- Prices for arranging a well with an adapter

- What equipment is needed for arranging the structure

- Step-by-step instructions for installing the adapter in the casing

- Downhole Pump Performance Calculator

- Video - Downhole adapter tie-in

- Types of equipment for wells

- Some Tips

- Advantages and disadvantages of the well adapter

- Using a well adapter

- Installation stage

- Mounting the main unit

- Installing the block

- Necessary materials for work

- The choice of downhole devices - how to navigate?

Prices for arranging a well with an adapter

The cost of arranging a well with a depth of 20 m on a turnkey basis with a caisson (at the beginning of 2020) - from 86 thousand rubles. Own source of year-round water supply of the same depth, but equipped with an adapter, costs from 55 thousand rubles.

What is included in the price:

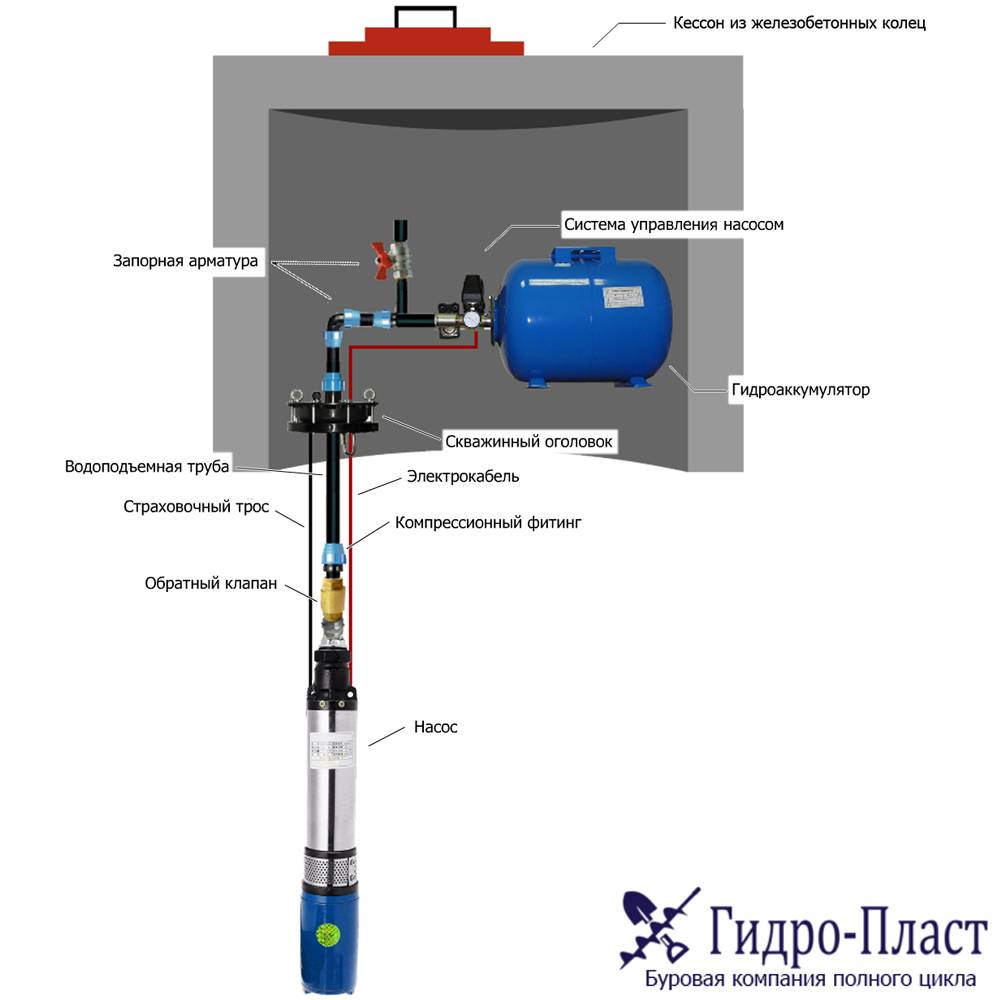

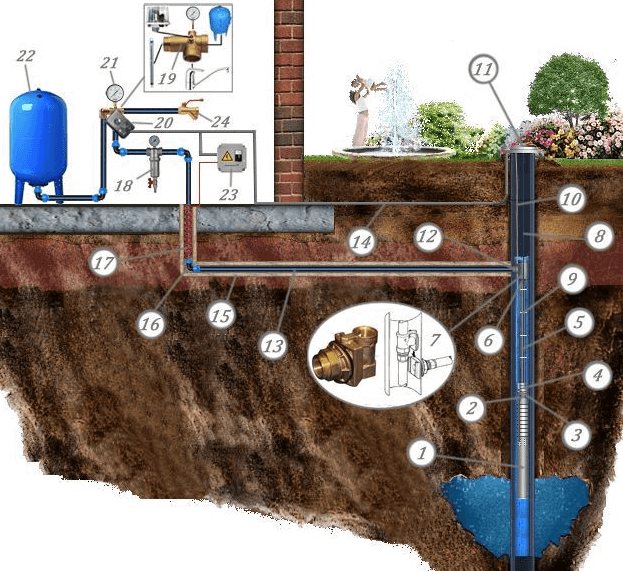

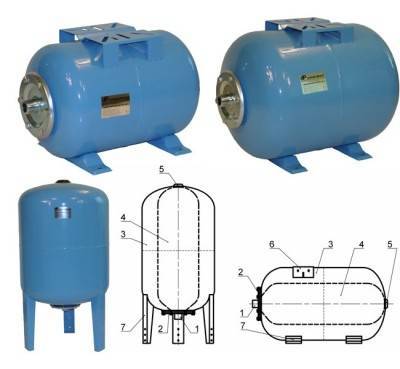

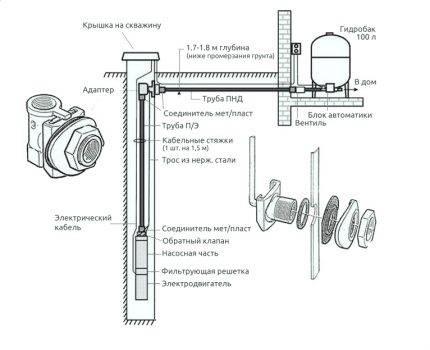

- Equipment - borehole pump (submersible), stainless cable and clamp, PVA cable, borehole adapter, hydraulic accumulator for at least 100 l, pressure switch, compression check valve.

- Pipeline details - ball valve, five-outlet fitting, HDPE pipe, couplings.

- Well cover.

- Installation work - arranging a pit for an adapter, installation of a pipeline, installation and commissioning of equipment.

- Fare.

Installation of the same well with a depth of 120 m with an adapter will cost from 77 thousand rubles. The price can be greatly affected by the distance from the city in which the selected company is located to the site. It is recommended to supplement the pump automation kit with a dry-running sensor or a float switch (if the pressure switch does not have a protection function against running without water).

Insulated well with adapter.

What equipment is needed for arranging the structure

To equip an artesian well with your own hands, you will need:

- water lifting equipment;

- cap;

- hydraulic tank;

- additional equipment for pressure, level, water flow control;

- frost protection: pit, caisson or adapter.

When buying a submersible pump, it is important to correctly calculate the required power. The model is selected according to performance and diameter. You can’t save on this equipment, because

the performance of the entire water supply system of the site depends on it

You can’t save on this equipment, because. the performance of the entire water supply system of the site depends on it.

The best option is a model in a high-strength hermetic case, equipped with sensors, filter units, and automation. As for brands, Grundfos water-lifting equipment deserves special attention.

Typically, a submersible pump is installed at a height of about 1-1.5 m from the bottom of the hydraulic structure, however, in an artesian well, it can be located much higher, because. pressure waters rise above the horizon.

The immersion depth for an artesian source should be calculated based on the indicators static and dynamic levels water.

To keep artesian water crystal clear, the production pipe must be protected from debris, surface water and other adverse environmental factors. This structural element is used to securely fasten the submersible pump cable.

The head consists of a cover, clamps, carabiner, flange and seal. Models of industrial production do not need to be welded to the casing, they are fastened with bolts that press the cover against the seal, thus ensuring a complete seal of the wellhead. Features of mounting homemade heads depend on the design of the devices.

The hydraulic accumulator is an important unit of an autonomous water supply system. It is necessary to ensure the normal operation of the water supply, protect the pump from constant on-off and prevent water hammer. The battery is a water tank, additionally equipped with pressure sensors and automation.

When the pump is turned on, water first enters the tank, and from it is supplied to the draw-off points. The water levels at which the pump turns on and off can be controlled using pressure sensors. On sale there are hydraulic tanks with a capacity of 10 to 1000 liters. Each well owner can choose the model that best suits their system.

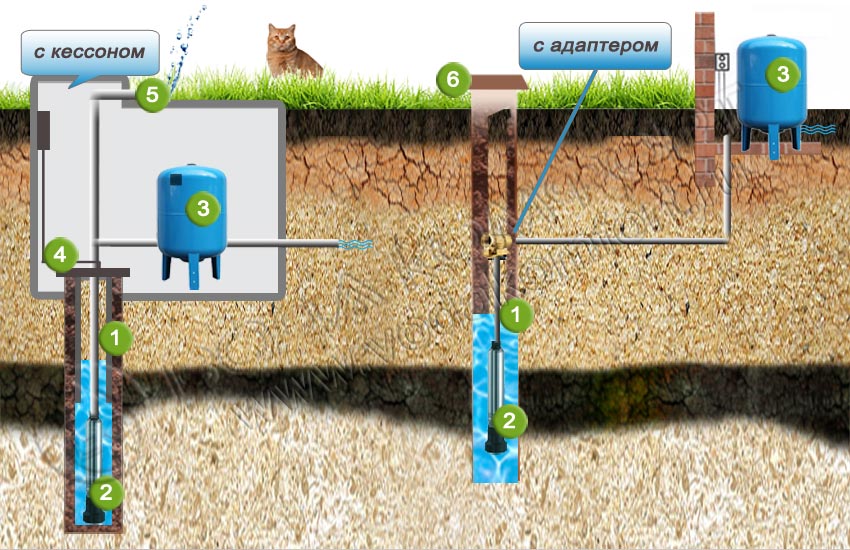

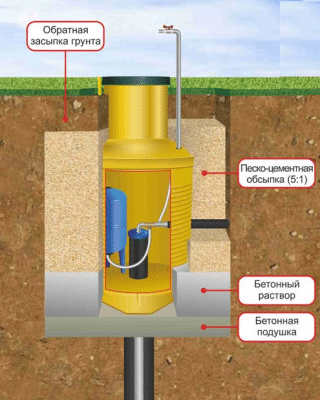

The well must be protected from freezing. For these purposes, you can make a pit, install a caisson, an adapter. The traditional option is a pit. It is a small pit, the walls of which are reinforced with concrete or brickwork. From above, the structure is closed with a heavy lid with a hatch. It is undesirable to install any equipment in the pit, becauseeven with good waterproofing, the walls still let moisture through, the design is not airtight.

A more modern and technological analogue of the pit is the caisson. This design is best purchased at a specialized store. Industrial production caissons are pre-designed to accommodate all the necessary equipment. Plastic models are well insulated and airtight. Metal caissons often need additional insulation.

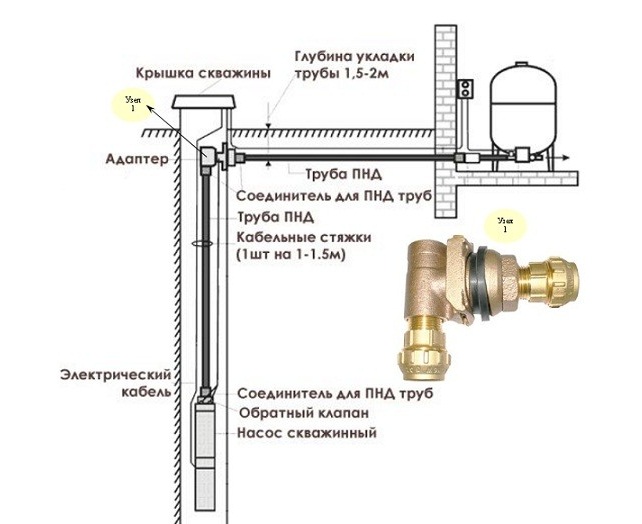

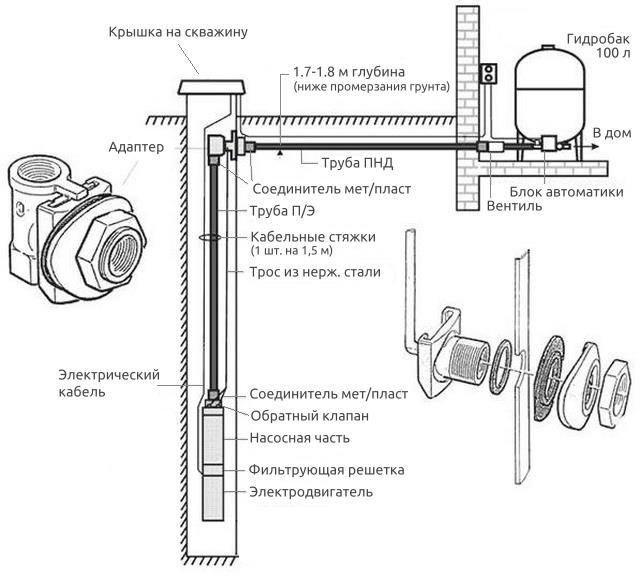

For a single-pipe artesian well, an arrangement using a pitless adapter is suitable. In this case, the function of the protective structure is performed by the casing pipe itself. The adapter can only be installed if the column is made of metal. There are serious difficulties with the operation of a plastic pipe, and the service life of the structure may be short-lived.

Step-by-step instructions for installing the adapter in the casing

Let's get acquainted with the installation steps; for the convenience of visitors, the information is presented in the form of a step-by-step guide. But first, let's get acquainted with the list of what is required for work:

- electric drill;

- FUM tape;

- bimetallic nozzle for an electric drill, corresponding to the diameter of the adapter outlet;

- building level;

- Adjustable wrench.

Well Adapter Installation Instructions

Step 1. First of all, the well itself, the casing and the ditch for the pipeline are equipped.

Digging a trench for a water pipeArrangement of a trench

Step 2. Everything necessary for the well equipment is being prepared, in particular, a pump. It is desirable that the cable for the pump be connected to the hose with plastic ties - this will make it easier to install the device.

Hose and cable are connected with a tie

Downhole Pump Performance Calculator

Step 3. The casing pipe is cut to the ground level, which is best done with a grinder. After that, it also cleans the place of the cut.

Use a protective mask or goggles Casing is cut Cleaning the cut

Step 4. Then the adapter itself is prepared. It is necessary to check its integrity and completeness - the device should not have dents, chips and other defects, and all the necessary parts must be included in the kit.

The adapter must be checked Checking the integrity of the elements

Step 5. A hole is drilled in the desired location of the casing pipe, corresponding to the diameter of the adapter. For this purpose, a crown nozzle having the required size is placed on the electric drill.

A hole needs to be drilled in the casing

Step 6. The outer part of the device, which will be connected to the water supply, is installed

To do this, it is carefully lowered into the casing pipe to the drilled hole so that the branch pipe with a threaded connection eventually comes out. Then a rubber seal is installed outside and pressure ring

At the end, the nut is carefully tightened.

The outer part of the device is installed. The seal is put on. The nut is tightened.

Step 7. Next, a connector with a pipeline is screwed to the outer part of the adapter. It is recommended to pre-wrap the threads with FUM tape to increase tightness (as an option, you can use plumbing thread instead of tape).

Connector with water pipeConnector is screwed

Step 8. The outer part of the adapter is connected to the pipeline leading to the house using a connector.

The pipeline is connectedAnother photo of the process

Step 9. At the top casing parts well cover is installed. To fix it, a hex key is used.

Well coverThe cover is installedUse a hex wrench to fix the cover

Step 10. A safety cable is attached to the pump, due to which the load on the adapter will decrease, which means that the service life of the latter will increase.

Step 11. The pump is lowered with a power cable, hose and cable deep into the well. For this work, assistants will be required, since it requires the application of considerable physical strength.

The pump is lowered into the well The pump is lowered with power cable, hose and rope The pump is almost lowered

Step 12. The end of the hose, which is immersed with pumping equipment, is cut off, after which the other part of the adapter is prepared - it is connected to the fitting. The finished structure is fixed at the end of the hose, which was cut off earlier.

The hose is cut offThe second part of the adapterConnecting the second part of the adapter to the fitting

Step 13. The mounting tube is screwed to the top threaded connection located on the inside of the adapter. Further, with the help of a pipe, the part is inserted into the well and connected to the outer part (the above-mentioned dovetail connection is used). Then the pipe is unscrewed and removed.

Mounting pipe is screwed onConnection point

Step 14. The safety cable is fixed on the well cover. The system is being tested for functionality. If everything is done correctly, then a strong stream of water will come out of the water supply.

The safety cable is fixedTest run of the equipment

That's all, the well is equipped, and the adapter for it is installed.Now you have clean and high-quality drinking water at your disposal!

Video - Downhole adapter tie-in

The downhole adapter, located in the cavity of the water intake channel, prevents the hole from icing up in winter. The device is a metal tee that allows you to bring the flow of water from the well into a pipeline located in the soil. The use of an adapter allows you to reduce the cost of creating a water supply system for a country house.

Types of equipment for wells

On sale you can find various equipment for wells. The most popular is the classification by type of material.

- Bronze products appeared on sale in the second half of the 20th century. It is worth noting that today it is almost impossible to find such equipment on sale. This is due to the high cost of bronze.

- It is customary to use the brass variety in technical pipelines, since it does not affect the quality of drinking water.

- The most common downhole adapters are made from various stainless alloys. For example, it can be steel alloyed with chromium. Such equipment is more reliable and practical than brass or bronze products.

Some Tips

Having decided to equip the well with an adapter (in retail chains they are called Pitless adapter), you get a reliable water supply system and save on the timing of the work and the cost of their implementation. However, when buying it, you need to remember the following:

- In order for the product to maintain its tightness throughout the entire period of operation and to ensure the possibility of repeated installation and dismantling of the deep pump, it must be of high quality.Do not buy adapters from obscure manufacturers that do not have a manufacturer's warranty.

- Having decided to buy a Pitless adapter, be sure to check with the seller how difficult it is to find spare parts for this product in retail chains, first of all, o-rings and a removable part assembly. What is the probability that in a couple of (or better, in five) years this product will still be produced.

- Having settled on the indicated option, you will have to place all the equipment of your water supply system in the house itself and, preferably, in a separate room.

Video with the pros and cons of the adapter and caisson:

If you also have a main water supply, then it is useful to install an avk valve with flanges to be able to shut it off. Depending on the situation, it will be possible to choose the source of water supply.

Advantages and disadvantages of the well adapter

Like any other technical device, a well adapter has its own set of advantages and disadvantages. To begin with, we will indicate what are the advantages of such a product and how it is better than the currently more popular caissons and pits.

Cost is the first and main advantage of the adapter for the well, which manufacturers and sellers of such products pay attention to the owners of country houses. Indeed, the arrangement of the adapter in the casing will eventually come out 5-6 times cheaper than the installation of the caisson

Therefore, if for some reason you have a limited budget for the construction of a country house and its water supply, pay attention to a similar method of connecting a well to a water supply.

Lack of excavation work during the arrangement - the adapter does not require long (or expensive, if an excavator is involved) soil extraction. This advantage is especially important in the case when the well passes next to any other communications, and it is expensive and undesirable to transfer them.

Fast installation - the complete installation process of the adapter for the well takes several hours. If saving time is important to you or you don’t have the opportunity to devote too much time to building a house, give preference not to a caisson or pit, but to an adapter.

Simplicity of arrangement - installing such equipment for a well with your own hands does not require any special skills and knowledge of the nuances. It is enough to have the right tools, basic skills in handling them and a little time.

Compactness - the casing pipe together with the adapter will not take up much space on the site and will not be a “spot” that spoils the appearance of your new and beautiful homestead. In fact, only the cover of the well with a diameter of about 30-40 cm will be located above the ground.

Tightness - the simplest caisson of concrete rings in the period from February to May is often filled with melt water. They, in turn, are mixed with the liquid coming from the well, spoiling the taste and quality. For a metal or plastic casing pipe together with an adapter for a well, such a phenomenon is practically impossible with proper installation.

Well adapter (borehole adapter) 1 inch, BRONZE, С84400

The adapter has many advantages

Now let's move on to the disadvantages inherent in borehole adapters. Firstly, the average service life of such a product is lower than that of a high-quality caisson.This becomes especially noticeable in the case when not the highest quality adapter for the well was purchased - not from copper or brass, but from alloys of unknown origin and composition.

Secondly, the adapter for the well requires regular replacement of rubber gaskets, which is associated with digging the casing every 2-3 years. Otherwise, the tightness of the structure will be broken and, over time, melt water will begin to get there - just like in a cheap caisson of concrete rings. Also, earthworks will require a possible repair of the adapter for the well.

Rubber seals need to be changed periodically.

Thirdly, with excessively long operation, the outer and inner parts of the product, connected according to the dovetail principle, can literally boil. A similar phenomenon was observed at least once by those who tried to dismantle old water or sewer pipes, which had not been touched before for many years.

Downhole adapter

Fourthly, the well pipe with an adapter is really small in size. But this also means that most of the equipment cannot be placed there, as in plastic or metal caisson. Therefore, the adapter has to be mounted directly in the house, taking away the usable area from the latter. In addition, not every pump is suitable for an adapter in size - it is worth remembering this when choosing equipment for a well.

Using a well adapter

A pavilion or caisson is the best way to protect the source of water supply. However, both of these solutions are by no means cheap. If we are talking about a solid country house and a vast plot, the significant financial costs of arranging the well are undoubtedly justified.

But what about the developer who does not have an endless budget, builds a poor rural house or a modest summer cottage? For arranging a well in a country house, there is an economical alternative solution - a borehole adapter.

With it, the water pipe coming from the house can be inserted directly into the well casing. No caisson is needed. True, if maintenance is necessary, the adapter will have to be dug up, because it is in the ground. But the need for this rarely arises.

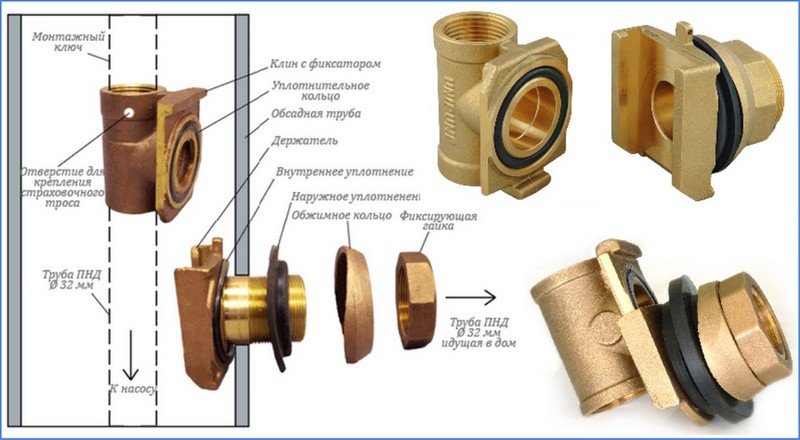

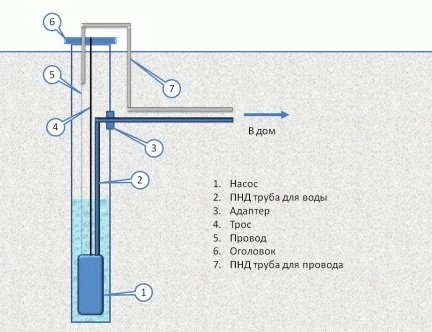

The downhole adapter is a collapsible fitting consisting of two parts: external and internal. The outer part is located outside the casing and serves to connect to the water pipe going into the house.

Connected to the mating interior pump pipe. Both parts of the adapter, connected on the casing pipe, have a radius shape that repeats the diameter of the wellbore. The elements are connected through a double hermetic seal.

The adapter in the casing is inserted into a pre-drilled hole. When installing, carefully check the tightness of the connections.

The adapter must be placed below the freezing depth of the ground and installation must be done with great care. The casing pipe remains on the surface of the earth, it is left sticking out low above the ground level. A cover is mounted on top, into which an electric cable is inserted to power the submersible pump.

In severe frosts, cold will penetrate into the well through the casing. Therefore, if winter temperatures drop below -20 °C, we recommend cover the well for the winter spruce paws, straw or insulate in another way.

The only but significant advantage of the adapter over the caisson is its cheapness.Among the disadvantages: the complexity of maintaining the equipment, poor protection against mechanical damage to the electrical cable, less reliable suspension of the pump (it does not rest on a cable, but on only one water pipe).

Arrangement using a downhole adapter. Both the adapter and the water pipe must be below the freezing depth of the ground.

Arrangement using a downhole adapter. Both the adapter and the water pipe must be below the freezing depth of the ground.

And yes water supply equipment can only be installed in the home. You can mount the adapter yourself, but you will need a special wrench with a long nozzle, some technical skill and a lot of patience.

In conclusion, we say that the "cheap and angry" downhole adapter is really cheap. However, it may not always be applicable and does not provide the same level of source protection and durability as a caisson.

Installation stage

Installation of the downhole adapter makes it possible to carry out repair work at any time by disconnecting the mating block and again without any problems lowering it into the well

In order for the process to run smoothly, it is important to choose the right submersible pump, evaluating the dimensions of the casing, taking into account the characteristics of the pitless device, otherwise the equipment will touch the protruding parts in the design

- The casing string is excavated to the required depth (if the work is carried out at the stage of well creation, the casing pipe is installed);

- After cutting a hole of the required diameter, the main unit of equipment is installed;

- Put a cover on the well;

- Attach a pipe that provides water entry into the house;

- The mating part of the adapter is connected to the downhole pump hose;

- As soon as the pump is lowered into place, the device blocks are connected.

Mounting the main unit

To mount the adapter, the pipe is drilled with a hole cutter made of bimetallic material, the diameter of which is selected according to the size of the device. After preparing the hole, the main unit of equipment is lowered into the pipe and fixed with a crimp ring, additionally providing rubber seals on the inside and outside. For complete tightness, tightening of parts with an adjustable wrench is required.

When installing the adapter, a special threaded pipe is used. It is screwed into the hole on the adapter and removed after mounting the device.

When the water pipe is connected to the outer element of the device, the threaded connection provided is additionally strengthened.

Installing the block

Before connecting the pump to the mating unit, the assembled fixed equipment is lowered to the estimated depth, after which the pipe is cut and connected to the mating unit.

When all the components are ready, using a mounting pipe screwed into the hole on the adapter, the mating block is lowered into the casing string, fixing both parts of the device together. Then the mounting pipe is unscrewed.

If the water pipes differ in diameter, there is a joint between a metal and a plastic pipe, in addition to the pitless device, a flange adapter for cast-iron pipes is required, consisting of a coupling and a flange itself, the material of which is high quality stainless steel. Such a connection is easily and quickly assembled and dismantled, thereby guaranteeing convenient maintenance of the plumbing system.

WATCH VIDEO

Making an adapter for a well with your own hands is extremely difficult. After all, such a design must withstand the pressure of the water column, be resistant to corrosion and destruction, therefore, the requirements are imposed not only on the features of the system, but also on the materials of the parts. Therefore, the plastic adapter used in other situations is a solution that is not even subject to consideration. You can only install a ready-made brass or bronze adapter with your own hands, following the instructions above.

Necessary materials for work

To install a downhole adapter, you will need a set of tools and materials:

- bayonet blade;

- wrenches;

- metal pegs;

- crown cutter made of metal alloy;

- neutral water-repellent lubricant for processing the tie-in place before burying the adapter into the ground and silicone sealant;

- the adapter itself and the puller to it - a steel tube for mounting with a thread on the end;

- FUM tape;

- fittings for connection.

After purchase, the adapter must be prepared for installation - remove the factory grease, seal the seal ring with a sealant. Properly done work will protect pipes from freezing in winter and from any deformations.

The choice of downhole devices - how to navigate?

Adapters are made from special alloys. At the moment, there are accessories for wells made of the innovative DZR composition (products from it are guaranteed to be used for 25 years), stainless steel (at least 20 years), brass and bronze (service time - 7–25 years). Bronze and brass structures are gradually fading into the background. When used, they can release various substances (as a result of natural oxidation), which adversely affect human health.Therefore, it is not recommended to purchase them.

Arrangement of a borehole adapter

Stainless alloys and DZR compositions do not have these problems. They are highly resistant to rust and oxidation, are used for a long time and rarely fail. Products made of DZR alloy are more expensive than stainless steel adapters. The most trouble-free devices for wells are considered to be devices under the Debe brand. They are made in Sweden from DZR alloy. It's better to use them. American Granby Harvard adapters also have good performance. They are made from stainless steel.

If you are planning to equip a well with low financial costs, pay attention to brass and bronze products under the brands Unipump (Russia) and Baker (USA). Of the entire range of such adapters, these have earned the most positive feedback from consumers.

They are easily mounted by hand, have an affordable cost and a long period of trouble-free operation. Important point! Adapters are available for various pipe sections for water supply systems. The most common devices for wells are 1.25 and 1 inch. The cross section of the pipeline, which stretches from the accumulator (it is always placed in the house) to the pump in the well, determines the technical parameters of the adapter itself.