- Performance, filters, management

- Mounting

- How to hide equipment?

- Helpful Hints

- Differences between a kitchen exhaust system and ventilation

- System construction process

- Circuit design or development

- Detailing and assembly of the system

- Pipes for hoods: tips and tricks for choosing

- Shapes and sizes of ventilation pipes: selection rules

- How to calculate the minimum dimensions of a plastic pipe

- Varieties and materials for the production of plastic pipes

- Polyvinyl chloride (PVC)

- Polyurethane

- Polypropylene

- The use of ventilation pipes in everyday life

- Air duct calculation

- Calculation of the air capacity of the ventilation system

- Method for calculating the cross section of air ducts

- Is it possible to do without an air duct?

Performance, filters, management

According to sanitary standards for kitchens, ten air changes are recommended every hour. Therefore, when calculating the performance of the hood, you should focus on the volume of the kitchen, expressed in cubic meters. To do this, multiply the length, width and height of the room, and increase the result ten times.

For example, for a kitchen with an area of three by four meters and a ceiling height of three meters, you will need an extractor hood with a capacity of (3 m X 4 m X 3 m X 10) 360 cubic meters per hour. And this is the minimum value.

Sellers recommend taking a hood for the kitchen with some power reserve. If the performance of the device is lower, it simply cannot cope with cleaning the kitchen air from pollution. How to calculate the power of a kitchen hood is written in detail here.

Grease filters differ in composition as:

- organic (based on synthetic winterizer);

- paper (based on non-woven fabric);

- synthetic (based on acrylic);

- metal (aluminum or steel).

Paper filters are a one-time option and need to be replaced with new ones each time they become dirty. Synthetic counterparts can be washed, but this must be done very carefully, as they are easily damaged. From time to time they will also have to be replaced, although not as often as paper ones.

Metal filters are considered the most reliable, they are wear-resistant cassettes. Coal varieties, which are used only in recirculation plants, also cannot be treated. They must be replaced in a timely manner, otherwise the performance of the hood may be significantly reduced.

When choosing a hood, you should pay attention to its type of control. Electronic control usually allows:

- automatically adjust the performance level;

- change operating modes;

- set the device to turn on and off automatically;

- inclusion of built-in lighting in the presence of movement near the stove;

- light indication of the status of filters, etc.

Among the useful functions of the hood built into the cabinet, one can note the residual stroke mode: the fans run for some time after the hood is turned off to ensure the most complete removal of contaminants.

The additional ventilation mode allows you to automatically start the hood at low power at certain intervals in order to maintain optimal air exchange in the kitchen.

Mounting

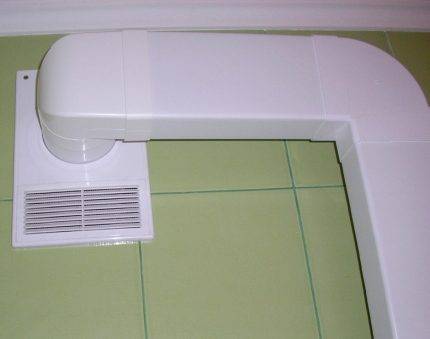

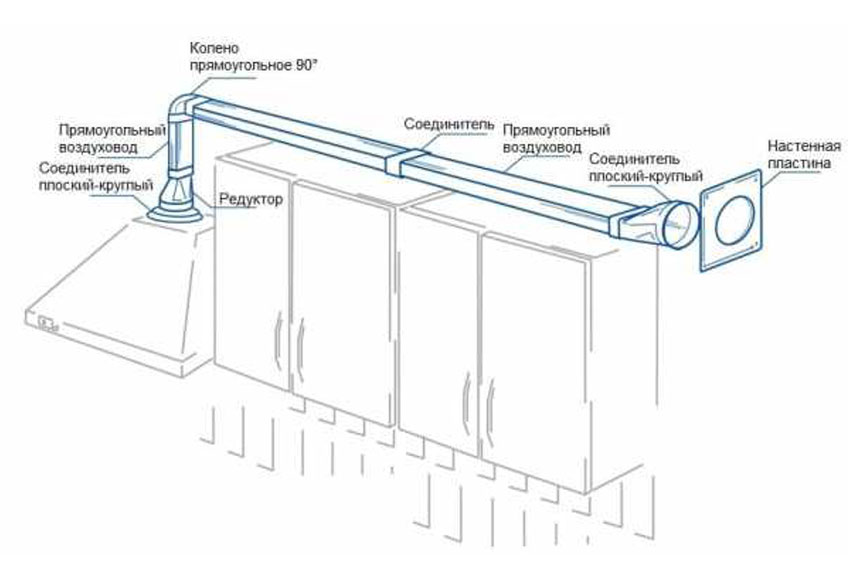

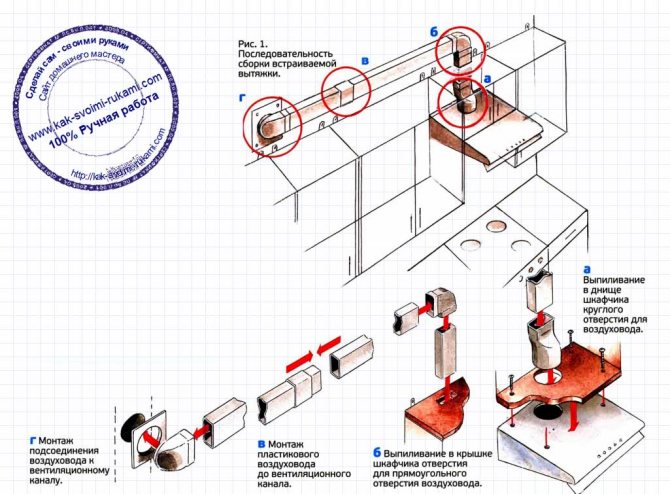

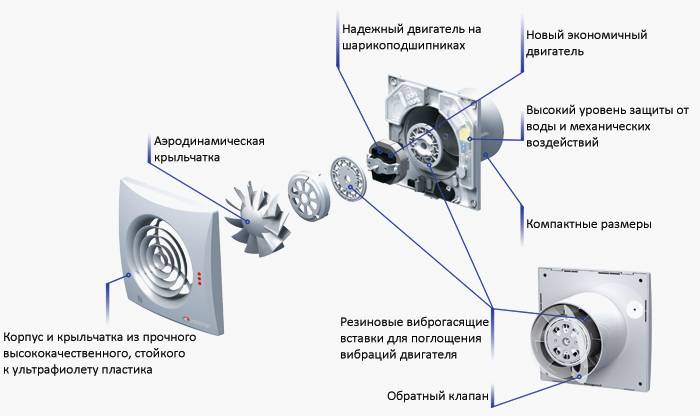

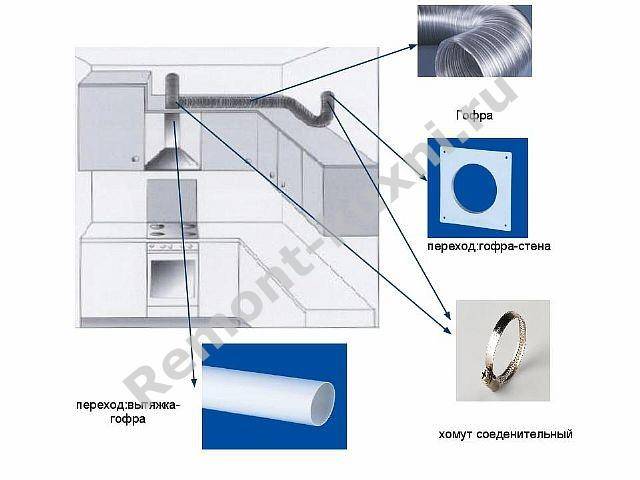

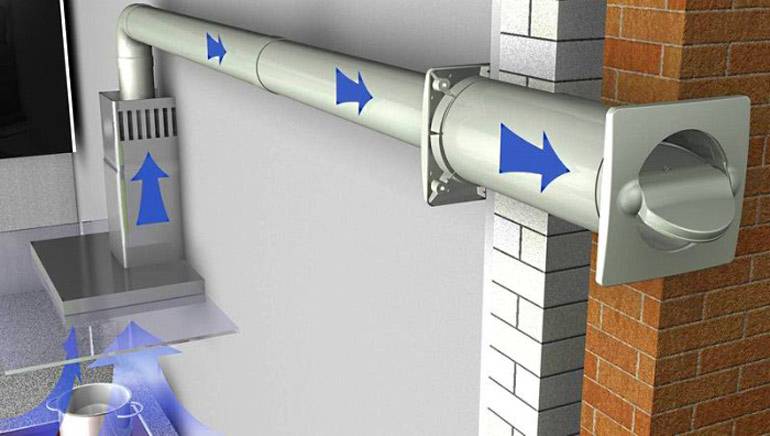

It is quite possible to install the air duct with your own hands. Corrugated options are considered the simplest in these matters. You just need to cut it into pieces of the required size, and then connect it to the corresponding parts of the hood and shaft in the kitchen. It is better to replace a simple ventilation grill with a special one - into which a connecting pipe is built. For fastening in this case, special crimp clamps are usually used. For maximum reliability, the joints are treated with a sealing compound.

Air ducts made of PVC raw materials are installed in the same way. The pipe is cut with a hacksaw into separate parts of the desired size, after which it is attached to the parts of the hood using adapters. The pipe should go deep into the nozzle by 50 mm (approximately). Mounting areas should be coated with silicone compound.

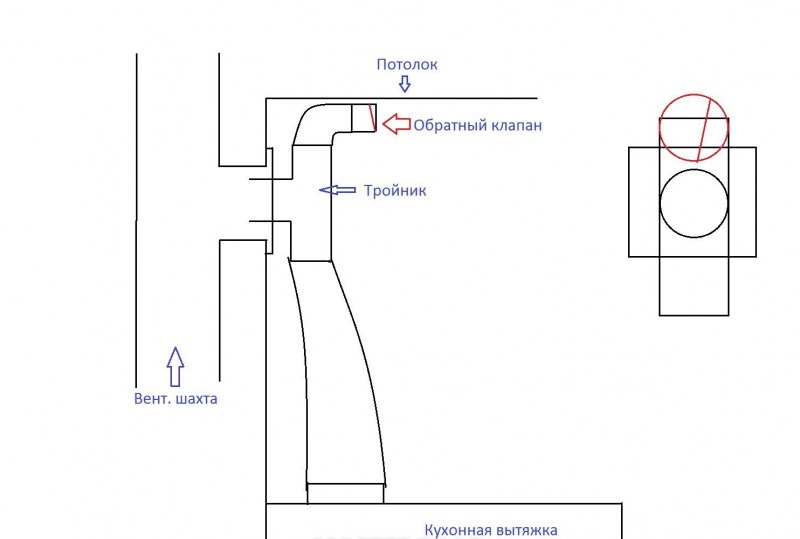

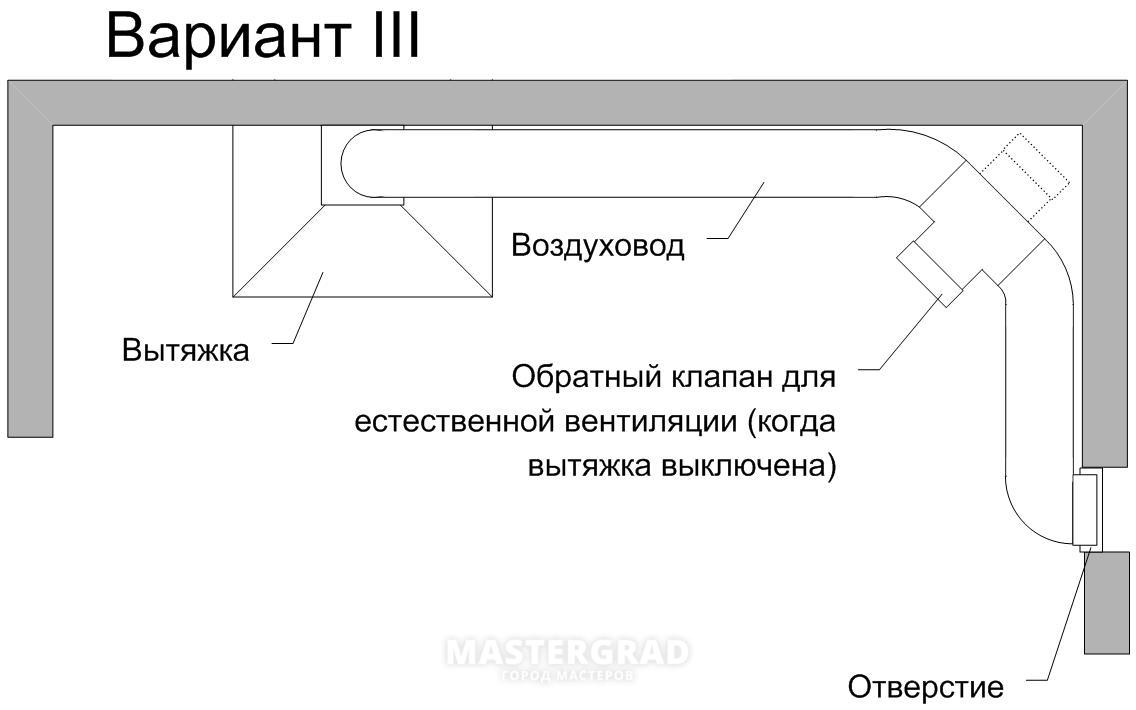

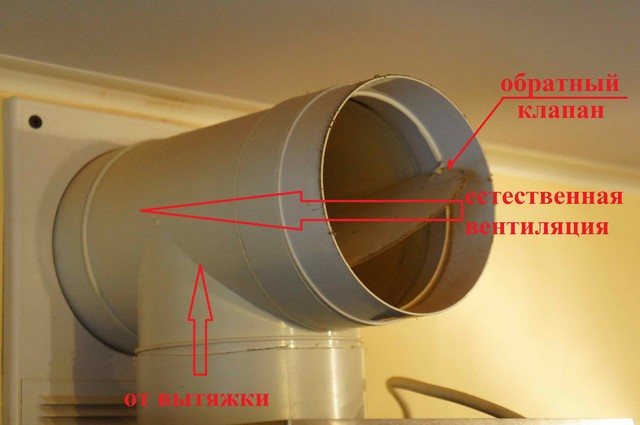

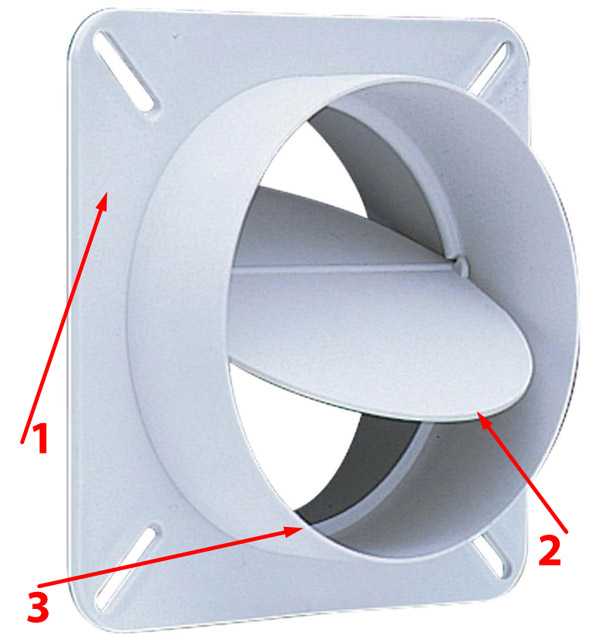

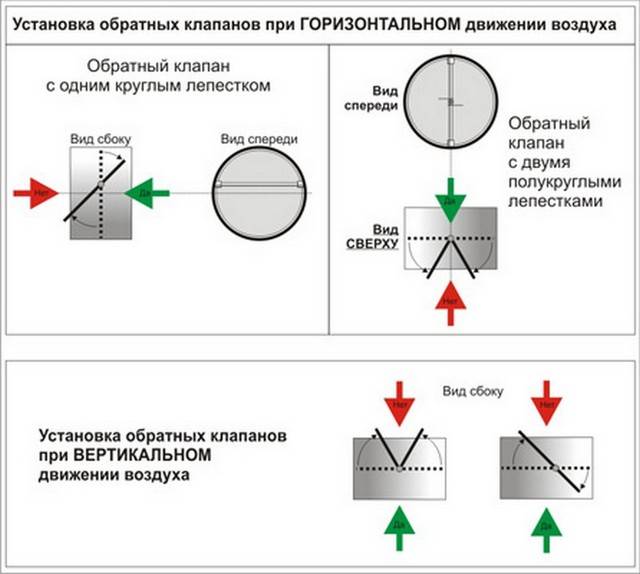

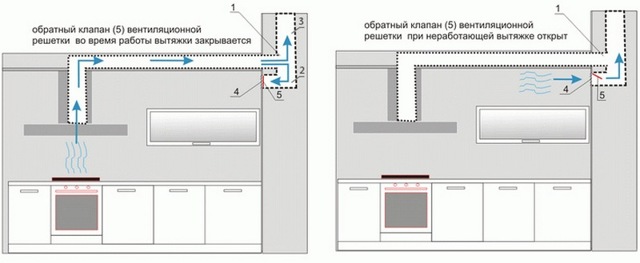

If you have installed a high-power extractor hood in the kitchen, then the reverse thrust effect may have an effect. Simply put, there will be odors in the room coming from the ventilation shaft. This applies to particularly powerful specimens, the performance level of which is from 600 to 700 cubic meters of air per hour. In order not to encounter this trouble, it is worth fixing the check valve.

These devices are made in two main variations:

- membranous;

- in the form of a plastic disk on an axle.

How to hide equipment?

Plastic parts are much easier to fit into various interiors, especially when compared with metal ones.However, they can also spoil the appearance of the kitchen ensemble. That is why most owners prefer to simply close such elements. There are many ways to do it right.

Let's consider the most common of them.

- It is permissible to hide the duct pipes under a stretch or multi-level ceiling. To this end, you need to assemble a box of drywall sheets - it will perfectly hide the entire system. However, this method can only be used if a major renovation is planned in the kitchen with a complete replacement of the ceiling base. If the hood is installed after finishing work is completed, then it will hardly be possible to hide it under the indicated structures.

- To mask the air duct, they often buy a special PVC box (sometimes other materials are used). Such designs will play a decorative role, so they are usually selected to match the decoration of the room. And also in such boxes you can additionally build spotlights.

- The hood can be hidden in the furniture in the kitchen if it is made to order. To do this, you need to notify the master of your preferences.

Helpful Hints

When choosing an air duct, one rule should be taken into account: the diameter of the pipe for the hood must correspond to the diameter of the hole that leads to the shaft. When choosing flexible options, you need to consider that you can do no more than 3 knees and bends.

It is recommended to install the hood in accordance with the direction of air movement. Otherwise, the service life of the device may be reduced, especially if it is a plastic part. The hood can also be taken outside. For this purpose, a hole of a suitable size must be made in the wall of the house.However, do not forget that before carrying out these operations, you need to obtain permission from the BTI and housing and communal services.

The worst option is a corrugated plastic pipe that acts as an air vent. It is better to give preference to an aluminum copy. It is not recommended to place metal corrugations in the same ensemble with a kitchen set made of natural wood. Such an interior will look disharmonious and even ridiculous.

Corrugated pipes during installation are recommended to be stretched to their full length. Thus, it will be possible to avoid contamination in the internal part, which will provoke unnecessary noise during the operation of the system. Today, many users prefer built-in hoods. In these models, the air duct must be placed in the inside of the cabinet or fixed on its upper part.

In the next video, you will find the installation of an air duct for a kitchen hood.

Differences between a kitchen exhaust system and ventilation

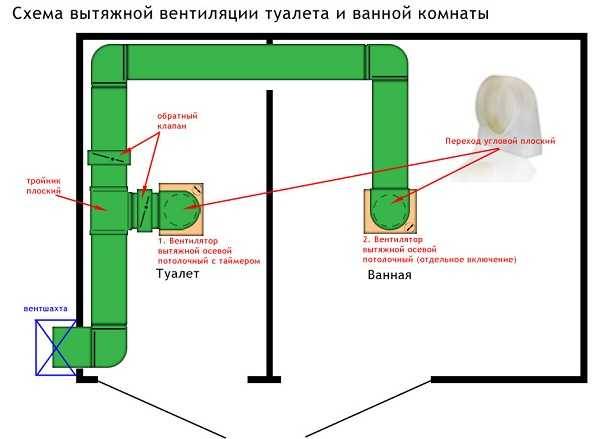

The ventilation system is designed to constantly update the air in the room. It is equipped in the kitchen and toilets. The most commonly used scheme is natural motivation. The throughput for the kitchen is 60 cubic meters per hour, for the toilet - 25. With poor ventilation, condensate accumulates in the house, and fungus may appear over time. This is dangerous for the development of diseases of the respiratory system.

In the ventilation device, air exits through special channels inside the walls to the roof or to the attic. The movement of flows is carried out due to the temperature difference inside the house and outside, as well as the pressure difference.New air enters the room through the cracks of windows and doors.

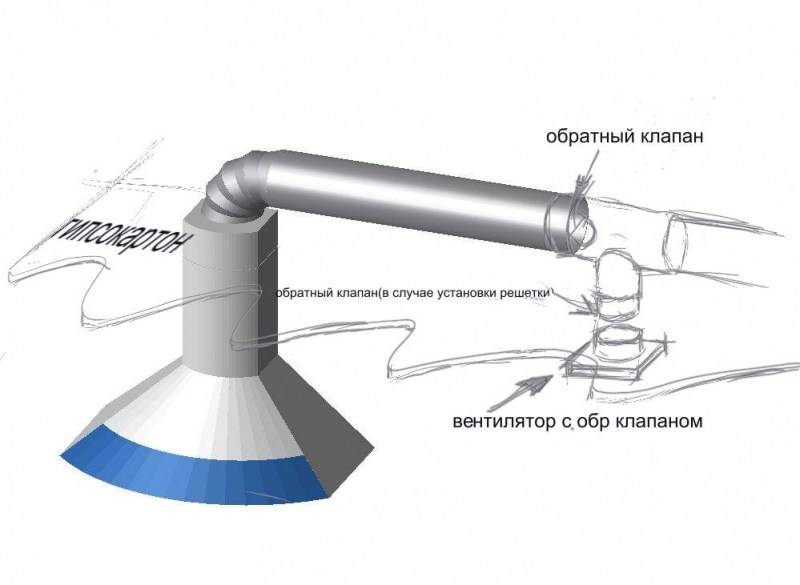

An exhaust system is installed in the kitchen to remove odors, excess moisture and oily waste generated during the cooking process. The hood, thanks to the operation of the fan, forcibly draws air from the kitchen, then it is discharged through the duct into the ventilation duct. The installation of air ducts for the kitchen hood should be carried out so as not to disturb the ventilation of the room.

System construction process

The exhaust ventilation device in the kitchen or in the bathroom begins with the layout of the entire system. After that, materials are selected and calculated. Never rush into calculations. Everything must be done in a measured and calm manner.

When designing, keep in mind that what matters in ventilation is its functionality, with the ability to make the most of all the conditions in each room. If you make a mistake, you will have to use mechanical air blowers, which will significantly increase the cost of the system.

For normal operation of the gravity type system, it is desirable that the ducts have as few turns as possible. It is recommended to install turbine deflectors on chimneys towering above the roof - they will increase the outflow

Installation steps:

- Ventilation design.

- Purchase of equipment: sewer pipes, installation products, fasteners, fittings, mounting metal tapes.

- Installation of brackets and clamps at the places of ventilation communications.

- A ventilation riser is assembled from large pipes.

- Assembly and installation of air ducts.

- Connecting all branches to each other.

- Sealing connections. There is no special need for this, but it does not hurt.

- Installation of fans and valves, if provided.

- Installation of ventilation dampers.

The finish of all types of installation work is testing the system for performance. All actions are to check the traction. To do this, attach a piece of paper or a napkin to the exhaust channels.

Circuit design or development

The creation of a ventilation project begins with elementary calculations and the collection of information, then:

- Calculate the rate of air exchange throughout the house. This indicator depends on the volume of all premises, their purpose and the number of residents. In living rooms, the air must be completely replaced 1 time per 1 hour, and in technical rooms (toilet / bath) - at least 3 times per 1 hour. Adding the resulting numbers, we get a performance indicator, taking into account which the diameter and height of the ventilation equipment will be selected.

- Draw a diagram of the movement of air currents. Immediately estimate the position of the intake and supply channels.

- Draw a duct diagram. For now, ignore the details, stick to the rules and try to fit the system without complicating the design. This is the most difficult stage of the work. Hiding ventilation from bulky plastic pipes is not so easy.

Sketches are ready. Take some time to think about what devices you will have embedded in the system and where they will be located.

Detailing and assembly of the system

Having solved all the questions on the scheme and giving it a final look, it's time to move on to detailing.

First, calculations are also carried out, the components of the system, equipment are selected and the budget is reduced, then:

- The cross section and area of air ducts are calculated. The maximum speed of quiet air movement is taken into account - otherwise there will be a rumble in the house.

- All dimensions are transferred to the diagram.

- Detailing. A list of all the necessary elements is compiled, indicating the sections.

- The total cost of the components of the ventilation system is calculated. Match your desires to your budget. At this stage, you will have to change the components several times, abandoning the desired in favor of the real.

- The final project is drawn. Do not forget about the nodes of the passage of ventilation channels through the roof, ceiling, walls, insulating and consumable materials, ventilation grilles, fasteners and all other little things that will eventually result in a decent amount.

It remains to find, buy and install. Not much has been written, but it will take a lot of nerves, time and effort to implement the plan. Having mounted the entire system, it is still impossible to say that everything is ready.

Air ducts from sewer pipes are assembled in accordance with the draft. PP pipes and fittings are connected by butt soldering, PVC by cold welding

The ventilation system made of plastic sewer pipes still needs to be tested and refined during operation. It is also not so easy to achieve coordinated work of each element of the system. If the natural ventilation option is not effective enough, it is worth upgrading by installing exhaust valves or their supply counterparts.

Pipes for hoods: tips and tricks for choosing

When choosing pipes for an air duct, most consumers are primarily guided by aesthetic considerations, which is quite justified. Therefore, before buying, it is recommended to determine exactly how the box will be mounted: outside or behind furniture, behind a false wall or above a false ceiling.

A shiny corrugated pipe definitely spoils the interior of the kitchen, so if we are talking about an open location, then most often they choose smooth plastic pipes that can be painted in a color that matches the design of the ceiling or walls. The most beautifully fits into an open interior is a rectangular or square pipe for the kitchen. A round hood is less aesthetically pleasing, but creates minimal airflow resistance, minimizing noise.

If we are talking about a hidden laying method, then it is better to give preference to a corrugated metal pipe. It is much easier to mount it, since it does not require the use of adapters and corners. If it is necessary to overcome an obstacle on the way to the ventilation duct, it is enough to simply bend such a pipe. However, additional costs will be required to mask corrugated products. In addition, if access to the duct is required, then the entire conspiracy will have to be dismantled.

Shapes and sizes of ventilation pipes: selection rules

The diameter of the round ventilation pipes must correspond to the cross section of the outlet pipe on the kitchen hood. It should be remembered that it is round boxes that create minimal resistance to air flow. As for the shape, a straight pipe is optimal, however, sharp corners are not allowed during the installation of air ducts.

Plastic pipes with a circular cross section can have a diameter in the range of 10-20 cm

The ideal length of the duct should be no more than 3 m. If this figure is higher, then the fan must be of maximum power.The corrugation diameters used in household ventilation are 10, 12.5 and 15 cm.

standard sizes of plastic pipes for ventilation square and rectangular shapes are as follows: 8 × 8, 10 × 10, 12.5 × 12.5, 5.5 × 11, 5 × 12, 6 × 20.4 and 9 × 22 cm. The diameter of the plastic pipe can be 10 , 12.5, 15 and 20 cm.

How to calculate the minimum dimensions of a plastic pipe

The cross-section of square and rectangular plastic ventilation pipes must be equal to the cross-sectional area of the round hood pipe. If the diameter is narrowed, then the performance of the system will deteriorate, the fan will be overloaded, and the noise will increase. As a result, vibration will occur and the fasteners will weaken. The minimum section size is allowed only when a powerful fan is installed in the hood, but it is not used to the maximum.

Properly selected pipe size affects the quality of the hood

It is best to take a pipe whose cross section will be slightly larger than the diameter of the nozzle. If the diameter of the pipe significantly exceeds the cross-sectional area of the fitting, then this will entail additional costs and problems with its masking.

It is not necessary to calculate the size of the section of the hood hood. It should be equal to the diameter of the outlet pipe. If the hood has a certain power reserve, but is not used at full capacity, then the cross section can be slightly narrowed. To calculate its minimum value, the formula will help:

Smin=Sp*(Qr*Qmax), where:

Smin is the minimum cross-sectional index;

Sp is the section of the branch pipe indicated in the product passport;

Qp is the volume of air to be removed;

Qmax - the maximum indicator of the volume of air to be removed, it is indicated in the passport of the hood.

Qr is calculated using a different formula: Qr = Vkitchen * 12 * 1.3 m³. Vkitchen is the area of the room.According to sanitary standards, 12 is an indicator of air exchange, that is, the air in the kitchen should change 12 times per hour. 1.3 is the power loss factor in the duct and ventilation shaft.

The size of a plastic pipe can be calculated using a special formula

Varieties and materials for the production of plastic pipes

There are several types of modern plastics:

- Polyvinyl chloride (PVC).

- Polyurethane.

- Polypropylene.

Each has its own advantages and almost all have one single drawback.

The use of polypropylene pipes for arranging ventilation of an industrial building

Polyvinyl chloride (PVC)

This is the cheapest, lightest and most durable option, easily processed both industrially and at home. Under normal climatic conditions, it is practically eternal and harmless: it decomposes, if not hundreds, then certainly decades, so that ventilation ducts and various products from it will outlive the house itself.

But there is one severe limitation in use. This plastic contains chlorine, and the decomposition temperature of PVC (160-180°C) is lower than the plasticity temperature (200-220°C). Therefore, it cannot be formed with a burner and, moreover, it cannot be used where relatively high temperatures are used.

Round ventilation pipe made of polyvinyl chloride (PVC)

During decomposition, chlorine compounds and, first of all, HCl will be released. This gas with moisture forms hydrochloric acid itself, therefore it is dangerous for the eyes and respiratory tract, although in everything else it is simply unpleasant or almost invisible.

Thus, polyvinyl chloride is an ideal plastic for ventilation, partially excluding the kitchen, water heater, fireplace and those places where temperatures in excess of 120 ° C can occur (it is believed that this is the “top bar” for human safety).

Rectangular flat PVC pipes for arranging air ducts

Polyurethane

This plastic differs little from PVC, but can withstand temperatures up to 280 ° C without problems. At a higher temperature, decomposition begins with the release of nitrogen compounds, which is many times more dangerous than chlorine compounds.

Its high cost is considered a relative disadvantage, but it combines two seemingly incongruous factors: ductility and wear resistance. The plasticity of polyurethanes exceeds the resistance of granite and steel to fracture stresses. The finished product made of polyurethane can be bent an infinite number of times - it will not crack and will retain its original shape as soon as the stress disappears.

Polyurethane is ideal for domestic temperature parts, especially where shifts and distortions are possible: coupling rings, all kinds of nozzles and areas where there may be high domestic temperatures.

Polyurethane hose for installation of exhaust ventilation systems

Polypropylene

This plastic is ideal for molding. Already at 180°C, it is surprisingly plastic, so that any pipe can be twisted even just in hot steam, and the burner can be bent at any angle. At the same time, it is durable, and at high temperatures it does not emit anything dangerous by itself (impurity dyes or special additives can be dangerous). It is in the middle price category, but sufficient to make it not only the components of plastic ventilation systems, but also heating batteries.

Polypropylene is a relatively expensive but versatile safe plastic.

Ventilation pipes and components made of polypropylene

The use of ventilation pipes in everyday life

Residential buildings must be ventilated. A person in the process of breathing releases carbon dioxide and moisture, cooking - moisture, soot, fat, carbon dioxide, sanitary appliances - a lot of moisture. Moisture settles on walls and furniture, which leads to the formation of mold. Carbon dioxide and combustion products, odors from cooking lead to rapid fatigue, irritation of the respiratory tract, deterioration of health, and a decrease in efficiency. Some of the substances formed during frying are carcinogens.

In old Soviet-built houses with small apartments and leaky doors, ventilation in the kitchen and bathroom simultaneously removed part of the air from the living rooms. At the same time, ventilation ducts were built into the structure of the building. In private houses, ventilation was not provided at all - the situation with carbon dioxide was saved by a stove with a chimney: the air for the stove was taken from the house and removed along with the combustion products of the fuel outside the dwelling. Fresh air entered houses and apartments through leaks in wooden windows and doors. Burnt and soot just settled on the walls and ceiling - they had to be whitewashed every year.

In modern houses, in addition to the hood, additional ventilation systems are often installed - exhaust and supply and exhaust. In passive and energy-efficient houses, supply and exhaust ventilation with heat recovery is a mandatory component of the house design.

Air duct calculation

The calculation of ventilation ducts is one of the most important stages in the design of an air supply system. Before proceeding with the direct selection of the cross-sectional area of the wires, it is necessary to determine the ventilation performance by air.

Plastic air ducts are a high-quality and reliable product with a long service life.

Calculation of the air capacity of the ventilation system

First you need a plan of the object, which indicates the area and purpose of all rooms. Air supply is provided only in those rooms in which people stay for a long time (living room, bedroom, office). Air is not supplied to the corridors, as it gets there from the living rooms, and then to the kitchens and bathrooms. From there, the air flow is discharged through the exhaust ventilation. This scheme prevents the spread of unpleasant odors throughout the house or apartment.

The amount of air supplied for each type of dwelling is calculated using MGSN 3.01.01. and SNiP 41-01-2003. The standard volume for 1 person in each room is 60 m³/h. For a bedroom, this figure can be reduced by 2 times to 30 m³ / h

It is also worth noting that the calculation takes into account only people who are in the room for a long time.

The next step is to calculate the air exchange rate. The multiplicity shows how many times per hour there is a complete renewal of the air in the room. The minimum value is one. This value prevents the atmosphere from stagnating in rooms.

Before installing the pipes of the ventilation system, the necessary measurements are made and a technical design is drawn up

Based on the foregoing, to determine the air flow, it is required to calculate two parameters of air exchange: by the multiplicity and by the number of people, from which the larger value is selected.

Calculation by the number of people:

L = N x Lnormal, where

L – supply ventilation power, m³/h;

N is the number of people;

Lnormal - normalized value of air consumption per person (typical - 60 m³ / h, in a state of sleep - 30 m³ / h).

Calculation by air exchange rate:

L = b x S x H, where

L – supply ventilation power, m³/h;

b - air ratio (residential premises - from 1 to 2, offices - from 2 to 3);

S is the area of the room, m²;

H - vertical dimensions of the room (height), m².

After calculating the air exchange for each room, the obtained values are summarized for each method. More will be the required ventilation performance. For example, typical values are:

- rooms and apartments - 100-500 m³ / h;

- cottages - 500-2000 m³ / h;

- offices – 1000-10000 m³/h

Ventilation hoses are light weight and highly flexible

Method for calculating the cross section of air ducts

To calculate the area of air ducts, it is necessary to know the volume of air that must flow through them over a period of time (according to the previous calculation stage) and the maximum flow rate. The design values of the cross section decrease with increasing air velocity, however, the noise level increases. In practice, for cottages and apartments, the speed value is selected within 3-4 m / s.

It should be noted that the use of low-speed wires with large dimensions is not always possible due to the complexity of placement in the overhead space.It is possible to reduce the height of the structure using rectangular air ducts, which, with a similar cross-sectional area, have smaller dimensions compared to a round shape. However, mounting round flexible ducts is faster and easier.

Computer modeling of internal engineering networks of ventilation

The calculation of the duct area is made according to the formula:

Sc \u003d L x 2.778 / V, where

Sc - the estimated size of the wire section, cm²;

L – air consumption, m³/h;

V is the air velocity in the wire, m/s;

2.778 is a constant for converting different dimensions.

Calculation of the actual cross-sectional area of a circular duct is made according to the formula:

Calculation of the actual area of rectangular plastic air ducts is carried out according to the formula:

S = A x B / 100, where

S – actual air duct area, cm²;

A and B are the cross-sectional dimensions of the rectangular air duct, mm.

The quality of the outflow of polluted air depends on how correctly the ventilation system is calculated.

Calculations start from the main canal and are carried out for each branch. The air speed in the main channel can be increased up to 6-8 m/s. It should be added that in domestic ventilation systems, as a rule, round ducts with a diameter of 100-250 mm or rectangular ones with a similar cross-sectional area are used. It is very convenient to use the Vents catalogs for choosing plastic air ducts for ventilation.

Is it possible to do without an air duct?

Alternatively, you can install hoods that work on the principle of recirculation. Usually their power and efficiency is lower. Installation of an air duct for such an extract is not required. Sometimes they organize the removal of air to the street. A hole is made in the wall after agreement with the BTI and housing and communal services.According to SNiPs, the distance to the nearest window should be at least 8 m. As a rule, this is only possible on the upper floors.

Or install an outer box through which the air rises to the level of the roof. This is necessary so that the exhaust air from the kitchen does not enter the neighbors of the upper floors through the windows. This option is often used by the owners of cafes and restaurants, which are located on the 1st floor of a multi-storey building.

So, you need to correctly connect the hood to the ventilation, so as not to disturb the air exchange in the room

This is important primarily for health. In many modern house designs, several channels are immediately provided: one for ventilation with natural current, the other for connecting an exhaust hood

Their accelerating mines are separated. If the house has already been built, it is important to take into account all the nuances: the volume of the room, the frequency of cooking, the size and capacity of the ventilation ducts. Only after that, purchase a hood and air ducts for it, having thought in advance how to arrange them aesthetically.