- How to connect a dispenser with your own hands?

- How to choose a device for the home

- Purpose and advantages of grease traps

- Why is it needed?

- KS-Zh-2V - from 45,000 rubles

- Homemade grease trap

- Why do you need a grease trap under the sink

- Means and methods for cleaning grease traps

- under the sink

- sewer

- Device Features

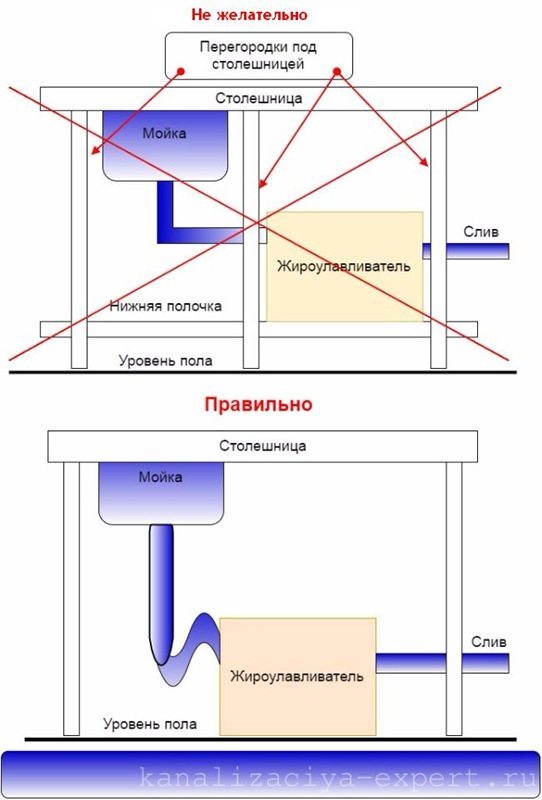

- How to install a grease trap under the sink

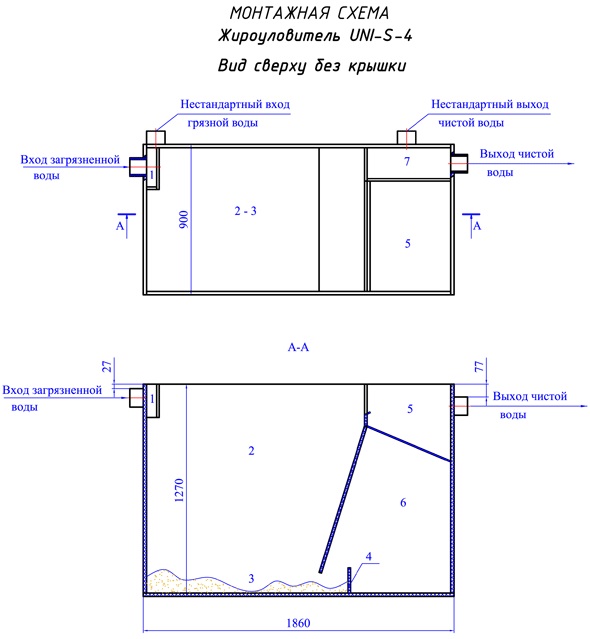

- Grease trap device

- Grease trap installation

- Methods for cleaning containers from deposits

- Step-by-step video maintenance instruction ↑

- How to choose or make your own handy cabinet under the sink for the kitchen

- EVO STOK 1.0-70 - from 10,577 rubles

- Overview of popular manufacturers of grease traps under the sink

- "Fifth Element"

- Flotenk

- Evo stock

- Making your own fat trap

- What to consider when choosing?

- Conclusion

- Grease trap installation guide

- Instructions on how to make a grease trap with your own hands?

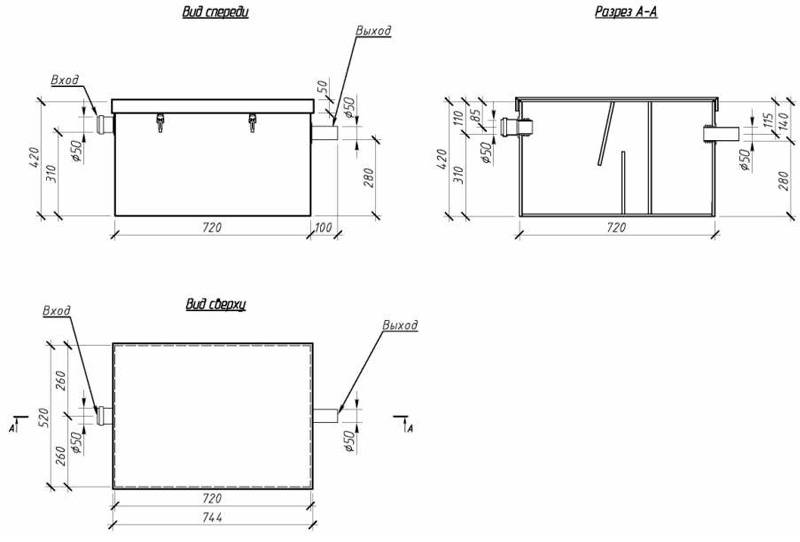

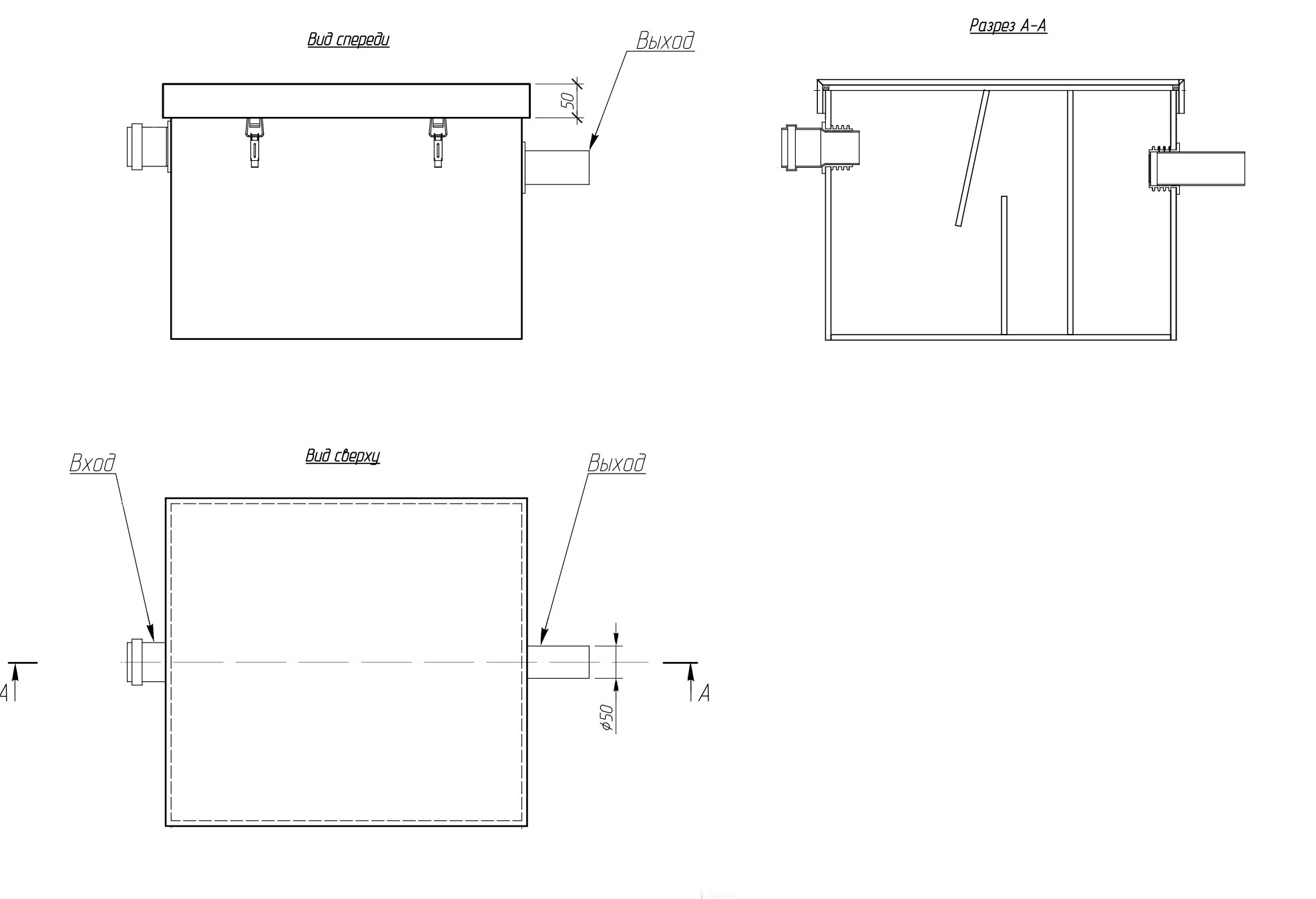

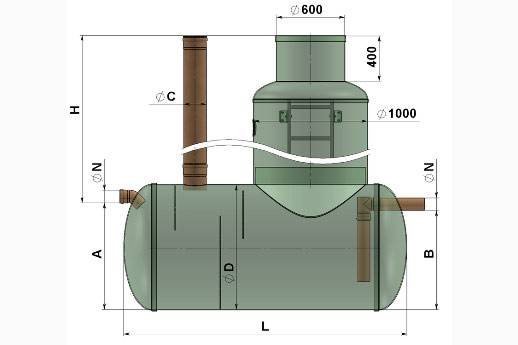

- Calculation of parameters and drawing preparation

- Where is the grease trap located?

- Tools and materials

- Assembly order

How to connect a dispenser with your own hands?

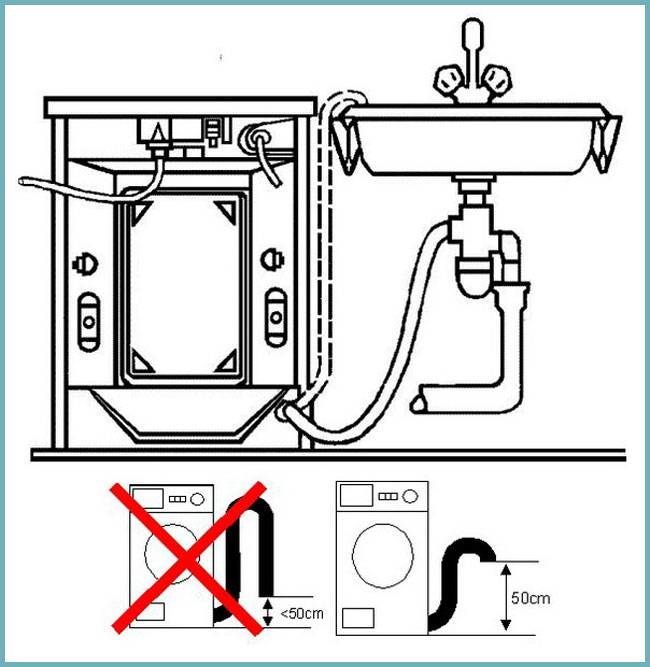

Installation food waste grinder under the sink requires some skills

It is especially important to understand that the dispenser is an electrical appliance. This means that the power supply must comply with the specifications of the device.

Grounding and moisture protection are necessary conditions.

As a rule, in houses and apartments where there was no disposer before, corrugated fan pipes are installed. They must be replaced with smooth ones, since organic decaying residues with an inevitable, difficult-to-remove smell of rot will definitely accumulate in the folds of the corrugations.

Next, you need to check that the size of the drain hole of the sink and the connected equipment match. The standard suggests that the diameter of the drain hole should be approximately 90 mm.

If the sizes do not match, it is necessary to replace the sink with a modern one or figure out how to switch to the desired diameter.

Then you should install a circuit breaker or socket near the sink. Protection from moisture is the main condition for these electrical installation products.

If the products are contaminated, they must be cleaned.

Installing a dispenser is much easier when the sink is new and not yet built into the overall design of the table. It is enough to turn it over for ease of installation.

How to choose a device for the home

The initial stage of choosing a grease trap is not carried out in a hardware store or on the Internet, but in the planned place of its installation. Before buying a device, you need to decide on a number of parameters that will help narrow down your options to a few models.

First of all, it is worth evaluating:

- Dimensions of free space under the sink. It should be borne in mind that there should be space on top for removing the cover, and on the sides for connecting pipes.

- The diameter of the sewer pipes in the kitchen. It is better to buy a grease trap with the same hole size so as not to use additional plastic adapters.

- Number of car washes served.When calculating the performance, it is necessary to take into account the simultaneous flow of effluents from all open taps.

- Stock characteristics. With a large amount of solid particles in the drained water, it is recommended to install grease trap models with several partitions.

- The presence of a sewer riser or a fan pipe near the sink - the channel is necessary to prevent the failure of the water seal on the siphon. Models with an air duct are preferred, but not every apartment or house has the ability to connect them to a sewer riser.

- Availability of free space for equipment maintenance work. When removing fat, waste with an unpleasant odor can fall behind the body of the grease trap, so it must be possible to clean this space

- Body material. For installation under the sink, a conventional plastic grease trap will suffice, but if it is open for viewing, then you can buy a more expensive and aesthetic stainless steel model.

- Wash volume. Sometimes it is required to dump water from a fully filled sink in one gulp. This amount of liquid is one of the characteristics of the grease trap and must be indicated in the instructions.

After taking into account all the above nuances, you can proceed to the direct selection of a suitable device from the options offered on the market.

The price of a budget plastic grease trap roughly corresponds to the cost of washing along with furniture, a tap and a siphon, so you need to plan its purchase in advance (+)

The price of a budget plastic grease trap roughly corresponds to the cost of washing along with furniture, a tap and a siphon, so you need to plan its purchase in advance (+)

The price of plastic models depends mainly on the volume of the tank and the complexity of the internal structure. With the same parameters, it is better to choose the cheaper option, because a more expensive model is unlikely to be of better quality.

Purpose and advantages of grease traps

More complex models of fat traps are used in large enterprises and are designed to effectively treat wastewater from solid particles, fat-containing and oily impurities.

According to sanitary standards in meat and dairy industries and in public catering establishments, the installation of grease trapping equipment for sewers is mandatory.

Industrial devices are installed at the outlet of a treatment plant that performs primary wastewater treatment.

Installing a fat trap will protect the sewerage of any catering establishment or production facility from contamination with fat and oil inclusions

Industrial devices are designed by manufacturers to ensure that clean water, purified from impurities, enters the sewer system by separating and further removing the fatty component of the waste mass.

Installing a grease trap will avoid the failure of the sewer due to the effects of fat deposits. It also protects the environment from the release of harmful impurities that can cause irreparable damage to the environment.

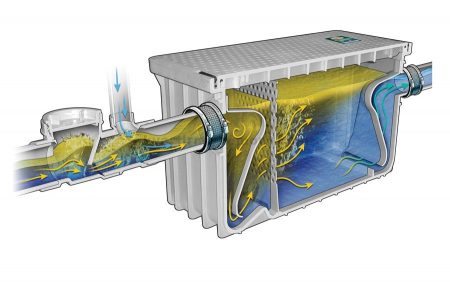

Such separators are indispensable not only in production, but in everyday life. They reliably protect sewer pipes from the occurrence of fatty valves or congestion. At the 1st stage, the device receives domestic water, separates fat and oil accumulations.

At the 2nd stage, the final separation of fatty deposits and the output of effectively purified water into the sewer system are observed. The device retains non-emulsified fats and removes them from wastewater.

A grease trap installed under the sink is often used in home kitchens, cafes, restaurants, pastry shops and fast food establishments.

The use of grease trapping equipment has a number of advantages:

- The tightness of the equipment. Due to the tightness of the housing, the possibility of foreign liquid entering the filter is excluded.

- Practicality and versatility. Installation of various additional devices is possible. The sensor for the accumulation of harmful substances is in particular demand.

- No unpleasant odors. Due to the tightness of the housing, odors that usually occur during the breakdown of fats do not penetrate into the room.

- Ease of installation. Installation of fat traps for the premises does not require special skills and is carried out in 4 stages.

- Ease of maintenance. Cleaning most models of fat traps does not require much effort, it can be done manually using improvised means.

- Acceptable cost. Devices have a low price compared to other types of filters.

In addition to these advantages, the device that collects fat also has a long service life. All equipment is made of high quality and wear-resistant materials, which guarantees its durability.

An important advantage of using a grease trap is the preservation of the environment, which is especially important in modern times.

Why is it needed?

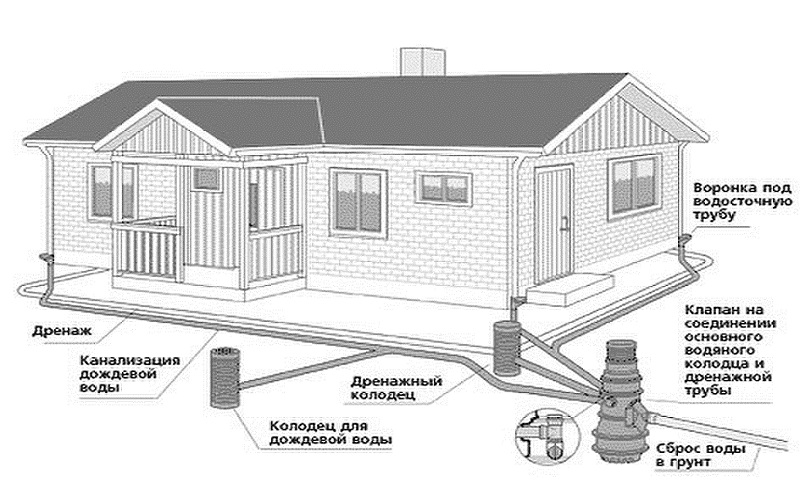

If local sewerage is being installed, then it makes sense to use all the possibilities that increase the efficiency of the system and its durability. A household grease trap installed at the beginning of the system will eliminate the risk of clogging pipes, narrowing their diameter, and the appearance of an unpleasant odor.

The installation of grease traps in public catering wastewater systems is mandatory. But is it worth installing equipment in a private house? Each owner can decide this question on his own, after evaluating the benefits of using grease traps.It:

Keeping pipes clean. Fat impurities, once in a cold environment, turn into flakes that settle on the walls of the pipes. Over time, fat covers the walls of the pipes with a rather thick layer, gradually reducing the diameter of the pipe. Over time, a fatty plug can completely block the lumen of the pipe, which will lead to a shutdown of the sewage system.

Extending the life of pipes. During the decomposition of fat, not only unpleasantly smelling gases are formed, but also caustic substances that gradually destroy the pipes. Does not contribute to the durability of the pipeline and regular cleaning of sewers using chemicals. And it will be necessary to resort to such cleaning regularly so that the sewer system is not clogged with grease.

All of the above indicates the feasibility of installing household grease traps even in apartments, but it is especially important to use the device if an autonomous sewage system is used in a private household. Moreover, it is quite possible to install a grease separator with your own hands.

KS-Zh-2V - from 45,000 rubles

KS-Zh - a line of non-volatile well-type grease traps. Designed to treat industrial wastewater before being discharged into the city sewer. "2V" - vertical layout of the device. Installed in the ground, cleaned through the hatch.

The advantages of the "younger" model of the KS-Zh line are the performance and working volume of the device. Thanks to which the flow up to 300 liters per minute is effectively processed. The minimum service interval of the device is six months.

Of the minuses - constant investments will be required: for the calculation - to the designer, for the preparation of the site and installation of the device - to specialized craftsmen, for cleaning - to a professional vacuum cleaner.

To control the current level of fat, it is best to use a customizable sensor, which is offered by the manufacturer as an option.

| Productivity, m³/h | 7.2 |

| Peak discharge, l/min | 300 |

| Dimensions (height/diameter), mm | 1300/800 |

| electrical equipment | Non-volatile, medium density sensors are optionally mounted. |

| Producing country | Russia |

Industrial KS-Zh in the video from the manufacturer:

Homemade grease trap

It is not difficult to assemble a cleaning module of this type for a sink with your own hands. The main thing is to know how it should work. Everything else is purely technical. But there is one point that must be taken into account. This is the volume of the container.

In order to understand what is at stake, it is necessary to give an example of the calculation. First of all, it is necessary to determine the performance of the device. In fact, this is a value that is determined by multiplying the number of sinks for which a grease trap is installed and the speed of the water in the water supply. If the unit is installed under one sink, then the first value is "1". The second position is standard - 0.1 l / s. Multiplying one by the other, that is: 1x0.1 \u003d 0.1. This is performance.

Secondly, it is the volume of the tank that is determined. Here is another formula: V=60 x t x N, where:

t is the time for which the separation of water from fat occurs, it is considered that it is equal to 6 minutes;

N is the performance that was calculated above.

Now we substitute the values \u200b\u200bin the formula: V \u003d 60x6x0.1 \u003d 36 l

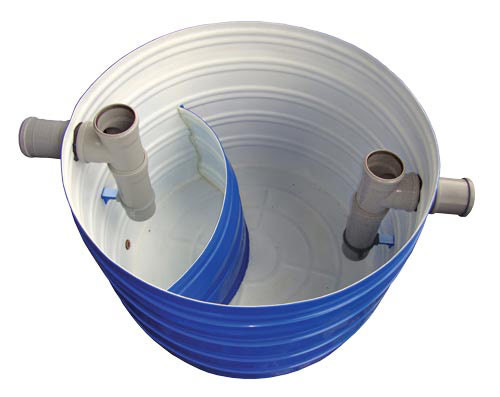

Under this value it will be necessary to find a sealed container. It can have a different shape, the main thing is the volume is not less than the calculated one.By the way, the photo below shows a homemade round cross-section grease trap made from a metal barrel. It has only one partition and a small first compartment. But this design is enough to remove fat and oils from under one sinks in the kitchen. The only requirement for it is a hermetically sealed lid.

It should be noted that the variety of homemade grease traps is huge. As practice shows, the shape of the product is not important here, the properly organized passage of drains through the partitions is important here. Exactly the same as described above in the article.

A few words about how to properly clean the device from accumulated greasy contaminants. Everything is quite simple.

- You need to remove the cover.

- Oil accumulations floating on the surface of the water in the compartments must be removed with any not very deep volumetric object. It might even be a cup. The main thing is to collect pollution as much as possible.

- All this is collected in a bucket or basin.

- After that, the cover is installed in place.

The cabinet on which the sink is installed is not always voluminous. Therefore, you may encounter difficulties in the process of cleaning the device. But you should not disconnect it from the sink and sewer, it is better to do everything inside the cabinet. It will take a little time, so be patient.

Why do you need a grease trap under the sink

Owners of private houses, cottages and other places can often find sewers that work autonomously. In it, after a long operation, blockages occur in the pipes. This is due to dirt, grease and food particles that do not dissolve in water. They stay in the sewers. Clogging can occur as a result of poor installation of pipes, their incorrect slope.But most often, the cause of blockage is large particles and oily water. This problem is eliminated by a household grease trap.

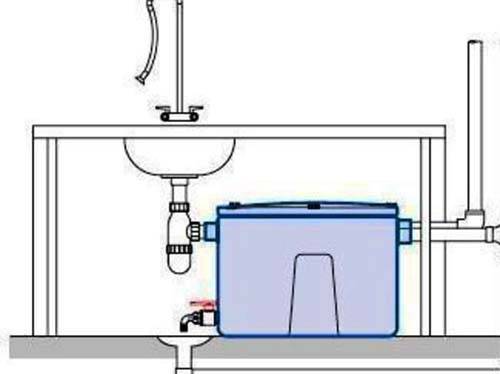

Grease trap installed under the sink

The grease trap has long been used in queuing organizations. In such places, pipes are very often contaminated, as dishes are constantly washed there and large particles are dumped into the pipes.

The unit can be seen in:

- Cafe;

- Barah;

- Restaurants;

- Canteens.

With such a device, a pump for additional pressure is also installed. In these cases, the grease trap is installed under the sink. It is needed to receive the primary streams of water that you have already used. For example, washing food or dirty dishes. The unit acts as a small septic tank that retains grease and oil. Also, in summer cottages, a grease trap can be installed in the well. In this case, for installation in a well, it is better to buy a unit in a specialized store, since a kitchen grease trap may not be suitable for use in suburban areas.

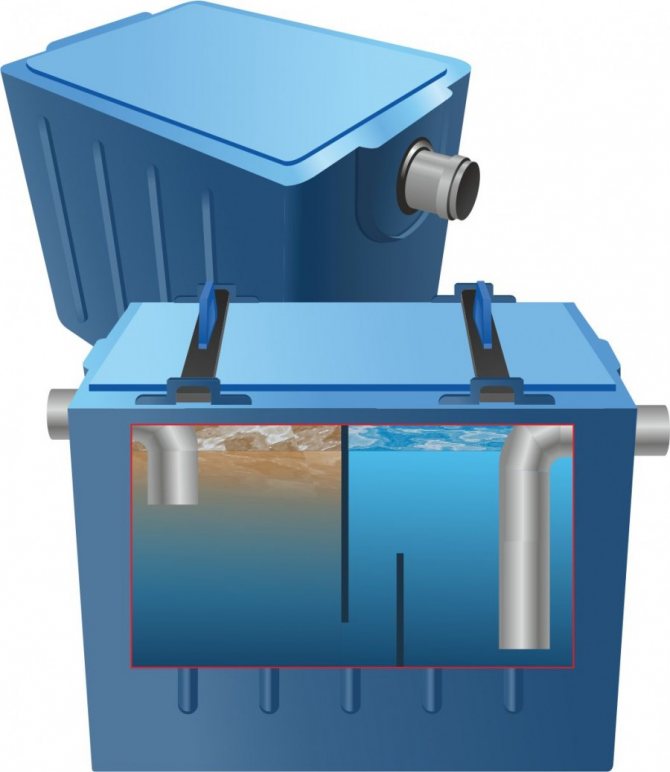

The principle of operation of the device looks like a sump mechanism. The grease trap looks like a container that has a rectangular shape. Inside it are chambers separated from each other by special partitions. This is a kind of wall separator.

The need for a grease trap for washing is due to the cleanliness of the pipes. If you do not install such a structure on time, then within a couple of years your pipes will become completely unusable. This can lead to their cleaning already from the inside, or to a complete replacement of the pipeline. Installation will not take much time, and there will be a clear benefit. Therefore, it is better to install a grease trap under the sink as early as possible.

Means and methods for cleaning grease traps

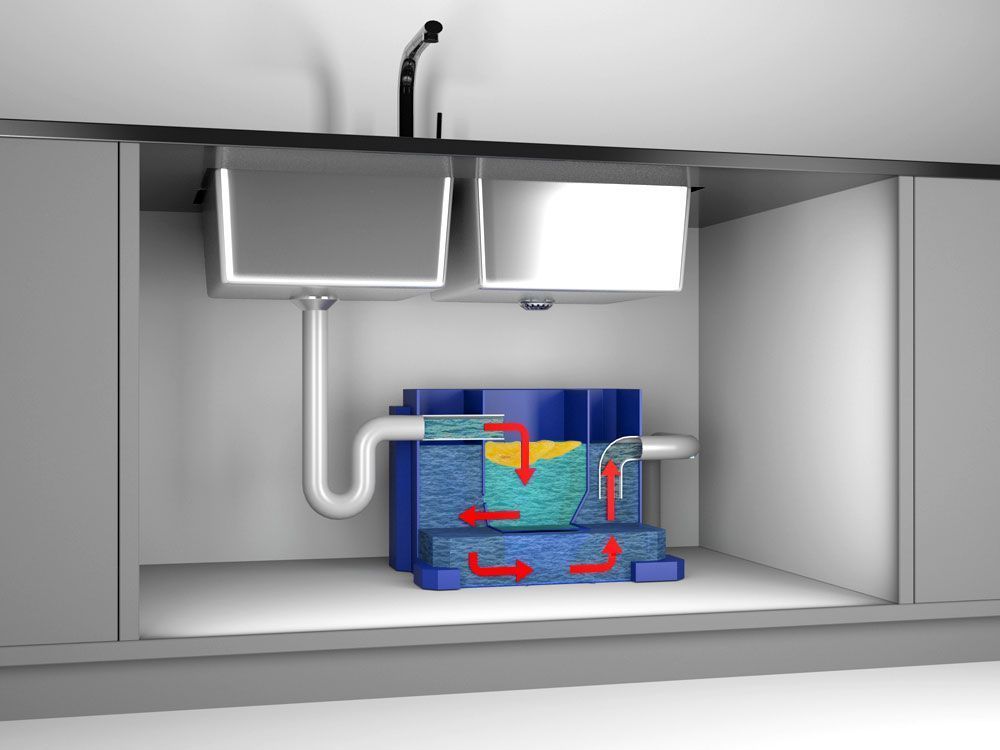

Fat is lighter than water and always floats to the surface - on this principle the work of the grease trap is based. The body of the container of the device is divided by partitions that trap fat and solid heavy waste particles and let water through. With the accumulation of fat mass and organic matter, they must be removed. The frequency of cleaning depends on the degree of contamination of the drains, the performance of the grease trap, and is determined visually or using a sensor signal. On devices of large volume, you can install automation, which will itself determine the need for cleaning and pump out fat from the system. Household small separators up to 50 liters are even easier to maintain, this can be done manually.

under the sink

Already when installing the container under the sink, you should take care of the space around the structure and the possibility of free cleaning of the grease trap.

Follow these simple steps every day:

- In the morning, look under the sink and check the integrity of the connections and the level of fat.

-

In the evening, turn on the hot water and fill the container with fresh water.

This will help to avoid stagnation of water and the appearance of an unpleasant odor, as well as to detect a possible leak in time.

If the sensor or visual inspection shows that the fat level has reached a critical level, then it is time to clean the system, the standard frequency is 1 time per week.

Sequencing:

-

Open the lid, if possible, disconnect the device from the pipeline and collect the fat mass from above using a special spatula that comes with the separator.

-

Collect settled solid fractions from the bottom, remove particles from the pipes. Cleaning will be easier if the device is equipped with a compartment for settled organics and a fat collection tray.

-

Rinse the box with hot water, you can add disinfectant solutions and detergents.

To increase the degree of cleaning and protect the grease trap from rapid contamination, you can use special live bacteria that process fat mass and solid particles, leaving only a slight sediment in the water. They work effectively in the temperature range from 5 to 40 ºС.

sewer

You can set the scheduled frequency of service and preventive maintenance, without waiting for the critical filling of the grease trap, for example, once a month, and for large tanks at enterprises - once every six months. If there is no sensor, then the level of fat mass is determined using a probe.

Cleaning of sewer separators can be carried out manually and automatically. A small container in the basement of 100 liters is cleaned similarly to a household one, and a large-volume unit dug into the ground is cleaned using a separate technology:

-

If the grease trap is equipped with a built-in electric pump, then it must be de-energized.

-

Open the lid of the container and pump out the contents along with the fat mass using a vacuum pump, and for large underground separators you will need a sewer machine.

-

Rinse the sump with strong water pressure. It is recommended that a container standing indoors be treated with steam to eliminate unpleasant odors.

- Inspect the chamber and nozzles, if necessary, additionally clean with your hands.

Inspection authorities always look at the availability of documents confirming the regular maintenance of the equipment and its compliance with sanitary standards.Therefore, for large grease traps, it is advisable to conclude an agreement on an ongoing basis with a sewage company and receive acts on the disposal of fat and flushing the system.

With proper care and cleaning, the grease trap will not cause trouble and will work effectively for 30-35 years. The sewer system will also become much cleaner, the septic tank will not clog and will last longer, which will bring tangible financial benefits as a result.

Device Features

What is a grease trap - this is a container that is located on the path of drains from catering establishments: restaurants, canteens, cafes, pasties, food production, private houses and apartments, rushing into the sanitary collector.

Purpose of the tank:

- separation, collection and removal of oil and fat from wastewater;

- protection of sewers and treatment tanks from possible grease plugs;

- savings on maintenance of the sewer system.

It is enough to attach the grease trap to the sewer, it will be possible to avoid many of the problems inherent in catering enterprises and industries related to the manufacture of food products.

The purchase of this simple device that separates fat waste from water will save money on cleaning drain pipes.

The right grease trapping and drain protection equipment can help those who are concerned about sewer clogs and related problems. Without such equipment, a catering point cannot be opened, a large amount of fat drains harms the sewerage system.

How to install a grease trap under the sink

The work of any grease traps, both industrial and domestic types, is quite simple.Fat is lighter than water, so it gradually accumulates on its surface, forming a film, which, in turn, is discharged into sedimentation tanks specially adapted for this purpose. As the sedimentation tanks accumulate with fatty deposits, they are mechanically cleaned.

Grease trap device

The use of household grease traps allows you to keep the kitchen space in constant cleanliness. In addition, the advantages of grease traps are as follows:

- The use of grease traps allows you to avoid unpleasant odors in the kitchen from the sink;

- When using this equipment, there is no clogging of sewer pipes. You can read about how to clean the sewer by clicking on the underlined link;

- Ability to purify wastewater by 25-30%.

If the grease trap has not yet been purchased, but only its choice is being made, then you should know this. To choose a grease trap for washing, you should calculate its performance. To do this, you need to multiply the height, length and width of the sink, thereby finding out its displacement.

In addition, you should decide on the type of grease trap, since it can be storage type and flow.

Grease trap installation

In order to install the grease trap with your own hands, you should carefully study the attached instructions for the selected equipment, as well as follow the simple tips below:

1

To install the grease trap, it is necessary to choose a solid and, no less important, flat surface. Also, there must be free access to the installation site of the grease trap during operation.

As a rule, the installation of the separator is most often carried out directly under the kitchen sink, or near the dishwasher.

2.The installation site of the grease trap is selected, then it follows, proceeds to the next step, connecting the inlet pipe with the sink sewer hose or any other equipment from which wastewater will be discharged.

3. Then the outlet pipe of the grease trap is connected to the sewer system through a rubber seal.

4. After the installation of the grease trap under the sink is completed, it must be filled with water to check the tightness of all joints and connections.

5. Then you can close the upper part of the grease trap with a lid and use the sink.

As you can see, installing a grease trap under the sink is a simple job, which is no more complicated than installing a sololift or other similar equipment.

Methods for cleaning containers from deposits

There will be no problems with cleaning household grease traps for washing. They are usually small in volume, so they can be easily disconnected from the sewer and cleaned by hand. The performance of such devices is 0.1-2 l / s. Models of higher productivity are considered industrial, and for their maintenance you have to resort to either pumps or special equipment.

Industrial models are equipped with automation that monitors the level of contamination and signals the need for preventive maintenance. In household appliances, such devices are most often not provided, you have to regularly check the containers. Below we offer a detailed video instruction for manual cleaning of the grease separator.

Cleaning the industrial grease trap

Step-by-step video maintenance instruction ↑

When choosing and making a grease trap for washing with your own hands, pay attention to the quality of the material from which the body is made. This affects the life of the device.

Plastic and fiberglass models do not withstand strong impacts well, so you need to take care of the correct installation of the devices. If you plan to buy a device of industrial production, give preference to manufacturers that provide a guarantee. Otherwise, devices of different brands differ little from each other.

When choosing such an intuitive and simple piece of furniture, it is important to pay attention to details, because a kitchen sink cabinet can become an additional …

How to choose or make your own handy cabinet under the sink for the kitchen

There is a common joke that travel lovers often visit the capital of the apartment - the kitchen. This is truly the most visited place in the house. Gathering here...

EVO STOK 1.0-70 - from 10,577 rubles

A non-volatile device with a one-piece cast body and a working space divided into three sections by fixed partitions. A tight-fitting lid and a removable tray on the inlet pipe are structurally provided. All the elements that are required to seal the device at the inlet-outlet are present in the basic configuration of the device.

To remove debris from similar models used in food processing units, it is necessary to completely drain the water. In EVO STOK 1.0-70, coarse sediment settles in a quick-release filter tray. Of the obvious inconveniences during operation, there is a specific smell (comes from the device if you do not clean it every day, but simply control the level of accumulated fat).

It is best to clean the container before starting work, until the fat has melted.If during operation it turns out that with a relatively clean device, the sewer pipe is clogged with grease, it is necessary to check that the technical characteristics of the device correspond to the actual potential of the connected sanitary appliances.

| Productivity, m³/h | 1 |

| Peak discharge, l/min | 70 |

| Weight, kg | 15 |

| Dimensions (LxWxH), mm | 620x470x420 |

| Branch pipe height (inlet/outlet), mm | 345/320 |

| electrical equipment | non-volatile |

| Producing country | Russia |

Checking the performance of EVO STOK 1.0-70 is shown in the video:

Overview of popular manufacturers of grease traps under the sink

Now there are no difficulties with buying a "trap" for fat. The device is produced not only by foreign, but also by Russian manufacturers. Of course, you can always add something new to the design of the device, but in most cases the design is almost identical. Therefore, we intend to focus on the reputation and fame of the manufacturer.

A popular Russian company under whose name, as a rule, industrial equipment is produced.

"Fifth Element"

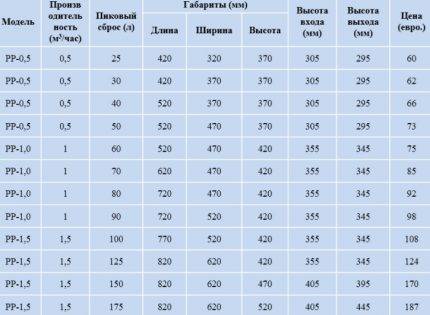

An enterprise that produces very inexpensive PP grease traps, which are intended not only for industrial, but also for domestic use.

Flotenk

Another Russian company engaged in the production of domestic / industrial equipment for sewers. In the manufacture of fiberglass is used, the service life of which can reach 50 years.

Evo stock

A company from Russia specializing in polypropylene grease separators for domestic/industrial use.Reinforced plastic can also be used in the manufacture.

A Finnish company that produces high-quality polyethylene grease traps under the EuroREK Omega brand.

Making your own fat trap

Manufacturing sewer grease trap do-it-yourself begins with the calculation of its parameters. The performance of the device P is calculated by the formula:

P \u003d n x Ps, where n is the number of washes in the house, Ps is the rate of water flow in the system - the average is 0.1 l / s. If the kitchen has only one sink, n=1. Then P=0.1 l/s.

To determine the volume of the device, use the formula V = 60 x P x t, where t is the time of fat settling, an average of 6 minutes. We get 36 l or 0.036 m³. Now it is easy to find out the parameters of the container for the grease trap - 0.3 m, 0.3 m and 0.4 m.

In order to construct do-it-yourself grease trap, you need to study the following step-by-step instructions:

- We find a suitable container (the shape of a rectangular parallelepiped) made of food-grade plastic, polypropylene, fiberglass, galvanized steel or stainless steel. The container must have a tight lid. You can use a plastic toy box. A duralumin corner from an old aquarium, where the glass is cracked, will do. It is removed, and a box is made of fiberglass sheets 6 mm thick on the frame. Cutting them is not easy, but the design will turn out to be durable, waterproof.

- We make holes on the side walls of the box for the input-output of water Ø 50 mm (with an electric jigsaw, and preferably with a wood burner). We clean the edge of the holes with sandpaper. We place them opposite. The distance from these holes to the top edge of the box is 5 cm.

- Under the hole we install (end) a pipe Ø 100 mm, with a length equal to 2/3 of the height of the box.We glue it so that the bottom edge rises 30-40 mm above the bottom of the box. Then we put a branch pipe Ø 50 mm inside the pipe. Its lower edge is 50 mm higher than the lower edge of the pipe.

- We connect the tee (elbow Ø 50 mm) to the upper end of the branch pipe. Of the two free ends, one will enter the hole, and the other, directed upwards, will act as a ventilation duct.

- We fix the nozzles on the holes, using seals, epoxy resin.

- We insert 2 partitions into the box. We fix one barrier with hot glue in the upper part, at least 10 cm above the bottom. And the second partition (its length is 2/3 of the height of the box), we will attach at the bottom. Thus, the fat trap will turn out with three sections.

- We mount the inlet elbow, and smear all joints with silicone sealant. Where the cover is connected to the box, it is necessary to glue the sealing tape. After closing the lid, we wait for the sealant to solidify. Apparatus for trapping fat before entering the sewer - ready.

- In order for the partitions to withstand the pressure of water, it is better to take epoxy resin instead of hot glue, and it is better to wrap the partitions themselves with rubber bands.

- Connections from the sink to the grease trap, and then from it to the sewer, are made of corrugated plastic pipes with rubber seals.

What to consider when choosing?

At the time of purchase, the volume and type of device are taken into account. For domestic purposes, the cheapest models with a simple design are suitable.

If the grease trap is installed in a cafe, a model with a filling sensor and the possibility of autonomous operation due to aeration of drains is selected. You also need to take into account the structural features and the ability to install a specific model in a technical room.

If the dimensions do not allow, you need to choose models that are buried in the ground.

Conclusion

Sink grease trap with two bathtubs.

Grease trap installation guide

For installation, you first need to choose the right place. The grease trap must be placed on a level surface. To connect to the sink, the inlet pipe of the device is connected to the drain pipe.

After that, the outlet pipe is connected to the sewer pipe. Then it remains only to check the tightness of all connections by filling the device with water.

Instructions on how to make a grease trap with your own hands?

In order not to spend money on ready-made models, you can make such a device with your own hands. To do this, you need to correctly calculate the dimensions, select materials and determine the location.

Calculation of parameters and drawing preparation

When drawing up a drawing, you must first indicate the location of the holes. The lower edge of the outlet pipe must be located 4-5 cm below the middle of the inlet.

The slot in the inlet pipe must be made next to the grease trap cover.

Having considered the simplest schemes of such devices, it is not difficult to draw up an individual drawing, since you only need to adjust the dimensions so that the case fits in the space under the sink.

Where is the grease trap located?

The grease trap is located in the space under the sink in such a way that it is convenient to attach it to the sink and sewer pipe.

If the device is industrial, it is installed in a technical room or outdoors. Installation is done in such a way as to prevent grease from entering the city sewer system.

Tools and materials

To make a metal grease trap, you first need to select metal plates of a suitable size. During work, rubber seals, pipes and sealant will be required.

From the tools you need to prepare a grinder, a welding machine and sandpaper. Welding of metal sheets is carried out according to a previously drawn up drawing. First, a box is created, and then 2 plates are welded inside.

The easiest way is to create a grease trap from a capacious plastic container, in which you only need to fix the plastic plates with a sealant.

Assembly order

To assemble the grease trap, you need to cut 8 plates to size, 5 of which will be the basis of the box. The rest are needed to insert inside and create a cover. It is they who act as barriers that do not allow fat to pass during draining.

After that, the upper part of the box is welded with a large hole for the lid. A hole that is too small will not allow efficient cleaning.

After the entire box is welded, it is necessary to drill holes for the pipes, and then place the o-rings in them, securing them with a sealant.

If the device is made from a ready-made plastic case, you just need to fix the plates inside the container and cut holes for the pipes.

After the grease trap is ready, its pipes are connected to the sewer pipe and sink drain.

It is interesting: sewer aerator – principle of operation, types, installation instructions with video