- How is the vacuum valve arranged?

- Installation of a water seal

- Specifications, diameters and manufacturers

- Types of check valves and the principle of their operation

- Swivel (petal)

- Lift check valve for sewerage

- What is a sewer vacuum valve and how to install it

- Why you need a vacuum valve

- Valve device and its installation

- Species and types

- According to the principle of action, they are divided into:

- By type of construction:

- According to the connection method, there are valves:

- Types of check valves and the principle of their operation

- Swivel (petal)

- Lift check valve for sewerage

- Ball check valve

- Wafer type

- When is the only solution to install a vacuum valve?

- Advantages and disadvantages of the sewer element

- How does a vacuum valve work and how is it arranged?

- Dry option

- Advantages of the option

- Types

- Signs of a sewer problem

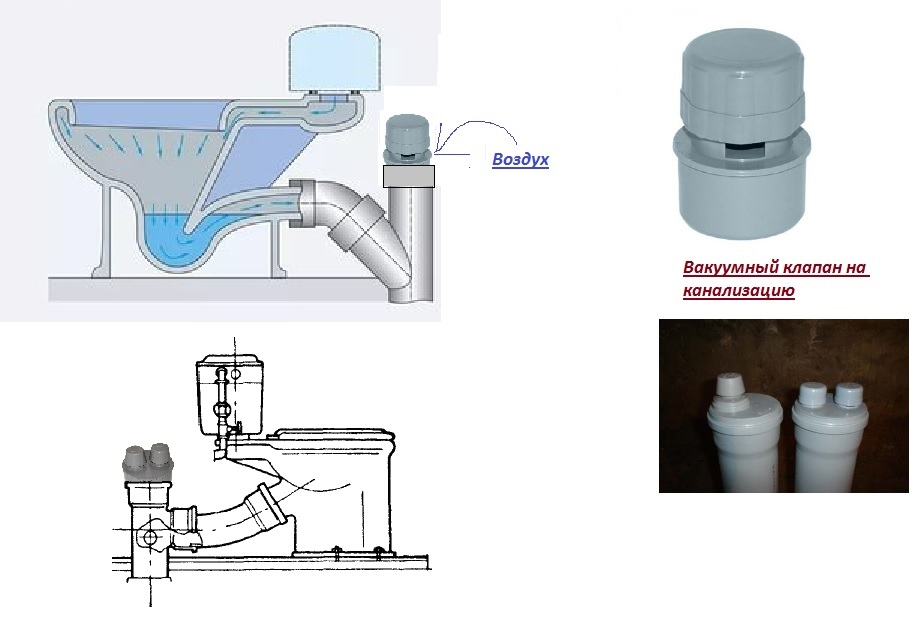

How is the vacuum valve arranged?

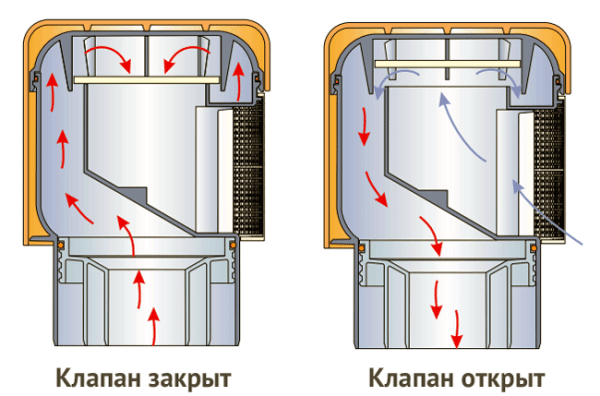

Already from the purpose of this device it is clear that it must remain closed at excess pressure in the sewer pipe or when it is equal to atmospheric pressure. But if a vacuum occurs in the pipe, the valve mechanism must ensure the opening of the passage for air to enter from the outside.

The principle is easily implemented with the "attraction" of ordinary gravitational forces.The diagram below shows the device of one of the models of aerators. Despite the possible difference in the design of valves from different manufacturers, the principle remains practically the same.

An example of a device and a demonstration of the principle of operation of a vacuum valve for sewers.

The entire valve mechanism is assembled in a polymer housing (item 1). By itself, the device implies only a horizontal arrangement, therefore, in its lower part, one or another device is necessarily provided for a tight connection with a sewer pipe. In the example shown, this is an elastic cuff (pos. 2) for inserting the aerator into a socket or even just into a cut pipe. There may be a connecting node in the form of a standard socket of sewer pipes or other options. But always this installation is simple, reliable and understandable.

Air can enter the aerator through the intake grille or slotted holes (item 3). They are located on the bottom or side of the valve "head", but outside air will almost always push against the valve diaphragm from below.

This is very easy to explain. The valve damper (pos. 5) is located in the seat allotted to it (pos. 4) and fits snugly to its edges with an elastic cuff (membrane), not letting air from the pipe into the room. And the fit is provided by the banal gravity of this damper. That is, even if the atmospheric pressure and the pressure established in the pipe (riser) are equal, the valve will be closed. Some more excess pressure in the pipe can contribute to this, since gas formation almost never stops in the sewer. That is, the flap will thereby be pressed even more against the saddle (in the diagram, this is the left fragment).

But if for one reason or another even a slight vacuum is created in the pipe, atmospheric pressure will overcome gravity and lift the damper above the saddle. As the saying goes, “nature abhors a vacuum,” and outside air will rush into the pipe, equalizing the pressure and preventing the siphons from breaking.

To prevent the damper from warping, it may have special guides (pos. 6). However, many models do without them - centering is done due to the cylindrical shape of the valve assembly.

Aerator for 110 mm pipe - model with two valve heads. One of them was dismantled to demonstrate its simple device.

Out of pure curiosity, you can “disassemble” a few more vacuum valves of various models. But we still won't find any fundamental differences there.

Differences in the design of various models of valves are unprincipled.

By the way, since the device is being considered, you can immediately draw the attention of readers to the “Achilles heel” of any valve. This, of course, is the membrane itself, or rather, that area of it, which is pressed against the valve seat by gravity.

And here we are not talking about wear (if it is, it is very invisible), but about other obstacles that can place the sash in a hermetic fit:

- Over time, dust can accumulate on the valve seat or on the membrane itself, which can turn into hard lumps of dirt that prevent the leaf from fitting snugly. Often, the owners are informed about this by the “aroma” of sewerage that has appeared in the premises. The first thing to do with such a “bell” is to check the cleanliness of the membrane and its fit, to carefully clean the assembly from contamination.

- The second conclusion is that the vacuum valve must be installed only in a heated room at home. Otherwise, with the onset of cold weather, drops of condensate may freeze on the seat or on the membrane, and the valve mechanism will not fit. And in general, too large temperature drops do not benefit the rubber membrane - it begins to “tan” in the cold, losing the necessary elasticity.

Otherwise, the mechanism is utterly simple, and it is difficult to come up with any circumstances that would lead to a breakdown of the vacuum valve.

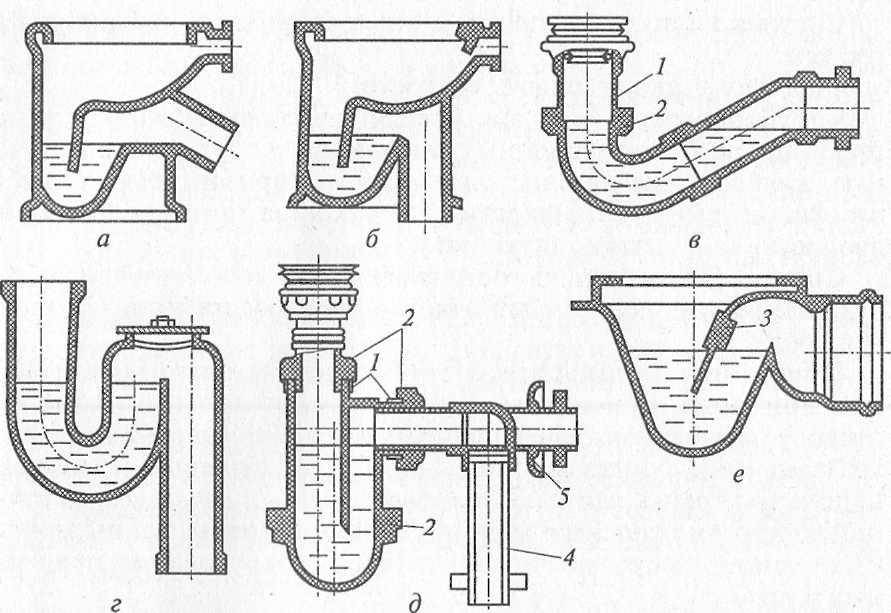

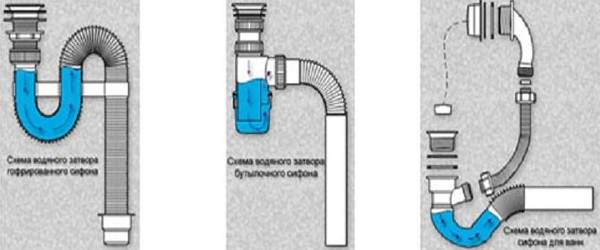

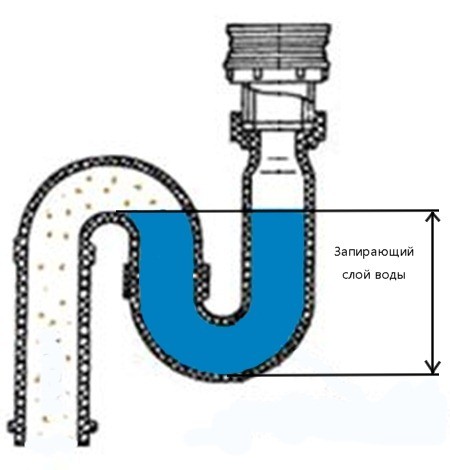

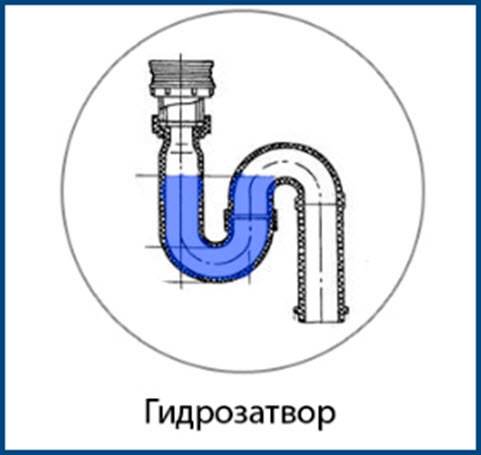

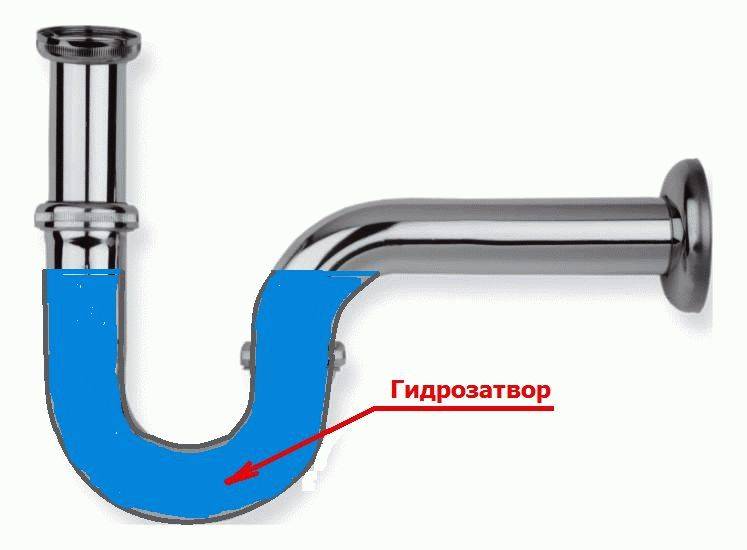

Installation of a water seal

Installing a siphon does not cause problems. First, a grate is installed that protects the sewer from large particles, then the device is screwed to the outlet with a nut. Then put the siphon on the drain pipe and fix it.

Connecting the siphon to the bathroom is not much different from the previous one. The only difference is the connection of the overflow pipe. But even here there should be no difficulty.

In conclusion, it should be said that without a water seal, sewerage will only cause problems. In order for it to work efficiently and for a long time, periodically clean it of sediment and rinse it.

Video: Dacha Sewerage. How to do. Water seal ;

Specifications, diameters and manufacturers

Important technical parameters of the device are:

- Diameter. Selected according to pipe dimensions. The diameter can be 5, 7.5 or 11 cm. The first 2 types are installed on in-house systems, the last on the riser. Some valves can be placed on sewer elements of different sizes. This is made possible by the introduction of a stepped branch pipe. On pipes of non-standard sizes, tees with a vent valve are installed.

- throughput. This parameter reflects the volume of air entering per second. Up to 25 l/s of gas is required for 1 l/s of waste water. The valve capacity can reach 37 l/s.

In our country, you can purchase vacuum valves manufactured by HL (Austria), McAlpine (Great Britain), Wavin (Poland), Evroplast (Ukraine), Ostendorf (Germany).

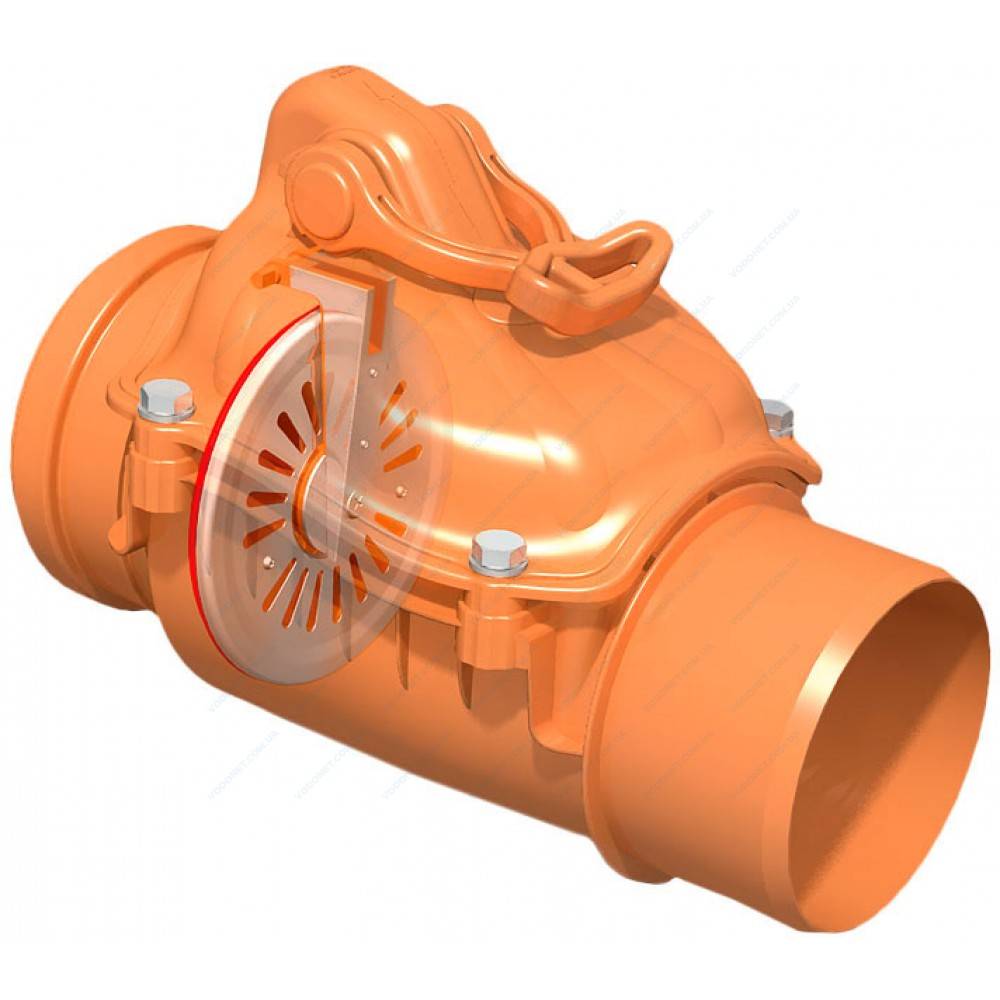

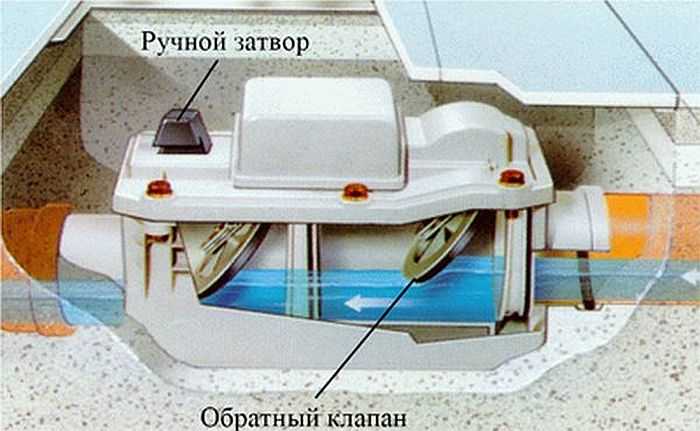

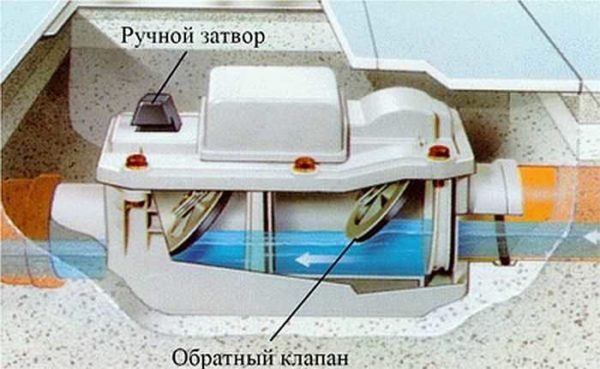

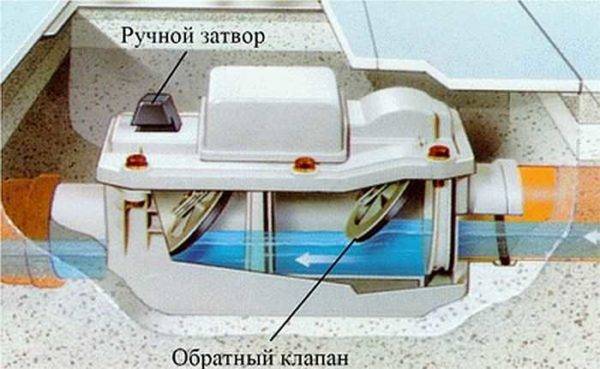

Types of check valves and the principle of their operation

The main task of the check (shut-off) valve is to block the flow going in the opposite direction. To do this, a movable barrier is placed in these mechanical devices. The basic principle of operation is that in a calm state, the mechanical damper is lowered down, blocking the lumen of the sewer pipe and preventing the reverse flow from passing. When drains appear, it rises (moves to the side), the drains leave, and it closes again. By the type of this barrier and the principle of its operation, this equipment differs.

Swivel (petal)

In sewer valves of this type, a spring-loaded round membrane (plate) is installed. If the flow moves in the “right” direction, it turns, rising up does not interfere with drains. If the movement starts in the other direction, the membrane (plate) is pressed against the rim inside the valve, tightly and hermetically blocking the pipe lumen. Some models have a manual shutter. This is the second membrane, which can be controlled using a button mounted on the body.

Due to the shape of the membrane, such shut-off valves are also called flap valves, and sometimes you can hear the term “slams” - this is because of the way they work - the membrane slams if there is no drain.

The figure shows how the check valve for sewerage works.

The device itself is larger than the pipe on which it is installed. So in the pipeline there is first an expansion, and then a narrowing of the lumen, and these are potential places for blockages to form. To be able to quickly eliminate blockages, a removable cover is made in the upper part of the check valve body. By removing it, the problem can be quickly eliminated.

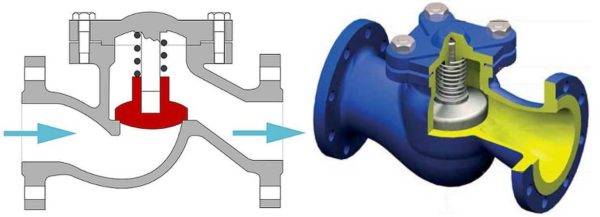

Lift check valve for sewerage

This type of locking device for a sewer pipe is so named because when the drains pass in the “correct” direction, the locking element rises. Drains press on the plate blocking the passage, compressing the spring, which rises. There are no drains - the spring is unclenched, the passage is locked. When effluents come in from the "wrong" side, there is no way to open the passage. This is achieved by a non-linear hull shape.

What is a sewer vacuum valve and how to install it

Often, when performing sewerage, builders make a mistake, since they do not provide for its ventilation, this is especially true for inexperienced developers. The consequences of such a mistake can result in the appearance of a characteristic unpleasant smell in the house. A vacuum sewer valve, to which, in fact, this article is devoted, will help to eliminate this problem.

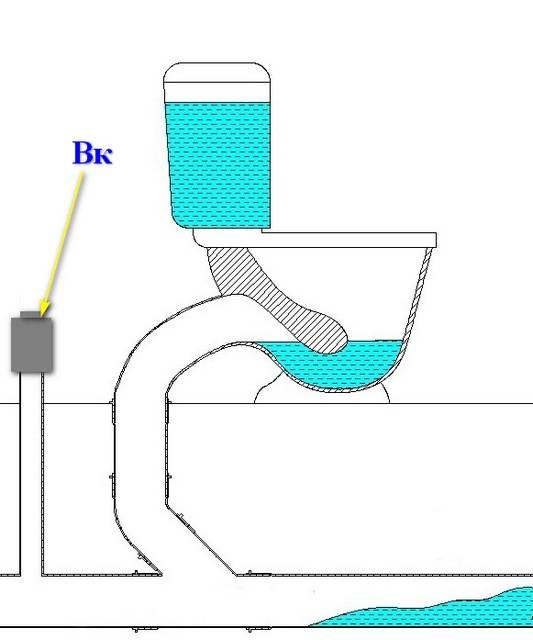

Why you need a vacuum valve

Many inexperienced craftsmen doubt why a sewer vacuum valve is needed at all, because every plumbing fixture is equipped with a water seal that does not let in any odors?

In fact, the mechanism of the system is more complex than it might seem at first glance:

- When a large amount of water is drained into the toilet, a vacuum occurs inside the system. As a result, water is sucked from the hydraulic seals. Despite the fact that the suction is partial, it is enough to create an unpleasant smell of sewerage in the room.

- Hot water regularly enters the system, as a result of which vapors rise up.

If there is ventilation in the house, but it is just clogged, then it can be cleaned. Of course, it is quite difficult to cope with this task with your own hands, but a specialist will be able to quickly solve the problem.

If there is no ventilation in the house, and it is technically expensive or difficult to build, then the way out of this situation is to install a vacuum valve. I must say that a special need for this device arises if an automatic washing machine is installed in the house, which discharges water into the system under pressure. Sometimes there are even cases when, after connecting the machine, it becomes necessary to install a second, additional valve.

Valve device and its installation

The principle of operation of the vacuum sewer valve is quite simple. When the drains move along the riser, thereby creating a vacuum, the shut-off element of the valve opens, resulting in air leakage.When the pressure in the system equalizes, the spring returns the valve to its place, as a result of which the further movement of gases becomes impossible, respectively, unpleasant odors do not penetrate into the room.

The principle of operation of the device

The standard vacuum sewer valve has a plastic body. The main structural element is a stem that raises the side outlet. When the pressure in the system decreases, the stem lowers, as a result of which the hole is blocked.

To prevent the stem from rising higher than necessary, a rubber gasket is located above it. I must say that there are designs in which a rubber membrane is used instead of a stem. Their disadvantage is the rapid wear of the membrane, as a result of which it must be changed regularly.

The price of vacuum valves with a membrane is slightly lower than devices with a stem, however, it is not advisable to purchase them due to their quick failure.

Pictured is a typical 50mm valve.

It should be noted that there are two types of vacuum valves:

Species and types

The valve on the sewer riser can have different types of design. They differ in certain ways. There are samples intended for installation:

- on a vertical riser;

- directly to the drain of a certain device - a toilet bowl, a bathtub, etc.

According to the principle of action, they are divided into:

- automatic sewer air valve. It has a relatively low bandwidth, so it is used mainly in private systems;

- anti-vacuum. Able to both supply air flow into the system and release excess pressure from it (if necessary). Can work simultaneously with several pipes;

- combined view. The operation of such devices demonstrates the possibilities of both types.

By type of construction:

- membrane (or lifting). The working body is a flexible membrane installed in a PVC housing. When the pressure changes, the membrane bends, passing upward air flow;

- cylindrical. These are reliable metal constructions, the body is made in the form of a cylinder with a thread for the cover. The device works like a classic check valve and is considered one of the best solutions for the sewer system of a private house;

- lever. They also have a metal body. It works on the principle of a gravity valve, where under the influence of passing masses the lid opens and then closes by gravity. In practice, a hand-tuned spring is usually used instead of natural weight.

According to the connection method, there are valves:

- threaded;

- flanged;

- coupling.

Choosing the best option

depends on system type, installation location and other factors. Most

demanded are devices that can work simultaneously with

multiple pipelines.

There are home craftsmen

who manufacture similar devices for fan pipes. Homemade valves in

normally cover the outlet, and when the pressure changes, they open,

letting air in or out. Typically, such structures have to be placed on pipelines in

large private houses with an extensive sewerage system and their own

septic tank. They give a large amount of gas, which creates a high load on

system and requires correction using mechanical devices. In addition, such

devices allow you to protect the system from the penetration of insects, rodents,

ingress of debris and dust.

Types of check valves and the principle of their operation

The main task of the check (shut-off) valve is to block the flow going in the opposite direction. To do this, a movable barrier is placed in these mechanical devices. The basic principle of operation is that in a calm state, the mechanical damper is lowered down, blocking the lumen of the sewer pipe and preventing the reverse flow from passing. When drains appear, it rises (moves to the side), the drains leave, and it closes again. By the type of this barrier and the principle of its operation, this equipment differs.

Swivel (petal)

In sewer valves of this type, a spring-loaded round membrane (plate) is installed. If the flow moves in the “right” direction, it turns, rising up does not interfere with drains. If the movement starts in the other direction, the membrane (plate) is pressed against the rim inside the valve, tightly and hermetically blocking the pipe lumen. Some models have a manual shutter. This is the second membrane, which can be controlled using a button mounted on the body.

Due to the shape of the membrane, such shut-off valves are also called flap valves, and sometimes you can hear the term “slams” - this is because of the way they work - the membrane slams if there is no drain.

The figure shows how the check valve for sewerage works.

The device itself is larger than the pipe on which it is installed.So in the pipeline there is first an expansion, and then a narrowing of the lumen, and these are potential places for blockages to form. To be able to quickly eliminate blockages, a removable cover is made in the upper part of the check valve body. By removing it, the problem can be quickly eliminated.

Lift check valve for sewerage

This type of locking device for a sewer pipe is so named because when the drains pass in the “correct” direction, the locking element rises. Drains press on the plate blocking the passage, compressing the spring, which rises. There are no drains - the spring is unclenched, the passage is locked. When effluents come in from the "wrong" side, there is no way to open the passage. This is achieved by a non-linear hull shape.

Scheme of the device of the lifting sewer valve

The lift check valve is more reliable, but its design is such that it often clogs and requires periodic cleaning. Why do you need to remove the cover (unscrew four bolts), clean or replace the mechanism.

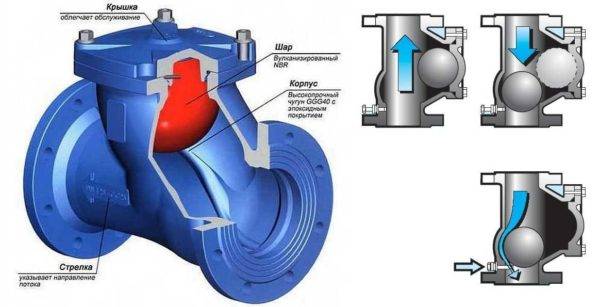

Ball check valve

Another option for a locking device in a check valve is a ball. In these devices, the internal structure of the case plays an important role. Its upper part is designed in such a way that when passing through the drains, the ball rolls into a special recess in the body, opening the passage.

The structure of the ball check valve for sewerage

When it is dry in the pipe, it blocks the section; when the flow passes in the opposite direction, it blocks the lumen of the pipe. The main drawback of this design is the leakage of drains during flooding - the ball and the side wall of the body do not always fit perfectly, which leads to the fact that some of the drains still seep through.But mass flooding and a geyser from the toilet will not be for sure.

Why you need an air valve in the sewer and how to install it, read here.

Wafer type

Many people like this type of check valves more because of their miniature size. This is a very small cylinder, inside of which a rotary damper is installed. It may consist of two parts that are attached to the central rod, or it may look like a small plate, attached to the housing wall in one place with the help of a spring.

Wafer Type Check Valve

Despite its compactness, it is better not to install this type of check valve on the sewer: this is plumbing equipment and it will not work well on the sewer. The second disadvantage is the impossibility of quick cleaning - the design is such that you can get to the valve only by disassembling the connection.

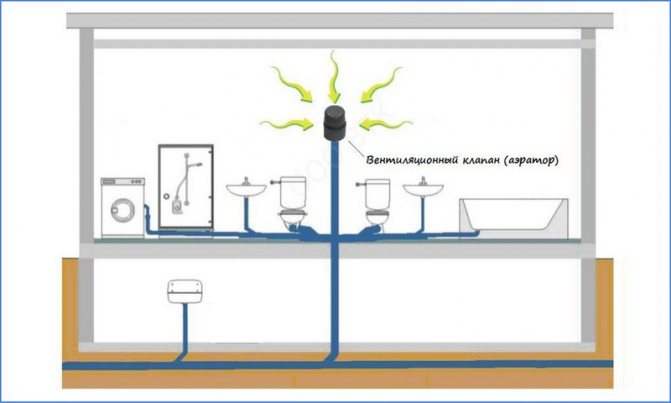

When is the only solution to install a vacuum valve?

As a rule, pipes are used to connect the toilet to the central sewerage system, inside which gases are always present. In any case, a large amount of both cold and hot water is flushed into the sewer, while, according to the law of physics, hot steam rises.

To quickly solve such a problem, you need to immediately tighten the plug at the end of the riser. To eliminate unpleasant odors, you need to install special water seals. If there is no ventilation on the riser, then due to the powerful flow of water in the pipe, a vacuum is created when the toilet is drained. As a result of this phenomenon, the contents of the nearby water seal are taken. After some time, an unpleasant smell from the sewer may be felt in the room.To prevent such a nuisance, many experts recommend installing a vacuum valve at the highest point of the riser.

You can decide whether to install this element by paying attention to the following tips:

- Using a vacuum valve, you can effectively solve the problem of ventilation of the sewer riser in a low-rise building. If there is a simultaneous drain of several toilet bowls, then the device is unlikely to cope with its intended purpose;

- you cannot independently cut off the fan riser leading to the attic in a house with several floors in order to install a vacuum valve. In such situations, apartments located on the upper floors are unlikely to suffer from unpleasant odors, but on the lower floors there will be a clear sewer smell. One way or another, experts will identify the cause of the problem, which will have to be fixed at their own expense.

Advantages and disadvantages of the sewer element

The advantages of a vacuum valve include:

- no need to make a special hole in the roof to remove the riser pipe. The roofing remains intact, while the process of installing the sewerage system is greatly simplified;

- the sewer riser ends exactly inside the building, so the appearance of the house will not deteriorate due to the installation of numerous pipes to create ventilation, which are not cheap;

- there is no need to perform periodic maintenance and repair of the device.

The disadvantages include:

- danger of failure under heavy load on the sewer system;

- the vacuum valve is quite expensive, this is due to the fact that the device is made by hand.

How does a vacuum valve work and how is it arranged?

If normal pressure is observed in the sewer pipeline, then this device will be closed. As a result of this phenomenon, protection against the ingress of unpleasant odors and harmful fumes into the room is provided. When pressure is released, such as when flushing a toilet, the vacuum valve opens automatically, allowing air into the system. In the process, pressure equalization is performed.

Such an element for sewage can be used to create local aeration. To do this, the valve is installed on the pipes of plumbing devices, the use of which involves a large flow of water.

In order for such a solution to be as effective as possible, you must follow the installation rules:

- the valve must be installed on the sewer riser above the point of supply of the plumbing device;

- installation must be carried out in a room that is well ventilated, it can be an attic, a toilet or a bathroom. In addition, access to the device for periodic technical inspection should be provided;

- the vacuum valve should only be installed on the vertical area of the pipe.

This sewer device is a simple fitting, so you can attach it using a seal.

The item package includes the following parts:

- a plastic case with a side hole;

- a rod that, if necessary, is able to open a side hole;

- so that the stem does not move up, a special rubber gasket is installed;

- the rod assembly is securely closed with a protective cover connected to the body.

On sale there are vacuum valves having a diameter of 50 and 110 mm.The first option can be installed in homes equipped with no more than two plumbing fixtures or in cases where a small water flow is provided.

Dry option

The dry seal for sewerage has more advanced characteristics than traditional water seals. This model has a different principle of operation, it operates on the principle of a nipple. The device is made in the form of a polymer tube with threads on both sides. For the manufacture of the model, polypropylene is most often used.

Inside the housing there is a special membrane that prevents the reverse movement of water and sewer gases. That is, the membrane performs the functions that a water plug performs in a conventional shutter.

If a conventional shutter ceases to perform its functions during a long period of inactivity due to the drying of water, then the dry version will function normally under these conditions.

Advantages of the option

Option advantage:

- the device does not need water for normal operation;

- the model can be installed even in unheated rooms, as there is no threat of destruction due to freezing water. This option is suitable, for example, for a summer cottage, which is not used in the cold season;

- dry siphons are compact and convenient;

- breaking a dry shutter is much more difficult than a water one;

- exclude the reverse flow of dirty water, which may occur during the formation of a blockage;

- the shutter can be installed both vertically and horizontally;

- water does not stagnate in the shutter, in which harmful bacterial flora can develop;

- has excellent sound insulation;

- has a long service life.

Types

Dry shutters are available in several versions, each of them has its own characteristics.Here are the most common options:

- Membrane. This is the simplest and most common option. The shutter functions due to the spring membrane, which opens if water enters from the drain hole, but remains closed until the water is not used.

- Float. This option can be called transitional between dry and water seal. The device is equipped with a float valve. When liquid enters, the float floats so as not to interfere with the liquid leaving. And after the water leaves, the float falls into place, sealing the lumen of the sewer pipe.

- Pendulum. The valve in such a gate has a single attachment point. When water enters the drain, the pendulum deflects, opening the passage. Then, under the influence of gravitational forces, the valve returns to its place.

- With molecular memory. This is a high-tech option, such shutters are quite expensive. Thanks to new technologies, the membrane elements reliably seal the pipe lumen after the flow of water to the drain stops.

So, there are different options for water seals for sewers. The choice of option is carried out depending on the type of sanitary element, as well as operating conditions. The installation of water seals is a prerequisite for the assembly of an internal sewerage system. If they are missing or incorrectly installed in the apartment will definitely have an unpleasant smell sewerage.

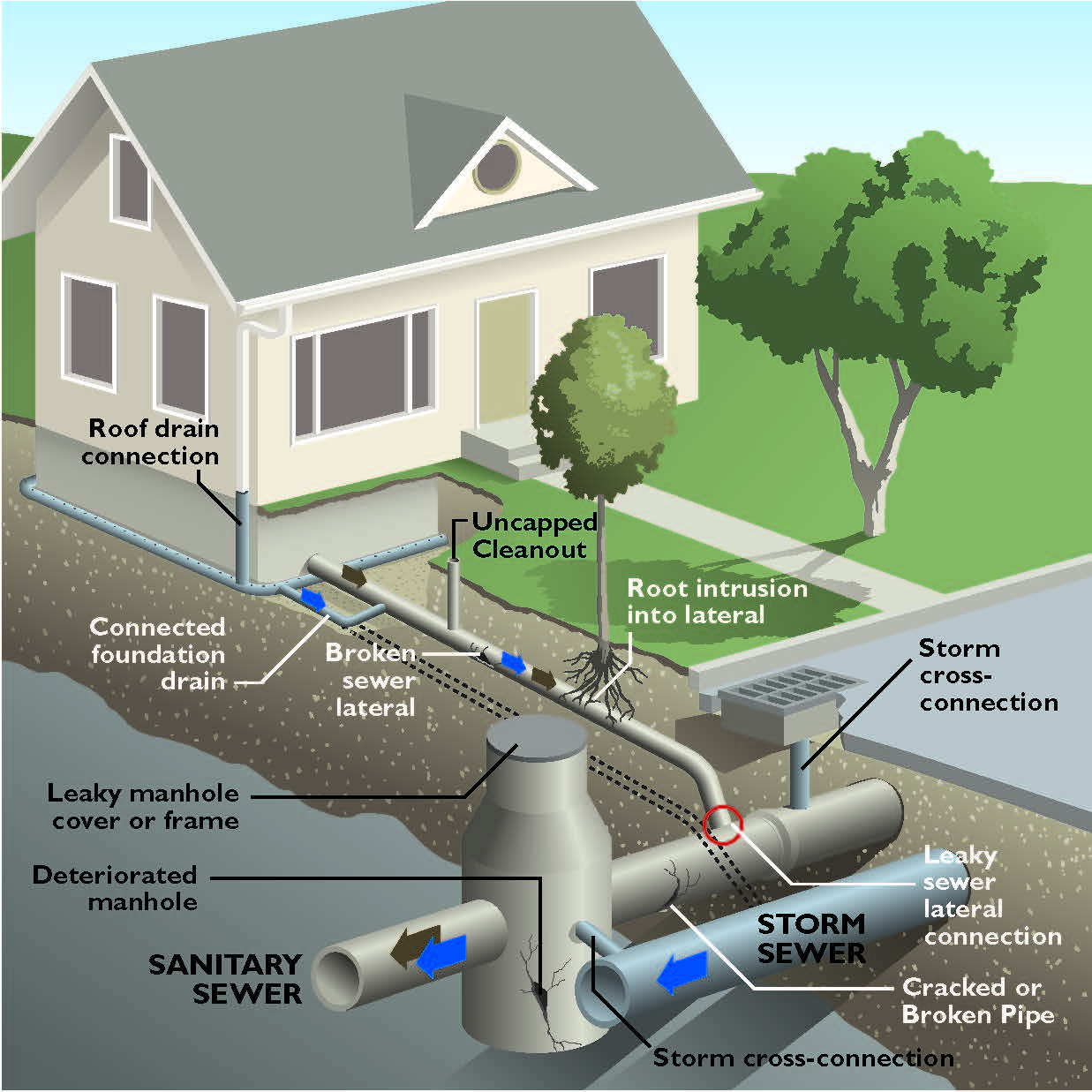

Signs of a sewer problem

Violations in the sewerage system can be identified by characteristic signs.

These are:

- the presence of extraneous sounds;

- the spread of bad odors.

In houses with a long-established sewer network, it is necessary first of all to check for damage to all elements of the network.Deviations in the operation of the new system may indicate incorrect installation.

If during the inspection it was possible to exclude such causes of possible damage as cracks in pipelines, blockages in sewers or ventilation ducts, incorrect pipe slope, then insufficient air flow is most likely the cause of the problems. In this case, installing a vacuum valve will help troubleshoot the system.

There can be several reasons for the improper operation of the sewerage: clogging in the pipes, violations of the installation rules, blocking by the residents of the upper floors of the ventilation (fan riser). Sometimes only a specialist can identify the source of trouble.

This is interesting: How to hide and decorate heating pipes - 3 options in instructions