorative overlays, compression rings, fixing bolts.

Installation example of a horizontal coaxial chimney that exits through a wall:

Measures for the installation of a horizontal coaxial chimney are recognized as the easiest in terms of execution, therefore they are recommended for self-installation. At the end of the work, the boiler is put into operation and the tightness of the connected pipe is checked.

Chimney Requirements

The selection of elements is carried out taking into account the requirements of the technical characteristics of the heater. In order for the system to work smoothly, the basic principles of chimney design must be observed:

- A round shape is preferred, since combustion products and dust accumulate in the corners of the pipe. Round chimneys require less cleaning than rectangular and square ones.

- The cross section of the pipe must not be less than the diameter of the heater nozzle. It is calculated that for every kilowatt of power, 8 sq. see section. Usually, information on the required size of the chimney is contained in the instructions for the heater.

- Each heater requires its own chimney. In some cases, you can deviate from this rule, but then the devices should be located at the same height, the distance between the connection points is 1 m or more. And the size of the pipe section should take into account the total power of the heat generators.

- The total length of the horizontal sections of the chimney cannot exceed 1 m; violation of this rule reduces the draft force.

- The chimney ends 0.5-1.5 m above the ridge, on a flat roof - 0.5 m above the surface.

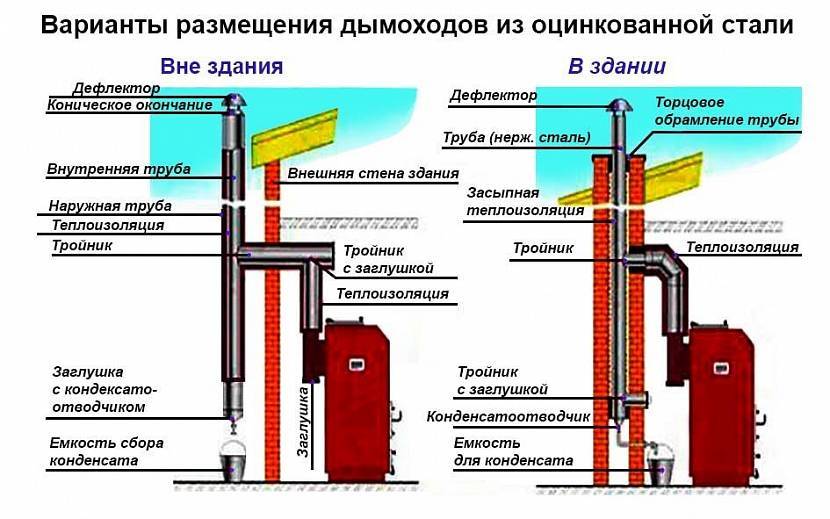

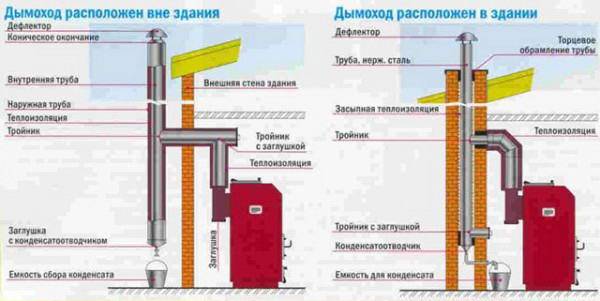

Scheme of external and internal chimney

Scheme of external and internal chimney

Bet on a chimney in the form of a steel pipe

Why steel? Before analyzing the features of such a chimney, it is useful to briefly consider all types of thematic design:

- Brick chimneys - retain heat for a long time, remove smoke well, but require a stable foundation and are difficult to build;

- Ceramic chimneys are quite reliable, but expensive due to the use of refractory ceramic profiles and asbestos-cement or polymer pipes;

- Metal chimneys are easy to build, durable and easy to use.

Therefore, when thinking about how to build a brick chimney with your own hands, you must take into account the costs of organizing an additional foundation, transporting bricks, etc.

Chimney installation

The installation of a chimney in a private house begins with laying the foundation. First, a pit is pulled out, which corresponds to the size of the chimney. The depth of the pit is about 30 cm. A layer of crushed stone with gravel is poured into the bottom of the pit, and then a layer of sand. The thickness of these layers should be approximately equal (that is, 15 cm each). Crushed stone and sand are compacted and leveled.

After preparing the "cushion", you can start pouring the cement screed. It is recommended to do this with a liquid solution, since in this case a better leveling of the surface is achieved. Then you should wait until the screed completely hardens and only after that proceed to the direct laying of the chimney. First lay the first layer of bricks. The angles are then displayed using a level or plumb line.

The masonry is raised to the level at which the chimney sleeve should be connected. It is connected to the oven using metal corners. The free ends of the corners are inserted into the chimney. The junction is carefully smeared with clay mortar. The sleeve is organized like a wall chimney. Then continue the normal laying of bricks.

Chimney assembly instructions

So, a suitable laying scheme has been selected, materials have been purchased. Before installing the smoke channel, perform the following preparatory work:

Lay the route of the future gas duct. Make sure that when crossing a wall or ceiling, the pipeline does not fall on supporting structures - racks of a frame house, roof beams, rafters.

Install a boiler or stove

Here it is important to choose a place well so that the chimney does not turn more than 2 times (the entrance to the tee is considered the third turn).

Protect the combustible lining of the ceiling and the walls adjacent to the heat generator from fire. Use galvanized sheet + basalt board, mineralite slabs or other fire resistant materials.

Make a passage hole in the outer wall or ceiling (depending on which scheme you have chosen).

First, try to collect chimney fragments on the ground, according to the developed scheme. Make sure all parts and fasteners are included.

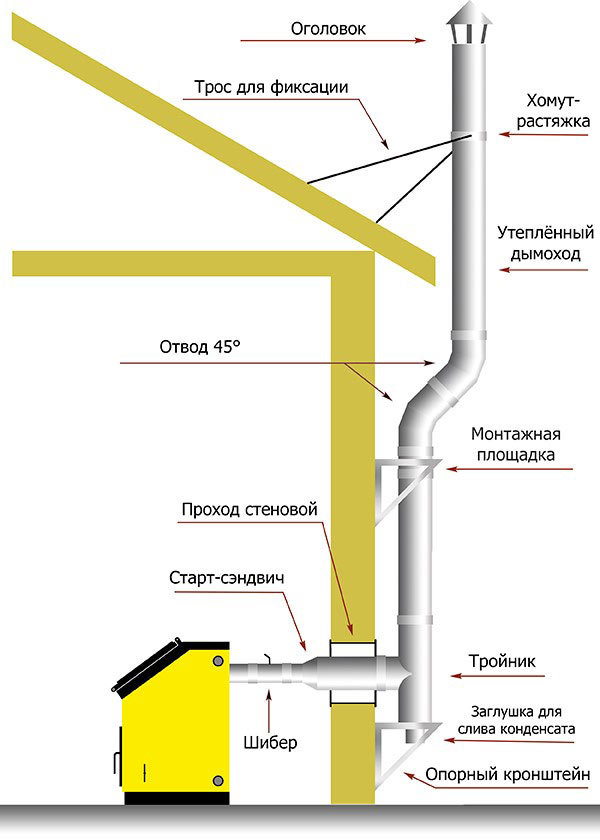

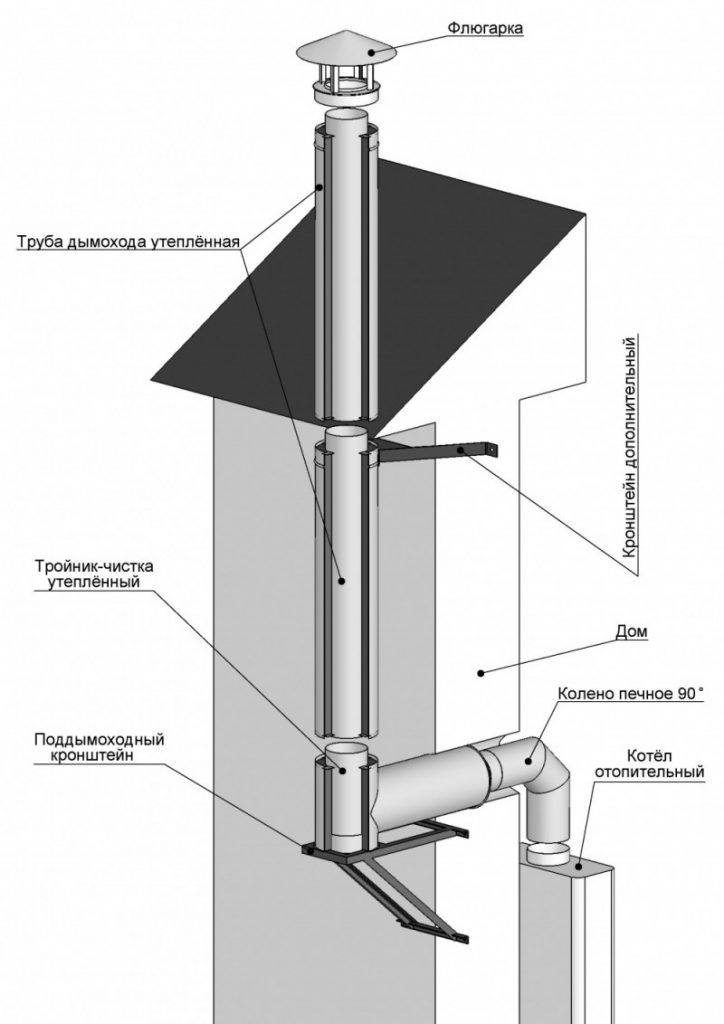

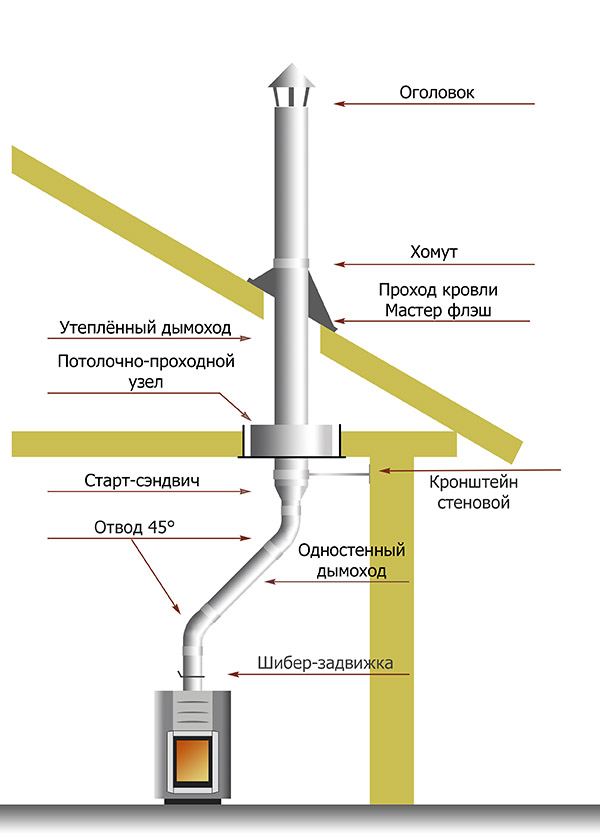

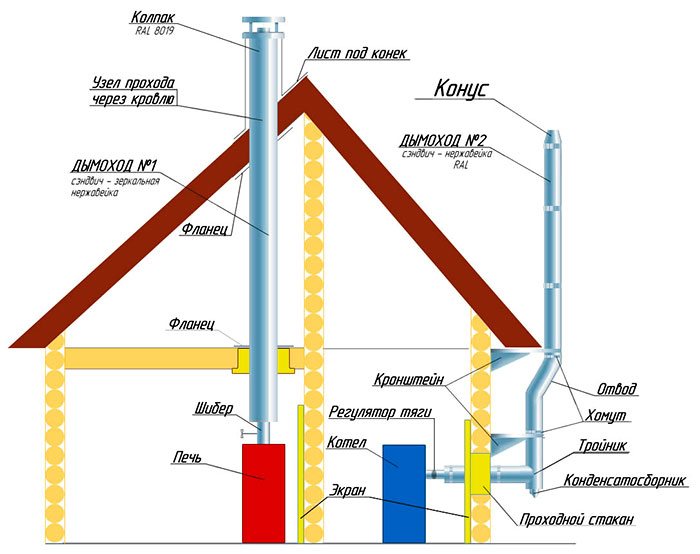

An example of a wiring diagram for installing a chimney inside the house

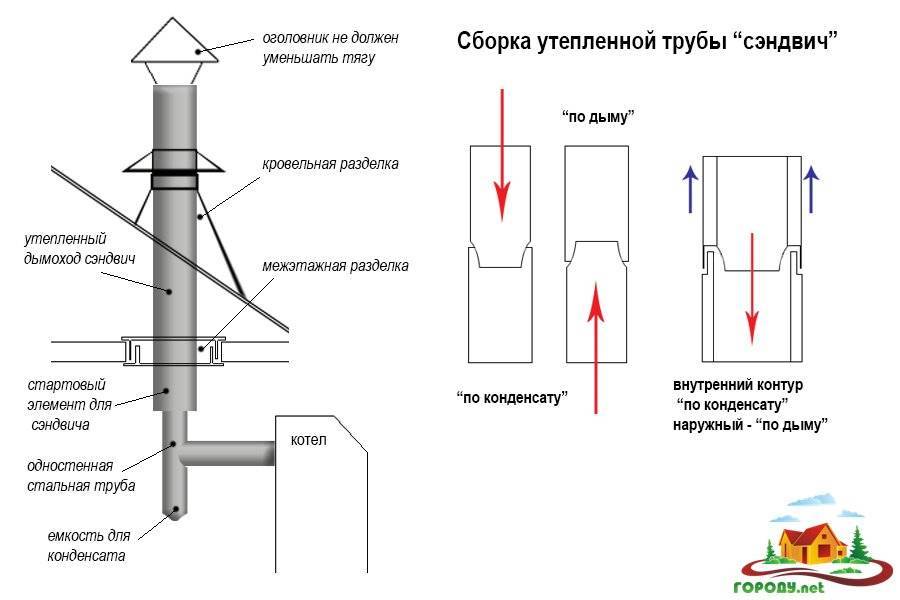

How to install a sandwich chimney with your own hands:

- The chimney must not load the boiler with its own weight. Fix the supporting parts - floor stand, wall brackets. Be aware of setbacks for combustible structures, move the pipe to a safe distance. For plastered brick or concrete walls, the minimum interval is 50 mm.

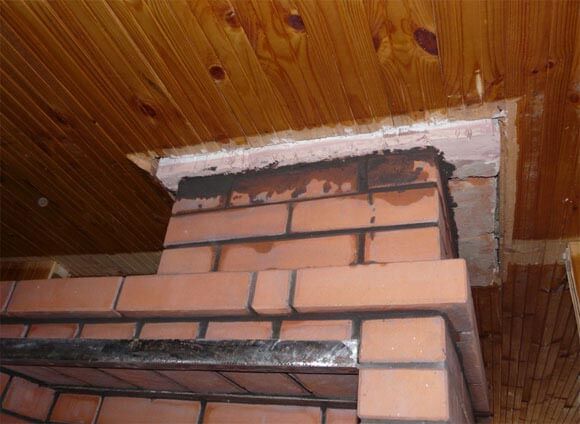

- Assemble the ceiling assembly (PPU). To prevent the metal box from touching the wood, lay strips of basalt cardboard at the joints. Lay basalt insulation into the inner cavity of the box when you run the pipe.

- Start the installation of the flue from the heat generator. Install a coupling, a section of an ordinary stainless pipe, then go to a sandwich.

- The correct connection of pipes is “by condensate”. The bell of the upper section (mother) is put on the lower (dad). Metal releases on the sandwich will block the junction on both sides, then the condensate inside the channel and precipitation from the outside will safely flow down the walls.

- After connecting adjacent modules, the joint is additionally crimped with a special bandage. Do not confuse it with fastening clamps.

- A tee with an inspection and a steam trap can be assembled on the ground, then attached to a horizontal chimney and supported on a bracket.

- Further installation of the sandwich pipe is carried out from the bottom up. Every 1.5 ... 2 m, the trunk is attached to building elements that can withstand the weight of the chimney. We cover the upper cut with an appropriate nozzle that protects the insulation from precipitation.

- The channel laid through the roof is sealed with a “roof”, whose upper edge goes under the roofing, the lower one remains on top. Additionally, a skirt is placed above the "roof", covering the gap around the pipe.

If the end of the gas duct rises 1.5 m above the last anchorage point, it should be secured with braces against wind swing. Another option is to make a square or triangular mast from steel corners. The chimney is installed inside the lattice tower on regular fixtures.

How is the chimney

Chimney requirements:

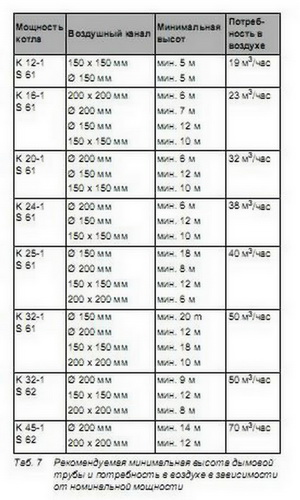

- Be vertical with a pipe height of at least 5m. The recommended pipe height depending on the boiler power is shown in the table below.

- Permissible tilt angle - 45.

- Have a cleaning in the lower part (modern boilers are not required).

- From the floor-standing boiler, the chimney pipe rises vertically (at least 1 m), only then is it allowed to move to a horizontal plane. The wall-mounted boiler is hung as close as possible to the main chimney, in order to immediately build a horizontal connection. Horizontal sections reduce draft, it is recommended to place the heating units as close to the chimney as possible.

- The cross section is determined according to the recommendations for the boiler.For example, a 25 * 25 cm pipe in brick is suitable for a 12 kW fireplace.

- Minimum number of turns.

- It is allowed to combine chimneys into one main pipe. In this case, the diameter of the water place is not less than the sum of the sections of all chimneys that are connected.

- The head of the chimney is located 1.5 m from the ridge (no less). The closer the system is to the skate, the higher the thrust.

The main mistakes during installation

Competent experts note that there are the most common mistakes that people make:

- Incorrect materials that are completely not intended for these purposes.

- The use of one chimney opening for several heating devices.

- Incorrect chimney insulation procedure.

- Inaccurate repairs.

All of the above reasons usually prevent the competent installation of a chimney in a house that has a gas boiler. If you have never done this work yourself, then be sure to consult with a specialist. In addition, watch training videos and photos, this will help you understand whether you can do such a difficult job with your own hands.

Installation rules

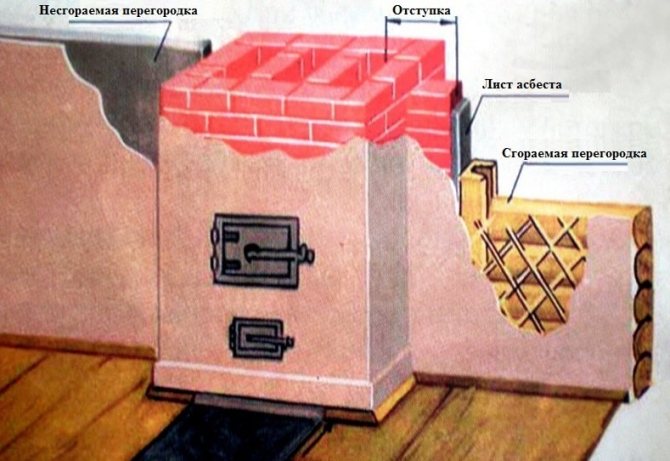

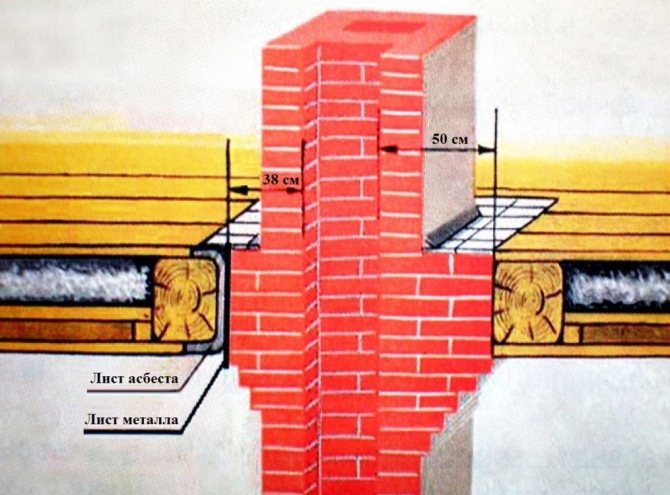

- Fire safety should be the most important guideline in the construction of a chimney structure for a solid fuel boiler. The distance from the walls of the chimney to other surfaces must be at least 38 cm. When building an internal type chimney, it is necessary to carefully isolate the places where it passes through the ceilings.

- The walls must not be narrower than 10 cm, including insulation.

- The height directly affects the efficiency of the removal of gases and the traction force in the chimney system. It is necessary that the top point of the chimney be at least a meter away from the roof.

- Accurate calculation of the area of the internal section. It is necessary that this value remains constant throughout the chimney in order to avoid a decrease in efficiency.

- The maximum length of horizontal sections in the system is 1 m.

- The design must necessarily have a condensate collector and doors for maintenance.

How to calculate the diameter of the chimney for solid fuel boiler

| Height, m | The ratio of the sections of the furnace hole and the chimney | |

| Cylindrical pipe | square pipe | |

| 4-8 | 0,83 | 0,72 |

| 8-12 | 1 | 0,9 |

| 12-16 | 1,12 | 1 |

| 16-20 | 1,25 | 1,1 |

Brick chimney technology.

A brick chimney must stand strictly vertically and, if possible, have a flat, without protrusions, inner surface. If necessary, make a withdrawal, it should not go to the side by more than a meter and at an angle of at least 60 degrees to the horizon.

The internal section of the stove chimney should not be less than 140x140 mm and pipe height not less than 5 m from the level of the grate, to create sufficient traction. But if the height of the chimney is less than 5m, then you can install a deflector-diffuser, a nozzle that improves traction due to ejection.

If the house is two-story and on the second floor there is also a stove, stove, fireplace, then a separate chimney is made for each hearth. Since the draft is better at the lower hearth, and with simultaneous heating, the upper one will certainly smoke.

In places where a chimney made of bricks adjoins wooden structures with their own hands, they make a thickening of the masonry, cutting, in 1-1.5 bricks. The distance of beams and combustible structures to the furnace pipes should be not less than 25 cm. This distance is covered from below with sheets of asbestos cement or metal, and from above they are covered with expanded clay or sand.

So that the chimney is not covered with snow, it is brought to a height of half a meter relative to the roof.Do not forget to protect the end of the chimney head from being destroyed by atmospheric precipitation; for this, you can use a metal cap or turn it around with sheet steel.

In the place where the brick chimney passes through the roof, an otter is made to close the gap between the chimney and the roof. To ensure a normal drain, the slots are covered with sheets of roofing steel.

To avoid tipping over the draft into the chimney, its head is made beveled or a deflector can be installed.

Do-it-yourself tool for laying a brick chimney chimney:

* Solution. Clay-sand or lime-sand.

* Brick. Red, fireclay or hearth.

* Hammer pick, trowel, trowel.

* Rule, level, plumb, meter.

* Container for solution.

* Asbestos-cement slab.

* Sheet iron.

Steps for making a brick chimney:

1) You will need to stock up on the tools and materials that you will need when laying out the chimney. These are brick, sheet iron, mortar, mortar container and masonry trowel. Wear gloves for extra protection.

2) Next you need Familiarize yourself with the structure of your chimney. It consists of a neck, a riser, a head, a smoke damper and a metal cap. They lay out a brick pipe from bricks that are connected with mortar. We use an asbestos-cement slab to isolate the pipe from wooden structures.

3) We carry out brickwork tightly, do not leave gaps. We apply a little mortar to the place where the brick is laid (bed), level it, moisten the brick in water, apply a little more mortar to the end or mating edge and put the brick in a sliding motion with pressure towards the vertical seam in place.In case of unsuccessful laying, the brick is removed, it is unnecessary to correct it by tapping, it is cleaned with the bed, wetted and re-laid. Otherwise, air leaks occur, which will spoil the craving for the furnace and the gas flow will increase. We identify and eliminate all existing leaks. Masonry joints should be 0.5 cm horizontal and 1 cm vertical. Every 5-6 rows of masonry, the inside of the chimney is wiped with a wet cloth, the seams are overwritten.

4) Making a section square or rectangular pipes (transverse). The shape of your pipe affects the level of resistance in the chimney (hydraulic). It is also a condition for maintaining and creating the necessary traction. A round sectional shape is also optimal, but it is very difficult to create such a shape using brickwork.

5) We avoid sloping chimneys during the production of the pipe, because additional air resistance occurs at the points of rotation. But if there is no way without turns, then they need to be done at an angle of 60 degrees. Also, do not make a large diameter pipe, as the gases will cool faster in this pipe and the heating efficiency will be lower.

6) Above the roof, to the thickness of a single brick, we lay out the walls of the chimney chimney, but do not forget about the headboard and the ridge canopy. The headband is best done without a cornice, because the wind should blow it perfectly and therefore such a solution will allow better removal of gases. Do-it-yourself lay the upper part of the brick chimney on sand-cement solution.

Do-it-yourself brick chimney is a very difficult and crucial moment, so you need to take this very seriously, but it is better to entrust this matter to specialists.

Source-Build Your Own House

main parameters

The advantage of shop models of galvanized steel chimneys is that manufacturers produce a wide range of sizes. In addition, among the factory products you can find double-circuit, equipped with thermal insulation, corrugated, with increased flexibility and single-circuit. When making a homemade chimney, you have to limit yourself to only single-circuit pipes. To the smoke exhaust system worked effectively, the following parameters should be taken into account:

- Pipe section size. In order for the smoke to come out of the furnace through the chimney, you need to choose the right diameter of the pipe. A pipe that is too thin does not provide the proper level, and therefore a reverse draft may form. A large-diameter chimney, on the contrary, removes the products of combustion into the atmosphere too quickly, so fuel consumption and energy losses increase. The more turns in the flue duct configuration, the thicker the pipe should be. In most cases, a galvanized steel pipe with a diameter of 100 mm is suitable. Recommended cross-section of a pipe of different power:

- Material. made from sheet metal. This material must be highly resistant to corrosion and moisture and high temperature. Therefore, simple galvanized steel is not enough, since the temperature in the chimney of solid fuel stoves and fireplaces exceeds 500-700 degrees. Therefore, for the manufacture of pipes, metal with increased heat resistance and resistance to corrosion is used.

- Wall thickness. The service life of a steel pipe chimney depends on the thickness of the metal used. Steel sheets with a thickness of 0.25-1.0 mm are used. The higher the temperature of the gases leaving the furnace, the thicker the metal should be taken.

Steel chimney manufacturing and installation technology

The manufacturing and installation technology is not particularly difficult: the main thing is to avoid gaps in the manufacture of components. Or just buy ready-made, so as not to worry about a possible gap in the welding seam.

Tools and materials

Required tools for creating fasteners and fitting metal parts and bends:

- rubber mallet

- Screwdriver for fastening brackets

- Screwdriver for tightening the clamps on the brackets

- Roulette for measurements.

Of the accessories you will need:

- Straight pipes

- Elbows at required angles

- insulation

- Pipes of larger diameter for sleeves

- Umbrella details

- You may need an adapter from the boiler to the chimney

- Brackets and clamps for pipe fixing

Pay attention to the steel grade. It is necessary that the steel be corrosion resistant and refractory

Ideally, the chimney material should be as smooth on the inside as possible to prevent soot from building up.

Adapters and other accessories for chimneys from steel pipes

Adapters and other accessories for chimneys from steel pipes

Calculations

You need to calculate the required amount of components using a tape measure. The length is taken along the axis of the future pipe. All bends are measured as if planned at 90 degrees. The missing part is then taken into account with the help of a multiplying factor. After that, the resulting pipe length is increased by 10-20%. If you plan to use purchased bends, then the required number of turns is considered. This completes the calculation, it remains to correctly assemble the purchased parts.

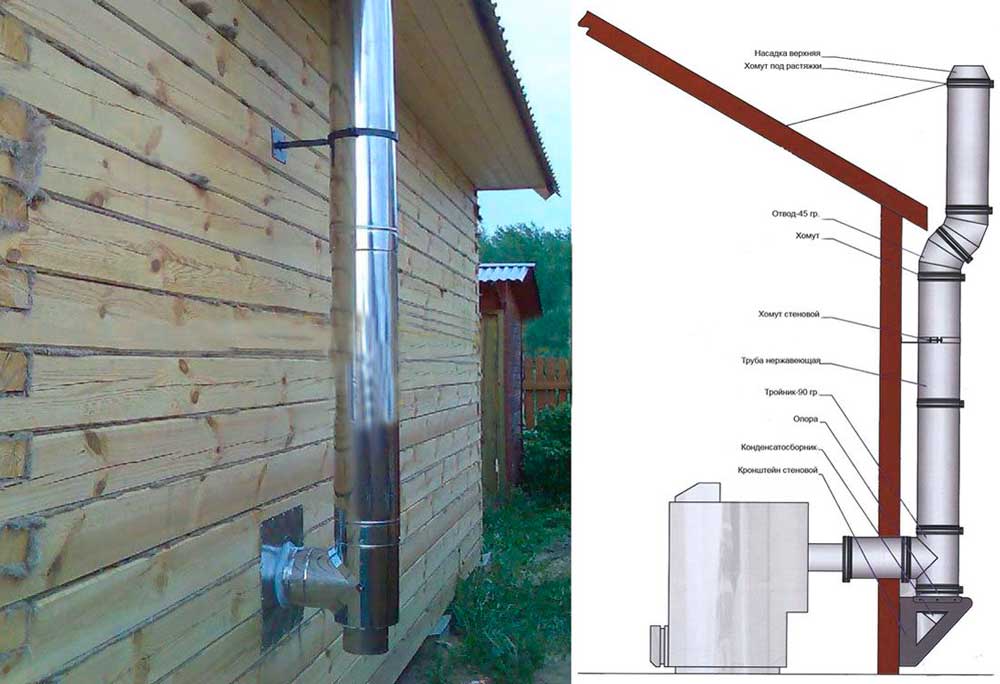

Assembly and installation rules

Steel parts need brackets. The minimum quantity is 2.One is installed indoors and one is outdoors. Brackets are installed first. Next, the pipe is installed from the boiler to the roof. The last compartment is mounted with the bolt already fixed.

A little advice: it is better to finally tighten the clamp on the brackets after the entire pipe has already been mounted. This will make the installation process much easier. It is also worth noting that the insulation of the pipe must be carried out immediately in the process of sleeving. That is, you need to follow the following procedure:

- Making a hole in the fence

- A sleeve is inserted, that is, a pipe of a larger diameter

- A chimney is passed through the sleeve

- The chimney compartment is connected to the previous

- The space between the sleeve and the pipe is filled with insulation. In this case, the pipe must be strictly in the center of the sleeve.

- Chimney installation in progress.

Bracket for fixing the chimney to the wall

Bracket for fixing the chimney to the wall

Wall preparation

Above, we have determined what should be the distance to combustible wall, and they also came to the conclusion that it is much more practical to finish them with refractories so as not to waste the space of the steam room. Now it's time to talk about how it's done.

So, we have three and a half options:

- we fix the refractory sheet on the wall;

- we plaster the wall;

- we make a brick casing for the furnace;

- we replace a part of a wooden wall with a brick.

Let us explain why 3.5 - often they hang a refractory on the wall and build a casing. Moreover, the latter is placed not only for the purpose of fire safety, but also simply for safety, as well as for the redistribution of heat. More about why is it needed and how to do it you will learn from this article.

As for refractory, you can use minerite - these are sheets of cement with fillers, reinforced with fibers.Excellent fire retardant. You just need to mount it correctly.

If the stove is close to the wall, then you will need two layers of mineralite with an air gap between them, which you will create using 3 cm ceramic bushings. The first layer is directly adjacent to the wooden wall, then there are bushings and the second layer of mineralite.

If the distance is longer, you can limit yourself to one layer, but it should not touch the wall either - the same bushings are used to attach it to the tree.

On top of the mineralite, you can put, for example, heat-resistant tiles (it is planted on heat-resistant mastic) or come up with another decorative design. As an option - mirror stainless steel. Its sheets perfectly reflect heat, but at the same time heat up themselves. Therefore, stainless steel is attached to a layer of any refractory - mineral wool, ceramic fiber, superisol, etc.

In principle, it is also possible to plaster a combustible wall (a layer of at least 2.5 cm) or use fire-resistant drywall.

Those who decide to bring the firebox into the dressing room either immediately put up a brick wall, or then cut out part of the log house or timber. In the brickwork, a place is left for a furnace tunnel with a margin, where a heat insulator, for example, mineral wool, is then clogged. The heat insulator is also used at the points of contact between brickwork and a wooden wall. If you do not want to replace the entire wall, make a portal - at least a meter long.

Kinds

To understand the material, it is worth clarifying some definitions:

- Furnaces are devices designed for the complete combustion of various types of solid materials, for heating the premises of objects, as assembled at the installation sites from fire-resistant materials - bricks, refractory concrete, fire-retardant pastes, non-combustible mastics; or factory-made from metal alloys.

- Fireplaces are types of stoves that are distinguished by a larger area of open furnace openings, the absence of smoke circulation.

- A chimney, a chimney is a shaft of rectangular, circular cross section, necessary to create an upward draft of heated flue products of the combustion process, their removal into the atmosphere.

Smoke channel, pipe can be of several types:

- mounted, based on the ceilings of construction sites;

- wall, passing inside the main walls;

- root, based on the foundation of buildings, floors, next to the heating unit.

- open;

- closed.

fire retreat

cutting

- to combustible structures of a construction site;

- to structures protected by wet plaster on a metal mesh, other fire-resistant materials.

Combustible materials in the composition of the ceiling can also be protected by fire-retardant plasters, fire-resistant (fireproof) drywall.

Fire cutting

Interference and obstacles

To interfere with the process of exiting smoke from the furnace, the occurrence of an area of \u200b\u200bhigh pressure, which, like a plug, “plugs” the chimney.

Cooled air in the chimney can become such an obstacle. That is why, increasing the height of the chimney makes sense only up to a certain limit, beyond which each centimeter of height will not increase the draft, but decrease it.

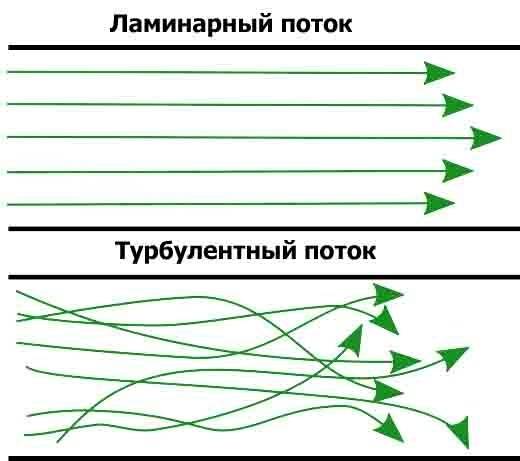

If the chimney has the right length, everything happens decorously and gracefully.But again, as long as all the particles of the air flow move at a relatively equal speed and in the same direction (this nature of the flow is called laminar).

Laminar and turbulent flows

But as soon as turbulence arises, or otherwise, turbulence, local zones of increased pressure immediately appear in the chimney, which, under certain conditions, will impede the movement of the flow.

There is no ideal even flow, there will always be turbulences, for example, at the walls of the chimney, but if the transverse dimensions are small and (or) the walls have significant irregularities, the turbulence zone can occupy the entire section of the chimney, weakening or completely blocking the draft.

Turbulence, the redistribution of zones of high and low pressure, can not only reduce or completely destroy draft, but even cause a phenomenon called reverse draft, in which air begins to flow into the furnace from the chimneypushing the products of combustion into the room.

Chimney located on one side of the furnace

Such a chimney is often called a root chimney. If we talk about the design, then this option is being built near the furnace, connecting to it, or attached to it. A feature of this variety is that it can be used for cast iron stoves, in contrast to the previous version.

It is also worth noting that it can be used for several stoves at once: if such a chimney passes through several floors at once, then stoves can be attached to it on each of these floors.

When using this type of smoke passage, it is important to accurately select all dimensions, otherwise it simply will not withstand the load and will not work effectively. Also, do not forget about cleaning the chimney of the furnace.

Manufacturing

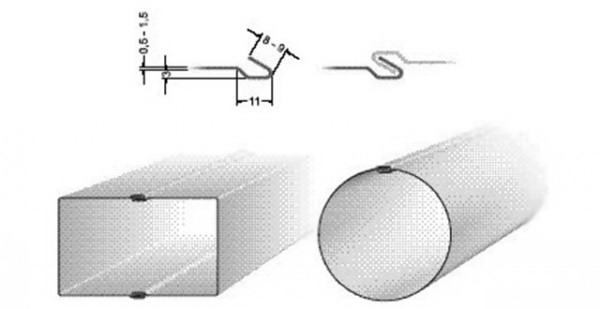

For the manufacture of pipes made of galvanized steel sheet you will need a rubber or wooden mallet of sufficient weight to bend the metal. Scissors are used in the process for metal cutting, a long ruler, a scriber for marking, a corner and a “gun” for bending. The bending process is as follows:

- First of all, a sheet of metal is marked out, using a scriber, drawing lines. On the one hand, the part is made 340 mm wide, and the other 330 mm, so that during assembly they can easily fit into each other. With the right cutting, you should get 7 strips 1250 mm long.

-

Using a metal corner and a mallet, both edges are bent at an angle of 90 degrees in opposite directions to a width of 0.7 mm. Then the blanks are turned over and the angle on the edges is adjusted to an angle of 135-145 degrees, gently tapping with a mallet.

-

The workpiece is moved to the "gun", a device for giving a sheet of metal a rounded shape with a diameter of 100 mm. The sheet laid on the “gun” is tapped with a mallet until the desired shape of the pipe is obtained.

- The edges of the workpiece are hooked together and placed on the gun. With the help of a rubber mallet, the place of adhesion of the edges of the sheet is made with a flat seam. The junction can be strengthened with metal rivets, however, this will require welding.

The scheme of bending the edges of the workpiece

The scheme of bending the edges of the workpiece

Gas chimneys

What materials are suitable for gas chimneys?

Due to the characteristics of the chemical composition of the smoke that appears during the combustion of gas, the main requirement for the material is resistance to chemical aggressive environments and corrosion. Thus, there are the following types of gas chimneys:

1. Stainless steel. The best option. Their advantages are light weight, resistance to various corrosions, excellent traction, operation up to 15 years.

2. Made of galvanized steel. Not the best option compared to stainless steel. Provides poor traction, more prone to corrosion. Operation no more than 5 years.

3. Ceramics. Gaining popularity. Operation up to 30 years. However, the high weight of the chimney must be taken into account when laying the foundation. The maximum thrust is only possible with vertical installation without errors.

4. Coaxial chimney. It has increased efficiency and safety, but at the same time a high price. It is a pipe within a pipe. One is for smoke removal, the other is for air supply.

5. Brick chimney. Shows negative qualities when using gas heating. Operation is short. It is permissible to use a brick chimney left over from stove heating only as an outer casing for an insert made of a more suitable material.

6. Asbestos cement. Outdated variant. Of the positive aspects - only low price.

Options for gas chimney enough. When choosing a material, it is worth starting from its quality characteristics. Do not save on your health and the safety of your loved ones.

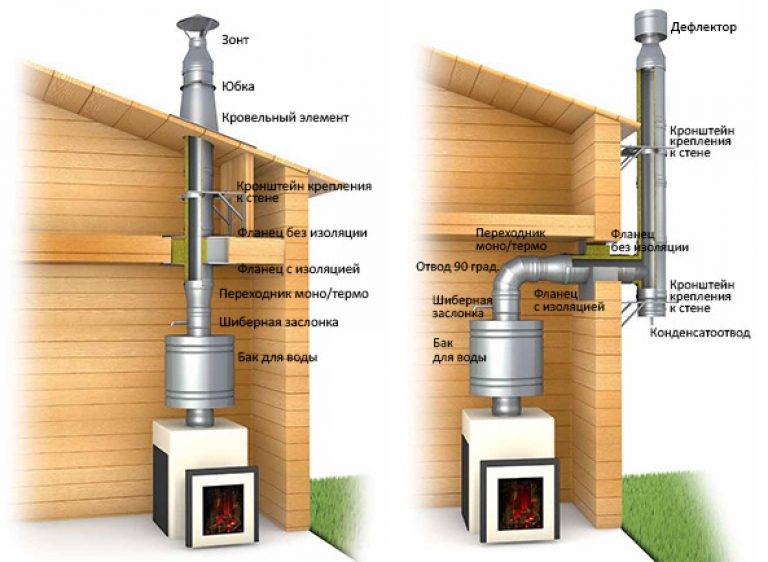

Does the type of boiler affect the choice of chimney?

The design of the chimney depends entirely on which boiler will be used - closed or open type.This dependence is explained by the different principle of operation of the boilers.

The open type is a burner with a heat carrier coil located on it. Air is needed to operate. Such a boiler requires the best possible traction.

Installation is carried out:

- Outside way. When conducting a chimney, you can use the external installation method by bringing a straight horizontal pipe through the wall, and then lifting it up to the required height. This method requires a high-quality heat-insulating layer.

- In an internal way. It is possible to pass the pipe internally through all the partitions. In this case, 2 slopes of 30° are acceptable.

The closed type is a chamber with a nozzle where air is injected. The blower blows the smoke into the chimney. In this case, the best solution would be to choose a coaxial chimney.

How to install a coaxial chimney?

The main positive characteristics of this type of chimney are:

- Easy installation;

- Safety;

- Compactness;

- By heating the incoming air, it cools the smoke.

Installation of such a chimney is permissible both in a vertical position and in a horizontal one. In the latter case, a slope of no more than 5% is required to protect the boiler from condensate. It should be borne in mind that the total length should not be more than 4 m. For installation, you will need to purchase special adapters and umbrellas.

Is it possible to change the chimney?

Often there are cases when the owner decides to switch from solid fuel to gas. Gas equipment requires a suitable chimney. But do not completely rebuild the chimney. It is enough to sleeve it in one of the ways:

1) Use of a stainless steel pipe.A stainless steel pipe of suitable length is installed inside the existing chimney. Its diameter must not be less than the boiler nozzle, and distance between pipe and the chimney is filled with insulation.

2. Furanflex technology is more expensive, but more durable. An elastic pipe under pressure is installed in the chimney, where it takes shape and hardens. Its advantages are in a seamless surface that provides complete tightness.

Thus, you can significantly save on materials, while complying with all regulatory requirements.

Chimney outlet methods

A homemade chimney can be brought outside through the roof or through the wall.

Most often, the device is taken out through the roof if the house is at the stage of construction or overhaul of the roof. If the building is already built, be prepared to replace the roof covering at the pipe outlet. This will require materials designed to contact high temperatures.

breeding chimney pipes do-it-yourself through the wall is suitable if the building has already been erected. This method has the following advantages:

- saving space inside the house;

- easier to mount than through the roof;

- maintaining the integrity of the roof and floors.

The disadvantages include:

- The efficiency is lower than when using an alternative method;

- the need for insulation of a structure located outside the house;

- negative impact on the appearance of the building.